Chemical pressure-reducing injection-increasing agent for injection well and preparation and use thereof

A technology of injection booster and water injection well, which is applied in chemical instruments and methods, wellbore/well components, and production fluids, etc. It can solve the problems of oil production rate reduction, water injection efficiency reduction, and poor injection water quality in oilfields, and achieve excellent resistance. Scaling performance, high chelating and dispersing performance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

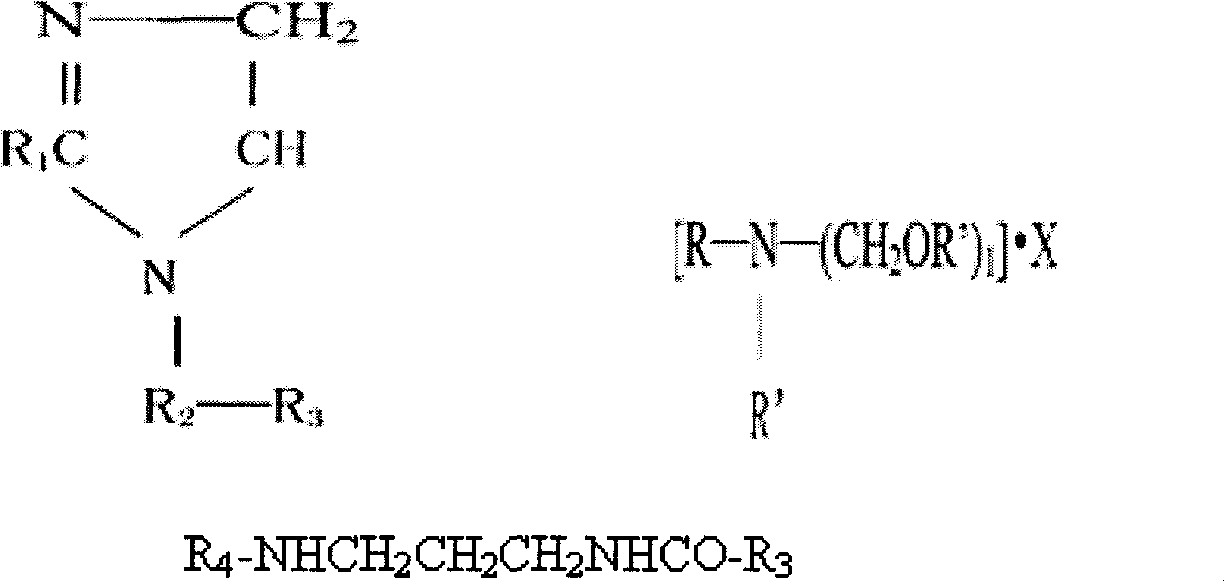

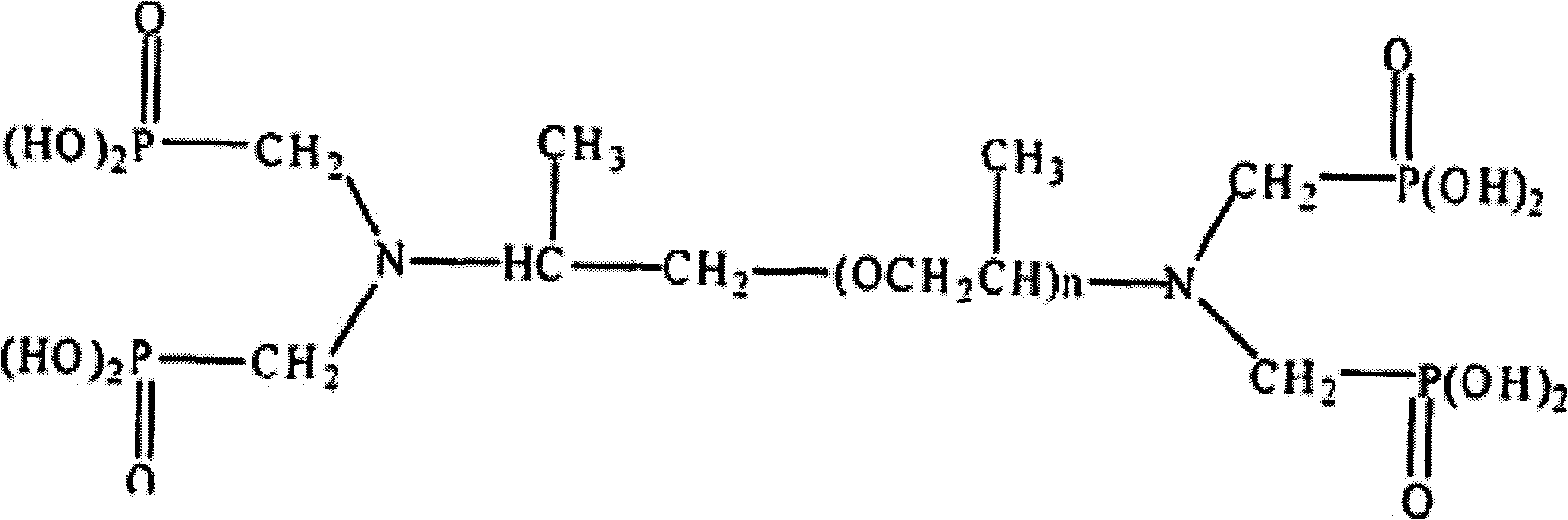

Method used

Image

Examples

Embodiment 1

[0033] Add a certain amount of water into a steel reaction kettle with a capacity of 1000 liters, add cetyltrimethylammonium bromide with a weight content of 0.03%, stir evenly, and add 0.05% by weight of MY / IMC-80BHH buffer Etching agent, stirring and dissolving completely, adding 0.02% polyaminopolyether methylene phosphonic acid by weight, stirring and dissolving completely, then adding 0.01 polyquaternium, 0.05% citric acid, 0.1% hydrochloric acid, and the balance For water, stir evenly to get the product.

[0034] Use method and effect: Wuqi Water Injection Station, in the water distribution room of the water injection station, use a dosing pump to pump the chemical pressure-reducing injection agent into the high-pressure pipeline according to the ratio of 0.1% of the water injected into the well of the station. As the injected water is injected into the formation, the measures The water injection pressure of the single well was 5.8MPa before, and the water injection pres...

Embodiment 2

[0036] Add a certain amount of water into a steel reaction kettle with a capacity of 1000 liters, add cetyltrimethylammonium bromide with a weight content of 0.3%, stir evenly, and add 0.1% by weight of MY / IMC-80BHH buffer Etching agent, stirring and dissolving completely, adding 0.01% polyamino polyether methylene phosphonic acid by weight, stirring and dissolving completely, then adding 0.03% polyquaternium by weight, 0.05% citric acid, 0.3% hydrochloric acid, and The amount is water, stir evenly, and the product is obtained.

[0037] Usage method and effect: In the water injection station of Xinhua No. 1 transfer station, in the water distribution room of the water injection station, use the dosing pump to pump the chemical pressure-reducing and increasing injection agent into the high-pressure pipeline according to the ratio of 0.3% of the water injected into the well of the station. As the injected water is injected into the formation, Before the measures, the water injec...

Embodiment 3

[0039] Add a certain amount of water into a steel reaction kettle with a capacity of 1000 liters, add 0.2% by weight of cetyltrimethylammonium bromide, stir well, add 0.2% by weight of MY / IMC-80BHH buffer etchant, stirring and dissolving completely, adding 0.2% polyamino polyether methylene phosphonic acid by weight, stirring and dissolving completely, then adding 0.02% polyquaternium, 0.03% citric acid, 0.3% hydrochloric acid, and The amount is water, stir evenly, and the product is obtained.

[0040] Use method and effect: Wangyao water injection station, in the water distribution room of the water injection station, use a dosing pump to pump the chemical pressure-reducing injection agent into the high-pressure pipeline according to the ratio of 0.2% of the water injected into the well of the station, and as the injected water is injected into the formation, the measures The water injection pressure of the single well was 18.6MPa before, and the water injection pressure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com