Patents

Literature

44results about How to "High quality yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing levulinic acid and furfural by hydrolyzing biomass

InactiveCN105669421AWidely distributedLarge specific surface areaOrganic compound preparationCarboxylic compound preparationLevulinic acidWater vapor

The invention discloses a method for preparing levulinic acid and furfural by hydrolyzing biomass. The method comprises the following steps of firstly, mixing the biomass with a catalyst, introducing water vapor to generate primary hydrolysis, discharging a gaseous phase of the primary hydrolysis and condensing to obtain an aqueous solution containing the furfural; secondly, introducing water vapor into the biomass subjected to primary hydrolysis to perform secondary hydrolysis, and discharging a gaseous phase of the secondary hydrolysis; thirdly, performing temperature and pressure reduction on the gaseous phase subjected to the secondary hydrolysis, enabling the gaseous phase to enter into a reaction kettle filled with the biomass, generating primary hydrolysis, discharging the gaseous phase of the primary hydrolysis, and condensing the gaseous phase to obtain an aqueous solution containing the furfural and the levulinic acid; fourthly, supplementing the catalyst into the reaction still in the third step, introducing water vapor for secondary hydrolysis, and discharging a gaseous phase of the secondary hydrolysis; fifthly, repeating the third step and the fourth step; sixthly, purifying and separating the aqueous solution in the first step from the aqueous solution in the third step to obtain the levulinic acid and the furfural. According to the method disclosed by the invention, the yields of the levulinic acid and the furfural are increased; the yield of the furfural reaches 60 percent or above 60 percent, and the yield of the levulinic acid reaches 50 percent or above 50 percent.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

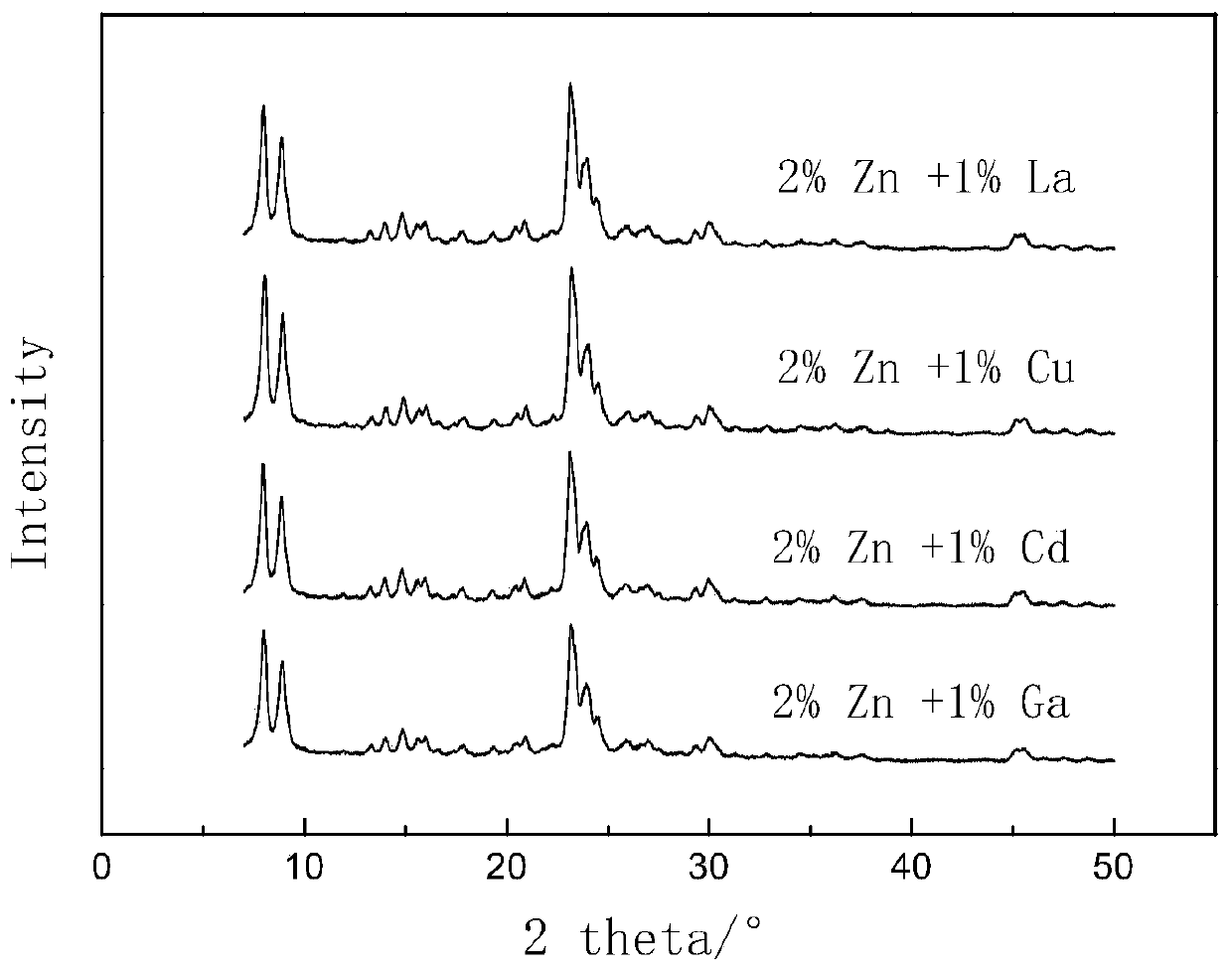

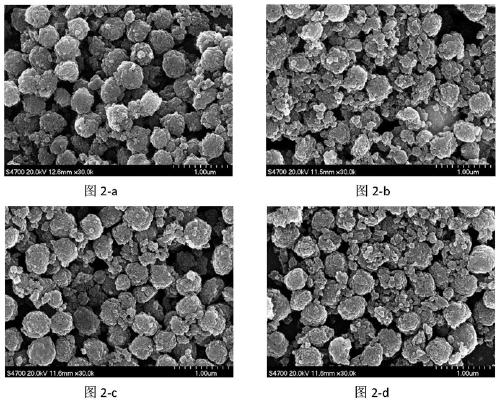

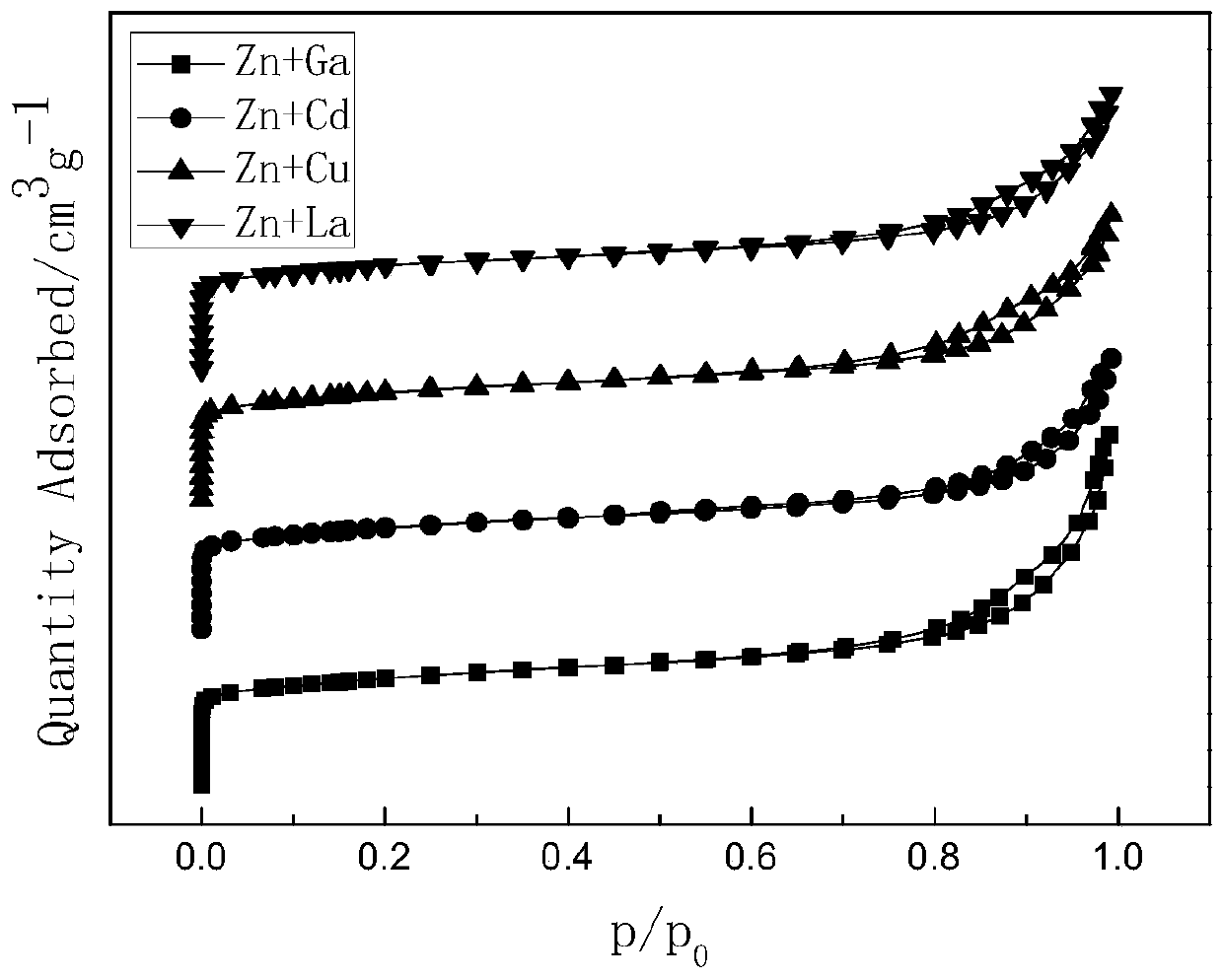

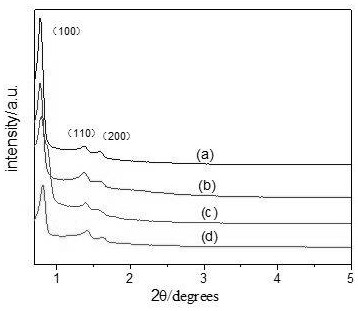

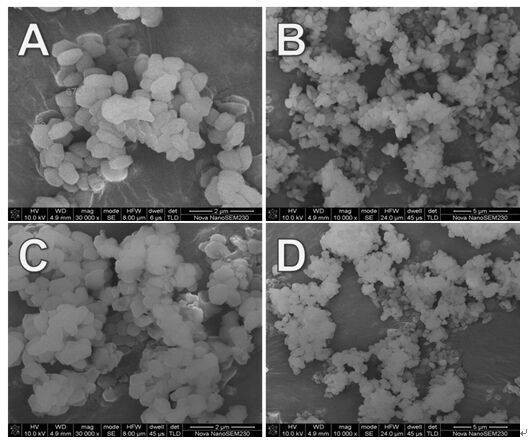

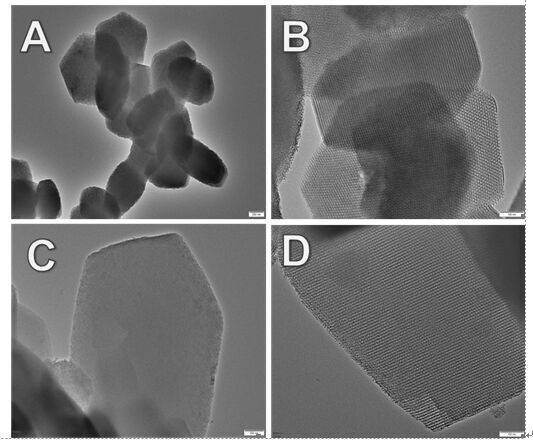

Bimetal-modified nano-HZSM-5 molecular sieve catalyst as well as preparation method and application thereof

InactiveCN109908949AHigh quality yieldModerate surface areaMolecular sieve catalystsCatalyst activation/preparationMolecular sieveSynthesis methods

The invention relates to a bimetal-modified nano-HZSM-5 molecular sieve catalyst as well as a preparation method and application thereof. An HZSM- molecular sieve catalyst is taken as a carrier and isloaded with metal Zn and metal A, wherein the metal A is selected from any of Ga, Cd, Cu and La. By performing bimetal modification on the HZSM-5 molecular sieve catalyst, the bimetal modified nano-HZSM-5 molecular sieve catalyst which is more suitable for a methanol aromatization reaction is obtained; HZSM-5 is independently synthesized, compared with the prior art, the aspects of the formula ofraw materials, a synthesis method and a process are improved, and the HZSM-5 molecular sieve catalyst which is better than the existing HZSM-5 is obtained; the modified molecular sieve catalyst is moderate in specific surface area and is more suitable for the methanol aromatization reaction.

Owner:BEIJING UNIV OF CHEM TECH

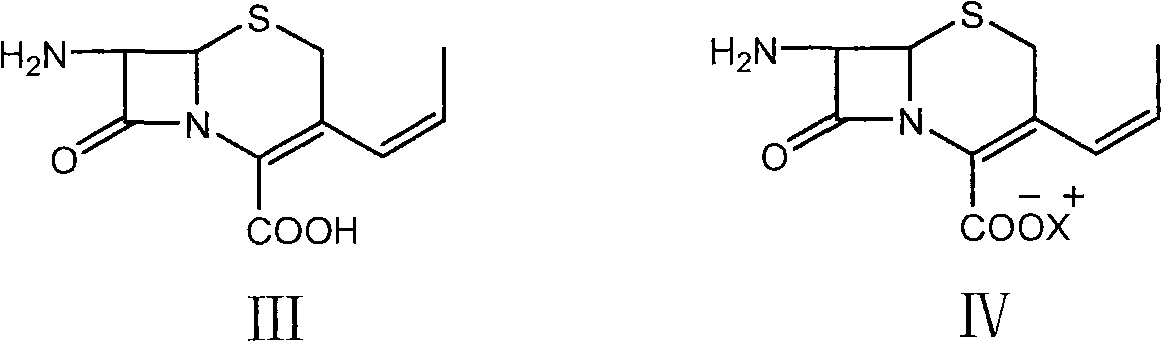

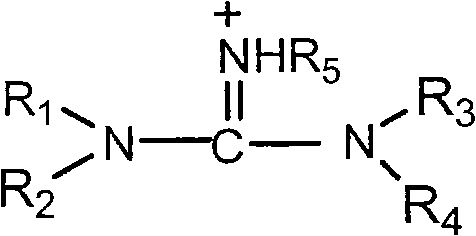

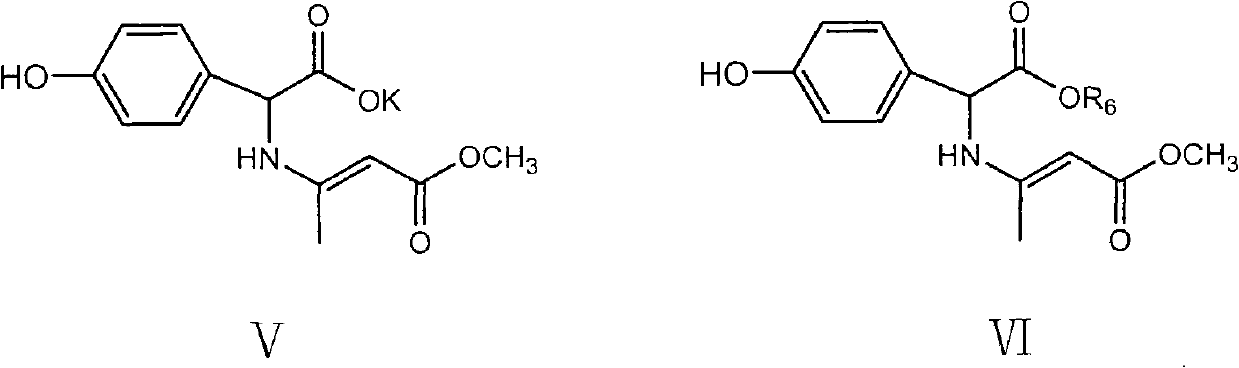

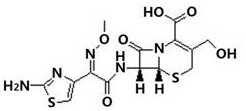

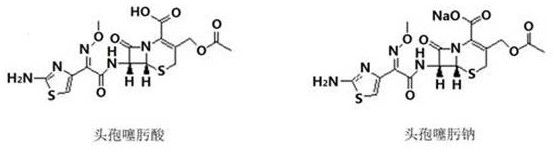

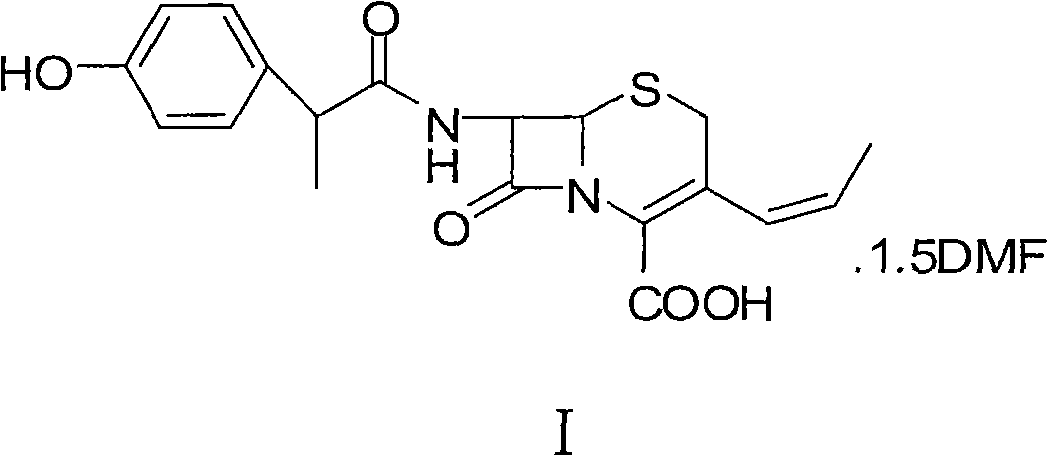

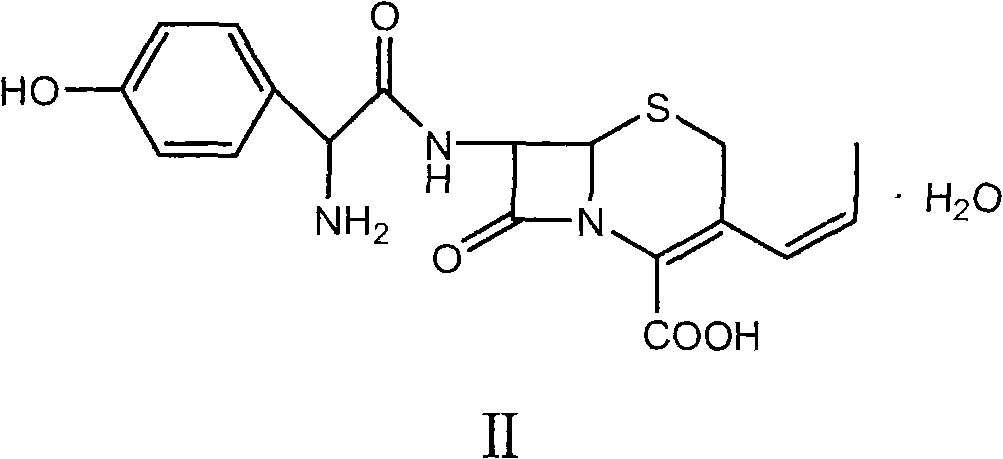

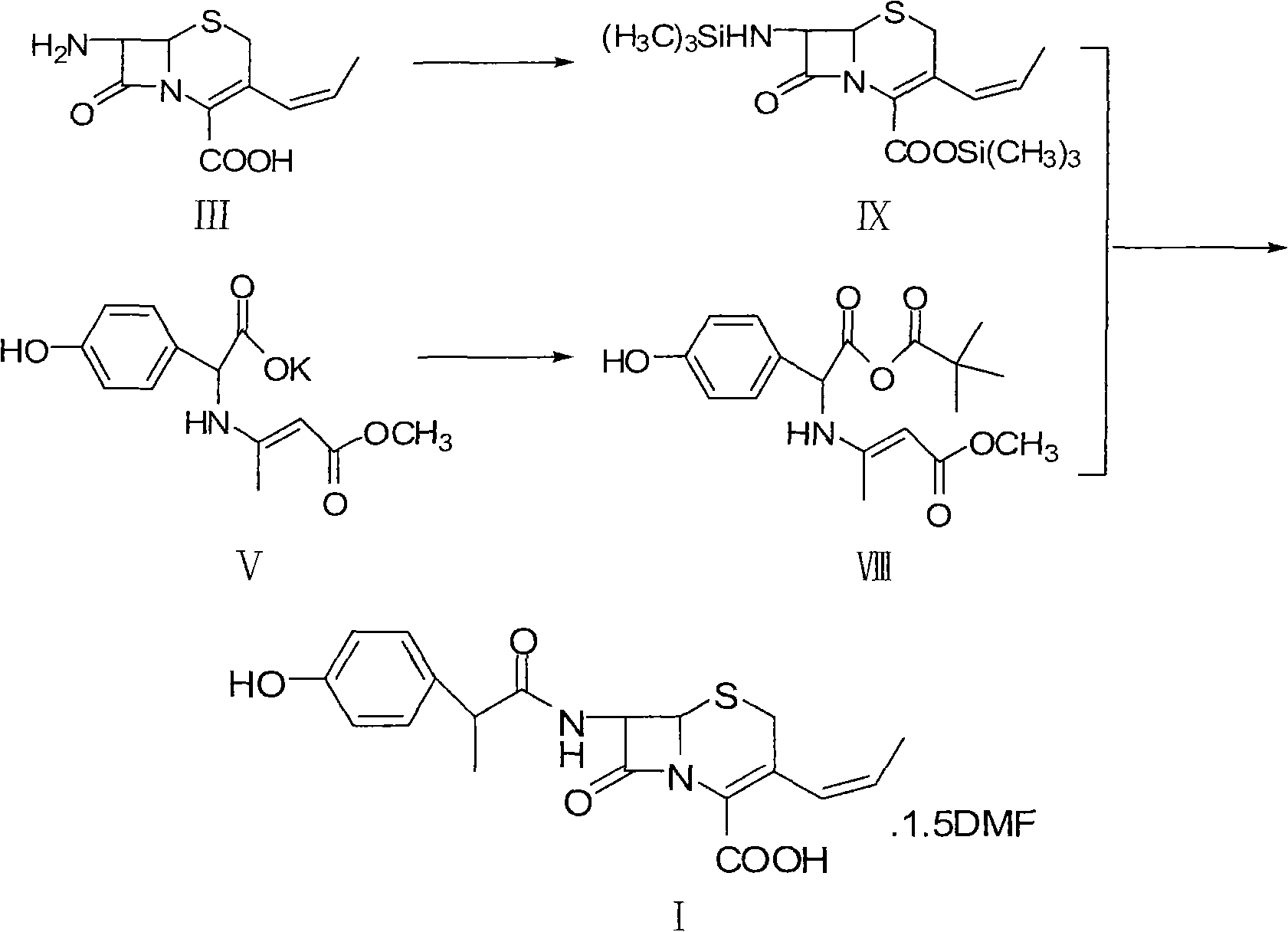

Method for preparing cefprozil dimethyl formamide solvate

The invention relates to an improved method for preparing a cefprozil dimethyl formamide (DMF) solvate; the method comprises the following steps of: taking a 7-APCA-guanidine salt shown by the formula IV and a mixed anhydride shown by the formula VI as raw materials to carry out a condensation reaction under alkaline conditions, hydrolyzing reaction liquid in the presence of acids, separating the liquid, adding DMF to a water phase, and regulating a pH value with an alkaline to obtain the cefprozil DMF solvate shown by the formula I. The method of the invention avoids the usage of silanizing reagent with expensive cost and instability, improves yield greatly and reduces production cost to form a more economic and efficient preparation technology, wherein X+ and R6 are defined according to claim 1.

Owner:CSPC MEGALITH BIOPHARMACEUTICAL CO LTD

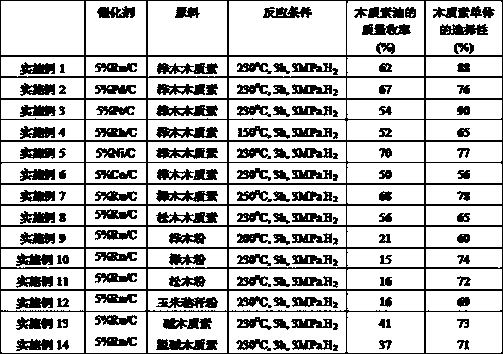

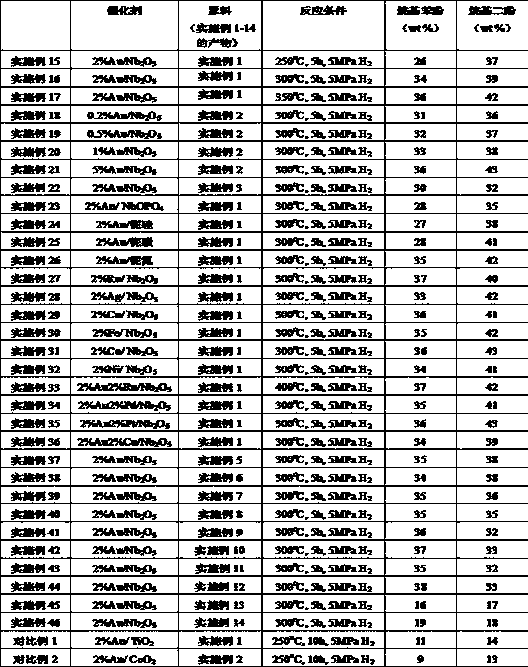

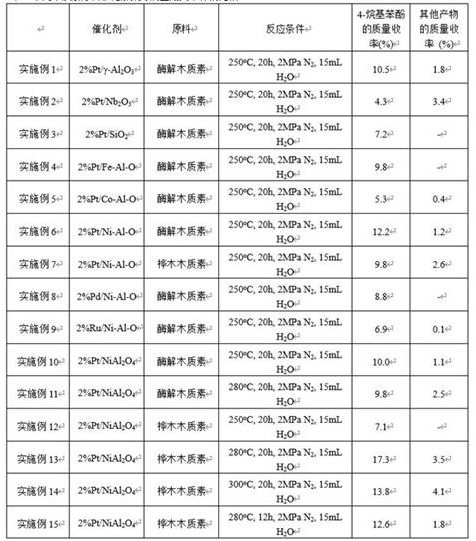

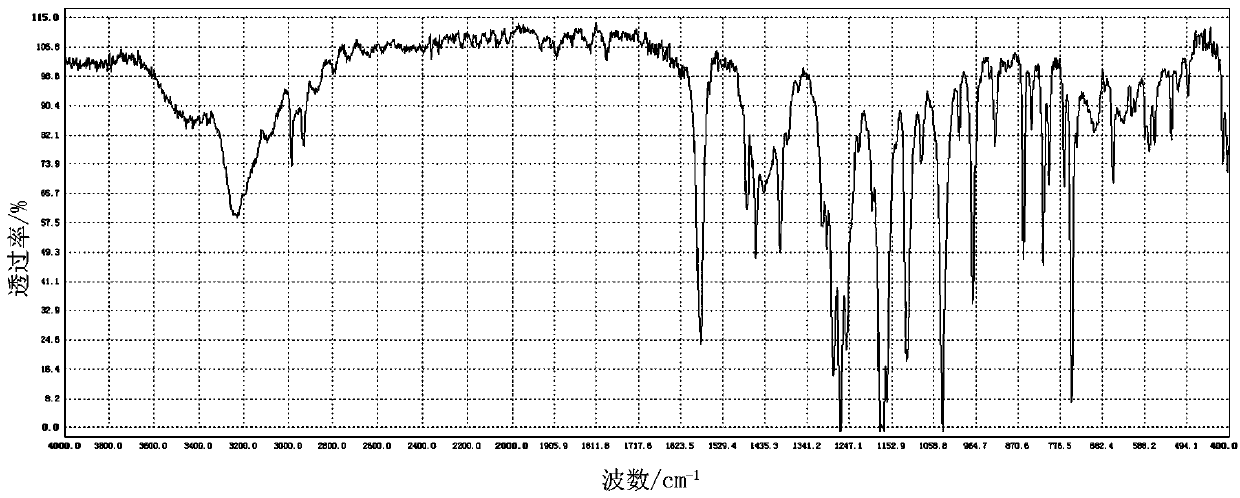

Method for preparing alkylphenol and alkyl diphenol from lignin oil

PendingCN109942378AWide variety of sourcesLow costOrganic chemistryOrganic compound preparationCellulosePtru catalyst

The invention relates to a method for preparing alkylphenol and alkyl diphenol from lignin oil. According to the method, the lignin oil is taken as the raw material and is utilized for preparing phenol products such as alkylphenol and alkyl diphenol through selective hydrogenation deoxygenation in equipment of a batch type reaction kettle, a fixed bed, a fluidized bed and the like under the effectof a niobium base material loaded metal catalyst. The lignin oil is prepared from lignin separated by virtue of various methods and lignocellulose containing lignin by virtue of a depolymerization method. The raw material sources are wide, and the cost is low. Meanwhile, the product is single and contains few byproducts, the separation is simple, and the separation energy consumption is reduced.Besides, phenol compounds are importable chemical products, can be used for preparing phenol and olefin through further catalytic cracking and have has wide application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH

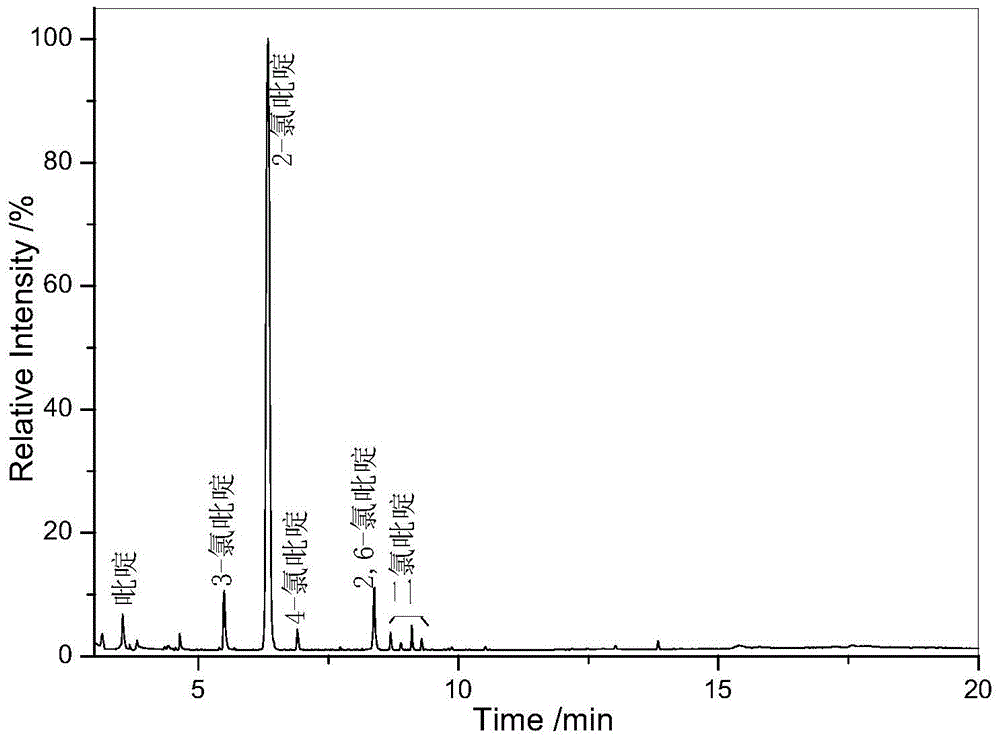

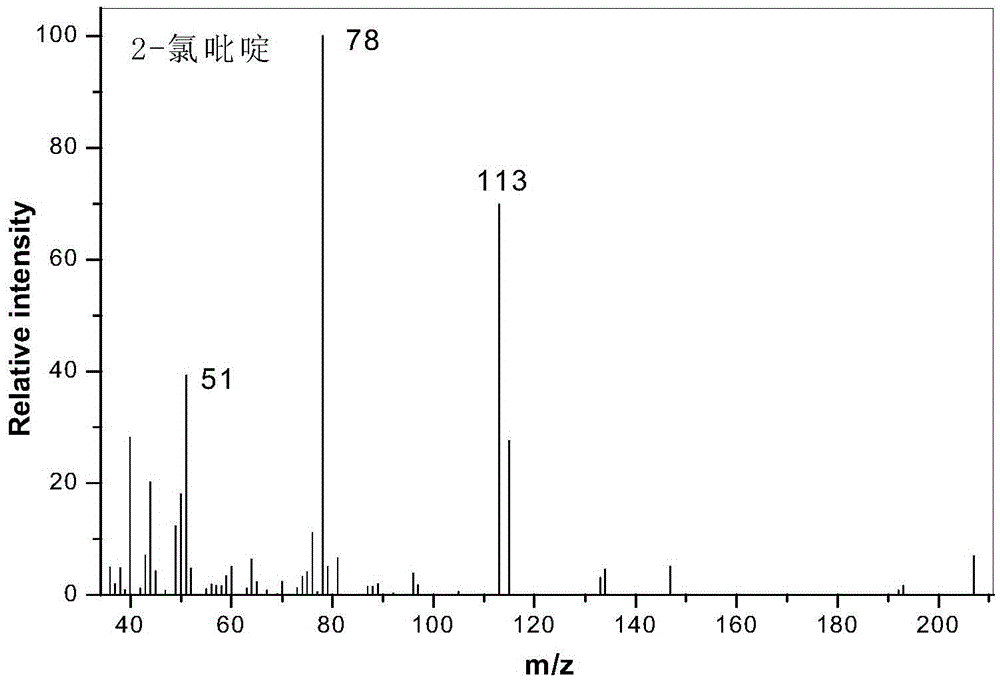

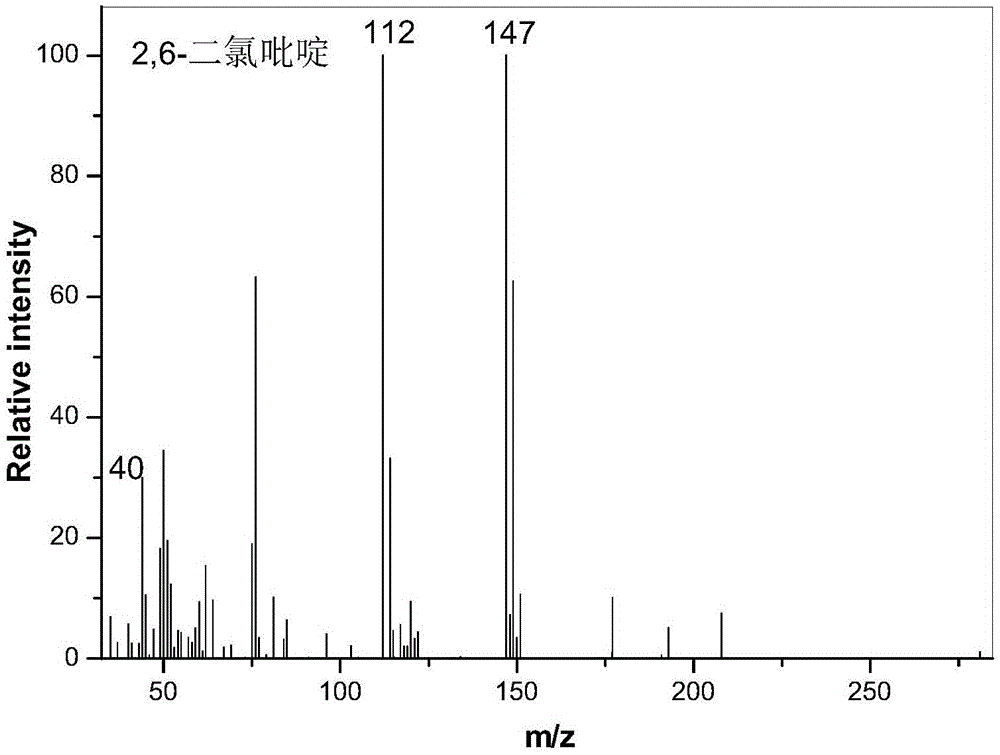

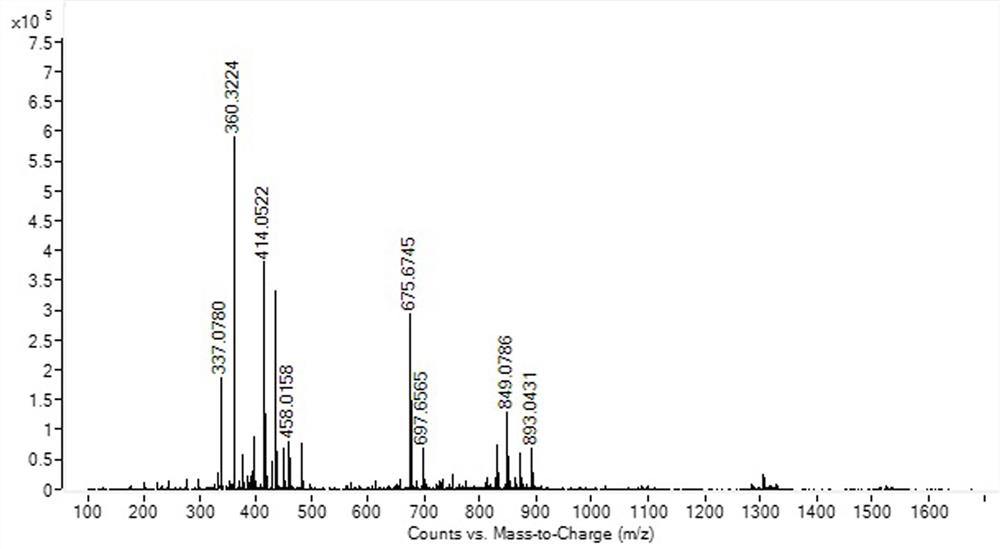

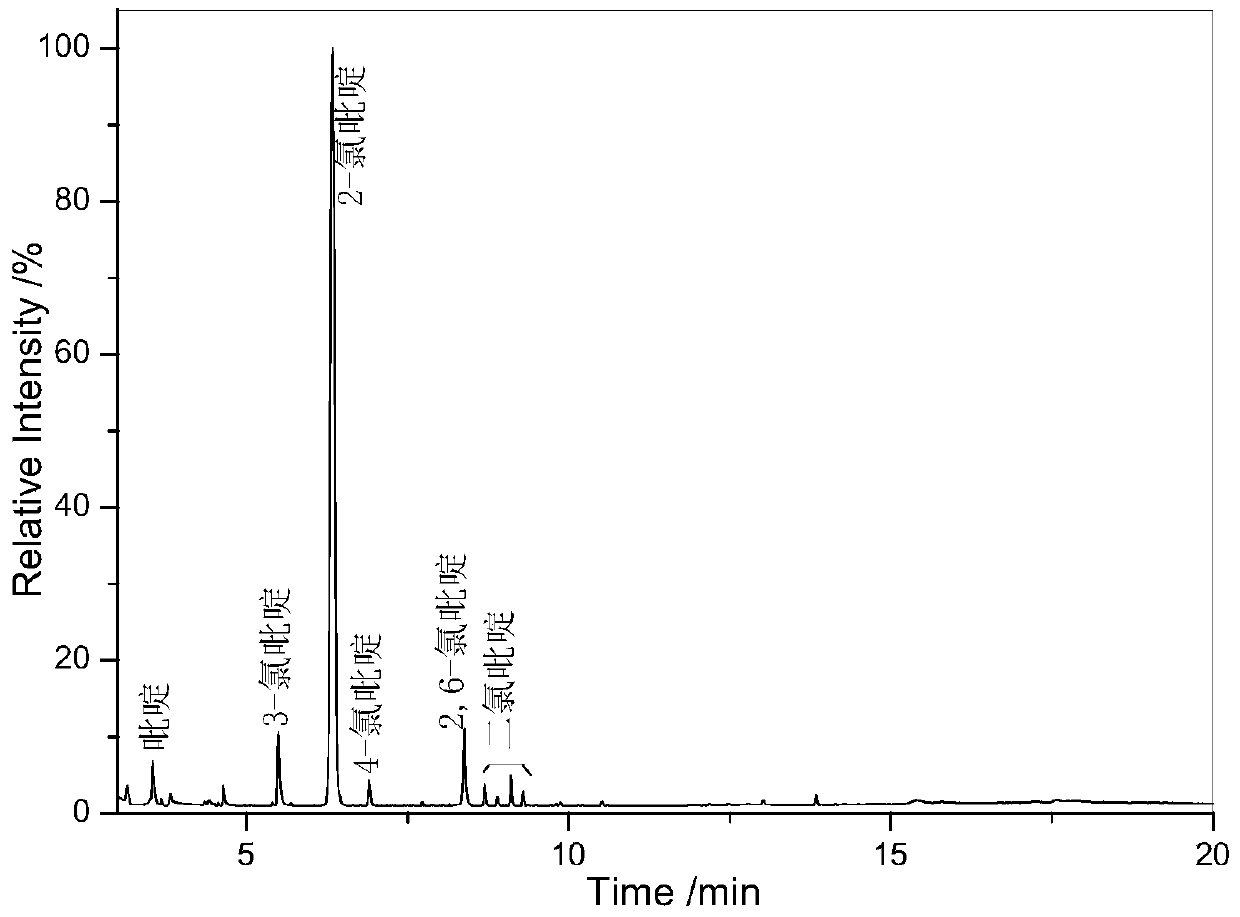

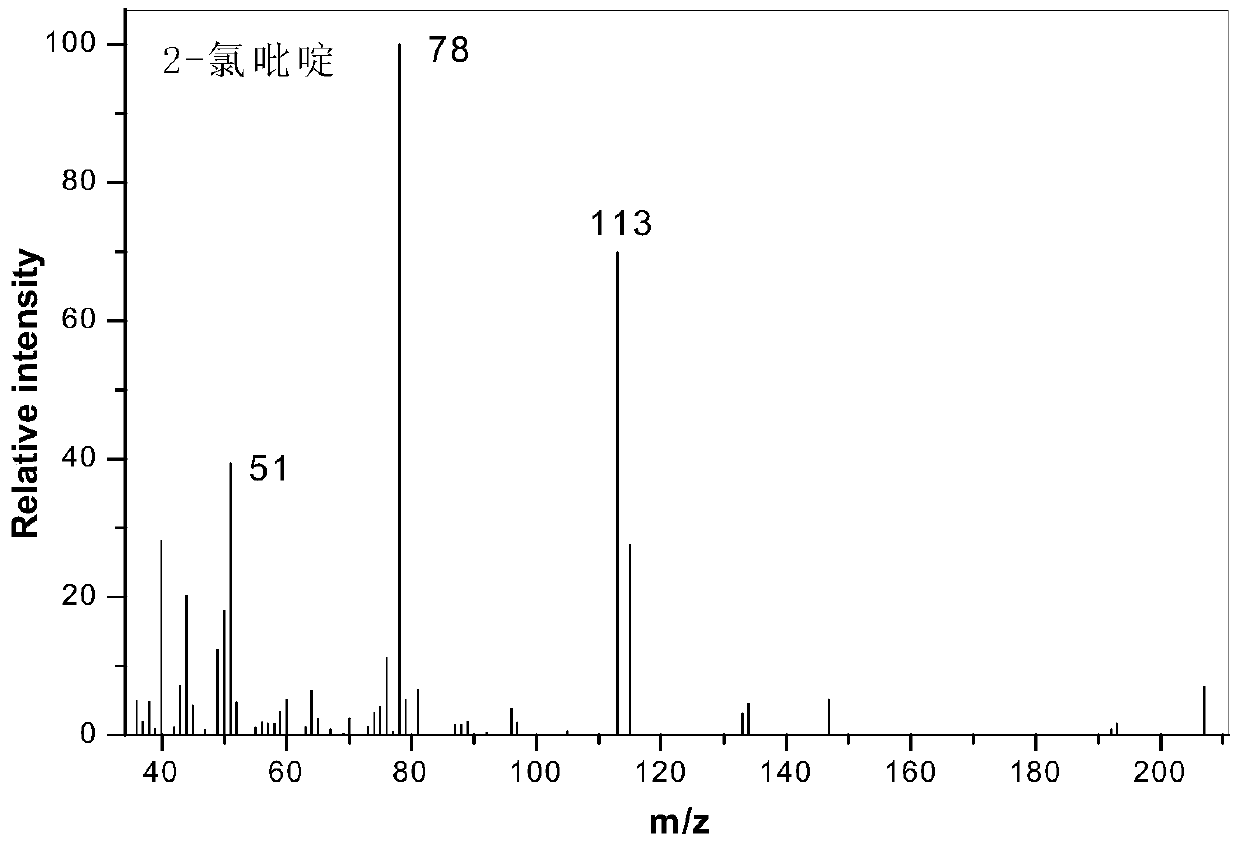

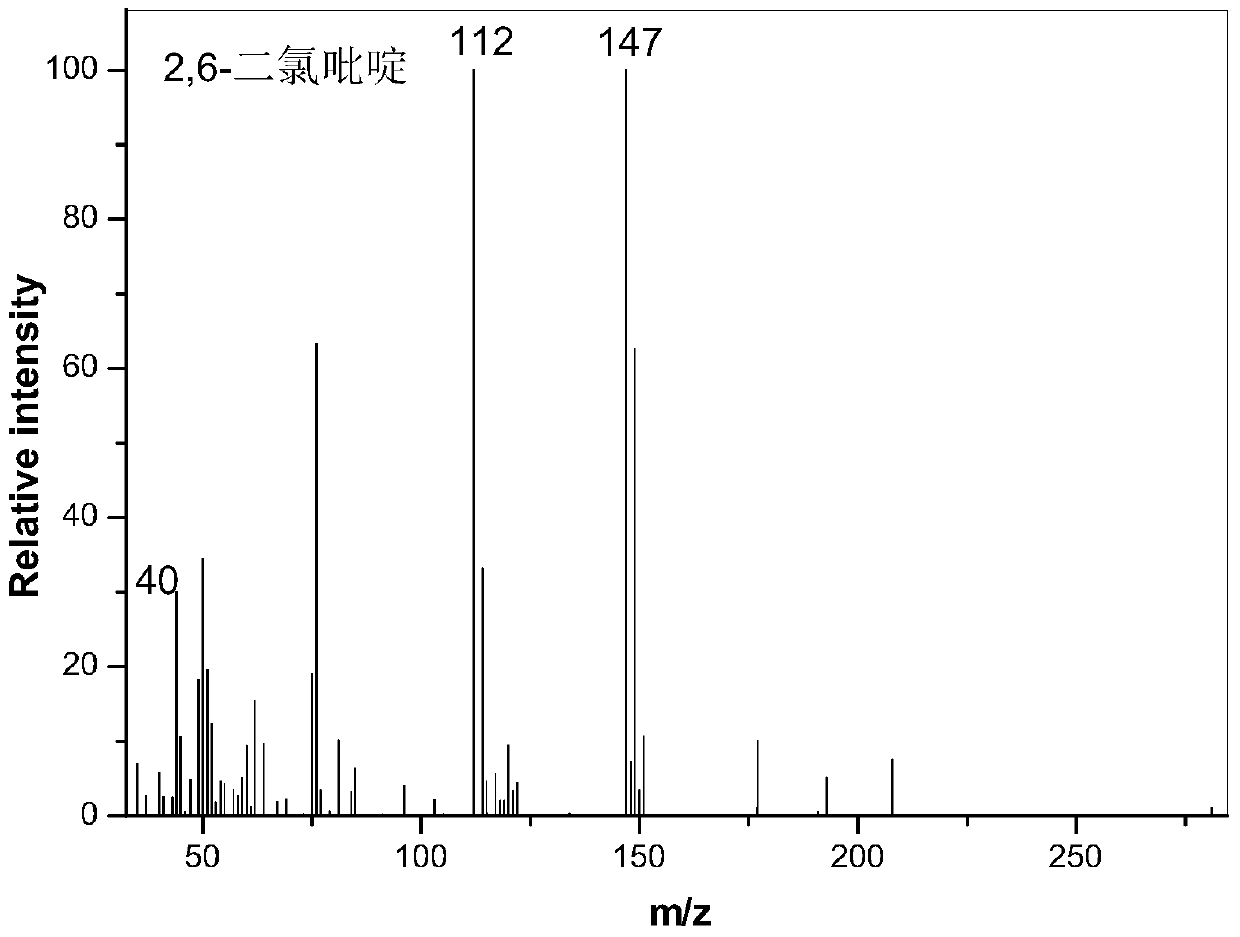

2-chloropyridine synthetic method

The invention discloses a 2-chloropyridine synthetic method, which belongs to the technical field of fine chemical engineering. The method comprises the following steps: adding pyridine into a hypochloric acid salt solution, uniformly mixing the solution, slowly adding hydrochloric acid drop by drop at room temperature, stirring a mixture and reacting the mixture for 1-2 hours; then heating the material to the temperature of 60-80 DEG C, continuously reacting the material for 1-2 hours; and finally, adding a certain amount of a NaOH solution and neutralizing the solution to a pH value of 9-11, extracting a reactant by using trichloromethane and separating the reactant; distilling an extract phase and removing a trichloromethane solvent in order, recovering the unreacted pyridine to obtain the chloropyridine product. According to the invention, a GC / MS analysis on the chloropyridine product is carried out, selectivity of 2-chloropyridine can reach 83%. The hydrochloric acid and hypochlorite by-product with low cost in industrial production can substitute a chlorinating agent such as Cl2, reaction condition is mild, selectivity is good, process is simple, cost is low, and environment and safety problems during the production process of 2-chloropyridine can be solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

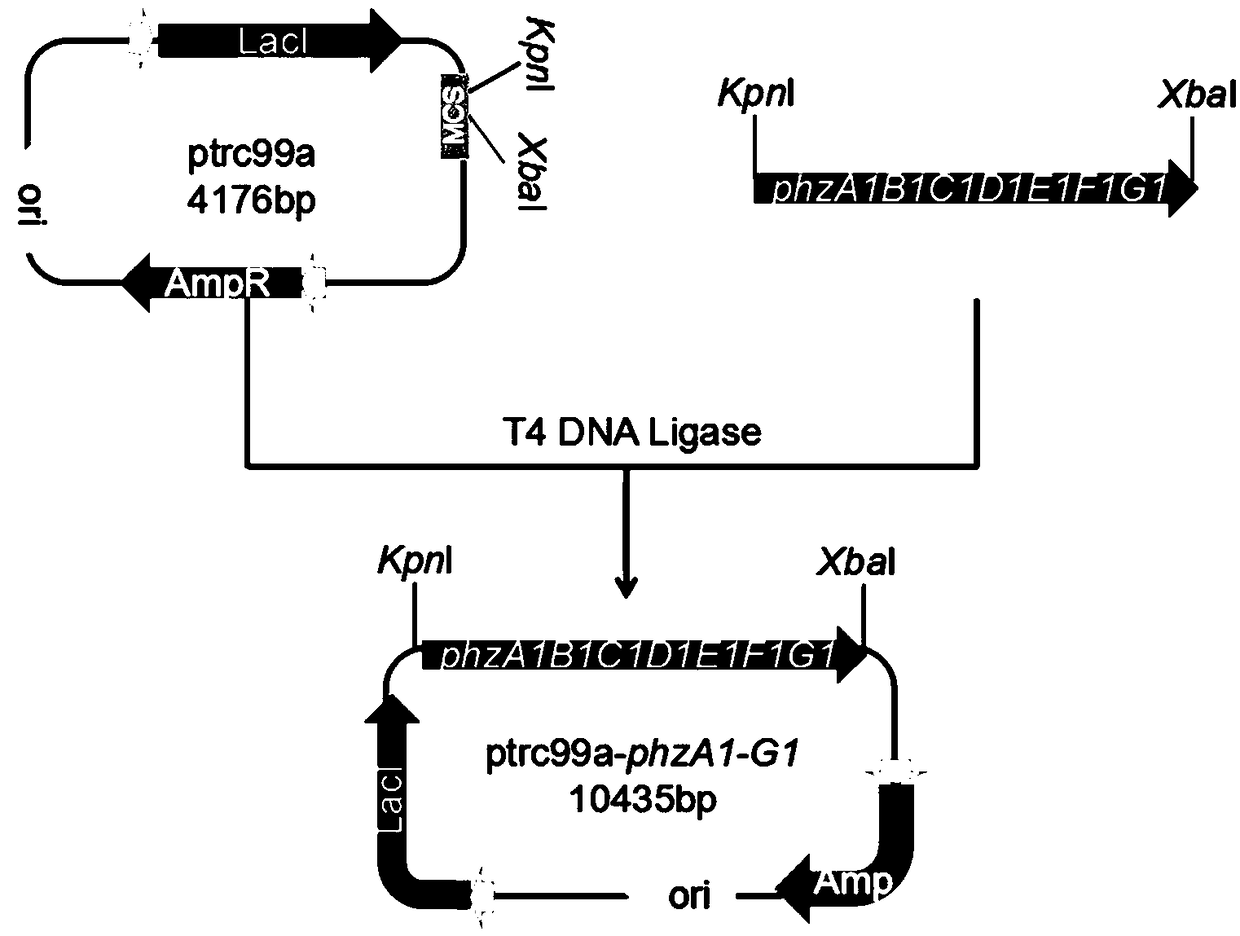

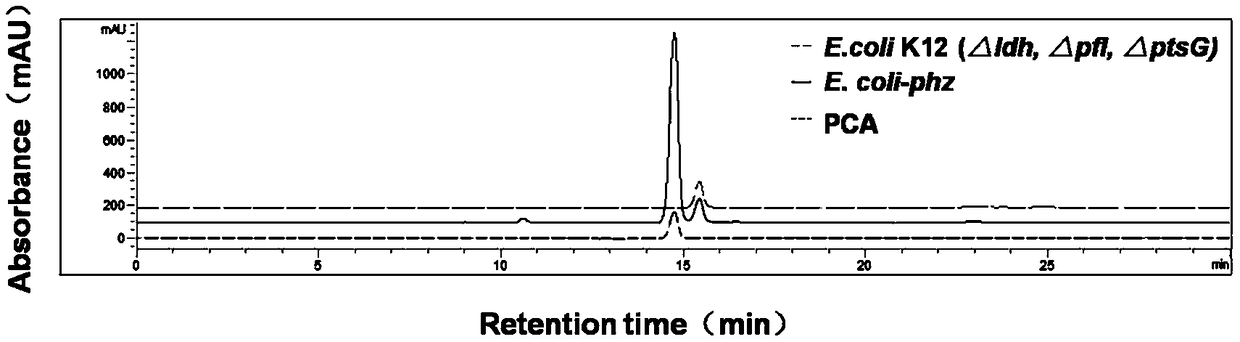

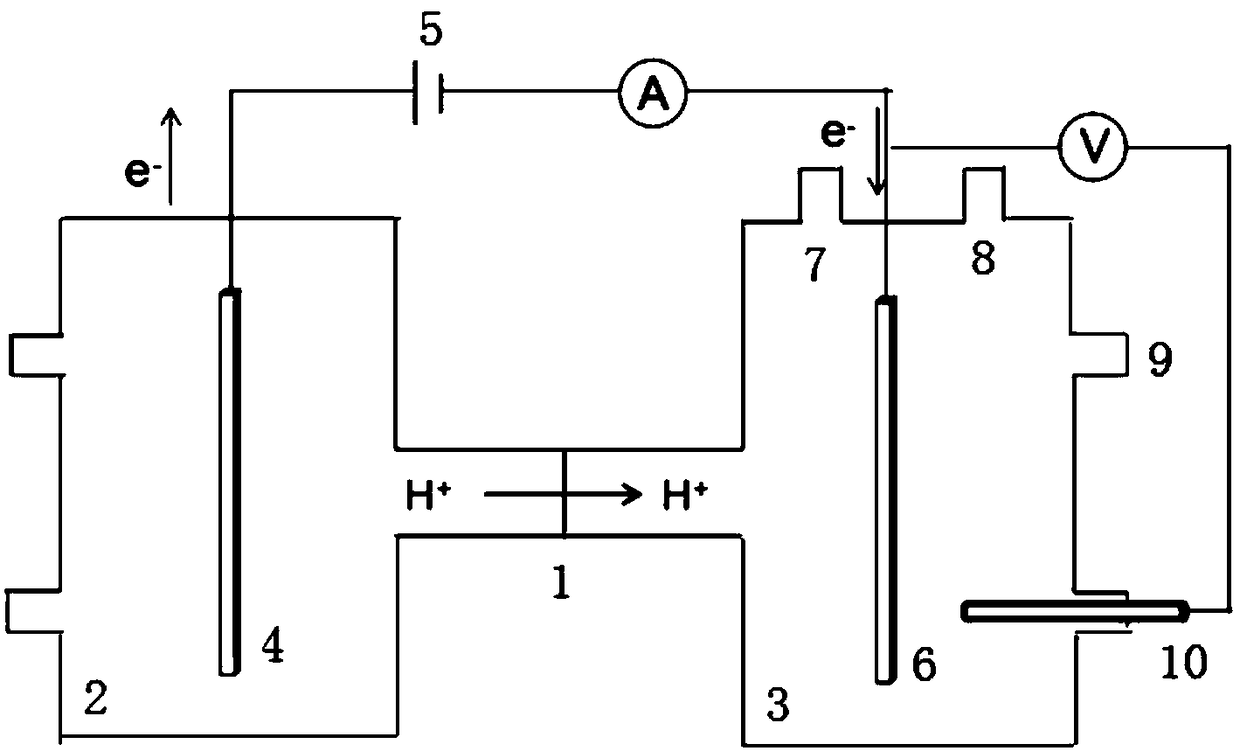

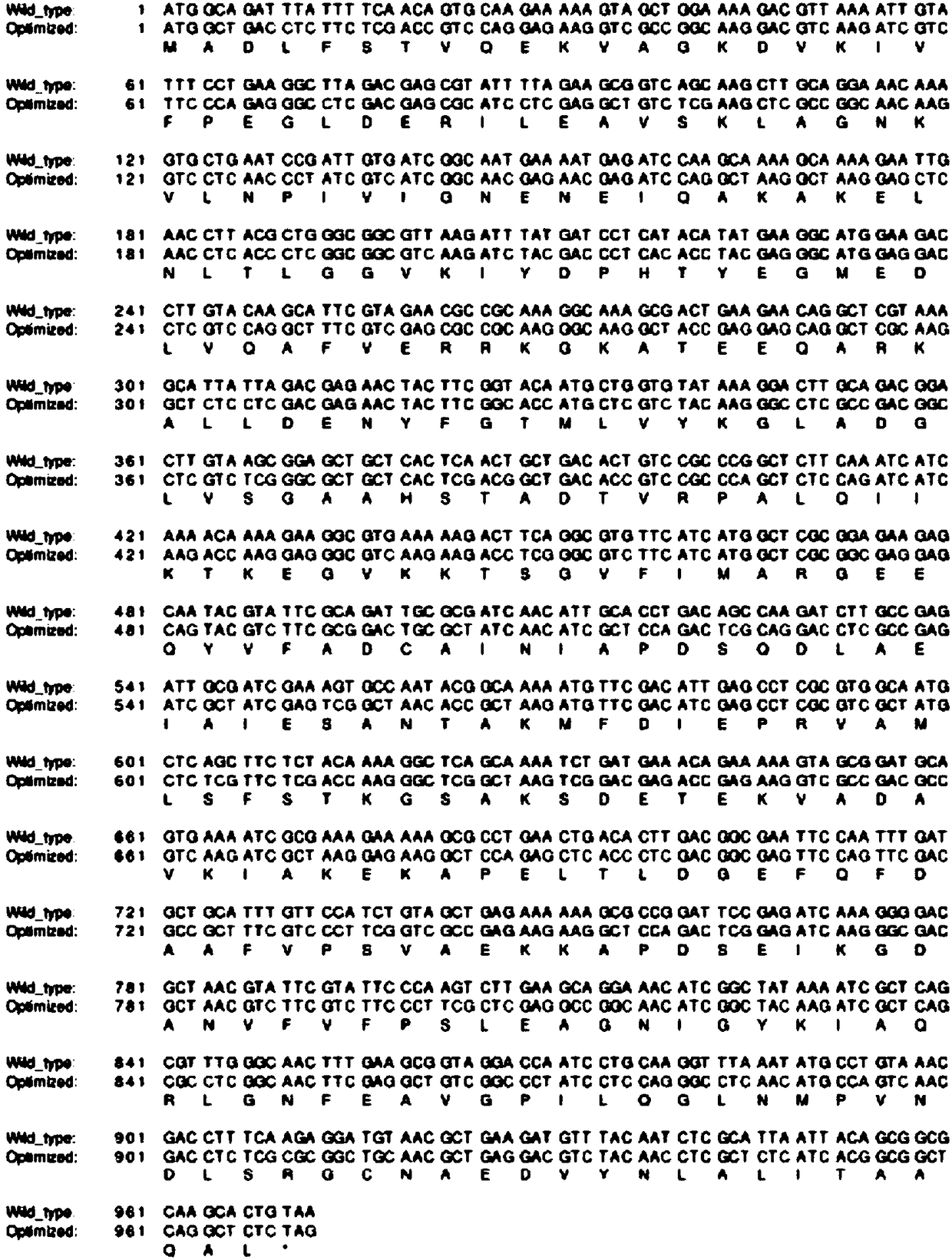

Recombinant escherichia coli and construction method and application thereof

ActiveCN109370970AImprove reducibilityIncrease productionBacteriaMicroorganism based processesEscherichia coliRecombinant escherichia coli

The invention discloses recombinant escherichia coli in which a phenazine-1-carboxylic acid synthetic gene is introduced and also discloses a construction method of the recombinant escherichia coli and application of the recombinant escherichia coli in succinic acid preparation. The succinic acid yield and conversion rate of the recombinant strain E. coli-phz are obviously higher than those of anoriginal strain E.coli K12(DeltaldhA, DeltapflB, DeltaptsG), fumaric acid is used as a carbon source, and compared with the original strain E.coli K12(DeltaldhA, DeltapflB, DeltaptsG), the succinic acid yield of the recombinant strain E. coli-phz is improved by 68%. Glucose is used as a carbon source, and compared with the original strain E.coli K12(DeltaldhA, DeltapflB, DeltaptsG), the mass yieldof the recombinant strain E. coli-phz is improved by 26%.

Owner:NANJING UNIV OF TECH

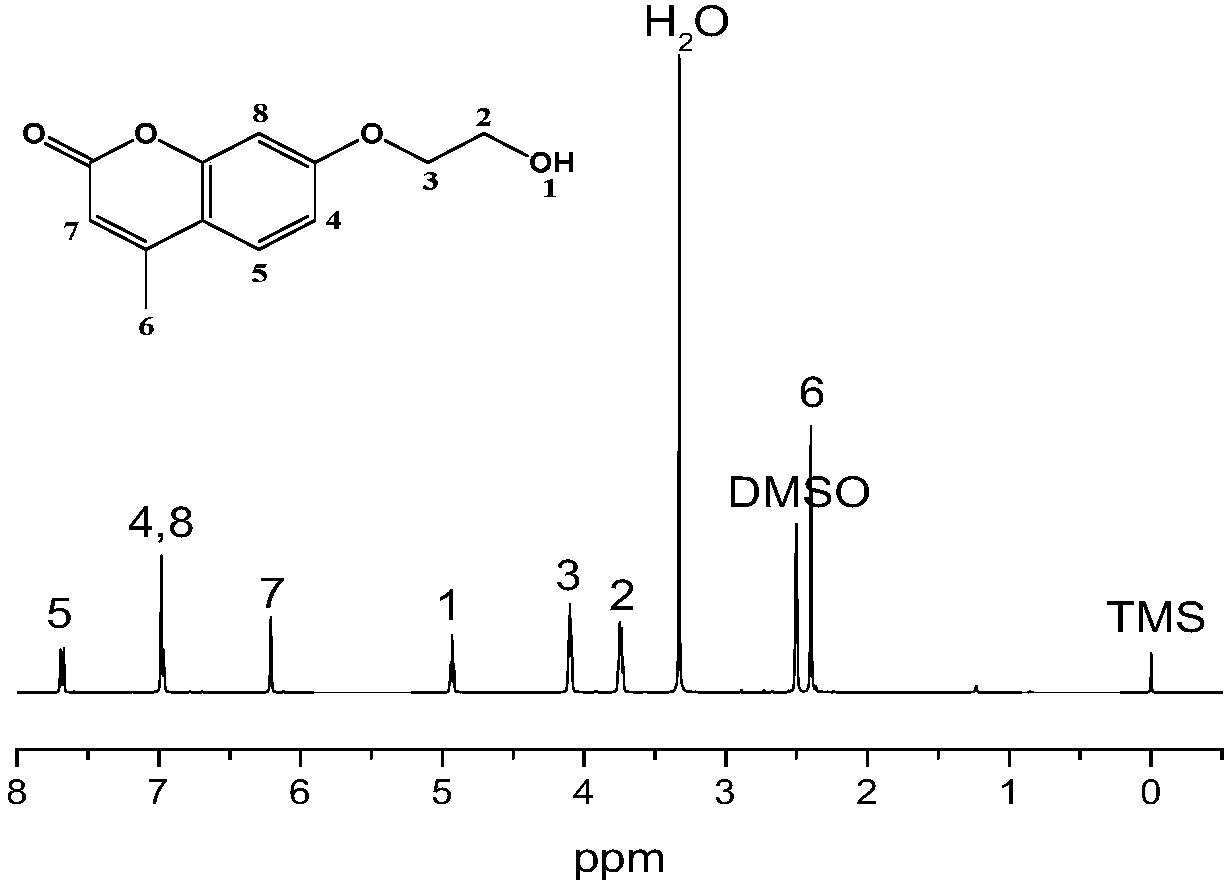

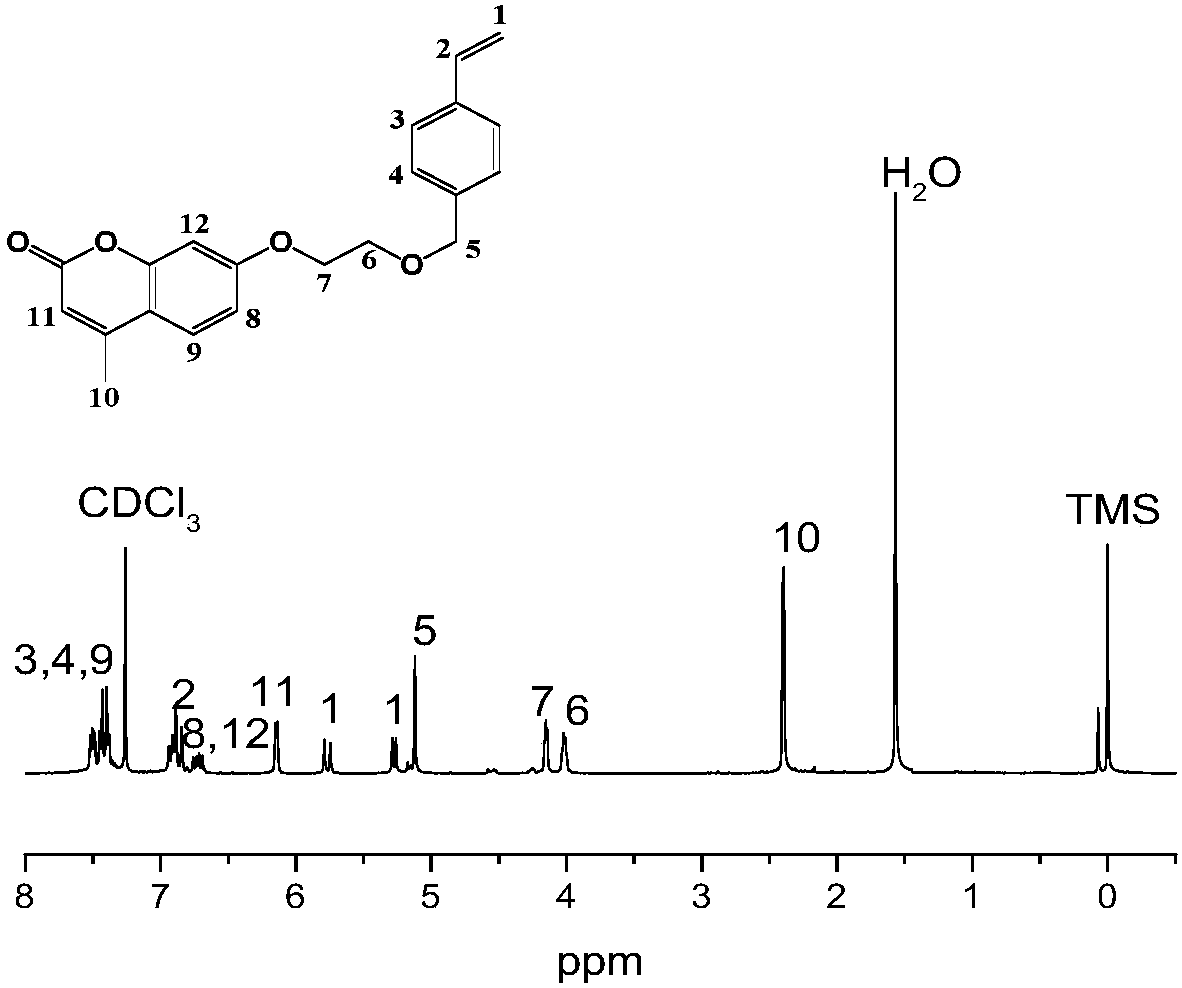

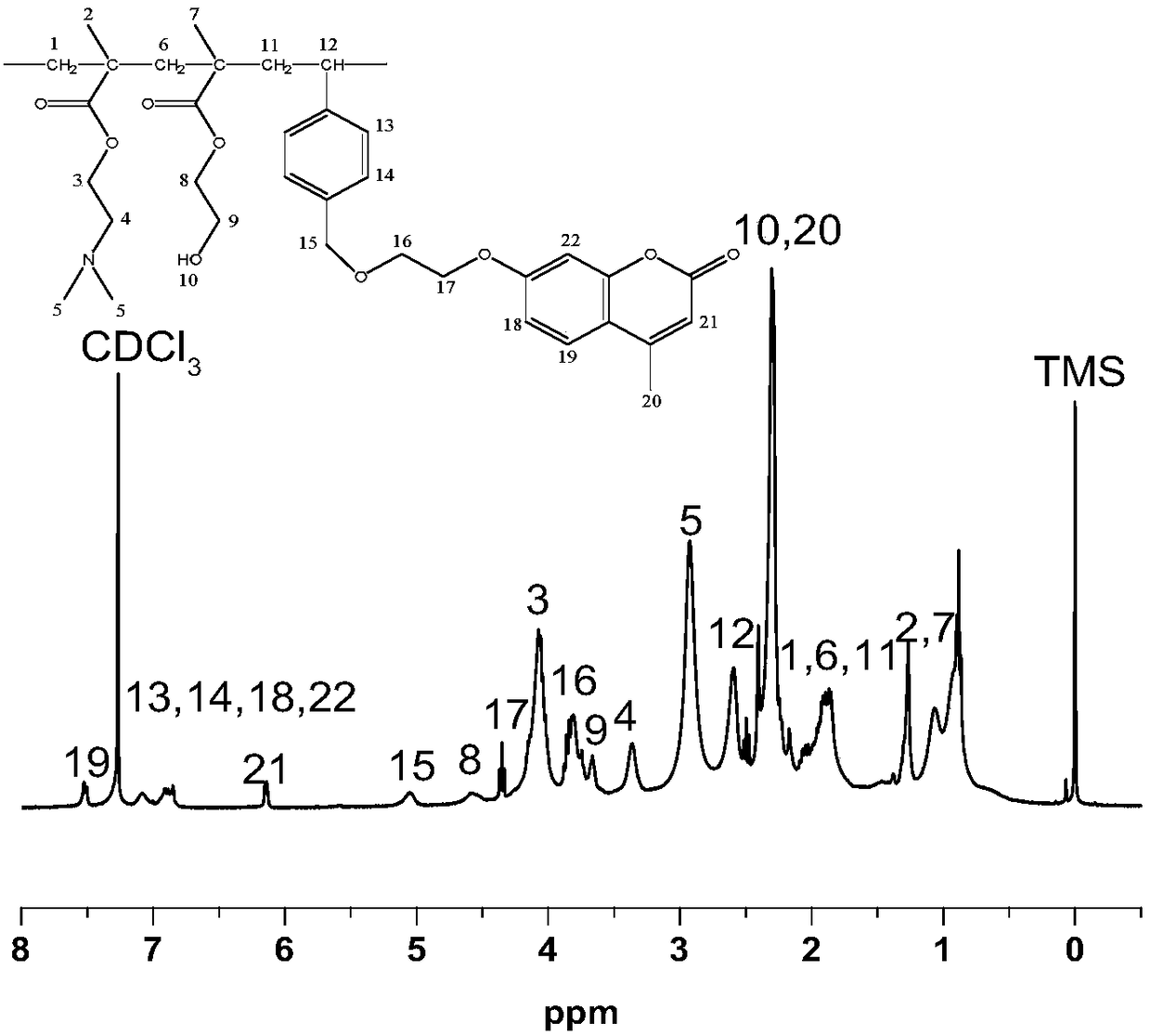

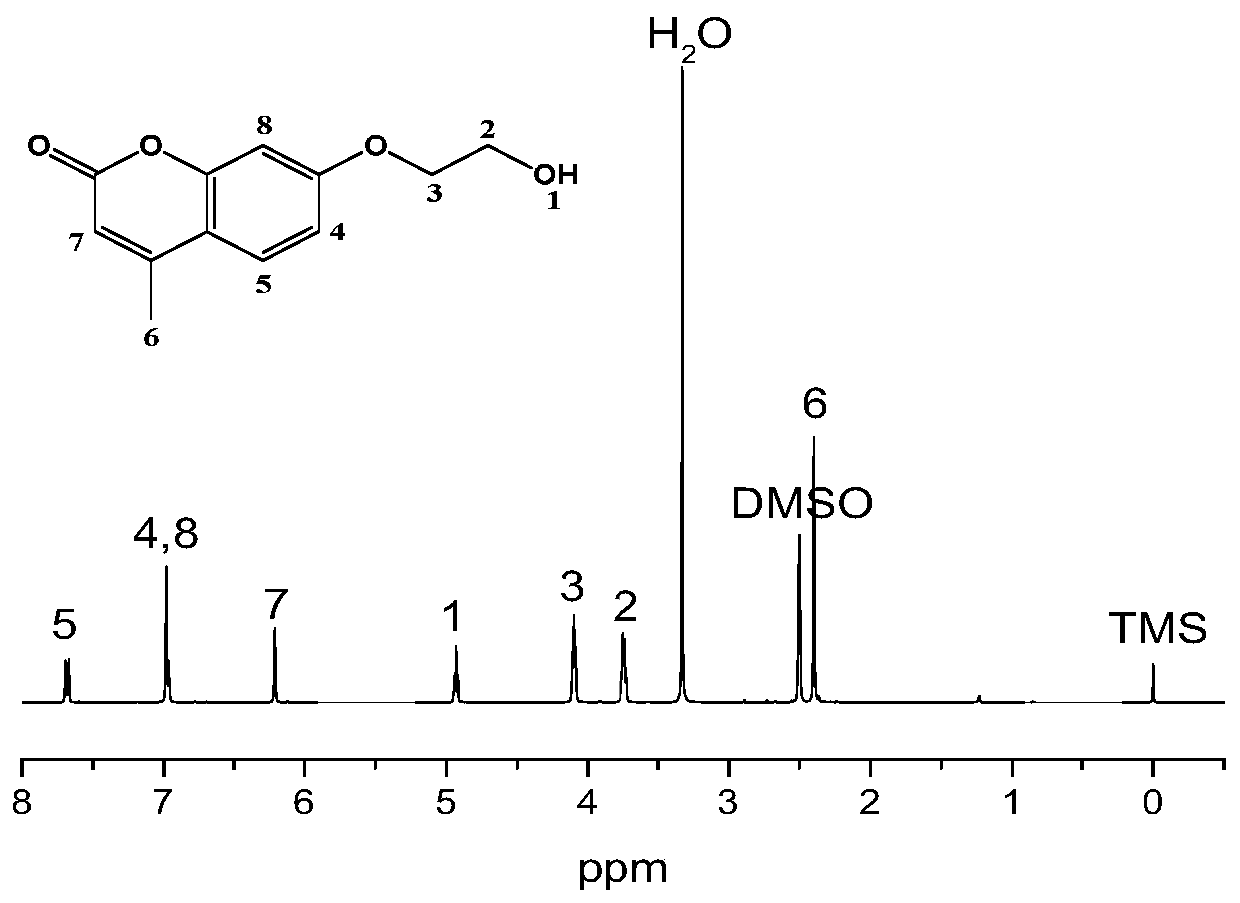

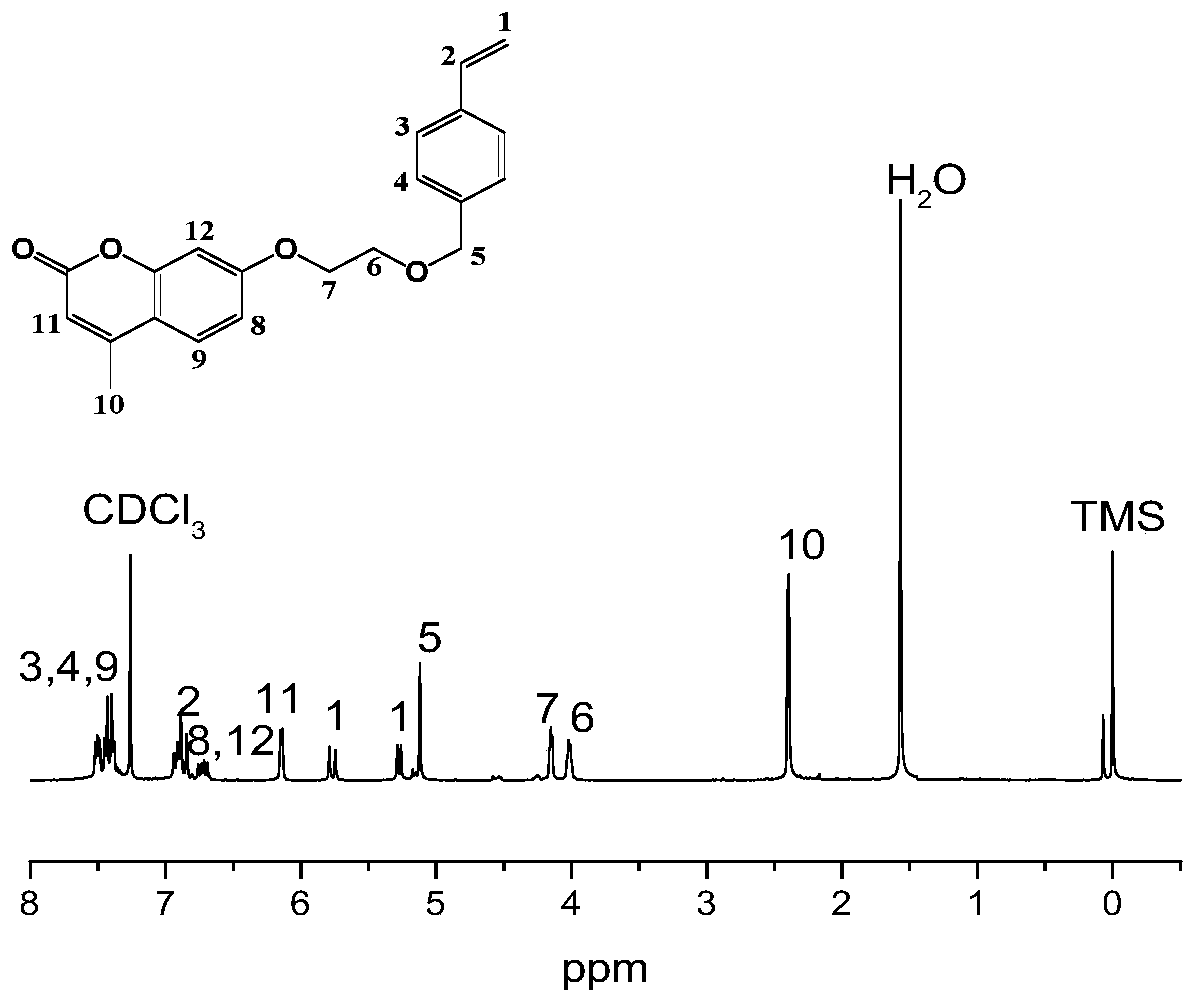

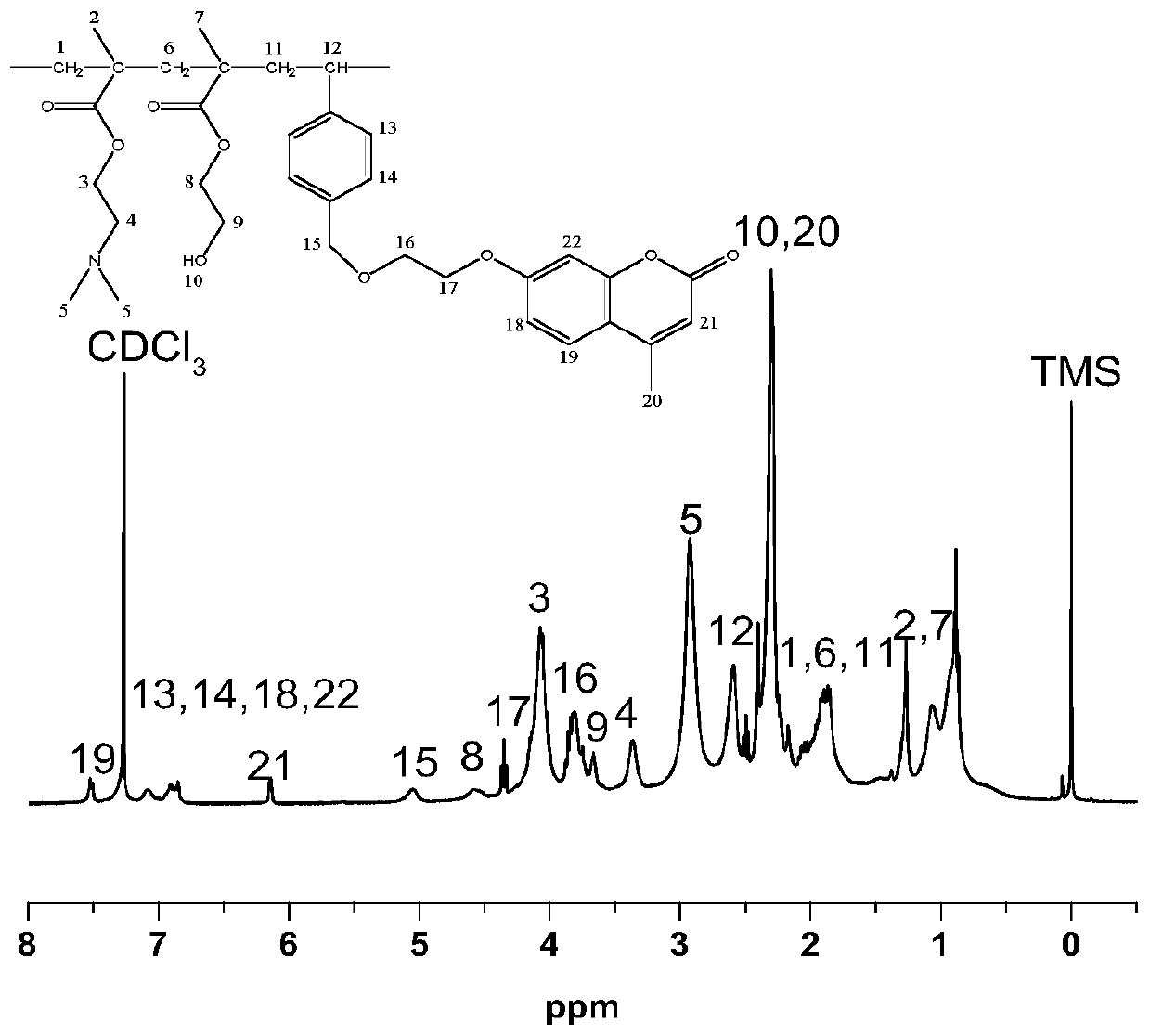

Coumarin derivative and preparation and application thereof

InactiveCN108586407AHigh quality yieldThe reaction conditions are mild and safeOrganic chemistryLuminescent compositionsPolymer scienceDouble bond

The invention discloses a coumarin derivative and preparation and application thereof. 7-hydroxy-4-methyl coumarin as a raw material is subjected to substitution reactions with halogenated ethyl alcohol and 4-vinylbenzyl chloride in sequence, and then 7-[2-(4-vinyl benzyloxy)-ethyoxyl]-4-methyl coumarin is obtained. The method has the advantages that the operation is simple, the conditions are mild, the product is easy to purify, and the yield is high, the coumarin derivative synthesized by using the method has polymerizable double-bond elements, alkoxy flexible spacers and coumarin photosensitive groups, and when the coumarin derivative as a photosensitive monomer used for synthesis of a photostimulation response polymer material, the polymerization efficiency can be obviously improved. The water solubility and the degradability of the polymer material synthesized by using the counmarin derivative can be improved, the hydrophily and the hydrophobicity of the polymer material are moreeasily regulated and controlled, and therefore, in the use process of the polymer material as a drug carrier, the drug encapsulation and release rates can be better controlled.

Owner:CENT SOUTH UNIV

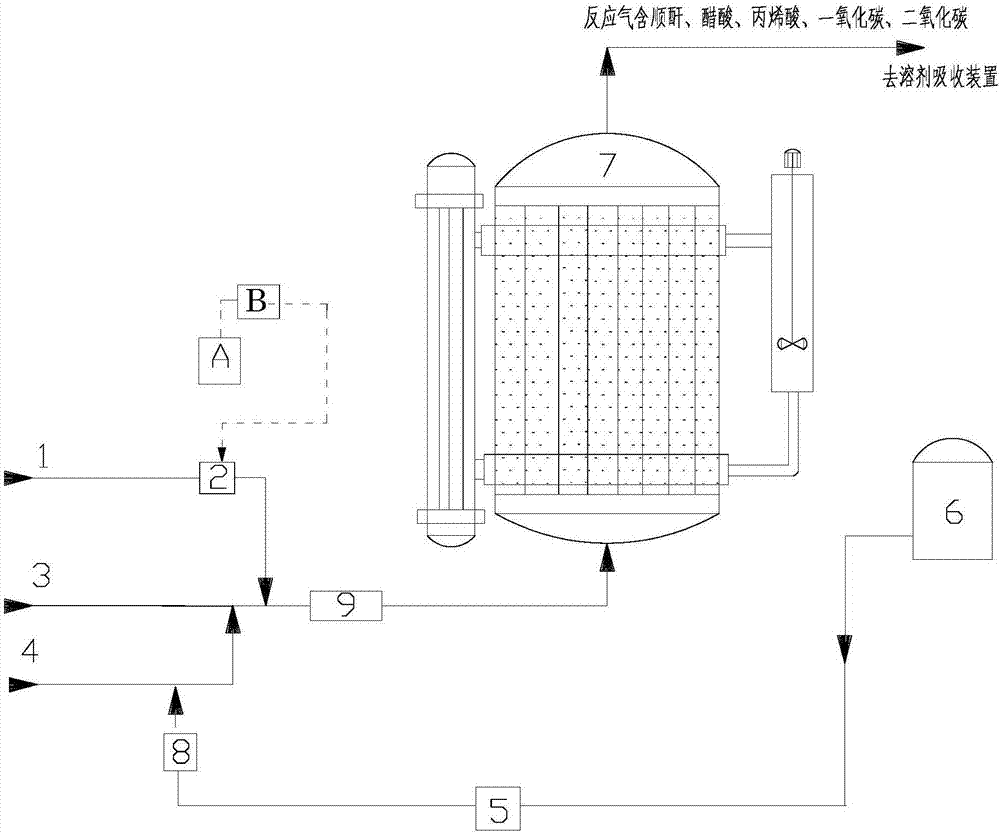

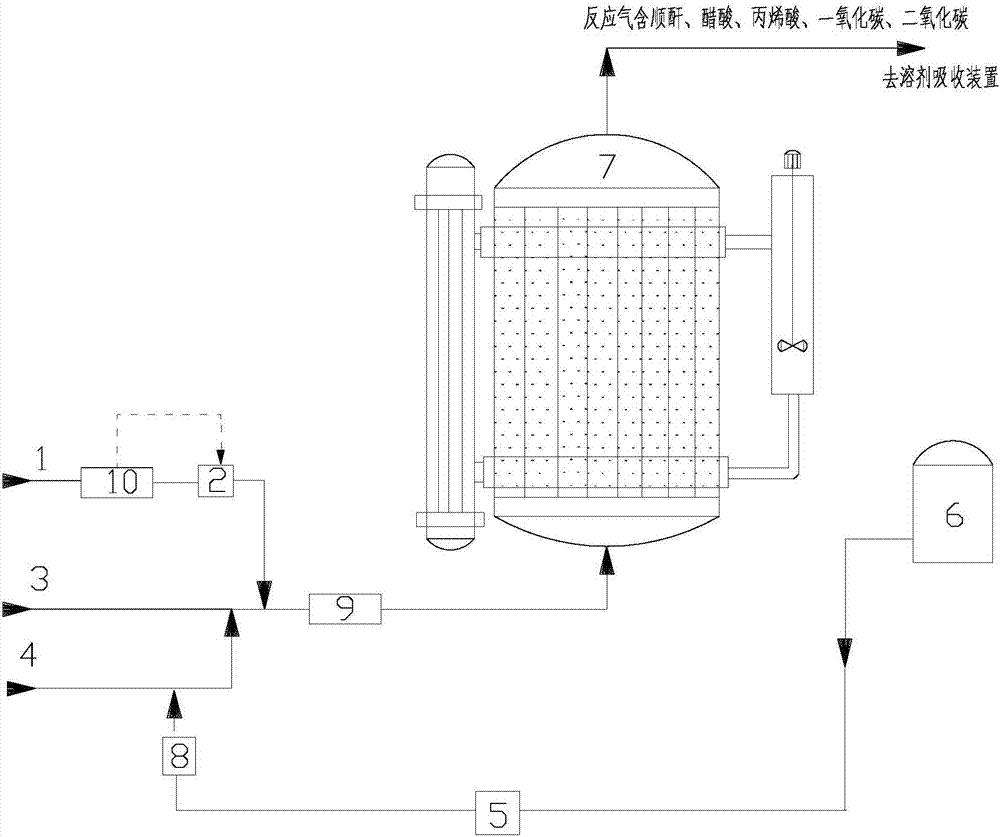

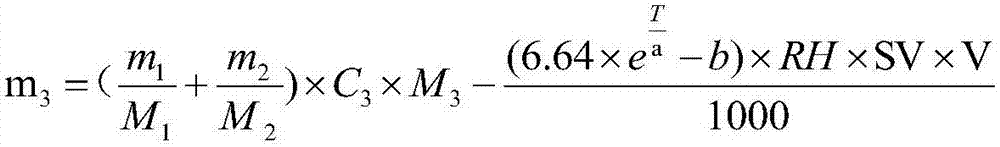

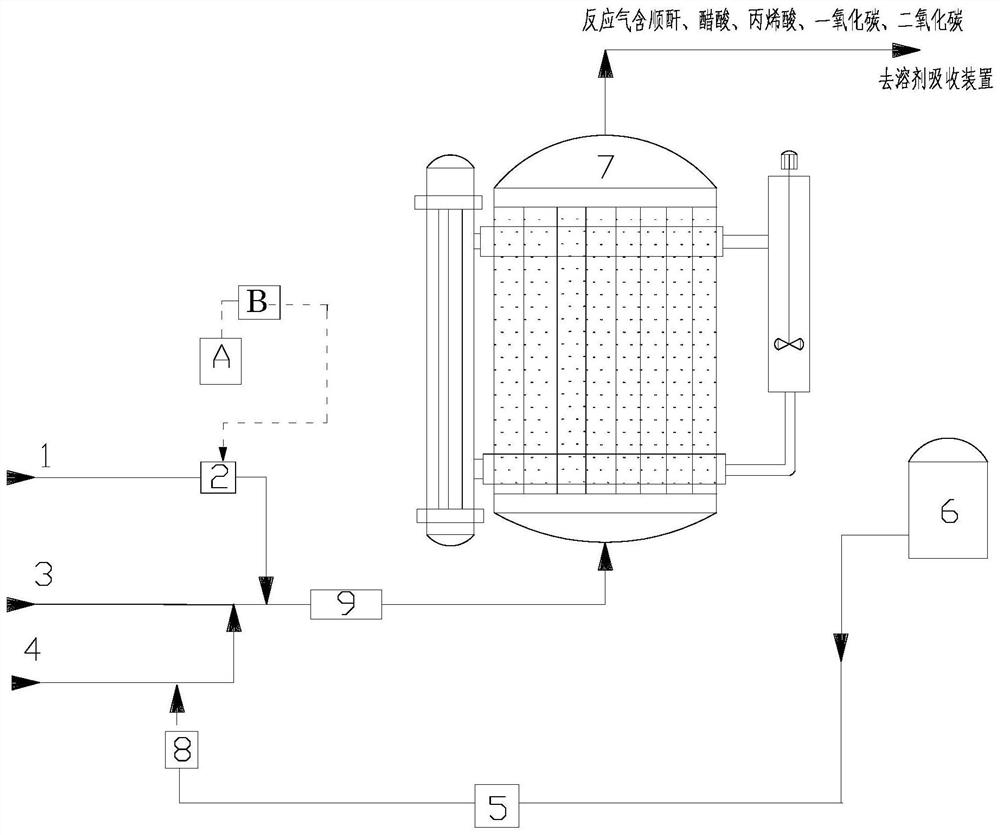

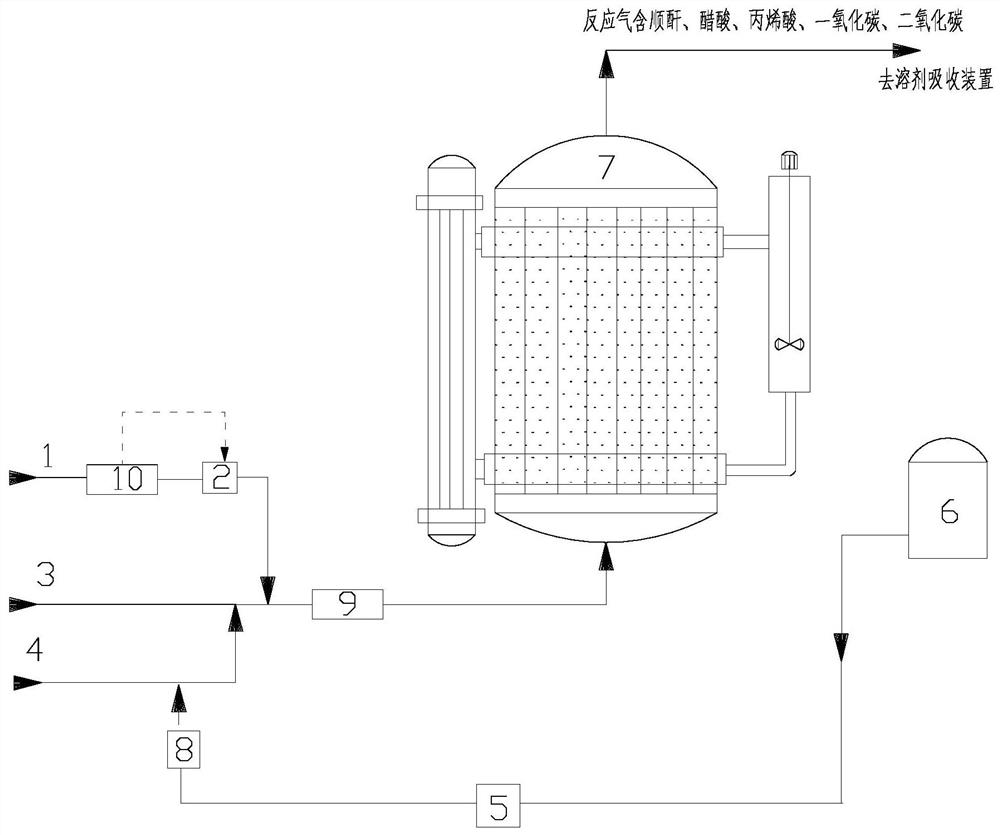

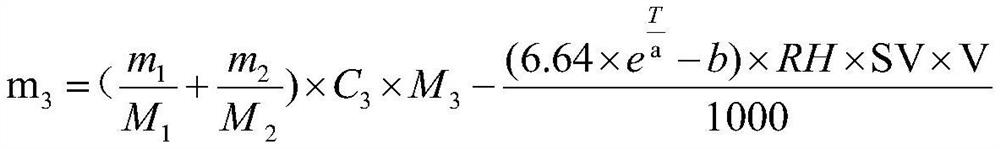

Method for controlling addition amount of VPO catalyst assistant water in MAH preparation process

The invention relates to a method for controlling the addition amount of a VPO (vanadium phosphorus oxide) catalyst assistant water in the MAH (maleic anhydride) preparation process. The method is characterized in that a water control valve connected to a shell-and-tube fixed bed reactor for preparing MAH is connected with an atmospheric thermohygrograph and a calculating module, the atmospheric thermohygrograph measures the ambient temperature T and the relative humidity RH, measured values are input into the calculating module, and the addition amount of the assistant water is calculated according to a formula and can be accurately controlled. The method realizes the accurate control of the addition amount of the catalyst bed assistant water to make the humidity of a butane mixed gas entering the reactor keep constant and be not affected by the humiture, improves the selectivity of a catalyst by 2.1%, improves the yield by 2.4%, and avoids uneven temperature distribution of the reactor, caused by concentration of phosphide at the feed inlet of the reactor due to too low amount of water, and increase of byproducts, caused by the excessive amount of the water.

Owner:SINOPEC YIZHENG CHEM FIBER +1

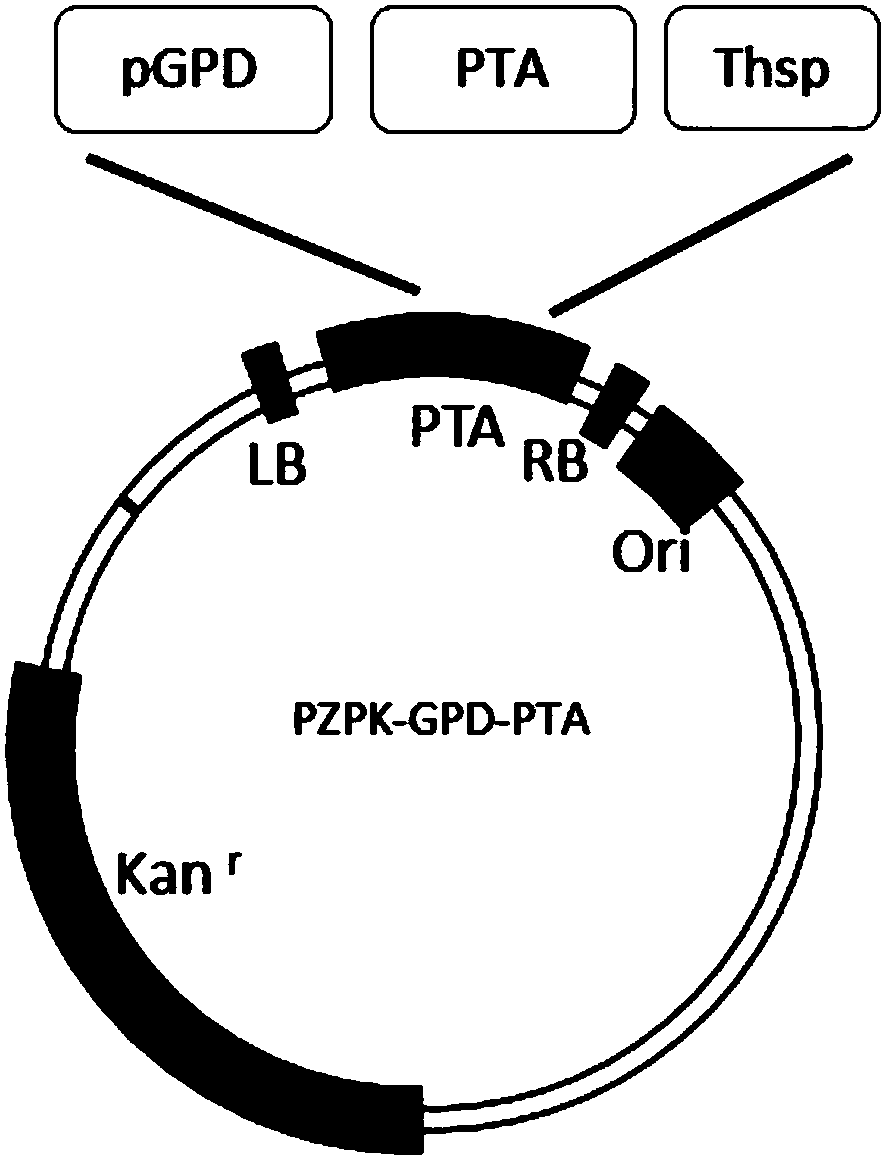

Method for promoting oleaginous yeasts for produce oil

InactiveCN108220324AImprove supply capacityIncrease supplyBiofuelsNucleic acid vectorBiotechnologyYeast

The invention discloses a method for constructing the efficient production of microbial oil strains by utilizing metabolic engineering strategies and application thereof. The invention relates to overexpression of acetyltransferase phosphate in oleaginous yeasts. The method can enhance the supply of oil synthesis precursor acetyl coenzymes A, improve the oil yield and effectively improve the economy of microbial oil.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

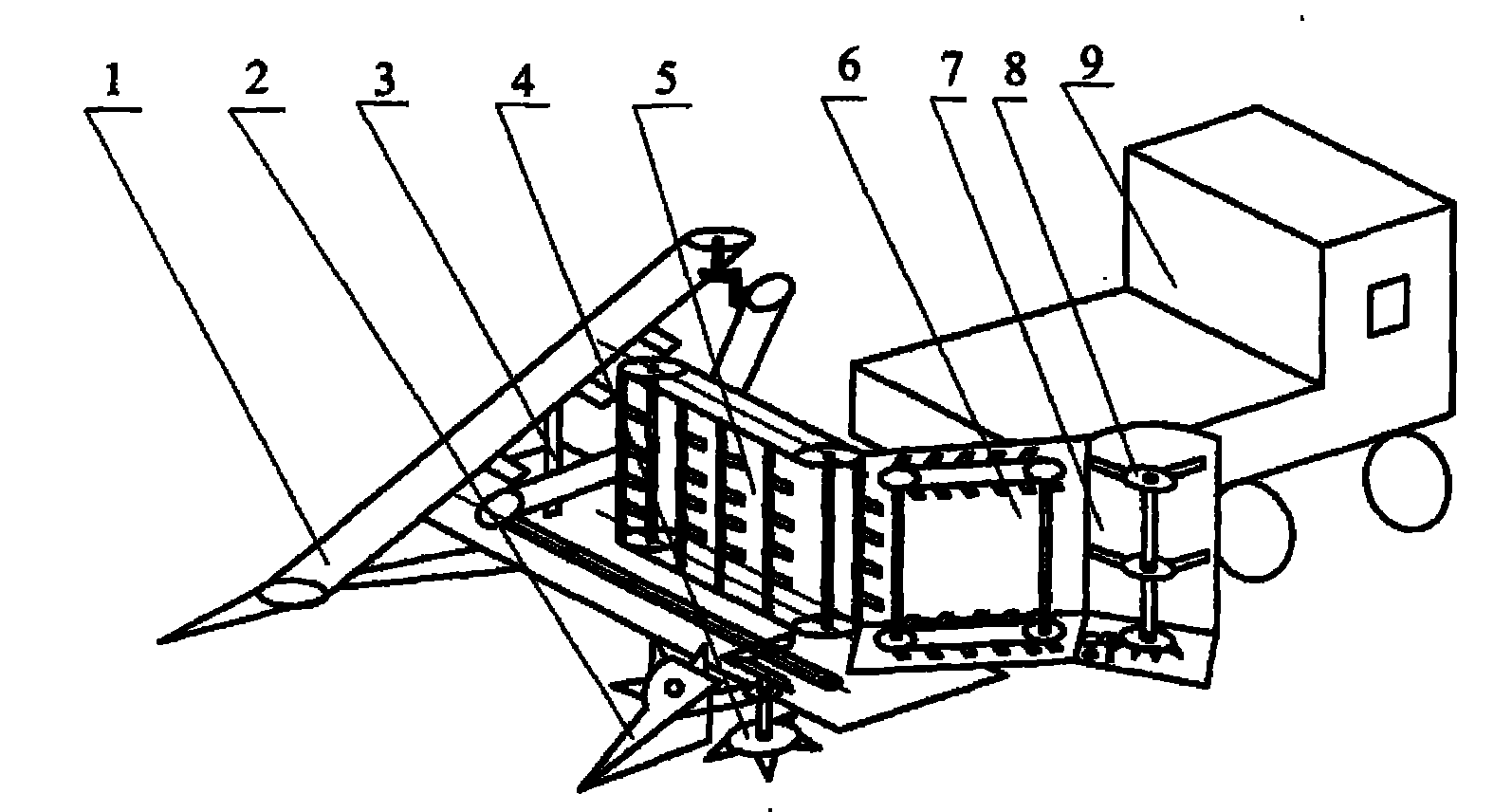

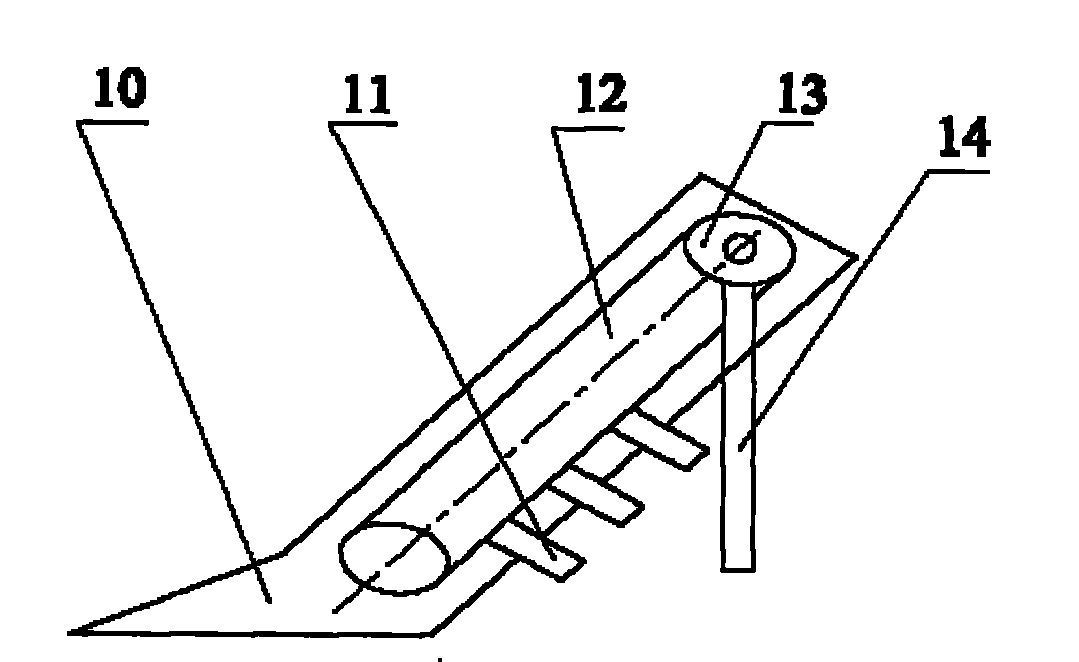

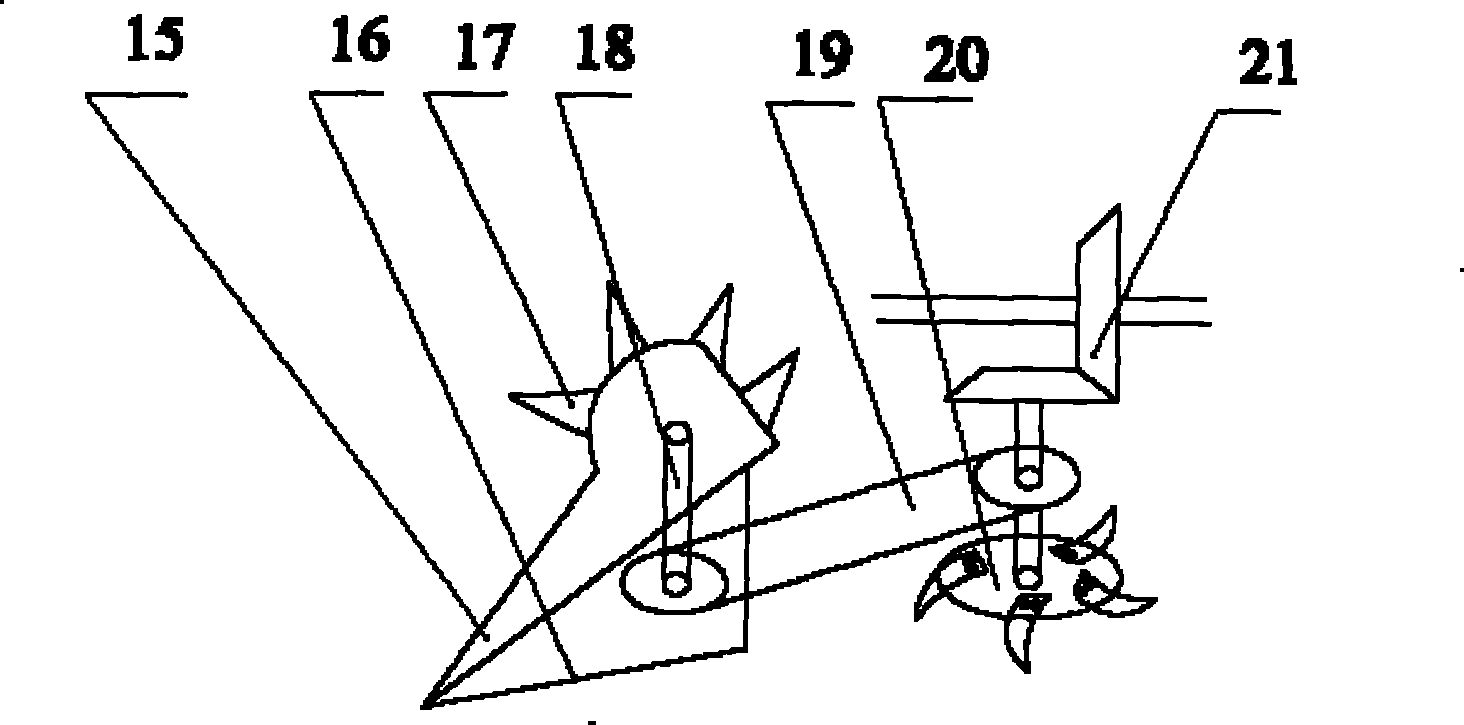

Ramie combine harvester

InactiveCN101491181BImprove performance qualityImprove fiber qualityOutside dividersAgricultural engineeringAgricultural machinery

The invention relates to a ramie combined harvester, which belongs to agricultural machinery, and mainly solves the harvest problem of ramie. The ramie combined harvester comprises a stander, a ramie supporting unit, a ramie drawing and cutting unit, a conveying unit, a stacking and laying unit and a traveling unit, wherein the ramie supporting unit, the ramie drawing and cutting unit, the conveying unit and the stacking and laying unit are fixedly connected with the stander to form a cutting table according to the pushing and supporting, cutting, conveying, stacking and laying procedures; and the traveling unit is connected with the cutting table to complete the traveling and cutting combined operation. The ramie combined harvester adopts a subsection harvest machinery proposal, completes the procedures of the supporting, the cutting, cutting for spreading and stacking for once, has light load, high efficiency and strong adaptability, and is widely suitable for cutting long-stalked plants such as ramie, jute, hemp, and the like.

Owner:WUHAN TEXTILE UNIV

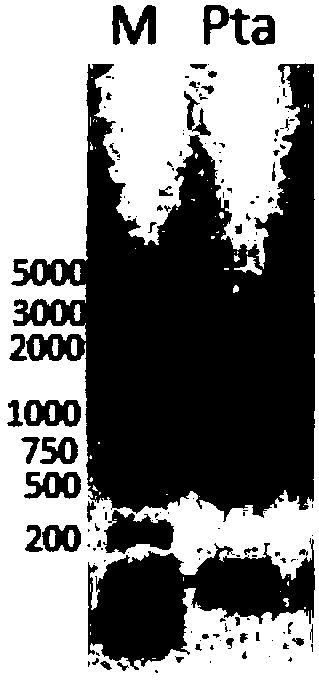

Production method for recombinant human granulocyte colony-stimulating factor

ActiveCN103233053BHigh expressionShort cycleMicroorganism based processesPeptide preparation methodsEscherichia coliInclusion bodies

Owner:BEIJING FOUR RINGS BIOPHARM

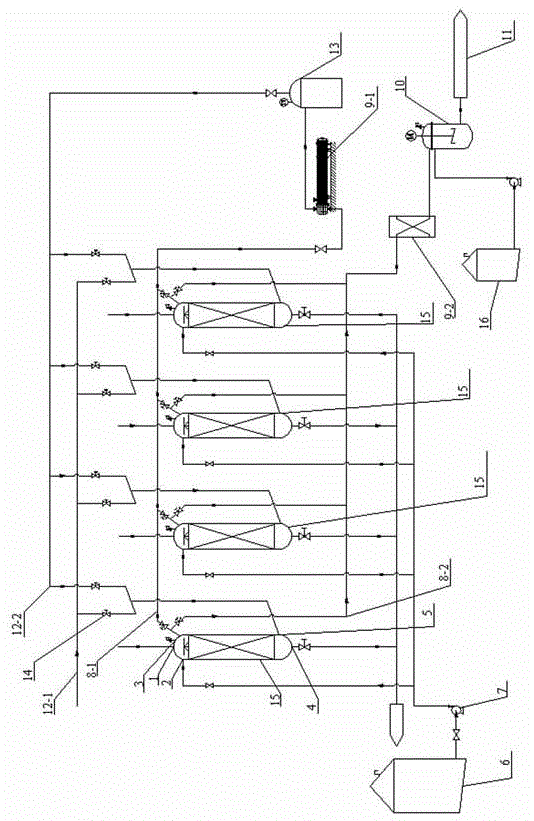

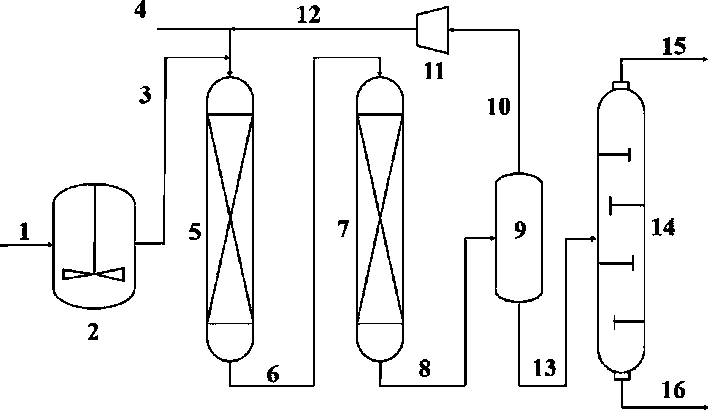

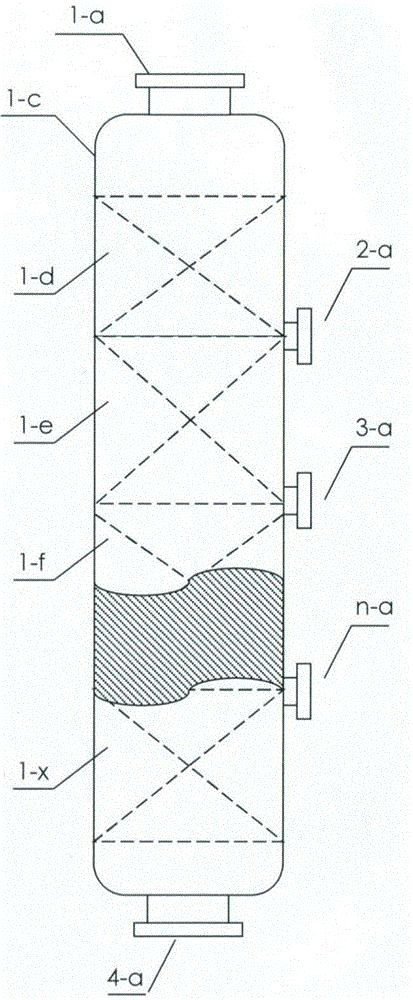

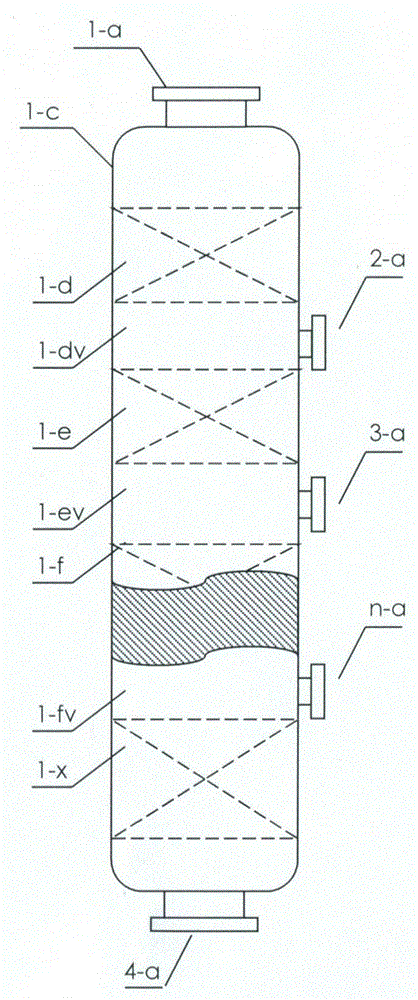

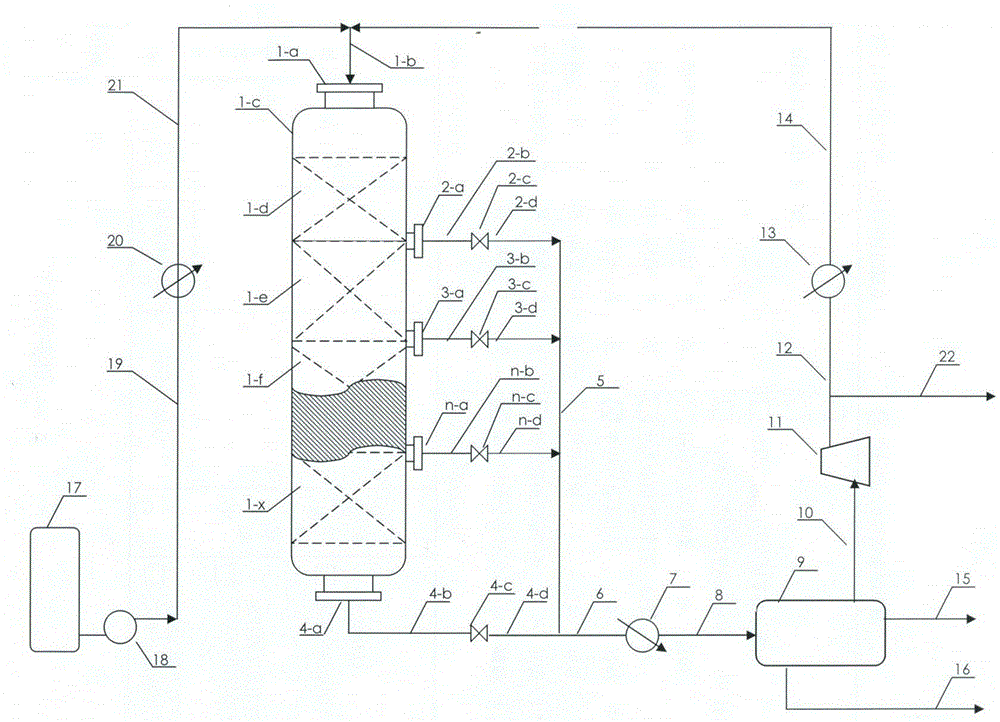

A continuous reaction process and reactor for methanol conversion to produce hydrocarbon mixture

ActiveCN104098424BSimple processEasy to operateHydrocarbon from oxygen organic compoundsChemical/physical processesHydrocarbon mixturesContinuous operation

The invention discloses a continuous reaction process utilizing methanol conversion to prepare a hydrocarbon mixture. The continuous reaction process comprises the following steps: raw material methanol enters a reactor from the pipe orifice at the top of the reactor; the methanol leaves the reactor from the first pipe orifice in the side wall of the reactor after the reaction of converting the methanol into the hydrocarbon mixture is completed in a first catalyst separating bed layer; when methanol penetration occurs in the previous catalyst separating bed layer, the next catalyst separating bed layer is put into the reaction through switching over outlets until all the valves of the pipe orifices in the side wall of the reactor are closed, only the top pipe orifice and the bottom pipe orifice of the reactor are opened, and the last catalyst separating bed layer in the reactor is in a using state at the moment. The continuous reaction process and the reactor have the advantages that the operation is simple, the continuous operation time is long, and the utilization rate of catalyst reaction activity during the reaction process is high.

Owner:SEDIN ENG +2

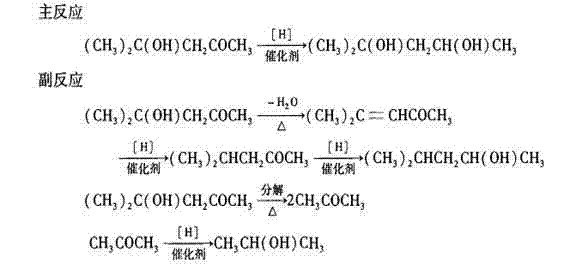

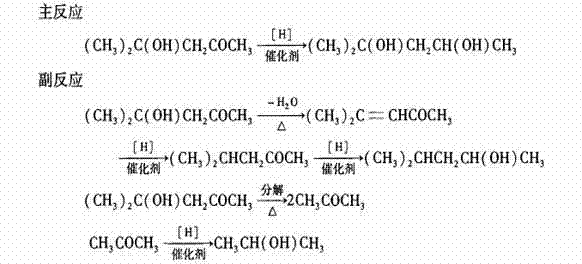

Process for synthesizing 2-methyl-2,4-pentendiol through hydrogenation reduction of diacetone alcohol

InactiveCN102329193BReduce generationHigh quality yieldOrganic compound preparationHydroxy compound preparationNickel catalystDiacetone alcohol

The invention relates to a process for synthesizing 2-methyl-2,4-pentendiol through hydrogenation reduction of diacetone alcohol, and belongs to the technical field of production processes of the 2-methyl-2,4-pentendiol. In the process, the diacetone alcohol is used as a raw material and is mixed with an aid, and then hydrogen is aerated under pressure under the action of a nickel catalyst to synthesize the 2-methyl-2,4-pentendiol through reduction replacement; and the aid is an alkaline compound, and the alkaline compound can be an alkaline inorganic compound or an alkaline organic compound which does not have a negative effect on hydrogenation reactions. By adding the aid, the disadvantages that the yield of products is low, more other byproducts are produced, the production cost is high, the process is difficult to operate, the separation of the products is difficult and the like existing in the conventional process are overcome, and other byproducts in the reduction process are reduced, so that the product yield of the synthesis of the 2-methyl-2,4-pentendiol is improved; and the purity of the 2-methyl-2,4-pentendiol is 99.5 percent, and the mass yield is improved to 99 percent. The process has the characteristics of simplicity, stable reaction, no pollution and the like, and is easy to operate.

Owner:荆州市宇鹏科技有限公司

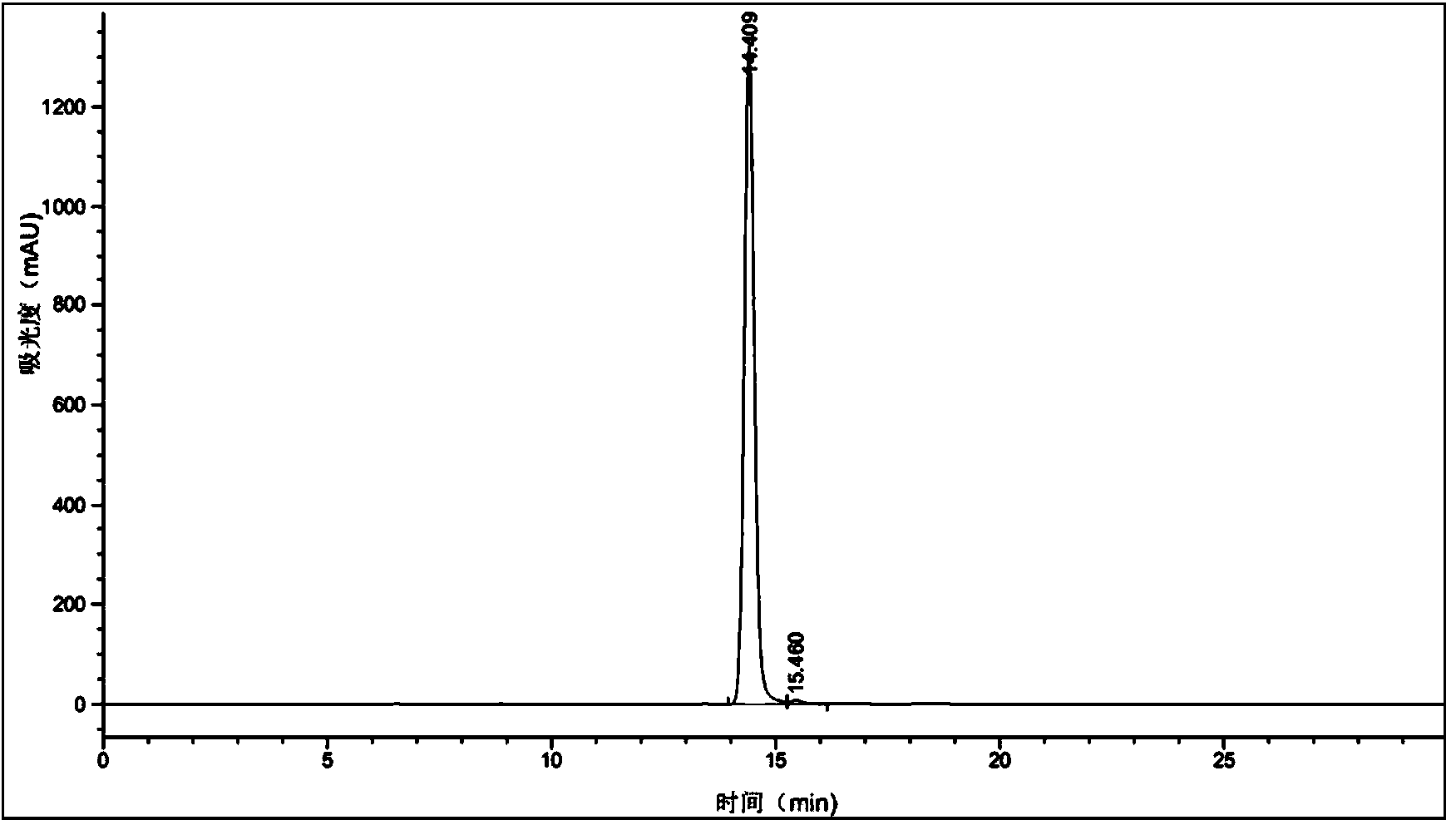

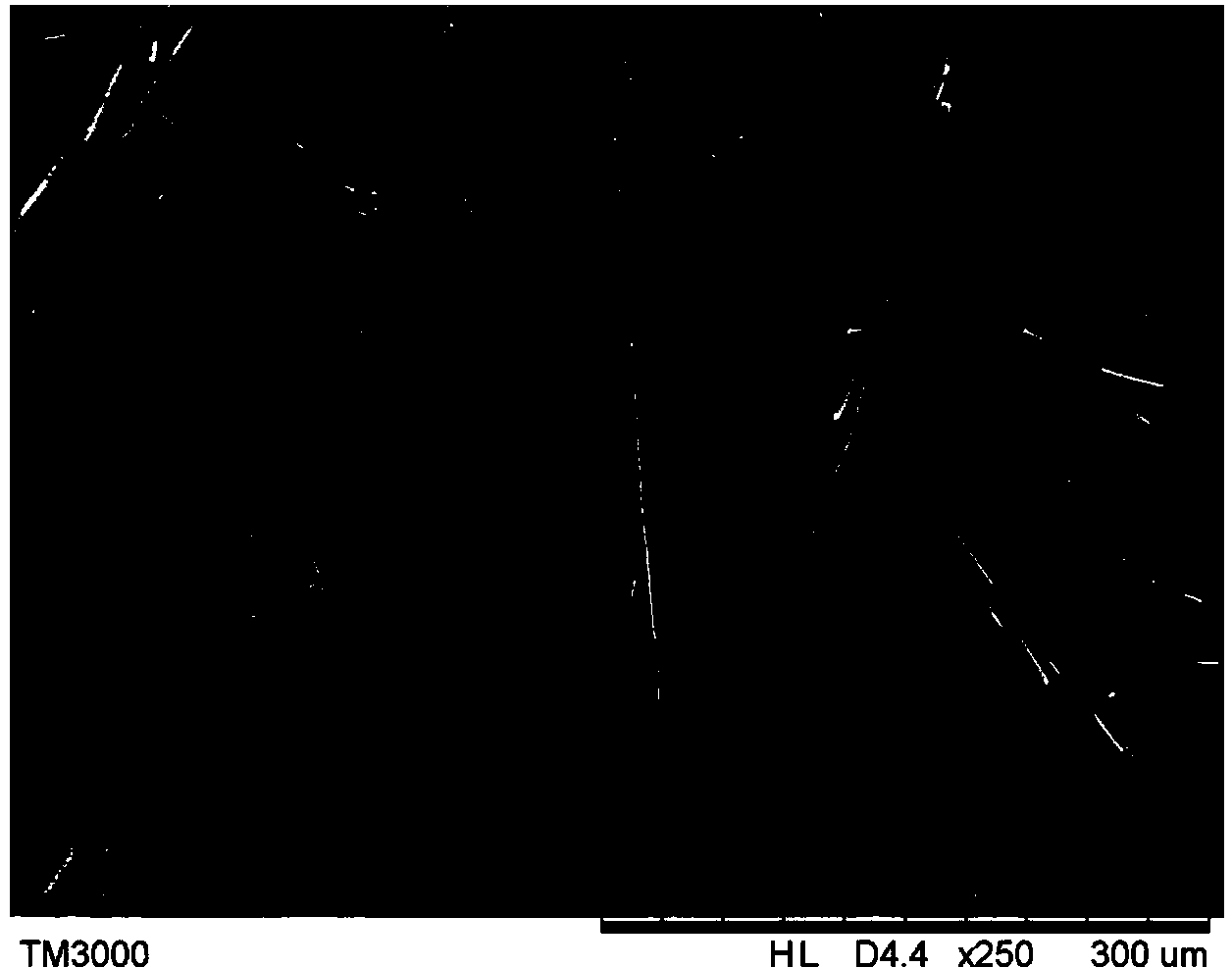

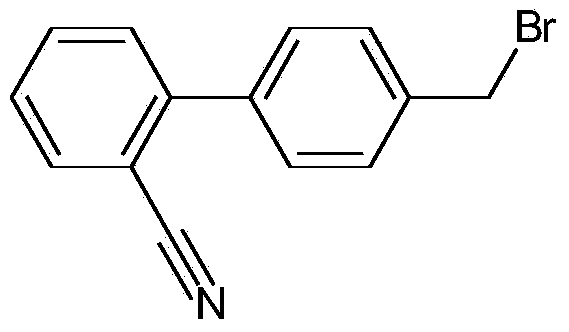

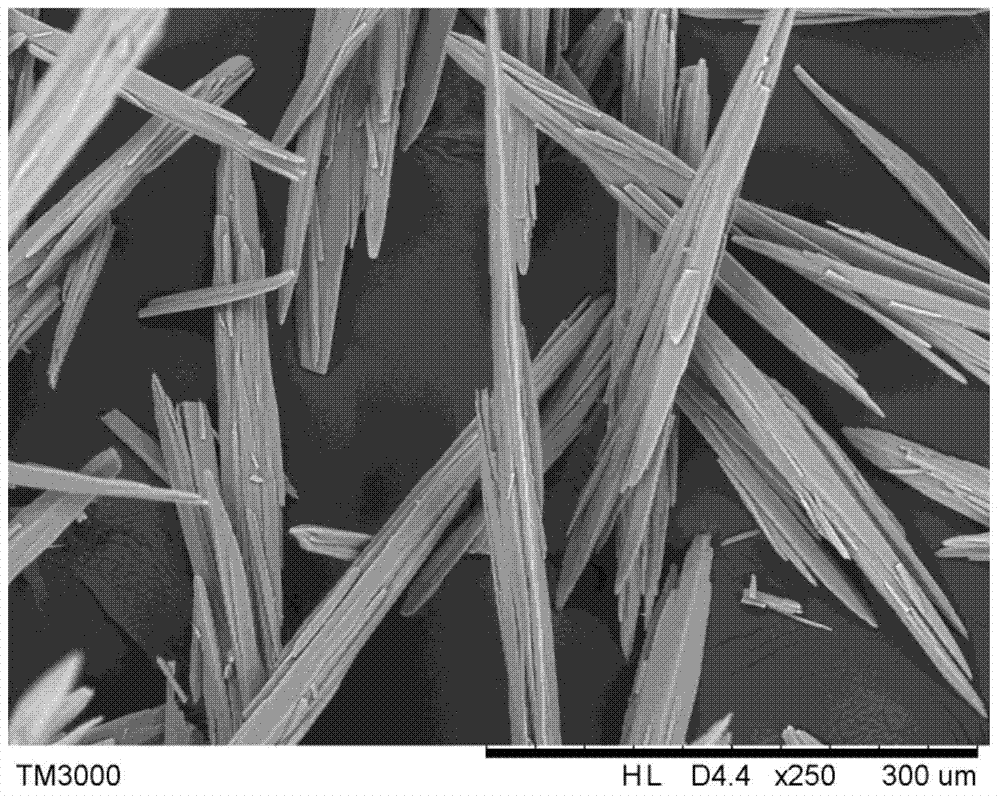

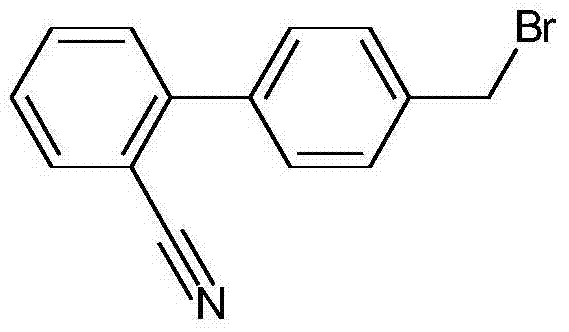

Crystallizing method for preparing high-purity 4-bromomethyl-2-cyanobiphenyl

ActiveCN103626677AHigh purityHigh quality yieldCarboxylic acid nitrile purification/separationGranularityElution

The invention relates to a crystallizing method for preparing high-purity 4-bromomethyl-2-cyanobiphenyl. The crystallizing method comprises the following steps: adding a 4-bromomethyl-2-cyanobiphenyl crude product in a solvent according to 0.4-0.65 g / mL of the solution concentration, stirring and dissolving the crude product at 40-60 DEG C, carrying out cooling and sterilization, reducing the temperature to 5-20 DEG C, keeping the temperature constant for 30-60 minutes, adding an elution agent to carry out solvent dilution crystallization, filtering, washing and drying the crystal mush to obtain the 4-bromomethyl-2-cyanobiphenyl product. The product color is purely white; the high performance liquid chromatography purity is up to 99.5%; the crystal granularity is large, the main granularity is about 100 microns, and the granularity distribution is uniform. During crystallization, the once through yield is high, so that the post treatment cost is saved. The method can provide the high-quality raw material for follow-up synthesis of sartan drug products, reduces unnecessary side reaction during the synthetic process, improves the quality indexes such as impurity and yield of the sartan drug products, and has good industrial application prospect.

Owner:TIANJIN UNIV

Preparation method of 3-hydroxymethyl cefotaxime

ActiveCN112458141ALess types of solventsMild reaction conditionsOrganic chemistryFermentationSolventCephalosporin-C deacetylase

The invention discloses a preparation method of 3-hydroxymethyl cefotaxime. The preparation method is characterized by comprising the following steps: adding cefotaxime into purified water at normal temperature, adjusting the pH value, then adding cephalosporin C deacetylase, filtering out the cephalosporin C deacetylase when the pH value is kept unchanged, collecting filtrate, dropwise adding a mixed solution of inorganic acid and an organic solvent, adjusting the pH value for crystallization, and performing filtering and drying after crystal growing to obtain the 3-hydroxymethyl cefotaxime.According to the preparation method, the cefotaxime is used as a raw material, a biological enzyme method is adopted, a chemical synthesis mode is avoided, the types of solvents are few, the method islow in toxicity and environmentally friendly, the reaction conditions are mild, the steps are simple, the product conversion rate is high, and the operation is simple and easy to control. The yield of a target product can reach 74%, and the purity can reach 97.6% at most. The blank of preparing the impurities by a biological enzyme method synthesis means is filled, subsequent structural analysisand pharmacological research are facilitated, and the method has important theoretical significance and practical application value for improving the quality of cefotaxime sodium, reducing the risk ofclinical medication and the like.

Owner:河北合佳创新医药科技有限公司

Crystallizing method for preparing high-purity 4-bromomethyl-2-cyanobiphenyl

ActiveCN103626677BHigh purityHigh quality yieldCarboxylic acid nitrile purification/separationSolventSide reaction

The invention relates to a crystallizing method for preparing high-purity 4-bromomethyl-2-cyanobiphenyl. The crystallizing method comprises the following steps: adding a 4-bromomethyl-2-cyanobiphenyl crude product in a solvent according to 0.4-0.65 g / mL of the solution concentration, stirring and dissolving the crude product at 40-60 DEG C, carrying out cooling and sterilization, reducing the temperature to 5-20 DEG C, keeping the temperature constant for 30-60 minutes, adding an elution agent to carry out solvent dilution crystallization, filtering, washing and drying the crystal mush to obtain the 4-bromomethyl-2-cyanobiphenyl product. The product color is purely white; the high performance liquid chromatography purity is up to 99.5%; the crystal granularity is large, the main granularity is about 100 microns, and the granularity distribution is uniform. During crystallization, the once through yield is high, so that the post treatment cost is saved. The method can provide the high-quality raw material for follow-up synthesis of sartan drug products, reduces unnecessary side reaction during the synthetic process, improves the quality indexes such as impurity and yield of the sartan drug products, and has good industrial application prospect.

Owner:TIANJIN UNIV

Injection molding technology for recycled polypropylene

InactiveCN111823476AInjection molding process is simple and convenientUniform and reliable qualityCoatingsProcess engineeringInjection moulding

The invention relates to an injection molding technology for recycled polypropylene. The injection molding technology comprises seven steps. The injection molding technology for recycled polypropyleneis simple and convenient, waste polypropylene is adopted to produce polypropylene products, wasting is reduced, and the situation that waste polypropylene is thrown all around, and the environment ispolluted is avoided; and the polypropylene products are unified and reliable in quality, high in quality and yield, excellent in performance and not prone to being fragile.

Owner:惠州日田塑胶制品有限公司

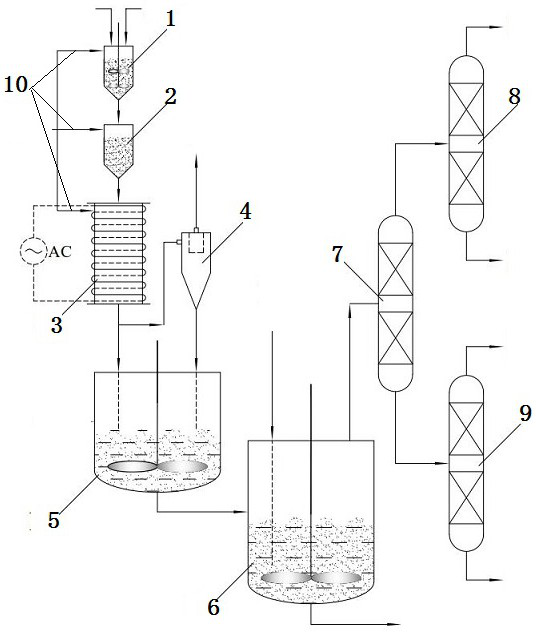

Method and reaction system for continuously producing disilane

ActiveCN114180580ARealize continuous productionHigh quality yieldFinal product manufactureSilicon hydridesSilica fumeChemistry

The invention discloses a method for assisting in processing silicon powder and metal powder by using thermal plasma under the condition of micro negative pressure so as to promote continuous reaction of the silicon powder and the metal powder to generate metal silicide powder. The invention also relates to a method for preparing disilane by using the metal silicide powder as a raw material to react with strong acid in a specific solvent, and a reaction system for realizing the method. According to the preparation method, silicon powder and metal powder are instantly melted and vaporized in a plasma core area by utilizing the high energy density of hot plasma, and then are rapidly cooled to finish alloying and chemical reaction and form nanoscale metal silicide powder; under the condition of micro-negative pressure, the formed nano-scale metal silicide powder reacts with strong acid in a specific solvent to generate silane series product gas, and the proportion of disilane is obviously higher than that of disilane in the existing production process; meanwhile, the whole technological process is carried out under the micro-negative pressure condition, operation is safe and easy to control, and continuous production can be achieved.

Owner:全椒亚格泰电子新材料科技有限公司

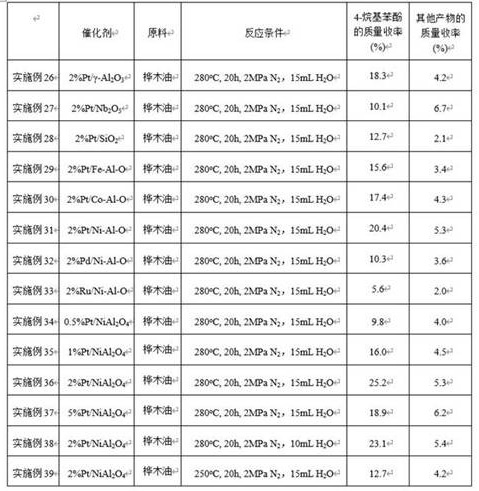

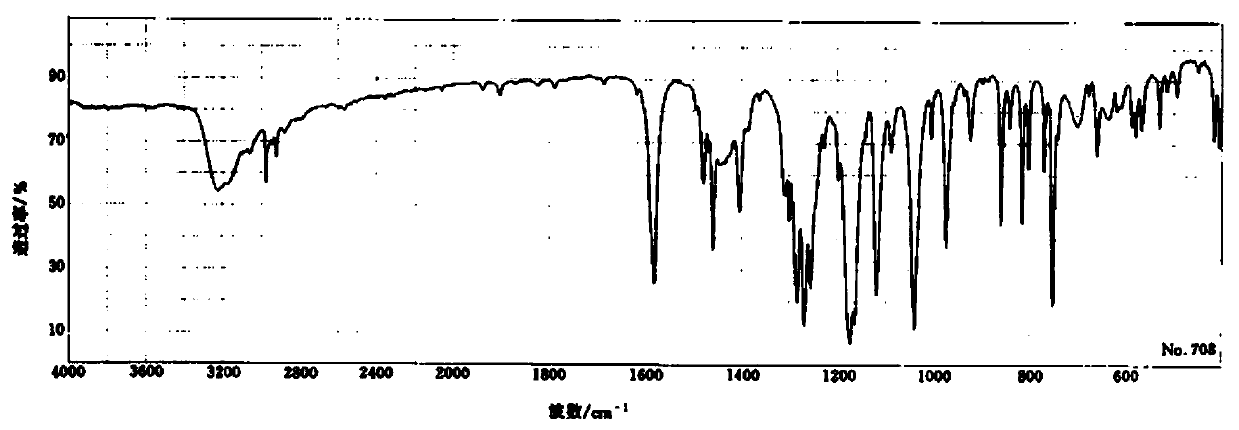

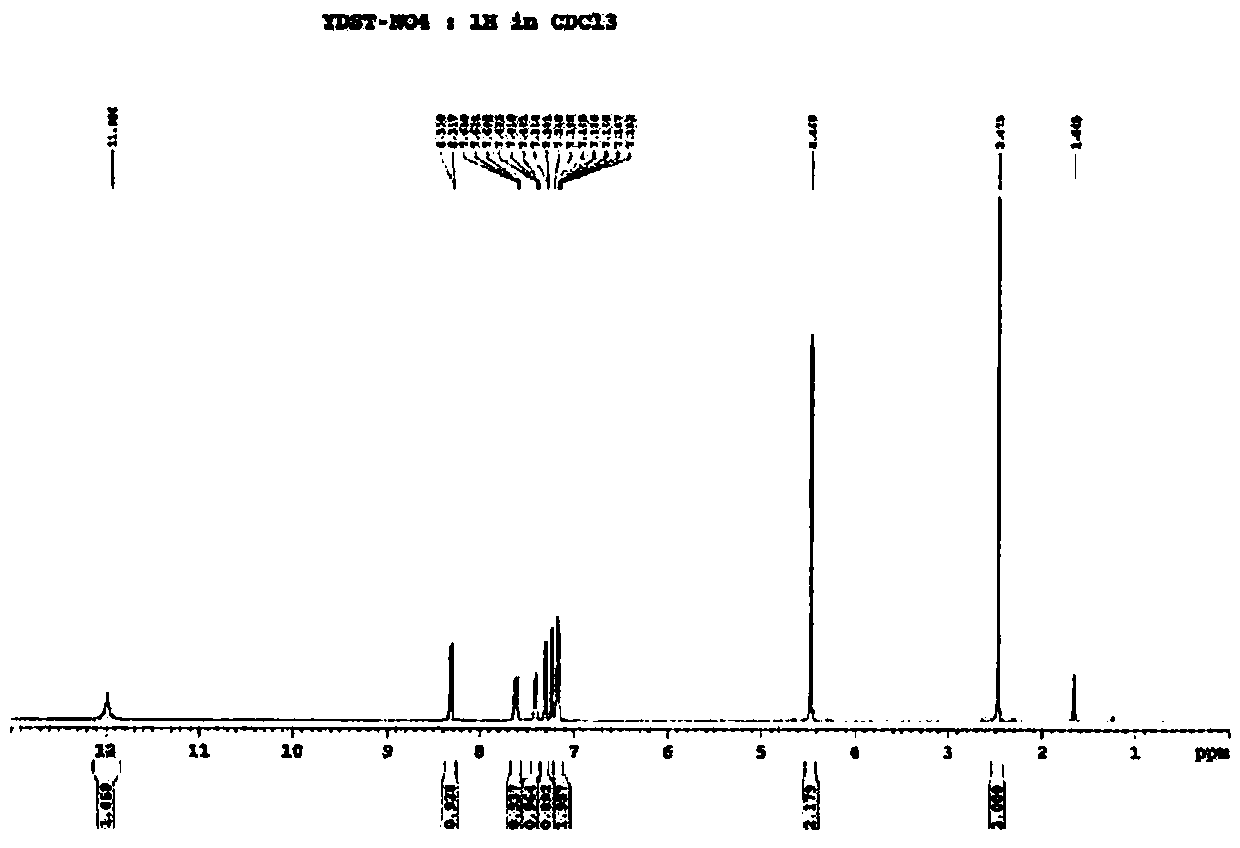

Method for preparing 4-alkylphenol by self-forming hydrogenolysis of lignin or lignin oil

PendingCN112479823ALow costReduce riskOrganic chemistryOrganic compound preparationPolyesterDepolymerization

The invention relates to a method for preparing 4-alkylphenol from lignin or lignin oil by a one-pot method without an external hydrogen source. According to the method, lignin or lignin oil is used as a raw material, and under the action of a metal catalyst loaded by a nickel-aluminum composite material, self-reforming hydrogen production and hydrogenolysis are carried out to obtain 4-alkylphenol. With birch organic lignin and lignin oil as raw materials, the yields of 4-alkylphenol are as high as 17wt% and 25wt% respectively. The lignin is obtained by taking biomass containing a lignin component as a raw material and adopting an acidolysis or biological enzyme depolymerization method. The lignin oil is obtained by taking biomass containing lignin component as a raw material through a hydrogenolysis depolymerization method. Raw materials are wide in source and low in cost. Meanwhile, the process does not need an additional hydrogen source, and is single in product, few in by-product,easy to separate and green in solvent. Besides, the phenolic product involved in the invention is an important chemical product, is suitable for the polyester industry, and has a wide application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of preparation technology of Lansoprazole

ActiveCN106928191BHigh quality yieldImprove solubilityOrganic chemistryLansoprazoleMercaptobenzimidazol

The invention provides a preparation technology of lansoprazole. The preparation technology comprises the following steps that 1, a raw material A 2-mercapto benzimidazole is dissolved into methanol in the presence of alkali, a raw material B 2-chloromethyl-3-methyl-4-(2,2,2,-trifluoroethoxyl)pyridine hydrochloride is added for a reaction, filtering is conducted by adding water, obtained precipitates are washed and dried, and then an intermediate C [[[3-methyl-4-(2,2,2,-trifluoroethoxyl)-2-pyridyl]methyl]sulfydryl]-H-benzimidazole is obtained; the intermediate C is dissolved into ethanol, a mixed solution of hydrogen peroxide, a catalyst and ethanol is added for a reaction, filtering is conducted by adding water, obtained precipitates are washed, and then the lansoprazole is obtained. According to the preparation technology, the yield is increased, the cost is reduced, the production cycle is shortened, and the preparation technology is more suitable for industrialized production.

Owner:HENAN KANGDA PHARMA

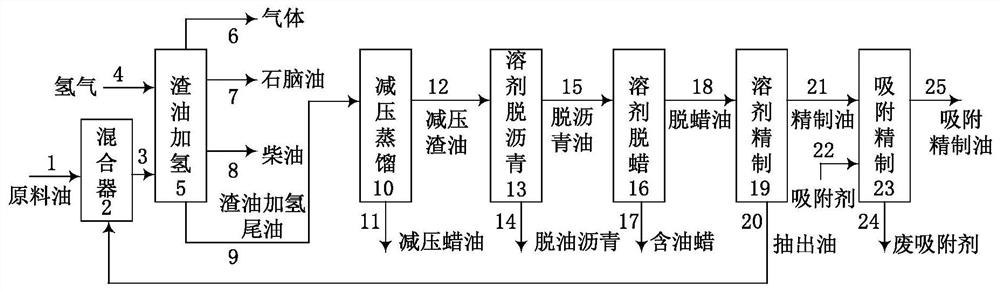

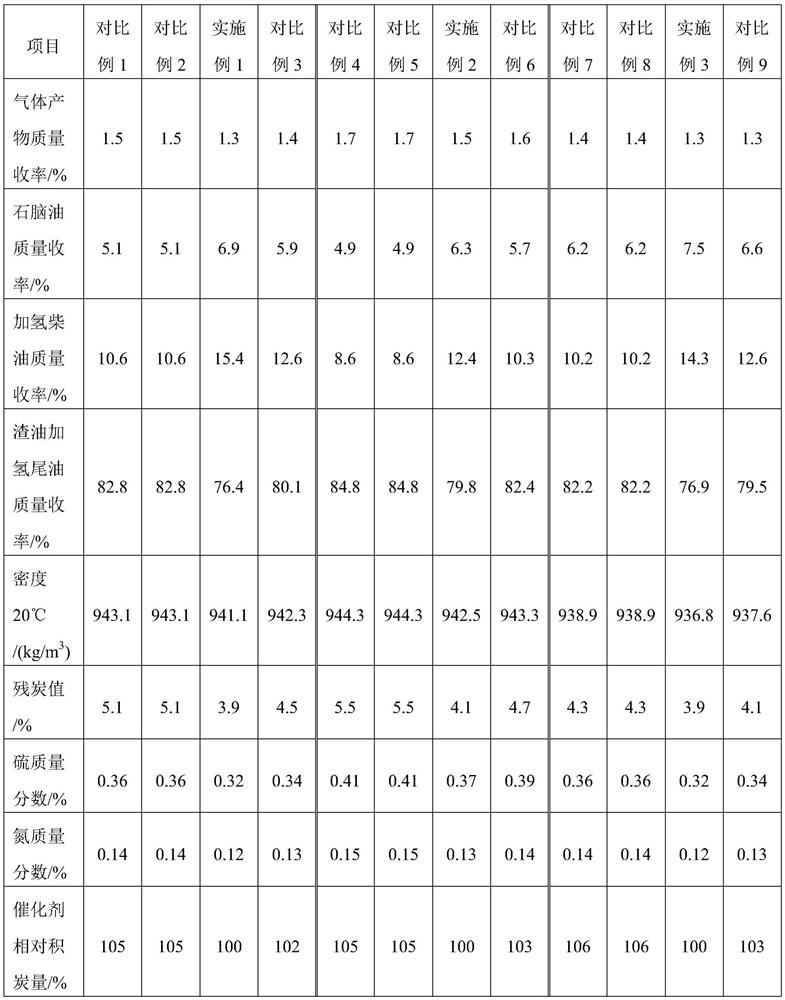

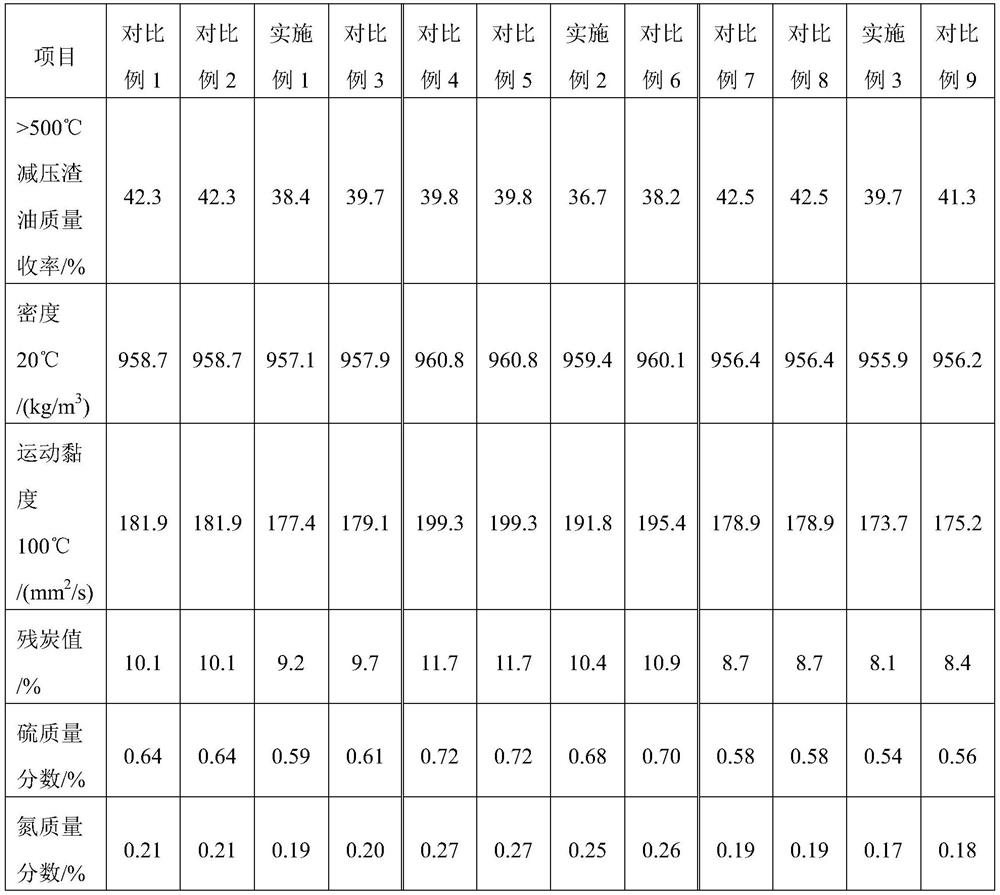

Combination process of residual oil hydrotreating and bright oil production

ActiveCN110607191BReduce viscosityIncrease aromaTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystPetrochemical

The invention relates to the field of petrochemical industry, and discloses a combination process of residual oil hydrogenation treatment and bright oil production, the process includes: contacting hydrogen, residual oil raw materials and co-solvent with a catalyst, and regenerating the separated hydrogenated residual oil tail oil Separation into vacuum wax oil and vacuum residue; use deasphalting solvent to solvent extract the vacuum residue to obtain extract and raffinate and remove the solvent to obtain deasphalted oil and deoiled asphalt; use dewaxing solvent to extract Solvent dewaxing the deasphalted oil to obtain dewaxed filtrate and wax paste and remove the solvent to obtain dewaxed oil and oily wax; use extraction solvent to solvent refine the dewaxed oil to obtain raffinate and extract and remove the solvent Refined oil and extracted oil are obtained; the refined oil is adsorbed and refined with an adsorbent, and bright oil is separated to obtain bright oil, and the co-solvent is solvent refined extracted oil. The method of the invention can reduce the coking amount of the catalyst, prolong the operation cycle of the device, and simultaneously produce bright stock meeting the lubricating oil base oil standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of 3-hydroxymethyl cefotaxime

ActiveCN112458141BReduce typesAvoid chemical synthesisOrganic chemistryFermentationEnzymatic synthesisChemical synthesis

The invention discloses a preparation method of 3-hydroxymethyl cefotaxime, which is characterized by comprising the following steps: adding cefotaxime to purified water at room temperature, adjusting the pH, adding cephalosporin C deacetylase, and maintaining the pH when the pH is maintained. When unchanged, the cephalosporin C deacetylase is filtered off, the filtrate is collected, the mixed solution of an inorganic acid and an organic solvent is added dropwise, the pH is adjusted to crystallize, the crystal is grown, filtered, and dried to obtain 3-hydroxymethylcefotaxime. The invention uses cefotaxime as raw material, adopts biological enzyme method, avoids the use of chemical synthesis methods, has few types of solvents, low toxicity and environmental protection, mild reaction conditions, simple steps, high product conversion rate, and simple and easy-to-control operations. The yield of the target product can reach 74%, and the purity can reach up to 97.6%. It fills the blank of preparing the impurity by biological enzymatic synthesis method, which is beneficial to the subsequent structure analysis and pharmacological research, and has important theoretical significance and practical application value for improving the quality of cefotaxime sodium and reducing the risk of clinical drug use.

Owner:河北合佳创新医药科技有限公司

A kind of coumarin derivative and its preparation and application

InactiveCN108586407BHigh quality yieldThe reaction conditions are mild and safeOrganic chemistryLuminescent compositionsPolymer scienceDouble bond

The invention discloses a coumarin derivative and preparation and application thereof. 7-hydroxy-4-methyl coumarin as a raw material is subjected to substitution reactions with halogenated ethyl alcohol and 4-vinylbenzyl chloride in sequence, and then 7-[2-(4-vinyl benzyloxy)-ethyoxyl]-4-methyl coumarin is obtained. The method has the advantages that the operation is simple, the conditions are mild, the product is easy to purify, and the yield is high, the coumarin derivative synthesized by using the method has polymerizable double-bond elements, alkoxy flexible spacers and coumarin photosensitive groups, and when the coumarin derivative as a photosensitive monomer used for synthesis of a photostimulation response polymer material, the polymerization efficiency can be obviously improved. The water solubility and the degradability of the polymer material synthesized by using the counmarin derivative can be improved, the hydrophily and the hydrophobicity of the polymer material are moreeasily regulated and controlled, and therefore, in the use process of the polymer material as a drug carrier, the drug encapsulation and release rates can be better controlled.

Owner:CENT SOUTH UNIV

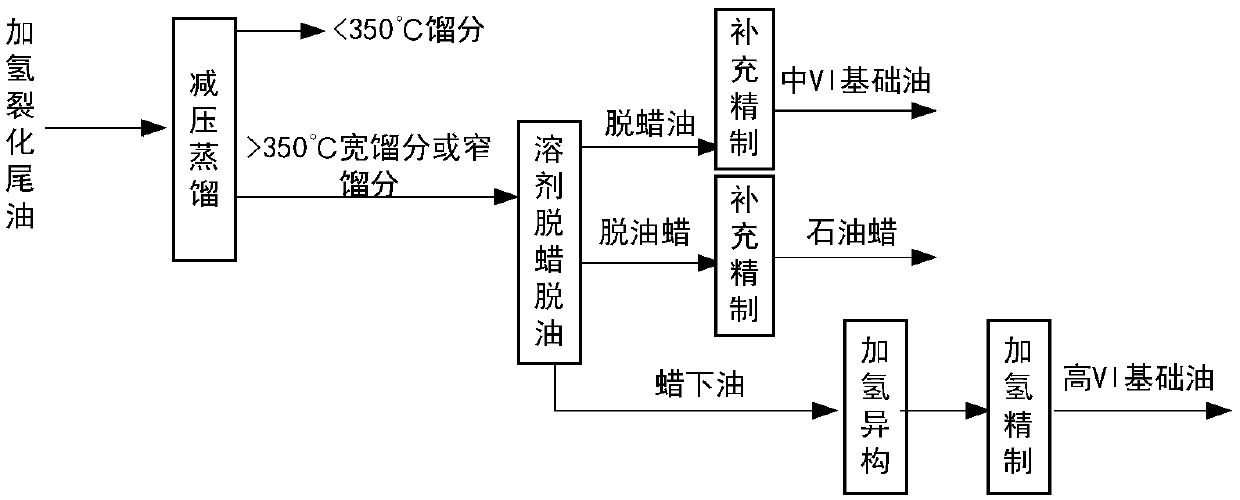

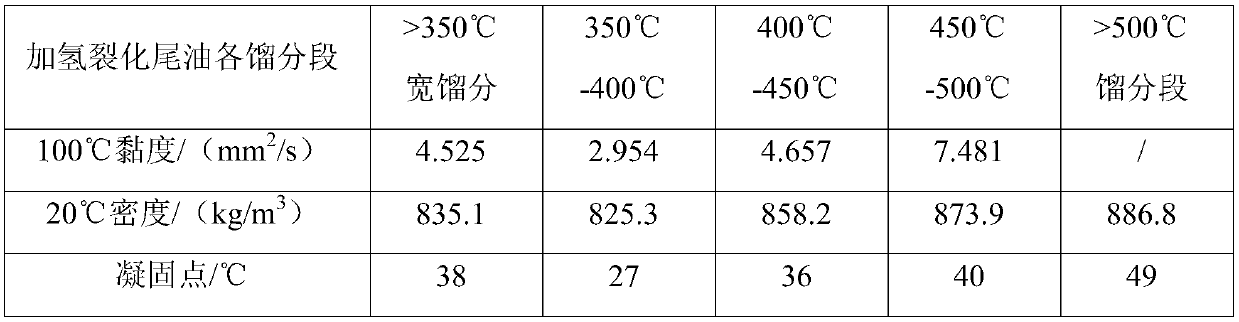

Method for simultaneously producing low-oil-content wax and medium and high viscosity index base oils

ActiveCN110607192ALow quality scoreHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxDistillation

The invention relates to the field of petrochemical industry, and discloses a method for simultaneously producing low-oil-content wax and medium and high viscosity index base oils, which comprises thefollowing steps: (1) separating a fraction with a distillation range of not less than 350 DEG C from hydrocracking tail oil; (2) under a dewaxing condition, contacting the fraction with a distillation range of not less than 350 DEG C with a dewaxing solvent to carry out solvent dewaxing so as to obtain dewaxed oil and oil-containing cerate, wherein the dewaxed oil is used as a raw material for producing viscosity index base oil; (3) under a deoiling condition, contacting the oil-containing cerate with a deoiling solvent to carry out solvent deoiling so as to obtain deoiled wax and dewaxed oil, wherein the deoiled wax is used as a raw material for producing petroleum wax; and (4) carrying out hydroisomerization and hydrofining on the under-wax oil to obtain the high-viscosity index base oil. The method provided by the invention can be used for producing the low-oil-content wax and the base oil with medium and high viscosity indexes at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of synthetic method of 2-chloropyridine

The invention discloses a 2-chloropyridine synthetic method, which belongs to the technical field of fine chemical engineering. The method comprises the following steps: adding pyridine into a hypochloric acid salt solution, uniformly mixing the solution, slowly adding hydrochloric acid drop by drop at room temperature, stirring a mixture and reacting the mixture for 1-2 hours; then heating the material to the temperature of 60-80 DEG C, continuously reacting the material for 1-2 hours; and finally, adding a certain amount of a NaOH solution and neutralizing the solution to a pH value of 9-11, extracting a reactant by using trichloromethane and separating the reactant; distilling an extract phase and removing a trichloromethane solvent in order, recovering the unreacted pyridine to obtain the chloropyridine product. According to the invention, a GC / MS analysis on the chloropyridine product is carried out, selectivity of 2-chloropyridine can reach 83%. The hydrochloric acid and hypochlorite by-product with low cost in industrial production can substitute a chlorinating agent such as Cl2, reaction condition is mild, selectivity is good, process is simple, cost is low, and environment and safety problems during the production process of 2-chloropyridine can be solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing cefprozil dimethyl formamide solvate

ActiveCN102443013BEnhanced nucleophilicityHigh clarityOrganic chemistryCombinatorial chemistryCefprozil

The present invention relates to an improved method for preparing cefprozil dimethylformamide solvate, the method is to use 7-APCA-guanidine salt shown in formula IV and mixed anhydride shown in formula VI as raw materials under alkaline conditions Condensation reaction is carried out, the obtained reaction solution is hydrolyzed in the presence of an acid, the liquid is separated, DMF is added to the water phase, and the pH value is adjusted with alkali to obtain the cefprozil DMF solvate shown in formula I. The method of the invention avoids the use of expensive and unstable silylating reagents, greatly improves the product yield, reduces production costs, and is a more economical and effective preparation process. Wherein, X+, R6 are as defined in claim 1.

Owner:CSPC MEGALITH BIOPHARMACEUTICAL CO LTD

A method for the catalytic synthesis of biodiesel by short mesoporous solid base molecular sieves

ActiveCN107876105BHigh activityLow reaction temperatureFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselPtru catalyst

Owner:XIANGTAN UNIV

A kind of preparation method of monascus yellow pigment

The invention provides a preparation method of a monascus yellow pigment, comprising the following steps: sulfonating: performing a sulfonation reaction by taking an ethanol-soluble monascus red pigment as a raw material, dilute sulphuric acid as a sulfonating agent and sulfamic acid as an assistant; collecting sediment: collecting the obtained sediment, washing by using dilute alkali or water, and collecting the washed sediment; alkaline hydrolysis: adding an alkaline hydrolysis agent in the washed sediment for alkaline hydrolysis, thus obtaining monascus yellow conversion liquid; desalting: adjusting pH of the obtained monascus yellow conversion liquid, and desalting by using an electric drive film method, thus obtaining monascus yellow low-salt liquid; dying: concentrating and drying the obtained monascus yellow low-salt liquid, thus obtaining the monascus yellow pigment. The preparation method belongs to the technical field of pigments; by adding the small amount of sulfamic acid as the assistant, quick sulfonation of the dilute sulphuric acid on the ethanol-soluble monascus red pigment can be realized, reaction conditions are mild, by products are few, operation safety is good, and the prepared monascus yellow pigment is high in color value, good in stability and high in mass yield.

Owner:GUANGDONG KELONG BIOLOGICAL SCI & TECH

A method for extracting L-methionine from fermentation broth

ActiveCN109020854BLow costEasy to operateOrganic compound preparationOrganic chemistry methodsBiotechnologyIon exchange

The invention discloses a method for extracting L-methionine from fermentation liquid. According to the method, regulating the pH of fermentation liquid comprisingcontaining L-methionine to 1.5 to 4;performing filtering; taking filter liquid; using strong acid type cation exchange resin for column chromatography; performing reduced pressure concentration on the eluent comprisingcontaining L-methionine; taking concentrated liquid; adding isopropanol for stirring and crystallization; taking crystals; washing the crystals by ultrapure water until no alcohol exists; performing drying to obtain the L-methionine. The ion exchange resin is used for the first time for separating the methionine from the fermentation liquid; the separation cost is greatly reduced; the yield and the purity can reachthe industrial production level. The method has the advantages that the operation is simple; the steps are short; the used reagent has low cost and can be easily obtained; the relatively good industrialization prospects are realized. The product obtaining yield in the whole process is high; the quality of the finally obtained product is high; the purity is as high as 99 percent; the mass yield isas high as 85 percent.

Owner:ZHEJIANG UNIV OF TECH

The method of controlling the water addition of vpo catalyst auxiliary agent in mah preparation process

The invention relates to a method for controlling the addition of water as a VPO catalyst additive in the MAH preparation process, which is characterized in that: the water control valve connected to the shell-and-tube fixed-bed reactor for preparing MAH is connected with an atmospheric humidity instrument and a calculation module , the ambient temperature T and relative humidity RH are measured by the atmospheric temperature and humidity meter, and the measured values are input into the calculation module, and calculated by the formula to accurately control the amount of additive water added. The invention realizes the precise control of the amount of water added to the catalyst bed auxiliary agent, keeps the humidity of the butane mixed gas entering the reactor at a constant value, and is not affected by the temperature and humidity of the environment; improves the high selectivity and yield of the catalyst , the selectivity increased by 2.1%, and the mass yield increased by 2.4%, avoiding: the phosphide is concentrated at the feed end of the reactor due to the low amount of water added, which makes the temperature distribution of the reactor uneven, and excessive water addition causes side effects The occurrence of product increase and so on.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com