Patents

Literature

86results about How to "Moderate surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of modified micron zero-valent iron and application method of modified micron zero-valent iron in remediation of heavy metal contaminated soil

ActiveCN106180735AAvoid secondary pollutionGood dispersionContaminated soil reclamationSoil treatmentSlag

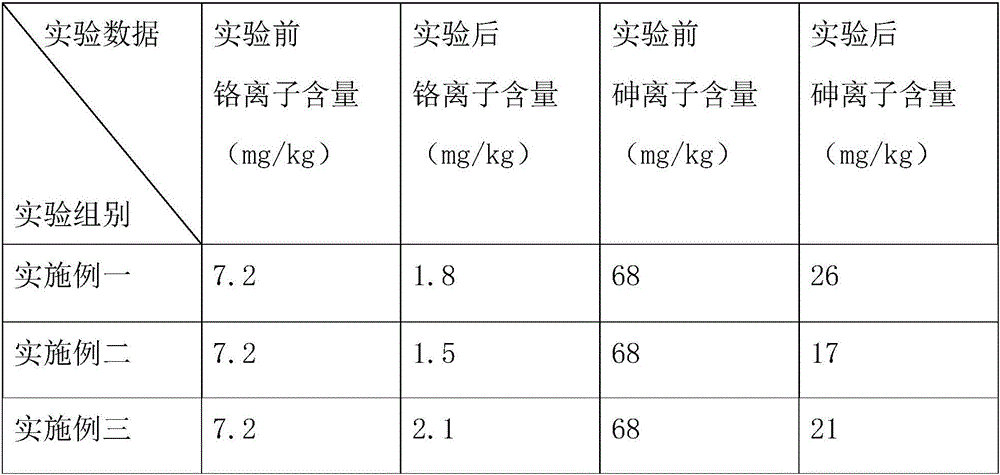

The invention discloses a preparation method of modified micron zero-valent iron and an application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil. The preparation method of the modified micron zero-valent iron comprises the steps of cleaning of iron raw materials, preparation of micro iron, ultrafine grinding and modifying treatment. A modifying agent composed of water, xanthan gum, sulfide, a stabilizing agent, zeolite and blast furnace slag is adopted in the step of modifying treatment. The preparation method of the modified micron zero-valent iron has the beneficial effects that the production process of the modified micron zero-valent iron is simple, and the effect similar or superior to micron zero-valent iron is achieved while the cost is reduced; and in addition, the reaction activity is controlled, the oxidation rate is decreased, excellent stability is obtained, and the acting time of the micron zero-valent iron is longer. By the adoption of the application method of the modified micron zero-valent iron, the remediation cost of heavy metal contaminated underground water is further reduced. According to the preparation method of the modified micron zero-valent iron and the application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil, organic fertilizer is added in the soil treatment process so that the fertility of soil can be improved, the structure of soil can be improved through humic acid produced by the organic fertilizer, heavy metal elements, such as lead, chromium and arsenic, in underground water can be removed, and the concentration of pollutants such as nitrate and perchlorate can be reduced.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

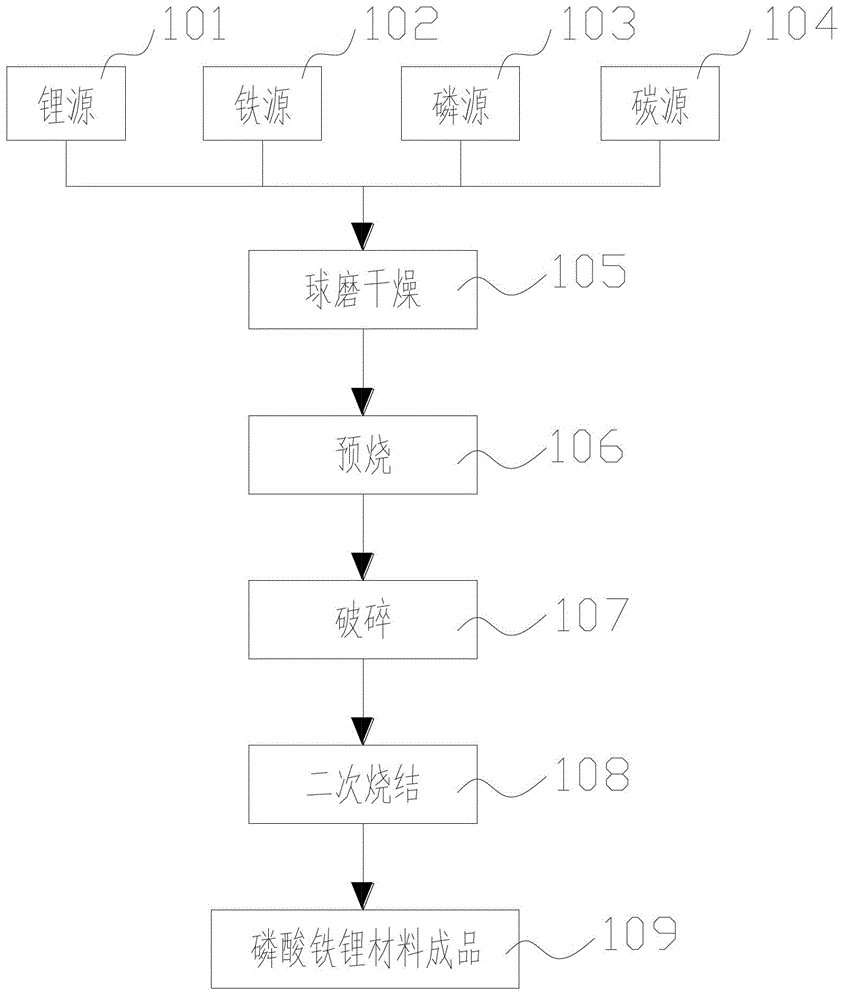

Method for preparing lithium iron phosphate material

ActiveCN102745663ASteps to reduce doping modificationSimple production processPhosphorus compoundsLithium iron phosphateBall mill

The invention discloses a method for preparing a lithium iron phosphate material. The method comprises the following steps of: mixing raw materials for preparing the lithium iron phosphate material, wherein the raw materials include a lithium source, an iron source, a phosphorus source and a carbon source, and the iron source is a mixture of ferrous iron and ferric iron; performing ball milling and drying on the mixed raw materials: putting the mixed raw materials into a ball mill for performing ball milling, and drying; pre-burning the ball-milled and dried raw materials to obtain a precursor of the lithium iron phosphate material; crushing the precursor of the lithium iron phosphate material obtained by pre-burning; and performing secondary sintering on the crushed precursor of the lithium iron phosphate material to obtain a finished lithium iron phosphate material. The lithium iron phosphate material prepared with the method has the advantages of high specific capacity, appropriate tap density, appropriate specific surface area, excellent circulating performance and excellent processing performance.

Owner:SICHUAN JINWANGTONG ELECTRONICS SCI & TECH

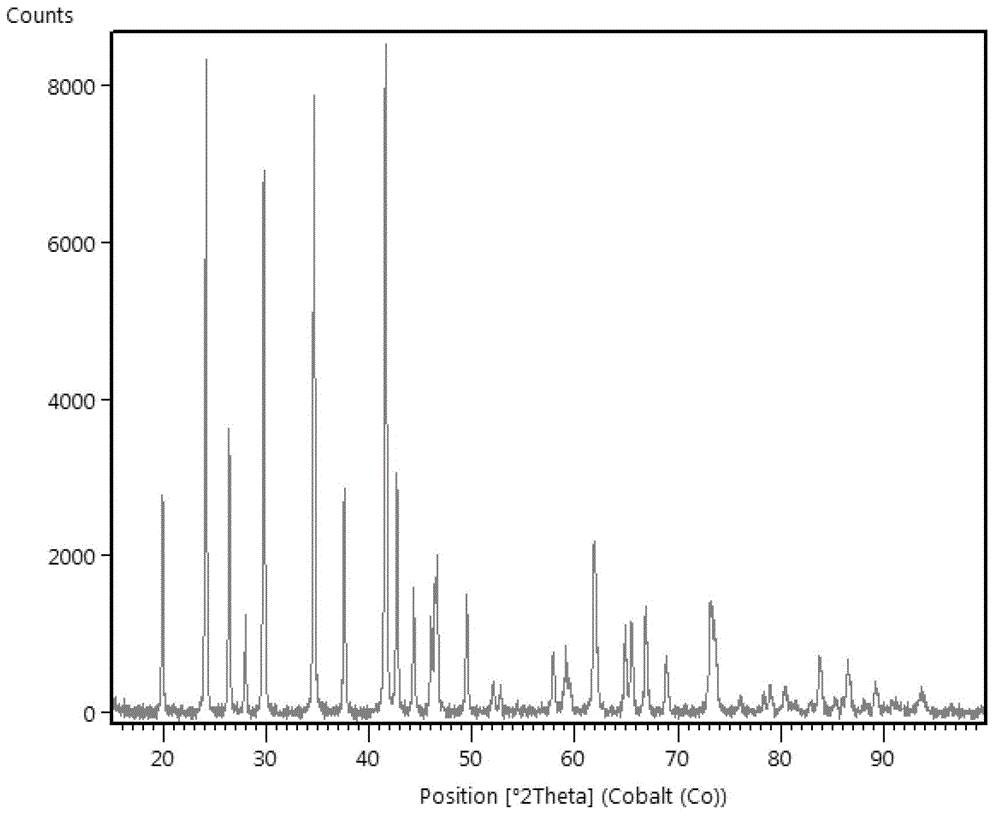

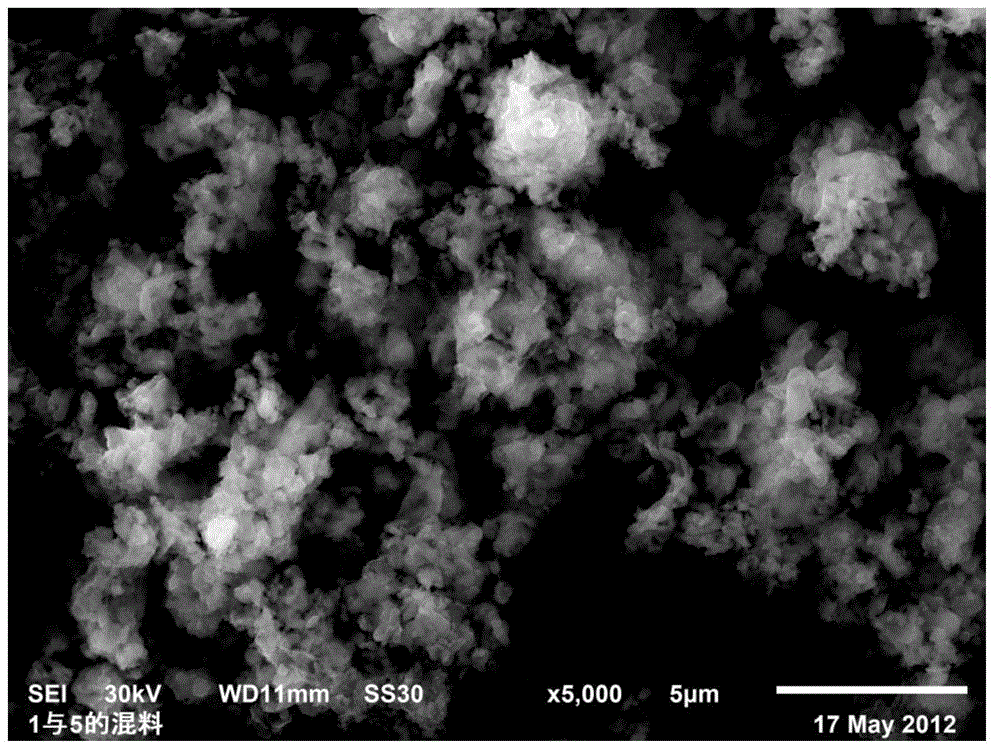

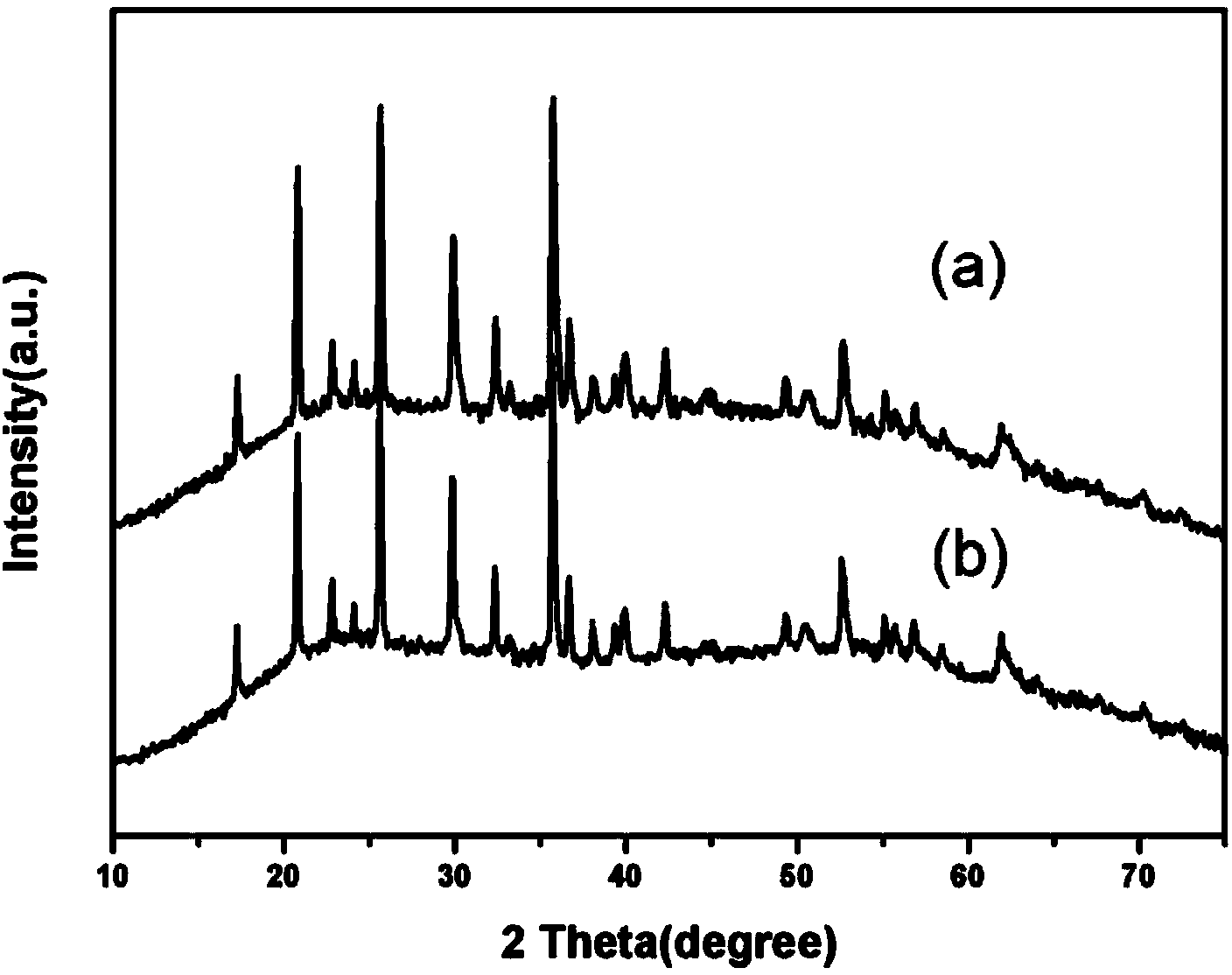

Preparation method of carbon-coated lithium iron phosphate with grade structure

InactiveCN103956493AAvoid FePO

<sub>4</sub>

productionHigh purityCell electrodesSecondary cellsHigh energyLithium-ion battery

The invention relates to a preparation method of a lithium iron phosphate material as a lithium ion battery positive electrode active substance. The preparation method comprises the following steps: dissolving a lithium source, an iron source and a phosphorus source in a reducing agent, adding a chelating agent, and uniformly stirring to form a mixed solution; performing a hydrothermal reaction; washing and drying to obtain lithium iron phosphate with a grade structure; and mixing with a carbon source, and calcining in a reducing atmosphere to obtain carbon-coated lithium iron phosphate with the grade structure. Compared with the prior art, the preparation method has the beneficial effects that the purity of the product is increased; the reducing agent has a reducing function, the chelating agent has a structure guiding function; the conductivity of lithium iron phosphate is enhanced, and the electrochemical property is improved; a resultant temperature interval is large, and a great application value and a bright development prospect are achieved; the specific capacity is high, the specific surface area is moderate, the cycle performance is good, the repeatability is high, the processing property is excellent, and the demand on a high energy storage device in practical production can be met.

Owner:WUHAN UNIV OF TECH

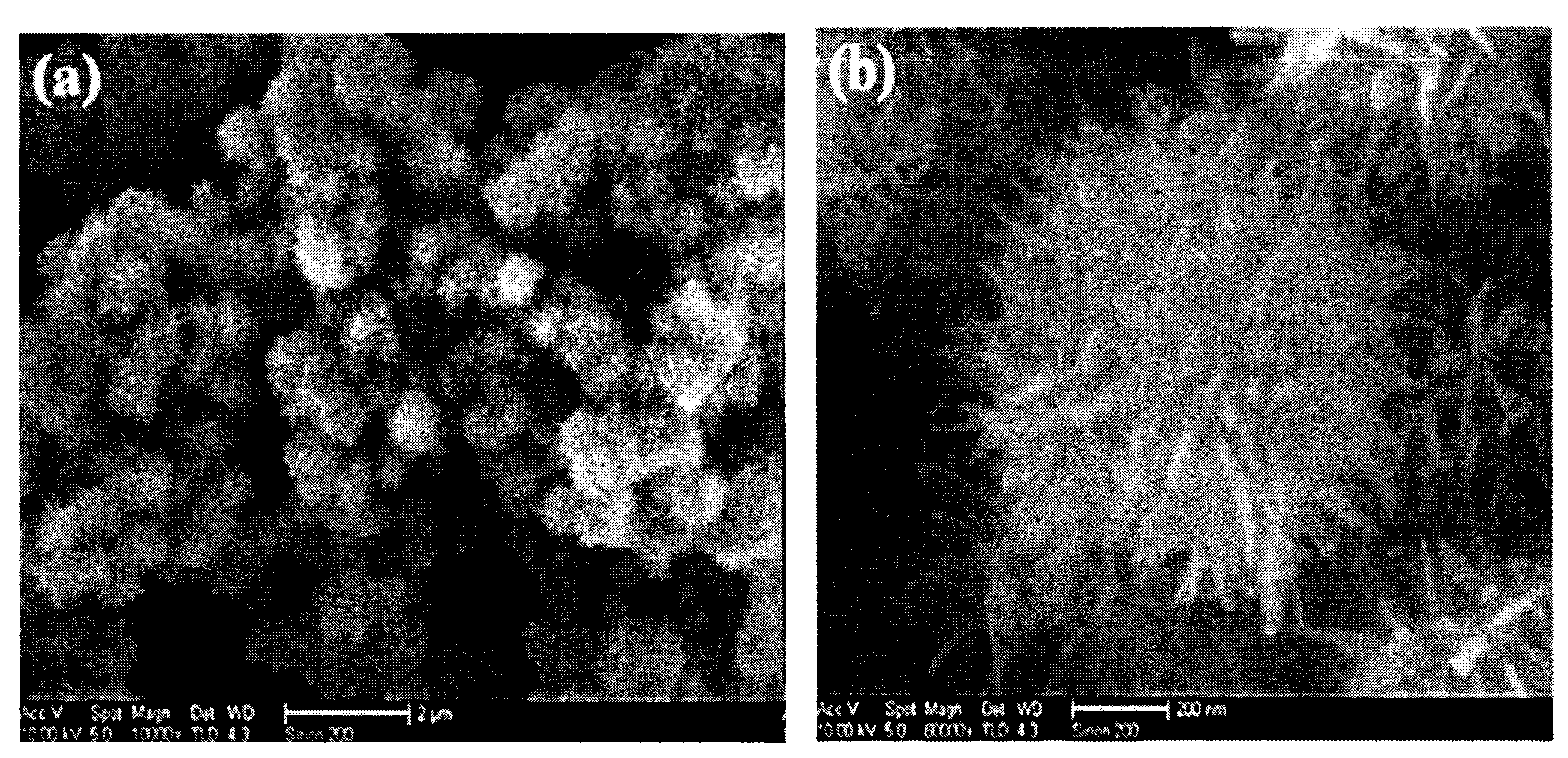

Nano ferric hydroxide and preparation method thereof

InactiveCN103172123AAvoid reunionNot easy to reuniteIron oxides/hydroxidesNanotechnologyFerric hydroxideDesorption

The invention discloses nano ferric hydroxide and a preparation method thereof. The shape of nano ferric hydroxide is a nano-sheet cluster, wherein the cluster diameter of the nano-sheet cluster is between 400 and 500nm, and the sheet length of nano-sheets forming the nano-sheet cluster is between 200 and 250nm, and the sheet width is between 20 and 25nm, and the sheet thickness is between 2 and 5nm; the nano-sheet cluster is formed by orthorhombic system alpha-ferric hydroxide, and the specific surface area of the nitrogen adsorption and desorption representation is between 100 and 105m<2> / g. The method comprises the following steps of: mixing ethylene glycol and deionized water, and performing ultrasonic to prepare ethylene glycol aqueous solution; respectively adding ferrous sulfate into the ethylene glycol aqueous solution, and performing ultrasonic to obtain ferrous sulfate mixed solution; adding urea into ethylene glycol aqueous solution, and performing ultrasonic to obtain urea mixed solution; injecting the urea mixed solution into the stirring ferrous sulfate mixed solution at a speed of 0.8-1.2ml / min according to a volume ratio of (0.8-1.2):3 to prepare a reaction solution; and injecting air into the reaction solution at a speed of 2.5- 3.5ml / min to prepare the target product. The nano ferric hydroxide can be widely applied to adsorption and photocatalytic decomposition of organic matters.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

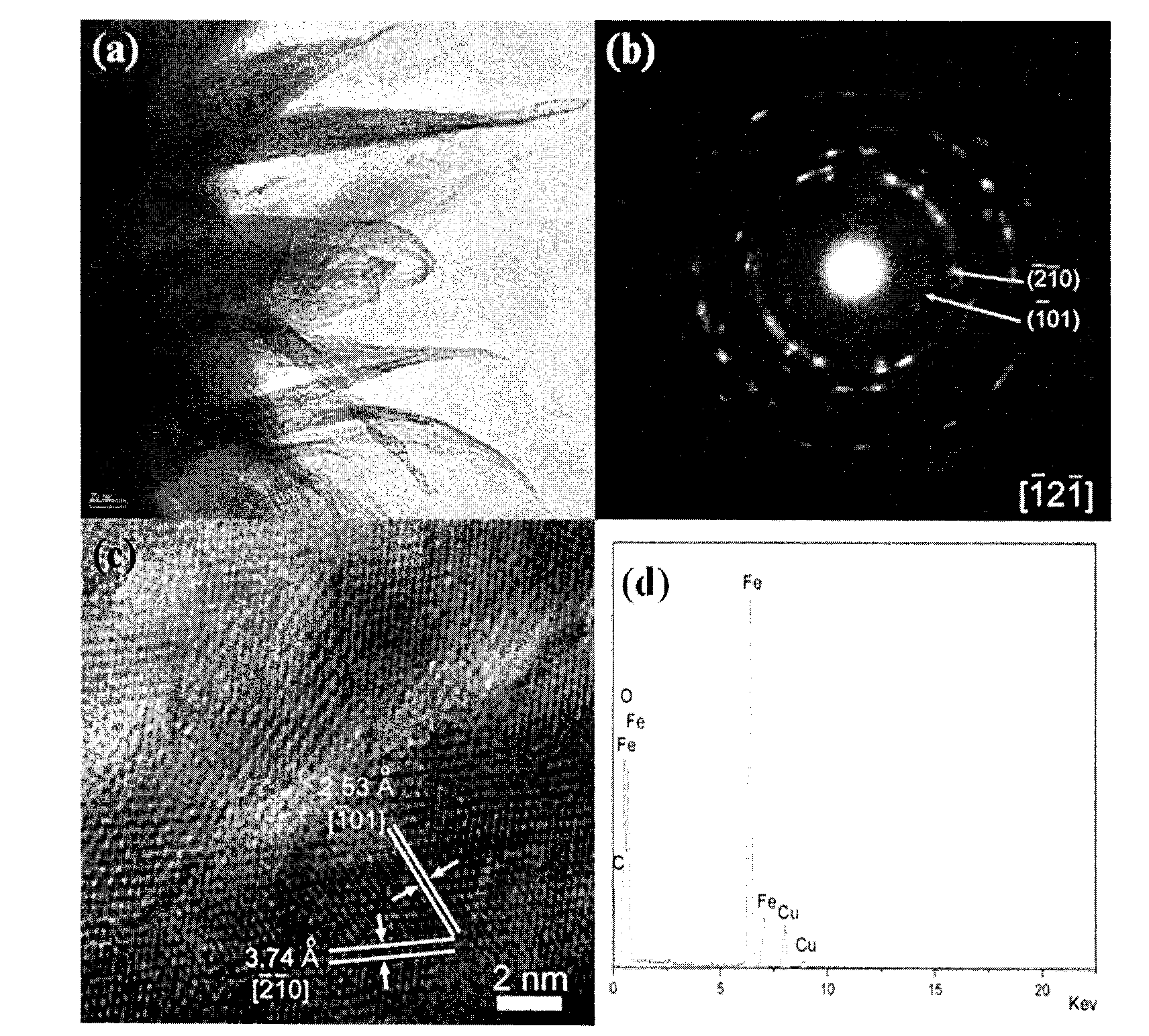

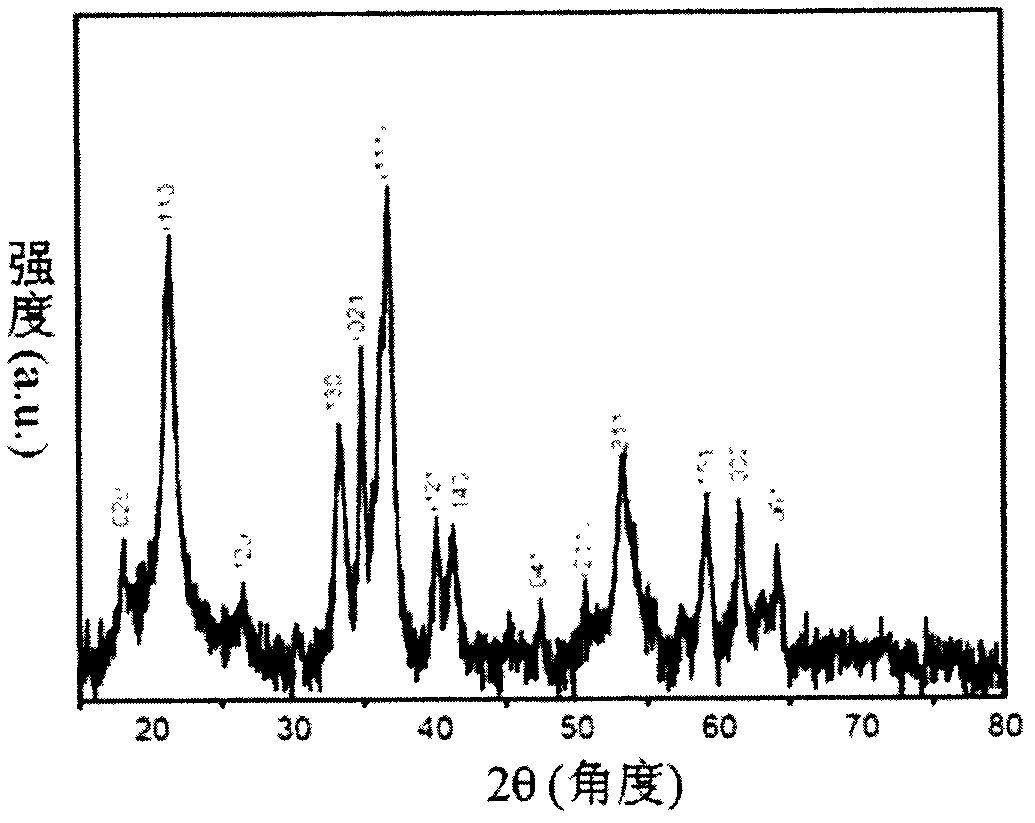

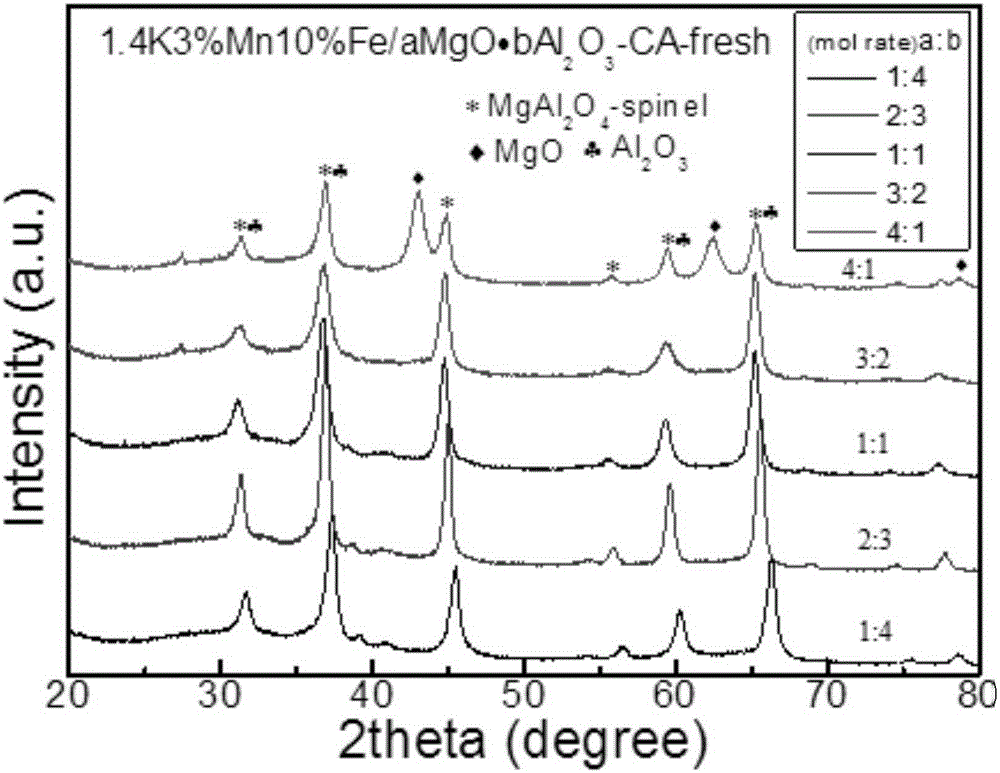

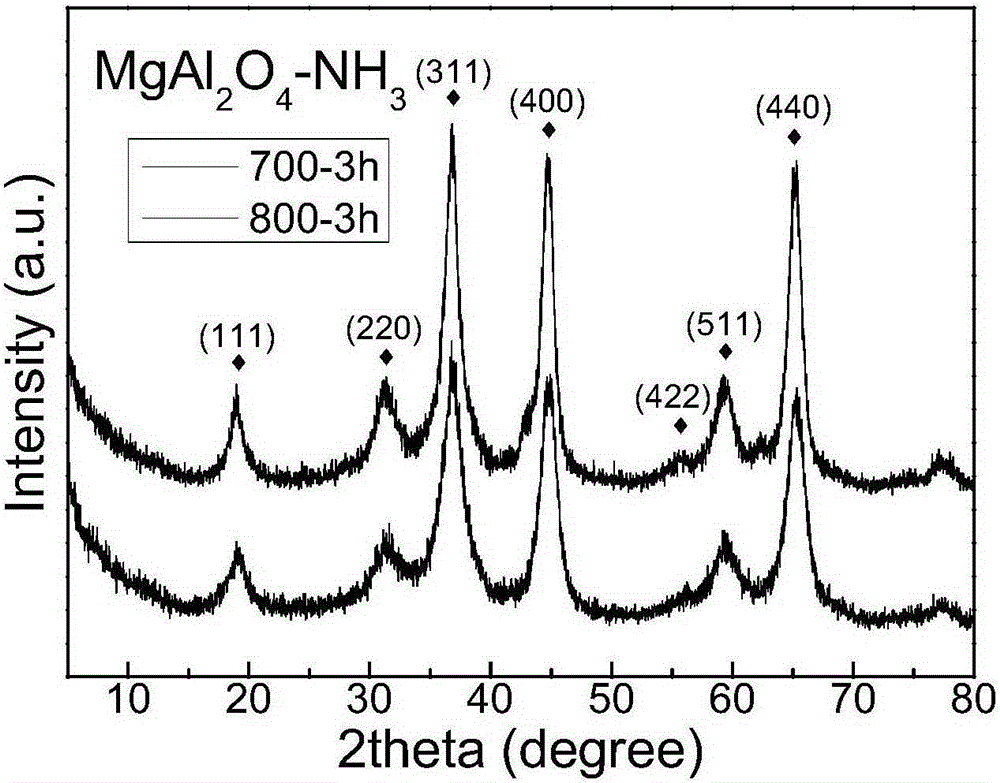

Catalyst for preparing light olefins through Fischer-Tropsch synthesis as well as preparation method and application of catalyst

ActiveCN105195169AHigh catalytic activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon by hydrocarbon crackingControllabilityComposite oxide

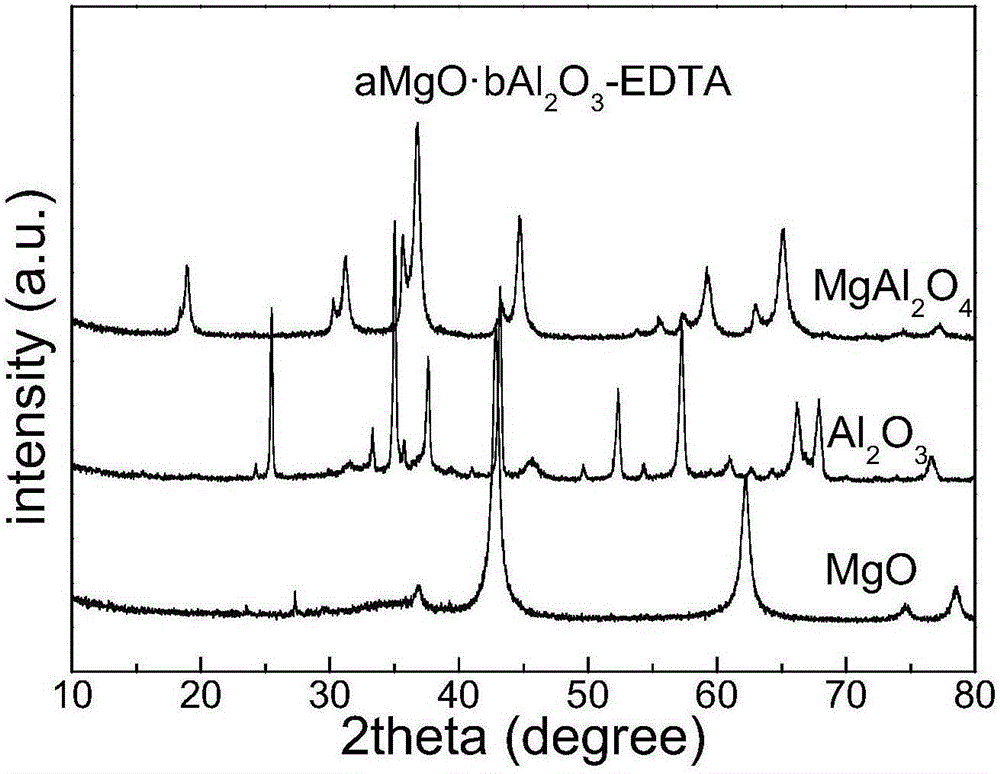

The invention relates to a catalyst for preparing light olefins through Fischer-Tropsch synthesis as well as a preparation method and an application of the catalyst. The catalyst comprises a metal Mg-Al composite oxide as well as Fe, K and Mn metal elements loaded on the metal Mg-Al composite oxide, wherein the chemical general formula of the metal Mg-Al composite oxide is aMgO*bAl2O3, a and b represent mole fractions of MgO and Al2O3 in the metal Mg-Al composite oxide respectively, a is larger than 0 and smaller than 100, b is larger than 0 and smaller than 100, and the sum of a and b is 100; the chemical general formula of the catalyst is xFe*yK*zMn*(100-x-y-z)(aMgO*bAl2O3), x, y and z represent mass fractions of the Fe, K and Mn metal elements loaded in the catalyst respectively, x is larger than 0 and smaller than or equal to 20, y is larger than 0 and smaller than or equal to 3, and z is larger than 0 and smaller than or equal to 15. Compared with the prior art, the catalyst as well as the preparation method and the application thereof has the advantages that the preparation technology is simple, conditions are mild, the controllability is good, the raw material selection range is wide, the economic cost is low, and the prepared catalyst is good in activity, high in selectivity, good in reaction stability and applicable to preparation of the light olefins through industrial Fischer-Tropsch synthesis and has the bright application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Synthesis of 1, 4-oxygen nitrogen heterocyclic hexane catalyst by ammonification of diethylene glycol and process thereof

InactiveCN1569328ASignificant progressHigh activityOrganic chemistryCatalyst activation/preparationNitrateMorpholine

The invention relates to diethylene glycol ammoniated morpholine catalyst and the process. Its character lies in: it uses gamma-Al2O3 or (gamma + theta)-Al2O3 as carrier, carrying at least two active components in Cu, Ni, CO. The manufacturing method is: the above mentioned carrier is baked under temperature of 700-800deg.C for 4-10 hours, acquires the preheated carrier, immersing at least two nitrite salt liquid with Cu, Ni, CO under 40-70deg.C, then they are dried after being filtered, baked under 400-600deg.C for 4 hours, then it is cooled to room temperature naturally. The DEG converting rate is 98.1-99.8mol%; the morpholine selectivity is 90.71-94.44mol%. The process is simple and the cost is low.

Owner:CNPC JILIN CHEM GROUP CORP

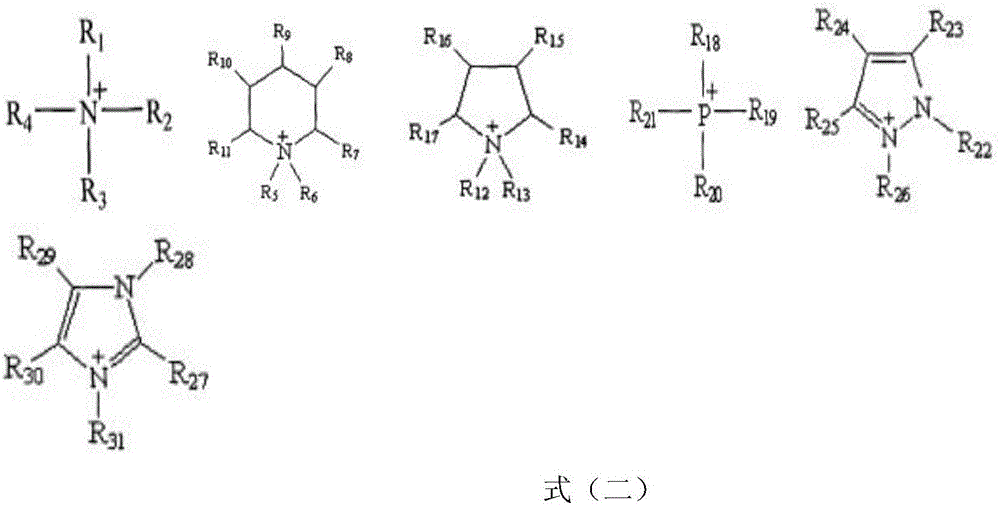

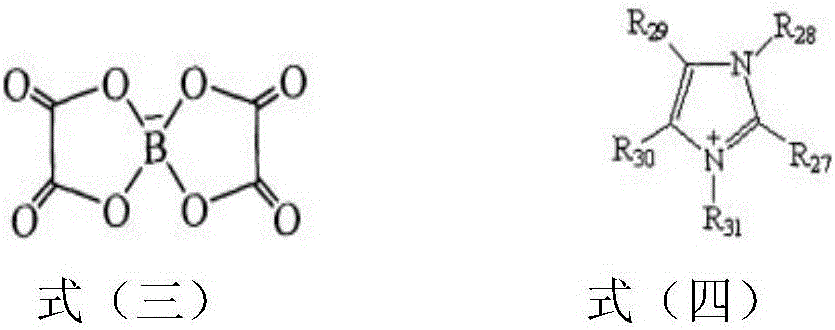

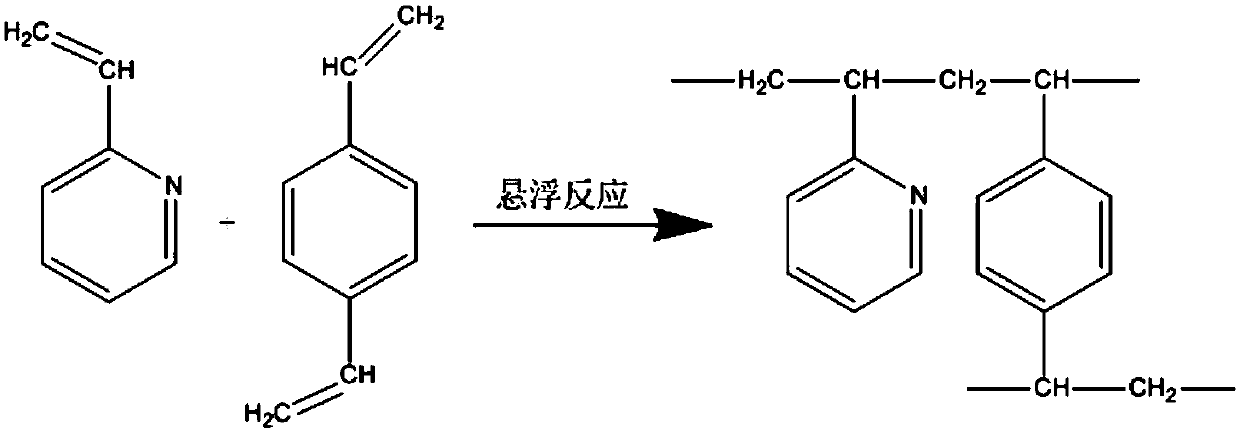

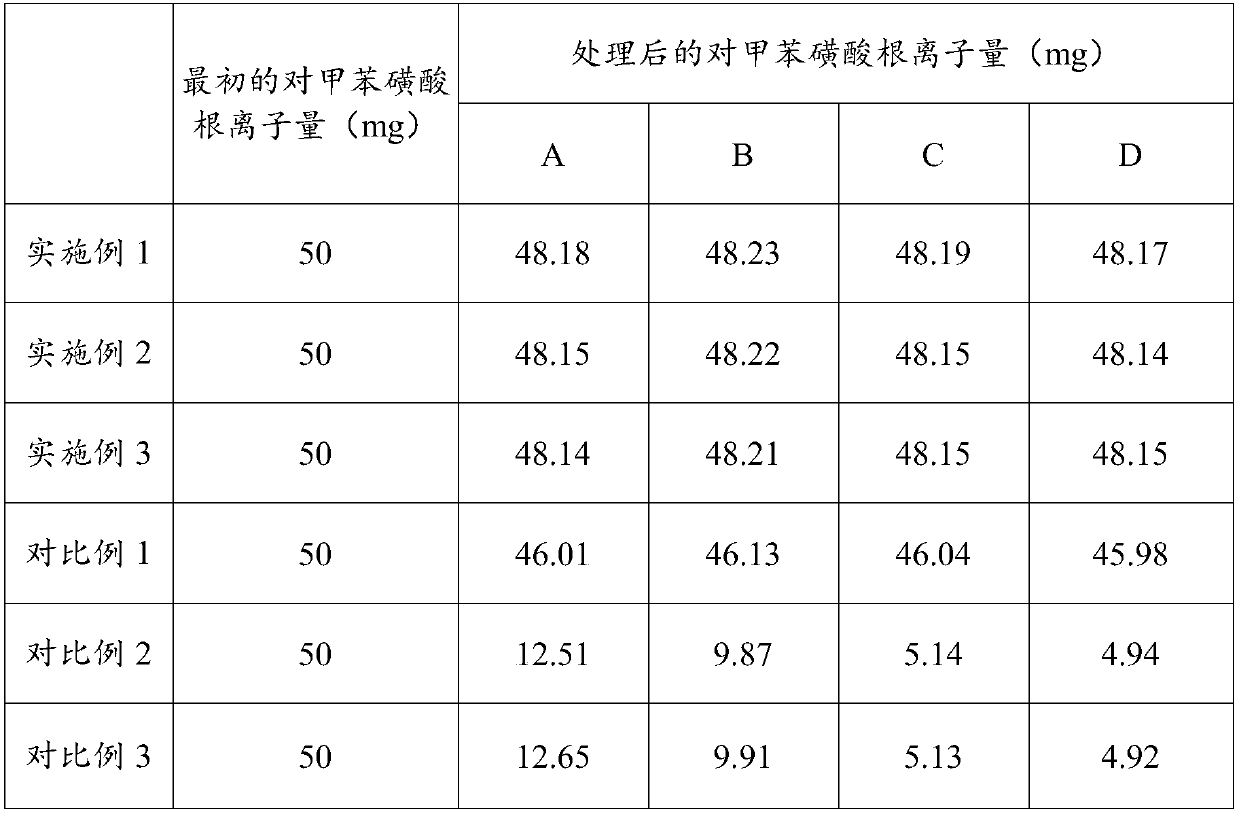

Preparation technology of selective resin for removing trace nitrate ion in water

InactiveCN102702412AImprove pore structureHigh selectivityWater/sewage treatment by ion-exchangeDivinylbenzenePhysisorption

The invention discloses a preparation technology of selective resin for removing trace nitrate ion in water and belongs to the field of preparation of organic high-molecular compound. The technology comprises the steps of respectively adding a water phase including purified water, a dispersing agent and a auxiliary dispersing agent and an oil phase including styrene, divinylbenzene, porogen and initiator to a polymerization reactor, carrying out suspension polymerization, and preparing the selective resin by chloromethylation and amination, wherein the porogen is mixed porogen prepared from 65-75 parts of toluene or benzene and 60-70 parts of white oil or isobutanol. By adopting the resin prepared from the mixed porogen, a hole structure inside the resin is improved, and the resin not only has proper specific surface area, but also has larger exchange capacity, and can remove the nitrate ion in the water by physical adsorption and chemical exchange methods at the same time, so that the selectivity on the nitrate ion is larger and trace nitrate ion in the water can be effectively removed.

Owner:ZIBO DONGDA HONGFANG CHEM

Method for preparing nanometer spherical copper powder

The invention relates to a method for preparing copper powder for the field of nanometer spherical electrocondution slurry, catalysts, ceramic capacitors and the like, in particular to a method for preparing nanometer spherical copper powder. The method is characterized by including the following steps that firstly, a precursor of the copper powder is prepared, wherein soluble copper salt reacts with a precipitating agent to generate precursor precipitation of the copper salt; secondly, a cladding body of the copper powder is prepared, the acquired precursor precipitation of the copper salt is used as a crystal nucleus, a cladding layer formed by a cladding agent is formed on the surface of the crystal nucleus through a physical crystallization method or a chemical crystallization method, and then centrifugal separation, filtration and drying are conducted; thirdly, acquired drying materials are kept warm for 0.5-2 hours in the reducing atmosphere or the vacuum atmosphere at the temperature ranging from 250 DEG C to 350 DEG C, and then the drying materials are processed for 2-6 hours at the high temperature ranging from 400 DEG C to 850 DEG C; fourthly, the cladding layer of the acquired materials is removed through acid washing or alkali washing, and the materials are dried and decentralized. The method for preparing the nanometer copper powder is low in cost, simple in operation, free of pollution and controllable in granularity.

Owner:NINGXIA ORIENT TANTALUM IND +1

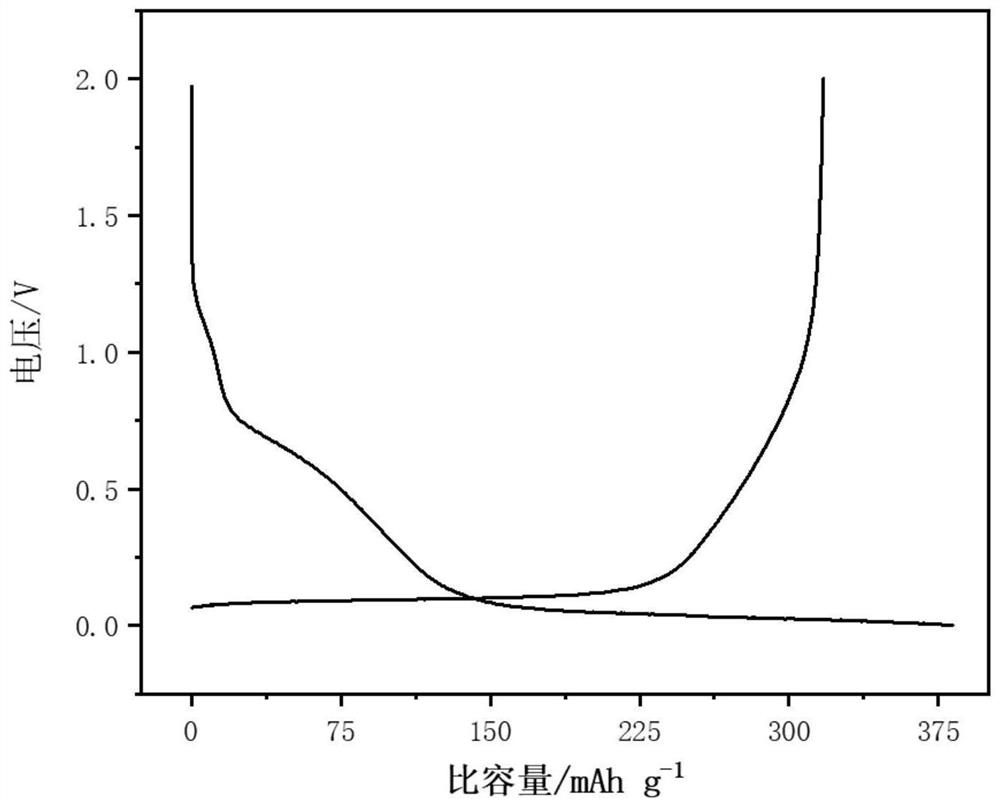

Hard carbon material and preparation method and application thereof

ActiveCN112225194AReduces the formation of crystals and impuritiesImprove charge and discharge capacityCell electrodesSecondary cellsCyclic stabilityMaterials science

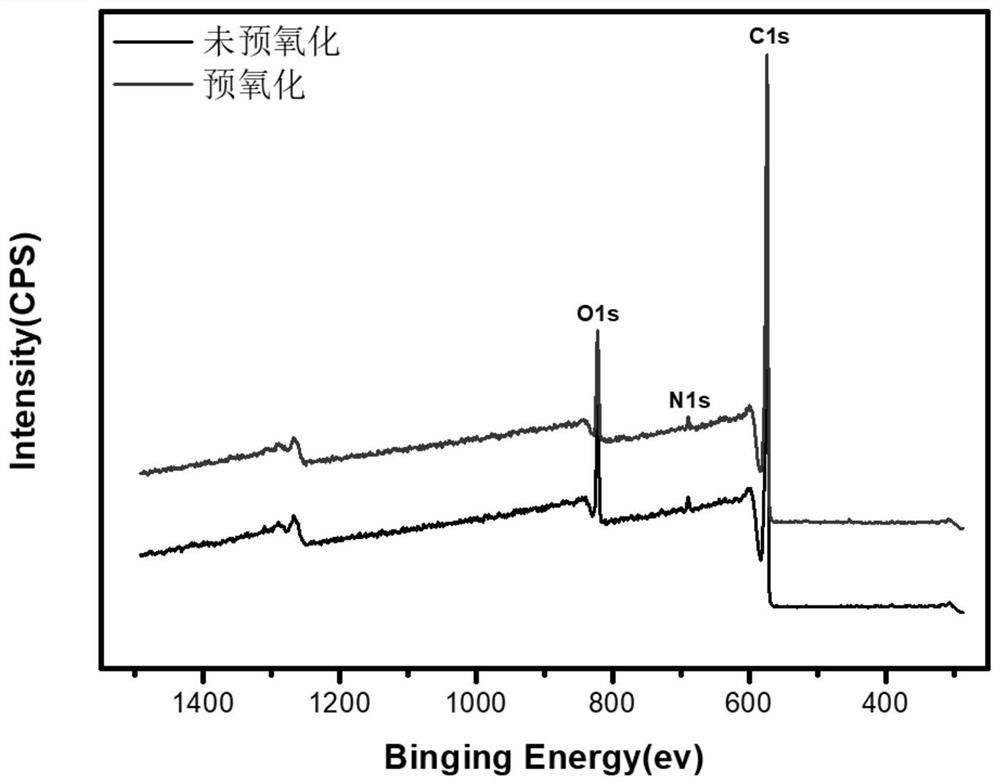

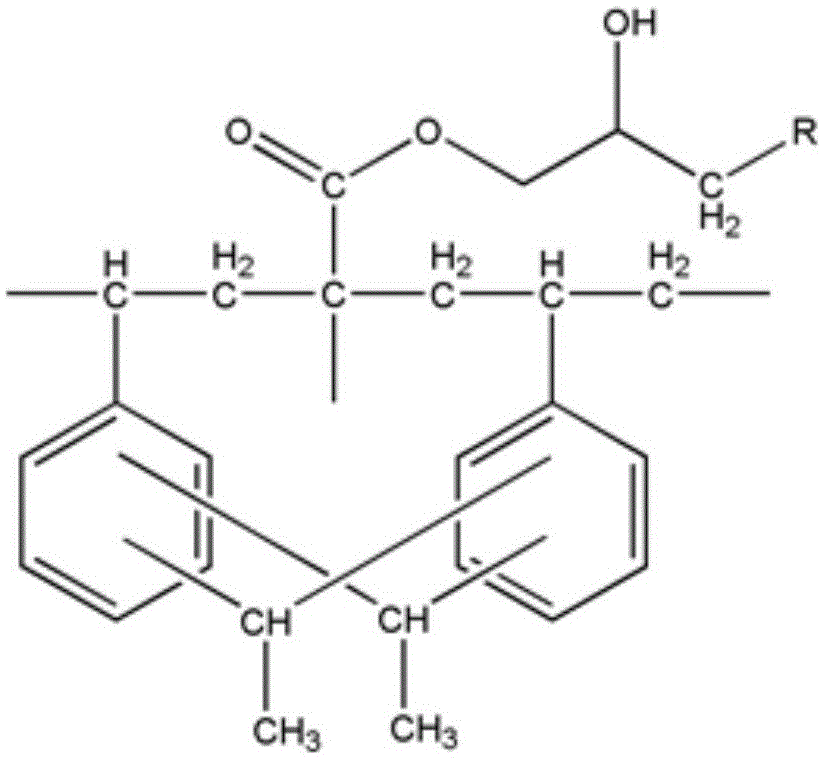

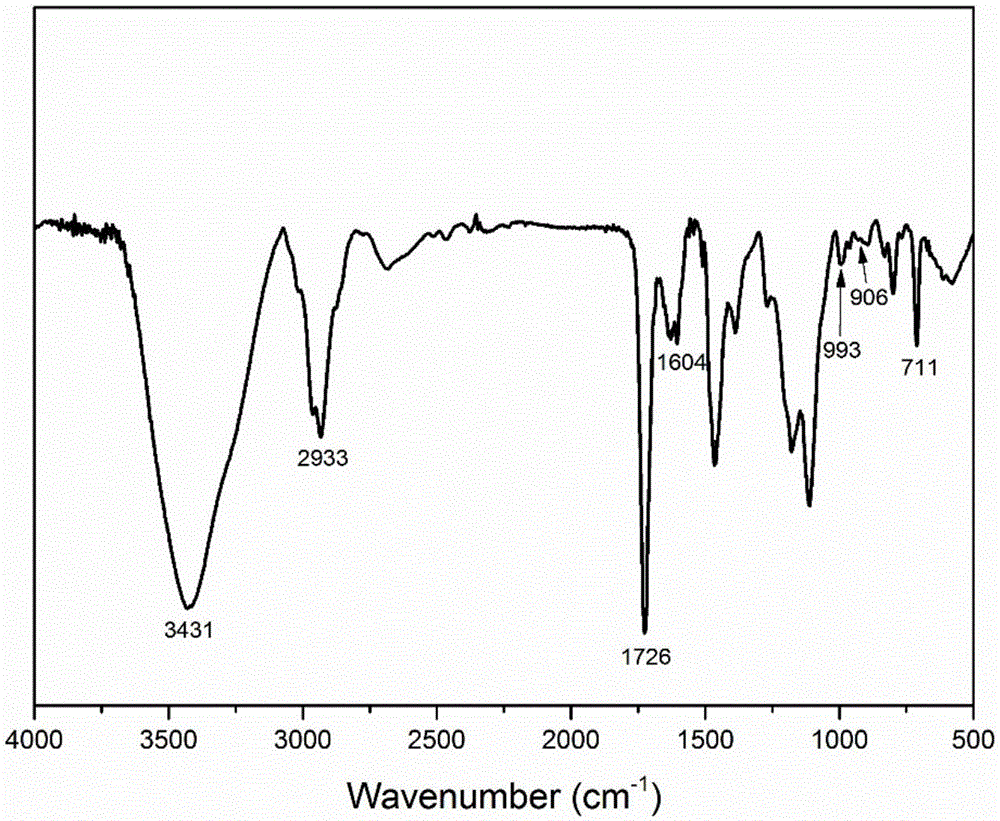

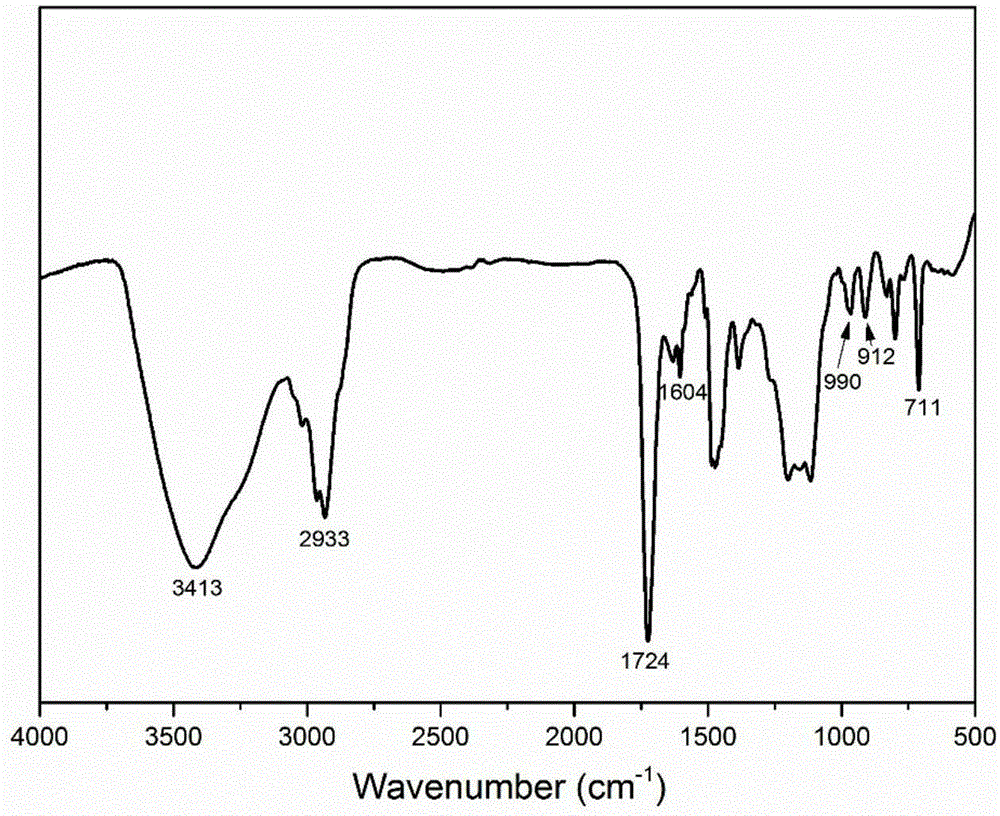

The invention relates to a hard carbon material as well as a preparation method and application thereof. A conductive additive is introduced into the hard carbon material precursor to improve the conductivity of an obtained material, and a large number of oxygen-containing functional groups are introduced in combination with variable-speed heating pre-oxidation, so that the crosslinking degree ofa material skeleton is increased, the strength of the material is improved, and the sodium storage specific capacity, the first-circle coulombic efficiency and the rate capability are remarkably improved. The hard carbon material has the advantages of high reversible capacity, high first-circle coulombic efficiency, good cycling stability and the like when being used for the sodium ion battery. The material has the characteristics of simple preparation method and cheap and easily available raw materials, and provides more choices for the negative electrode of the sodium-ion battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

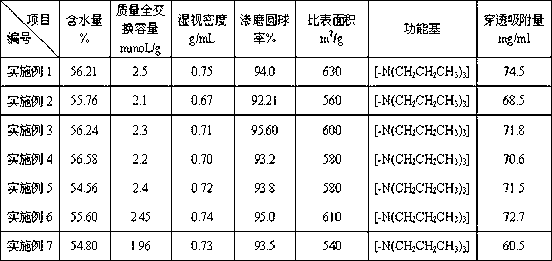

Amino-modifying interpenetrating resin adsorbent and preparing method thereof

InactiveCN105111365ALarge adsorption capacityFast adsorptionOther chemical processesOrganic solventFixed bed

The invention discloses a kind of mutual penetration amino modified resin adsorbent and its preparation method, belonging to the resin synthesis field, to overcome the existing only resin adopts the model of fixed bed and moving bed operation, adsorption rate is slow, aperture easily blocked, investment, operation cost is high. This invention adopts suspension polymerization technique, in containing a dispersant and water phase to oil instead of pH buffer should be resin white balls, oil phase by reaction monomer, crosslinking agent, initiator and solvent composition, resin white balls by organic solvent swelling after adding different volume of amine solution to react, then add the crosslinking agent, swelling, after join crosslinking initiator target product was got. The invention of the preparation of amino modified the mutual penetration of resin adsorbent particle size between 300-500 microns, with large aperture, surface area, moderate characteristics of regenerative adsorption effect is good.

Owner:NANJING NORMAL UNIVERSITY +1

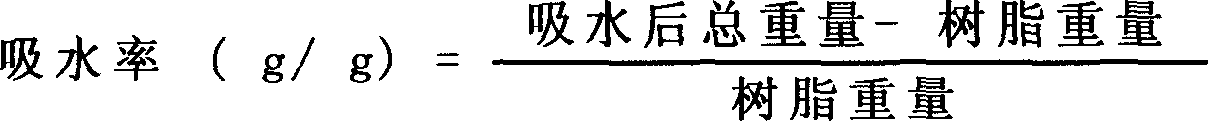

High water absorptive resin for sanitary material

The present invention features that the high water absorption resin for sanitary material is prepared through polymerization with acrylic acid and hydroxyethyl acrylate as monomers, sodium hydroxide as neutralizing agent, cross-linking agent and initiator and inside water solution, and post-treatment with surface treating agent. The present invention has no pellet formed after absorbing water, high water absorption, high water absorbing speed, high water absorbed gel strength, high dry property, high air permeability and high water keeping performance without overflow of the absorbed water, even if in heating and pressurizing condition.

Owner:SUZHOU UNIV

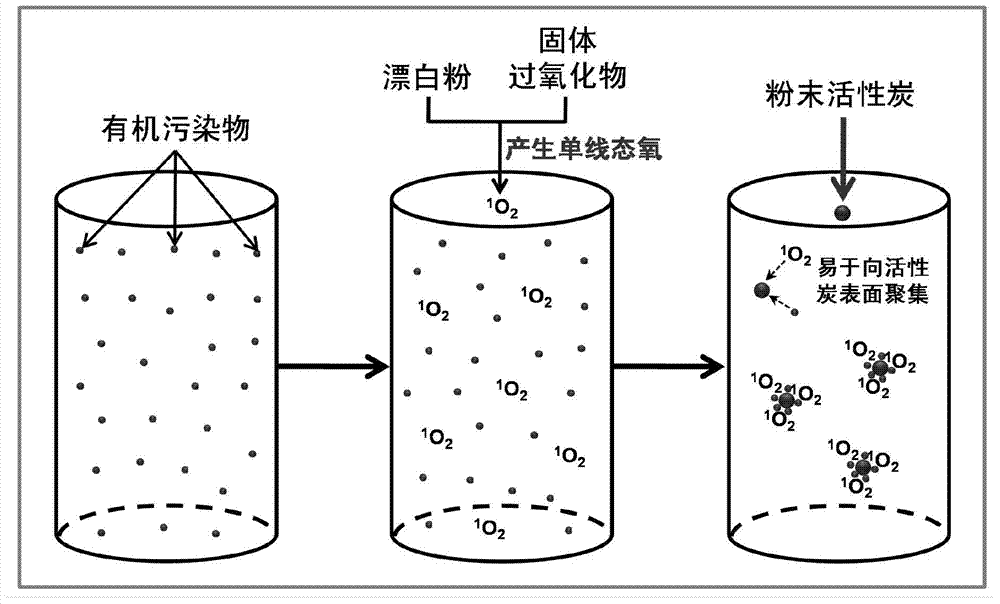

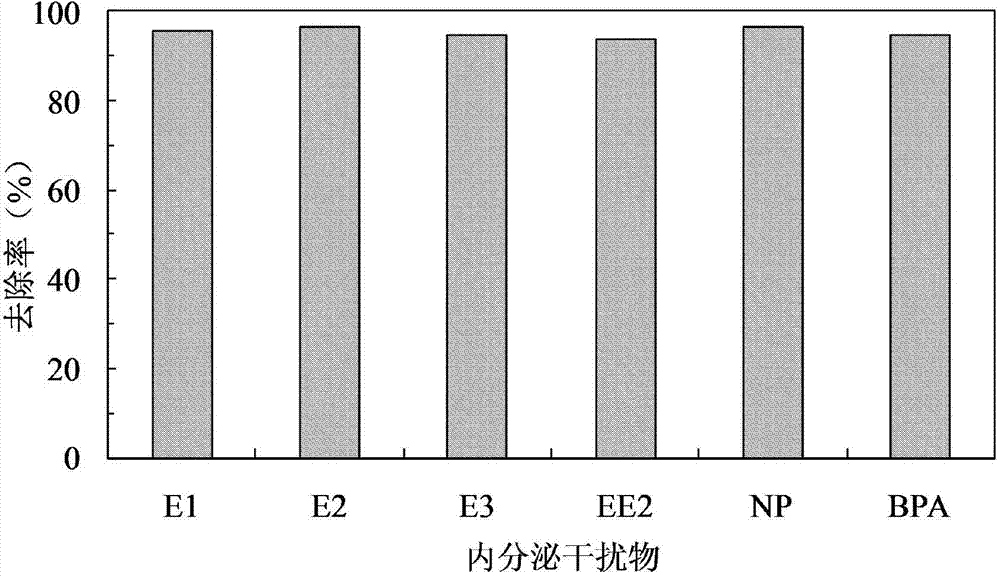

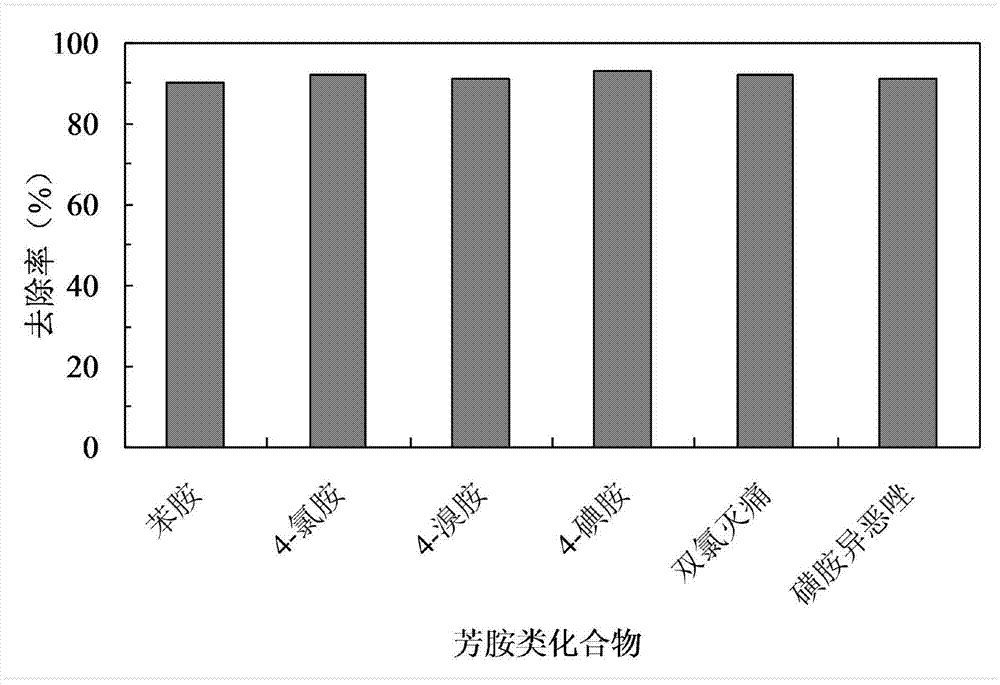

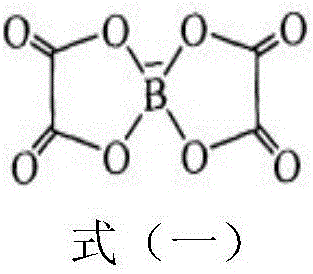

Water treatment compound agent for removing organic pollutants in oxidation mode with high-activity singlet oxygen and water treatment method thereof

ActiveCN103523897AHigh decontamination efficiencyReduce the impactWater/sewage treatment by oxidationHypochloriteDecomposition

The invention discloses a water treatment compound agent for removing organic pollutants in an oxidation mode with high-activity singlet oxygen and a water treatment method of the water treatment compound agent, and relates to water treatment agents and methods for removing pollution in oxidation modes. The problems that when the singlet oxygen is produced through a photosensitization method, a light source needs to be added, secondary pollution is generated, and the use efficiency of the singlet oxygen in a chemical method is low are solved. The water treatment compound agent is composed of bleaching powder, inorganic solid peroxide and powdered activated carbon, and the mass ratio of the bleaching powder to the inorganic solid peroxide to the powdered activated carbon is (1-10):1(1-10). According to the water treatment compound agent, hypochlorite ions provided by the bleaching powder reacts with hydrogen peroxide slowly released after the peroxide is dissolved in water to generate the high-activity singlet oxygen, and through a micro-interface provided by the powdered activated carbon, the self-decomposition of the singlet oxygen can be restrained, the survival time of the singlet oxygen can be prolonged, and the use ratio of the singlet oxygen is improved. The water treatment compound agent is high in efficiency of removing the organic pollutants in the oxidation mode, cannot generate poisonous and harmful by-products, and is convenient to transport and store and more suitable for emergency treatment.

Owner:哈尔滨工业大学高新技术开发总公司

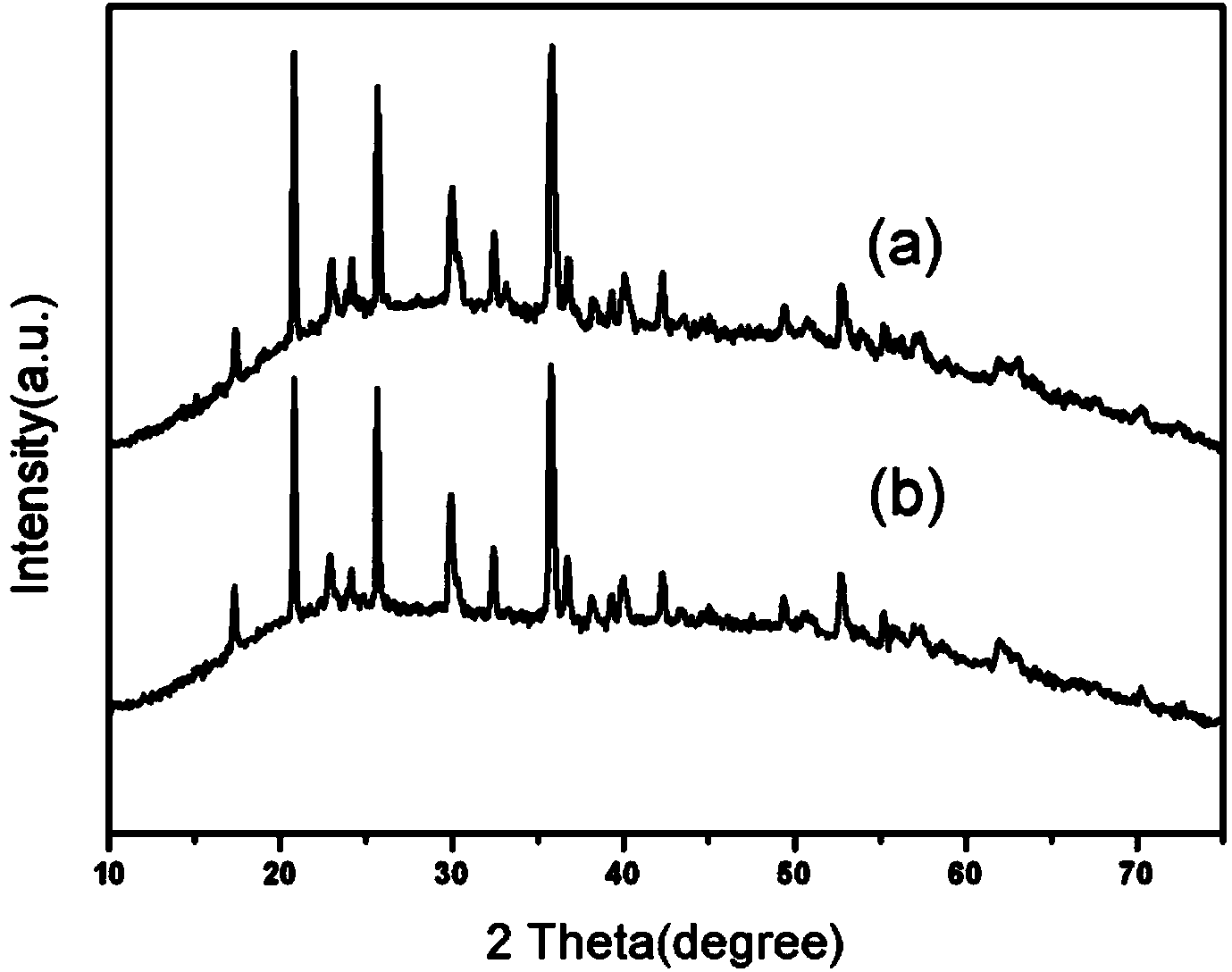

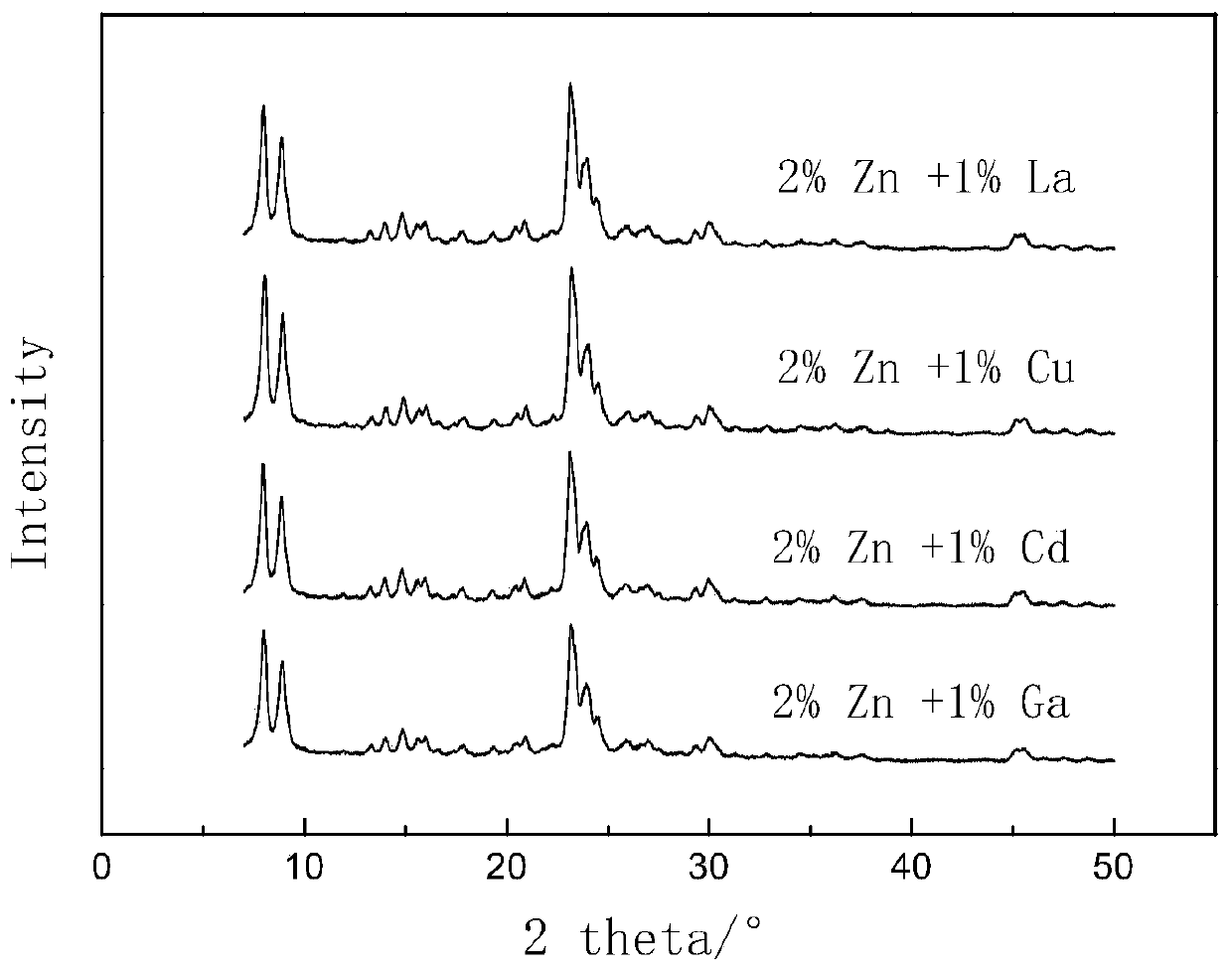

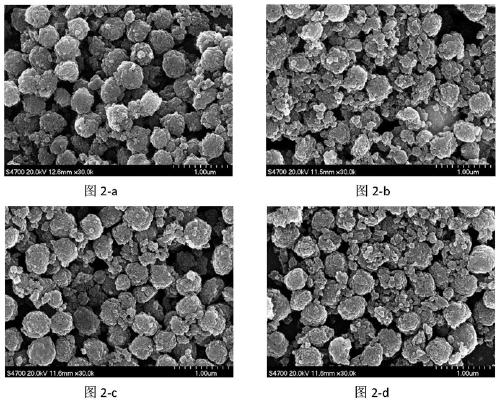

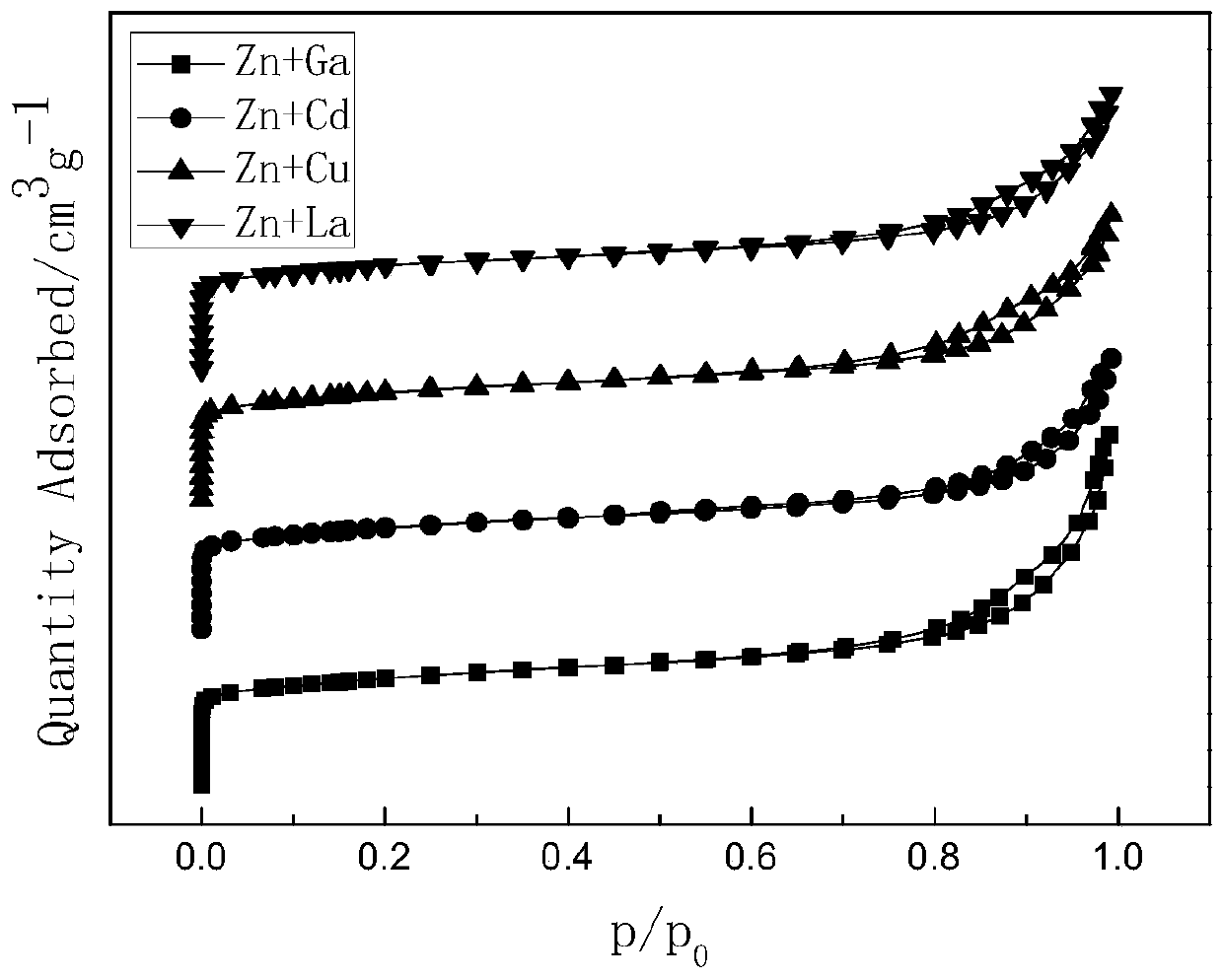

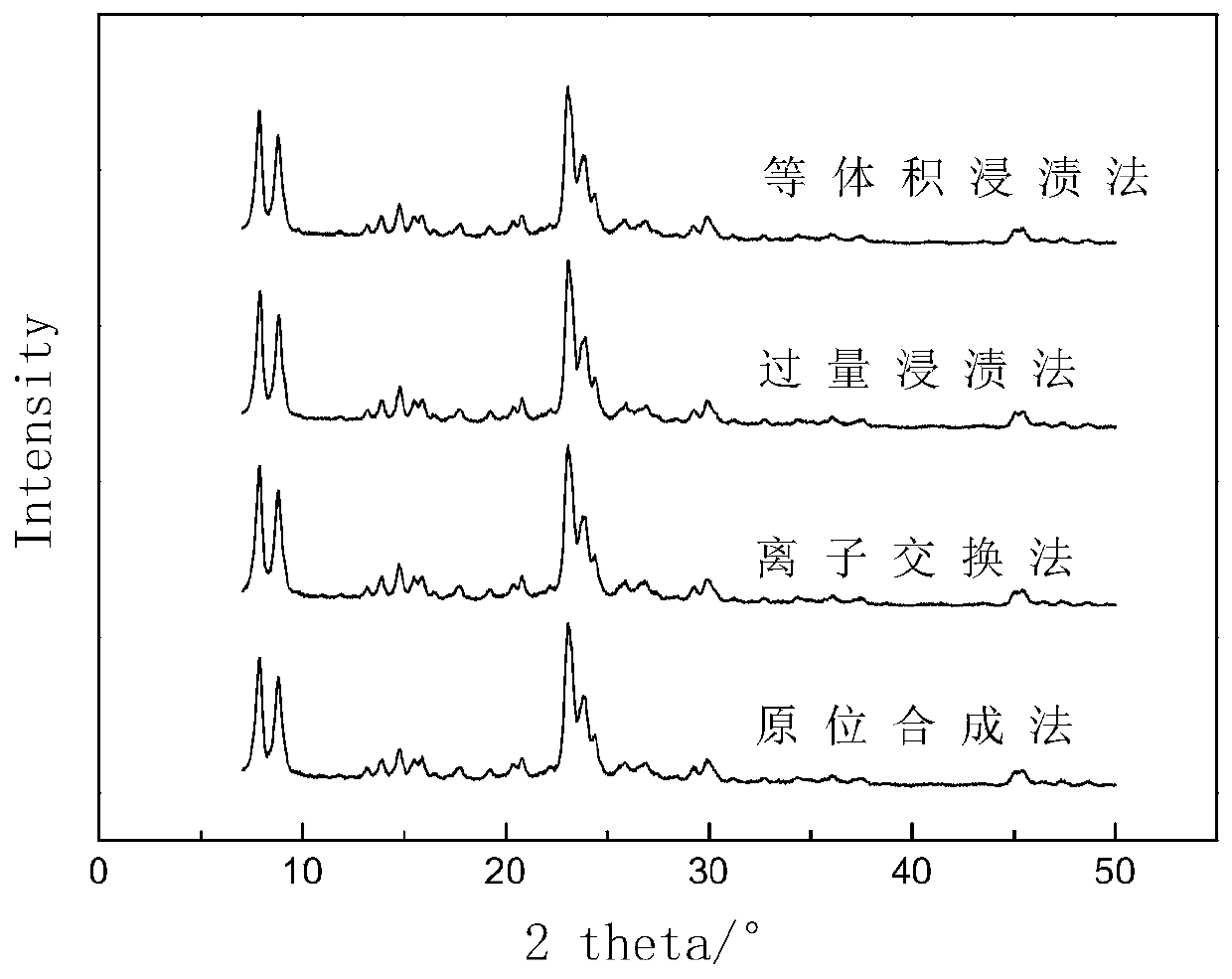

Bimetal-modified nano-HZSM-5 molecular sieve catalyst as well as preparation method and application thereof

InactiveCN109908949AHigh quality yieldModerate surface areaMolecular sieve catalystsCatalyst activation/preparationMolecular sieveSynthesis methods

The invention relates to a bimetal-modified nano-HZSM-5 molecular sieve catalyst as well as a preparation method and application thereof. An HZSM- molecular sieve catalyst is taken as a carrier and isloaded with metal Zn and metal A, wherein the metal A is selected from any of Ga, Cd, Cu and La. By performing bimetal modification on the HZSM-5 molecular sieve catalyst, the bimetal modified nano-HZSM-5 molecular sieve catalyst which is more suitable for a methanol aromatization reaction is obtained; HZSM-5 is independently synthesized, compared with the prior art, the aspects of the formula ofraw materials, a synthesis method and a process are improved, and the HZSM-5 molecular sieve catalyst which is better than the existing HZSM-5 is obtained; the modified molecular sieve catalyst is moderate in specific surface area and is more suitable for the methanol aromatization reaction.

Owner:BEIJING UNIV OF CHEM TECH

Metal modified nano HZSM-5 molecular sieve catalyst, preparation method and application thereof

InactiveCN109908948AHigh quality yield of aromaticsModerate surface areaMolecular sieve catalystsCatalyst activation/preparationMolecular sieveWater baths

The invention relates to a metal modified nano HZSM-5 molecular sieve catalyst, a preparation method and the application thereof. The preparation method of the metal modified nano HZSM-5 molecular sieve catalyst is characterized by comprising the following steps: adding the HZSM-5 molecular sieve catalyst as a carrier into a modified metal compound solution to form a turbid material; carrying outa water bath reaction of the turbid material under stirring to obtain a sticky precursor material; and drying and roasting the precursor material to obtain the metal modified nano HZSM-5 molecular sieve catalyst finally. By modifying the metal HZSM-5 molecular sieve catalyst with a metal, the metal modified nano HZSM-5 molecular sieve catalyst more suitable for methanol aromatization reaction is obtained, so that the highest selectivity of the methanol aromatization reaction reaches up to 36.76%.

Owner:BEIJING UNIV OF CHEM TECH

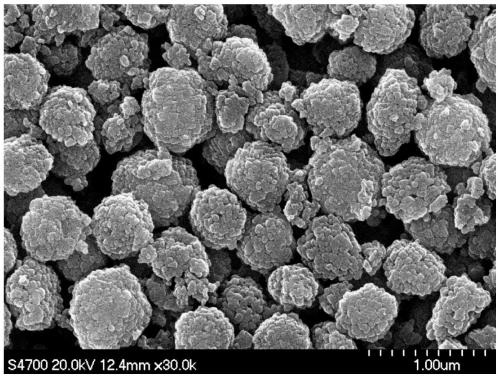

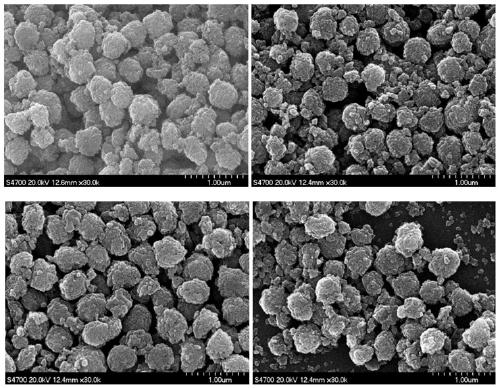

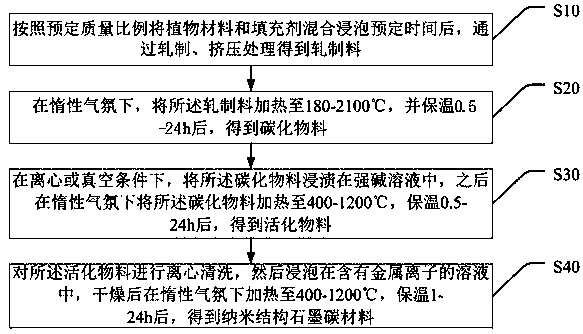

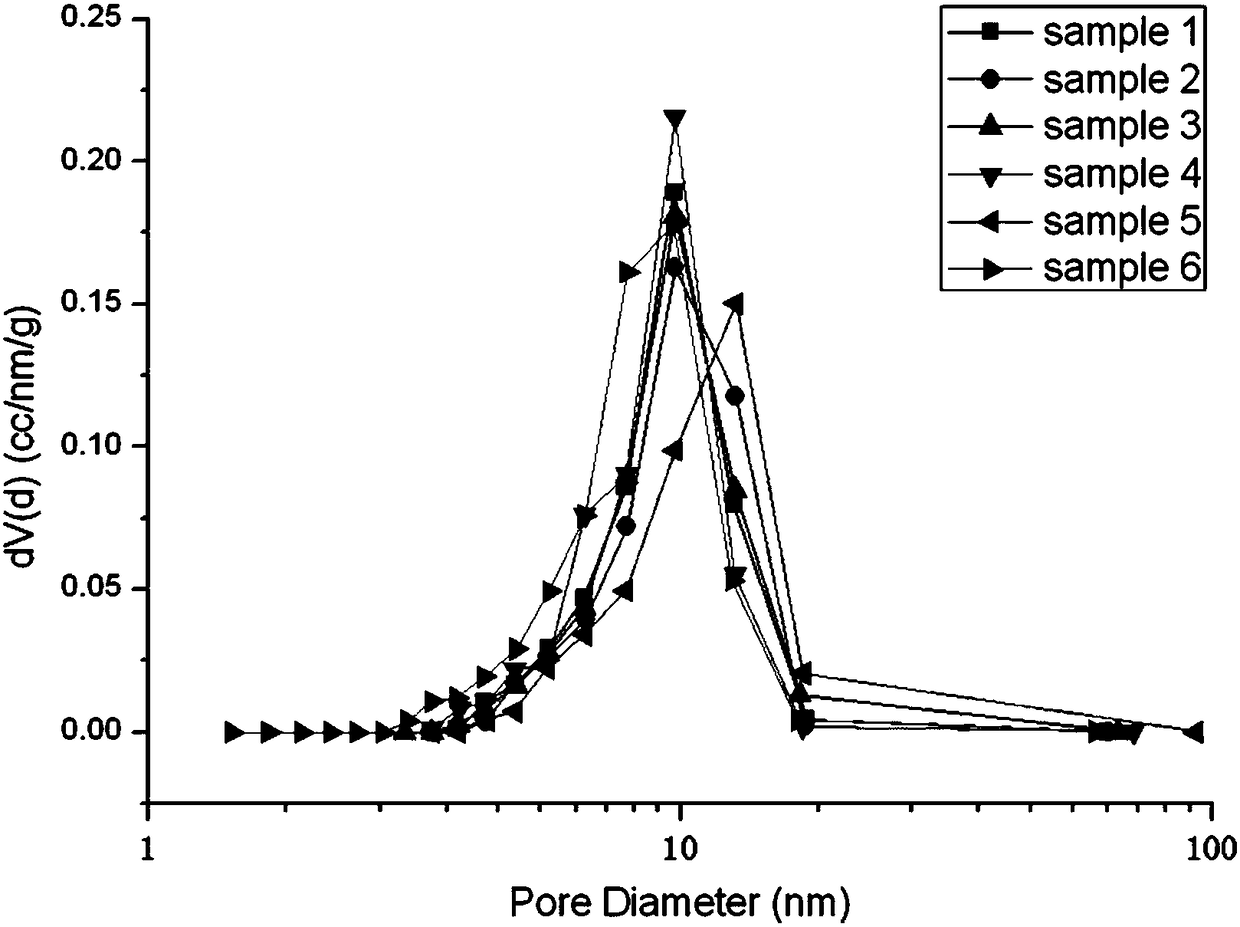

Nano-structure graphite carbon material as well as preparation method and application thereof

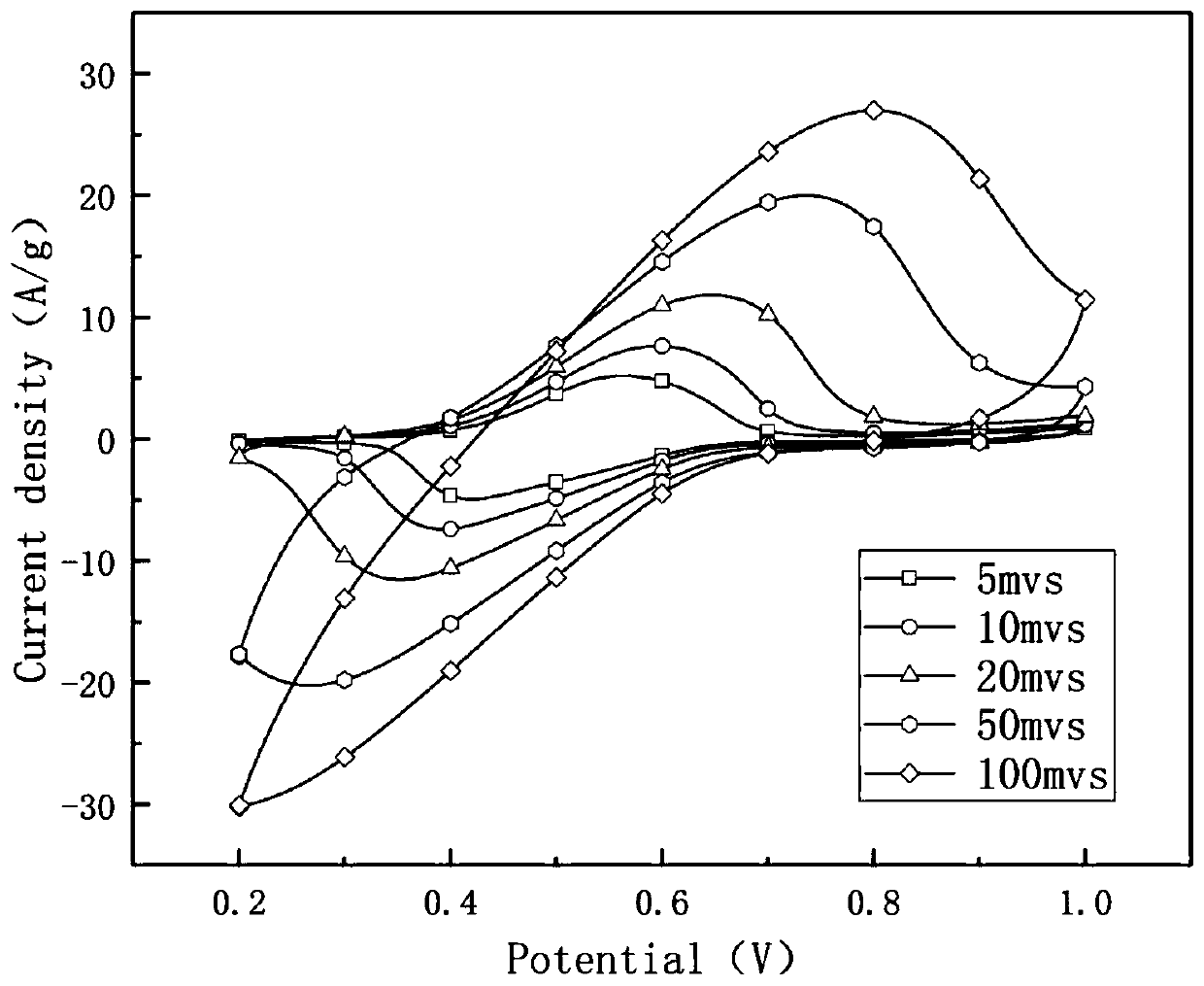

ActiveCN108101044AAppropriate specific surface areaIncrease capacityHybrid capacitor electrodesCell electrodesNanometreElectricity

The invention discloses a nano-structure graphite carbon material as well as a preparation method and application thereof. The method comprises the following steps: taking cheap plant materials and acarbon-containing compound as raw materials and sequentially performing treatment such as soaking, rolling, extrusion, carbonization, activation and graphitization to finally obtain the nano-structuregraphite carbon material. Nanometer holes naturally formed by a plant material compact layer are completely utilized, a filling agent is added, rolling and extrusion treatment are conducted, and theholes with the hole diameter being equal to or more than 100 nanometers are reduced, so that the nano-structure graphite carbon material has a three-dimensional porous structure; furthermore, the specific surface area is proper, material exchange and efficient circulation of an energy storage device are benefited, the capacity is increased, and charging speed and discharging speed are increased, so the nano-structure graphite carbon material is very suitable for preparation of an electrode of electricity storage devices.

Owner:谢金庚

Preparation method of micron spherical silicon oxide

The invention discloses a preparation method of micron spherical silicon oxide. The method mainly comprises the following steps: pre-mixing silicon oxide powder and colloidal silica solution, adding acid, an additive, a dispersing agent and organic amine, sufficiently mixing the materials to form slurry, injecting the slurry into an oil column for molding through a fluidic generator with a certainaperture, and conducting aging, washing, drying and roasting to obtain the micron spherical silicon oxide particles. The micron spherical silicon oxide particles obtained by the method of the invention have mesoporous characteristics, aperture size controllable within 2-50 nm, specific surface area of 200-450 m<2> / g, pore volume of 0.5-1.5 ml / g, and grain size of 1-500 [mu]m. The micron sphericalsilicon oxide prepared by the method of the invention can be applied to the fields such as heterogeneous catalytic reaction, absorptive separation materials and liquid chromatographic fillers.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

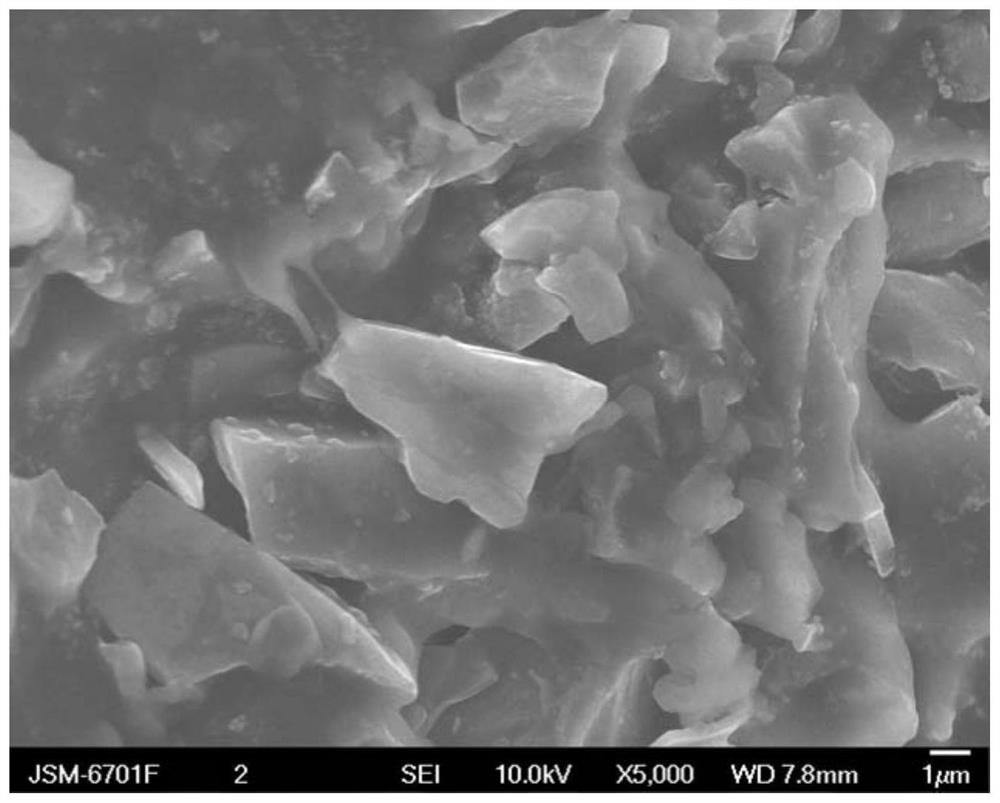

Spherical core-shell structure mixed graphite @ hard carbon composite material as well as preparation method and application thereof

ActiveCN109616638AImprove conductivityModerate surface areaCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a spherical core-shell structure mixed graphite @ hard carbon composite material as well as a preparation method and an application thereof. The spherical core-shell structuremixed graphite @ hard carbon composite material has a core-shell structure; the core is formed by mixing microcrystalline graphite and flake graphite, and the shell is a hard carbon layer. The preparation method comprises the following steps of mixing the flake graphite and the microcrystalline graphite through ball milling, and dispersing with a carbohydrate carbon source and a surfactant into asolution system, wherein the obtained mixed solution is subjected to spray drying to obtain a precursor; and the precursor is placed in an inert atmosphere for heat treatment to obtain the composite material. The method is easily available in raw materials, simple in preparation process and high in repeatability; the prepared spherical core-shell structure mixed graphite @ hard carbon composite material has the advantages of rich active sites, large specific surface area, high conductivity and the like, and when the composite material is applied to a lithium ion battery negative electrode material, high specific capacity, high cycling stability and excellent rate performance are shown, and wide industrial application prospect is achieved.

Owner:大理宸宇储能新材料有限公司

Method for preparing nano calcium carbonate

InactiveCN107324368AModerate surface areaRegular crystal formCalcium/strontium/barium carbonatesCarbideSlurry

The present invention provides a kind of preparation method of nano-calcium carbonate, comprises the following steps: (1) take out and weigh the quicklime obtained after the limestone is calcined at high temperature, digest the quicklime, and refine it into Ca( OH)2 slurry; (2) Prepare Ca(OH)2 raw slurry for refrigeration, add crystal form control agent to react, then add dispersant, carbonize with CO2, (3) thicken the cooked slurry after carbonization, add Activated by composite activator, dehydrated, dried, pulverized and classified to obtain 50-100nm nano-active calcium carbonate. By adopting the preparation method and surface modification method of nano-calcium carbonate of the present invention, the prepared nano-calcium carbonate has moderate specific surface area, regular crystal form, and good surface modification effect, which can greatly improve the excellent dispersion performance and ink absorption of calendered film products. performance, with very good market value.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Catalyst for producing vinyl acetate

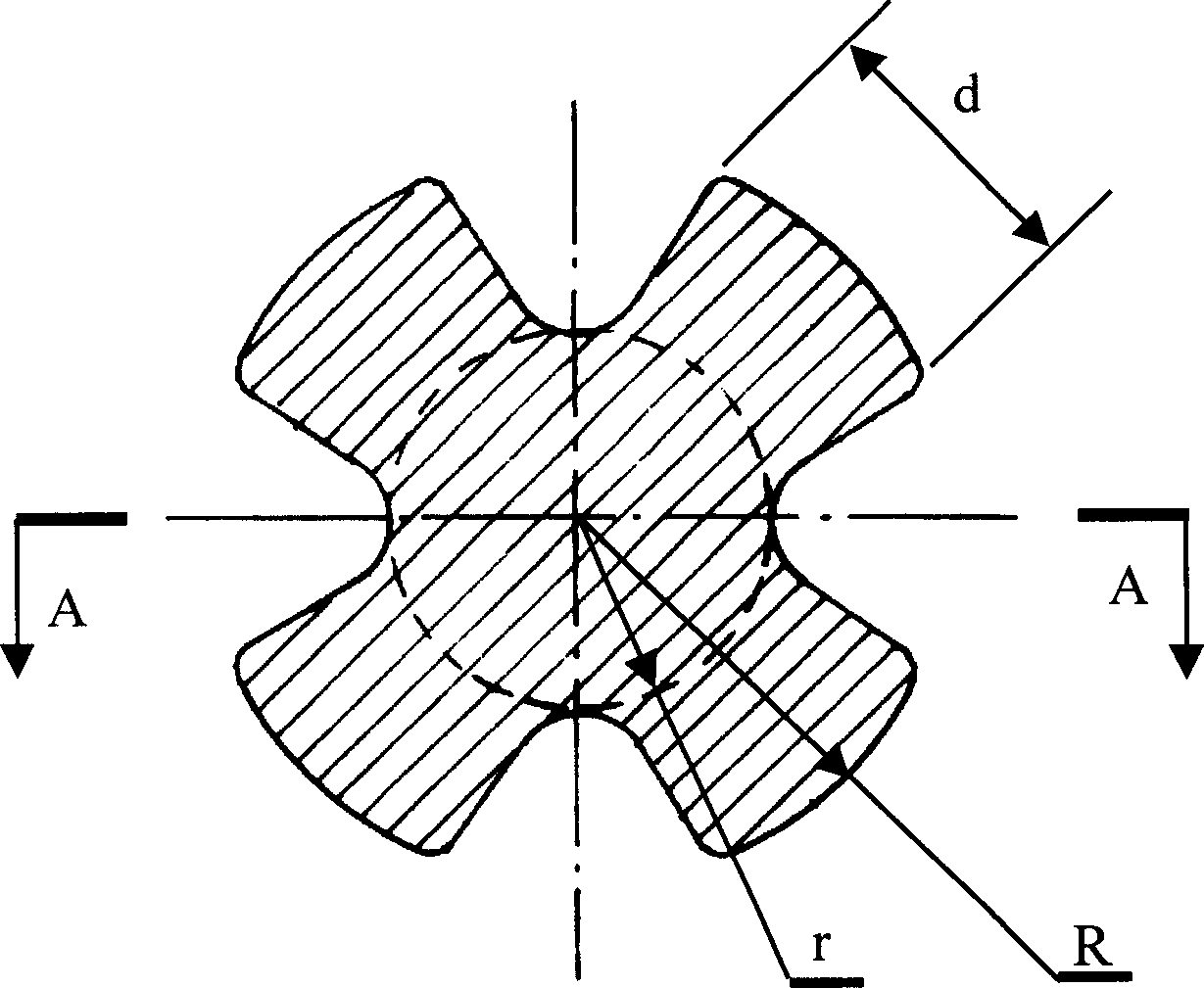

InactiveCN1428199ASuitable particle shapeSmall pressure drop lossOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsAcetic acidSpherical granule

The present invention relates to a catalyst for preparing vinyl acetate by using ethylene, acetic acid and oxygen gas or oxygen-containing gas as raw material and adopting gas-phase reaction. Its carrier is SiO2 or mixture of SiO2 and Al2O3, and the loaded active component contains Pd and KOAc, the active component is formed into egg-shell type non-uniform distribution, said catalyst is made into spherical granule, radium R of the sphere is 2-4 mm, and surrounding a central shaft of sphere, on the surface of the sphere 3-8 grooves whose cross-section is made into arched form are cut along the longitudinal direction, the groove is extended toward two ends of the central shaft from middle portion of the sphere and progressively exposed from surface of the sphere, and the distanced between grooves is greater than 1.5 mm. Said catalyst has high crushing strength, larger packing voidage and proper specific surface area.

Owner:CHINA PETROLEUM & CHEM CORP

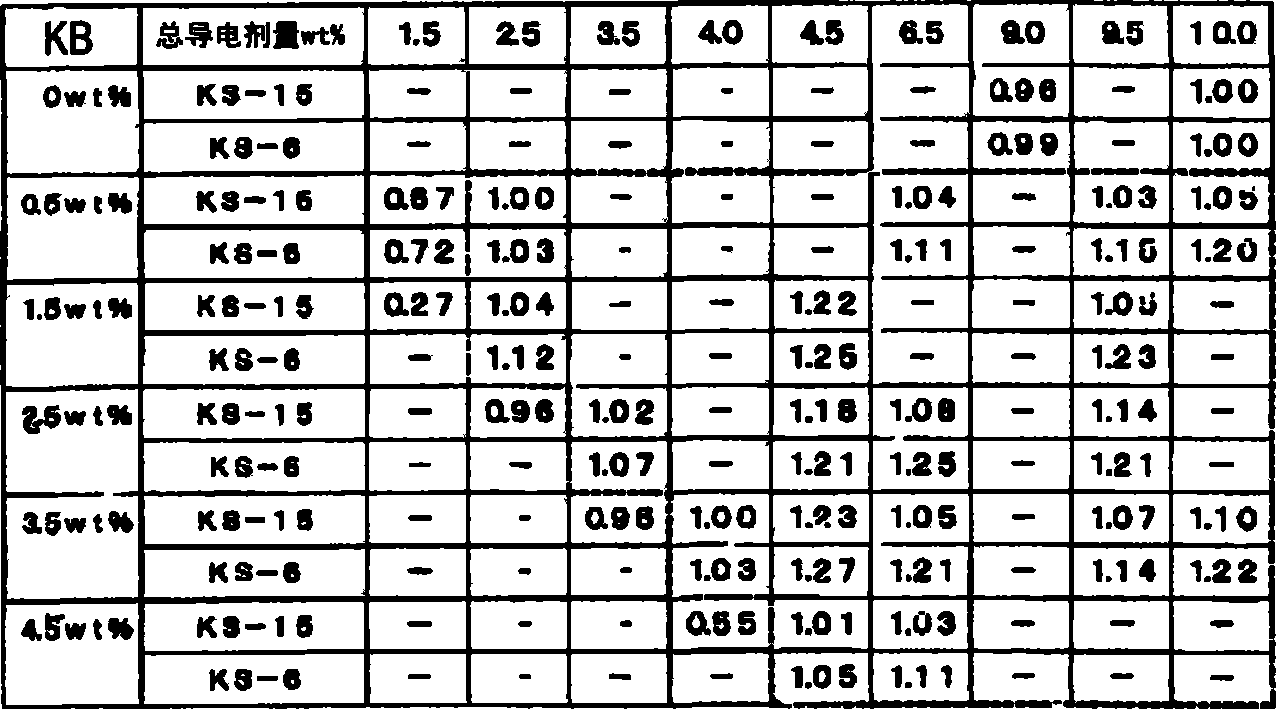

High-security long-life ternary material battery

ActiveCN106328926ASimple preparation procedureEasy to operateCell electrodesSecondary cells servicing/maintenanceAviationNew energy

The invention relates to a high-security long-life ternary material battery. Cathode size comprises the following solid matters by mass percent: 92.0-95.5% of ternary material, 3.0-7.0% of polyvinylidene fluoride and 1.5-2.5% of oily carbon nanofibers, and anode size comprises the following solid matters by mass percent: 90.0-93.5% of lithium titanate, 1.0-2.4% of sodium carboxymethylcellulose, 3.5-7.0% of a binding agent, 0.3-1.0% of SP type conductive carbon black, 0.5-1.8% of C45 type conductive carbon black and 1.2-2.4% of KS-6 type conductive carbon black. The high-security long-life ternary material battery provided by the invention is qualified in security, under room temperature condition, continuous charging and discharging is carried out according to 1C charge-discharge system, capacity retention ratio after 2000 cycles is higher than 80%, and operating requirements of a small electric tool, aviation, spaceflight and new energy automobiles can be met.

Owner:湖南锂顺能源科技有限公司

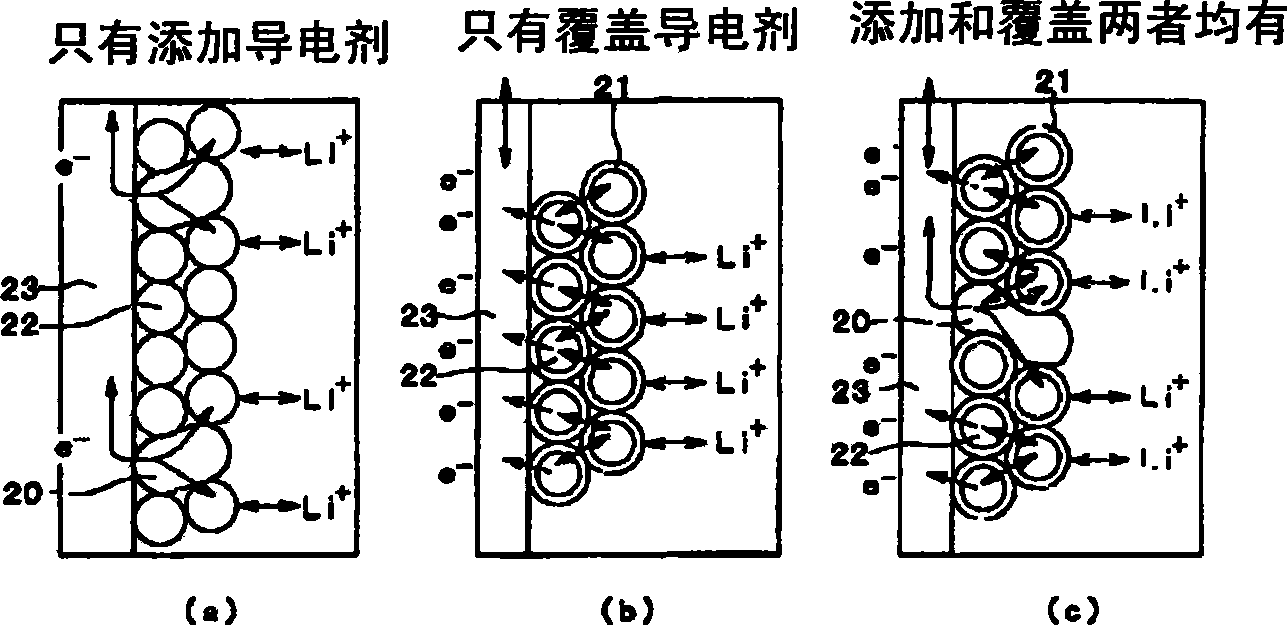

Secondary battery and anode active substance

InactiveCN101378124AIncrease capacityGood electrical polarizationFinal product manufactureActive material electrodesLow loadBattery cell

The invention provides an active material of the anode of a secondary battery, which has good capacity in both low load and high load; the active material of the anode is composed of multiple particles of a metal oxide which forms the body of the active material, a first conductive agent which covers the surfaces of all the particles of the metal oxide, and a second conductive agent which is between the particles of the metal oxide and the specific surface area thereof is less than the first conductive agent.

Owner:EVONIK DEGUSSA CHINA

Activated carbon as well as preparation method and application thereof

ActiveCN113120903AReasonable distributionModerate surface areaCarbon compoundsOther chemical processesActivated carbonPetroleum coke

The invention discloses activated carbon as well as a preparation method and application thereof. The accessibility A of the activated carbon is 1.4-2.2, wherein the accessibility A is a parameter for representing the methane adsorption and storage performance of the activated carbon. The preparation method of the activated carbon comprises the following steps: firstly, uniformly mixing petroleum coke, an activating agent and a transition metal compound, and performing activation reaction; and washing and drying the obtained activated product to obtain the activated carbon. The activated carbon obtained by the method is reasonable in pore distribution, has a proper specific surface area, has micropores capable of adsorbing a large amount of methane and mesopores capable of accelerating mass transfer, and has the advantages of good methane storage effect, simple preparation method and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for C12-C12 fat carboxylic acid ketonization and its application

ActiveCN100363098CSolution to short lifeInhibit cokingPreparation by hydrogenolysisCatalyst activation/preparationKetonic acidsCerium

The invention provides a C2-C12 aliphatic carboxylic acid ketone activator. The invention uses gamma-aluminum oxide as carrier and the single, double elements, and ternary elements of lanthanum, cerium, praseodymium and neodymium of light lanthanide series rare earth as active components. While the activating carrier method comprises (1) the heat treatment process while the treatment temperature is 480-800 Deg. C; (2) azotic acid aqueous solution method while the concentration of azotic acid aqueous solution is 5-45%; (3) evacuation method. In addition, the activator is prepared via the immersion method while it can be used to C2-C12 aliphatic carboxylic acid ketone.

Owner:PETROCHINA CO LTD

Coated hollow three-dimensional material preparation method and product and application thereof

InactiveCN110085833ALow priceShape is easy to controlSecondary cellsPositive electrodesMaterials preparationManganese

The invention discloses a coated hollow three-dimensional material preparation method and a product and application thereof. The method comprises the following steps: step 1, preparing a ferromanganese Prussian blue analogue nano-cube material; step 2, performing hydrochloric acid etching on the ferromanganese Prussian blue analogue nano-cube material obtained in the step 1; and step 3, coating the etched ferromanganese Prussian blue analogue nano-cube material with 3, 4-ethylene dioxythiophene monomer, wherein the poly 3,4-Ethylene dioxythiophene-coated ferromanganese Prussian blue analogue product prepared by the method can be applied to an electrode. The preparation method has the advantages of simple process, mild conditions and low preparation cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

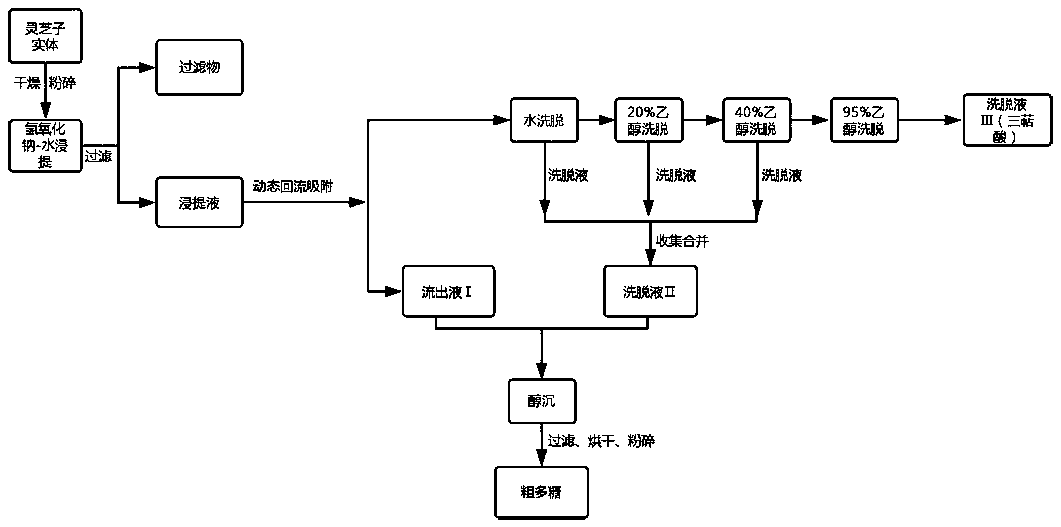

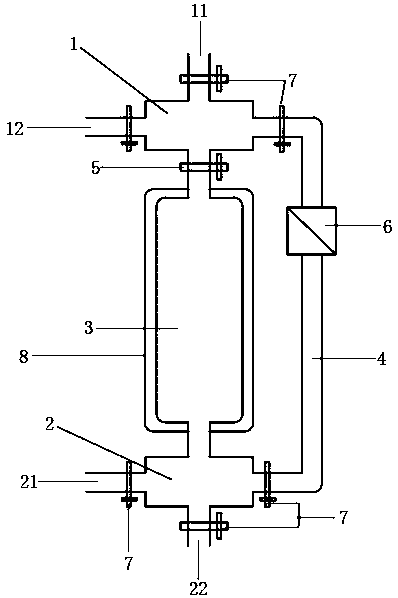

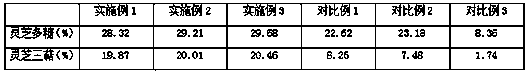

Method for extracting ganoderma triterpene and ganoderma lucidum polysaccharide from ganoderma lucidum

ActiveCN109893547AReduce hydrogen bondingWeaken the ester bondPlant ingredientsFiltrationEthanol precipitation

A method for extracting ganoderma triterpene and ganoderma lucidum polysaccharide from ganoderma lucidum comprises the steps as follows: (1) pretreatment of raw materials: placing crushed ganoderma lucidum fruiting bodies in a sodium hydroxide-aqueous solution for extraction, and performing filtration after ultrasonic treatment to obtain a filtrated material and an extract liquid; (2) pH adjustment: adjusting pH of the extract liquid to 2.0-4.5; (3) dynamic reflux adsorption: performing dynamic reflux adsorption on the extract liquid obtained in step B, and after adsorption, collecting an effluent I; (4) staged elution: dividing the elution process into four stages, mixing and collecting eluates III at the first three stages, and collecting an eluate III which is a ganoderma triterpene extract liquid at the fourth stage; (5) mixing the effluent I and the eluates II, adding ethanol for ethanol precipitation, and performing filtration, drying and crushing to obtain crude ganoderma lucidum polysaccharide. The extract rate of ganoderma triterpene acid and ganoderma lucidum polysaccharide and purity of ganoderma triterpene are effectively increased, the extraction scheme is easy to implement, and extracted products are safe and effective.

Owner:湖州柳荫生物科技有限公司

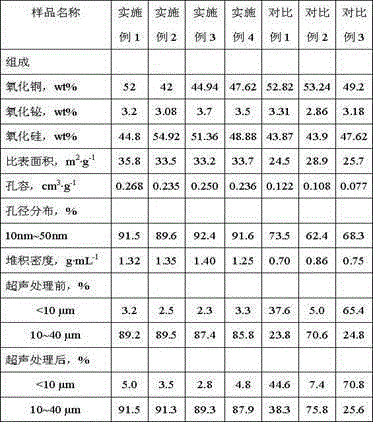

Macroporous weak-base anion-exchange resin and preparation method thereof

InactiveCN109575186AHigh selectivityEfficient removalAnion exchangers2-VinylpyridineBenzoyl peroxide

The invention discloses macroporous weak-base anion-exchange resin and a preparation method thereof. The macroporous weak-base anion-exchange resin comprises the following components: an oil phase anda water phase, wherein the oil phase is 60-80 parts of a 2-vinylpyridine monomer, 25-35 parts of a divinylbenzene cross-linking agent, 100-150% of polyurethane and modified hydroxymethyl cellulose asa mixed pore-foaming agent by monomer weight, and 1.5-3% of benzoyl peroxide and azodiisobutyronitrile as a mixed initiator by monomer weight; and the water phase is 480-600 parts of deionized water,2-3 parts of a hydroxypropyl methyl cellulose dispersing agent, and 38-42 parts of a sodium nitrite salting-out agent. The preparation method thereof comprises the following steps: adding the oil phase to the water phase, stirring, varying a temperature, and performing a curing reaction. The prepared macroporous weak-base anion-exchange resin has higher adsorptive selectivity, larger adsorptioncapacity and good heat resistance, and is capable of efficiently removing harmful or degradation-resistant anions of an arsenate ion, an aromatic sulfonate ion, a fumaric acid radical ion and the like, and prolonging service life thereof.

Owner:ANHUI SANXIN RESIN TECH

Method used for catalytic synthesis of fatty acid methyl ester with roasted hydrocalumite

PendingCN109289828ASuitable alkali strengthModerate surface areaFatty acid esterificationMetal/metal-oxides/metal-hydroxide catalystsCatalytic effectFatty acid methyl ester

The invention discloses a method used for catalytic synthesis of fatty acid methyl ester with roasted hydrocalumite. According to the method, soybean oil and methanol are taken as raw materials, and synthesis of the fatty acid methyl ester is carried out under catalytic effect of roasted hydrocalumite. The structure general formula of the roasted hydrocalumite is Ca<2+><1-x>Al<3+><x>(OH)2(CO<3><2->)<x / 2>.mH2O, wherein 0.3<=x<=0.35, m is used for representing the number of crystal water, and 1<=m<=3. The roasted hydrocalumite is a product of hydrocalumite after 2 to 8h of roasting at 400 to 800DEG C. The advantages are that: the catalyst preparation process is simple, cost is low, product yield is high, and catalyst separation is convenient.

Owner:湖南雄创新材料科技有限公司 +1

Preparation method of synthetic 1,4-butynediol catalyst

InactiveCN106669694AGuaranteed uniformityModerate surface areaOrganic compound preparationHydroxy compound preparationReaction temperatureDistilled water

The invention discloses a preparation method of a synthetic 1,4-butynediol catalyst. The preparation method comprises the following preparation steps of (1) preparing a copper and silicon mixed solution, a copper and bismuth mixed solution, a precipitant solution I and a precipitant solution II; (2) dripping the precipitant solution I into the copper and silicon mixed solution, so as to obtain copper and silicon precipitate slurry; (3) adding the copper and bismuth mixed solution into the copper and silicon precipitate slurry, wherein the usage amount of copper is the left copper amount; (4) compared with a precipitation condition in step (2), under the condition of lowering the reaction temperature by 5 to 30 DEG C, dripping the copper and bismuth mixed solution containing the copper and silicon precipitate into the precipitant solution II; (5) filtering a material, and adding a proper amount of distilled water; (6) spraying and drying the slurry, and calcining, so as to obtain the catalyst for producing synthetic 1,4-butynediol. The preparation method has the advantages that the particles of the catalyst are uniform, and the loss possibility in a use process is small; the preparation method of the catalyst is simple, the implementing is easy, and the repeatability is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

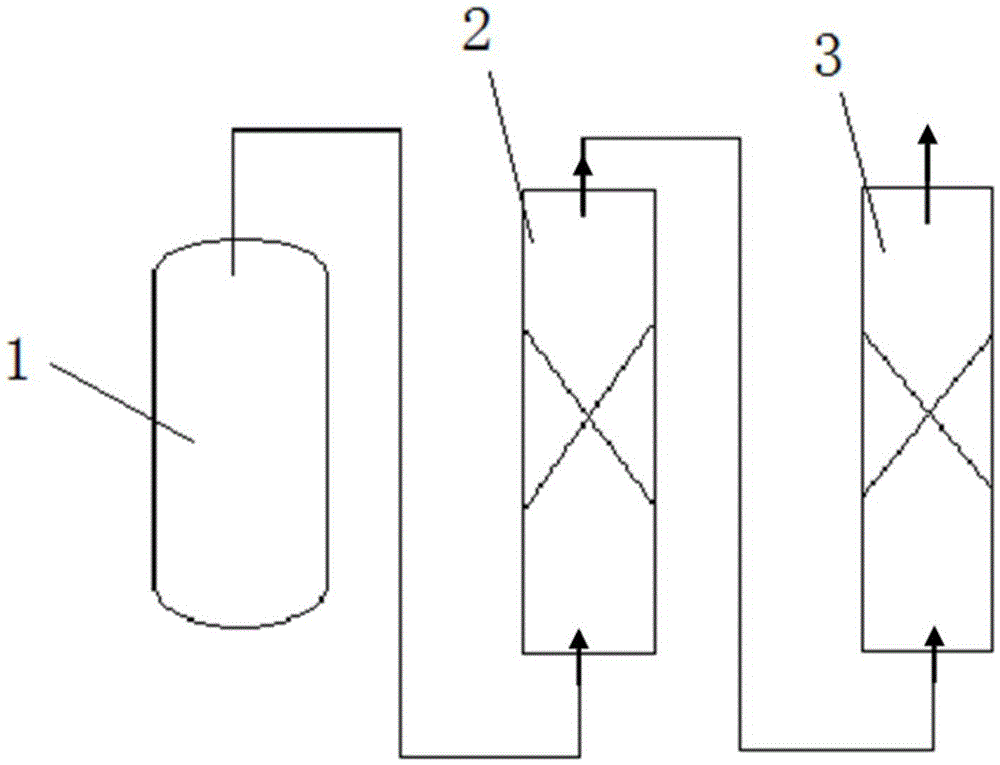

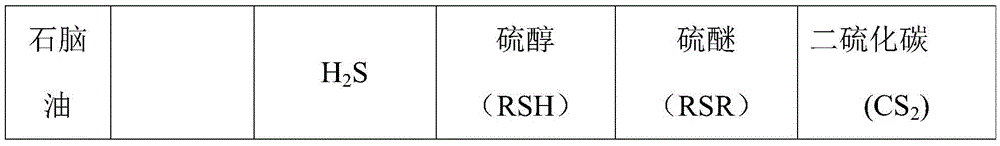

Method for removing sulfides in light oil

ActiveCN105623719ALow densityImprove bindingTreatment with plural serial refining stagesOrganic sulfide compoundActivated carbon

The invention discloses a method for removing sulfides in light oil. The method comprises the following steps that 1, on the condition that the temperature ranges from minus 5 DEG C to 90 DEG C and the pressure ranges from 0.1 MPa to 5 MPa, the light oil makes contact with magnetic iron oxide, first-stage desulfurization is conducted, inorganic sulfides in the light oil are removed, and the light oil with the inorganic sulfides removed is obtained; 2, on the condition that the temperature ranges from minus 5 DEG C to 90 DEG C and the pressure ranges from 0.1 MPa to 5 MPa, the light oil with the inorganic sulfides removed makes contact with activated carbon loaded with copper, second-stage desulfurization is conducted, organic sulfides in the light oil are removed, and the light oil with the organic sulfides removed is obtained, that is to say, the light oil with the sulfides removed is obtained. By means of the removing method, various sulfides in the light oil are effectively removed, the total sulfur content of the light oil with the sulfides removed does not exceed the national standard or the industrial standard, and the method has the advantages of being capable of achieving normal temperature operation, large in treatment capacity, free of waste alkali, low in energy consumption, simple in technology, easy and convenient to operate and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

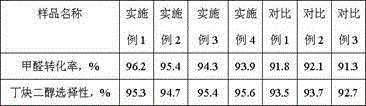

Preparation method of catalyst for coproducing isopropanol and methyl isobutyl ketone by acetone hydrogenation

ActiveCN102806086BLow content of active metal componentsExtended service lifeOxygen-containing compound preparationOrganic compound preparationMethyl isobutyl ketoneNitrate

The invention relates to a preparation method of a catalyst for coproducing isopropanol and methyl isobutyl ketone by acetone hydrogenation. The catalyst comprises an alumina carrier and Ni and Mg loaded on the gamma-Al2O3 carrier, and particularly comprises, by total weight, 10-18% of the Ni, 3-8% of the Mg and the balance alumina; and the BET specific surface area of the catalyst ranges from 100m<2> / g to 180m<2> / g, and the pore volume of the catalyst ranges from 0.35mL / g to 0.55mL / g. The preparation method includes steps of (1), preparing the carrier by details of weighing pseudo-boehmite powder, adding binders and extrusion assistants into the pseudo-boehmite powder, forming by strip extrusion or granulating by rotation, drying and calcining, cooling to reduce temperature so as to obtain the stripped or spherical carrier; (2), impregnating the carrier into magnesium nitrate by details of loading a magnesium additive onto the carrier by means of saturated impregnation, drying and then calcining for 2-6 hours at the temperature ranging from 400 DEG C to 500 DEG C; (3), loading the actively metallic nickel by details of impregnating for 10-24 hours and calcining for 2-6 hours at the temperature ranging from 350 DEG C to 480 DEG C; and (4), loading the actively metallic nickel again by details of drying a semi-finished product, impregnating the dried semi-finished product into impregnation liquid of nickel nitrate again, repeating the step (3) once, and calcining the semi-finished product for 2-4 hours at the temperature ranging from 400 DEG C to 450 DEG C so as to obtain the finished catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com