The method of controlling the water addition of vpo catalyst auxiliary agent in mah preparation process

A preparation process and catalyst technology, applied in the direction of organic chemistry, etc., can solve the problems of unspecified water control adding method and adding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

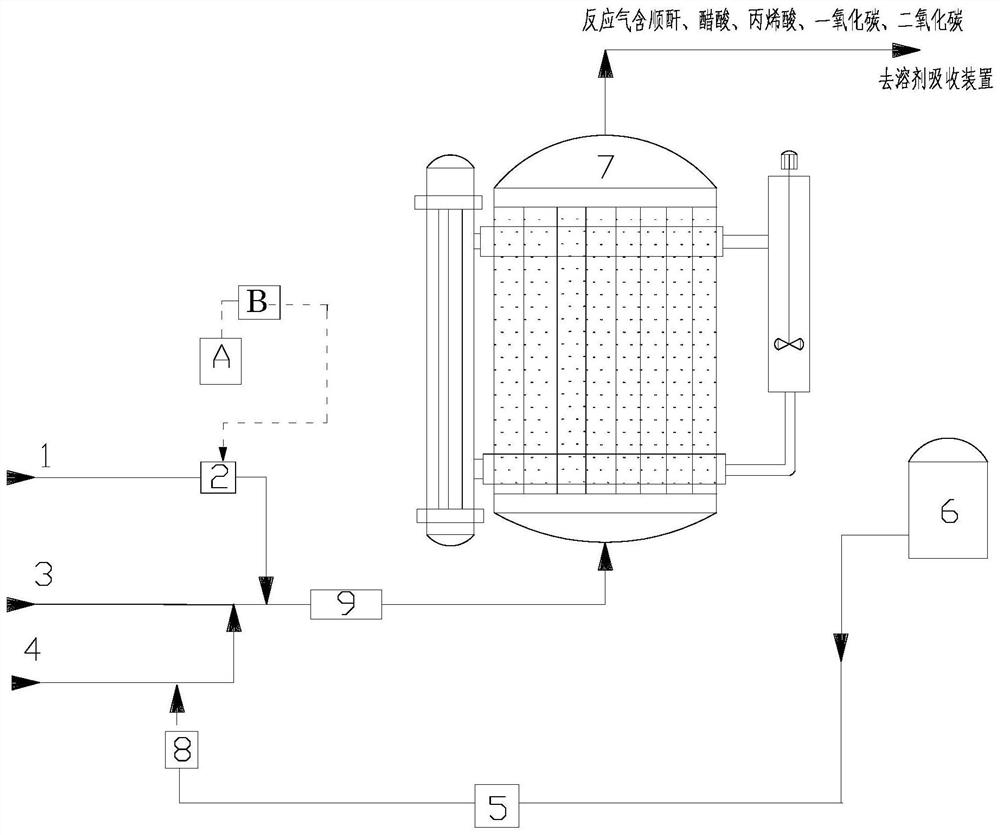

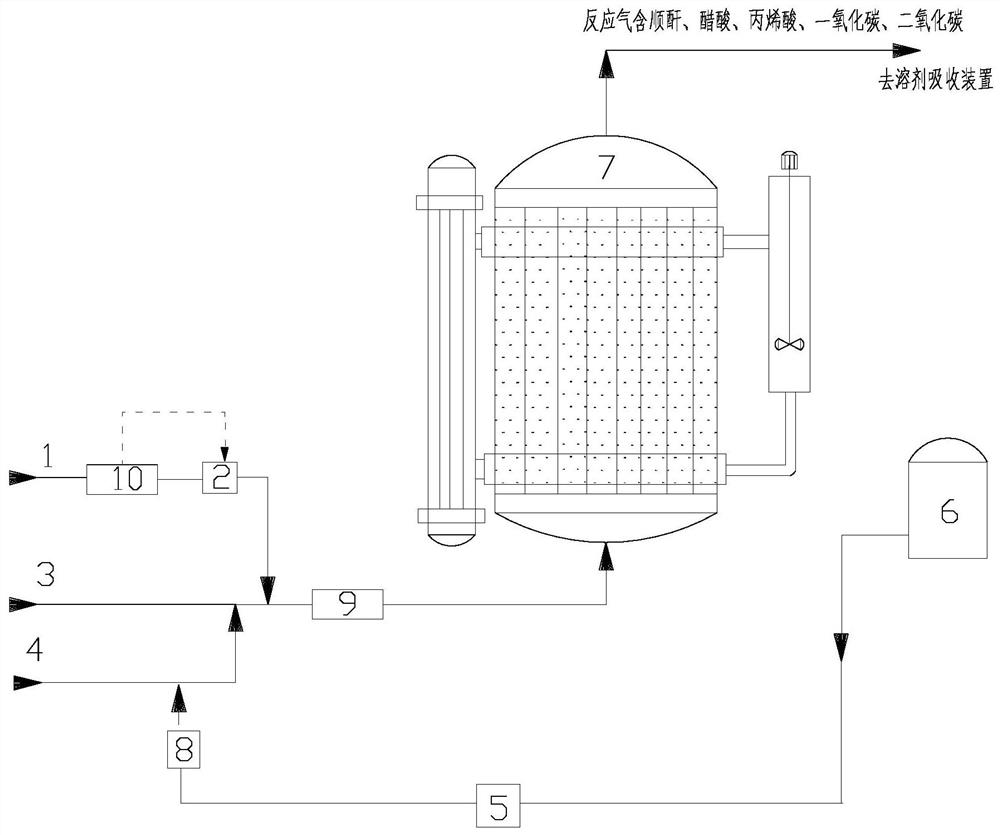

[0038] In the 120,000 tons / year MAH production unit provided by HUNSTMAN technology, n-butane is in the shell-and-tube fixed bed reactor under the condition of VPO catalyst, the catalyst bed height is 5900mm, the catalyst tube diameter is 25mm, and the butane concentration is 1.85mol %, Airspeed 1560h -1 , trimethyl phosphate (TMP) 8ppm, reactor inlet pressure 180Kpag, using figure 1 Water is added in the process flow shown to ensure that the water concentration in the mixed gas is 2.4mol%. The catalyst runs to 1935 hours, the conversion rate is 83.2%, the mass yield is 98.2%, and the selectivity is 70%; the conversion rate is 83.2%, the mass yield is 98.2%, and the selectivity is 70%; the operation is 2031 hours, and the conversion The yield is 83.2%, the mass yield is 98.2%, and the selectivity is 70%.

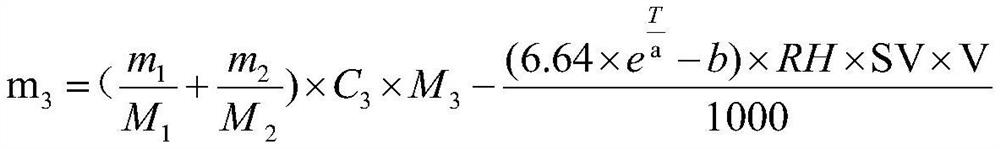

[0039] In summary, the present invention uses a temperature and humidity meter to measure the ambient temperature T and relative humidity RH, and calculates the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com