Preparation method of olefin ether and unsaturated carboxylic acid copolymer anti-sludging agent

A technology of carboxylic acid copolymer and olefin ether carboxylic acid, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. It can solve the problem of insufficient scale inhibition performance and poor inhibition of carbonic acid Calcium precipitation, poor calcium carbonate scale inhibition effect and other problems, to achieve the effect of improving scale inhibition performance, enhancing initiation efficiency, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

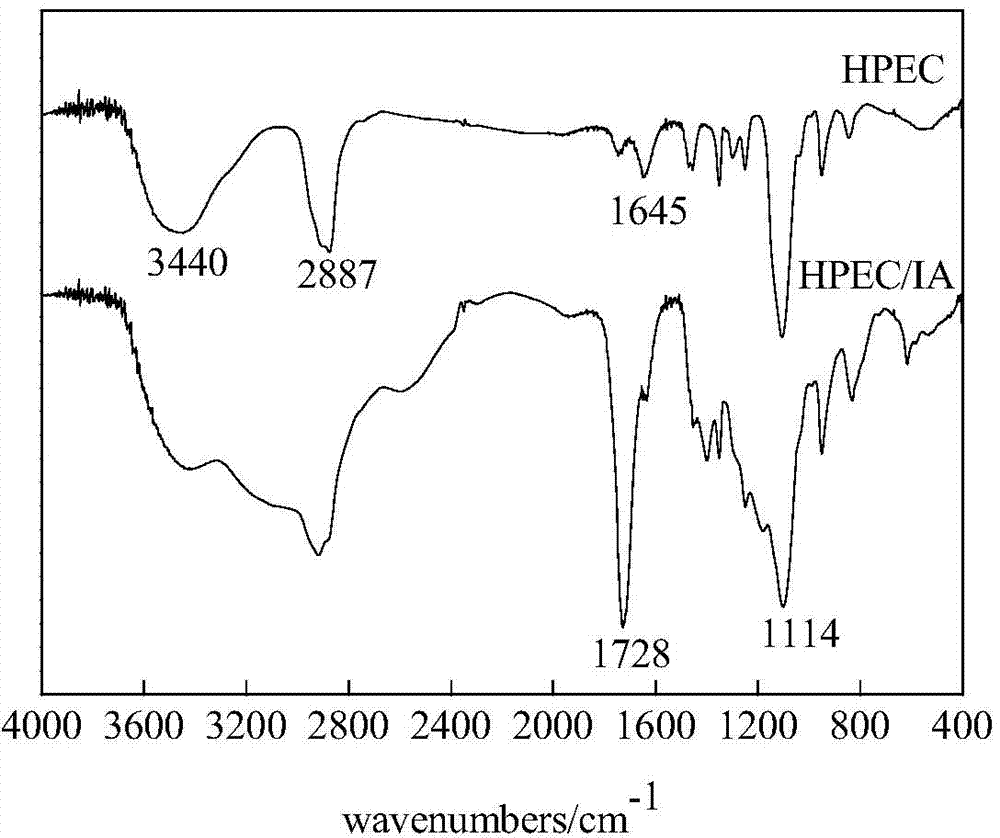

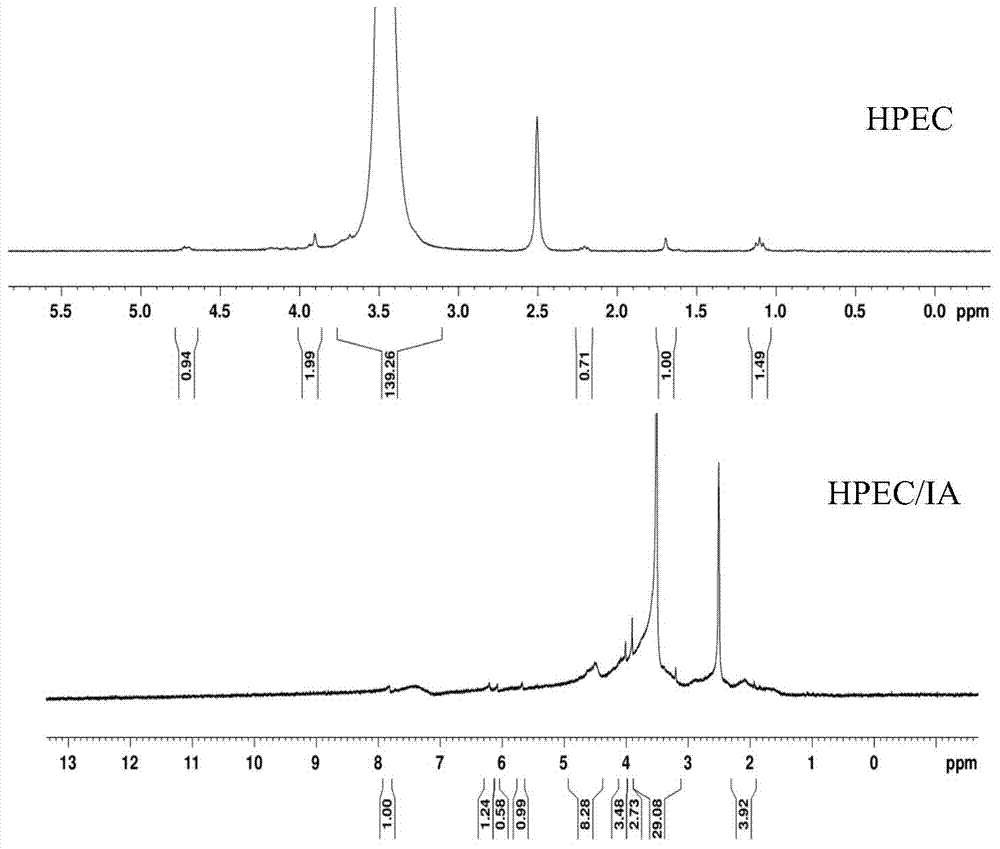

[0046] Add 7.5g of isobutenyl alcohol polyoxyethylene ether, 0.6g of sodium hydroxide and 15ml of absolute ethanol (0.789g / ml) into a four-neck flask, and after alkalization at 50°C for 1.0h, slowly dropwise add 1.985g of chloroacetic acid (dissolved After the ethanol solution in 5ml of absolute ethanol) was added dropwise, 0.6g of sodium hydroxide was added, and the temperature was raised to 90°C for 5h, and filtered, distilled, and vacuum-dried to obtain sodium isobutenol polyoxyethylene ether carboxylate (HPEC );

[0047] Add 2.0g sodium isobutenol polyoxyethylene ether carboxylate, 2.0g itaconic acid and 7.0g distilled water to the four-neck flask, mix well and heat up to 90°C, then slowly add 0.240g (dissolved in 1.0g distilled water) Sodium phosphate aqueous solution and 0.320g (dissolved in 2.0g distilled water) ammonium persulfate aqueous solution, the oxidant is added dropwise in batches, and the interval between drops is 10min. After the dropwise addition, react at ...

Embodiment 2

[0054] Add 7.5g of isobutenol polyoxyethylene ether, 0.6g of potassium hydroxide and 20ml of absolute ethanol to a four-neck flask, and after alkalization at 60°C for 1.0h, slowly add 2.279g of 3-chloropropionic acid (dissolved in 10ml of anhydrous Ethanol) ethanol solution, after the dropwise addition, add 0.6g of potassium hydroxide, heat up to 110°C for 3 hours, filter, distill, and dry in vacuo to obtain potassium isobutenol polyoxyethylene ether carboxylate;

[0055] Add 2.0g potassium isobutenol polyoxyethylene ether carboxylate, 2.0g aconitic acid and 8.0g distilled water to the four-neck flask, mix well and heat up to 100°C, then slowly add 0.200g (dissolved in 1.0g distilled water) sub Sodium phosphate aqueous solution and 0.320g (dissolved in 3.0g distilled water) ammonium persulfate aqueous solution, the oxidizing agent was added dropwise in 3 batches, and the interval between drops was 10min. After the dropwise addition, react at 100°C for 1.5h, and cool to room te...

Embodiment 3

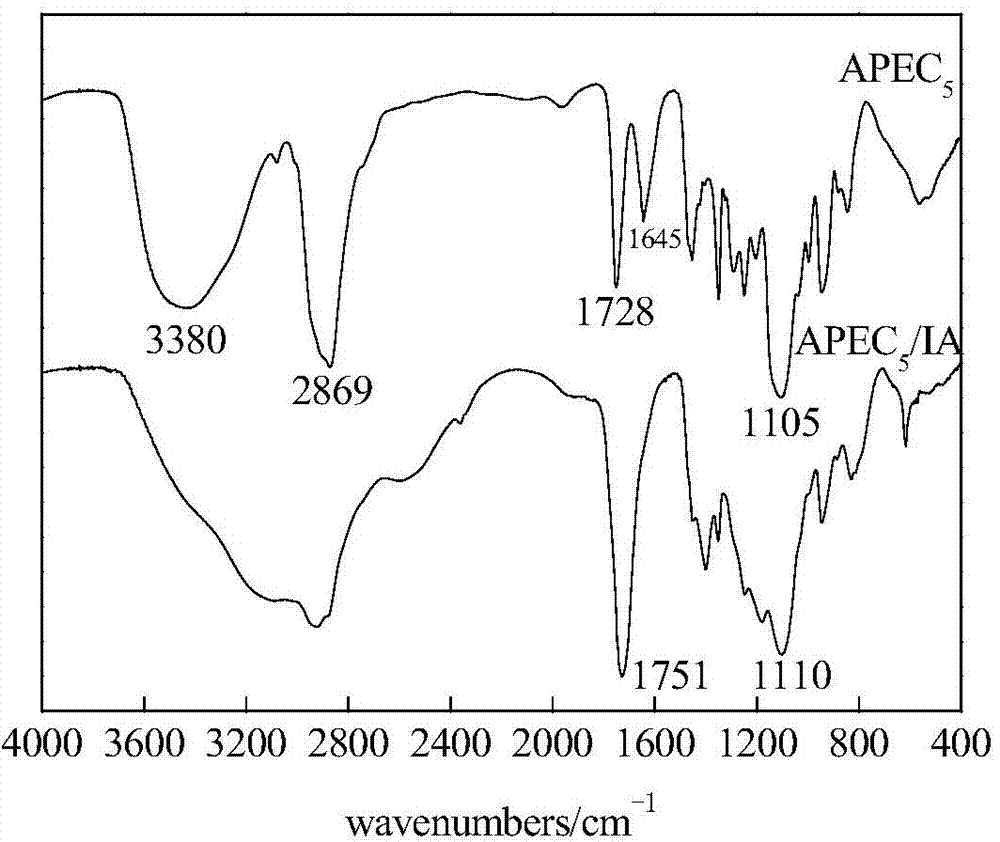

[0059] Add 7.5g of allyl alcohol polyoxyethylene ether, 0.8g of sodium hydroxide and 20ml of distilled water to a four-necked flask, and after alkalization at 40°C for 1.5h, slowly add 1.985g of chloroacetic acid (dissolved in 10ml of distilled water) aqueous solution dropwise. After the addition is complete, add 0.8g of sodium hydroxide, raise the temperature to 100°C for 4.0h, filter, distill, and vacuum dry to obtain sodium allyl alcohol polyoxyethylene ether carboxylate (APEC 5 );

[0060] Add 2.0g sodium allyl alcohol polyoxyethylene ether carboxylate, 4.0g itaconic acid and 8.0g distilled water to the four-neck flask, mix well and heat up to 110°C, then slowly add 0.360g (dissolved in 2.0g distilled water) sub Sodium bisulfate and 0.360g (dissolved in 3.0g distilled water) potassium persulfate aqueous solution, the oxidant was added dropwise in 3 batches, and the interval between drops was 10min. After the dropwise addition, react at 110°C for 1.0h, and cool to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com