Method and equipment for preparing compact thin film by electrostatic spraying method

A technology of electrostatic spraying and thin film, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc. It can solve the problems of difficult connection of film, easy cracking of film, unfavorable dense film and other problems, and achieves strong repeatability, The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

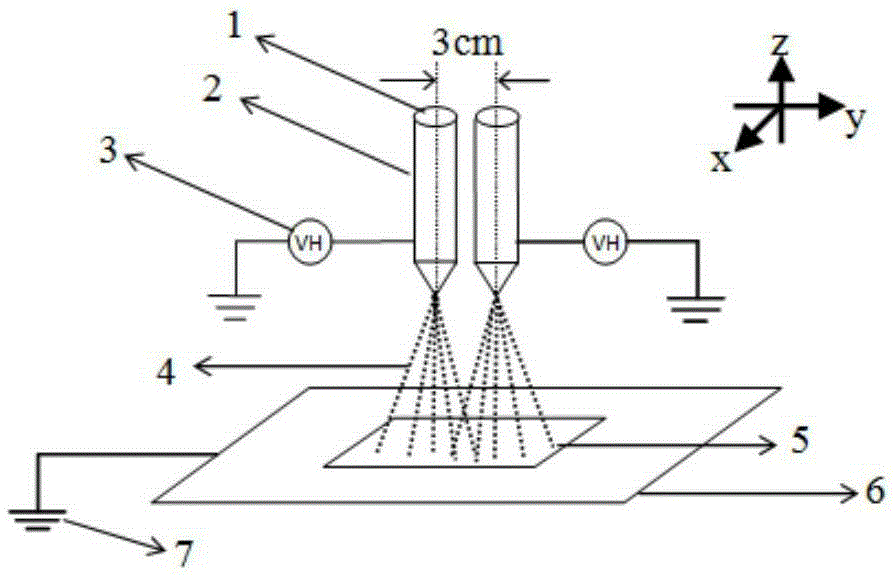

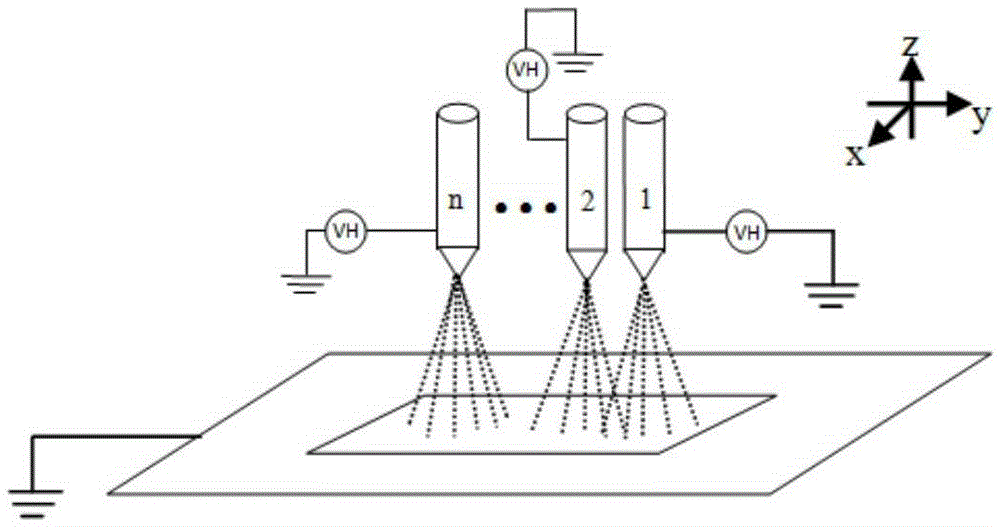

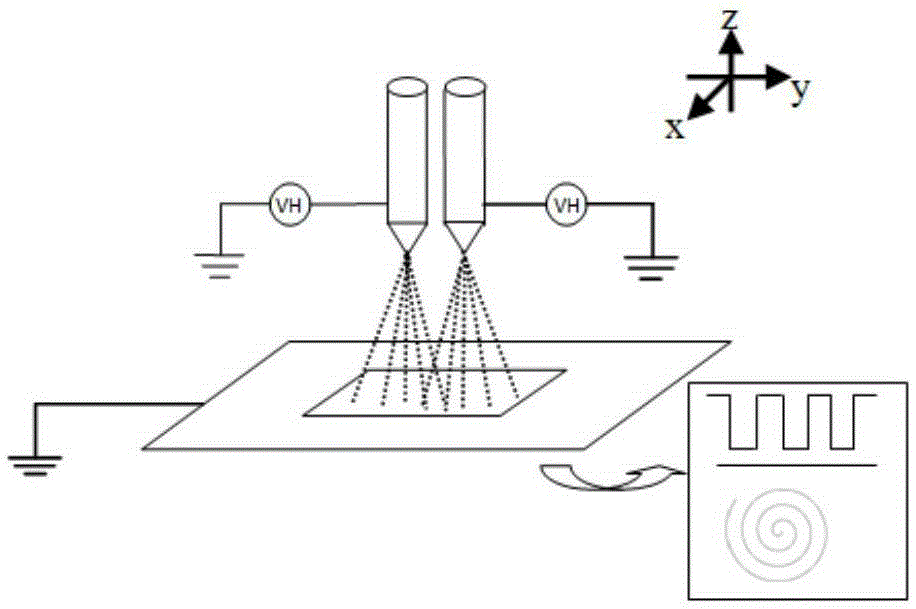

[0023] When using multiple nozzles to prepare the desired film, such as figure 2 As shown, an XY precision mechanical platform is built, which can be moved freely in three dimensions; multiple nozzles for electrostatic spraying are fixed on the mechanical platform, and the other end of the nozzles has a liquid injection tube and a wire for transmitting high-voltage electricity. The pioneer of high-voltage electric pair injection The body reactant liquid applies high-voltage DC static electricity, so that the droplets dripping from the nozzle are charged. When the molecules in the droplets are charged with the same sex, they will start to repel each other. After the electrostatic force is greater than the surface tension of the droplets, they will finally split into countless Fine droplets are ejected to form multiple jets. The relative positions of multiple nozzles are determined according to the coating requirements. Different distances can form different film structures on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com