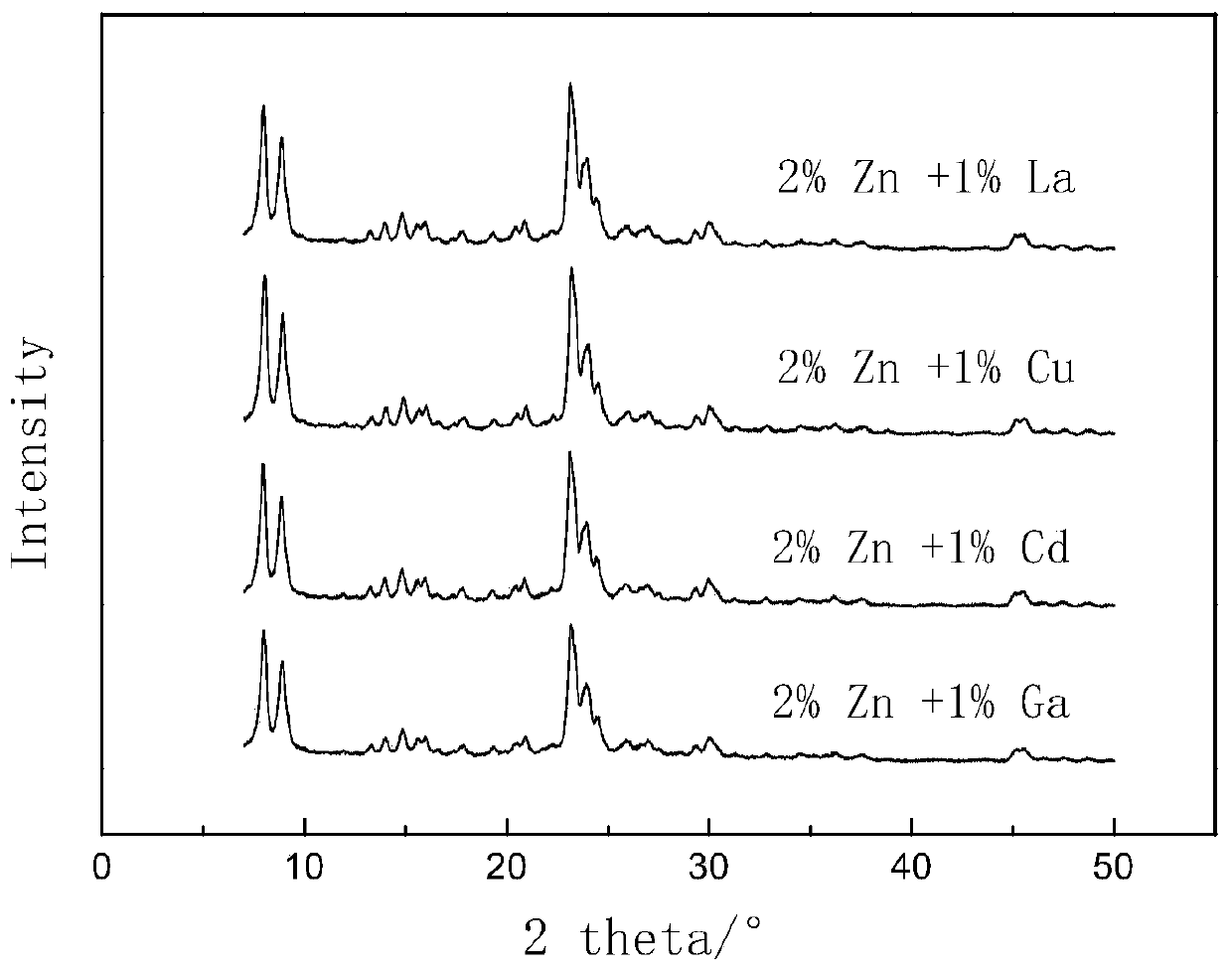

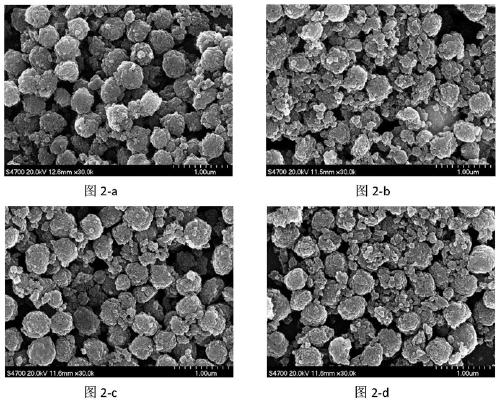

Bimetal-modified nano-HZSM-5 molecular sieve catalyst as well as preparation method and application thereof

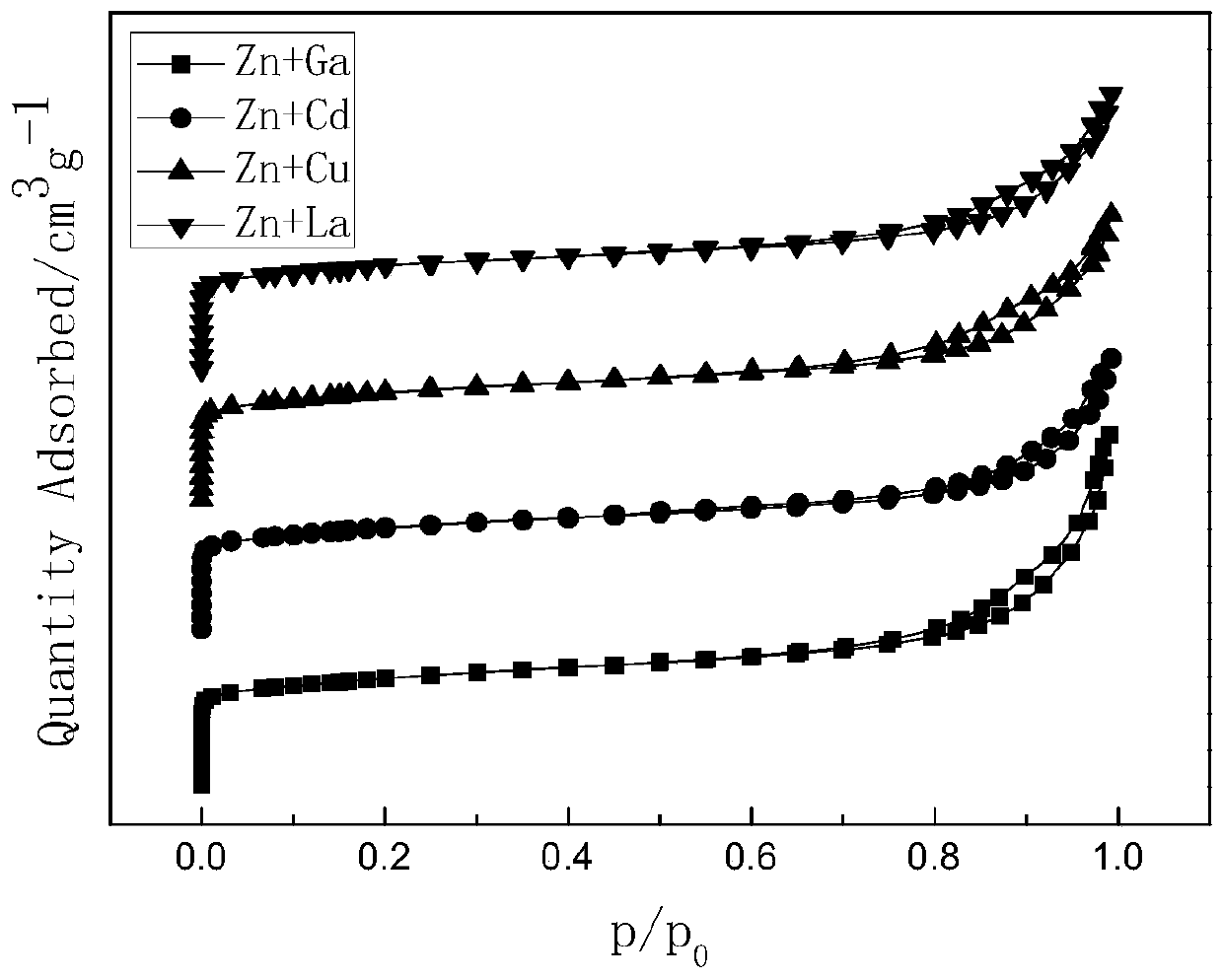

A molecular sieve and catalyst technology, applied in the field of catalyst materials, can solve the problems of unsatisfactory application of ZSM-5 modified catalyst, and achieve the effect of moderate specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of Zn-Ga-HZSM-5 molecular sieve catalyst, comprising the following steps:

[0036]Step 1), preparation of gel: according to raw material silicon aluminum ratio Si:Al=13, templating agent M:Al 2 o 3 =6.8, H 2 O: Al 2 o 3 =1149 takes each raw material, the quality of aluminum source is 0.297g, the H of weighing 10g 2 O and the template agent M are prepared into a template agent solution, after mixing evenly, keep stirring in a water bath at 30°C for 30min; another part of the water and 0.297g of NaAlO 2 (i.e. aluminum source) is formulated into an aluminum source solution, the aluminum source solution is added to the template solution, after mixing evenly, keep stirring in a 30°C water bath for 30 minutes to obtain the first mixed material; finally, the silicic acid Tetraethyl ester (i.e. silicon source) was added to the first mixed material, after mixing evenly, aging for 3 hours in a water bath at 30°C to obtain a gel material;

[0037] Step 2...

Embodiment 2

[0043] A preparation method of Zn-Cd-HZSM-5 molecular sieve catalyst, comprising the following steps:

[0044] Step 1), preparation of gel: according to raw material silicon aluminum ratio Si:Al=13, templating agent M:Al 2 o 3 =6.8, H 2 O: Al 2 o 3 =1149 takes each raw material, the quality of aluminum source is 0.297g, the H of weighing 10g 2 O and the template agent M are prepared into a template agent solution, after mixing evenly, keep stirring in a water bath at 30°C for 30min; another part of the water and 0.297g of NaAlO 2 (i.e. aluminum source) is formulated into an aluminum source solution, the aluminum source solution is added to the template solution, after mixing evenly, keep stirring in a 30°C water bath for 30 minutes to obtain the first mixed material; finally, the silicic acid Tetraethyl ester (i.e. silicon source) was added to the first mixed material, after mixing evenly, aging for 3 hours in a water bath at 30°C to obtain a gel material;

[0045] Step ...

Embodiment 3

[0051] A preparation method of Zn-Cu-HZSM-5 molecular sieve catalyst, comprising the following steps:

[0052] Step 1), preparation of gel: according to raw material silicon aluminum ratio Si:Al=13, templating agent M:Al 2 o 3 =6.8, H 2 O: Al 2 o 3 =1149 takes each raw material, the quality of aluminum source is 0.297g, the H of weighing 10g 2 O and the template agent M are prepared into a template agent solution, after mixing evenly, keep stirring in a water bath at 30°C for 30min; another part of the water and 0.297g of NaAlO 2 (i.e. aluminum source) is formulated into an aluminum source solution, the aluminum source solution is added to the template solution, after mixing evenly, keep stirring in a 30°C water bath for 30 minutes to obtain the first mixed material; finally, the silicic acid Tetraethyl ester (i.e. silicon source) was added to the first mixed material, after mixing evenly, aging for 3 hours in a water bath at 30°C to obtain a gel material;

[0053] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com