A method for the catalytic synthesis of biodiesel by short mesoporous solid base molecular sieves

A synthetic biology, short mesoporous technology, applied in chemical instruments and methods, biofuels, chemical/physical processes, etc., can solve the problems of difficult separation of ionic liquids, large amount of ionic liquids, and difficult separation of products, and achieve low operating costs , short reaction time and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

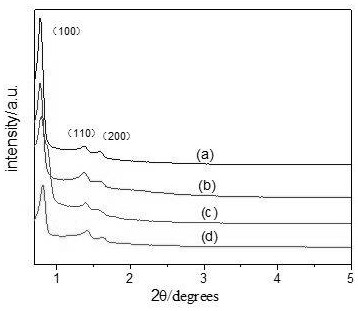

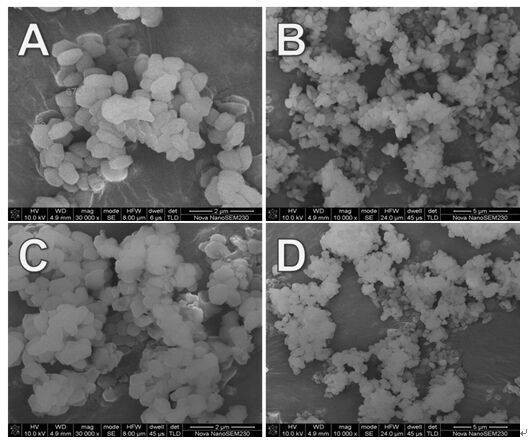

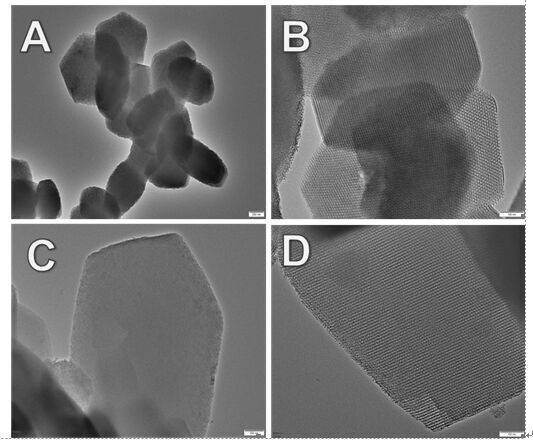

[0040] 1. Short Mesoporous Solid Base Molecular Sieve [Smim]CO 3 - Preparation of Zr-SBA-15

[0041] 1) Mix methylimidazole, silane coupling agent 3-chloropropyltriethoxysilane (CPTES), and toluene at a mass ratio of 1:3.05:20 at 110°C, condense and reflux for 24 hours with N2 to achieve formazan Imidazole N-alkylation reaction, after steaming the organic solvent toluene under reduced pressure, a kind of organosilicon ionic liquid compound [Smim]Cl (1-propyl (triethoxysilyl)-3-methyl imidazolium chloride), the organic solvent toluene used should be dehydrated with anhydrous magnesium sulfate before use to avoid hydrolysis of silane coupling agent (3-chloropropyltriethoxysilane) in water, ethoxy Water breakage occurs.

[0042] 2) At 40 °C, the surfactant polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) was mixed with ZrOCl 2 ·8H 2 O was added to 1.6mol / L HCl solution and stirred until P123 was completely dissolved to form a mixed solution,...

Embodiment 2

[0048] Example 2 The operation steps are the same as in Example 1, but the basic substance K exchanged with [Smim]Cl / Zr-SBA-15 anion 2 CO 3 Change to CH 3 COOK, a Short Mesoporous Solid Base Molecular Sieve [Smim]CH 3 COO / Zr-SBA-15, whose basicity pKa is 7.2~9.8, is used to catalyze the synthesis of biodiesel, and the mass yield of biodiesel product is 23.4%.

Embodiment 3

[0049] Example 3 The operation steps are the same as in Example 1, but the basic substance K exchanged with [Smim]Cl / Zr-SBA-15 anion 2 CO 3 Change it to KOH to make a short mesoporous solid base molecular sieve [Smim]OH / Zr-SBA-15, whose basicity pKa is 7.2~15.0, which is used to catalyze the synthesis of biodiesel, and the mass yield of the biodiesel product is 94.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com