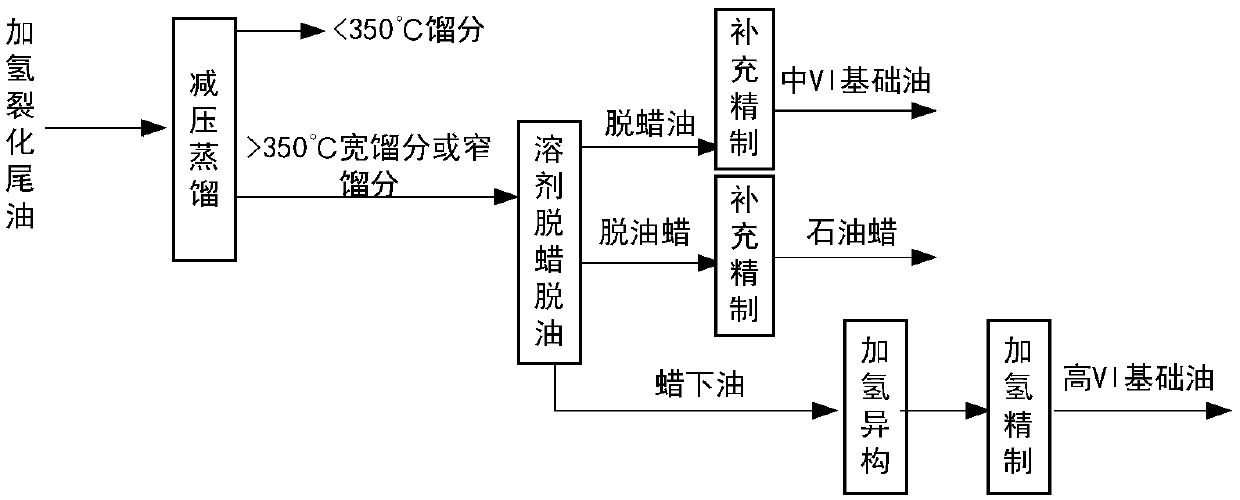

Method for simultaneously producing low-oil-content wax and medium and high viscosity index base oils

A technology containing oil wax and base oil, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil processing products, etc., can solve the problems of poor economic benefit, low product yield, low base oil viscosity index, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] This example is used to illustrate the method for producing low oil wax and medium and high viscosity index base oil by hydrocracking tail oil provided by the present invention.

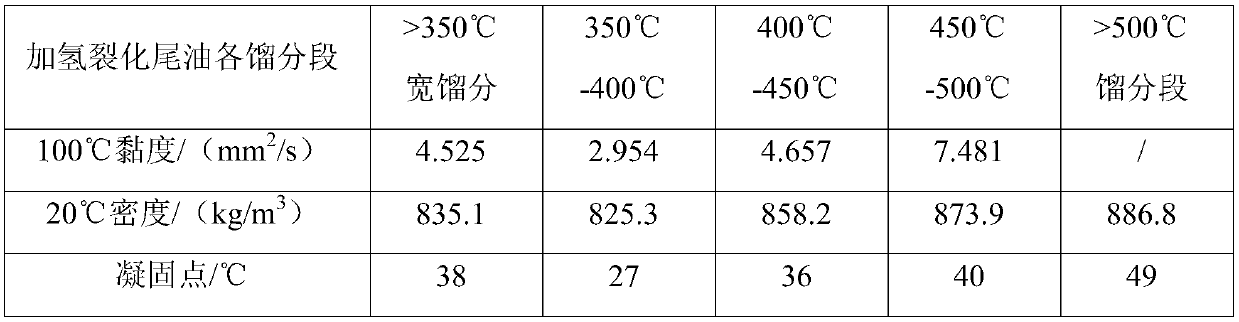

[0089] The >350°C distillate of hydrocracking tail oil is used as the raw material, and the properties of the raw material are shown in Table 1.

[0090] See Table 2 for solvent dewaxing, solvent deoiling conditions, deoiled wax, dewaxed oil and waxed oil properties of hydrocracking tail oil.

[0091] The ratio of the refractive index of the dewaxing solvent at the dewaxing filtration temperature to the refractive index of the mixture of liquid components in the feed oil and the dewaxing solvent at the filtration temperature is 0.96.

[0092] At a deoiling filtration temperature, the ratio of the refractive index of the deoiling solvent to the refractive index of the mixture of the liquid components in the raw oil and the deoiling solvent at the filtration temperature is 0.96.

[0093] See Ta...

Embodiment 2

[0096] This example is used to illustrate the method for producing low oil wax and medium and high viscosity index base oil by hydrocracking tail oil provided by the present invention.

[0097] The 350°C-400°C fraction of hydrocracking tail oil is used as the raw material, and the properties of the raw material are shown in Table 1.

[0098] See Table 2 for solvent dewaxing, solvent deoiling conditions, deoiled wax, dewaxed oil and waxed oil properties of hydrocracking tail oil.

[0099] The ratio of the refractive index of the dewaxing solvent at the dewaxing filtration temperature to the refractive index of the mixture of liquid components in the feed oil and the dewaxing solvent at the filtration temperature is 0.99.

[0100] At a deoiling filtration temperature, the ratio of the refractive index of the deoiling solvent to the refractive index of the mixture of the liquid components in the raw oil and the deoiling solvent at the filtration temperature is 0.97.

[0101] See...

Embodiment 3

[0103] This example is used to illustrate the method for producing low oil wax and medium and high viscosity index base oil by hydrocracking tail oil provided by the present invention.

[0104] The 400°C-450°C fraction of hydrocracking tail oil is used as the raw material, and the properties of the raw material are shown in Table 1.

[0105] The solvent dewaxing of hydrocracking tail oil, solvent deoiling conditions, properties of dewaxed oil and waxed oil are shown in Table 2.

[0106]The ratio of the refractive index of the dewaxing solvent at the dewaxing filtration temperature to the refractive index of the mixture of liquid components in the feed oil and the dewaxing solvent at the filtration temperature is 0.98.

[0107] At a stage of deoiling filtration temperature, the ratio of the refractive index of the deoiling solvent to the refractive index of the mixture of liquid components in the raw oil and the deoiling solvent at the filtration temperature is 0.99.

[0108] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com