Continuous flash-evaporation type fluidized drying bed for drying chlorinated polyethylene

A technology of chlorinated polyethylene and boiling drying bed, which is applied in drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of high labor intensity, long production cycle, inconvenient operation, etc., and achieve low labor intensity. , the production cycle is short, the effect of prolonging the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

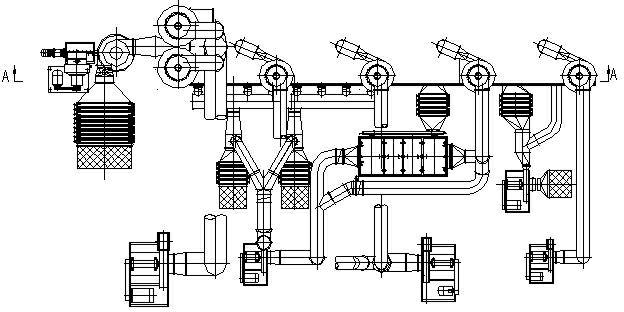

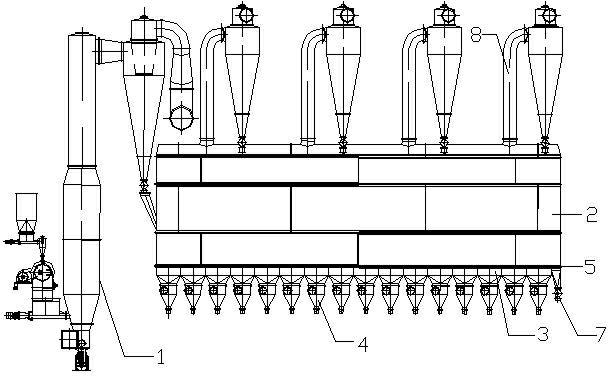

[0012] Embodiment 1, a kind of dry chlorinated polyethylene uses continuous flashing type fluidized drying bed, with reference to figure 1 , figure 2 , image 3 Shown, comprise flash drying device 1 and continuous type fluidized bed 2, it is characterized in that, the bottom of continuous type fluidized bed is provided with four drying chambers 3 that pass into different temperature air respectively, in each drying chamber, air It enters the drying chamber through four distributors 4 and a drying bed orifice 5 .

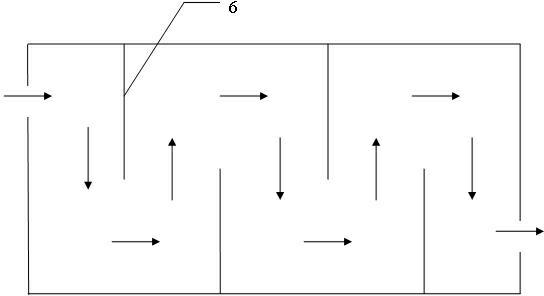

[0013] Above the fluidized bed, partitions 6 interspersed at intervals are arranged, and the material flows through the drying chamber along an S-shaped line on the bed.

[0014] The four drying chambers, according to the order from the closest to the farthest from the flash drying device, the air temperatures that are fed in order are 120°C, 140°C, 130°C, and 40°C.

[0015] During the production process, the chlorinated polyethylene material first enters the fla...

Embodiment 2

[0016] Example 2, a continuous flashing fluidized drying bed for drying chlorinated polyethylene, is similar to Example 1, the difference is that the four drying chambers are sequentially fed into The air temperature is 110°C, 135°C, 125°C, 45°C, and the mass fraction of water in the dried product is about 0.28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com