Patents

Literature

48results about How to "Control reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

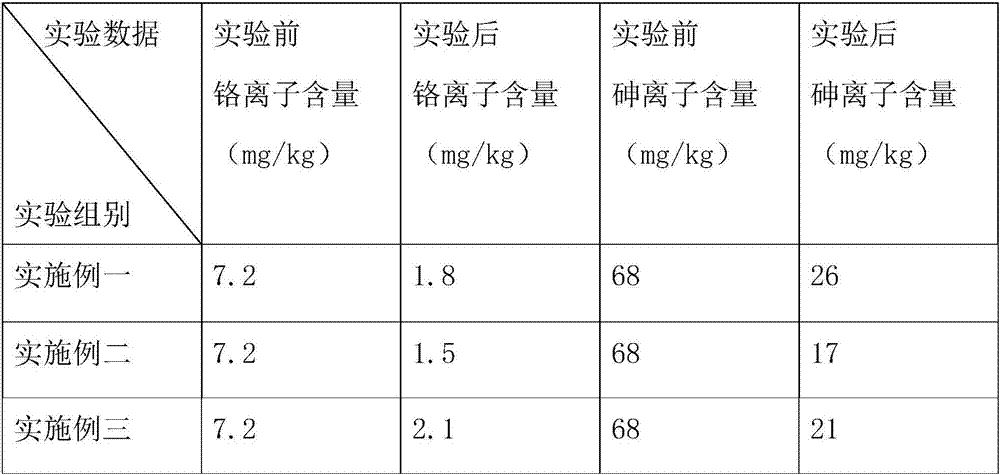

Preparation method of modified micron zero-valent iron and application method of modified micron zero-valent iron in remediation of heavy metal contaminated soil

ActiveCN106180735AAvoid secondary pollutionGood dispersionContaminated soil reclamationSoil treatmentSlag

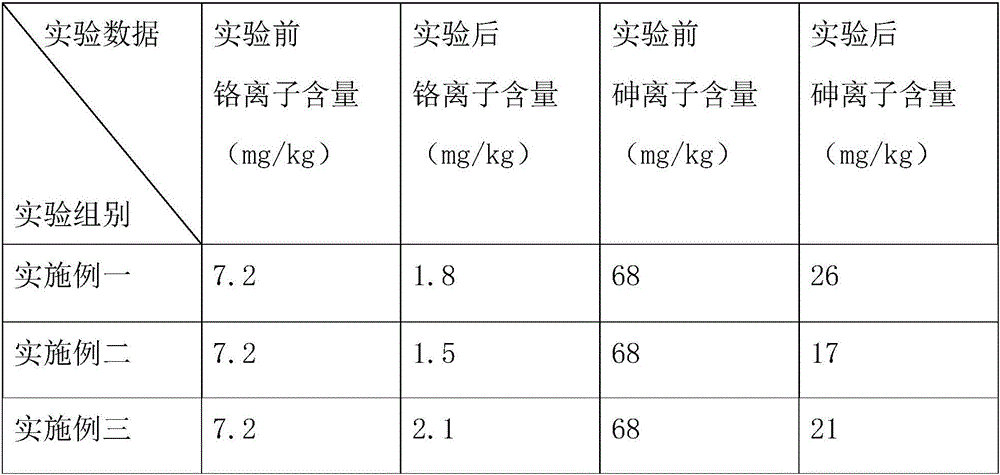

The invention discloses a preparation method of modified micron zero-valent iron and an application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil. The preparation method of the modified micron zero-valent iron comprises the steps of cleaning of iron raw materials, preparation of micro iron, ultrafine grinding and modifying treatment. A modifying agent composed of water, xanthan gum, sulfide, a stabilizing agent, zeolite and blast furnace slag is adopted in the step of modifying treatment. The preparation method of the modified micron zero-valent iron has the beneficial effects that the production process of the modified micron zero-valent iron is simple, and the effect similar or superior to micron zero-valent iron is achieved while the cost is reduced; and in addition, the reaction activity is controlled, the oxidation rate is decreased, excellent stability is obtained, and the acting time of the micron zero-valent iron is longer. By the adoption of the application method of the modified micron zero-valent iron, the remediation cost of heavy metal contaminated underground water is further reduced. According to the preparation method of the modified micron zero-valent iron and the application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil, organic fertilizer is added in the soil treatment process so that the fertility of soil can be improved, the structure of soil can be improved through humic acid produced by the organic fertilizer, heavy metal elements, such as lead, chromium and arsenic, in underground water can be removed, and the concentration of pollutants such as nitrate and perchlorate can be reduced.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

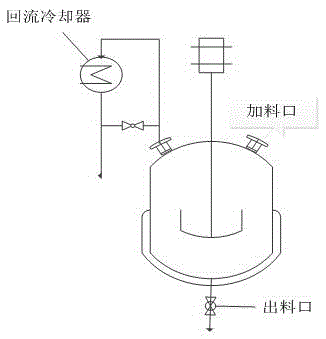

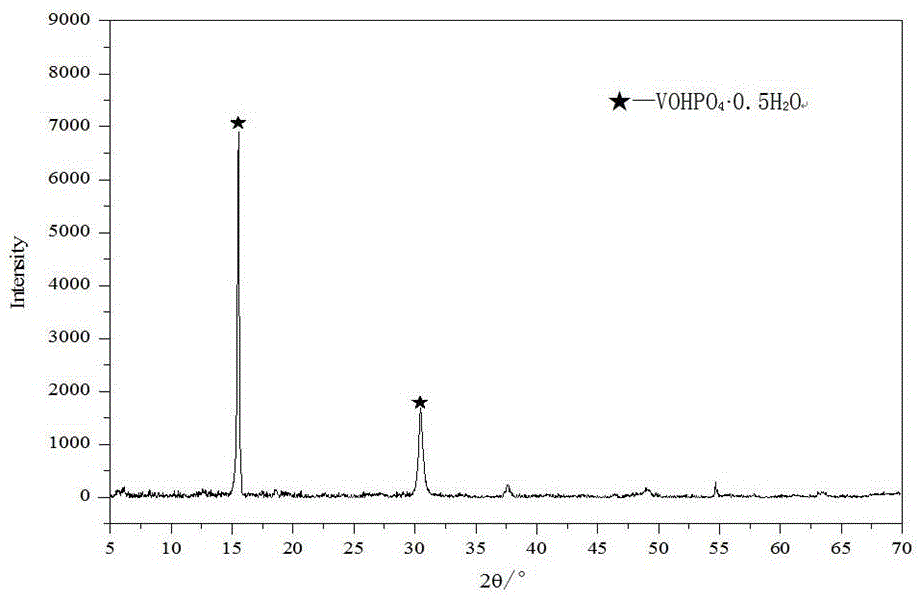

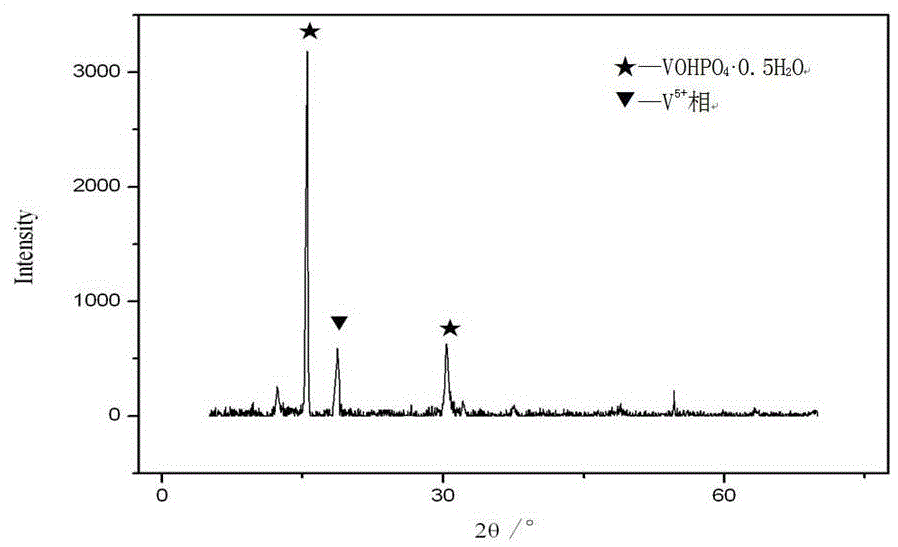

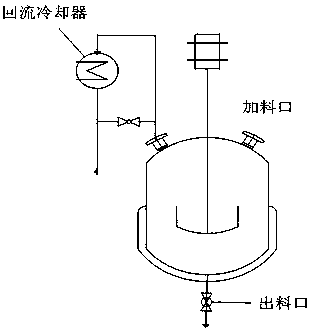

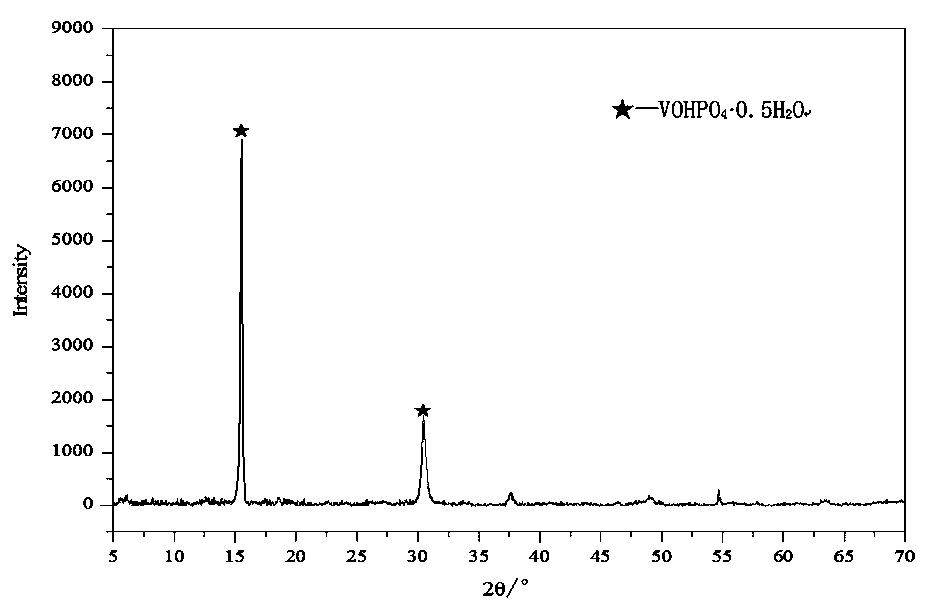

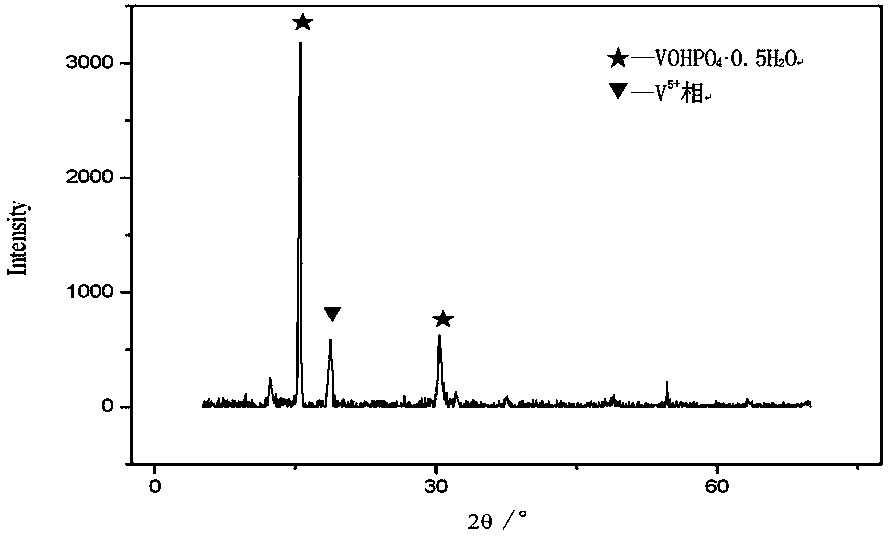

A preparing method of a vanadium phosphorus oxide catalyst for n-butane oxidation to produce maleic anhydride

ActiveCN105749941ALarge specific surface areaHigh pore volumeOrganic chemistryPhysical/chemical process catalystsPtru catalystVanadium atom

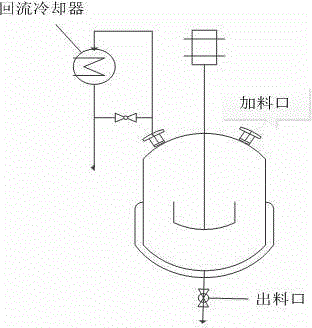

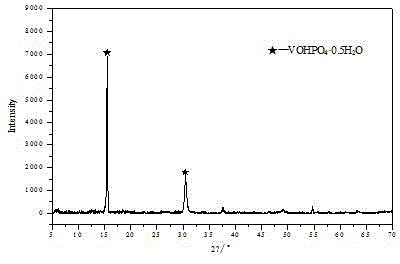

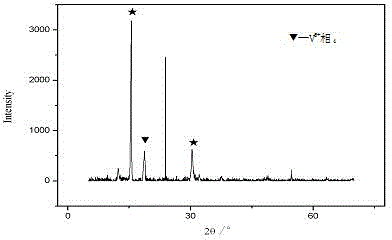

A preparing method of a vanadium phosphorus oxide catalyst is disclosed. The method includes preparing a catalyst precursor in a stirring reaction kettle, dipping the catalyst precursor in an organic peroxide to perform liquid phase oxidation treatment, and calcinating in an inert gas atmosphere so that the crystalline phase in the catalyst precursor is subjected to phase inversion and structured, namely the VOHPO4.<0.5>H2O phase in the precursor is converted into an active (VO)<2>P2O7 phase, and the V<5+> phase is converted into beta-VOPO4 phase. The method can quantificationally control the relative content V<4+> / V<5+> in the catalyst and can adjust synergistic effects between the V<4+> phase and the V<5+> phase so that performance of the catalyst is optimum. The catalyst prepared through the method is large in specific surface area and high in pore volume. When the catalyst is used for a catalytic reaction of oxidizing n-butane to produce maleic anhydride, the conversion ratio of the n-butane is 85-95 mol%, and selectivity of the maleic anhydride can be 72-86 mol%.

Owner:CHINA PETROLEUM & CHEM CORP +1

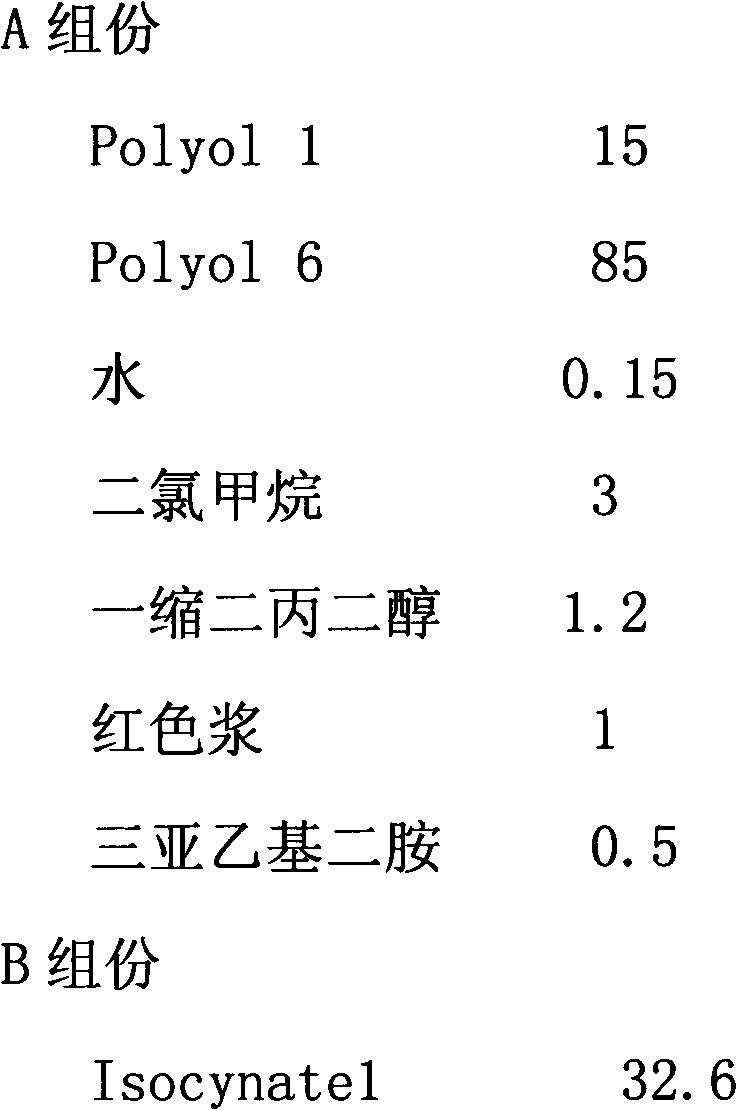

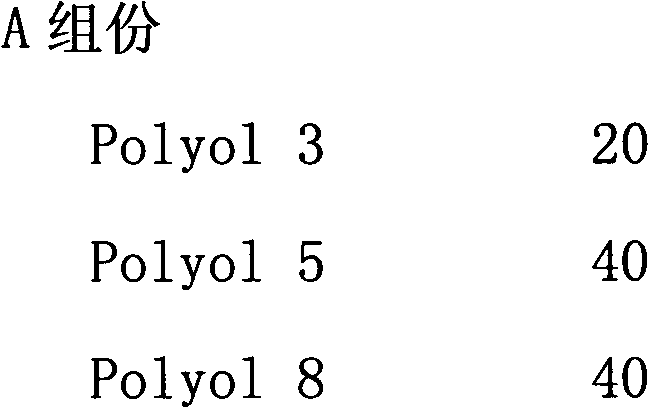

Viscose, high-performance artificial turf and preparation method thereof

ActiveCN101831265AGood water permeabilityImprove liquidityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses polyurethane viscose for preparing a high-performance artificial turf and a preparation method thereof, a method for preparing the artificial turf by using the viscose and the artificial turf obtained by the method. The polyurethane viscose is prepared from the following raw materials in part by mass: 100 parts of polyalcohol, 5 to 15 parts of chain extender, 0 to 5 parts of color paste, 100 to 200 parts of inorganic filler, 0.5 to 1.5 parts of catalyst, 30 to 100 parts of water inhibitor and 30 to 100 parts of isocyanate. The method for preparing the artificial turf by using the viscose comprises the following steps of: uniformly spraying the raw materials onto a main bottom lining of the artificial turf through a mechanical pump, scraping the materials through a scraper, pre-heating the materials by infrared, heating the materials in a drying channel, and finally curing, perforating and packing the materials. 600 to 1,000 grams of viscose is applied to each square meter of artificial turf, the tested pullout force of the grass can be more than 80N after the artificial turf is placed for 24 hours at the room temperature, and the main bottom lining is soft and has good toughness.

Owner:WANHUA CHEM BEIJING +1

Method for producing phenol resin

The invention discloses a production method of phenolic resin, which is characterized in that the materials and the step comprise: (1) backup phenol, formaldehyde, zinc acetate, barium hydroxide, xylene, and urea, (2) 60 percent of the quantity of phenol, zinc acetate, xylene, and formaldehyde are put into the reaction kettle and warmed up to 105 DEG C for 90 minutes, (3) monitoring of index of refraction, the barium hydroxide and the residual formaldehyde are put into the reaction kettle as index of refraction up to 1.45 to 1.50, warmed up to 100 to 102DEG C for 50 to 60 minutes, (4) resinification degree detection, dewater treatment is performed at opaque point of 50 to 52 DEG C, the urea is put into the reaction kettle as the temperature is decreased to 70 DEG C, and the finished product is generated as the temperature is generated to 50 DEG C. The invention has the advantages of reinforced ortho position reaction of the phenolic resin, strengthened activity of the phenolic resin, high solid content, low viscosity, long storage time, and elimination of low activity in process of the phenolic resin production.

Owner:湖南中野高科技特种材料有限公司

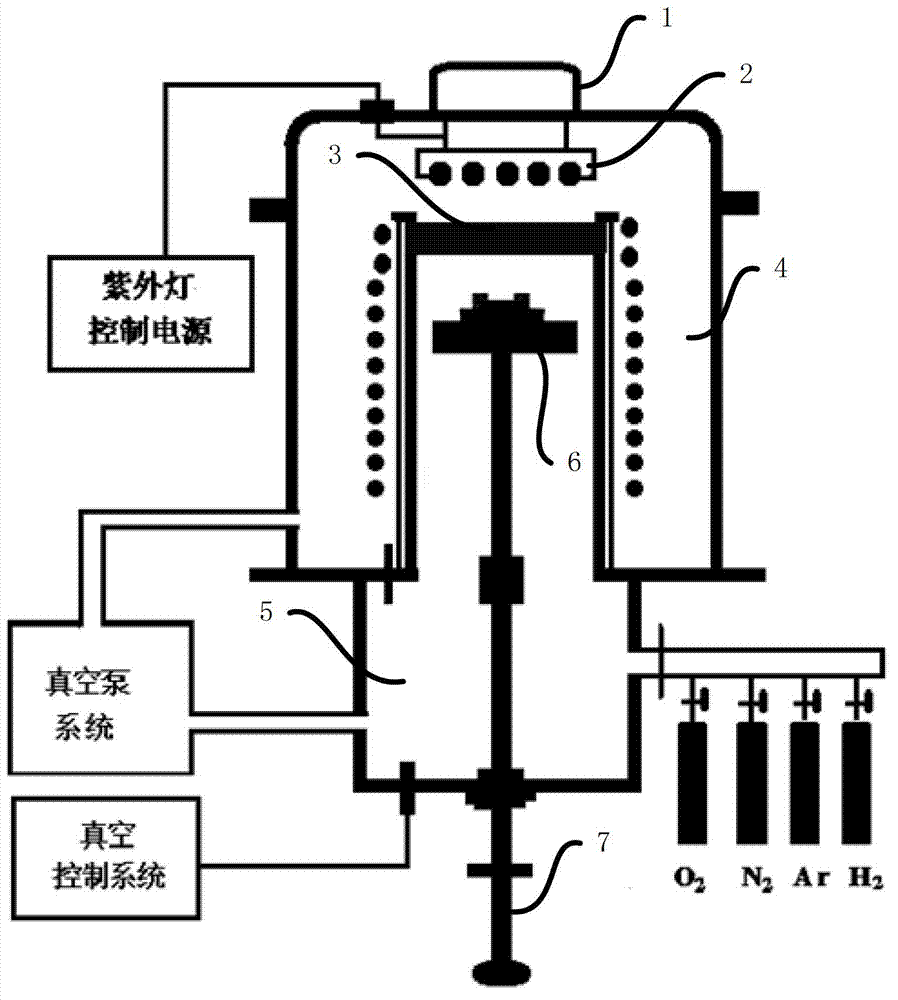

Vacuum device capable of integrating ultraviolet light chemistry and chemical vapor dry surface treatment

ActiveCN102969227AEasy to cleanEffective and accurate modificationSemiconductor/solid-state device manufacturingGas phaseControl system

The invention discloses a vacuum device capable of integrating ultraviolet light chemistry and chemical vapor dry surface treatment, which consists of a vacuum chamber, an ultraviolet light source system, a vacuum pump system and a vacuum device control system, wherein the vacuum chamber consists of a high vacuum internal chamber and a low vacuum external chamber; an ultraviolet lamp light source is fixed on the top of the external chamber; a sample table with an adjustable height is arranged in the internal chamber; and a heating and water-cooling system is arranged outside the internal chamber. The invention also provides a using method of the vacuum device. The vacuum device is capable of accurately controlling the processes of the ultraviolet light chemistry and the chemical vapor dry reaction, so that materials, devices and the like can be effectively cleaned and modified; and the invention has important application value in the fields of materials and nanoscale optoelectronic devices.

Owner:SHANGHAI JIAO TONG UNIV

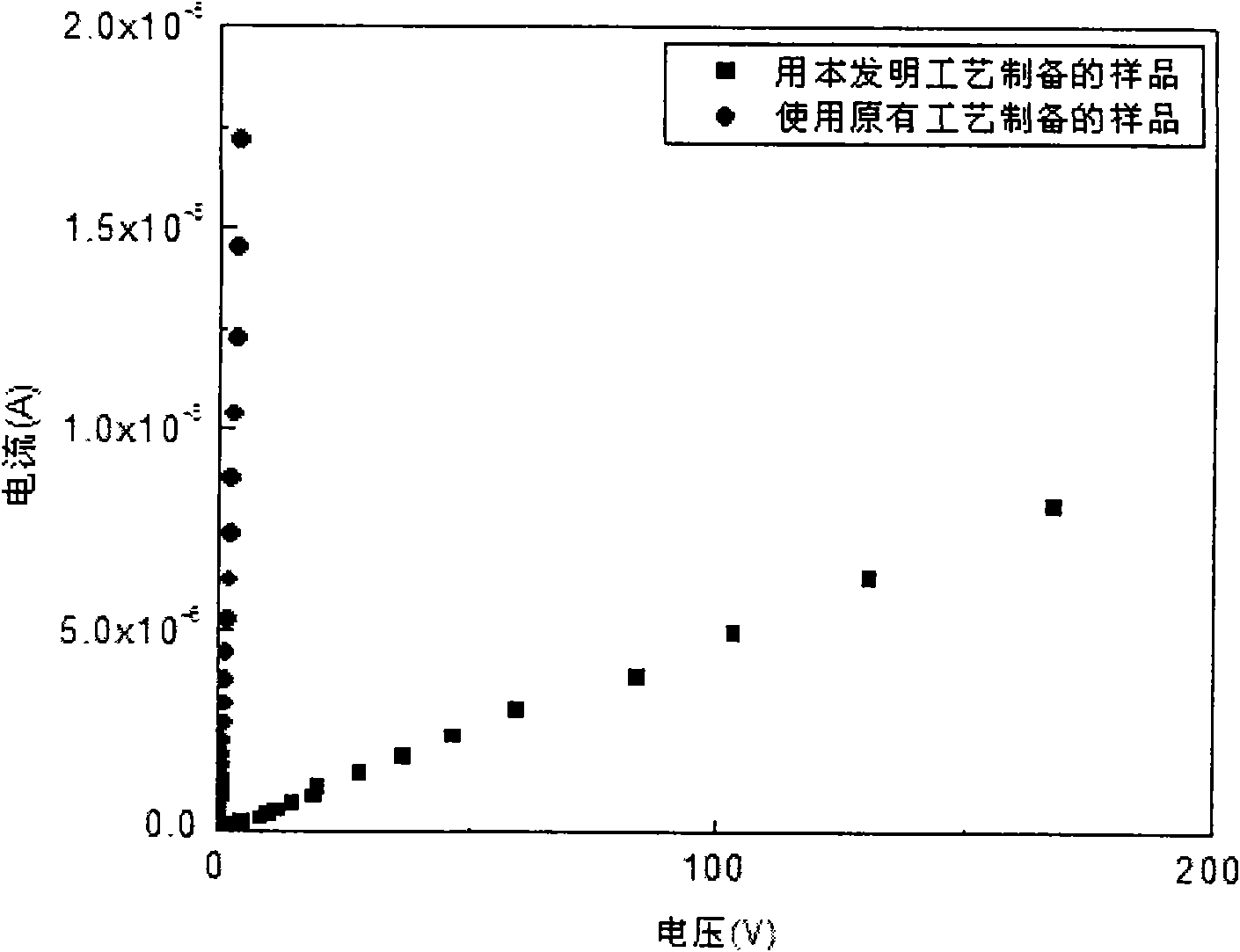

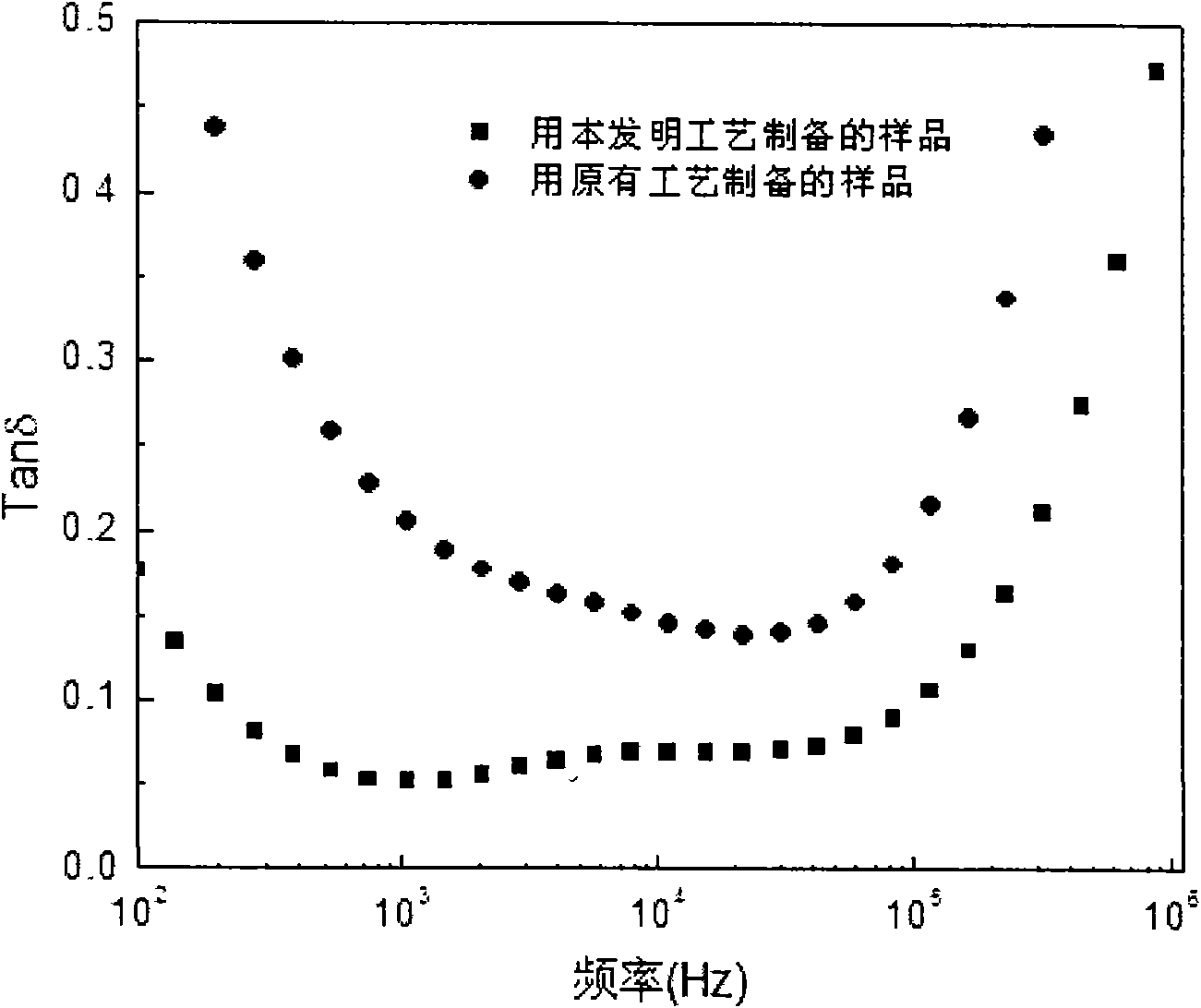

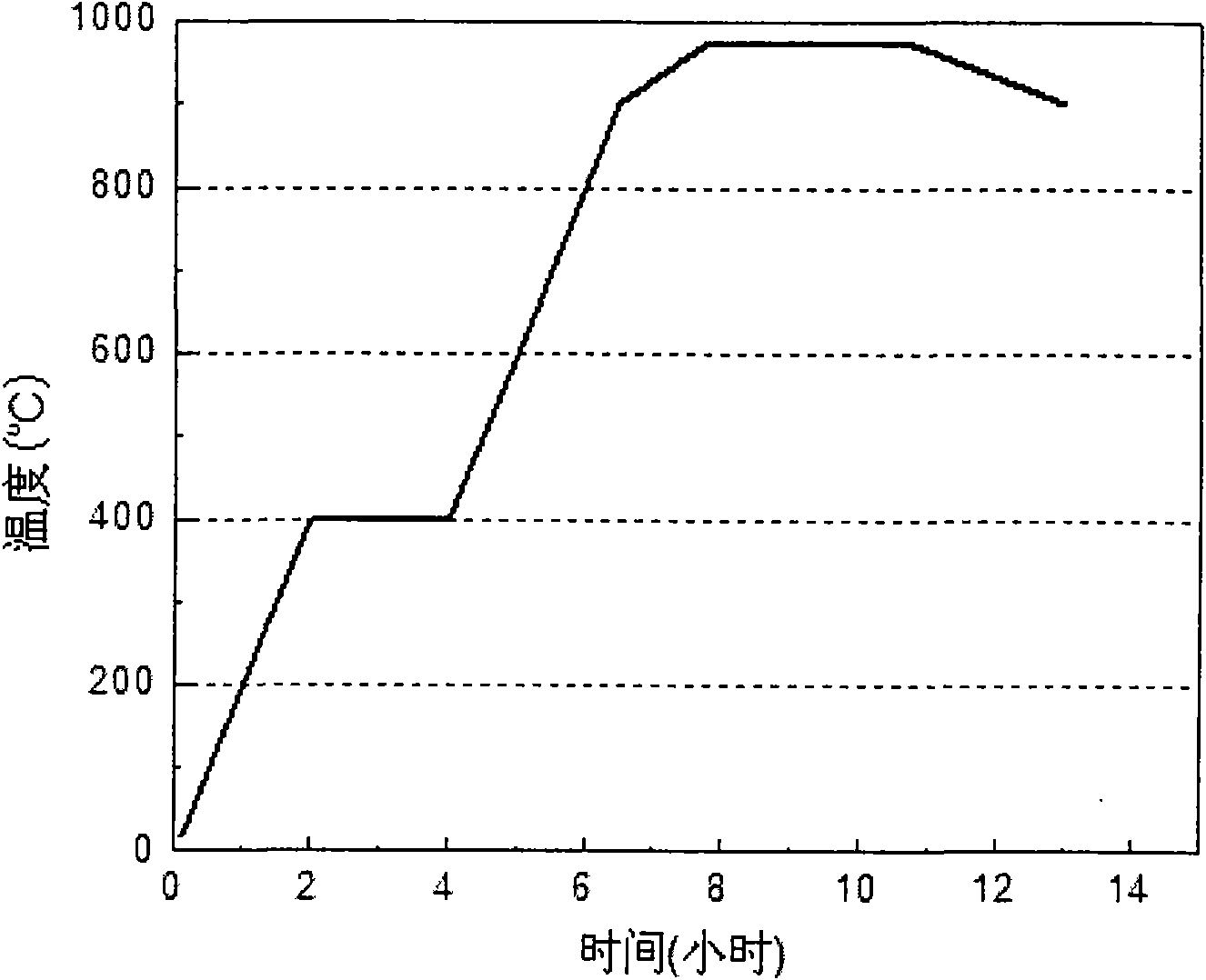

Method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics

ActiveCN101671174ASolve the problem of too much conductivitySuitable for industrial applicationsCeramic sinteringChemical reaction

The invention relates to a method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics, belonging to the technical field of high dielectric ceramic materials. The calcium copper titanate ceramics are prepared from initial raw materials of CaCO3 or CaO, CuO and TiO2, wherein after being mixed, the raw materials are processed by mix grinding and then processed by presintering at the temperature from 800 DEG C to 950 DEG C after mix grinding, hard blocks after presintering are cracked to be ground, and the powdered materials after presintering and grinding are prepared into green bodies with predetermined shapes; and the green bodies are heated to the sintering temperature ranging from 960 DEG C to 990 DEG C from room temperature, and heat preservation is carried out for 1 to 24 hours at the sintering temperature, thereby realizing the sintering densification of the ceramics. The preparation method controls performance parameters by controlling technological parameters, and structural changes and chemical reactions in a sintering process. The ceramic materials prepared by the method can meet the requirement on industrial application; and simultaneously, compared with the prior art, the preparation method can obviously reduce the energy consumption, is environment-friendly and reduces the production cost.

Owner:TSINGHUA UNIV

Transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic

ActiveCN105198443AConducive to initial sintering densificationFacilitate the realization of initial sintering densificationCeramic sinteringBoron nitride

The invention discloses a transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic and relates to a sintering method of boron nitride multi-phase ceramic. The invention aims at solving the problems that the crystal grains of the prepared multi-phase ceramic are coarse and the mechanical performance is poor for a reason that the sintering temperature of the existing boron nitride multi-phase ceramic. The method comprises the following steps: 1) preparing composite sintering assistant powder; 2) preparing composite powder; 3) increasing the temperature of the composite powder under a vacuum or inert atmosphere condition, increasing pressure and then decreasing the temperature to obtain the boron nitride multi-phase ceramic. The compactness of the boron nitride multi-phase ceramic prepared by adopting the method disclosed by the invention can reach more than 95 percent, the crystal grains of the material are fine and the comprehensive mechanical performance is excellent. The invention belongs to the field of preparation of boron nitride multi-phase ceramics.

Owner:HARBIN INST OF TECH

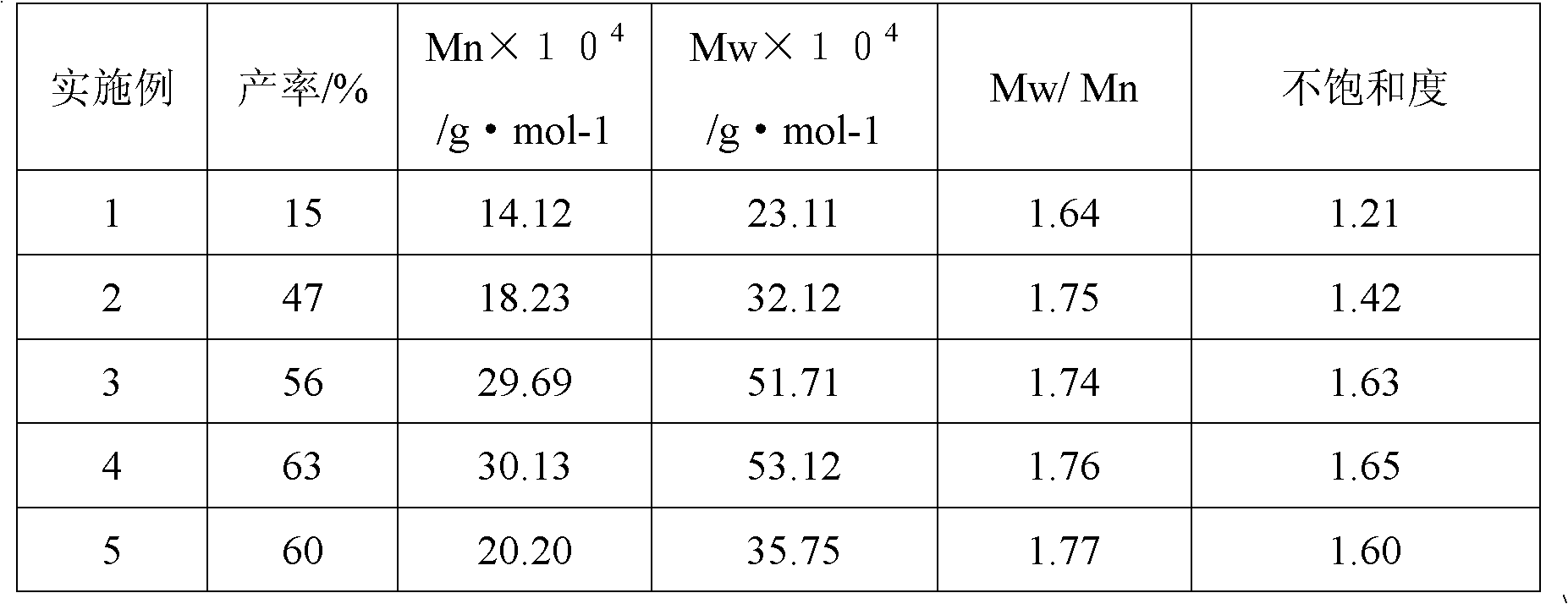

Solution method for synthesizing butyl rubber

The invention relates to a solution method for synthesizing butyl rubber. A mixture of C4-C8 monoolefine monomers and C4-C14 polyene hydrocarbon monomers is taken as a raw material, and in a system that hexane and chloromethane are solvents, polymerization reaction is initiated by an initiating system to prepare butyl rubber polymer, wherein the reaction pressure is normal pressure, the reaction temperature ranges from 0 to -90DEG C, and the initiating system has the concentration of 0.01-0.001mol / L, and is prepared by dissolving a main initiator, namely deionized water and a coinitiator, namely aluminum alkyl dihalide by using a polar solvent CH2Cl2 for mixing, and adding alkylol amines; the molar ratio of the coinitiator to the main initiator is 1:1-10:1, and the molar ratio of a third component to the main initiator is 1:10-1:25; and the adding amount of the mixed solvent is 1 to 50 times volume of the polymerization monomers. According to the method, reaction is mild, polymerization temperature is improved, the stability and initiation efficiency of the initiators are high, and the molecular weight distribution of the product is narrow.

Owner:PETROCHINA CO LTD

Method of producing maleic anhydride by oxidizing n-butane

ActiveCN106749125AMild severity of reactionReduce reaction hot spotsOrganic chemistryPhysical/chemical process catalystsMaleic anhydrideChemistry

The invention discloses a method of producing maleic anhydride by oxidizing n-butane. The method includes the following steps: mixing the n-butane with air; co-currently enabling the mixed reaction gas to pass through at least two vanadium-phosphorous oxide catalyst bed layers in series to perform a contact reaction with a vanadium-phosphorous oxide catalyst under an oxidizing reaction condition. The average valence of vanadium in a downstream catalyst bed layer is higher than that of vanadium in an upstream catalyst bed layer according to the contact sequence of the catalyst with the mixed reaction gas. The method reduces reaction hot spots in the bed layers and enables temperature distribution in the bed layers to be balanced, thus effectively inhibiting side-reactions, increasing product selectivity and increasing yield of the product, maleic anhydride.

Owner:CHINA PETROLEUM & CHEM CORP +1

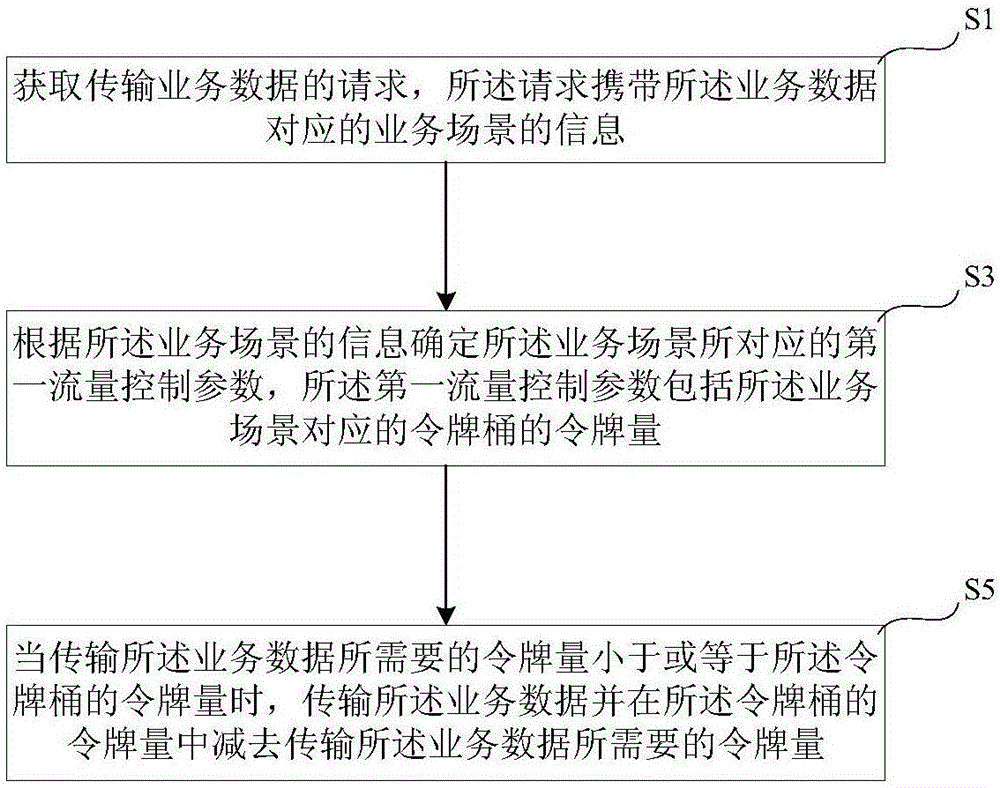

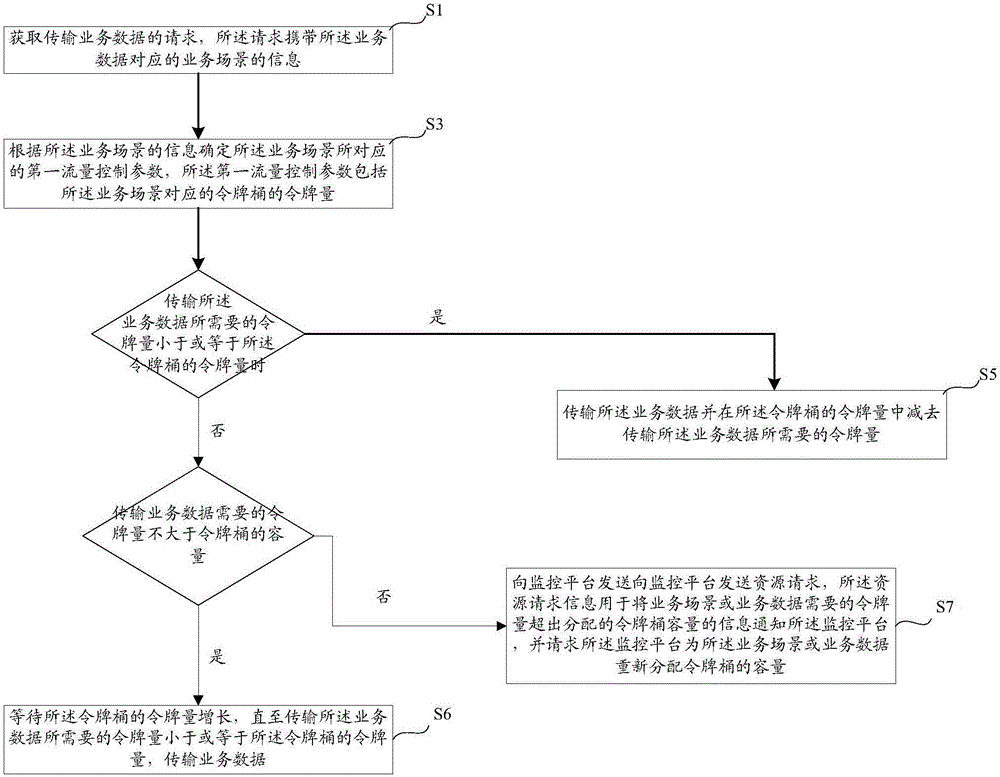

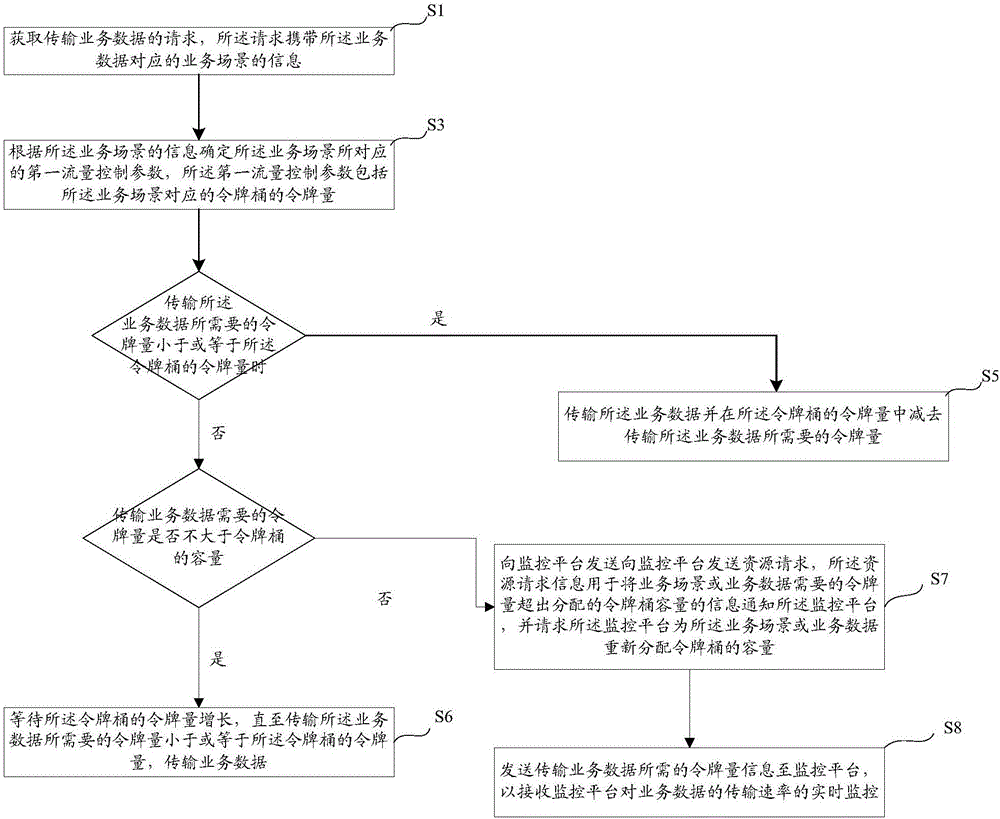

Flow control method and system

ActiveCN106713168AControl reactivityControl downtimeData switching networksData transmissionComputer science

The invention discloses a flow control method and system. The flow control method comprises the steps that a request for transmitting service data is acquired, wherein the request carries the information of a service scenario corresponding to the service data; according to the information of the service scenario, a first flow control parameter corresponding to the service scenario is determined, wherein the first flow control parameter comprises the token amount of the token bucket corresponding to the service scenario; and when the amount of tokens required to transmit the service data is less than or equal to the token amount of the token bucket, the service data are transmitted, and the amount of tokens required to transmit the service data is subtracted from the token amount of the token bucket. According to the technical scheme, the corresponding flow control parameter is used to control the speed of service data transmitting according to different service scenario information; the service data transmitting speed is controlled in real time; and real-time flow control is realized.

Owner:SHANGHAI AILONG INFORMATION TECH

Polyurethane reaction ball and preparing method thereof

The invention discloses a polyurethane reaction ball which is a microcellular polyurethane elastomer prepared through raw materials including polymer component A and prepolymer component B. The invention further discloses a method for preparing the reaction ball, which includes: mixing and stirring polyether polyols, foaming agents, chain extenders, color paste and catalysts to obtain the polymer component A; and evenly mixing and stirring the polymer component A and the prepolymer component B according to a certain proportion at temperature of 5-32 DEG C, and pouring the mixture into a reaction ball mold for aging to obtain the polyurethane reaction ball. The foam density of the reaction ball is 100-600kg / m<3>, hardness of the reaction ball is Shore A40+ / -10, free-falling resilience can reach 80-90%, and property requirements of high-level reaction balls are met. In addition, the polyurethane reaction ball and the preparing method thereof have good technology processing characteristics, spalling during contraction and mold opening is avoided, and product defective percentage is reduced.

Owner:WANHUA CHEM BEIJING +2

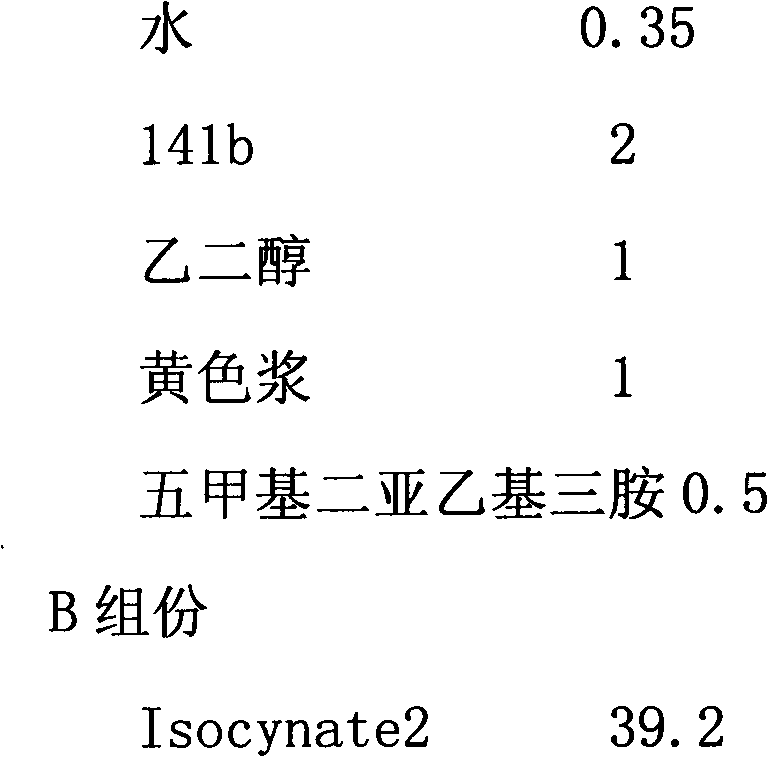

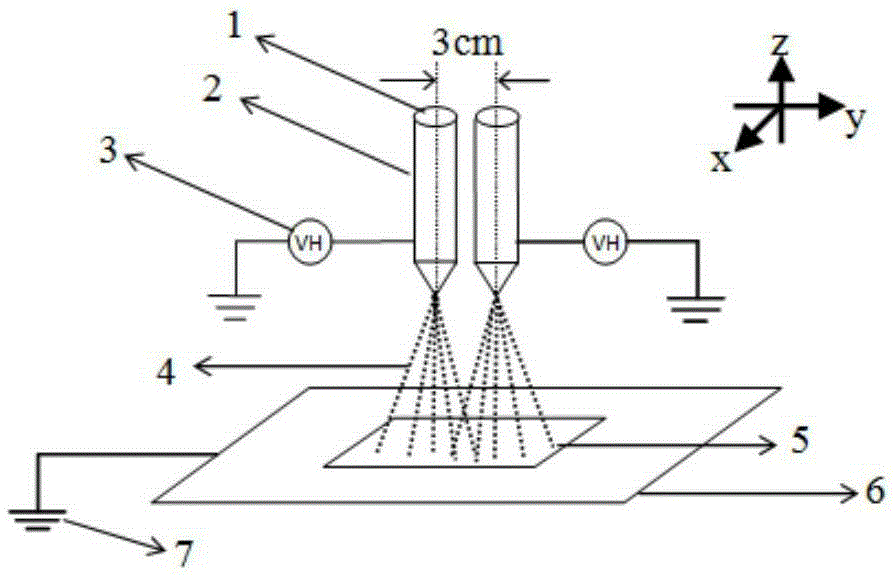

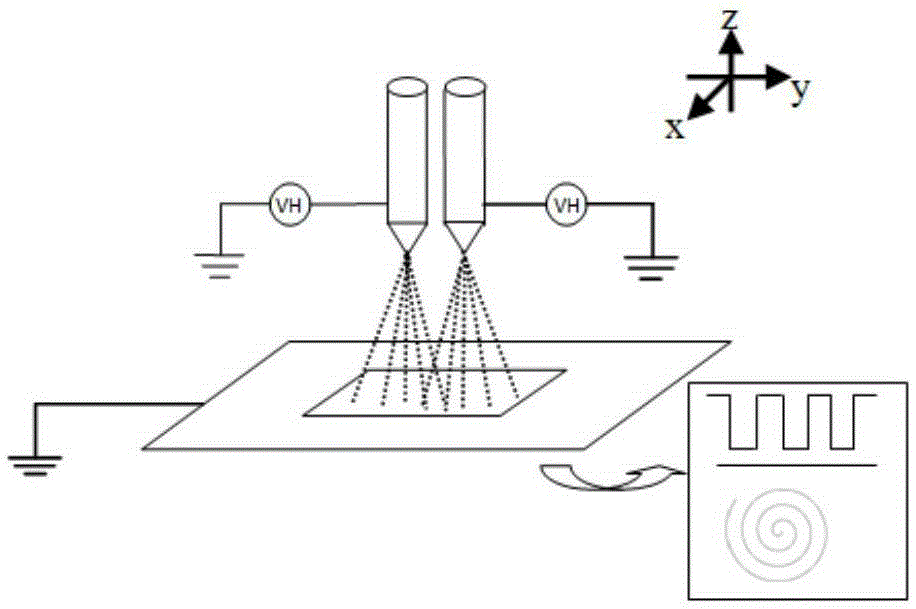

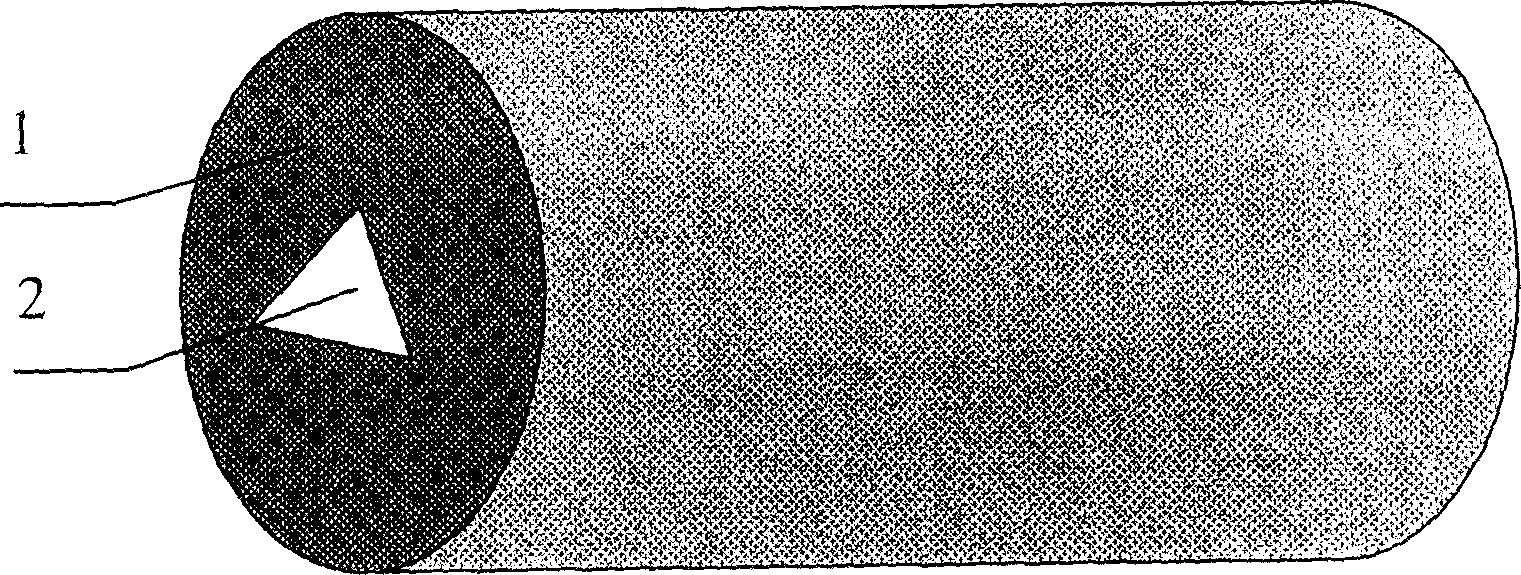

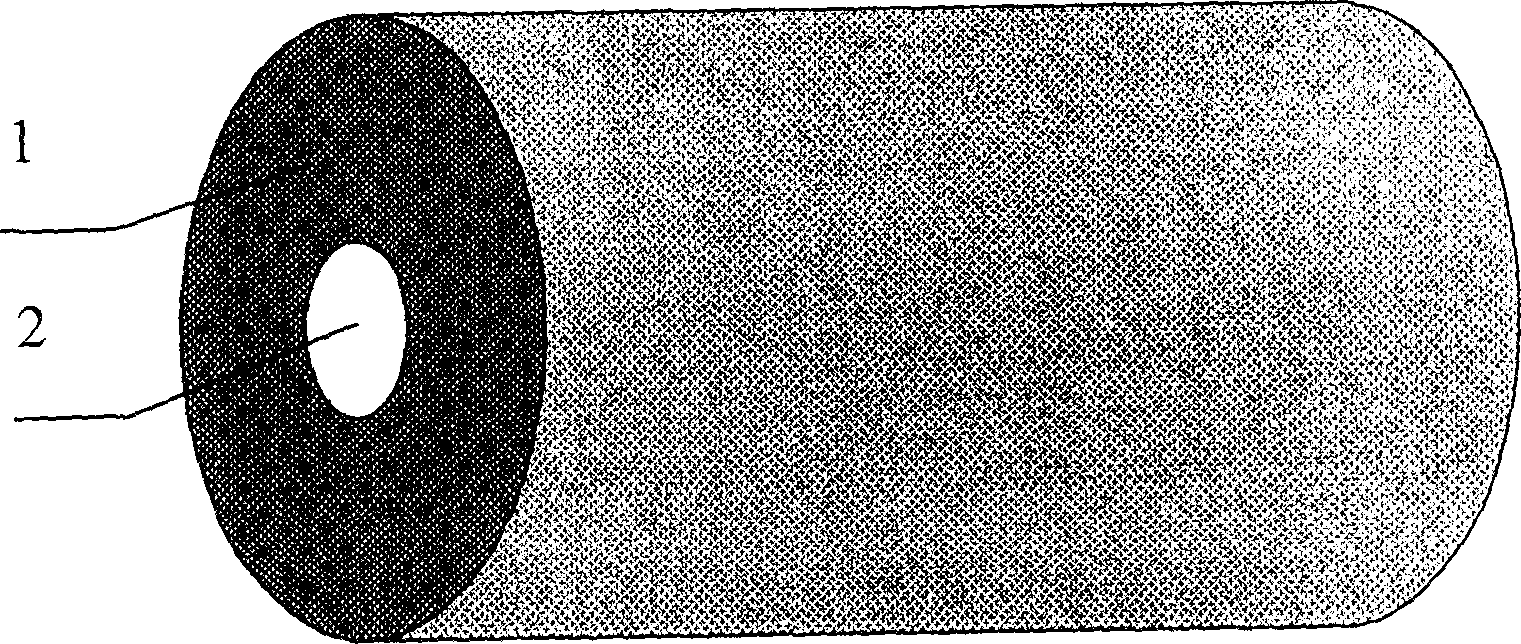

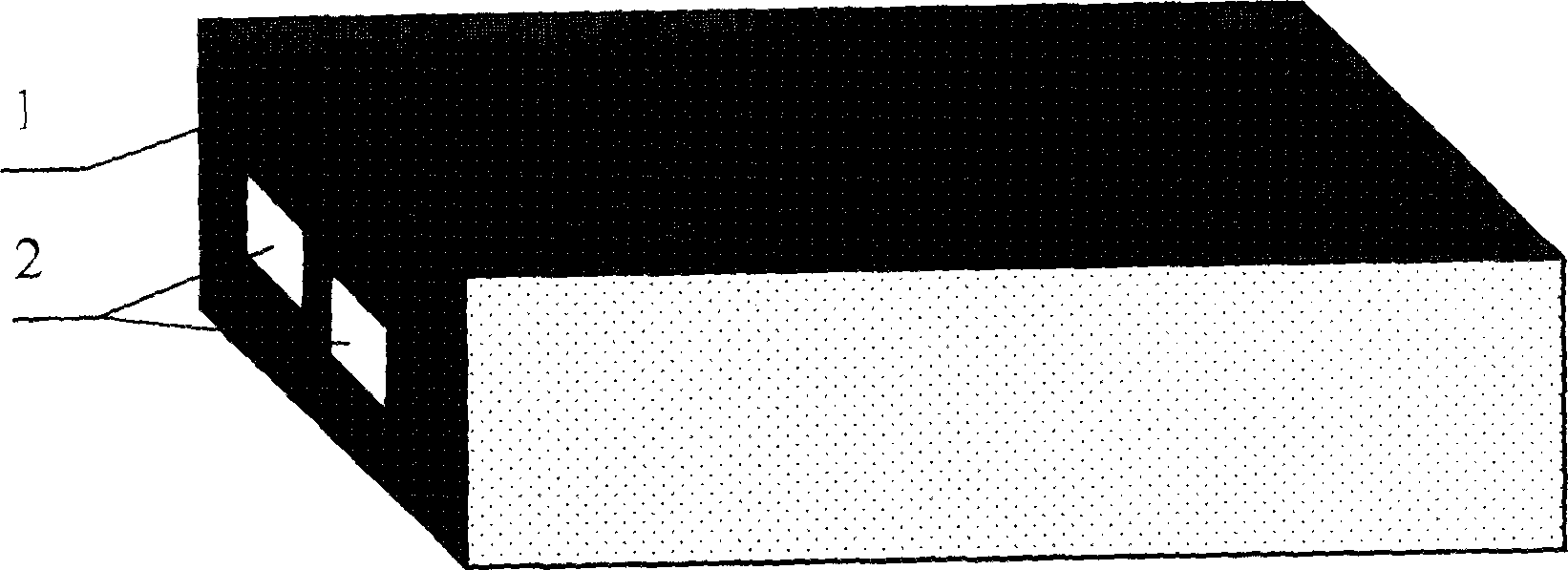

Method and equipment for preparing compact thin film by electrostatic spraying method

InactiveCN105289946AAvoid crackingControl reactivityLiquid surface applicatorsSpraying apparatusChemical reactionSpray nozzle

The invention provides a method for preparing a compact thin film by an electrostatic spraying method. The method comprises the following steps that at least two spray nozzles are adopted for spraying at least two kinds of precursors to the same substrate or collecting device; after meeting on the substrate or in the collecting process, the precursors carry out a chemical reaction so as to generate a thin film. According to the method, the spray nozzles simultaneously spray the precursors to the substrate or collecting device, or sequentially spray the precursors to the substrate or collecting device; the distance between the spray nozzles is adjustable; relative positions of the spray nozzles and the substrate or collecting device are adjustable. The method disclosed by the invention is low in cost, simple to operate, and high in repeatability; the thin film prepared by the method disclosed by the invention is not liable to crack.

Owner:NANJING UNIV OF SCI & TECH

Method for producing phenol resin

Owner:湖南中野高科技特种材料有限公司

Method for synthesizing isotropic silicon nitride powder adopting hollow type annular material-distribution

InactiveCN1799994AUniform fine permeabilityImprove permeabilityNitrogen compoundsCombustionMetallic materials

The invention discloses a homogeneous silicon nitride powder synthetic method of hollow ring-shaped cloth combustion in the inorganic non-metal material domain, which is characterized by the following: grinding to mix the silicon powder and silicon nitride powder at different proportions; placing the material in the combustion synthetic reaction device with poromeric hollow pipe according to the hollow ring-shaped cloth method after drying; charging 1-20 Mpa nitrogen gas in the vacuum device; inducing the combustion synthetic reaction through igniting. The invention realizes the complete nitridation of whole reactant at isothermal pattern, which improves the uniformity of silicon nitride powder.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing complex chemical compound

InactiveCN101225302ALow requirements for preparation conditionsQuality assuranceLuminescent compositionsProduct systemChemical compound

The invention relates to a preparation method of a complex chemical compound, which is characterized in that: degradable dispersion medium is added into the conventional coprecipitated product system, the isolation effectiveness produced by the dehydration and the decarburization of the dispersion medium at a special situation is utilized to prevent the aggregation of grains, thus, the reaction activity of the prepared complex chemical compound can meet the requirements of preparing luminescent materials with high performance based on the special specific surface area, and the grain sizes, the particle size distribution, the morphology, the luminous performance, the coating performance, the anti-deterioration performance and other specifications of the prepared luminescent material can meet optimizations. The preparation method of the complex chemical compound has the advantages of fast and controllable preparation process, easy realization of scale production and favorable product homogeneity.

Owner:GRIREM ADVANCED MATERIALS CO LTD

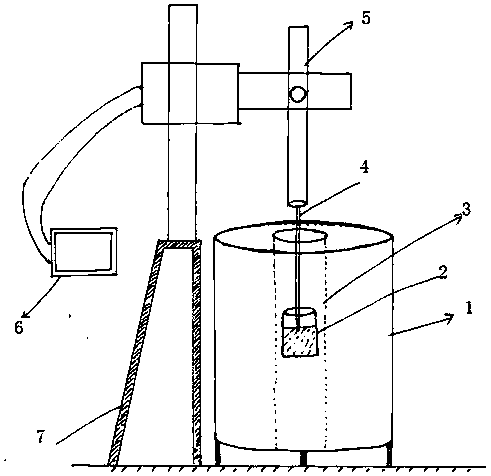

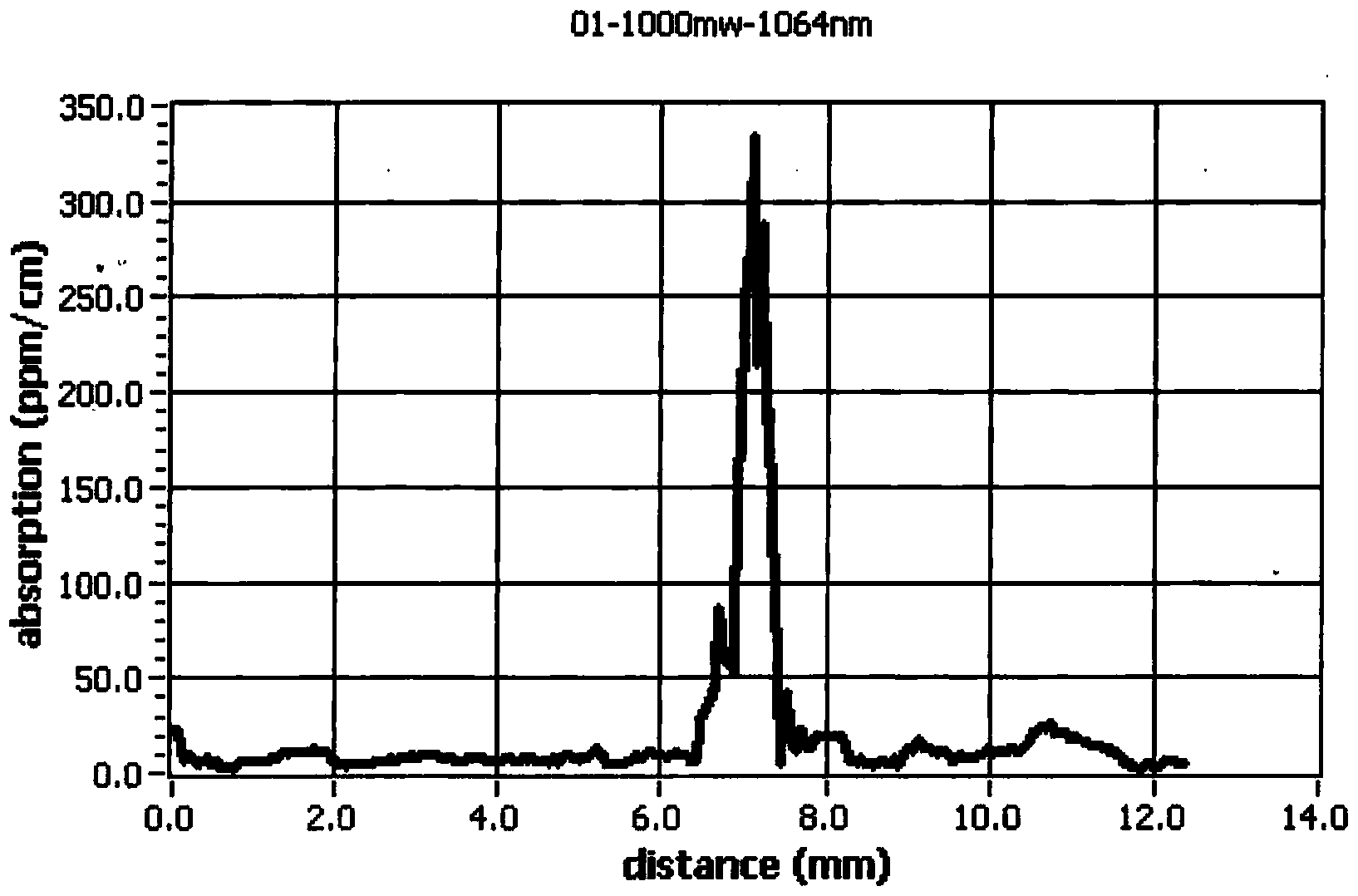

Preparation method of gray track resistance KTiOPO (GTR-KTP) crystals

ActiveCN103451731AAvoid pollutionImprove stabilityPolycrystalline material growthBy pulling from meltGreen-lightCrystal

The invention relates to a preparation method of gray track resistance KTiOPO (GTR-KTP) crystals. The method comprises the following steps: firstly preparing a KH2PO4 crystal material, and then carrying out sectional heating to form an even and stable high-temperature solution under a super environment; adopting a method of combining the top end with lifting to grow the GTR-KTP crystals. According to the KTP crystals prepared by the preparation method, an absorption coefficient of the KTP crystals is reduced; a gray track can be effectively prevented, so that the frequency doubling conversion efficiency of the KTP crystals is obviously enhanced; the GTR-KTP crystals are irradiated by a 100mw and 532nm of green light within 1000 seconds in a test; absorption of the system is basically kept stable; a good gray track resistant effect is displayed.

Owner:INNOWIT

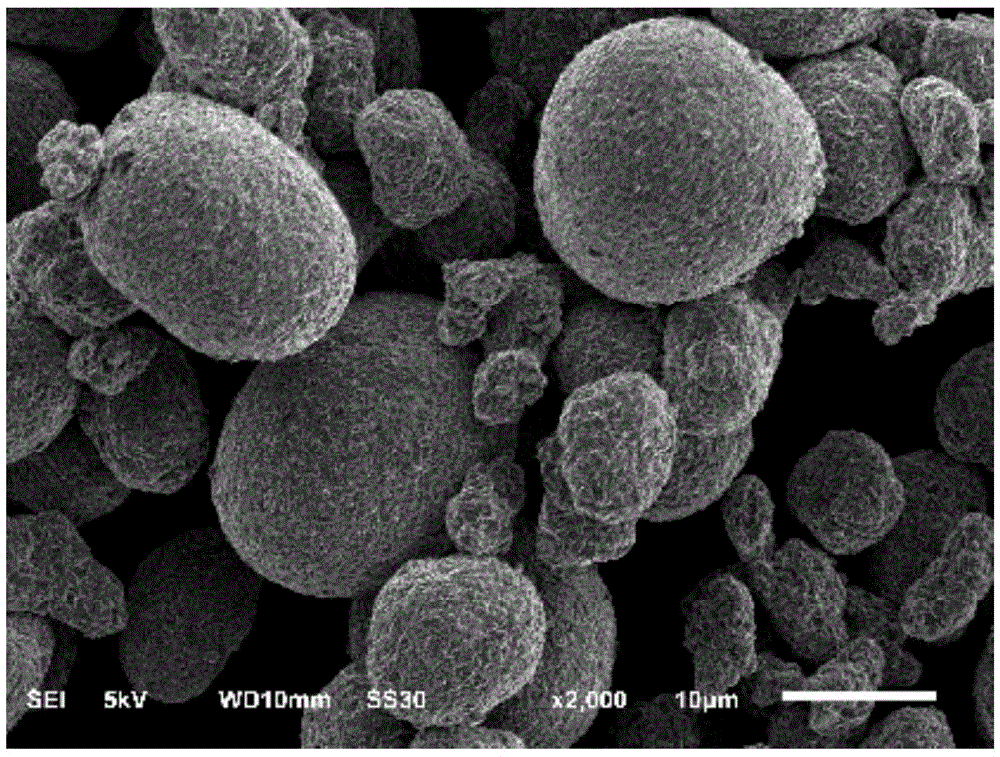

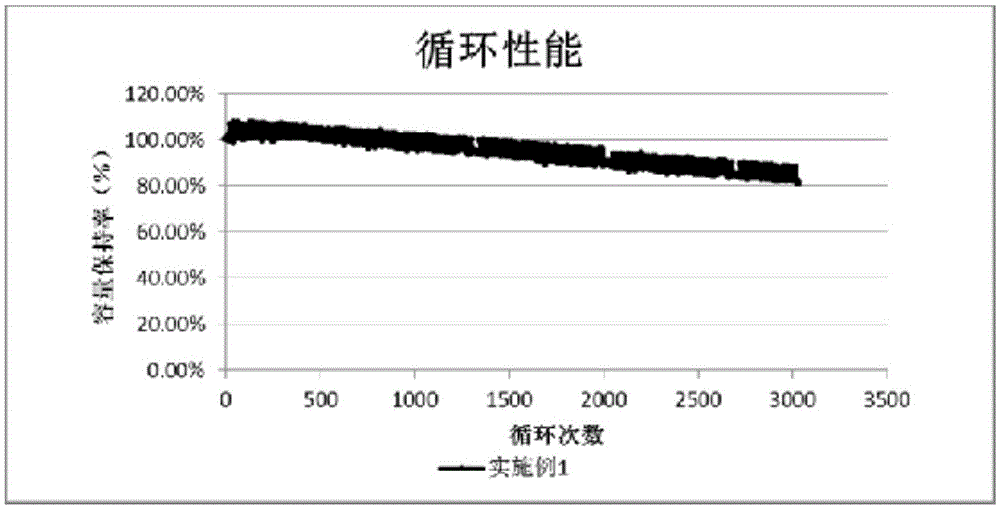

Industrial production method of nickel cobalt lithium manganite ternary positive electrode material with cycle life more than 3000 times

InactiveCN105591096AControl reactivityImprove cycle performanceCell electrodesSecondary cellsManganeseCobalt

The invention relates to a production technology of positive electrode materials of lithium ion batteries and particularly relates to an industrial production method of a nickel cobalt lithium manganite ternary positive electrode material with a cycle life more than 3000 times. The industrial production method comprises the following steps: (1) accurately weighing a nickel cobalt manganese hydroxide precursor with the D50 of 10.0-12.0 microns, wherein the total weight is about A tons; adding the precursor into an efficient mixer; meanwhile, accurately weighing B tons of lithium source according to a certain ratio (Li / Me) and adding the lithium source into the efficient mixer; uniformly mixing, wherein the weight ratio of A to B is (4:1) to (2:1); (2) feeding the mixture prepared by the step (1) into a sagger and conveying the sagger into a roller kiln; heating to a certain temperature at a certain speed and preserving the heat for certain time; adding the material into a cooling region, and cooling by air cooling and water cooling, wherein the cooling speed is 2.0 DEG C / min-5.0 DEG C / min, and the air inflow and the exhausting amount are accurately controlled to be 10.0m<3> / h-50.0<3> / h and 1000m<3> / h-3500m<3> / h respectively; and after discharging the mixture out of a furnace, roughly crushing and finely crushing to obtain LiNxCoyMn1-x-yO2 with the D50 of 11.0-14.0 microns, wherein x is more than or equal to 0.45 and less than or equal to 0.55 and y is more than or equal to 0.15 and less than or equal to 0.25. With the adoption of the method provided by the invention, the increasing of charge migration resistance in a circulating process can be reduced, the circulating performance of materials is improved, and more than or equal to 90% of the capacity can be kept after 2000 cycles.

Owner:GEM WUXI ENERGY MATERIAL CO LTD

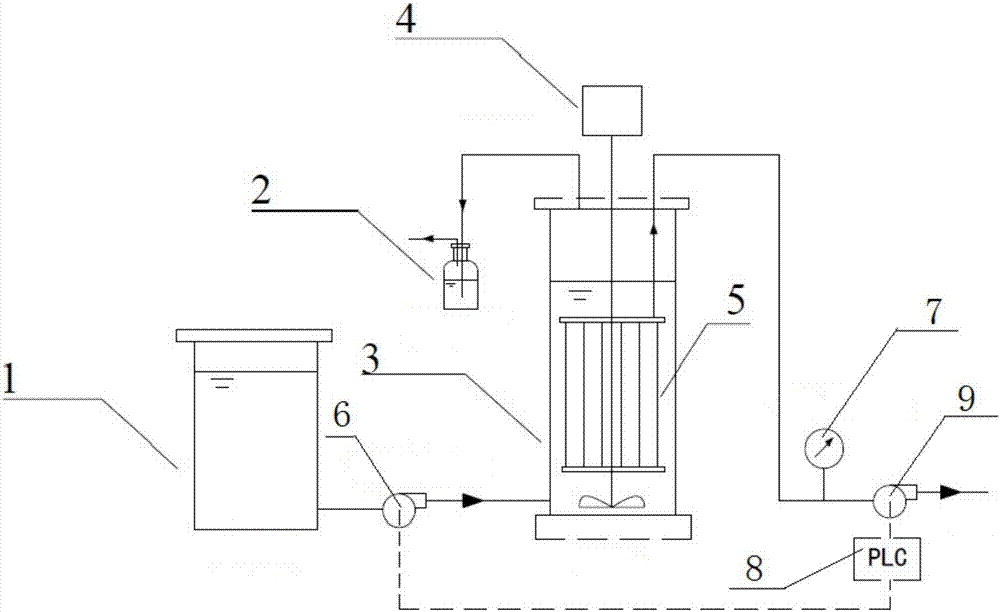

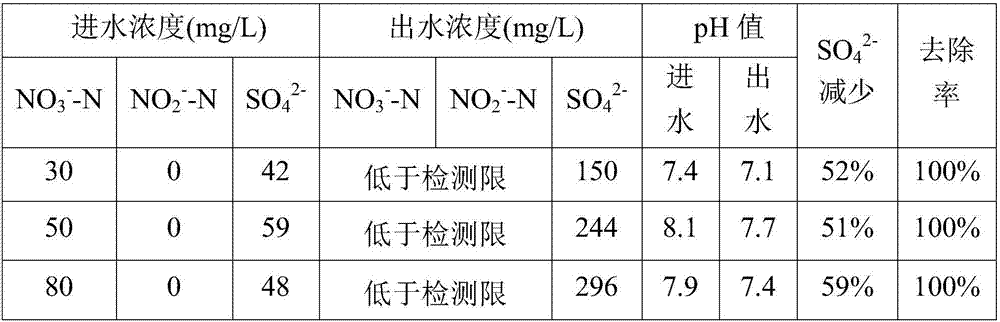

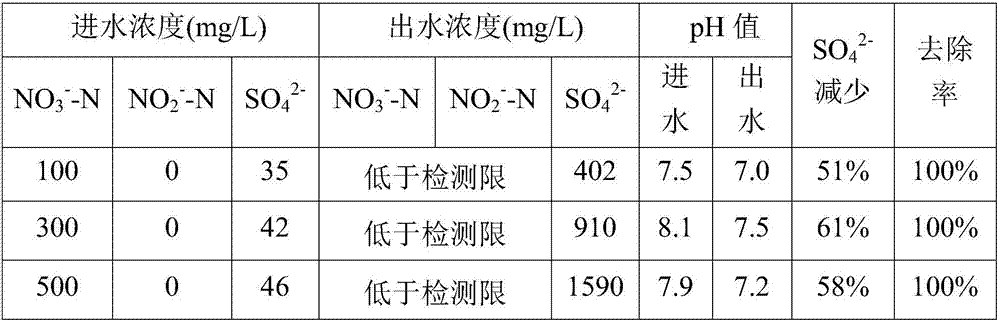

Method and system device for removing nitrate in water based on S-Fe collaborative autotrophic denitrification

InactiveCN107399829AReduce outputEmission reductionWater treatment parameter controlWater contaminantsWater basedHigh concentration

The invention discloses a method and system device for removing nitrate in water based on S-Fe collaborative autotrophic denitrification. The method comprises the steps of treating wastewater containing sulfate in an anoxic or anaerobic reactor by virtue of sulfur particles, iron particles and denitrifying bacteria, and separating water by virtue of a membrane module. The invention further provides the system device for implementing the method. According to the system device, the autotrophic denitrification of S and the autotrophic denitrification of Fe are collaborated in the reactor, denitrification and separation processes are combined together, activated sludge, S and Fe are fluidized through stirring, and efficient autotrophic denitrification is adequately carried out. According to the method, the autotrophic denitrification of S and the autotrophic denitrification of Fe are collaboratively coupled, and the control of the generation amount of sulfate radicals and the maintenance of the pH value of a reaction system are simultaneously realized. The method is suitable for treating medium-concentration and high-concentration nitrate wastewater, has the advantages of high nitrate removal rate, simplicity in operation, small occupied area, low operation cost and the like and will play an important role in treatment practice of nitrate wastewater.

Owner:江苏东材新材料有限责任公司 +1

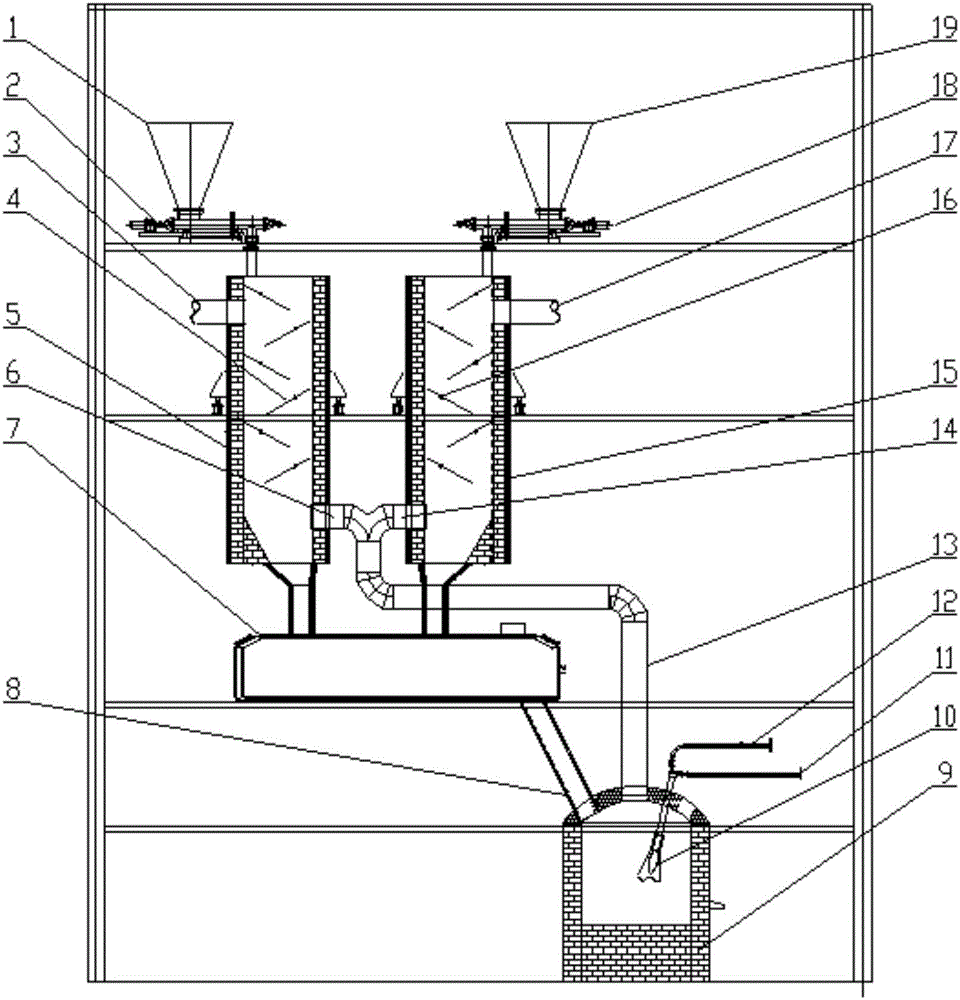

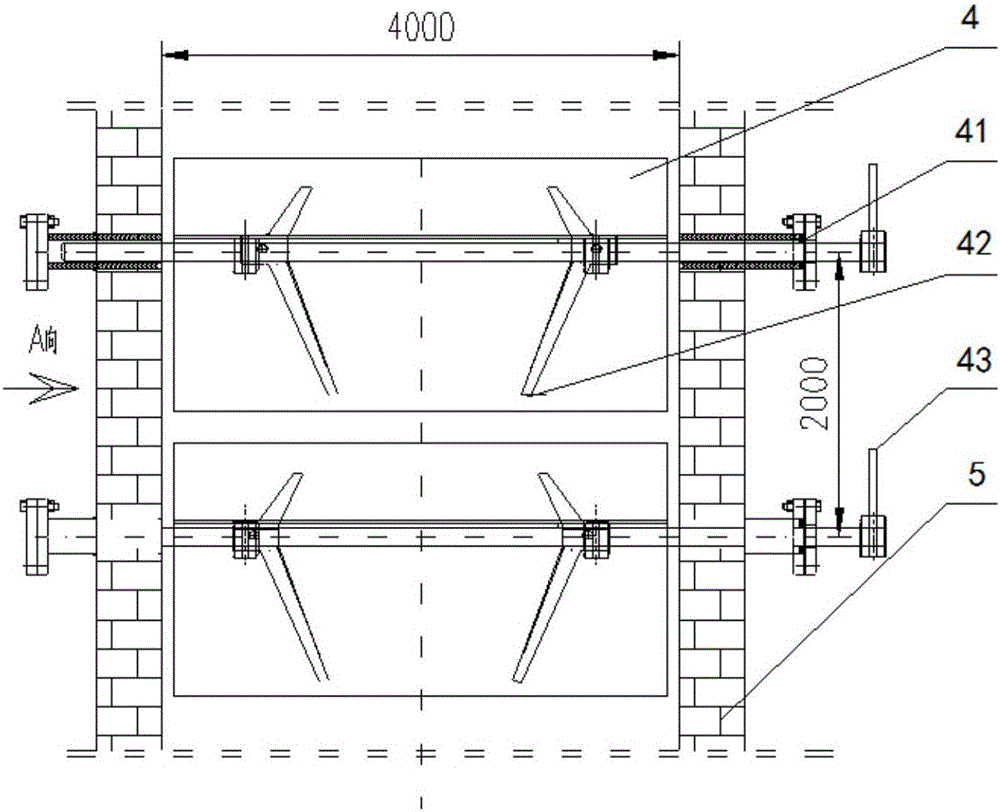

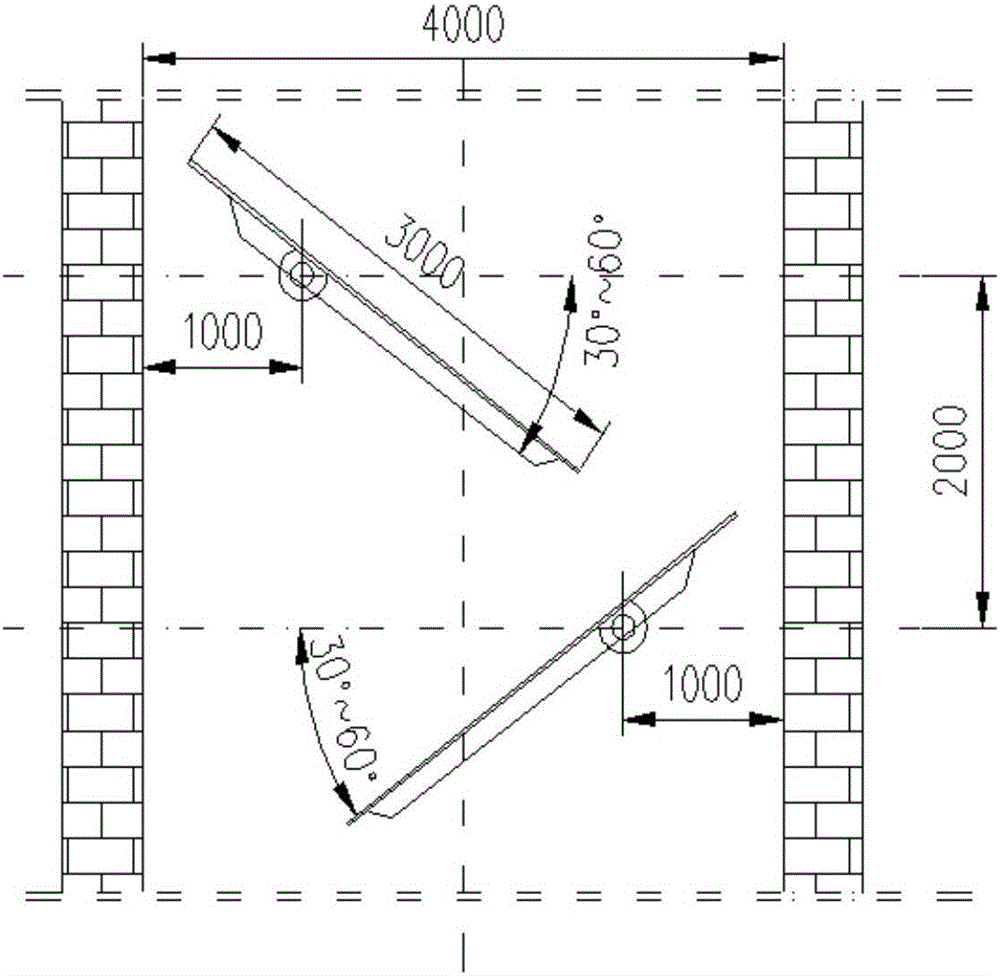

System and method for producing calcium carbide through high-temperature ball-pressing double-vertical-furnace

ActiveCN106082222ALow costReduce pulverization rateSpecial form destructive distillationShaft furnaceOxygen

The invention relates to a system and a method for producing calcium carbide through high-temperature ball-pressing double-vertical-furnace. The system comprises a vertical lime furnace, a high temperature pyrolyzing furnace, an oxygen thermal process calcium carbide furnace, a ball pressing machine and an oxygen coal gun, wherein the vertical lime furnace comprises a limestone flour inlet, a lime discharging opening and a vertical lime furnace smoke inlet; a baffle capable of adjusting inclining angle is arranged in a hearth of the vertical lime furnace; the high temperature pyrolyzing furnace comprises a coal dust feeding port, a carbon powder discharging opening, a carbon powder inlet and discharging opening; the baffle capable of adjusting inclining angle is arranged in the hearth of the high temperature pyrolyzing furnace; the ball pressing machine comprises a lime inlet, a carbon power inlet and discharging opening; the oxygen thermal process calcium carbide furnace comprises a lime feeding port, a carbon powder feeding port, a smoke outlet and a discharging opening; a spray gun of the oxygen coal gun is arranged in the oxygen thermal process calcium carbide furnace. According to the system and the method for producing calcium carbide through high-temperature ball-pressing double-vertical-furnace provided by the invention, the baffle capable of adjusting inclining angle is respectively arranged in the vertical lime furnace and the high temperature pyrolyzing furnace, so that the reaction and pyrolysis time of the materials in the furnace can be conveniently controlled and the reaction degree and efficiency of the materials can be ensured.

Owner:SHENWU TECH GRP CO LTD

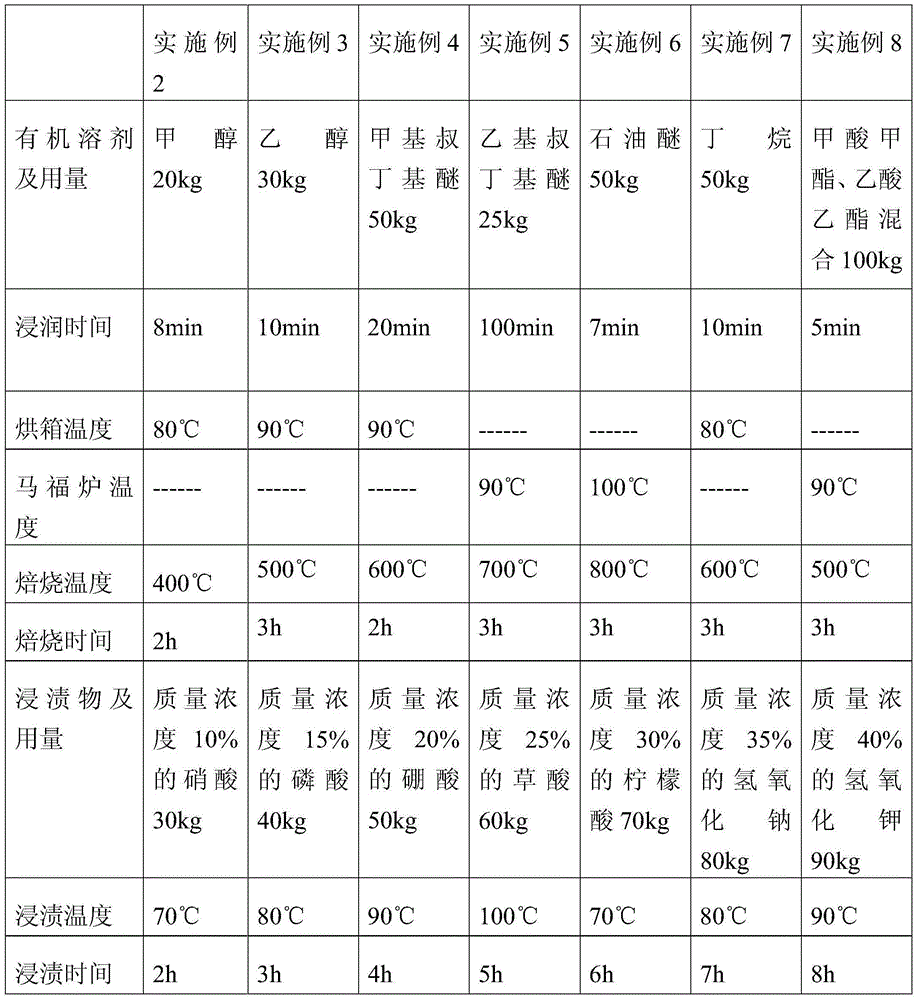

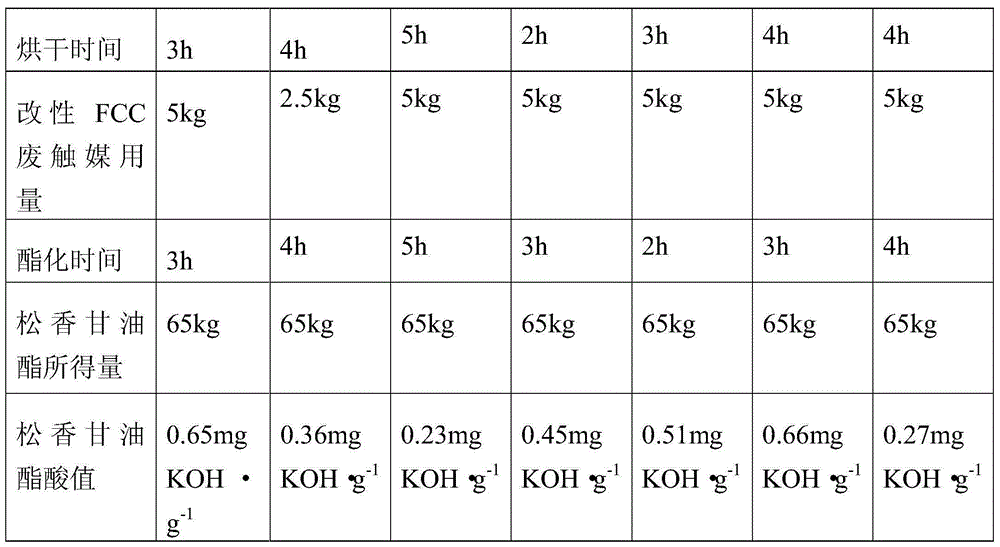

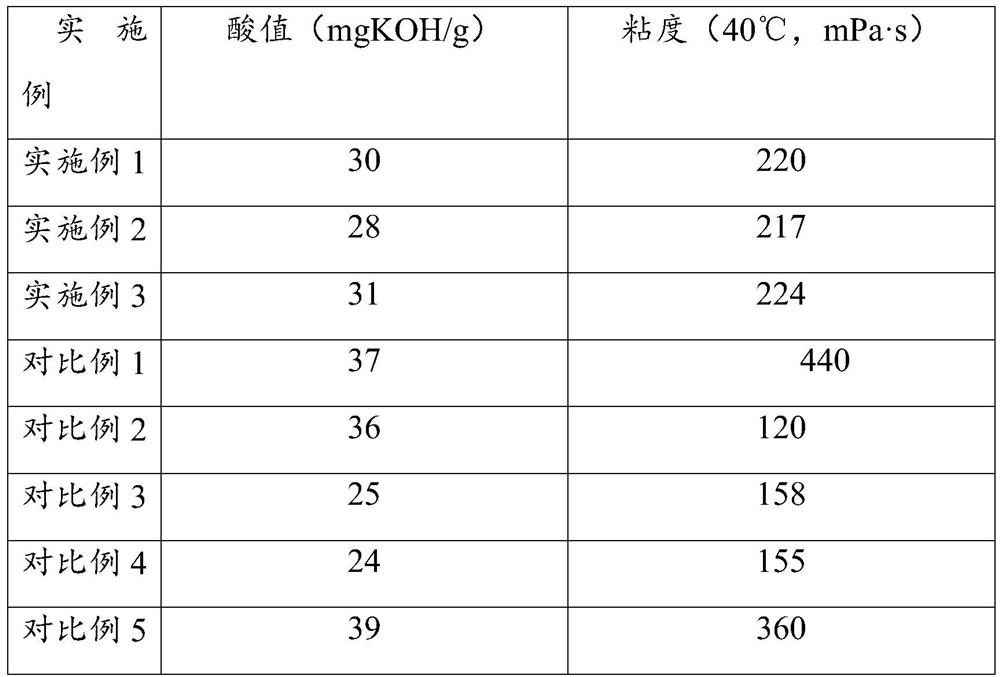

Internal vaporizing expansion method for regenerating modified FCC waste catalyst and application thereof

InactiveCN105214740AIncrease the areaIncrease the apertureOrganic chemistryOrganic compound preparationOrganic solventMuffle furnace

The invention discloses an internal vaporizing expansion method for regenerating a modified FCC waste catalyst and application thereof. The internal vaporizing expansion method is characterized by comprises the steps that 1, an FCC waste catalyst is wetted by using an organic solvent and then is put into a high-temperature drying oven or a muffle furnace of 80-100 DEG C to enable the organic solvent wetting and flowing into the FCC waste catalyst to be instantly vaporized and expand; 2, the FCC waste catalyst treated through the step 1 is subjected to roasting activation; 3, the FCC waste catalyst activated through the step 2 serves as a carrier, an impregnation method is adopted to load one of acid, alkali, metal ions. The modified FCC waste catalyst is used for esterification, condensation, cracking, hydrogenation and oxidation reaction. By means of the internal vaporizing expansion method, the FCC waste catalyst is utilized to prepare the modified and regenerated catalyst, the problem that a traditional FCC waste catalyst burying treatment method cause economic losses and soil, water and atmosphere pollution is solved, waste is turned into wealth, and dual benefits of economic value and environmental protection are obtained.

Owner:GUANGXI UNIV

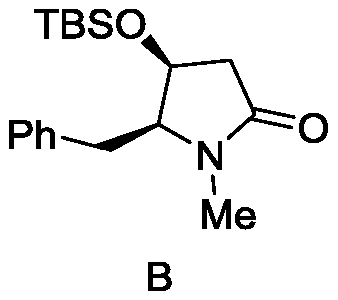

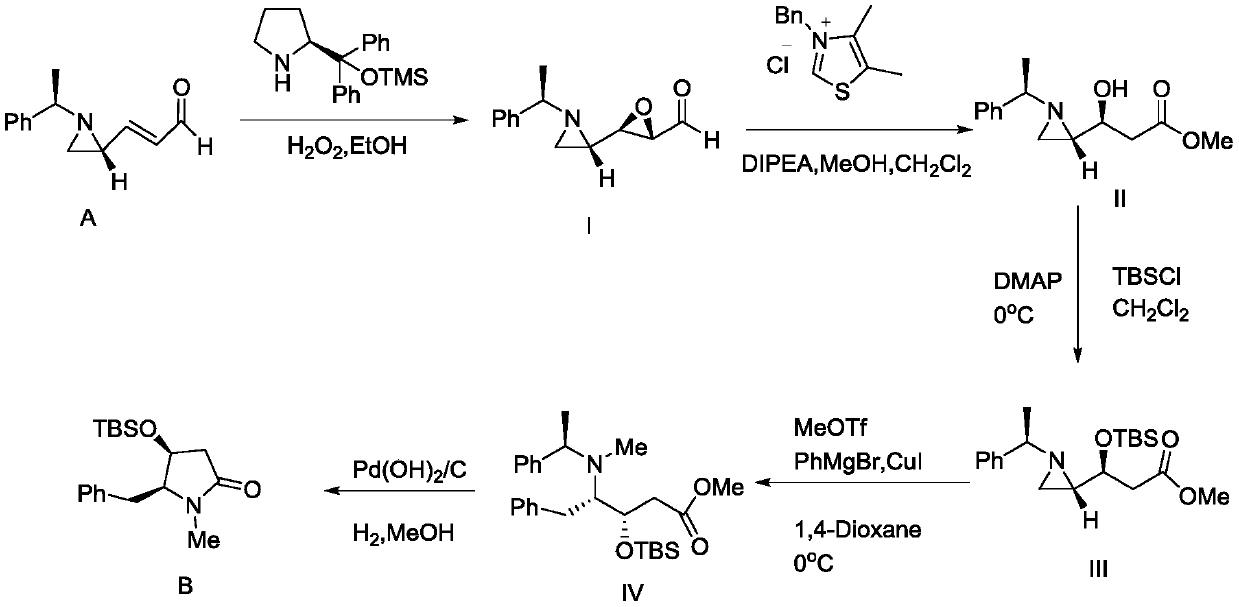

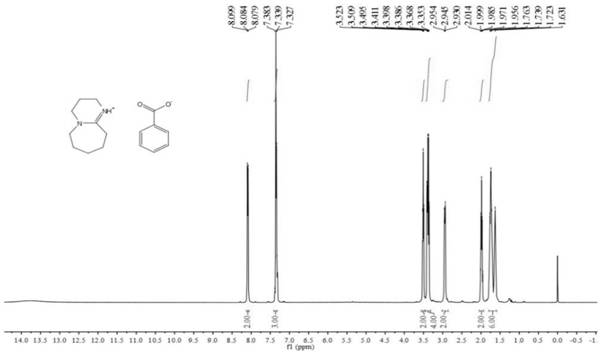

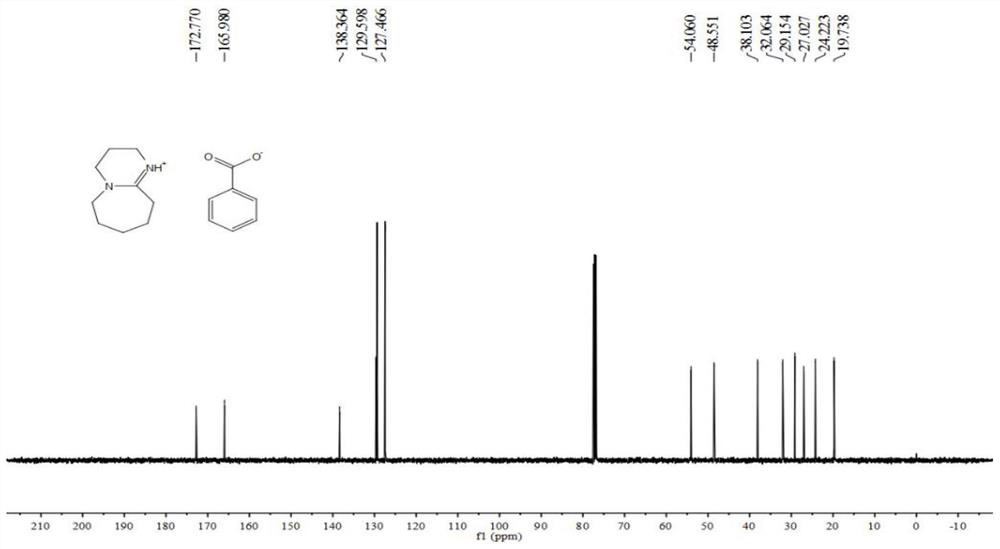

Preparation method of antitumor drug molecule (+)-Preussin intermediate

PendingCN110872317ASimple stepsControl reactivityGroup 4/14 element organic compoundsBulk chemical productionGrignard reagentRegioselectivity

The invention discloses a preparation method of an antitumor drug molecule (+)-Preussin intermediate, and the method comprises the following steps: carrying out epoxidation reaction on chiral aziridine-unsaturated aldehyde to generate chiral epoxide-aziridine, reacting the chiral epoxide-aziridine with methanol to reserve an aziridine ring by regioselectivity, and opening the epoxide ring to generate aziridine-beta-hydroxy ester; reactingthe aziridine-beta-hydroxy ester with a protective reagent TBSC1 to protect the beta position of the aziridine-beta-hydroxy ester, reacting with a Grignard reagent PhMgBr to generate an aziridine ring opening product, and finally carrying out reduction and cyclization reactions to generate the Preussin intermediate. According to the invention, the antitumor drug molecule (+)-Preussin medical intermediate is efficiently prepared only through a conventional organic reaction; according to the present invention, the problems of more impurities, easy configuration overturning, low yield, difficult purification and the like in the Preussin intermediate synthesis reaction are effectively solved, the total yield of the Preussin intermediate is substantially improved, the post-purification treatment is convenient, and the method has good economy, and is suitable for industrial production.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Low-smoke low-toxicity halogen-free flame-retardant resin as well as preparation method and application thereof

The invention discloses low-smoke low-toxicity halogen-free flame-retardant resin as well as a preparation method and application thereof. The low-smoke low-toxicity halogen-free flame-retardant resin is prepared from the following main raw materials in parts by weight: 80-120 parts of matrix resin, 0.05-0.2 part of accelerant, 0.01-0.1 part of polymerization inhibitor and 10-20 parts of flame retardant. Through preparation of matrix resin, selection of a special flame retardant and an auxiliary agent and limitation of the mass ratio of the matrix resin, the flame retardance and oxidation aging resistance of the flame-retardant resin are effectively improved, the flame-retardant resin has appropriate resin viscosity and excellent RTM process practicability, and a casting body prepared and formed by using an RTM process has good mechanical properties, and is suitable for popularization in the field of organic resin and has a wide development prospect.

Owner:镇江利德尔复合材料有限公司

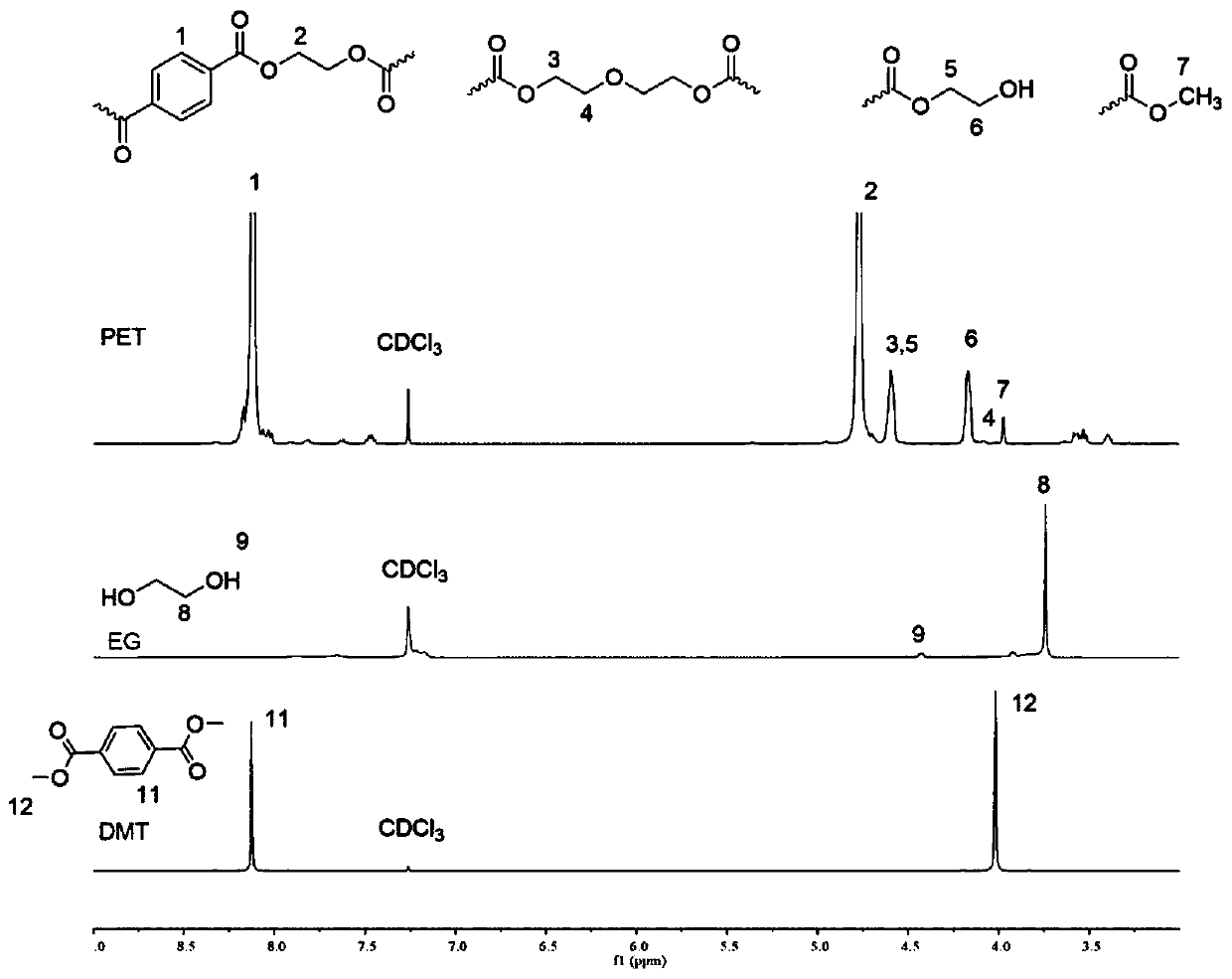

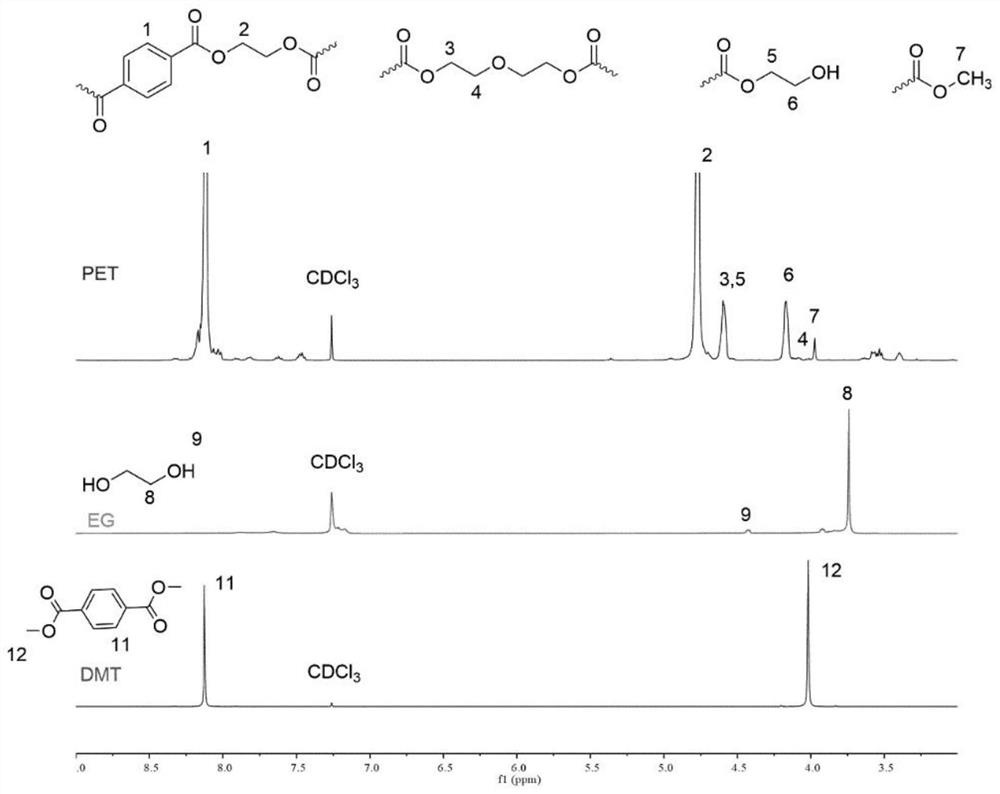

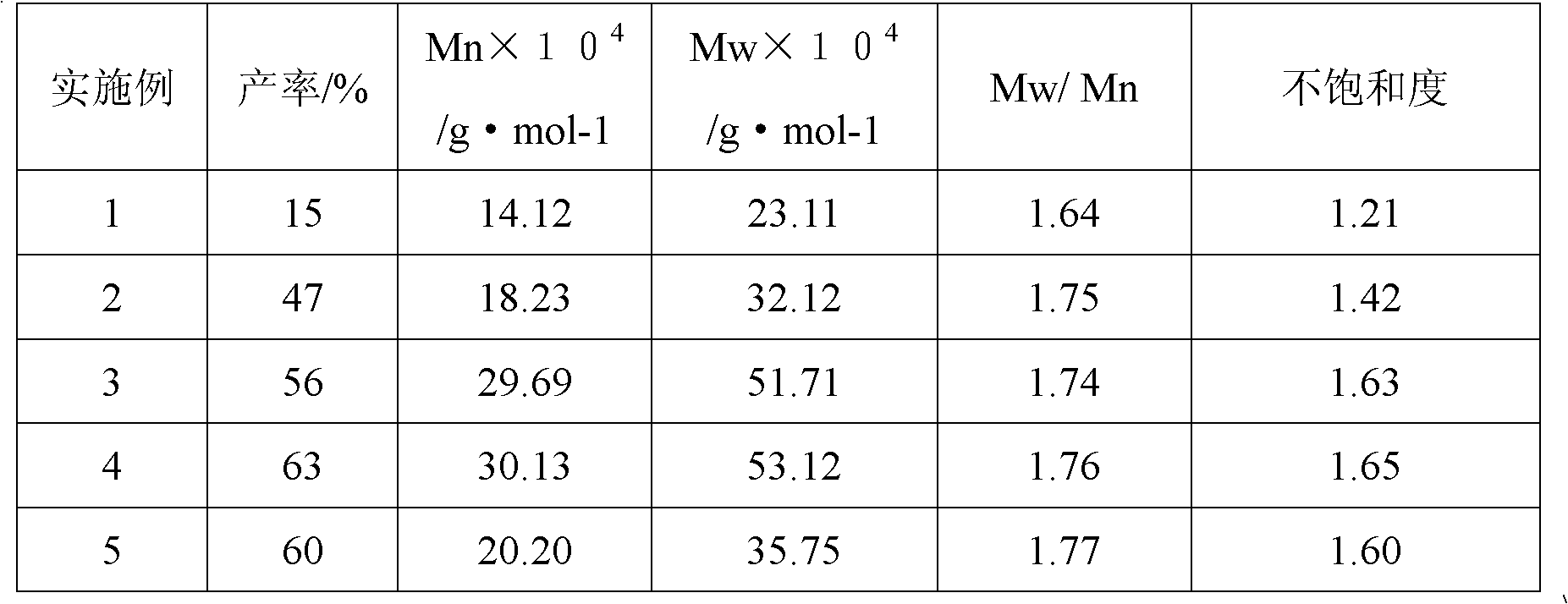

Preparation method of bio-based polyester

The invention belongs to the technical field of organic synthesis, and particularly relates to a preparation method of bio-based polyester. Terephthalic acid and derivatives thereof are synthesized into high-molecular-weight polyester compounds by adopting a two-step method. By adopting the method disclosed by the invention, efficient, mild and controllable polymerization reaction is realized, introduction of any metal in a catalytic polymerization reaction process is completely avoided, a depolymerization reaction of the catalyst in a secondary (or subsequent) process is avoided, polymer molecules with a predetermined structure are constructed, and design and control of the performance of a polymer material are realized.

Owner:NANJING UNIV OF TECH

Method for preparing polyphenylene sulfide resin and polyphenylene sulfide resin prepared by using method

The invention discloses a method for preparing polyphenylene sulfide resin and the polyphenylene sulfide resin prepared by using the method. The method comprises the steps of: performing a polycondensation reaction by adopting a sulfur-containing compound, an alkaline substance and p-dichlorobenzene as raw materials and fatty acid as a polycondensation assistant, conducting purification treatmentto obtain a primary product of the polyphenylene sulfide resin, and then performing a reaction between the primary product of the polyphenylene sulfide resin and terminal-group modifier at a high temperature to generate the polyphenylene sulfide resin. The preparation method has high yield and low cost, and the prepared polyphenylene sulfide resin has high reaction activity, high melting and crystallization temperatures and excellent heat resistance at the same time; the polyphenylene sulfide resin can be directly applied to extrusion and injection molding, and is particularly applicable to the fields of automobile parts, electronic / electrical equipment, chemical engineering, machinery industry and the like.

Owner:ZHEJIANG NHU CO LTD +2

Preparation of a modified micron zero-valent iron and its application method in remediation of soil heavy metal pollution

ActiveCN106180735BEasy to applyProlong the action timeContaminated soil reclamationSlagGroundwater remediation

The invention discloses a preparation method of modified micron zero-valent iron and its application method in the restoration of soil heavy metal pollution, including cleaning iron raw materials, preparing micron iron, ultrafine grinding, and modification treatment steps. Using water, xanthan gum, sulfide, stabilizer, zeolite, and a modifier composed of blast furnace slag, the beneficial effects of the present invention are: the production process of the micron zero-valent iron of the present invention is simple, and while reducing the cost, obtained The effect is similar to or better than that of nanometer zero-valent iron, and the reactivity is controlled, the oxidation rate is reduced, excellent stability is obtained, and the action time of micron zero-valent iron is longer. The method further reduces the cost of groundwater heavy metal restoration. The invention can improve the fertility of the soil by adding organic fertilizer in the soil treatment process, and the humic acid produced by the organic fertilizer can improve the structure of the soil, and can not only remove lead and chromium in the groundwater and arsenic and other heavy metal elements, and can also reduce the concentration of pollutants such as nitrate and perchlorate.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

A kind of method that n-butane oxidation prepares maleic anhydride

ActiveCN106749125BAverage temperature distributionMild severity of reactionOrganic chemistryPhysical/chemical process catalystsSide reactionButane

The invention discloses a method of producing maleic anhydride by oxidizing n-butane. The method includes the following steps: mixing the n-butane with air; co-currently enabling the mixed reaction gas to pass through at least two vanadium-phosphorous oxide catalyst bed layers in series to perform a contact reaction with a vanadium-phosphorous oxide catalyst under an oxidizing reaction condition. The average valence of vanadium in a downstream catalyst bed layer is higher than that of vanadium in an upstream catalyst bed layer according to the contact sequence of the catalyst with the mixed reaction gas. The method reduces reaction hot spots in the bed layers and enables temperature distribution in the bed layers to be balanced, thus effectively inhibiting side-reactions, increasing product selectivity and increasing yield of the product, maleic anhydride.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electro-conductive ceramic for electronic components and preparation method thereof

The invention discloses electro-conductive ceramic for electronic components, which is composed of, by mass, 30-40% of ceramic powder, 20-25% of diatomite, 3-7% of CaSiO3, 5-10% of CaCO3, 10-15% of SiO2, 3-5% of chromic oxide, 5-10% of nickel borate, 10-15% of barium titanate, 2-3% of polyacrylamide, and 2-3% of metal powder, all the components adding to 100% by mass. The invention also disclosesa preparation method of the electro-conductive ceramic, including: ball-milling the raw materials for two times, performing oxidization during the ball milling with oxygen and argon; and after oxidization, performing ultrasonic treatment and sintering, and finally press-shaping the electro-conductive ceramic. The electro-conductive ceramic is mainly prepared from ceramic powder and diatomite, which are abundant in source and low in cost, so that the product is suitable for large-scale production.

Owner:西安居正知识产权运营管理有限公司

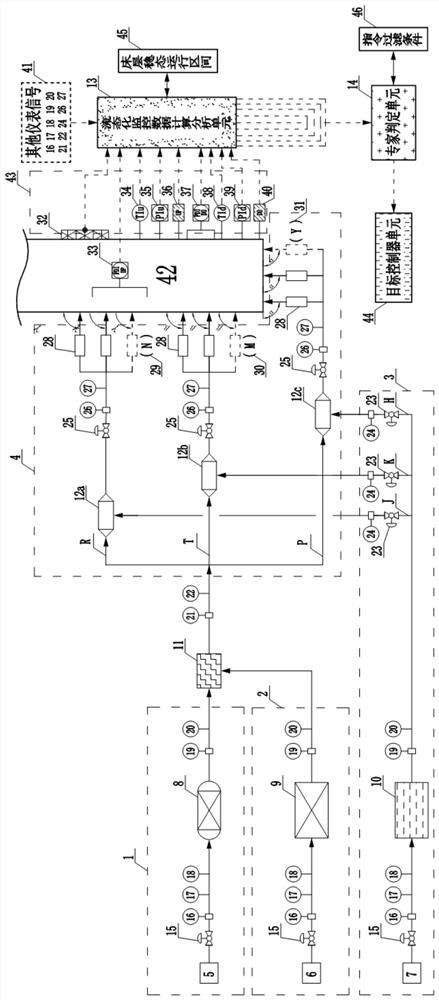

Dense-phase fluidization reaction control device and method

ActiveCN112546971AControl reactivityEffective Fluidization MonitoringTotal factory controlChemical/physical processesReaction control systemInert gas

The invention discloses a dense-phase fluidization reaction control device and method; the dense-phase fluidization reaction control device comprises a dense-phase fluidization reaction gas supply system and a dense-phase fluidization reaction control system; the dense-phase fluidization reaction gas supply system comprises a feed gas I unit, a feed gas II unit, an inert gas unit and a dense-phasefluidization reaction gas distribution unit; the dense-phase fluidization reaction control system comprises a dense-phase bed fluidization monitoring unit, a fluidization monitoring data calculationand analysis unit, an expert judgment unit, a target controller unit and other instrument signal units. The invention further provides the dense-phase fluidization reaction control method based on computer autonomous learning; the flow and the reaction activity of the feed gas entering the dense-phase zone of the reactor are controlled by analyzing the flow characteristics of a reaction bed layer,and then the dense-phase fluidization reaction process is controlled. The device and method are high in automation degree and efficient and convenient in data analysis, have the characteristic of machine learning, and have a wide application prospect in the field of dense-phase fluidization reaction control.

Owner:SHAANXI YANCHANG PETROLEUM GRP

A kind of preparation method of bio-based polyester

Owner:NANJING TECH UNIV

Solution method for synthesizing butyl rubber

The invention relates to a solution method for synthesizing butyl rubber. A mixture of C4-C8 monoolefine monomers and C4-C14 polyene hydrocarbon monomers is taken as a raw material, and in a system that hexane and chloromethane are solvents, polymerization reaction is initiated by an initiating system to prepare butyl rubber polymer, wherein the reaction pressure is normal pressure, the reaction temperature ranges from 0 to -90DEG C, and the initiating system has the concentration of 0.01-0.001mol / L, and is prepared by dissolving a main initiator, namely deionized water and a coinitiator, namely aluminum alkyl dihalide by using a polar solvent CH2Cl2 for mixing, and adding alkylol amines; the molar ratio of the coinitiator to the main initiator is 1:1-10:1, and the molar ratio of a third component to the main initiator is 1:10-1:25; and the adding amount of the mixed solvent is 1 to 50 times volume of the polymerization monomers. According to the method, reaction is mild, polymerization temperature is improved, the stability and initiation efficiency of the initiators are high, and the molecular weight distribution of the product is narrow.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com