Preparation method of modified micron zero-valent iron and application method of modified micron zero-valent iron in remediation of heavy metal contaminated soil

A zero-valent iron, modified technology, applied in the restoration of polluted soil and other directions, can solve the problems of high cost and poor restoration effect, and achieve the effect of removing pesticide residues, excellent stability and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

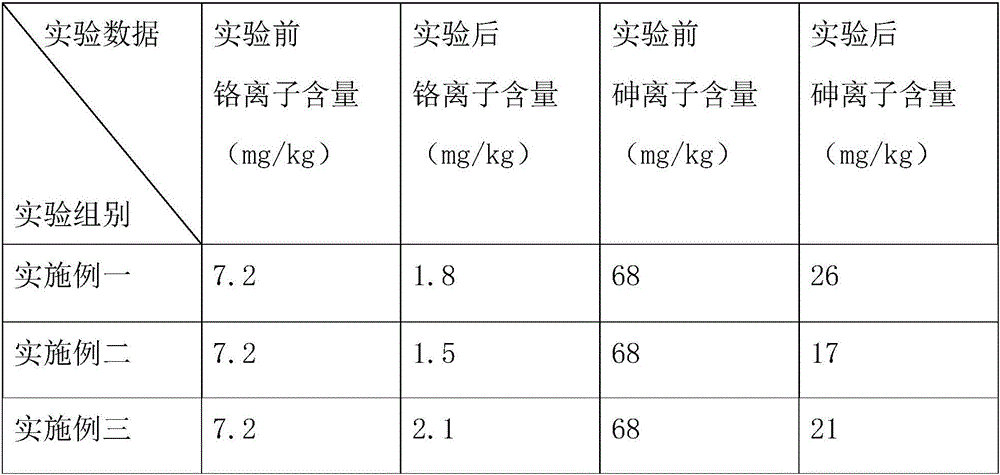

Embodiment 1

[0027] The invention provides a technical solution: a preparation method of modified micron zero-valent iron, comprising the following steps:

[0028] S1: Clean iron raw materials, use scrap iron as raw material, soak the raw material in clean water for 3 minutes, then add lye to the clean water and continue soaking for 5 minutes, then use clean water to wash away surface stains and oil stains, and then use scrap iron raw materials Place it in dilute hydrochloric acid liquid with a mass concentration of 5%, soak it and heat it, the heating temperature is 80 degrees Celsius, the reaction time is 10 minutes, and finally the scrap iron raw material is taken out and dried;

[0029] S2: Prepare micron iron, use high-energy ball mill, beat and pulverize the iron raw material after cleaning in the previous step for 50 minutes, then pass through a 200-mesh sieve for screening, and store the iron powder that passes the screening for future use, and continue if the particle diameter does...

Embodiment 2

[0038] The invention provides a technical solution: a preparation method of modified micron zero-valent iron, comprising the following steps:

[0039]S1: Clean iron raw materials, use scrap iron as raw material, soak the raw material in clean water for 4 minutes, then add lye to clean water and continue soaking for 6 minutes, then use clean water to wash away surface stains and oil stains, and then use scrap iron raw materials Place it in dilute hydrochloric acid liquid with a mass concentration of 5%, soak it and heat it, the heating temperature is 88 degrees Celsius, the reaction time is 13 minutes, and finally the scrap iron raw material is taken out and dried;

[0040] S2: Prepare micron iron, use high-energy ball mill, beat and pulverize the iron raw material after cleaning in the previous step for 56 minutes, then pass through a 200-mesh sieve for screening, and store the iron powder that passes the screening for future use, and continue if the particle diameter does not ...

Embodiment 3

[0049] The invention provides a technical solution: a preparation method of modified micron zero-valent iron, comprising the following steps:

[0050] S1: Clean the iron raw materials, use scrap iron as the raw material, soak the raw materials in clean water for 5 minutes, then add lye to the clean water and continue soaking for 8 minutes, then use clean water to wash away the surface stains and oil stains, and then use the scrap iron raw materials Place it in dilute hydrochloric acid liquid with a mass concentration of 5%, soak it and heat it, the heating temperature is 90 degrees Celsius, the reaction time is 15 minutes, and finally the scrap iron raw material is taken out and dried;

[0051] S2: Prepare micron iron, use high-energy ball mill, beat and pulverize the iron raw material after cleaning in the previous step for 60 minutes, then pass through a 200-mesh sieve for screening, and store the iron powder that passes the screening for future use, and continue if the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com