Patents

Literature

721results about How to "Easy to automate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

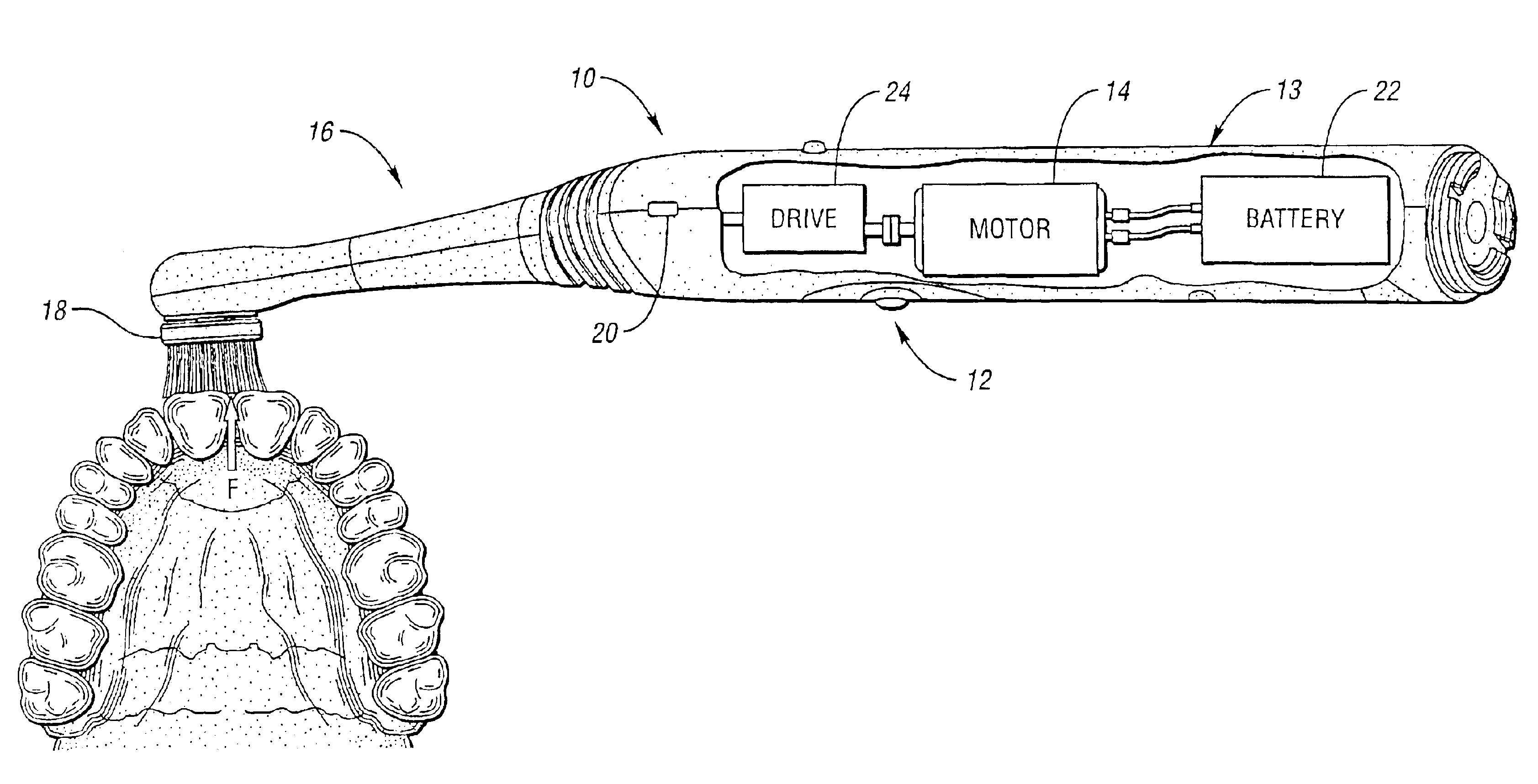

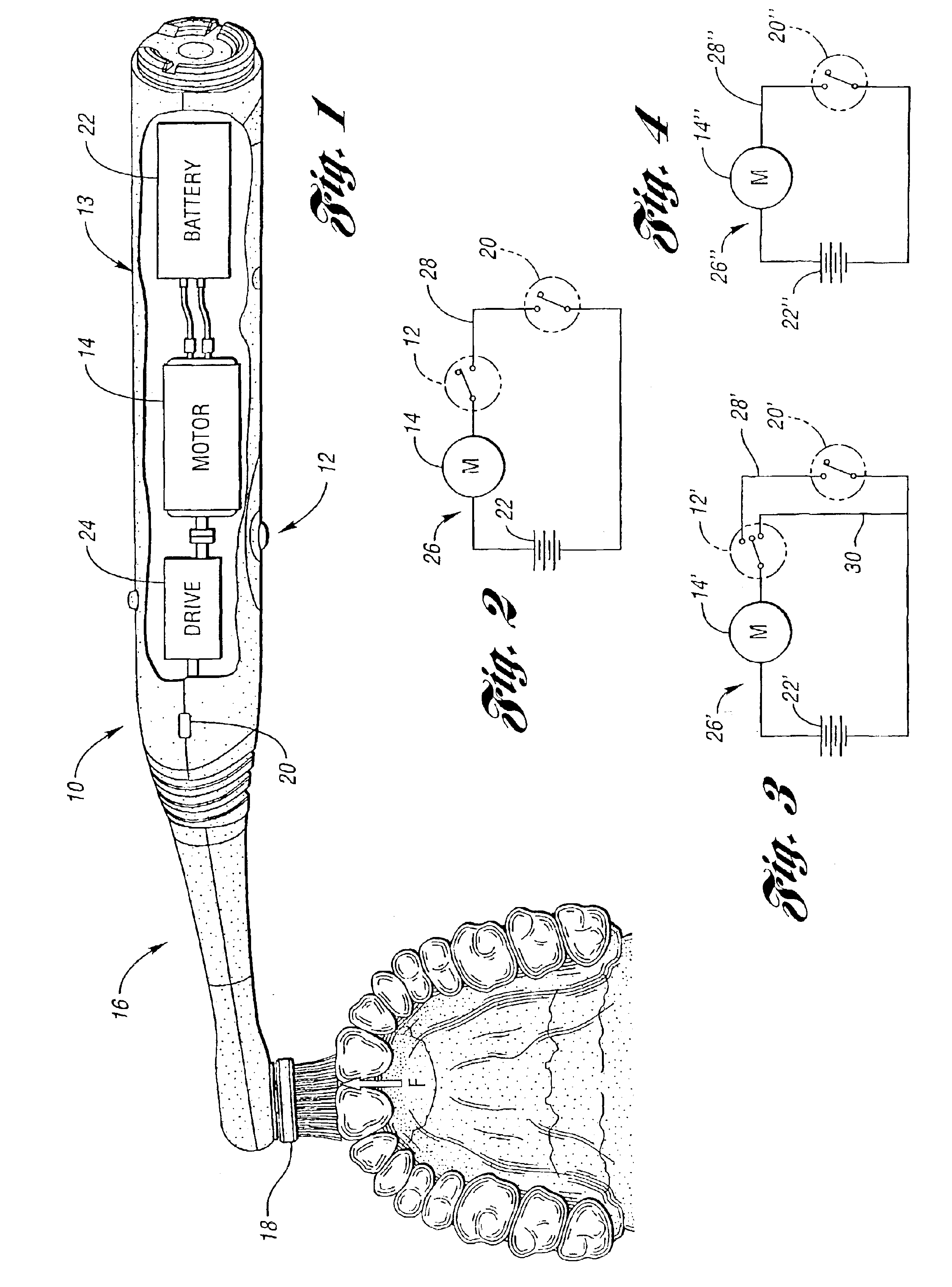

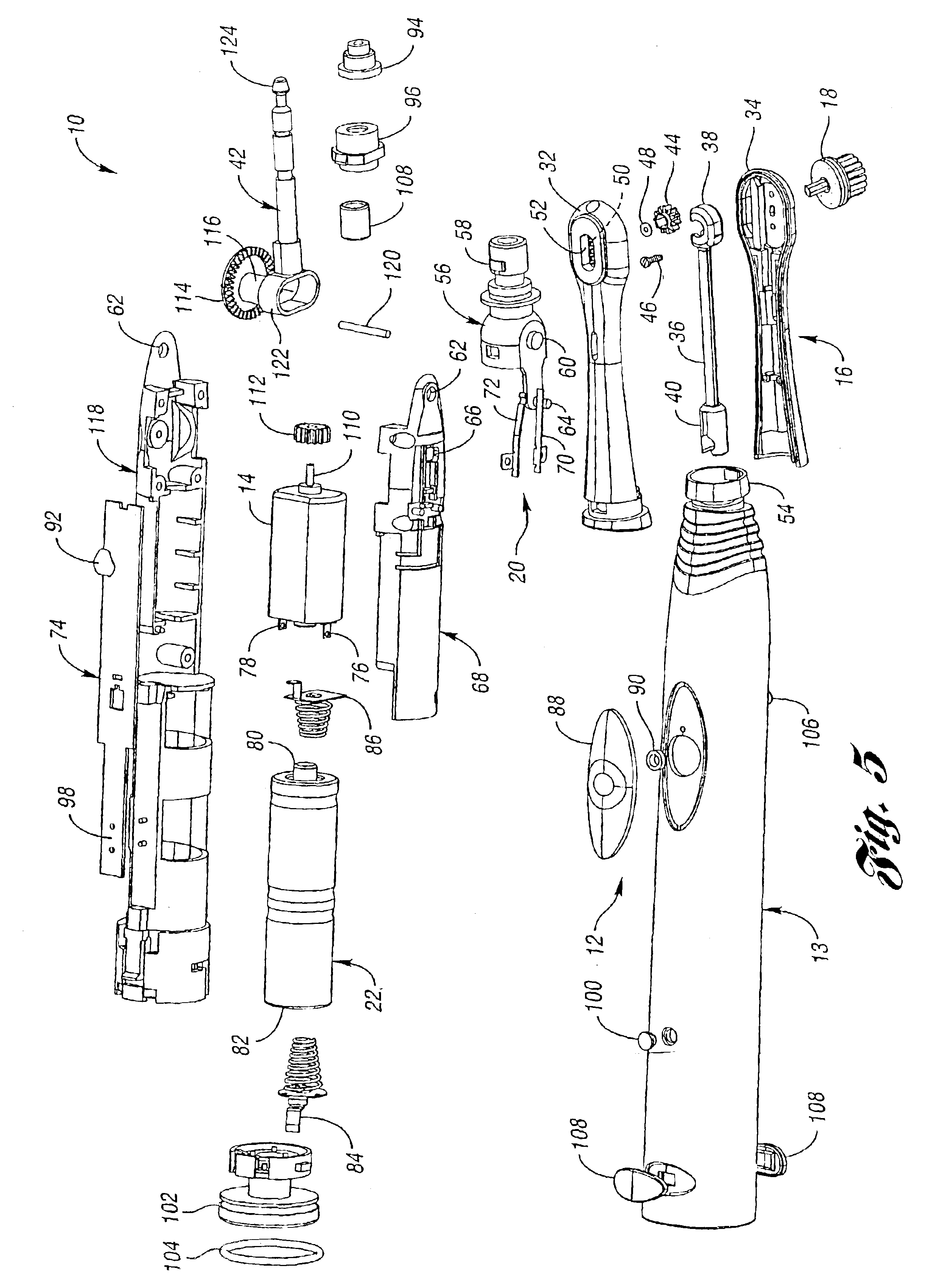

Automatic electric toothbrush

InactiveUS6952855B2Easy to replaceEasy to automateCarpet cleanersKitchenware cleanersBristleElectrical and Electronics engineering

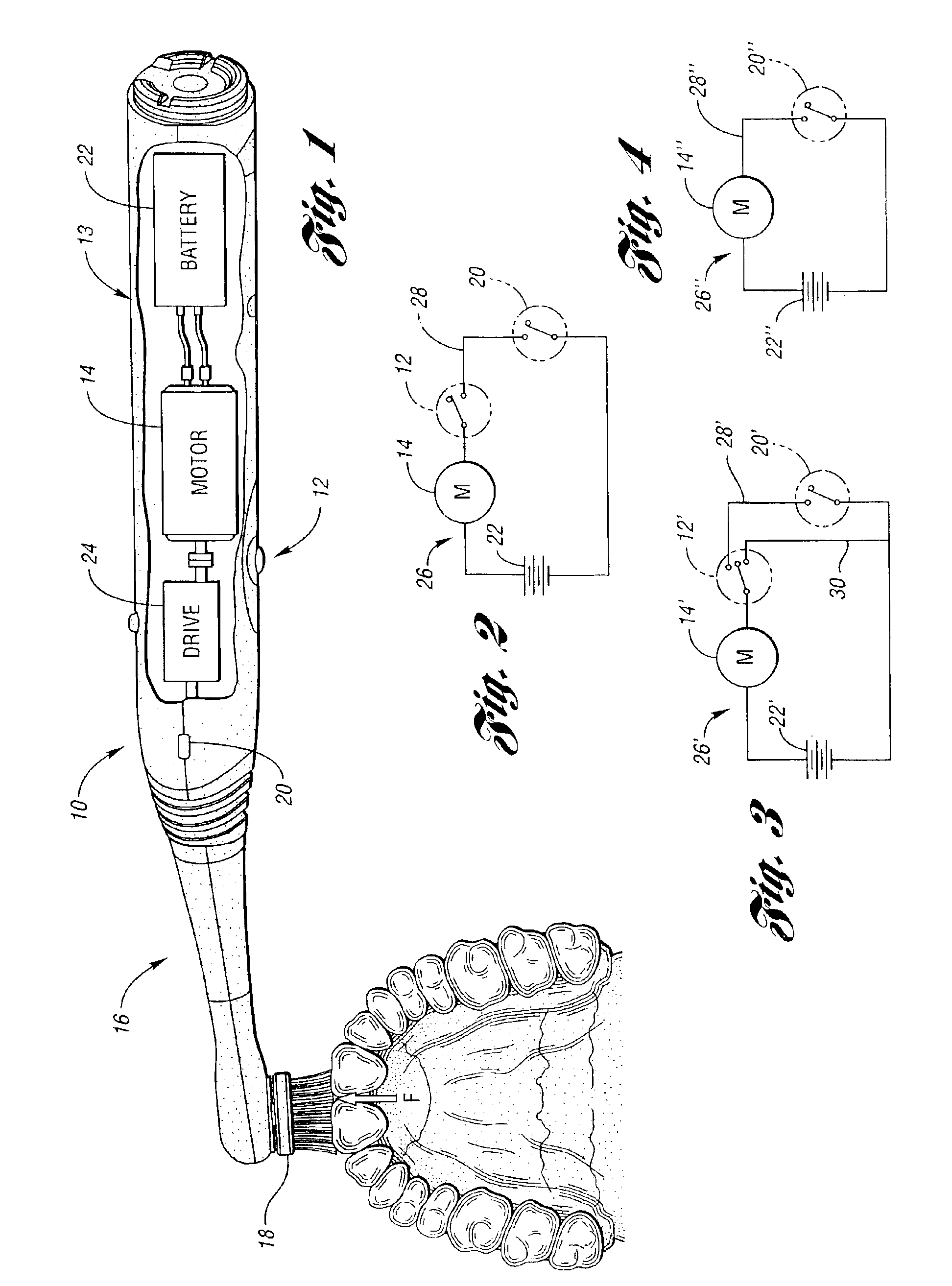

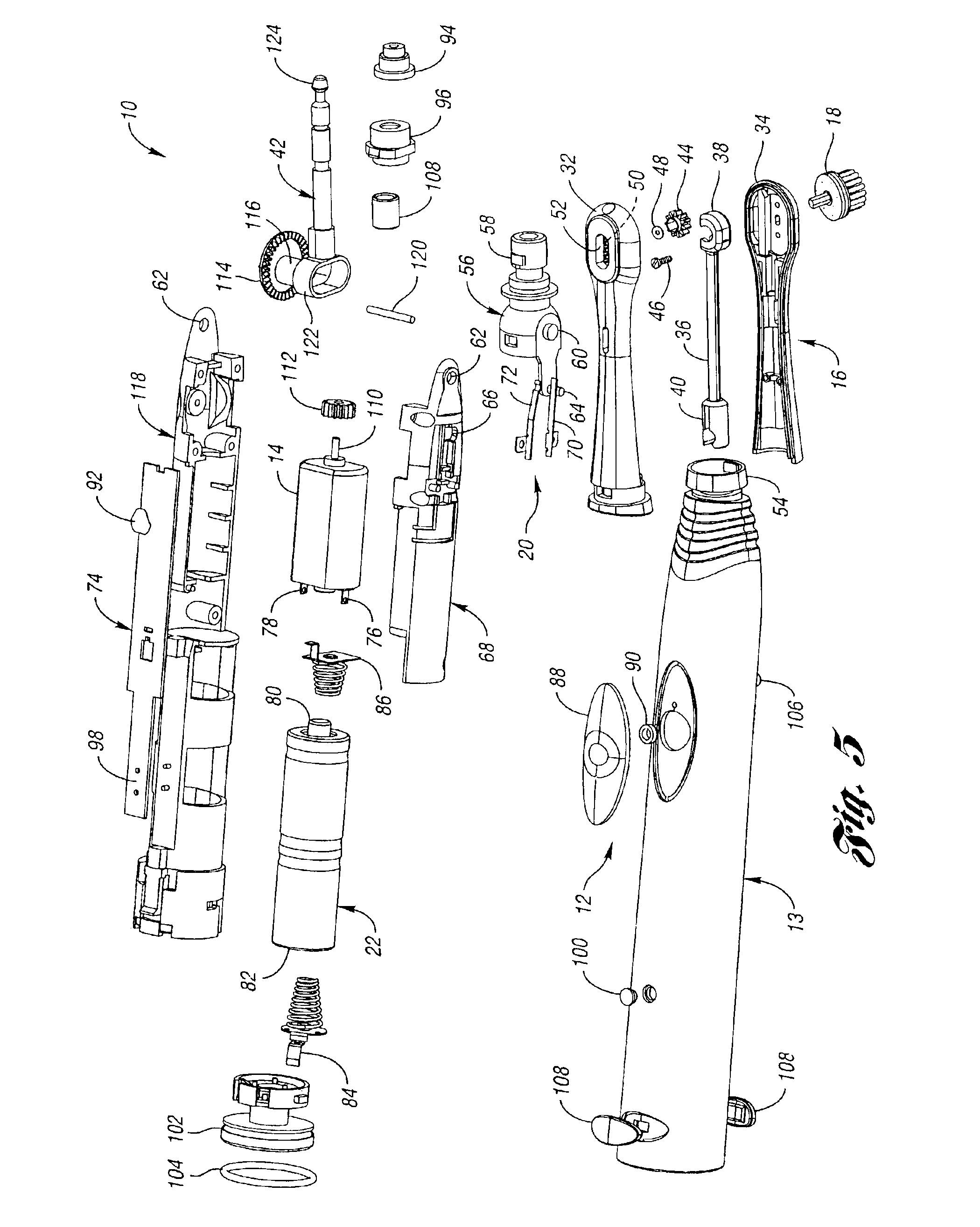

An motorized electric toothbrush (10) includes a removable brush head (16) and a switch (12) that allows the toothbrush (10) to be used in an “automatic” mode. The “automatic” mode provides for intermittent motorized operation, such that when the brush head (16) contacts the operator's teeth, a second switch (20) is automatically actuated and the motor (14) engaged. The brush head (16) is easily removed for replacement when the bristles become worn or allow use of the toothbrush (10) by multiple users.

Owner:FKA DISTRIBUTING CO LLC

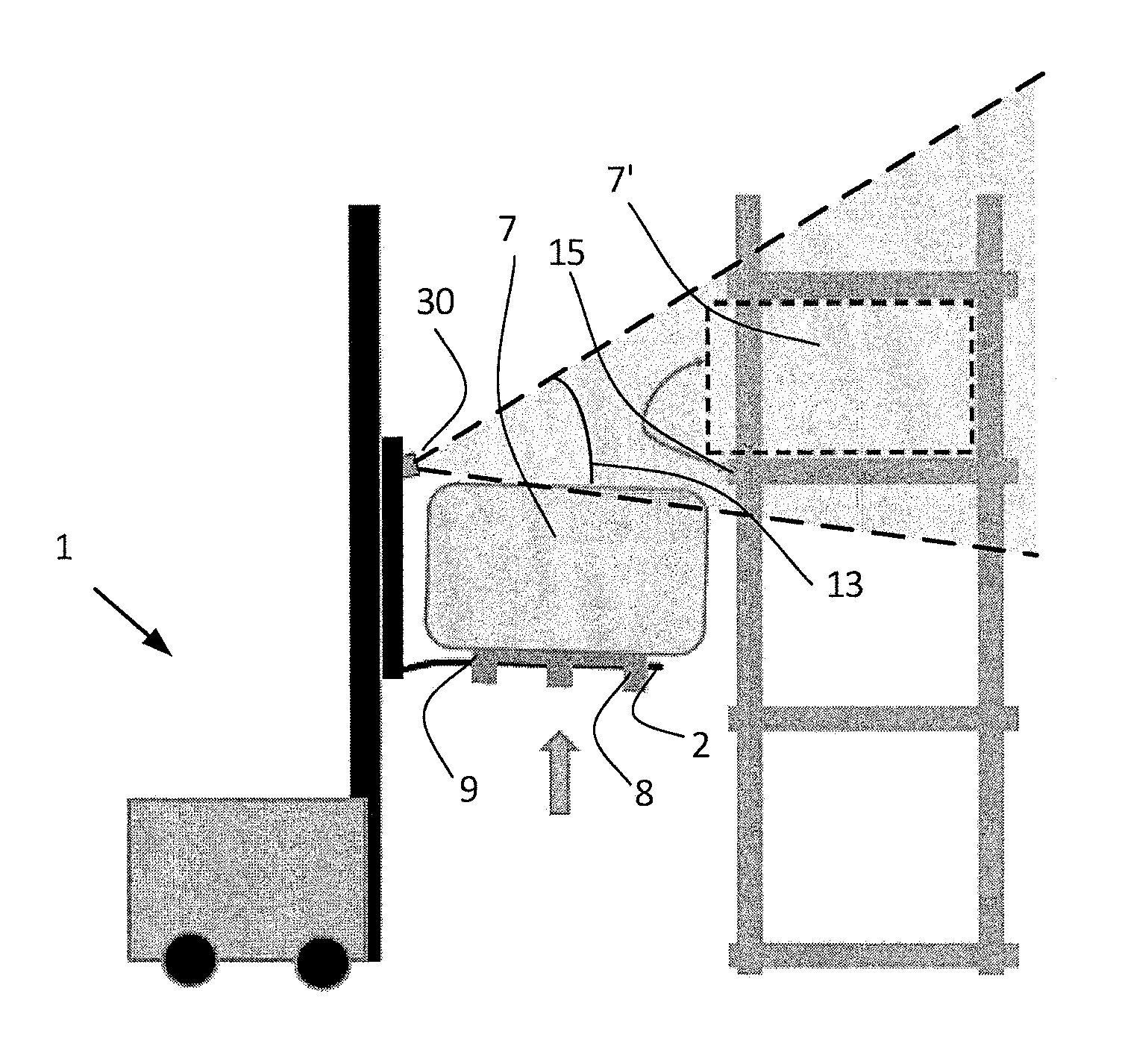

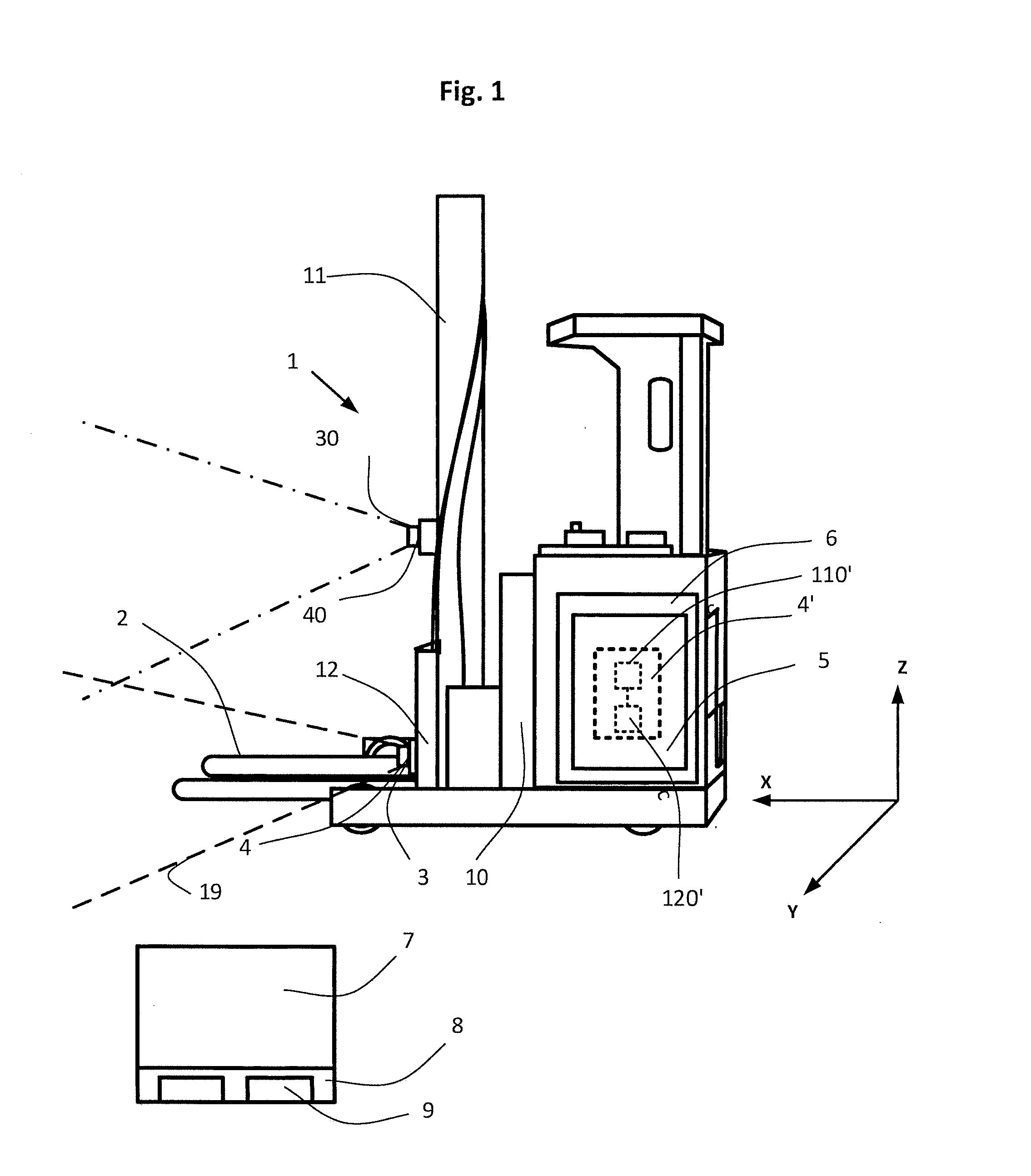

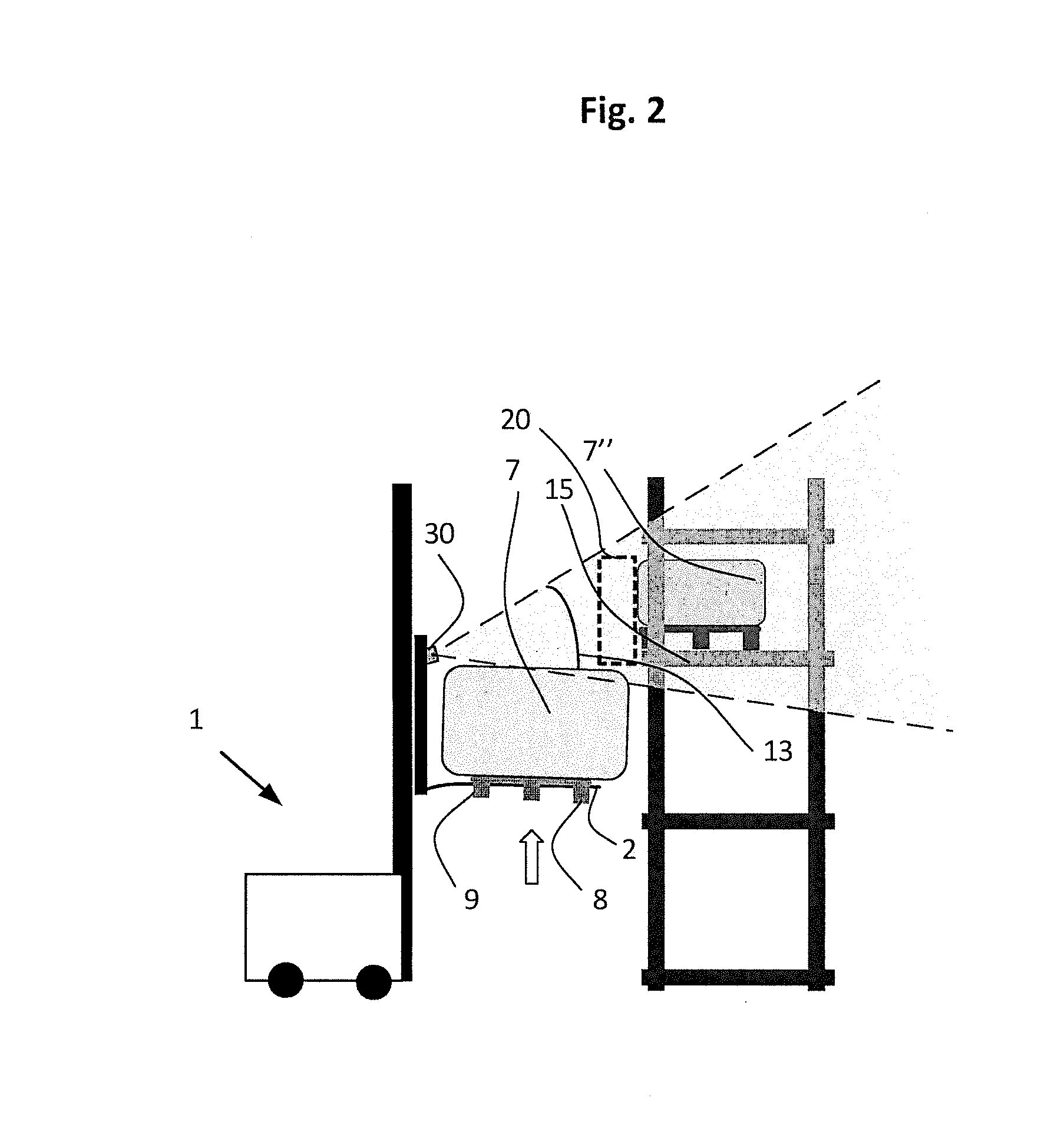

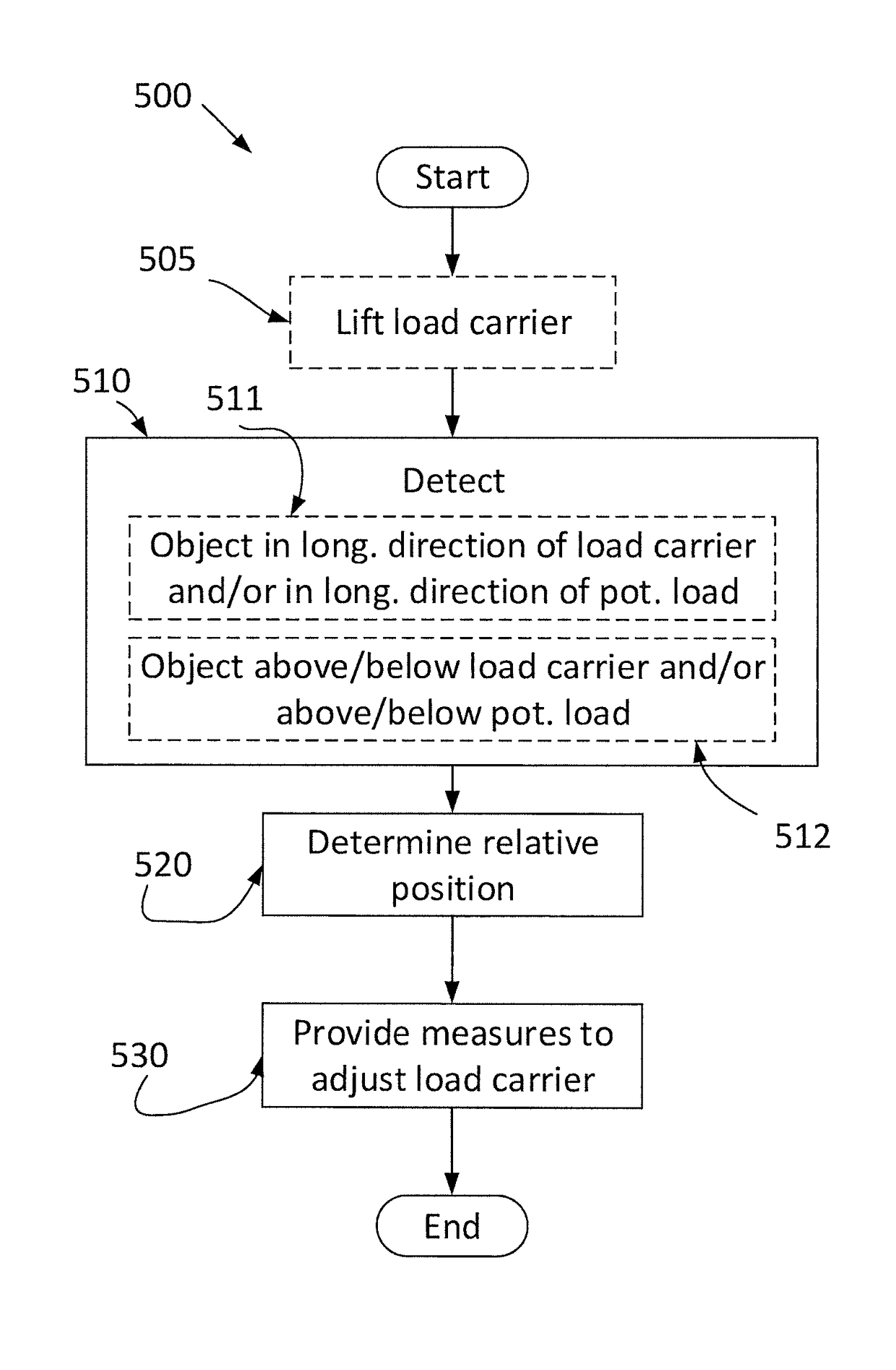

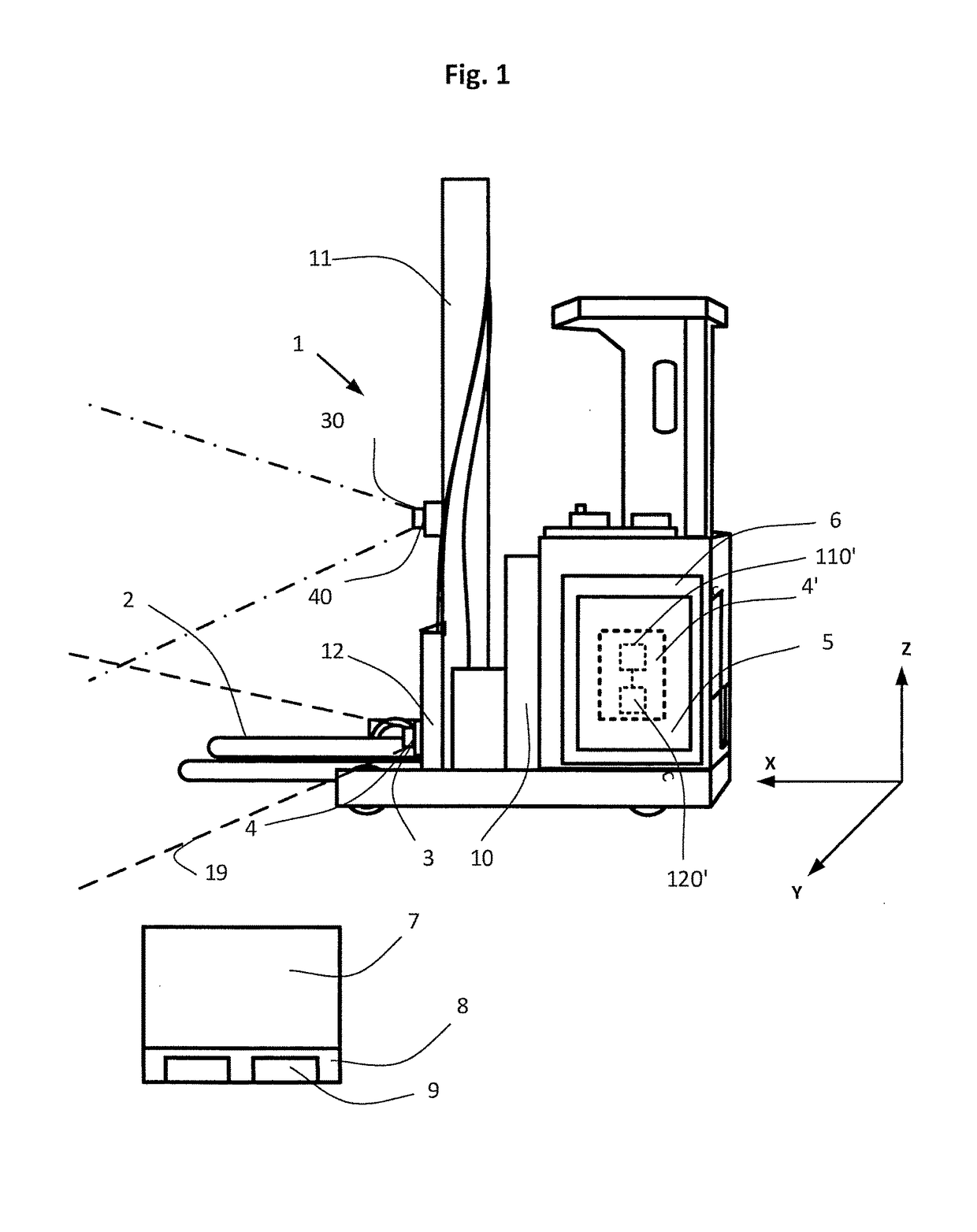

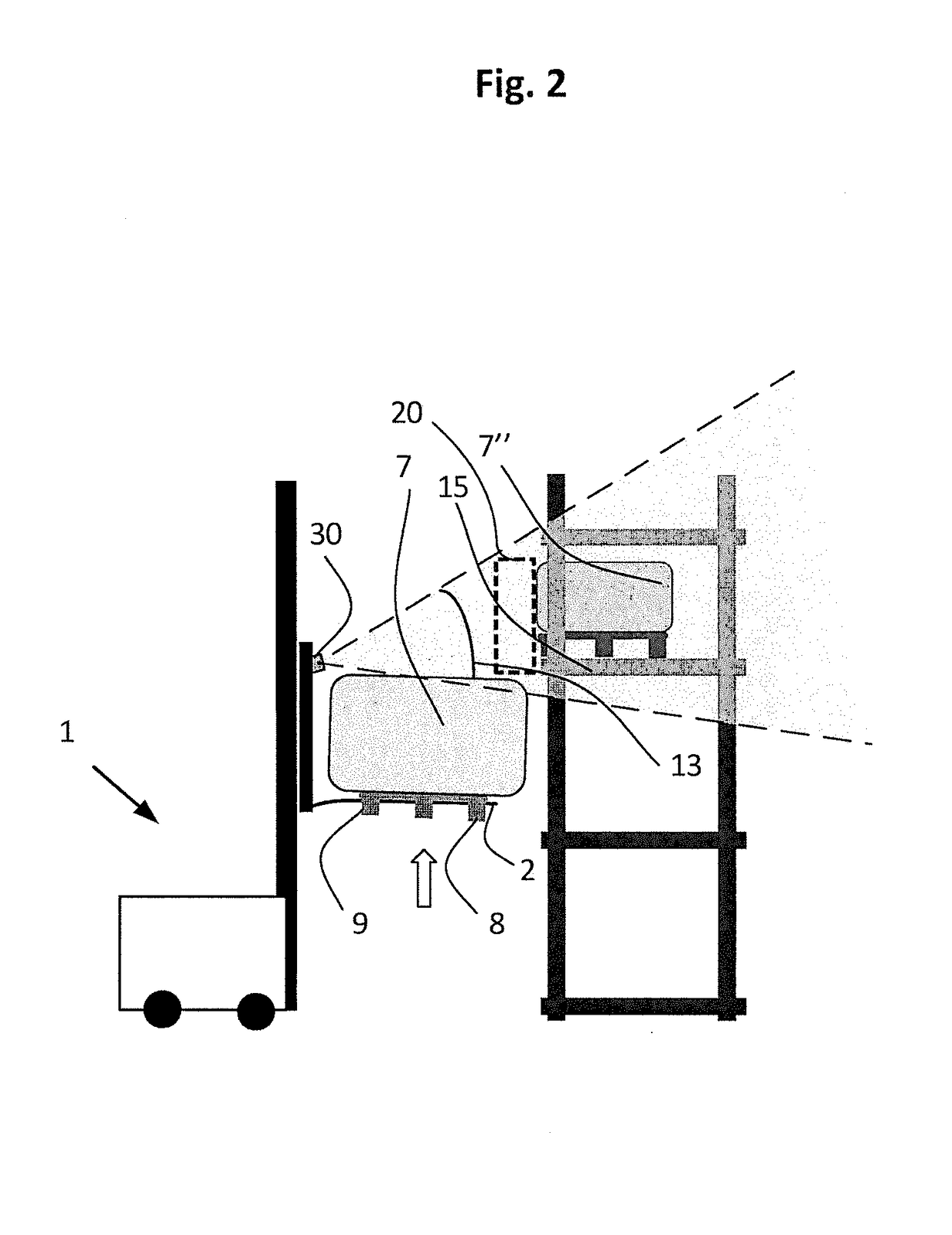

Fork-Lift Truck And Method For Operating a Fork-Lift Truck

ActiveUS20160090284A1Easy to implementImprove securityImage enhancementImage analysisEngineeringField of view

A fork-lift truck includes a load carrier, a first optical detector, an optical analysing unit, and a second optical detector. The analysing unit receives and analyses information from the second optical detector, wherein the first and second optical detector are movable together with the load carrier, and the first optical detector is positioned in relation to the load carrier, such that a first field of view includes at least a part of the load carrier and an extension of the load carrier. The second optical detector is positioned, such that a second field of view includes a predetermined volume above the load carrier The position and orientation of the second detector is calibrated in relation to a predetermined position on the fork-lift truck, in case one or more objects are positioned in the predetermined volume, at least one three-dimensional relative position can be determined.

Owner:TOYOTA MATERIAL HANDLING MFG SWEDEN

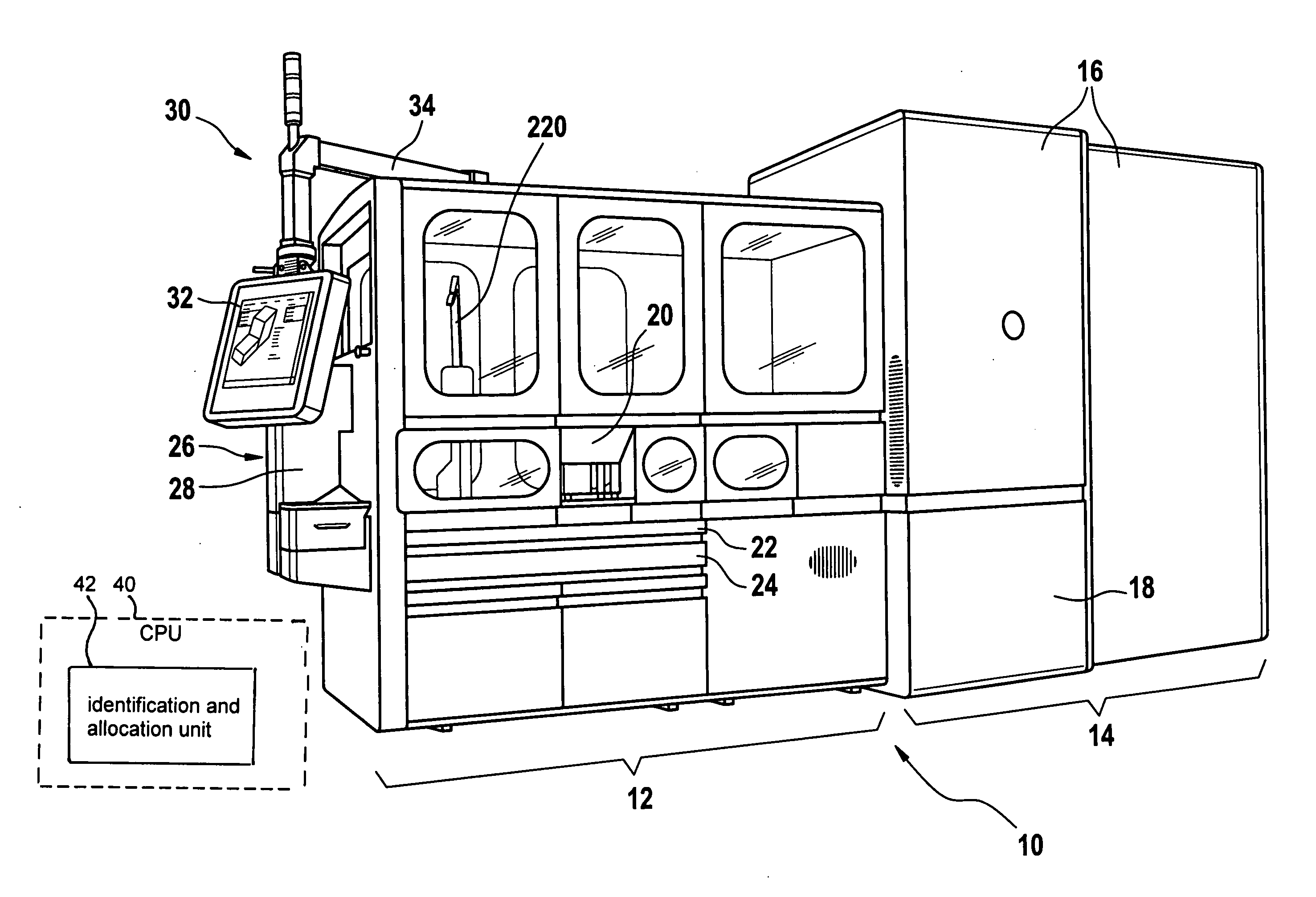

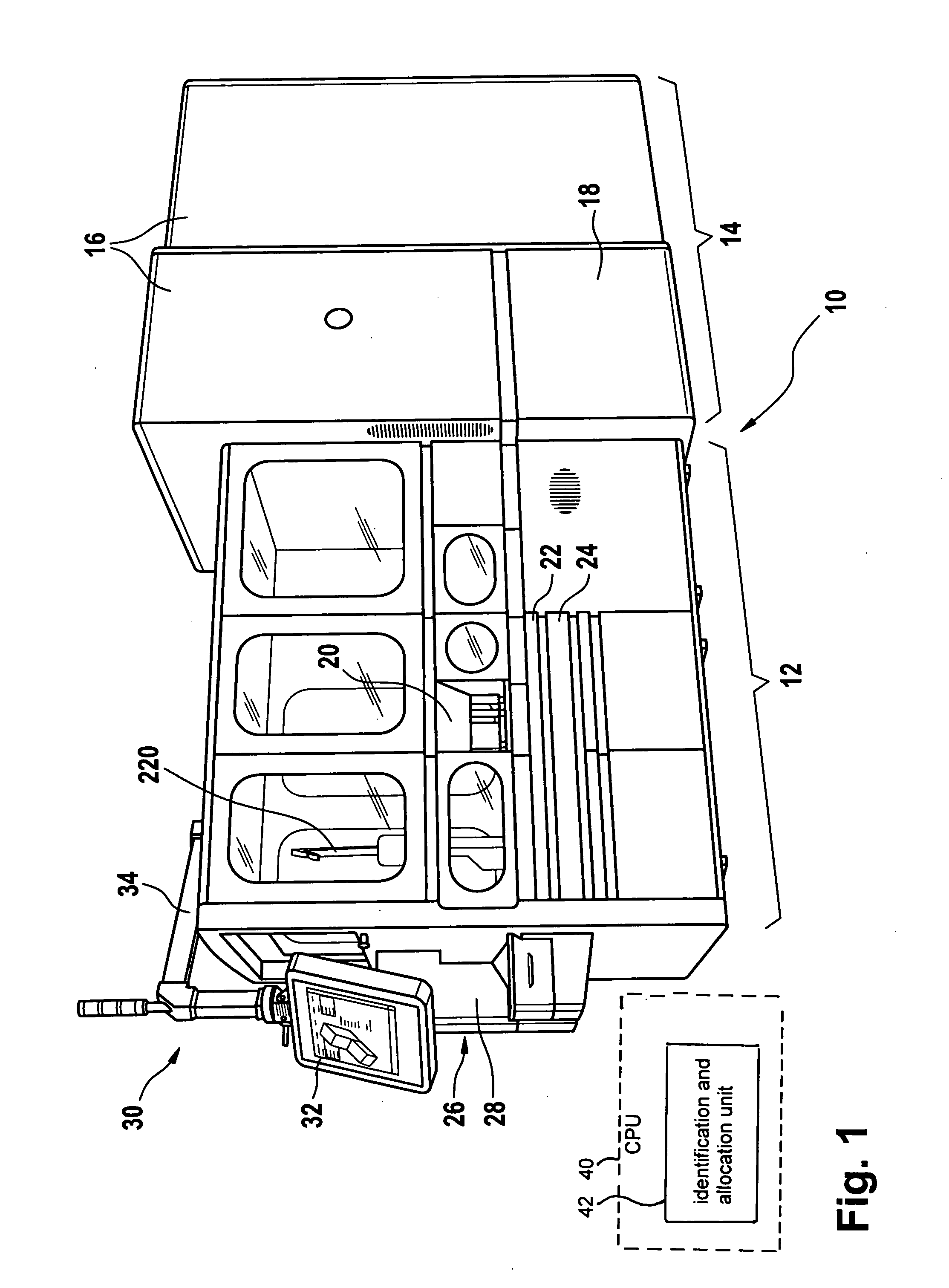

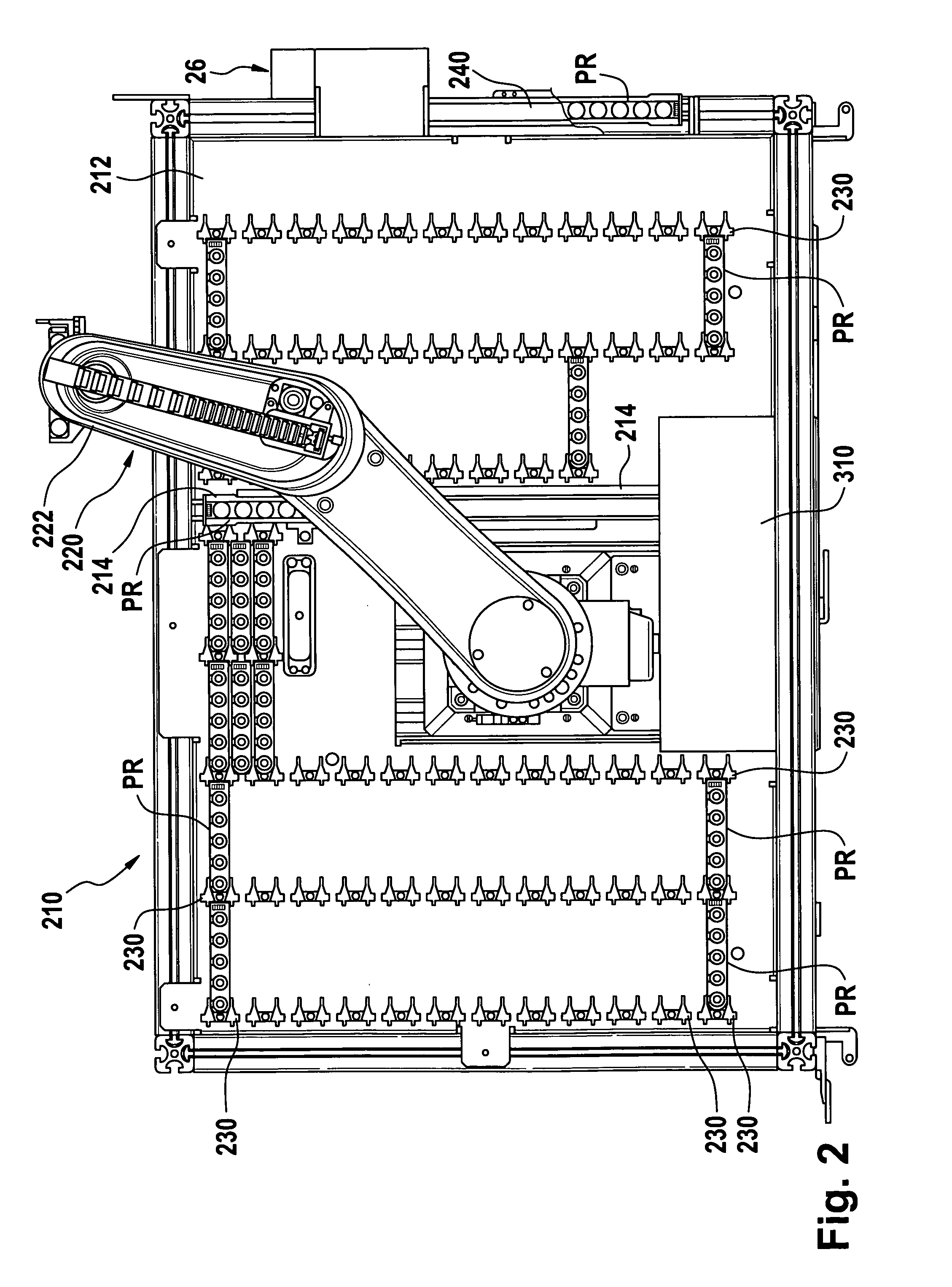

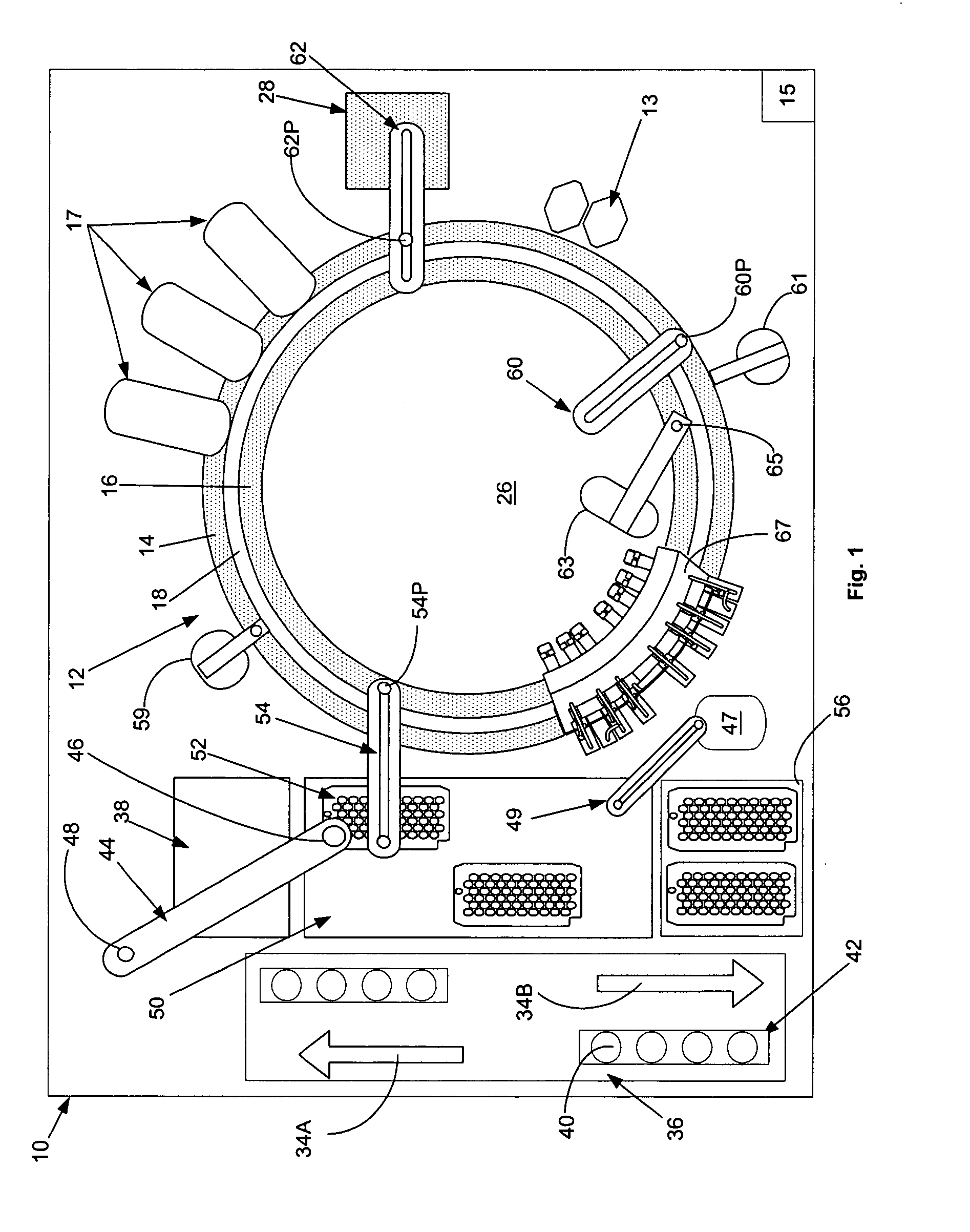

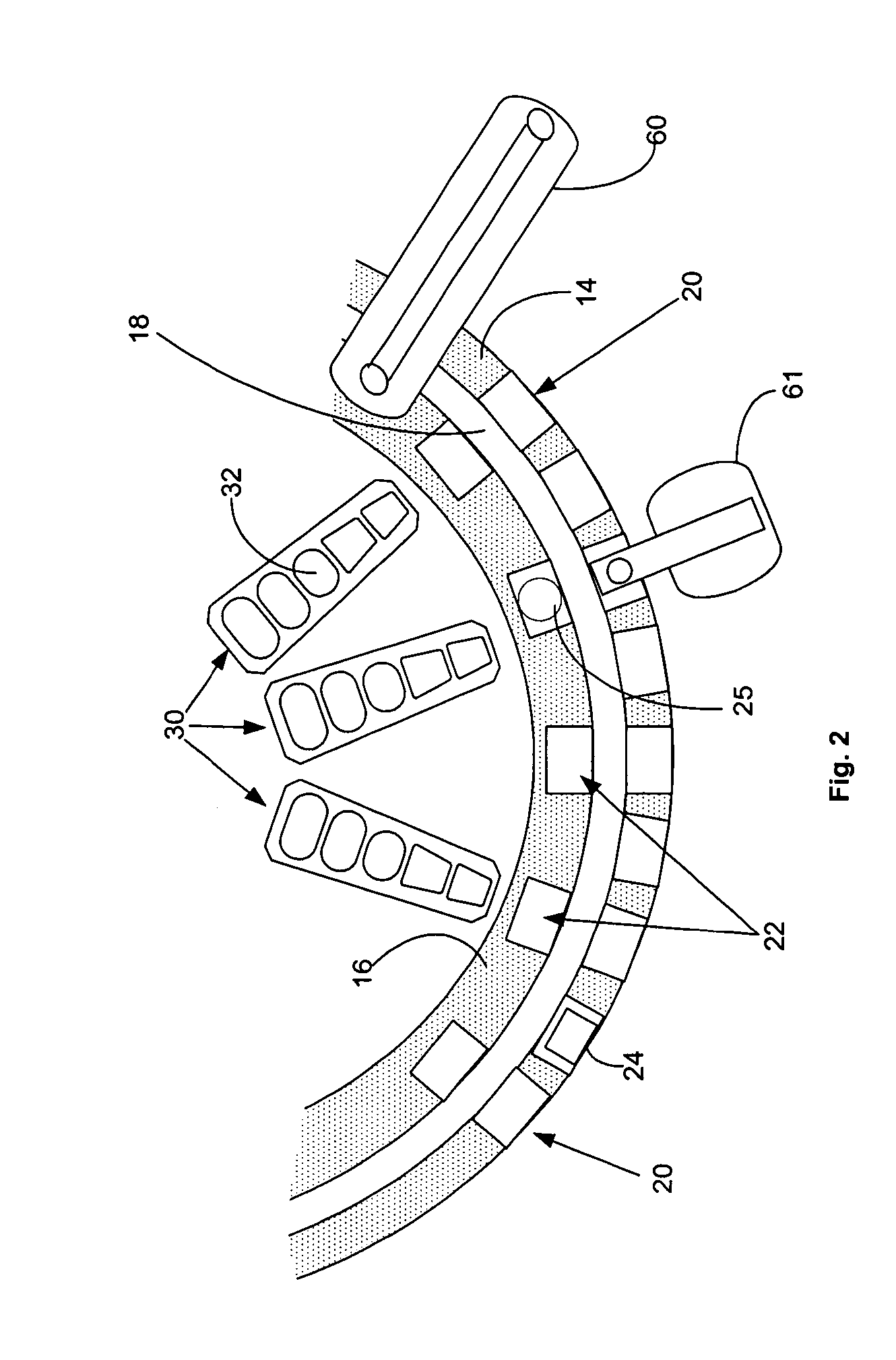

Method and laboratory system for handling sample tubes and an image analyzing unit

ActiveUS20100018330A1Reduce riskReduce breakageSamplingCharacter and pattern recognitionError processingEngineering

A method and laboratory system for handling sample tubes and an image analysing unit are disclosed. The laboratory system comprises a transfer unit for transferring incoming primary racks (PR) containing sample tubes (S), an image analysing unit (310), and an identification and allocation unit. The method to handle laboratory sample tubes includes steps of: transferring an incoming primary rack (PR) containing sample tubes (S) to the image analysing unit (310); determining, in the image analysing unit (310), geometry parameters of at least one sample tube contained in the primary rack by means of image analysing; comparing for each sample tube the determined geometry parameters with predetermined geometry criteria and identifying whether the sample tube's geometry fulfils the predetermined criteria; in case of fulfilment, categorising the sample tube as system conform; otherwise categorising the sample tube as non-system conform. Each sample tube identified as system conform is entered into further processing and each sample tube identified as non-system conform is entered into error processing.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

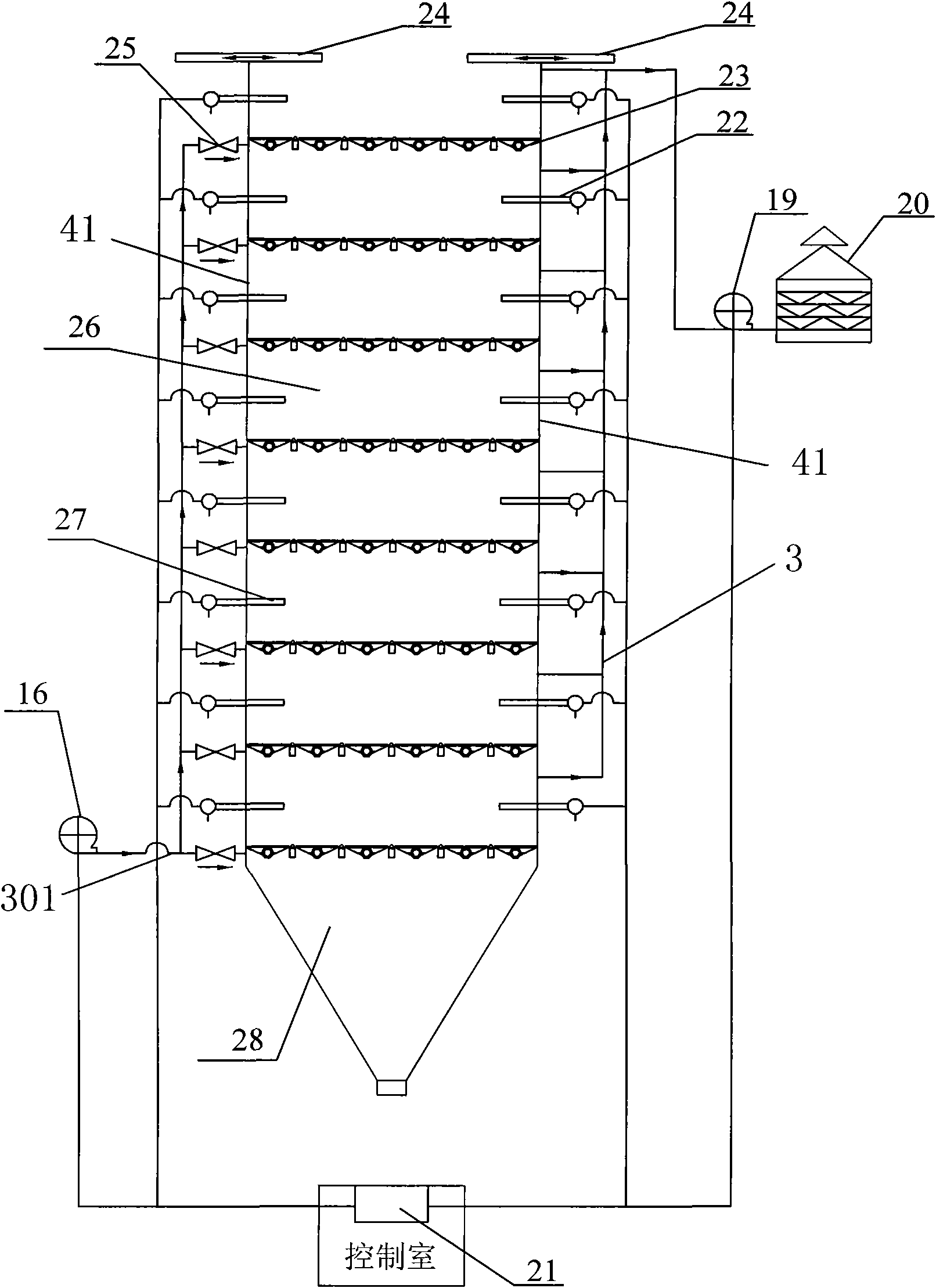

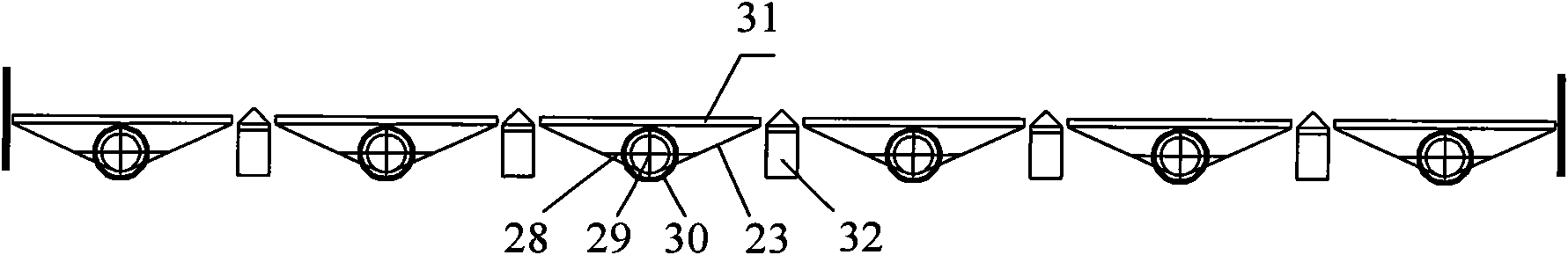

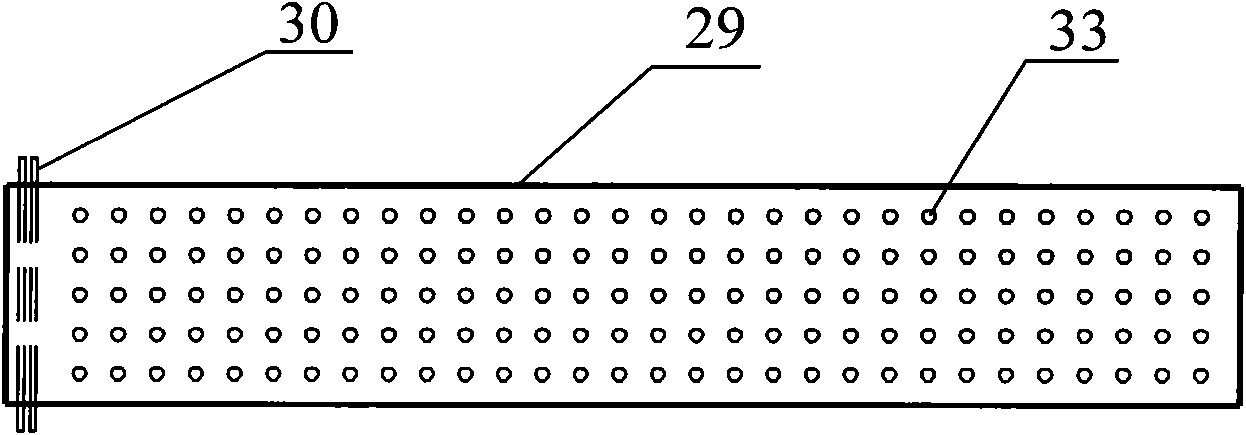

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

Fork-lift truck and method for operating a fork-lift truck

ActiveUS9828223B2Easy to automateImprove securityImage enhancementImage analysisEngineeringField of view

A fork-lift truck includes a load carrier, a first optical detector, an optical analyzing unit, and a second optical detector. The analyzing unit receives and analyses information from the second optical detector, wherein the first and second optical detector are movable together with the load carrier, and the first optical detector is positioned in relation to the load carrier, such that a first field of view includes at least a part of the load carrier and an extension of the load carrier. The second optical detector is positioned, such that a second field of view includes a predetermined volume above the load carrier The position and orientation of the second detector is calibrated in relation to a predetermined position on the fork-lift truck, in case one or more objects are positioned in the predetermined volume, at least one three-dimensional relative position can be determined.

Owner:TOYOTA MATERIAL HANDLING MFG SWEDEN

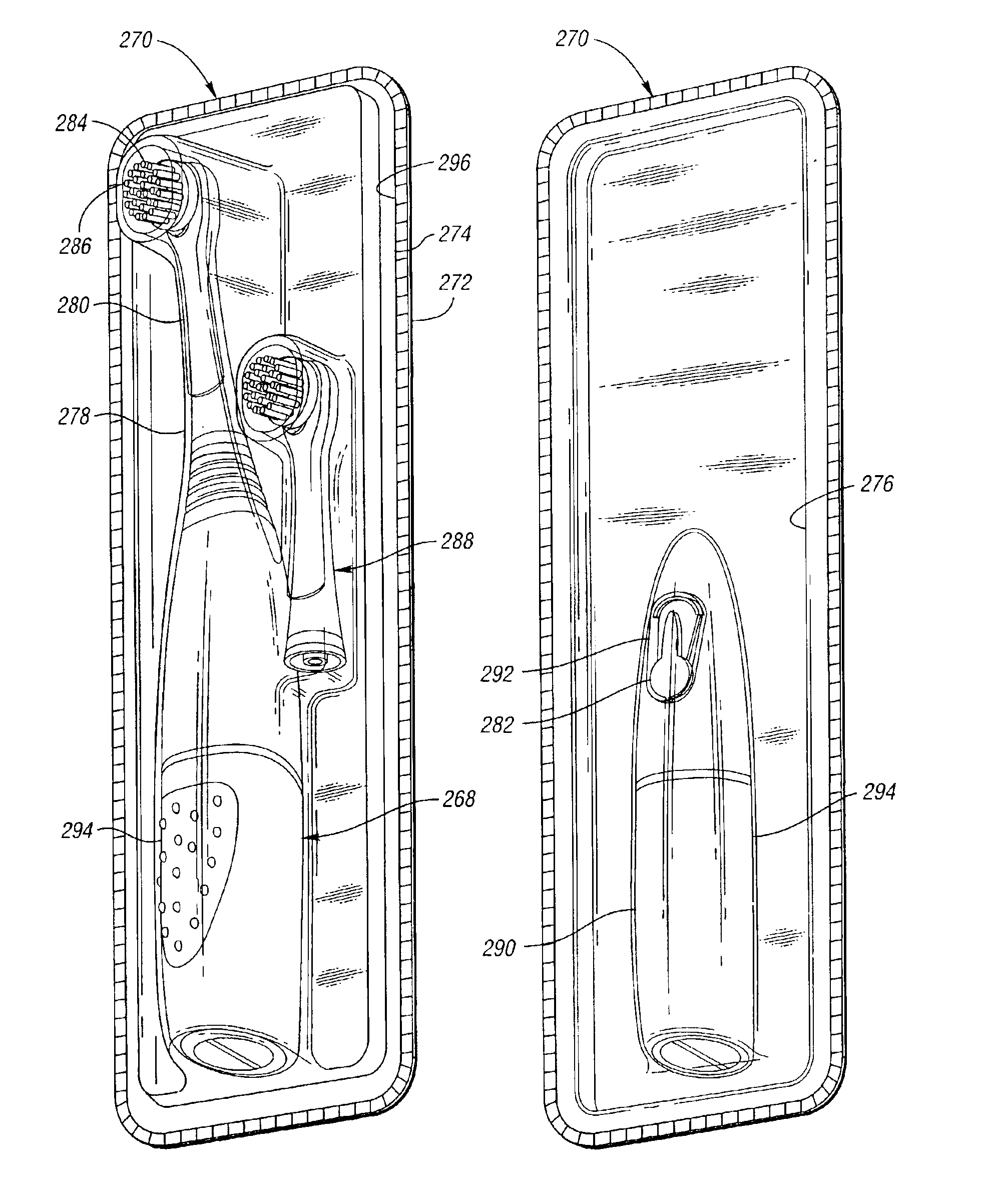

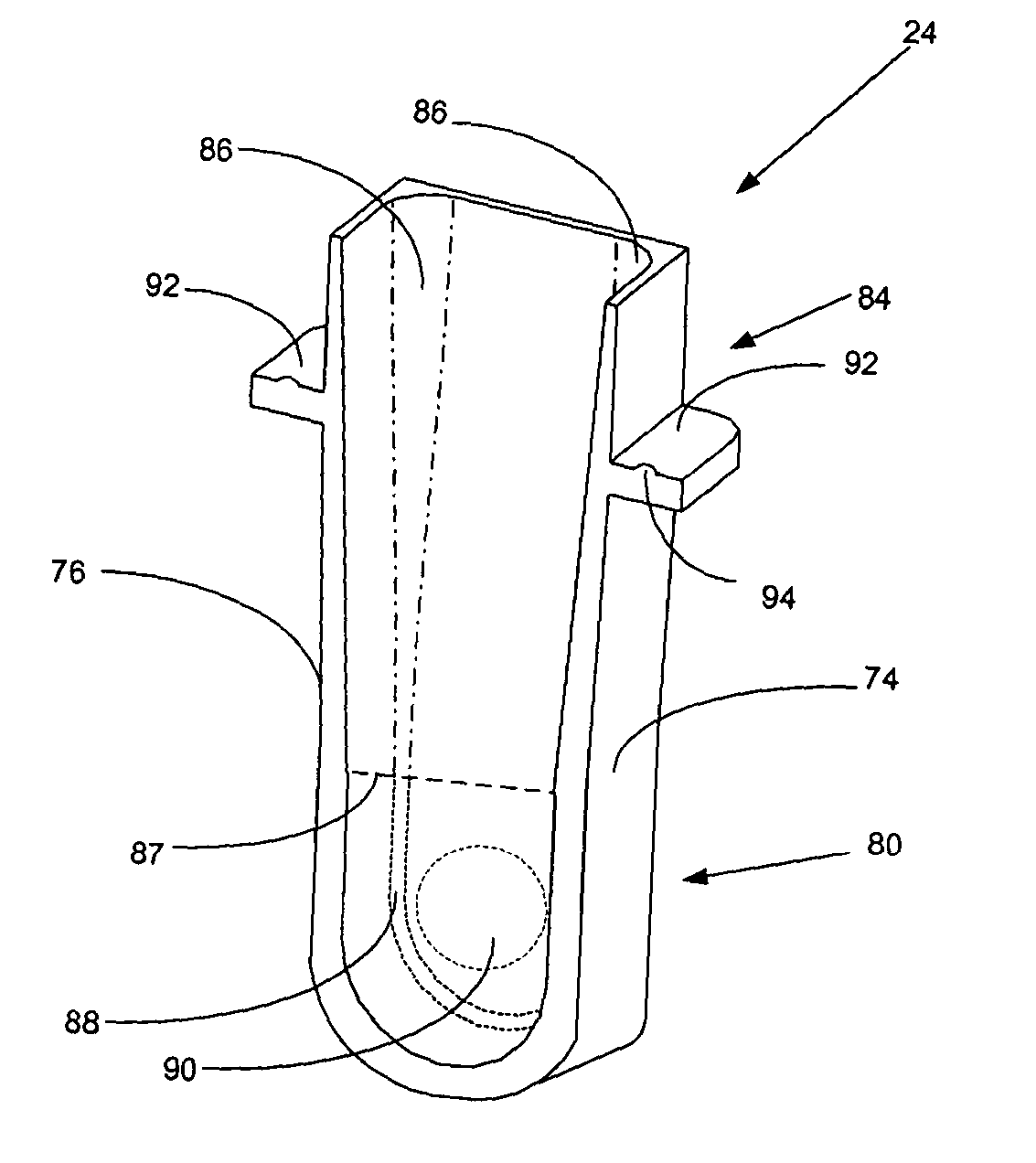

Automatic electric toothbrush in a display package

A motorized electric toothbrush in a display package includes a first switch to facilitate automatic motorized operation of the toothbrush. When the first switch is in one position, applying a force to a brush head portion of the toothbrush actuates a second switch and causes the motor to engage. A package body includes a flexible portion to allow an operator to apply a force to the brush head portion through the package body. The removable brush head portion is easily replaced when the bristles become worn, or to allow use of the toothbrush by another user.

Owner:FKA DISTRIBUTING CO LLC

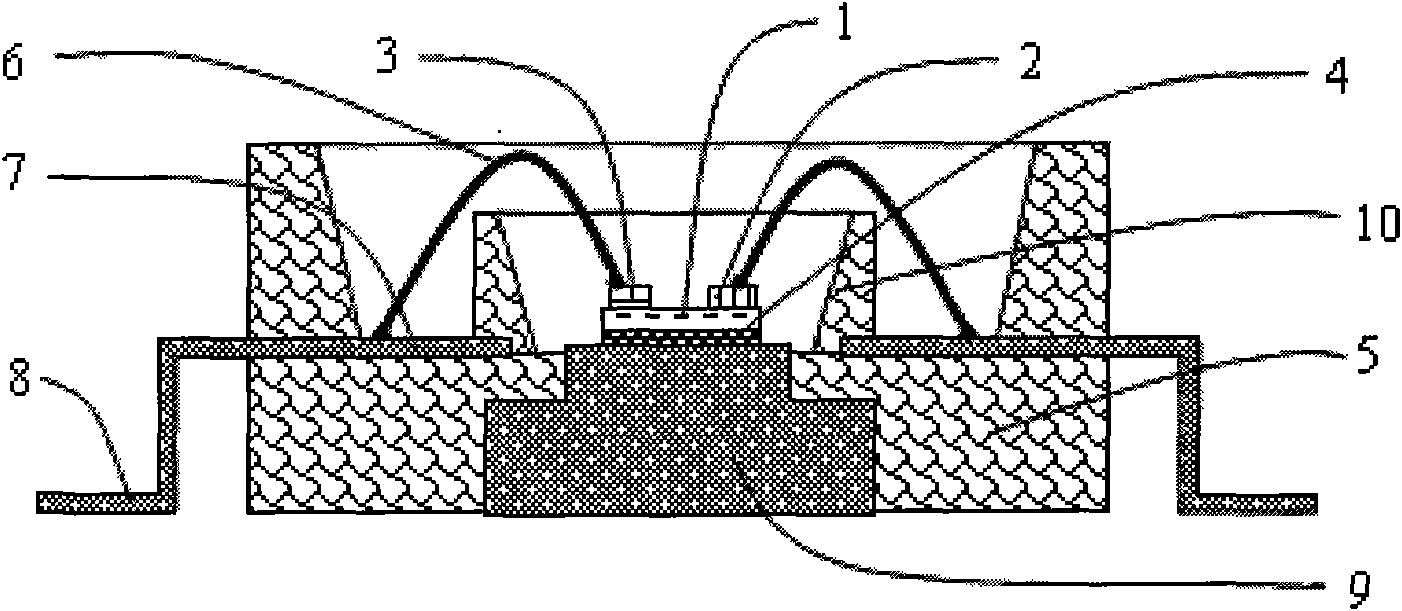

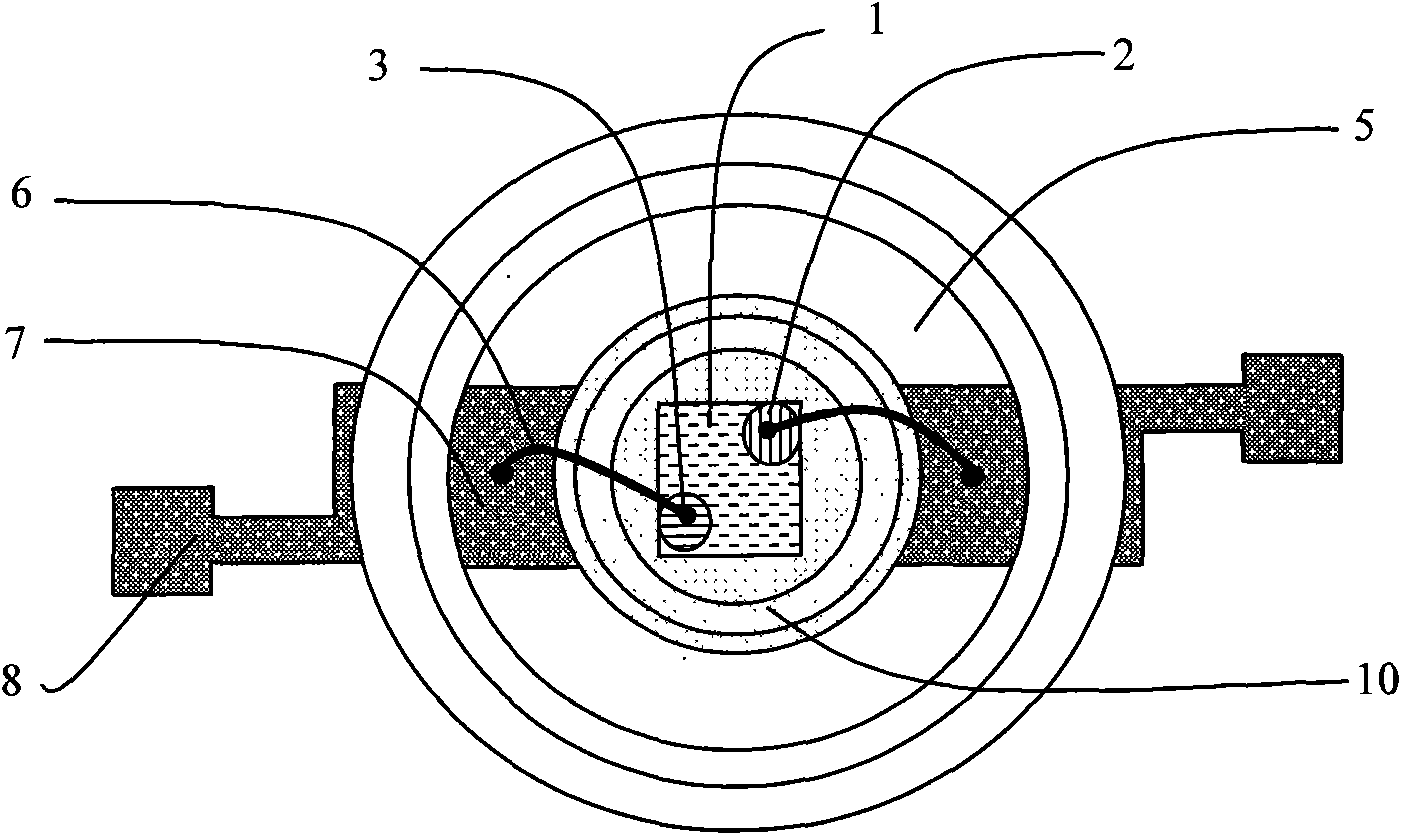

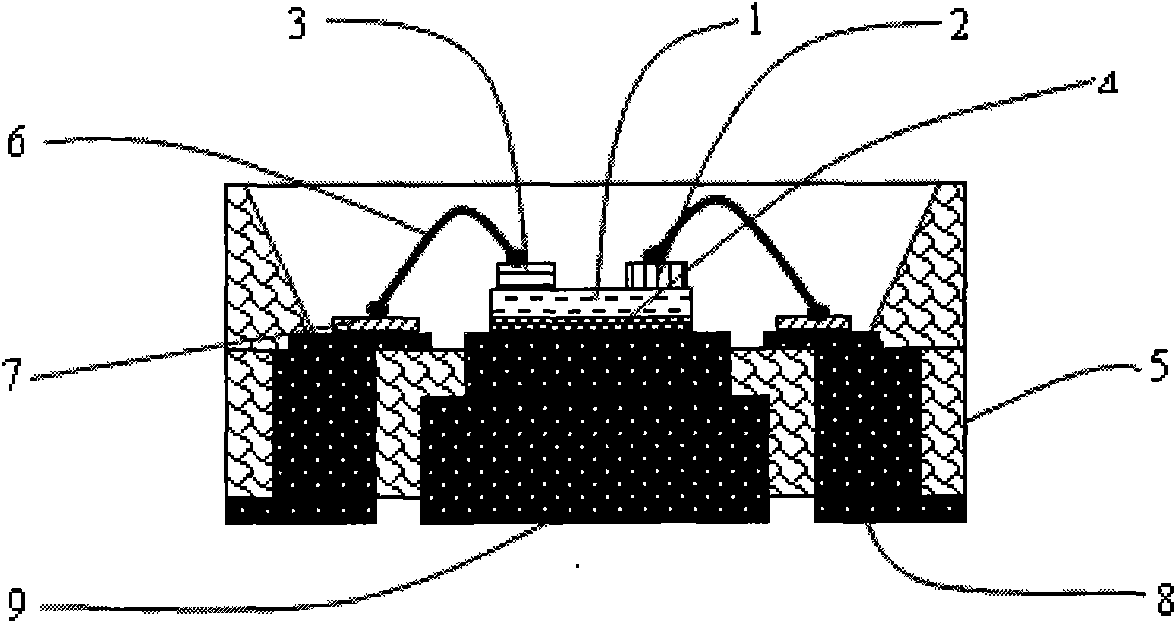

Flip-chip integrated encapsulation structure of LED and method thereof

InactiveCN101567411ABroaden applicationSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingMiniaturization

The invention provides a novel light emitting diode (LED) encapsulation structure which directly adopts a silicon dice substrate as both a surface mounting bracket and a radiation channel of an integrated structure support of an LED chip; a front electrode connecting layer is arranged on the front surface of the silicon dice substrate; the front electrode connecting layer on the front surface of the silicon dice substrate is connected with an electrode metal bonding pad at the back of the silicon dice substrate through a lead of a silicon groove side-wall or a lead of a through-hole of the silicon dice substrate; and at least one LED chip is welded directly by flip-chip on the front electrode connecting layer of the silicon dice substrate with an optical source through a metal bump. The invention also provides a method for manufacturing the LED encapsulation structure. The invention avoids steps of die bonding and gold-wire welding and enhances the connection reliability of chips and especially the connection reliability of multi-chip modules; and the invention leads the encapsulation of high-power LED and especially the encapsulation of multi-chip module to be miniaturized and also leads power-supply drive and circuits of LED protection and the like to be integrated on the silicon dice so as to provide a systematic and integrated encapsulation proposal for high-power LED illumination.

Owner:APT ELECTRONICS

Reaction cuvette having anti-wicking features for use in an automatic clinical analyzer

ActiveUS7138091B2Easy to automateWithdrawing sample devicesChemiluminescene/bioluminescenceCuvetteAutomated analyzer

A reaction cuvette having anti-wicking wall fillets that inhibit liquid wicking along an interior wall surface so that the reaction cuvette may be used in a cuvette-rewashing system in an automated analyzer and not be adversely affected by any reagent contaminants remaining from assays previously performed in said reaction cuvette. The anti-wicking wall fillets comprise a curvilinear taper extending from an open top downwards into the cuvette to form a rounded concave blend between the cuvette's front and back walls and side walls.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

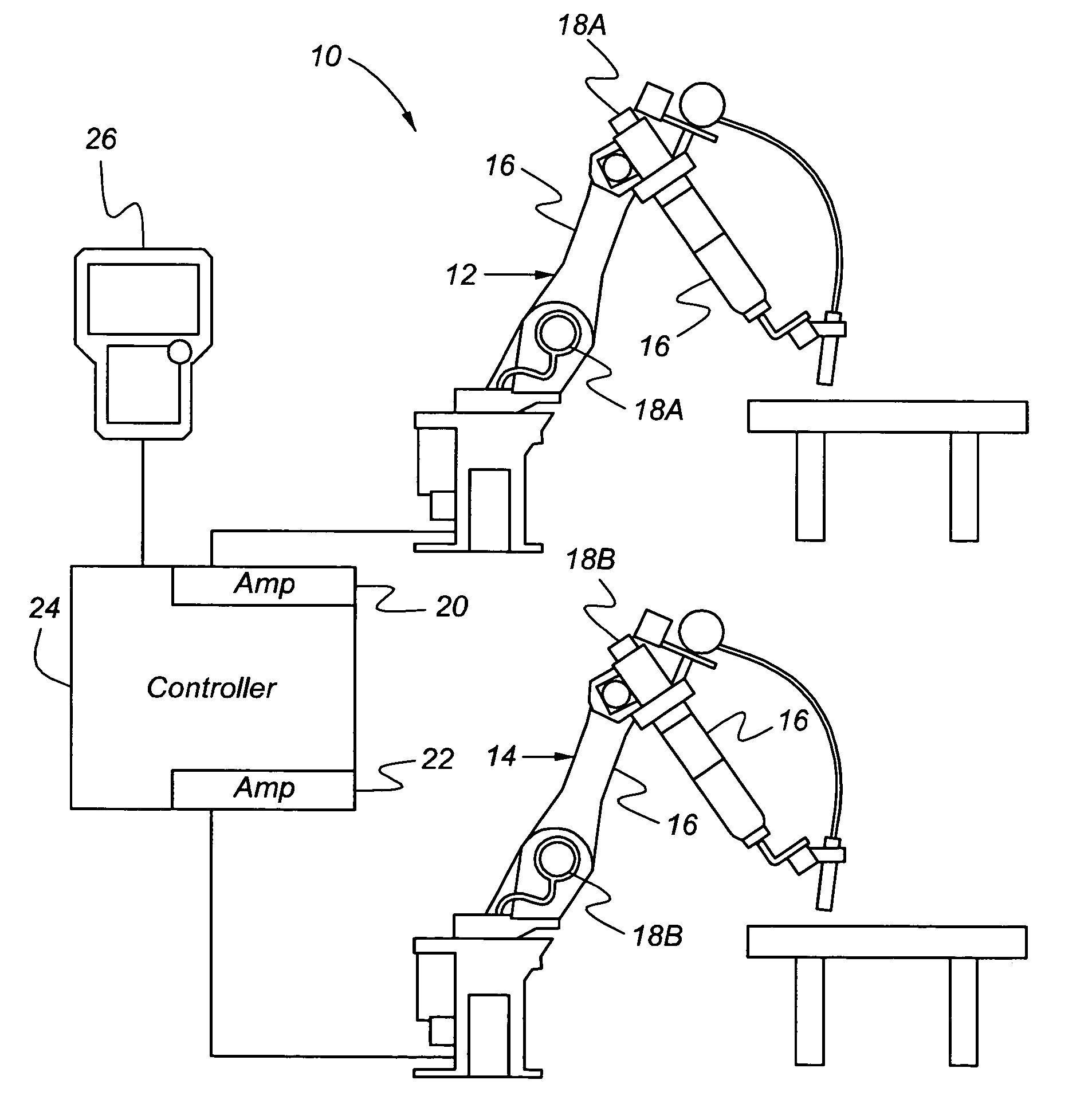

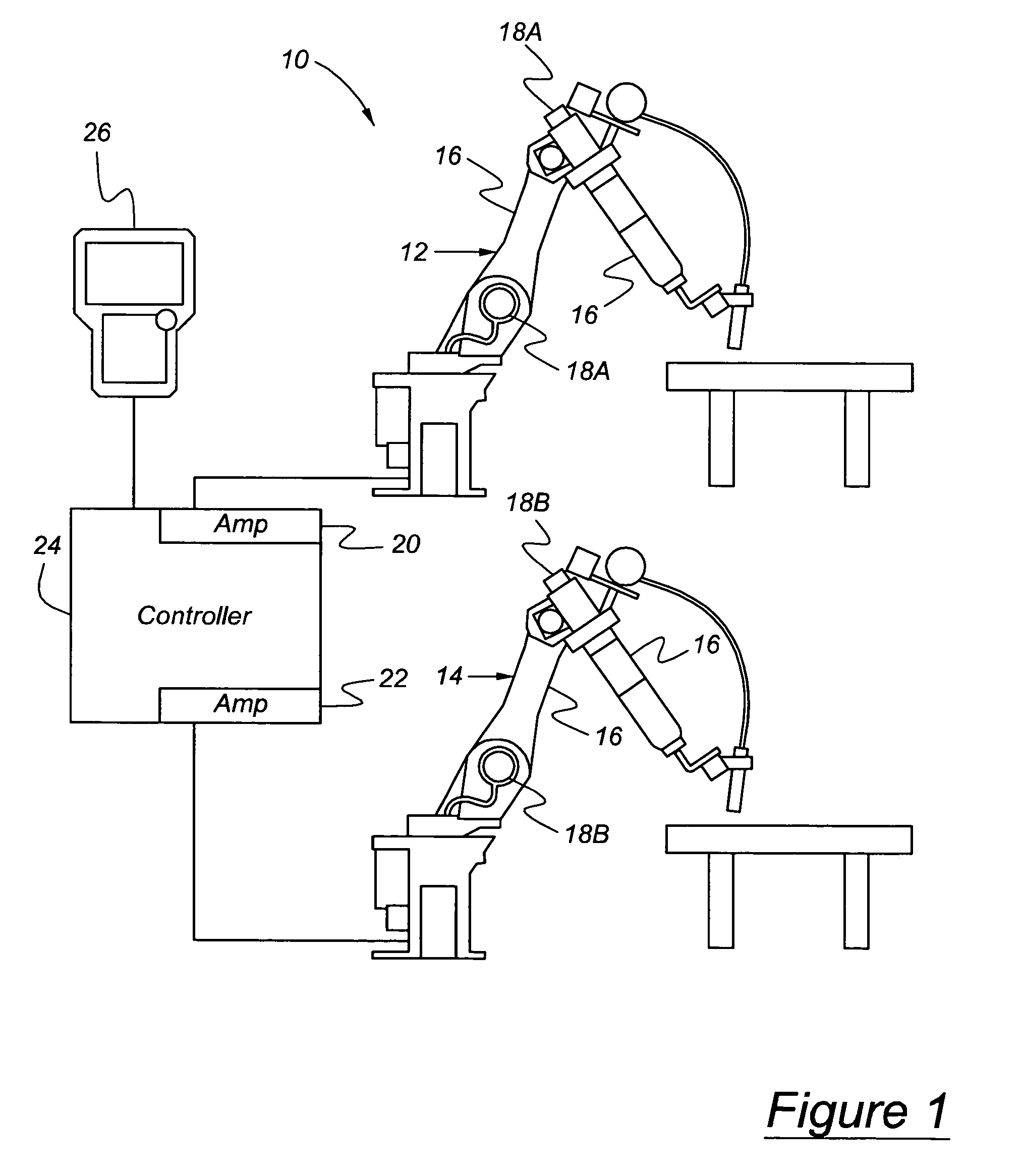

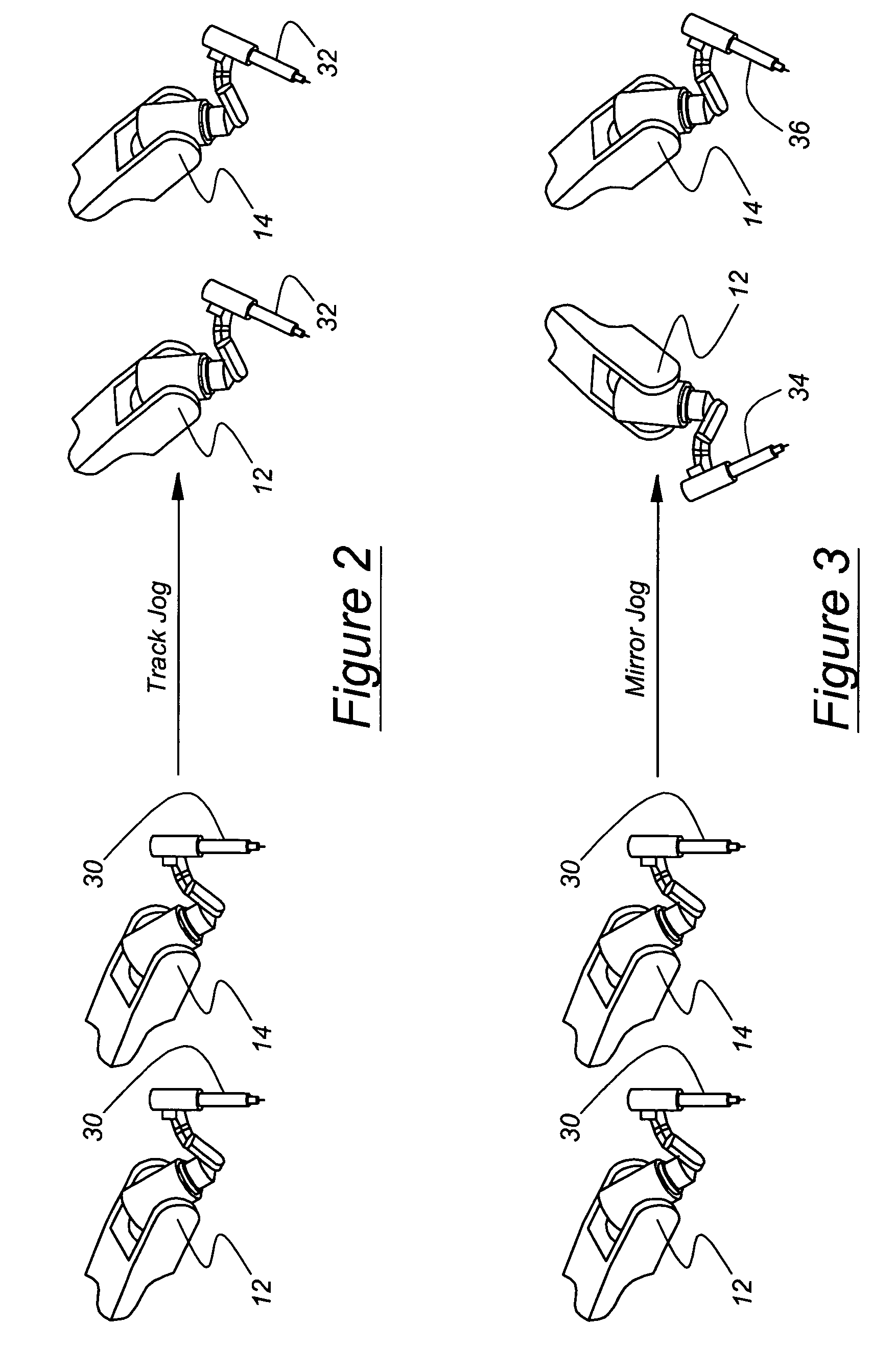

Multiple robot arm tracking and mirror jog

ActiveUS7211978B2Intuitive teachingShorten the timeProgramme-controlled manipulatorComputer controlMirror movementsEngineering

A system for performing the method of this invention includes a leader having a robot arm able to articulate about first axes and supporting an end effector. A follower includes a robot arm able to articulate about respective second axes. Servo motors articulate the leader arm about the first axes and the follower arm about the second axes. A user interface allows a user to jog the arm of the leader and to program movement of the arms for automatic execution such that the end effector reaches predetermined positions. A controller, operatively connected to the servo motors and the user interface, controls operation of the servo motors, moves the arm of the leader in accordance with the programmed movement, and moves the arm of the follower such that it tracks or mirrors movement of the leader.

Owner:FANUC ROBOTICS NORTH AMERICA

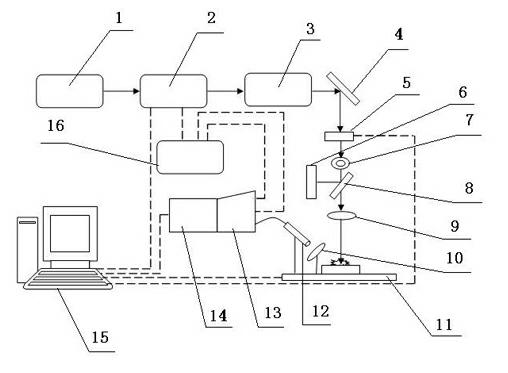

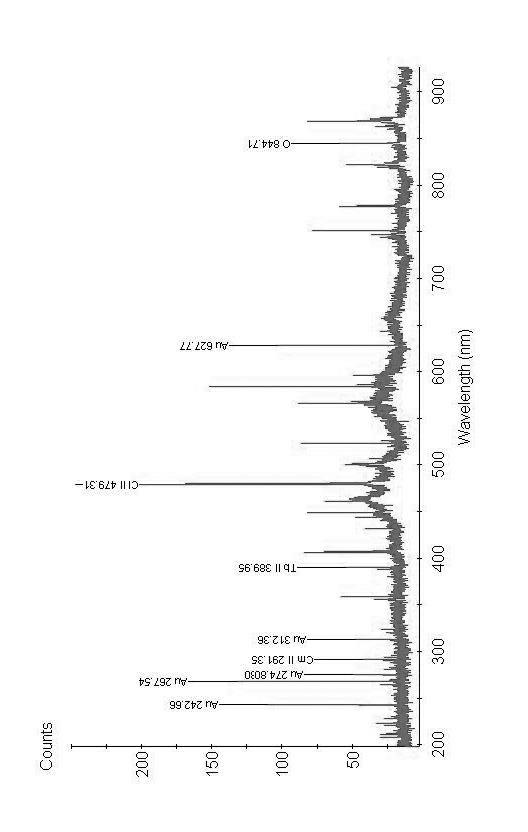

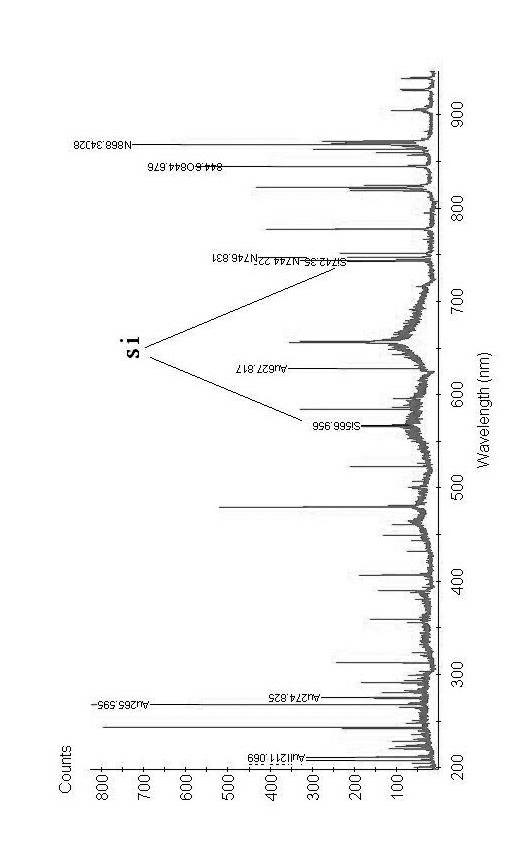

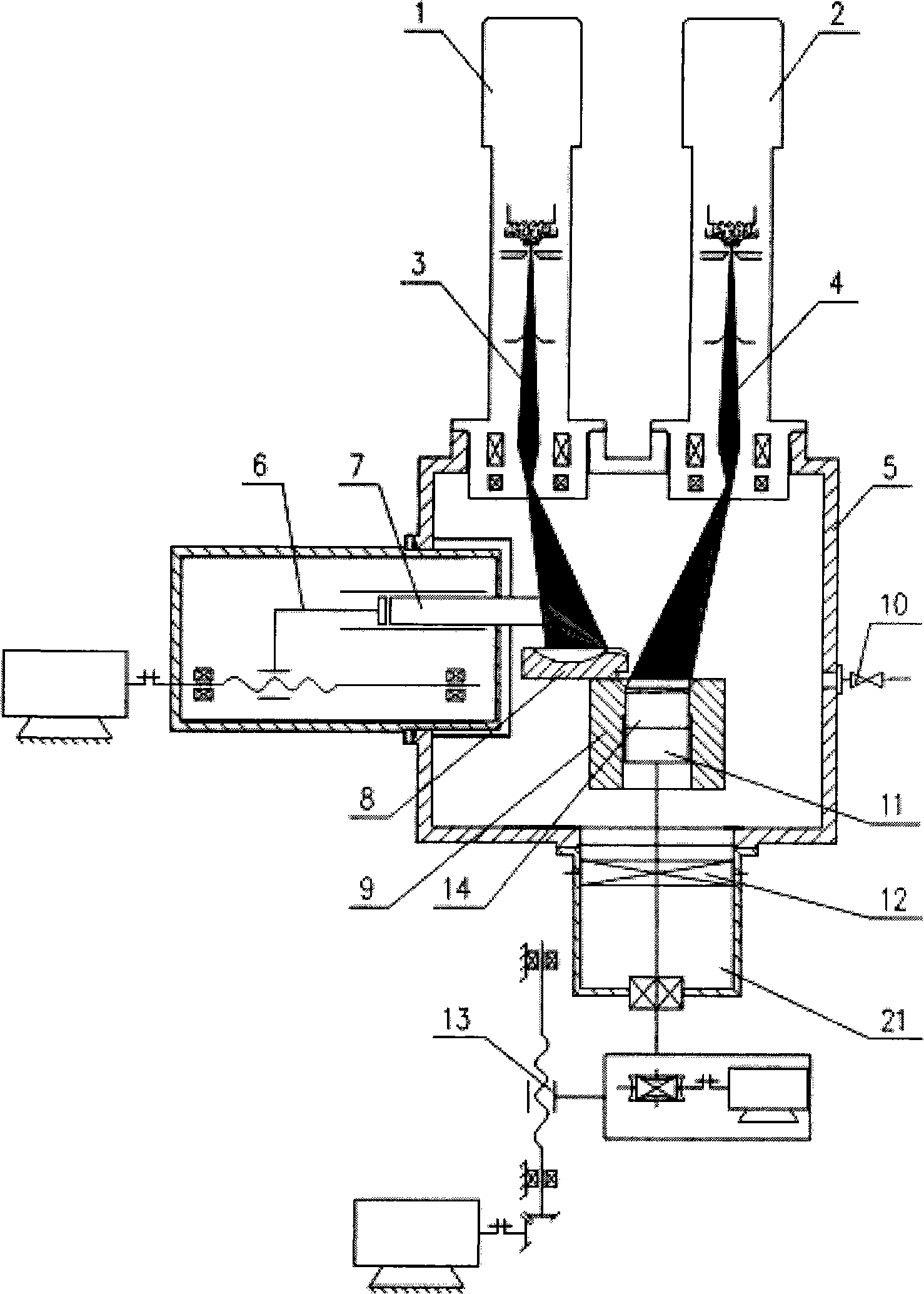

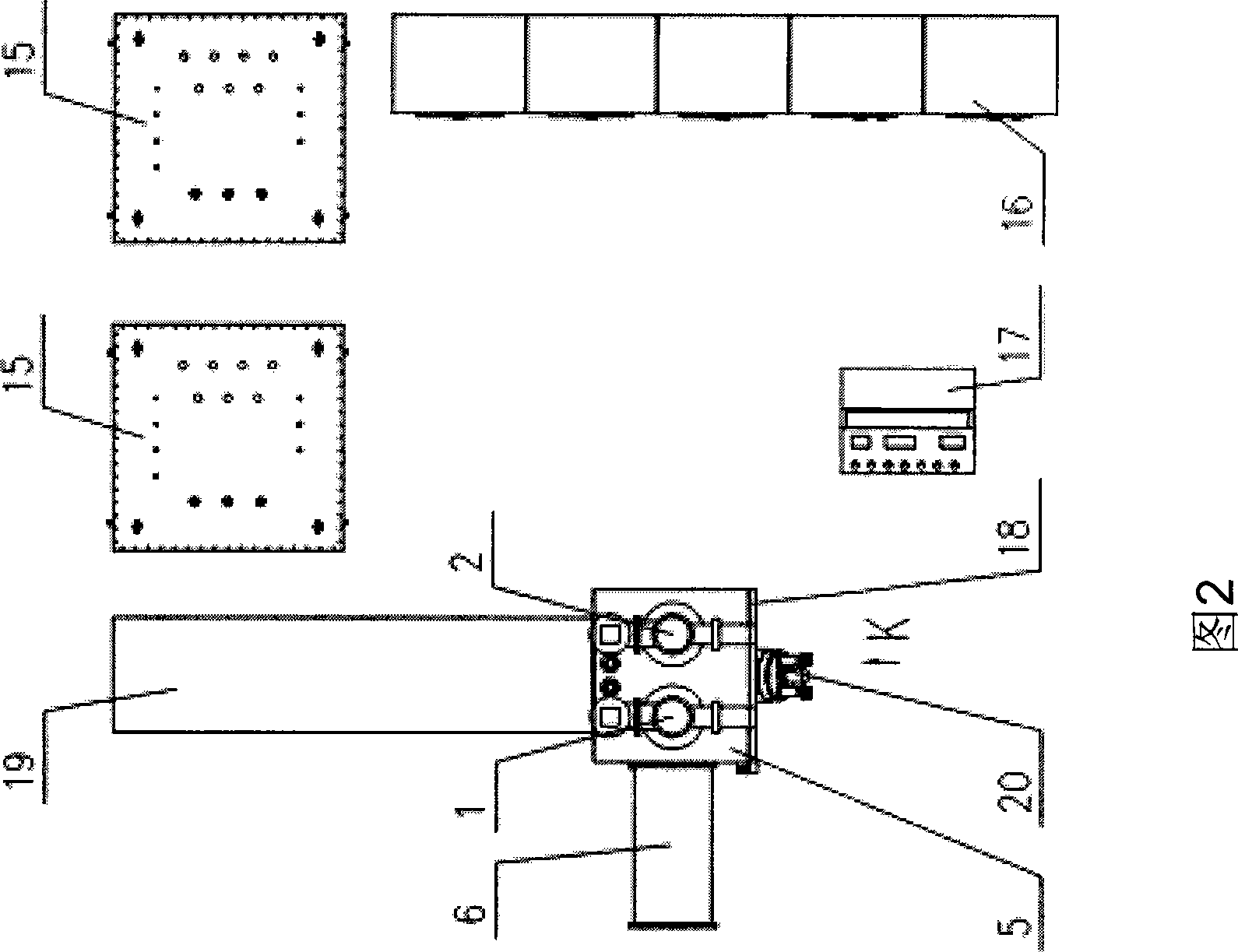

Femtosecond laser film micro-nanomachining real-time monitoring device

InactiveCN102636464AReduce processing efficiencyGuarantee processing qualityAnalysis by material excitationOptical pathData lines

The invention relates to a femtosecond laser film micro-nanomachining real-time monitoring device. The device comprises a laser generating system, an external light path system, a PC (poly carbonate) machine and a three-dimensional mobile platform, wherein laser sent by the laser generating system is focused on a focusing mirror through the external light path system; the device is also provided with a spectrum focusing mirror, a fiber optic probe, a spectrometer, an enlargement mode CCD (charge coupled device) and a time delay controller, wherein the spectrum focusing mirror and the fiber optic probe are fixed on the three-dimensional mobile platform; the spectrometer is connected with the fiber optic probe through data lines, and the spectrometer is also connected with the time delay controller through the data lines; and the time delay controller is connected with a femtosecond laser through a signal wire, and the femtosecond laser, the enlargement mode CCD, an optical gate and the three-dimensional mobile platform are connected with the PC machine through the signal lines. The device provided by the invention has the advantages that the equipment is simple, the operation is easy and simple, the applicability is wide, the film micromachining rapid detection is realized, the accuracy for detecting element is very high, the device almost can detect any element, and the detection efficiency and the reliability are greatly improved.

Owner:HUAIHAI INST OF TECH

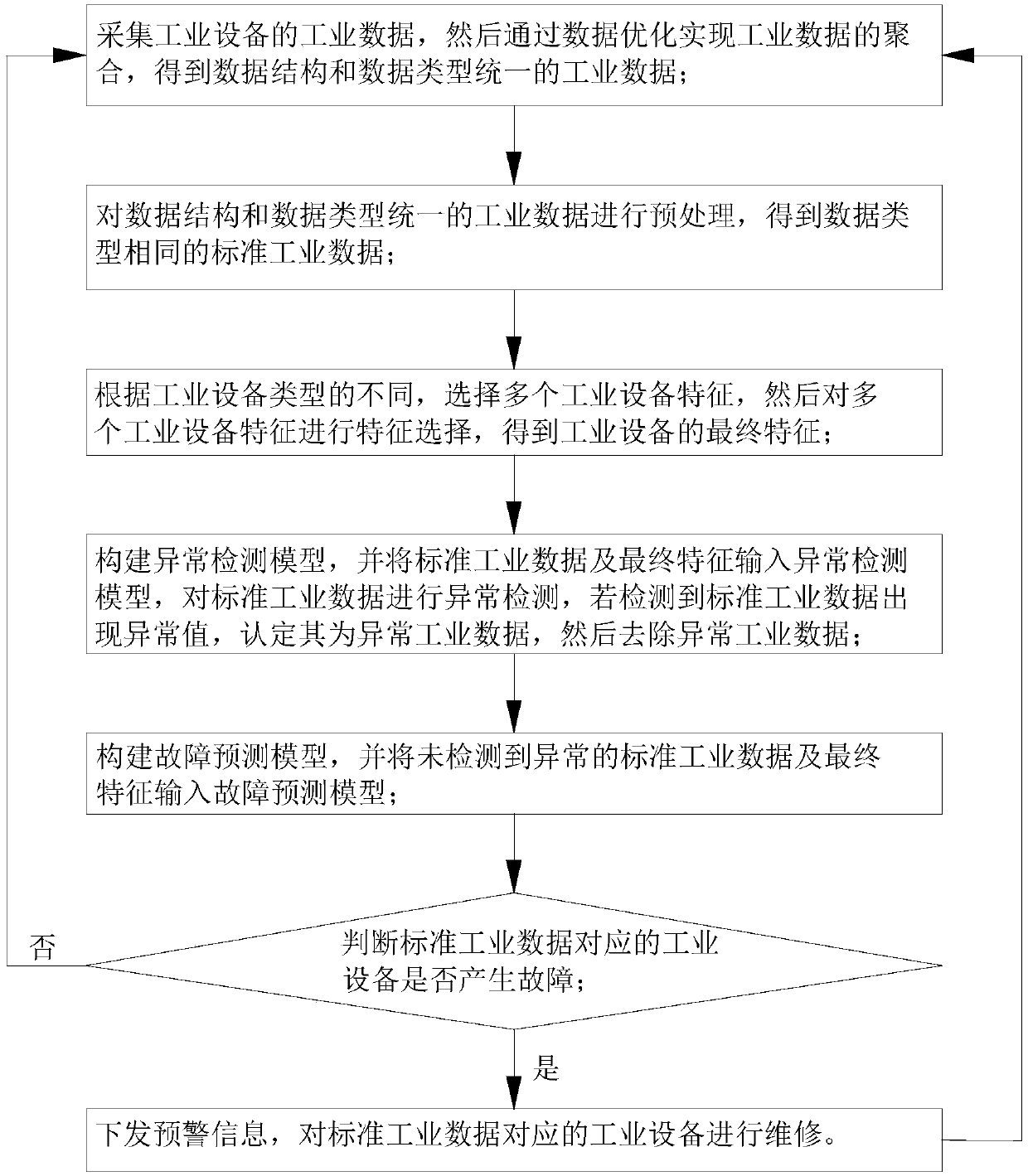

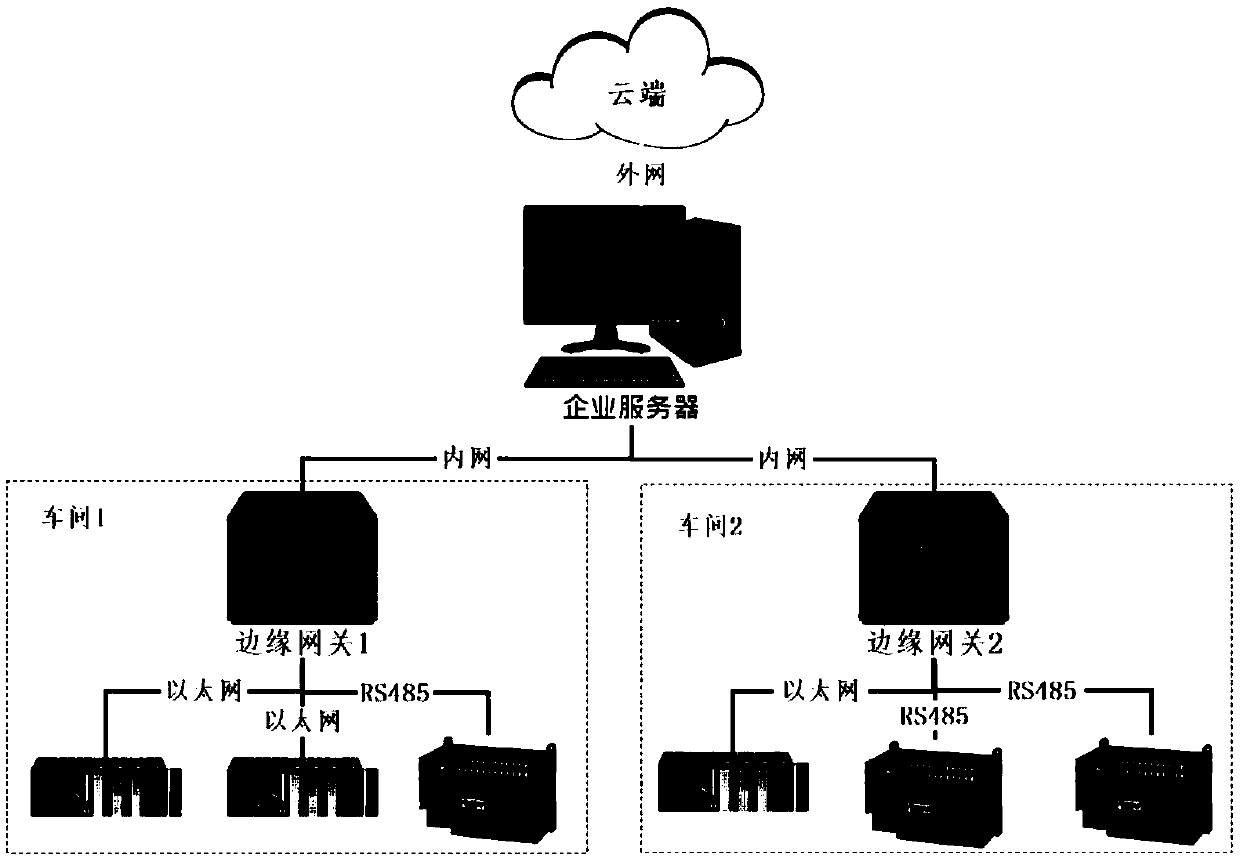

Predictive industrial equipment maintenance method and maintenance system based on edge computing

InactiveCN109635958AEnable predictive maintenanceAvoid Ineffective Manual WorkForecastingAnomaly detectionEdge computing

The invention relates to the technical field of industrial information collection and analysis, and aims to provide a predictive industrial equipment maintenance method and maintenance system based onedge computing. The invention discloses a predictive industrial equipment maintenance method based on edge calculation. The method comprises the following steps: S1, collecting industrial data; S2, preprocessing the industrial data to obtain standard industrial data; S3, performing feature selection to obtain a final feature; S4, constructing an abnormity detection model, inputting the standard industrial data and the final features into the abnormity detection model, and carrying out abnormity detection on the standard industrial data; and S5, constructing a fault prediction model, judging whether the industrial equipment corresponding to the standard industrial data has a fault or not, if yes, issuing early warning information, and if not, entering the step S1. A maintenance system comprises industrial equipment, an edge gateway and a server which are sequentially connected. Predictive maintenance of industrial equipment can be achieved, invalid manual operation is avoided, and automatic operation is facilitated.

Owner:成都航天科工大数据研究院有限公司

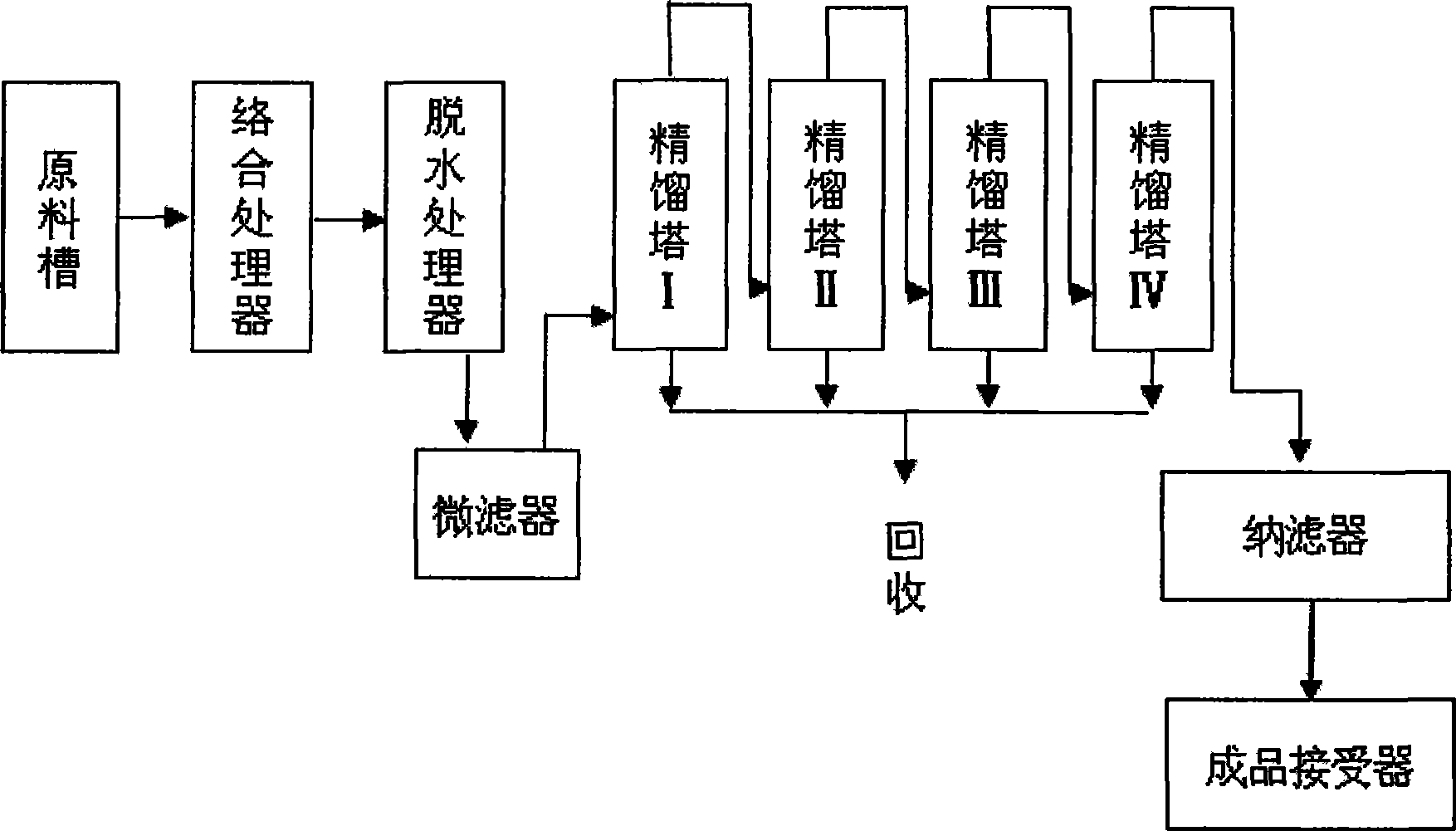

Method for preparing super-clean and high-purity isopropanol and apparatus thereof

ActiveCN101362675AEasy to processLow priceOrganic compound preparationHydroxy compound preparationSmall footprintImpurity

The invention relates to a method for preparing super-clean and high-purity isopropanol and a device thereof, and the high-purity isopropanol is mainly suitable for cleaning in the manufacture industry of large scale integrated circuit semiconductor devices in the microelectronic industry. The method is as follows: firstly, the industrial grade isopropanol material with mass percentage to be 98 percent is mixed with a metal ion complexing agent with 0.5-5 percent of the weight of the isopropanol material in a complexing processor, under the normal temperature and pressure, after 30-120 minutes, the mixture is fed into a dehydrating processor, and then mixed for 60-150 minutes with a dehydrating agent with 0.1-15 percent of the weight of the isopropanol material under the temperature of 60 DEG C to 100 DEG C in the dehydrating processor, and then the mixture is filtered by the microfiltration membrane under the operation pressure of 0.1-0.2MPa, the filtrate enters into a multilevel rectification tower, and the semi-finished product from the tower is filtered by a nanofiltration membrane under the purifying environment and the operation pressure of 0.5-0.8MPa, and then is fed into a finished product acceptor. The method has the advantages of strong continuity, good separation effect, high purity and low impurity content. The device has the advantages of small occupied area, convenient automatic operation, stable quality and continuous production.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

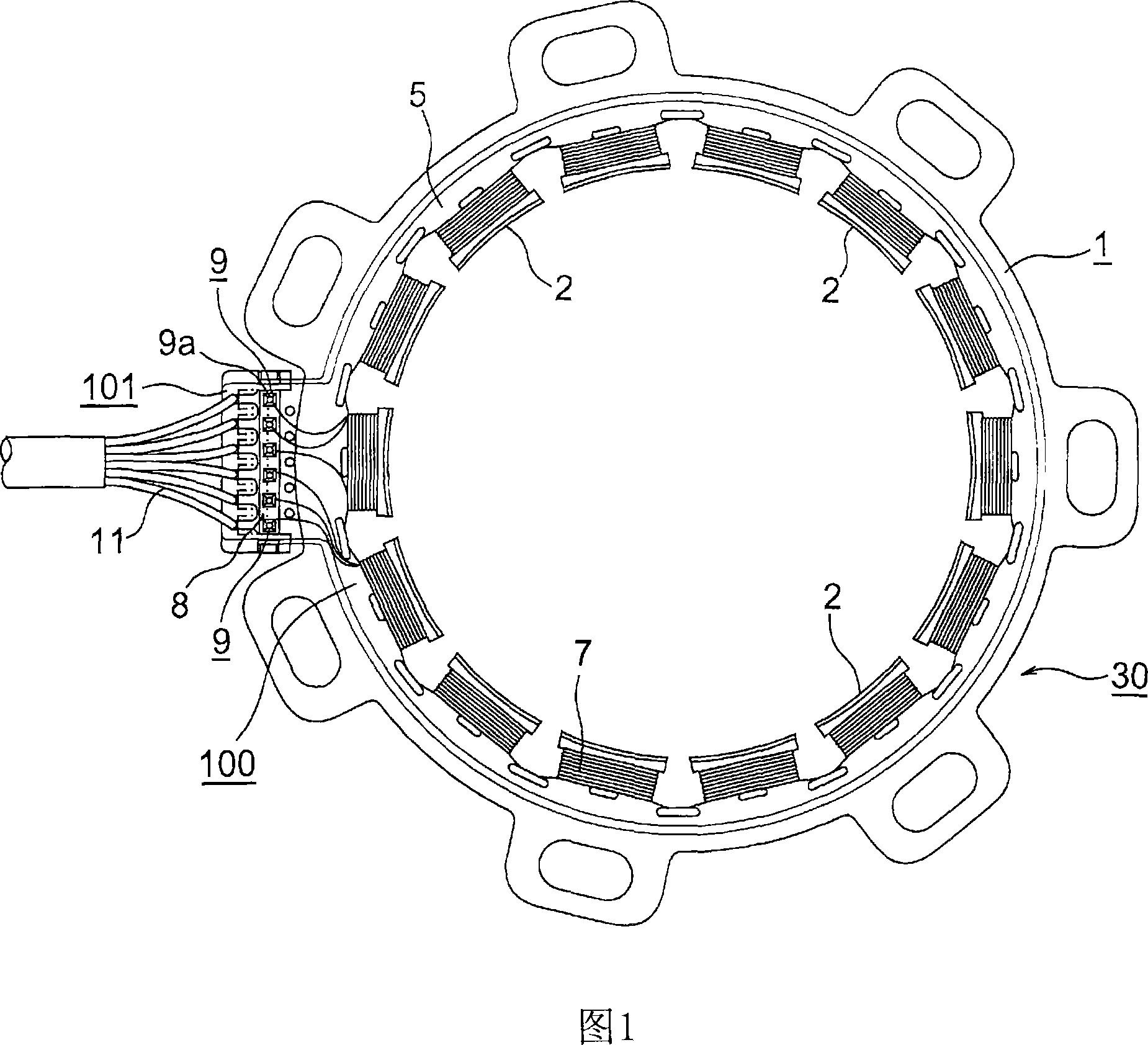

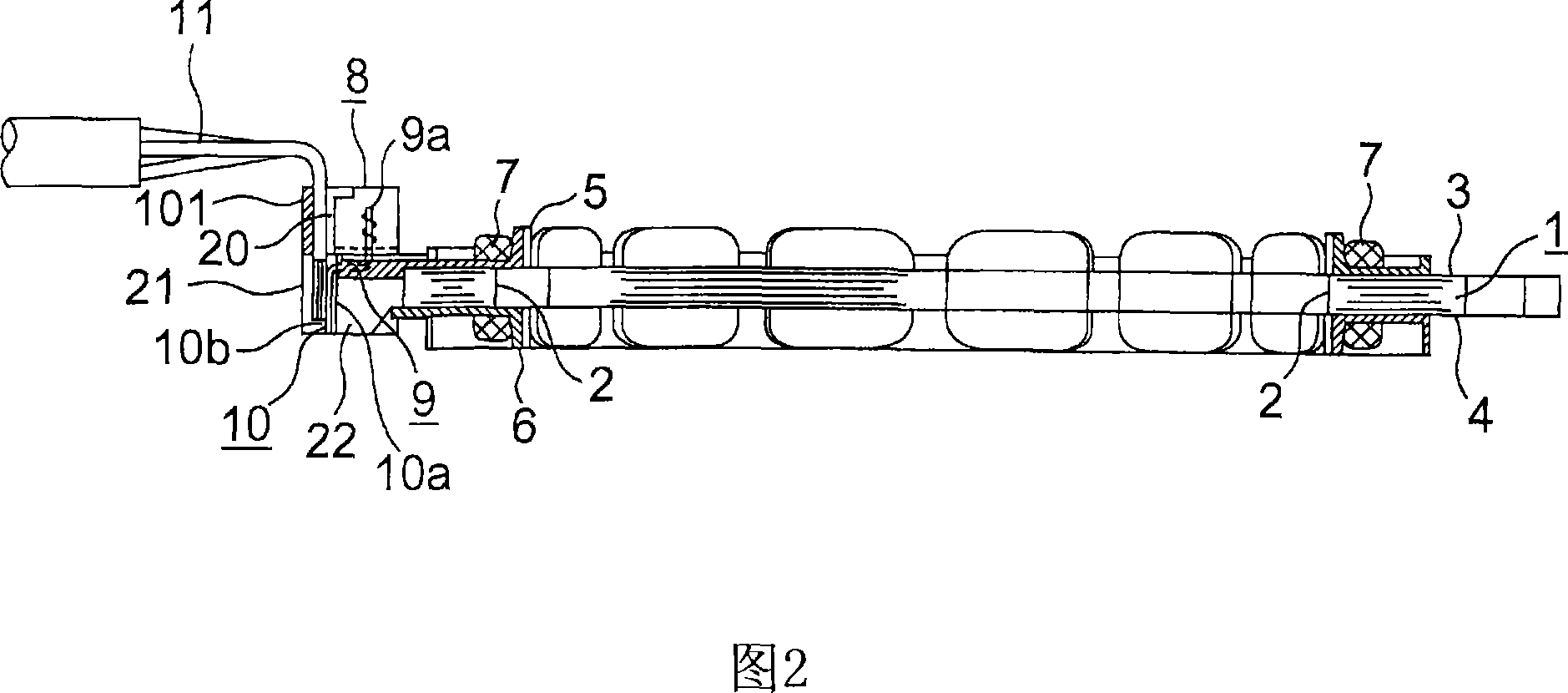

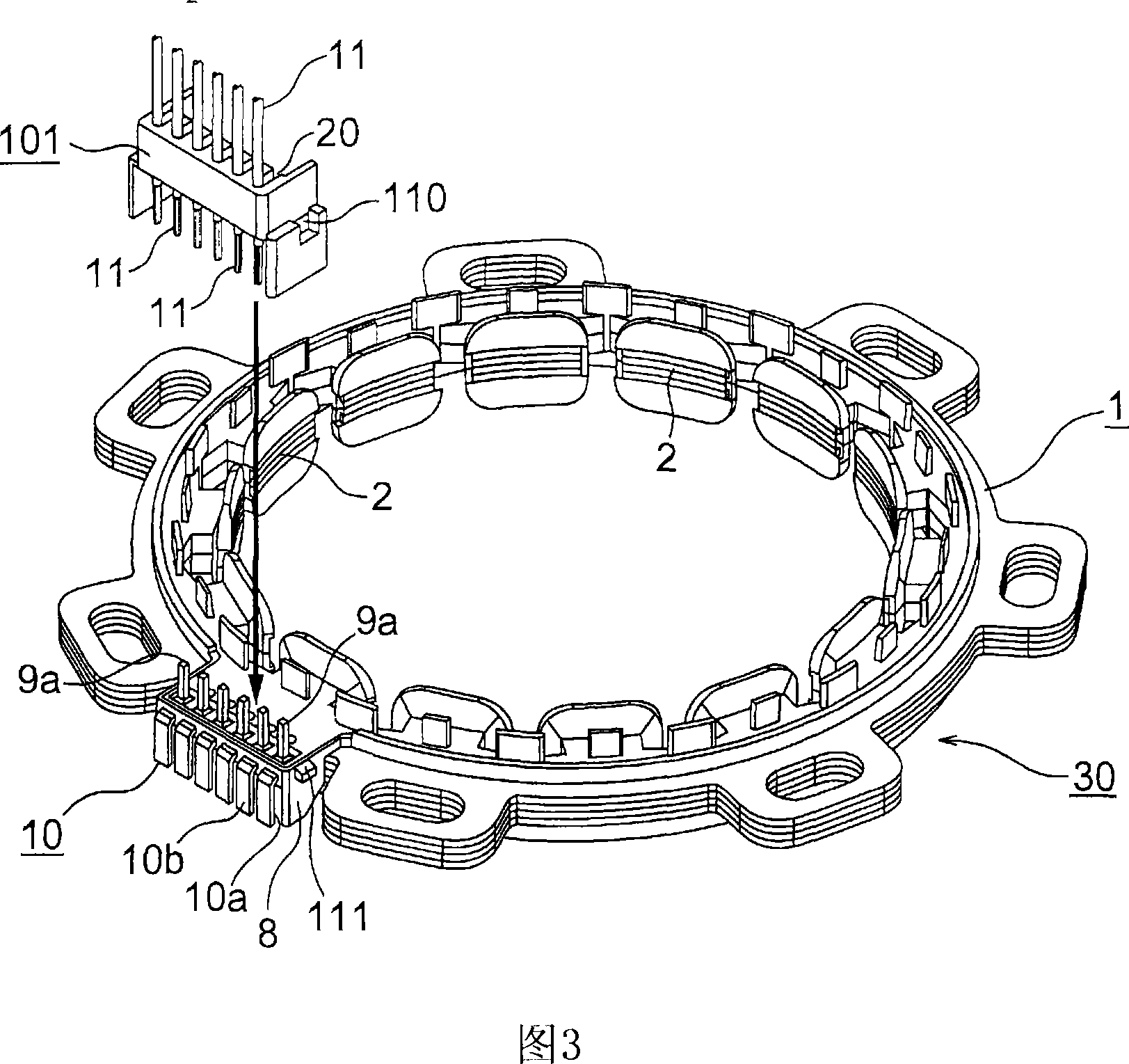

Resolver external conductor fixing structure

InactiveCN1938564AIncrease productivityEasy to automateWindingsMeasurement apparatus componentsEngineeringMechanical engineering

A resolver external conductor fixing structure, wherein a connection body to which leads are connected is formed detachable from a terminal pin holding part so that the leads can be disconnected during the assembly of a resolver and connected after the assembly. An insulation cover (100) is formed on a ring-like stator (1) by integral molding, the terminal pin holding part (8) is formed at a part of the insulation cover (100), and the connection body (101) having the leads (11) is formed detachable from the terminal pin holding part (8). Thus, during the assembly of the resolver, the leads (11) can be disconnected, and after the resolver is assembled, the leads (11) can be connected.

Owner:TAMAGAWA SEIKI CO LTD +1

Method for simultaneously detecting gene mutations of acetaldehyde dehydrogenase 2 and alcohol dehydrogenase 2

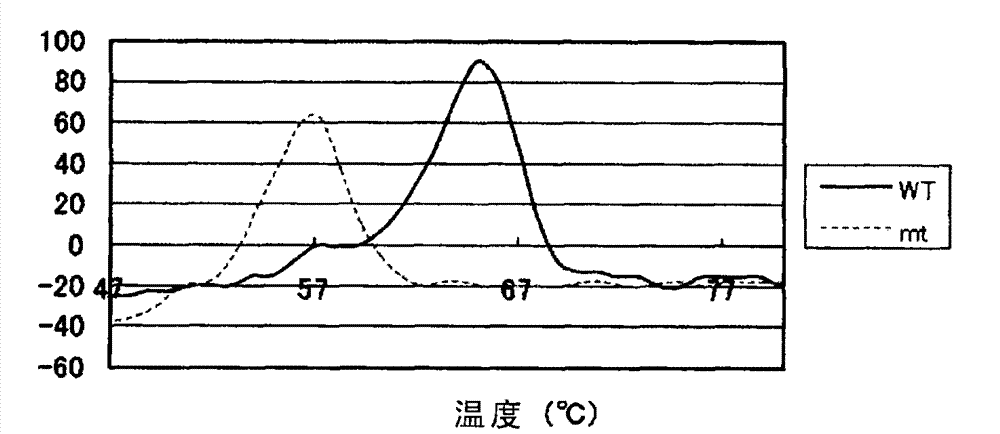

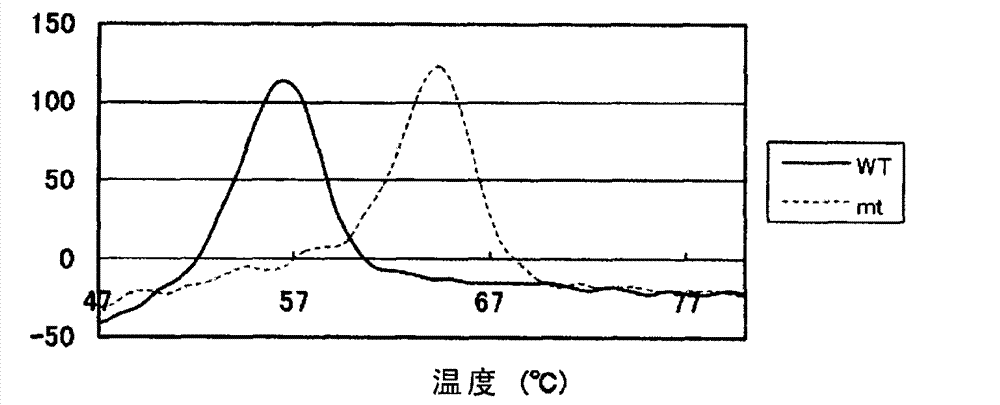

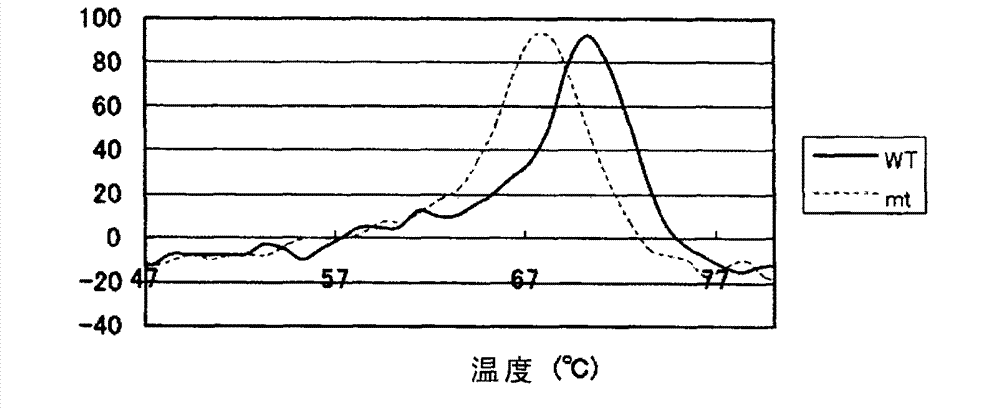

InactiveCN102758008ASimultaneous detection of genetic polymorphismsNo risk of contaminationMicrobiological testing/measurementFluorescence/phosphorescenceFluorescencePolymorphism Detection

The invention relates to a method for simultaneously detecting gene mutations of acetaldehyde dehydrogenase 2 and alcohol dehydrogenase 2. Concretely, a probe effective for detection of genetic polymorphism of the ALDH2 gene rs671 and the ADH2 gene rs1229984, a method for simultaneously detecting gene mutations and a kit for the purpose are provided. Thus the invention provides a probe for polymorphism detection, namely a probe for detection of at at least one type of genetic polymorphism of the ALDH2 gene rs671 and the ADH2 gene rs1229984, characterized in that: the probe comprises at least 1 type of fluorescently labeled oligonucleotide selected from (P1) to (P3') defined in the description.

Owner:ARKRAY INC

Vacuum electron beam melting furnace for polysilicon purification

ActiveCN101445957AIncrease productivityDoes not affect vacuumPolycrystalline material growthChemical industryIsolation valveTransformer

The invention provides a vacuum electron beam melting furnace for polysilicon purification. The melting furnace is characterized in that a melting chamber is square or cylindrical, a chamber wall is of a double water cooling structure or a coil water cooling structure; an electron gun is vertically and downwardly or horizontally arranged on the chamber wall of the melting chamber, a vacuum system is arranged at the rear of the melting chamber; an isolating valve is arranged between a feeding chamber and the melting chamber of a feed mechanism, and an inflation valve of an inflation system is arranged at the other side of the melting chamber; a discharge mechanism is arranged at the bottom of the melting chamber and connected with an ingot-pulling mechanism; the ingot-pulling isolating valve is arranged between discharge mechanism and the melting chamber; the melting chamber is internally provided with a water cooling crucible and a crystallizing crucible; all high-voltage devices of a high-voltage power supply of an electrical control system are arranged at a fuel tank filled with a transformer; and by adopting oil insulation of the transformer, the high-voltage power supply is connected with an electric cabinet which is connected with a console. The melting furnace has the advantages that a plurality of elements can be purified simultaneously, the production efficiency is high, energy consumption is low, energy-saving effect is excellent, and large-scale and automatic operation is easy to be implemented.

Owner:桂林实创真空数控设备有限公司

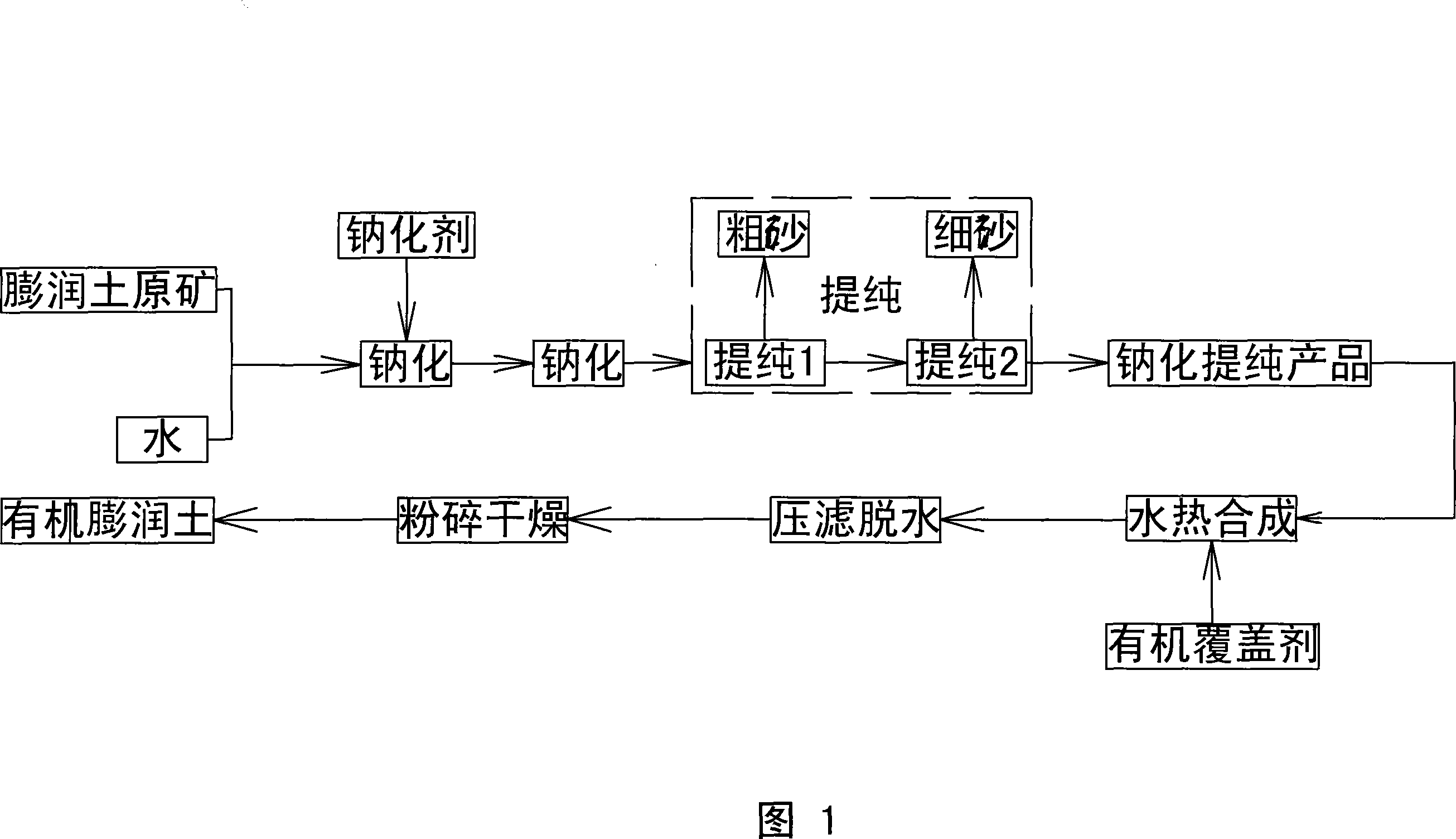

Method for preparing heavy-viscous organophilic bentonite

InactiveCN101224894AContinuously workingImprove stabilityPigmenting treatmentSilicon compoundsSodium BentonitePrinting ink

The invention provides a method for preparing high viscosity organophilic bentonite, which carries out steps of sodium treatment, purification, hydrothermal synthesis, dewatering by filter pressing, crashing and drying operation to bentonite raw ore to obtain the high viscosity organophilic bentonite. The invention can be directly applied to oil paint, printing ink, petroleum drilling slurry and heavy polymer and so on as a thickening suspension agent, a fluid deformation agent and an anti-sagging agent. Through systematic study on technologies of the sodium treatment modification, purification, organic compound and so on of the bentonite, the invention prepares organophilic bentonite jelly glue with stable product quality and excellent performance and determines a proper technical process flow and technical parameters.

Owner:苏州中材非金属矿工业设计研究院有限公司

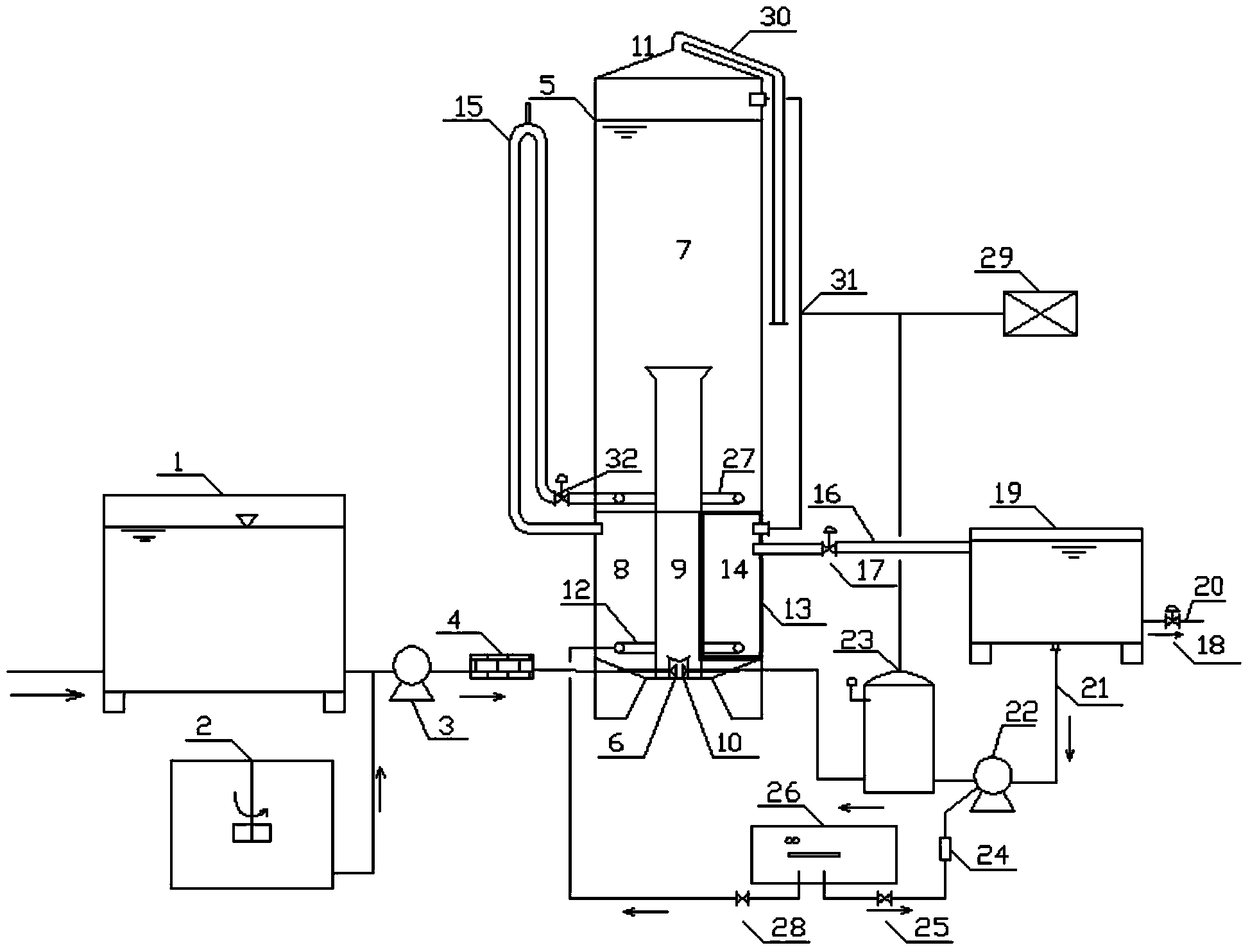

Multistage efficient ozone air floatation integrated device

ActiveCN104326522AIncrease profitReduce energy consumptionWater/sewage treatment by oxidationWater/sewage treatment by flotationSewageOxidation zone

The invention provides a multistage efficient ozone air floatation integrated device. A dissolved air floatation zone and an ozone oxidation zone are arranged reasonably so that dissolved air floatation zone and ozone oxidation are vertically combined in a column and multistage oxidization is realized; solid-liquid separation of insoluble floc particles and water is completed by virtue of dissolved air floatation, and then decolorization, deodorization, organic matter removal and sterilization are realized by virtue of ozone oxidization. The multistage efficient ozone air floatation integrated device is used for performing air floatation treatment and multistage oxidization on treated water; as a result, the shortcoming of low utilization rate of ozone is overcome, the minimization of energy consumption is realized, the utilization rate of ozone is greatly increased and the effect of sewage deep treatment is effectively guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +2

Welding method of deck structure of stainless steel compound plate for railway steel bridge

ActiveCN101797667AGuaranteed weld thicknessGuaranteed uncertaintyArc welding apparatusWelding/soldering/cutting articlesAusteniteTransition layer

The invention discloses a welding method of a deck structure of a stainless steel compound plate of a railway steel bridge, which comprises the following steps: selecting structural steel for a bridge with thickness of 16-20mm as a base layer, selecting austenitic stainless steel with thickness of 2-4mm as a multiple layer, and removing 3-6mm of cladding material materials at each of two edges of welding grooves in advance, wherein the groove angle is 45-65 degrees, and the groove spacing is 4-8mm; the method comprises the following steps: firstly, assembling positioned welding, and then, carrying out backing welding by CO2 gas shielded welding; then, carrying out welding of the base layer by submerged-arc welding; and finally, carrying out welding of a transition layer and the multiple layer by the CO2 gas shielded welding. By adopting a specific groove type, the invention eliminates uncertain human factors and solves the problems that the thickness of the deposited metal of the base layer is insufficient, the multiple layer can be molten by mistake when the substrate layer is welded, and the like; the reverse formation is good, so that the reverse back gouging process is omitted; and the invention has the advantages of good assembly quality and easy realization of mechanization and automation, improves the production efficiency, and is convenient for ensuring the corrosion resistance of the multiple layer.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

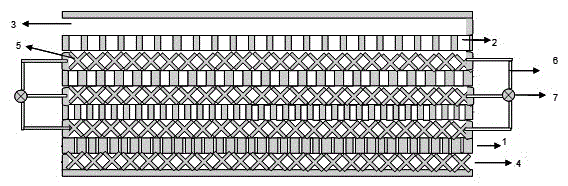

Multi-layer oil-water separator and working method therefor

InactiveCN105016504AGood separation effectExtend your lifeFatty/oily/floating substances removal devicesWater contaminantsOil–water separatorFiltration

The invention provides a multi-layer oil-water separator and a working method therefor. The separator comprises a water inlet and a water outlet, wherein a plurality of layers of separating materials are arranged between the water inlet and the water outlet; separating holes are formed in the separating materials; a runner is formed among the separating layers by virtue of a grid; the two sides of the grid are sealed; and the hole diameter of the separating holes is gradually reduced layer by layer from the water inlet to the water outlet. The multi-layer oil-water separator adopts a layer-by-layer filter mode, has good separating effect and relatively high filtration flux, and has cleaning and back cleaning functions, so that the service life of the separator is prolonged. The separator is compact in mechanism, high in integration and convenient for automatic operation and large-scale amplification.

Owner:WUXI LVZHIXING ENVIRONMENTAL PROTECTION CO LTD

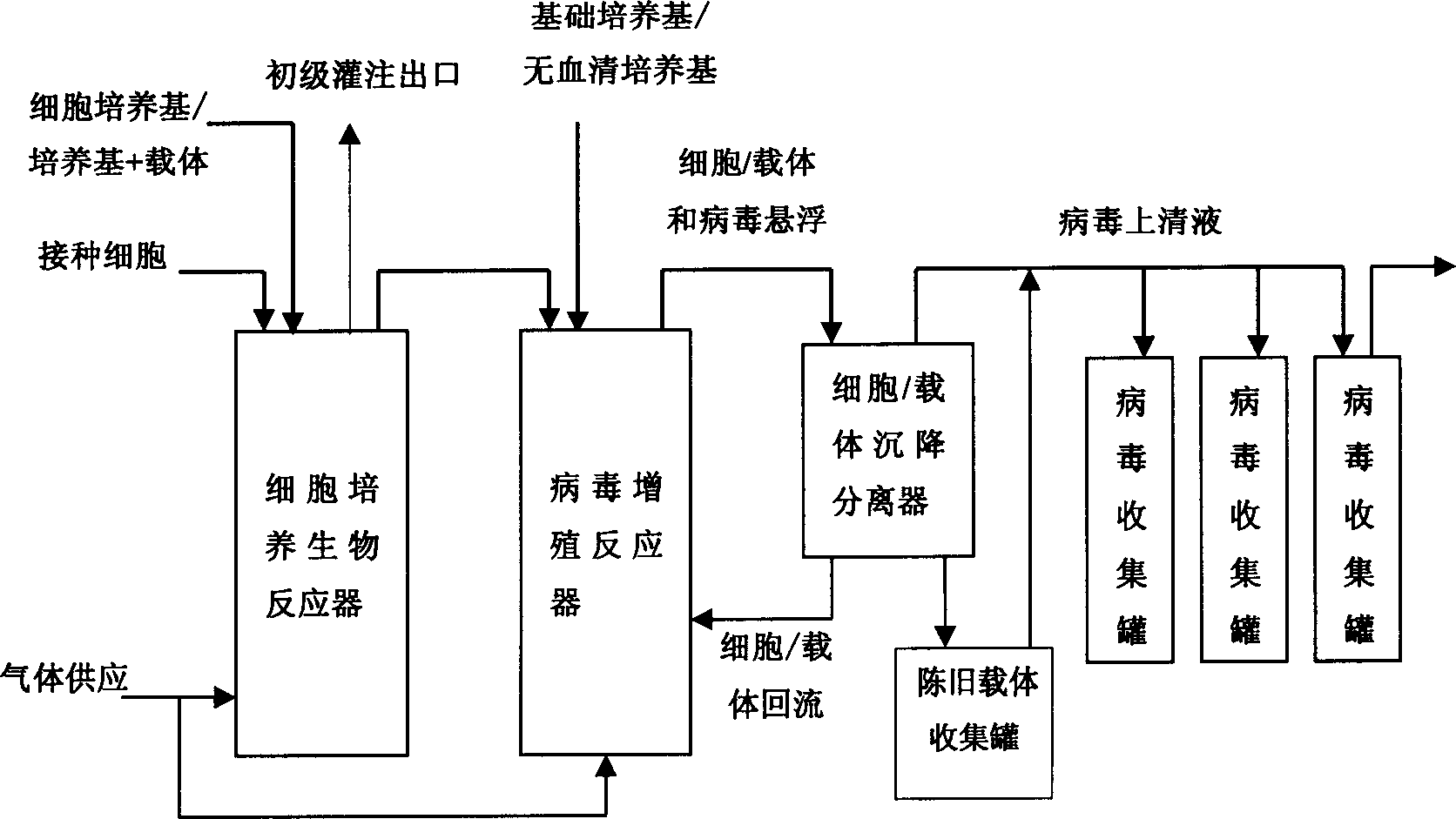

Method for safe continuous enclosed cell culture, virus production/ inactivation

ActiveCN1807599AImprove operational flexibilityEasy to automateViral antigen ingredientsInactivation/attenuationAutomatic controlSuspension culture

A method of cells culture, virus production / deactivation in safe, continuum and blocked style, belonging to bioengineering technical field, compring steps of: 1) Inoculate cells and suspension culture, therebycarry out the primary culture of cells; 2)Flowing add fresh medium, simultly pump out cells suspension to maintain cell culture biological reactor stable and guarantee cell amplificatation during residence time in reactor, accordingly carry out cell's continuous cultivation; 3) Pump out cells suspension into virus-containing virus breeding reactor to make virus infect and amplificate in cells preliminary; 4)As the inflow of cells suspension and outflow of virus-containing upper clean liquid, system dynamic balancing is maintained and virus continuous cultivation is achieved; 5) Collect the upper clean liquid pumped from virus breeding reactor and deactivate the virus, accordingly achieve continuously and obturately cells cultivation and virus deactivation. This method is convenient for automatic control and standardized production, also depresses the pollution chances and heightens production assurance coefficient.

Owner:上海丽坤生物科技股份有限公司

Preparation of raphanin sulfane

InactiveCN1982294AIncrease contentReduce manufacturing costOrganic chemistryOrganic compound preparationRaphaninEthyl acetate

Production of raphsulfane with brassin vegetables as raw materials is carried out by crushing for seeds, flowers, stems and leaves, hydrolyzing at specific pH value by myrosase, extracting by acetic ether, adsorbing by silica gel, removing impurities by acetic ether and eluting by mixed solution of isopropyl alcohol, alcohol and petroleum ether. It's cheap and simple and can be used for large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH

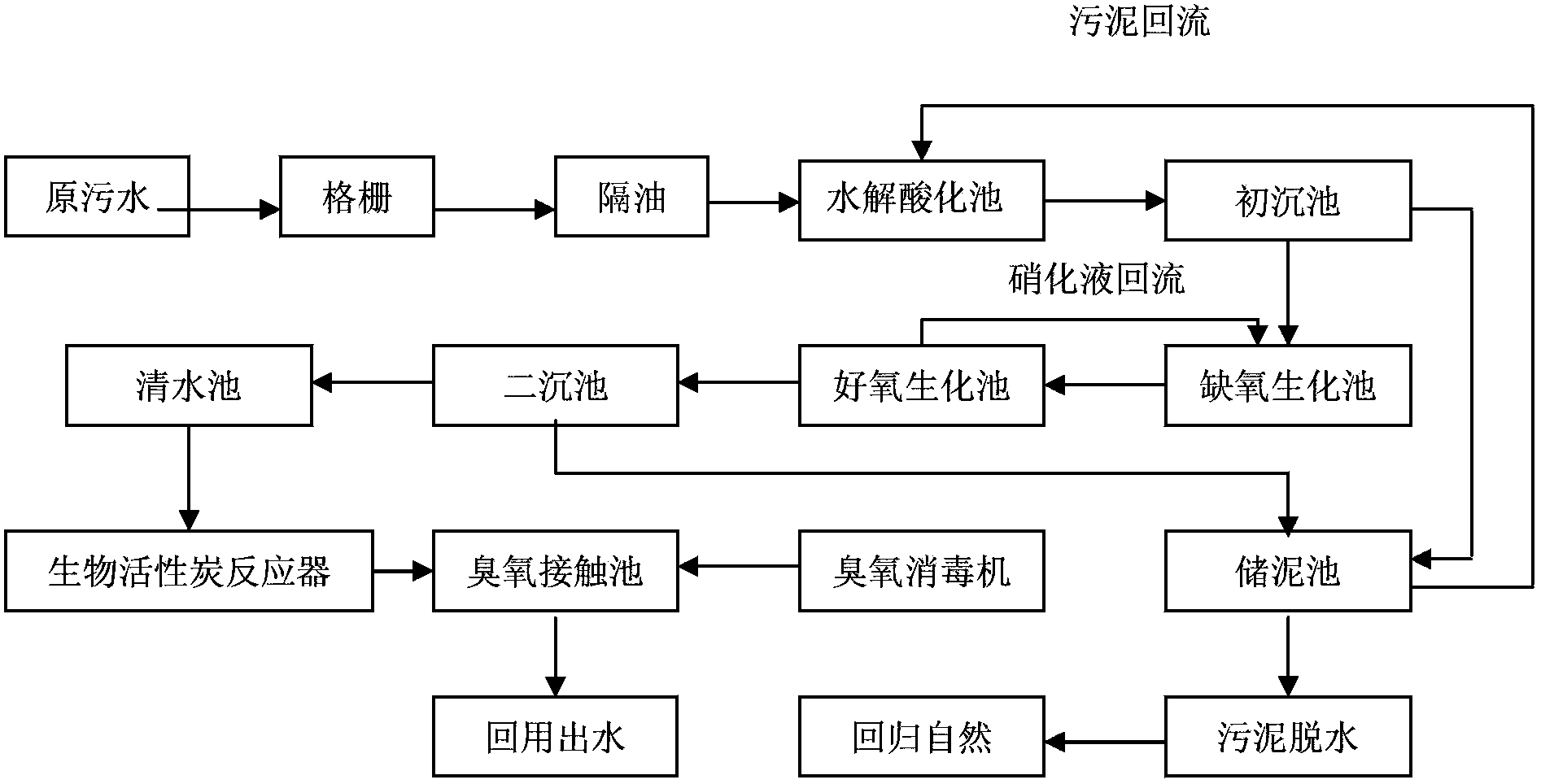

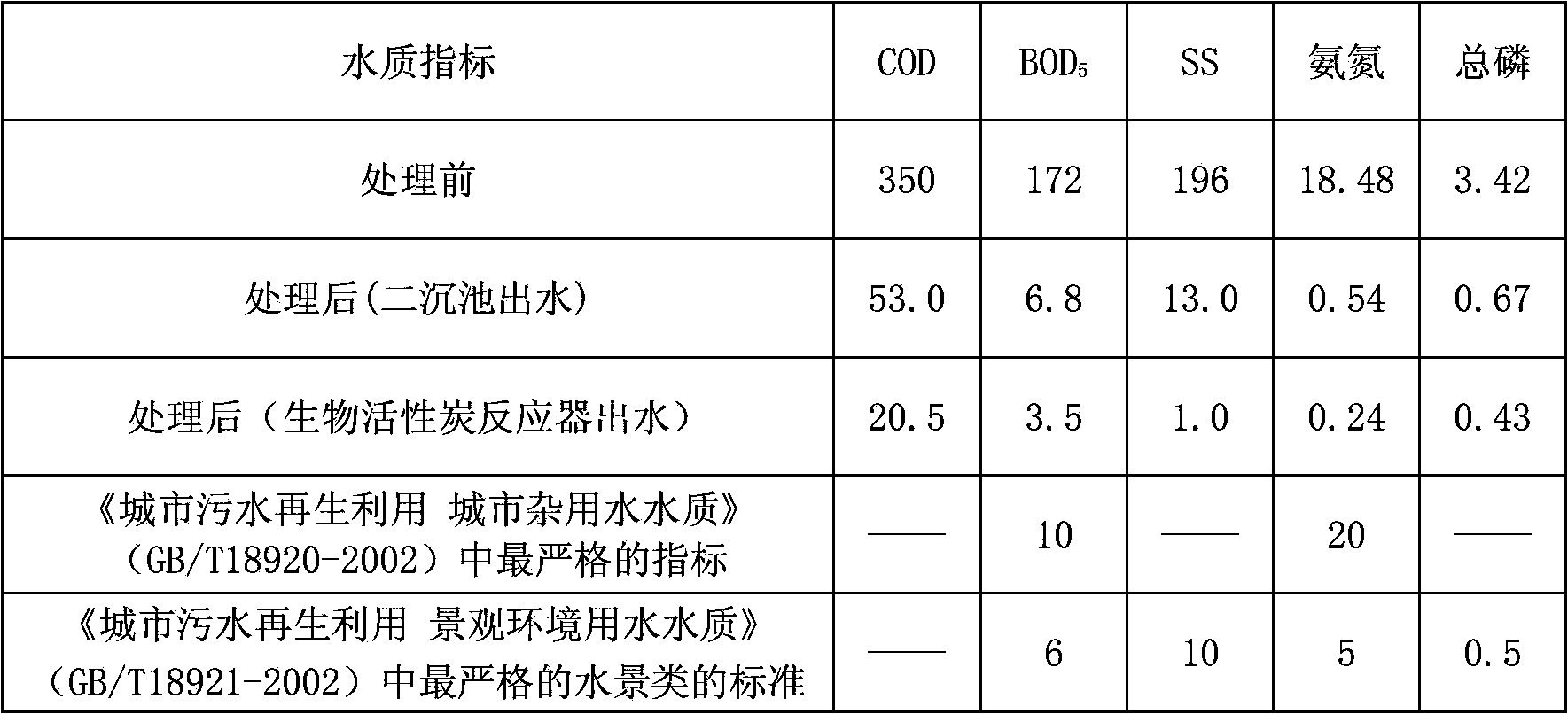

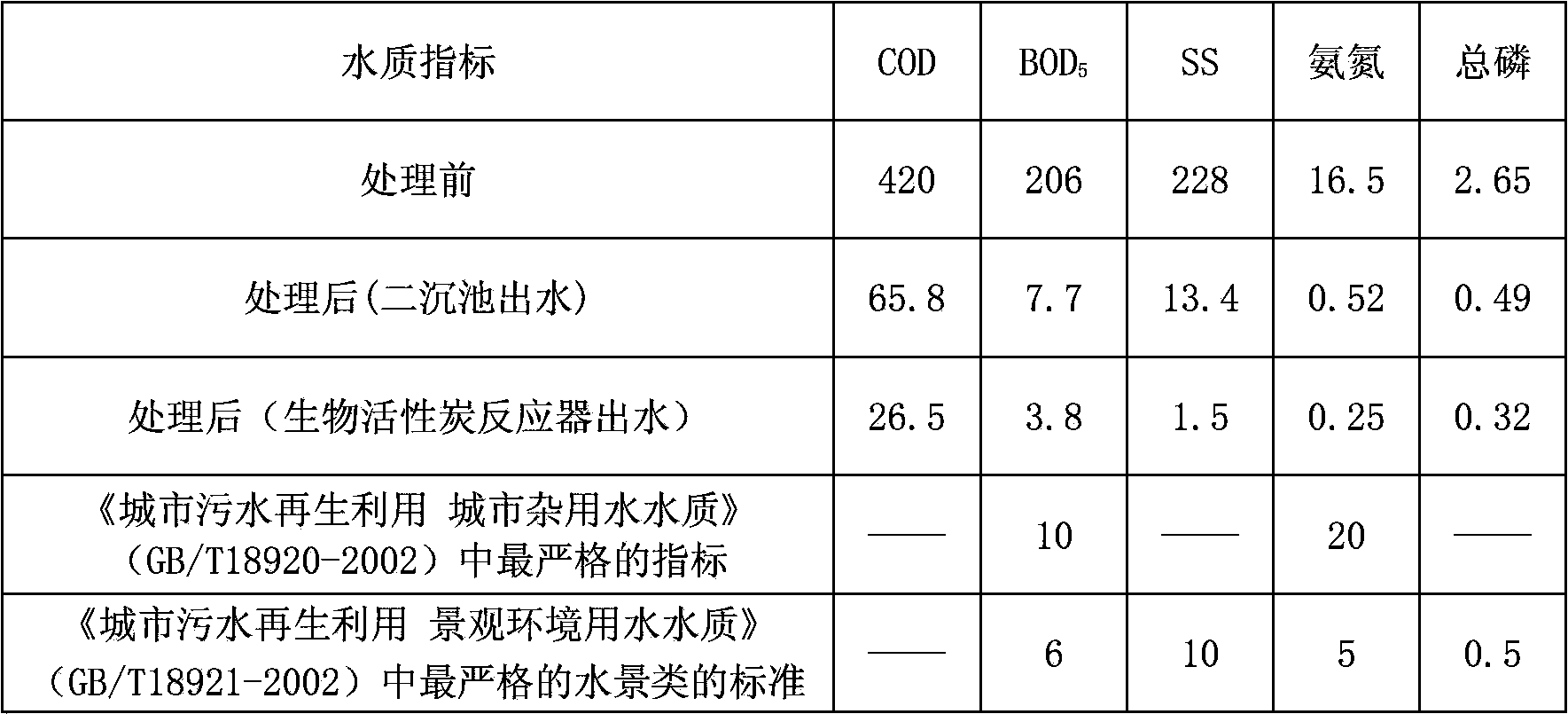

Sewage treatment method

ActiveCN103449658AReduce CODReduce pollutionMultistage water/sewage treatmentSludgeTherapeutic effect

The invention relates to a sewage treatment method. The method is as below: sending domestic sewage into an oil separator through a machinery grating, and then sending the sewage into a hydrolysis-acidification pool to decompose macro-molecular organic matters in the sewage into micromolecular organic matters, so as to remove part of COD; sending the sewage into a primary settling tank to concentrating sludge and discharging the sludge into a sludge storage tank; sending an upper clarified liquor into an anoxic biochemical pool; carrying out an denitrification reaction on the sewage and a nitrated liquid flowing back from an aerobic biochemical pool; introducing effluent into the aerobic biochemical pool for aerobic biochemical reaction, and sending the other part of the sewage into a secondary settling tank through an overflow weir; concentrating the sludge, discharging the sludge into the sludge storage tank and flowing the upper clarified liquor into a clear water tank; part of the sludge in the sludge storage tank flows back to the hydrolysis-acidification pool; and conveying clear water to a biological active carbon reactor, flowing outlet water into an ozone contact pool and disinfecting the water outlet for reuse. The method has stable treatment effect, generates a small amount of sludge; residual sludge returns to the nature; and treated sewage is reused in water-scenery and greening, so as to save sewage charge and reduce environmental pollution.

Owner:PETROCHINA CO LTD

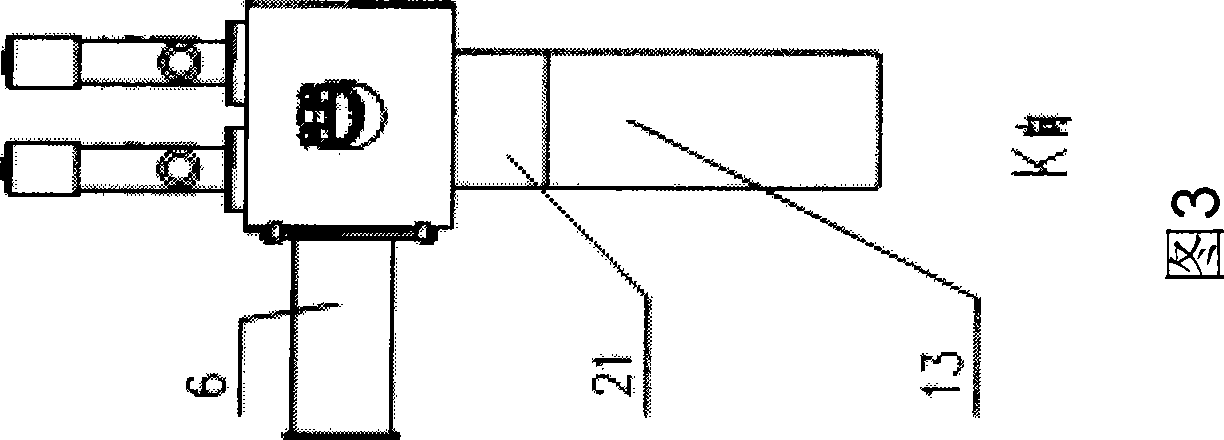

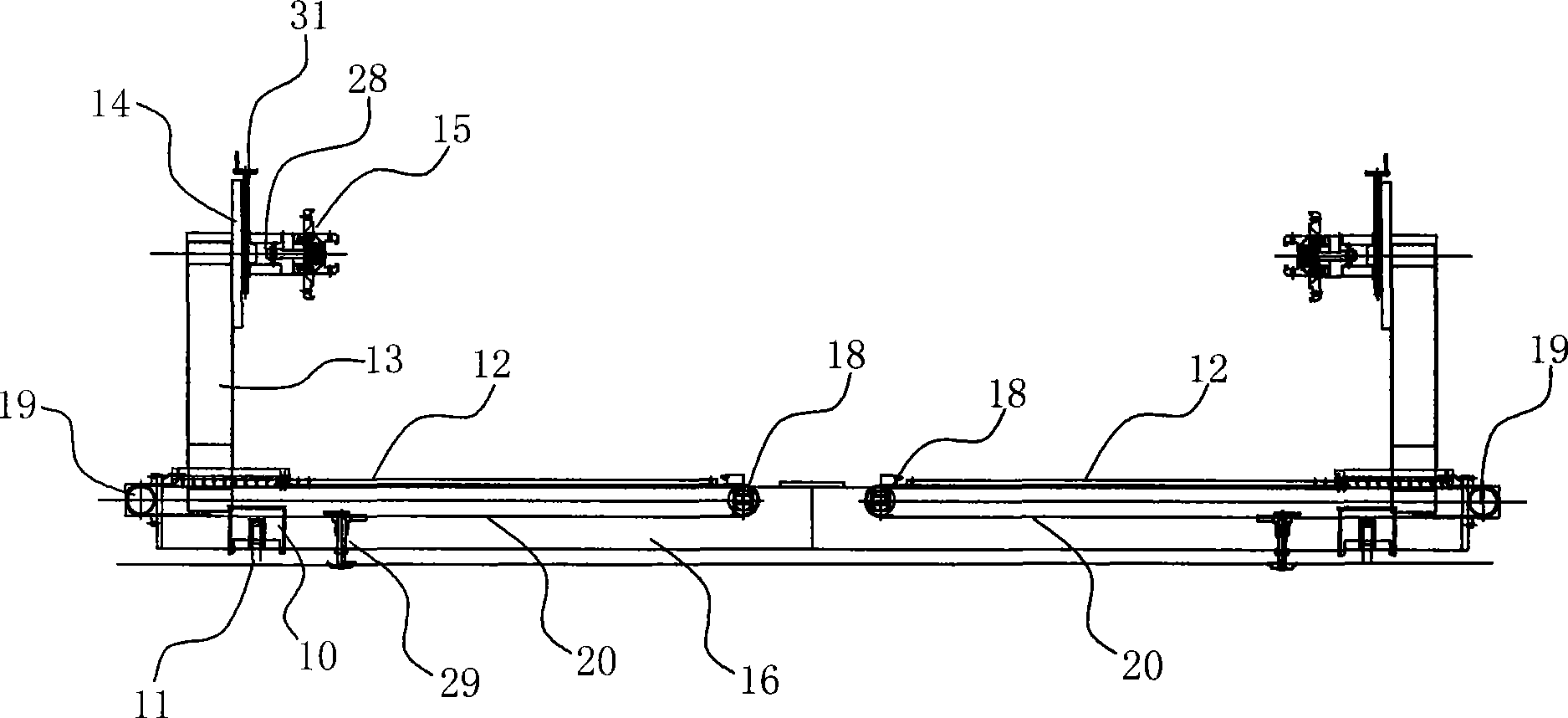

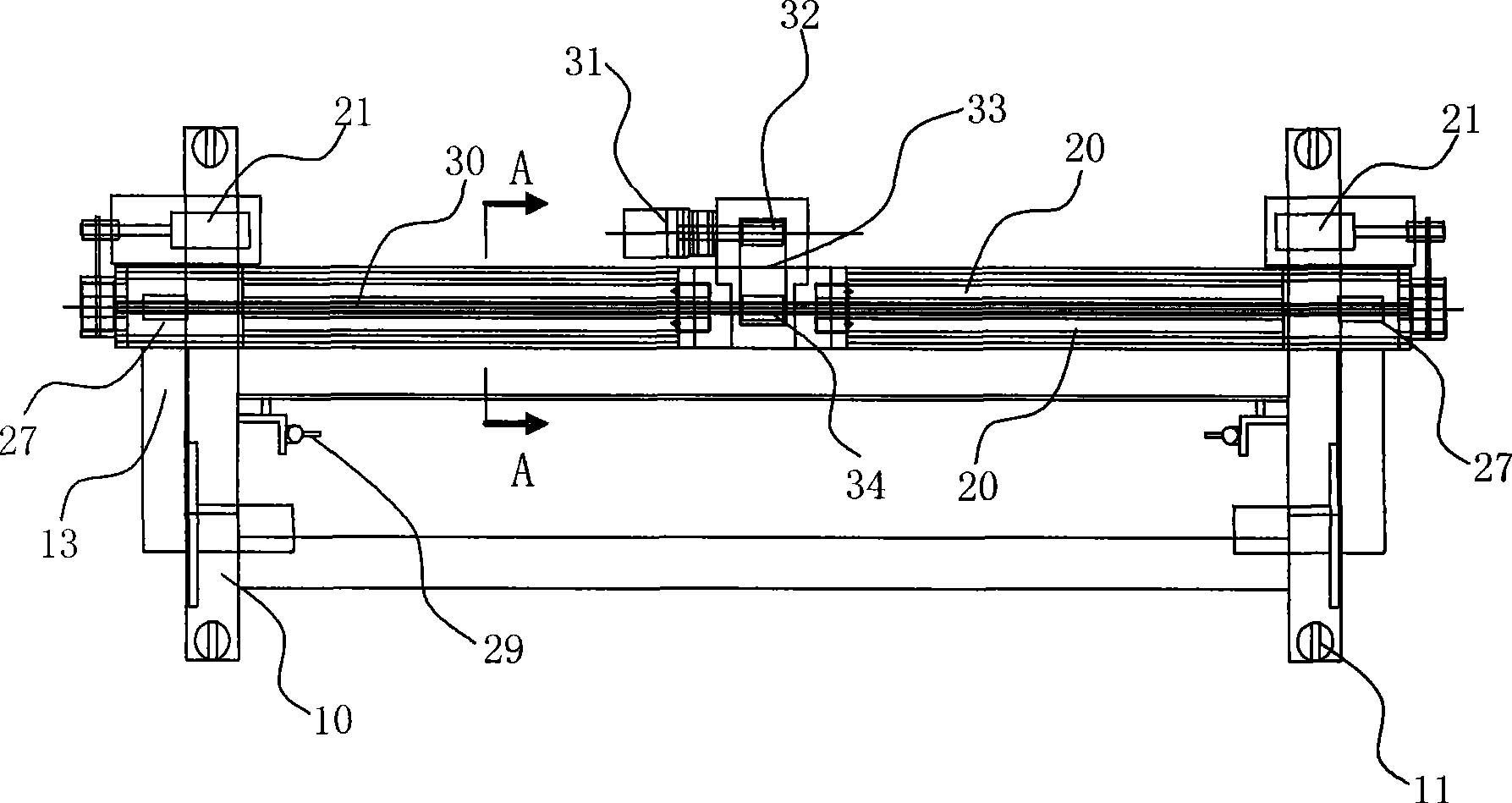

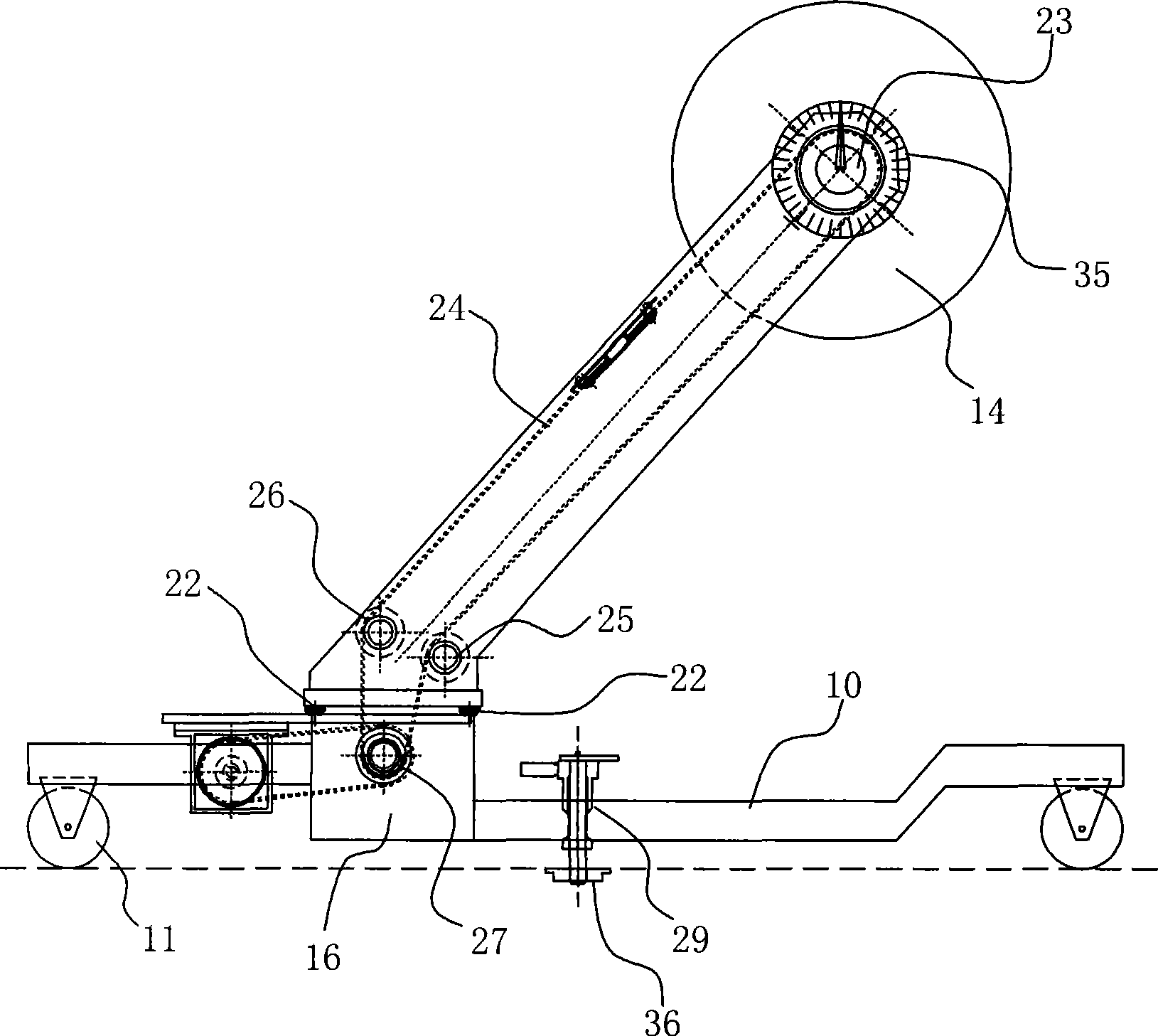

Transmission and reversion table for automatic production by extrusion manipulator

InactiveCN101433936AEasy flipEasy to automateMetal-working feeding devicesPositioning devicesManipulatorExtrusion

The invention relates to a transmission rockover table for automatically produced workpieces which is punched by a manipulator. The transmission rockover table solves the problem of rockover transmission of pull-down deep workpieces during automatic production of double-action presses. The rockover table comprises a framework pedestal, wherein a roller wheel is arranged below the framework pedestal, and the upper part of the framework pedestal is provided with a guide rail and a lateral sway machine frame which are distributed in the horizontal direction; a rockover machine frame which rotates opposite to the horizontal plane is arranged on the lateral sway machine frame; and a clamping device is arranged on the rockover machine frame. The rockover table can conveniently turn over the punched workpieces at an angle of +-180 DEG, so that the manipulator in the next procedure is convenient to grasp the workpieces.

Owner:CHERY AUTOMOBILE CO LTD

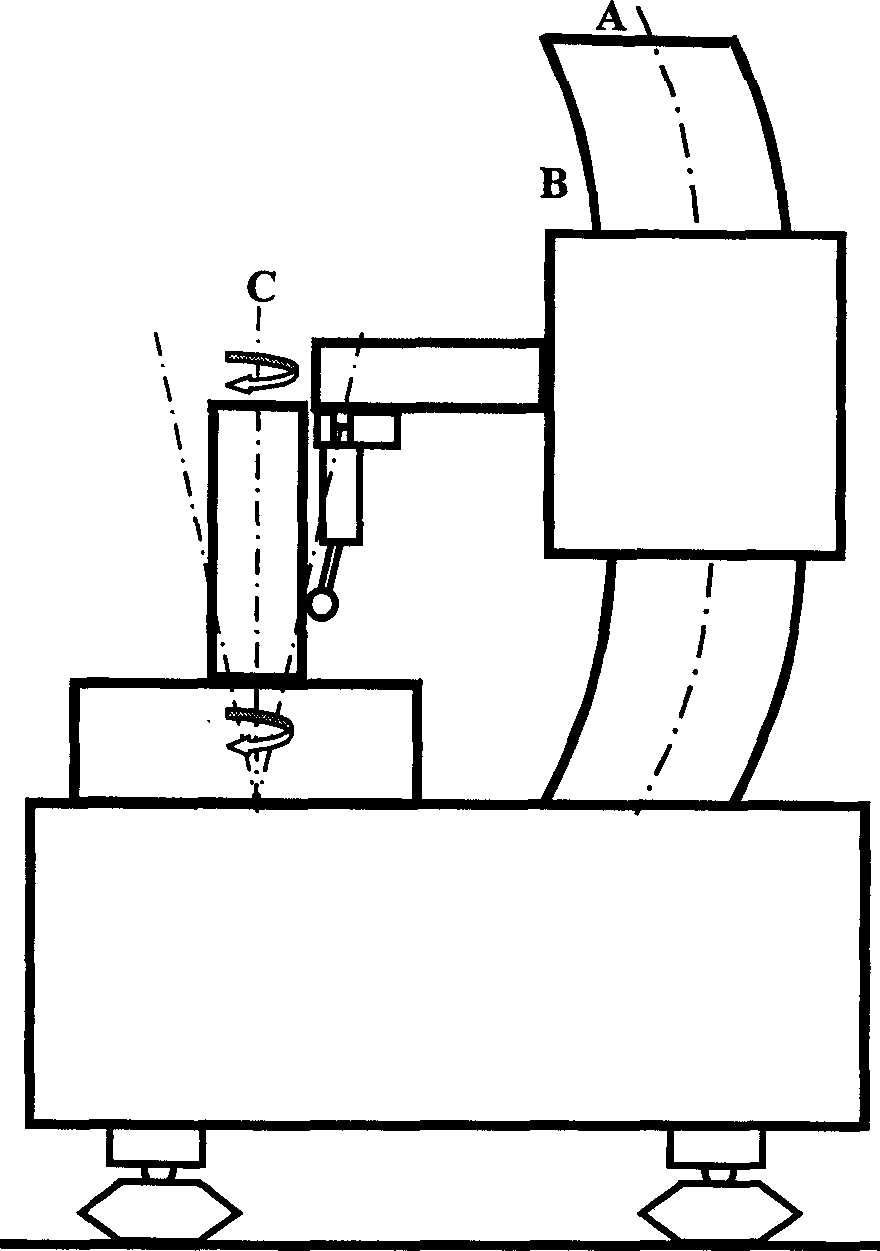

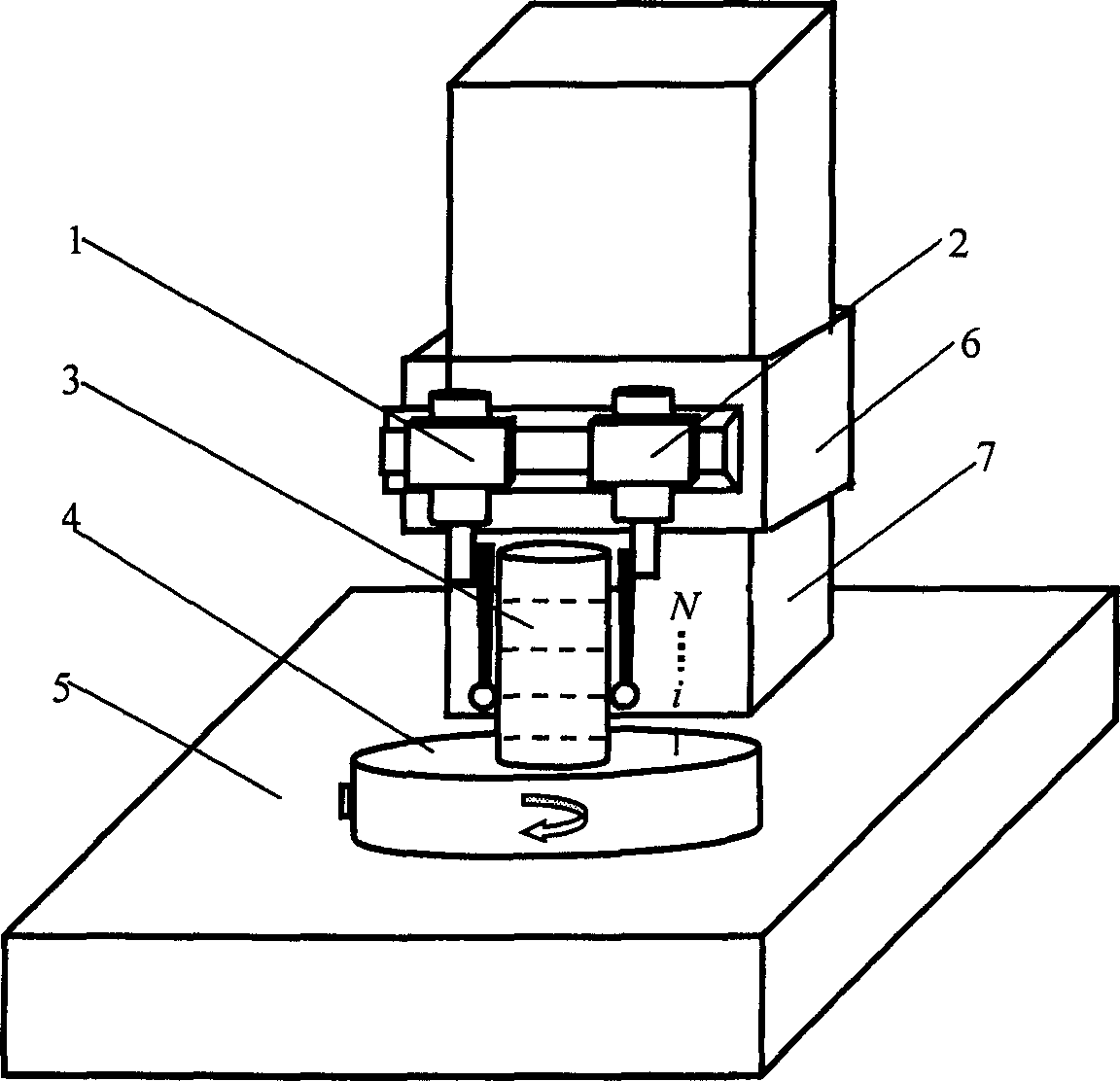

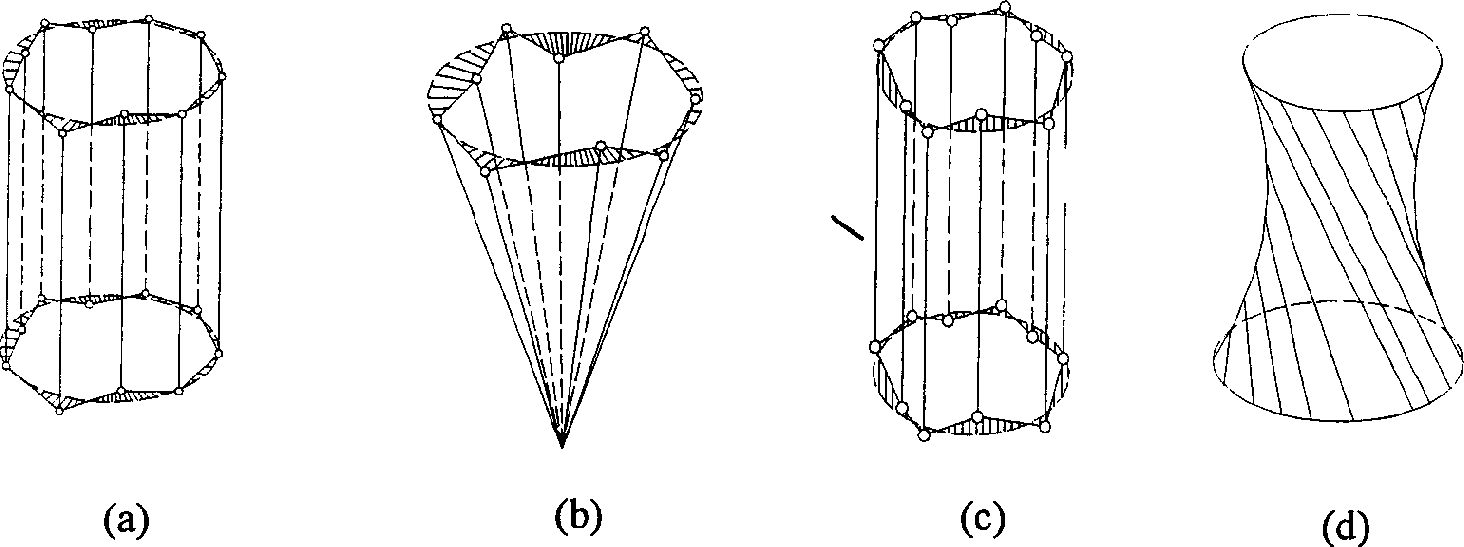

Cylindricity measuring method and device for separating reference errors of cylindricity instrument

InactiveCN1645033AEasy to measureEasy to automateMechanical counters/curvatures measurementsEngineeringWorkbench

A device for measuring cylindricity consists of vertical guide system formed by two transducers, rotating table base, guide airfloat case and vertical guide; as well as turntable for separating error. It is featured as placing the turntable on the rotating table and placing tested piece on the turntable for enabling it to rotate in following with the two separately, placing two transducers in radical symmetry at both sides of the tested piece for having them moved up and down in following with guide airfloat case along vertical guide.

Owner:严格集团股份有限公司

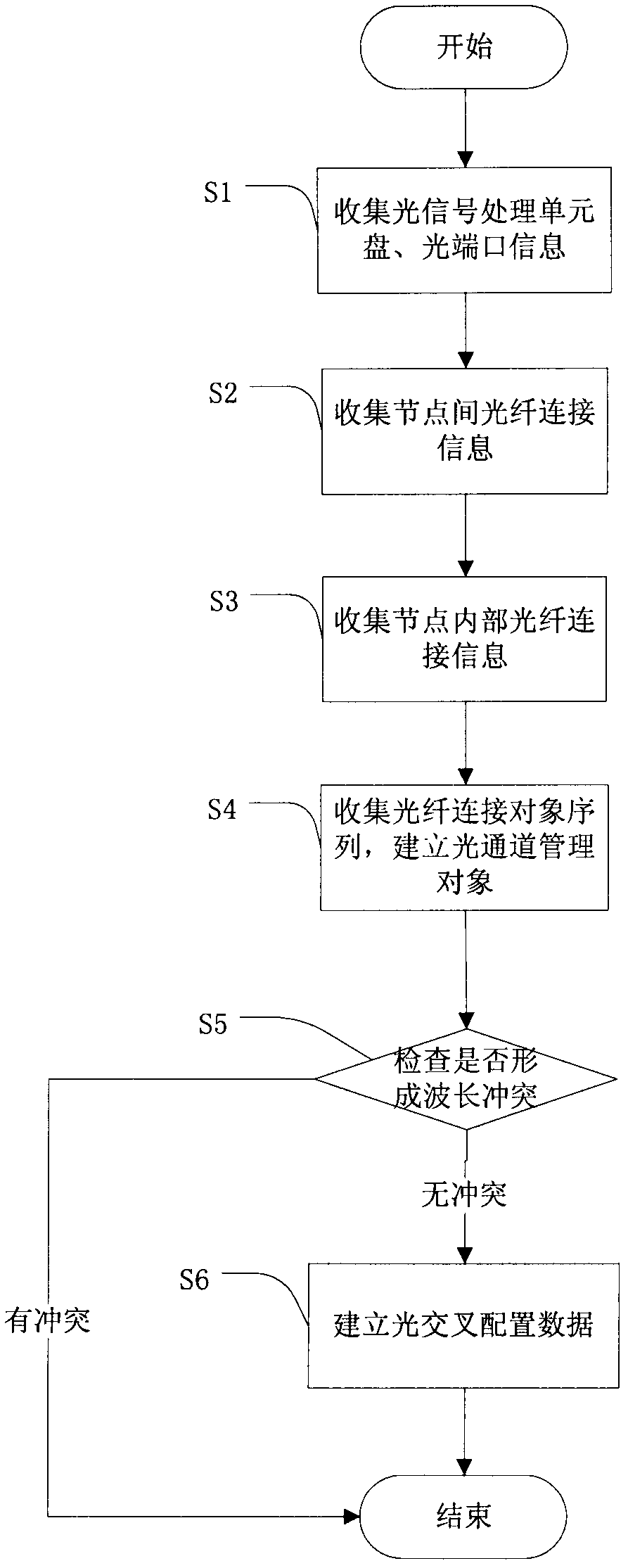

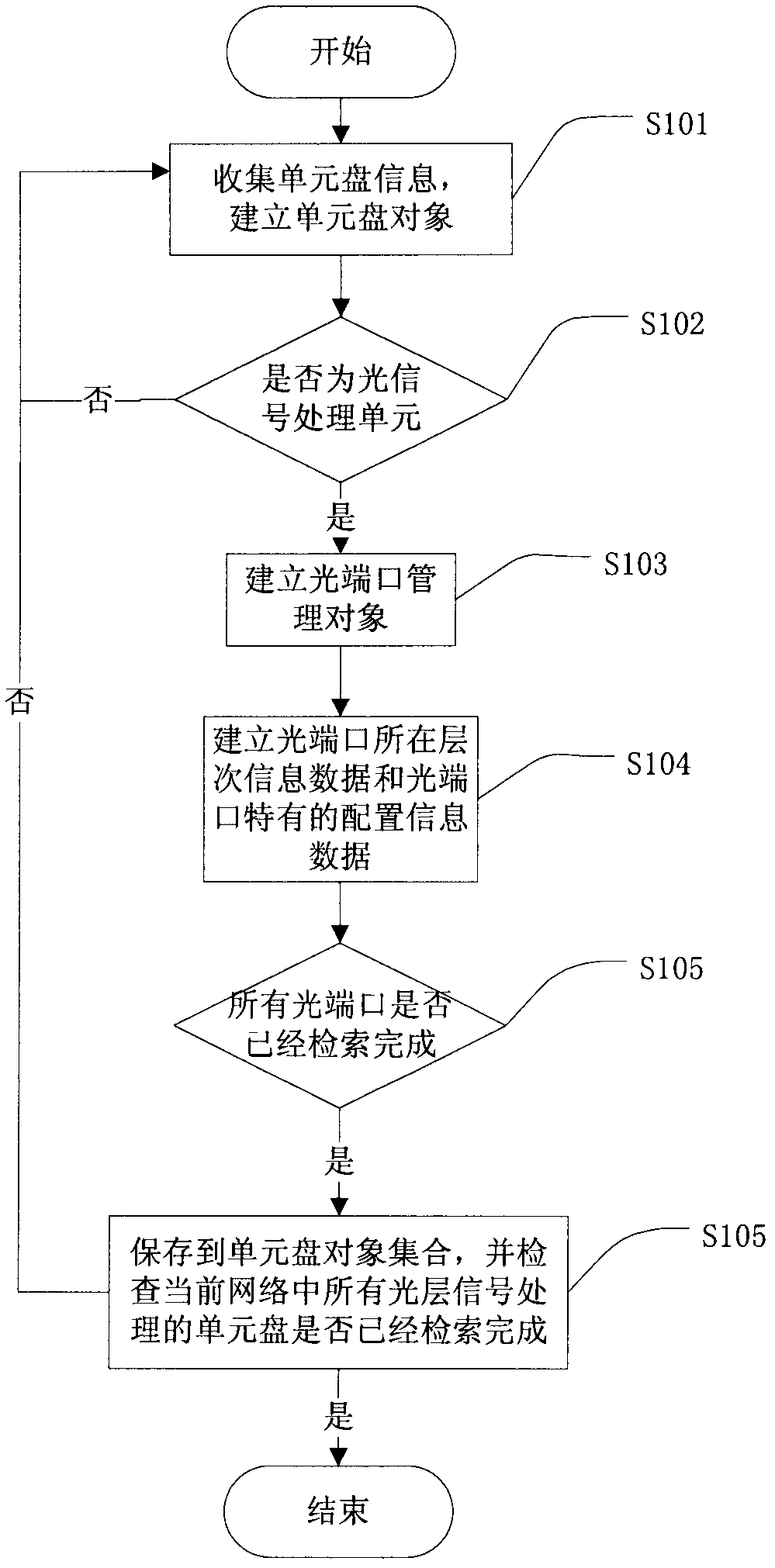

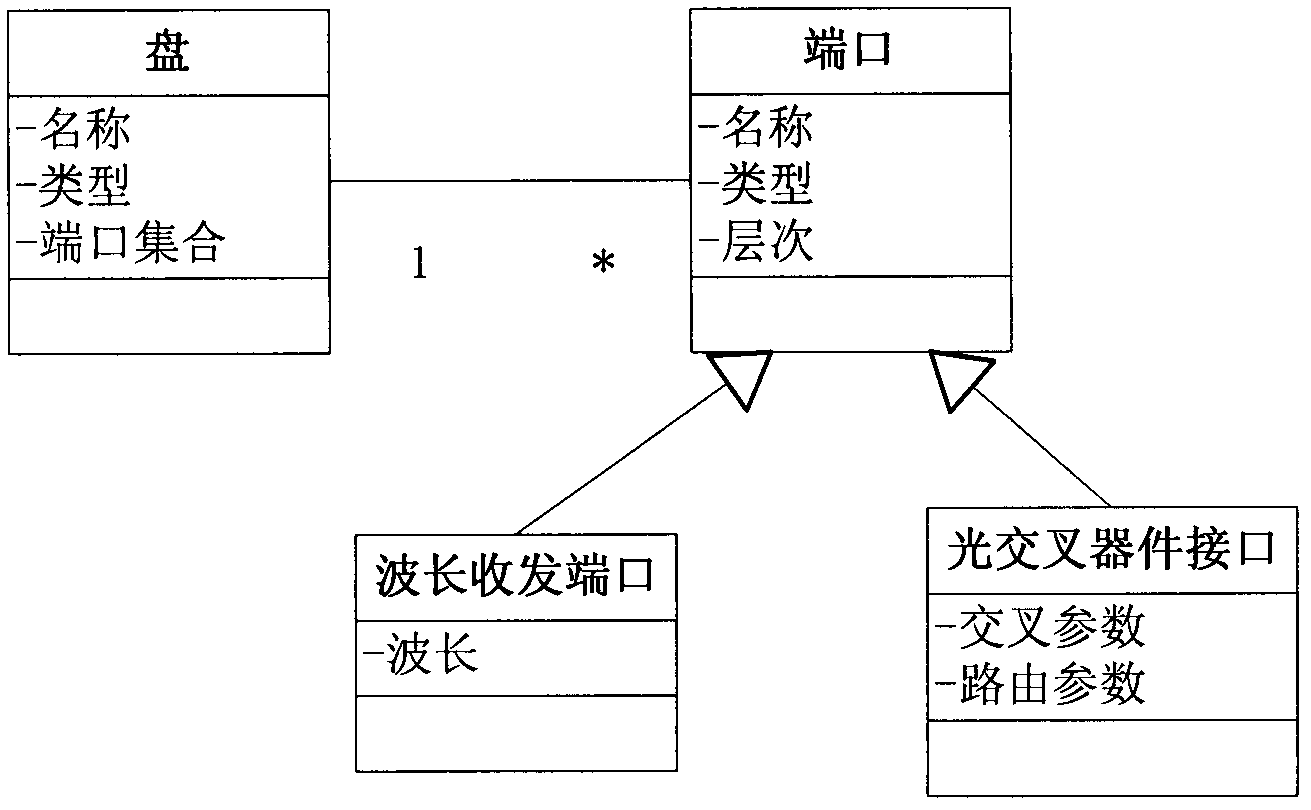

Method and device for peer-to-peer optical cross connection configuration

ActiveCN102547494AEasy to automateReduce operating costsMultiplex system selection arrangementsTime-division multiplexNODALCross connection

The invention discloses a method and a device for peer-to-peer optical cross connection configuration, and relates to the field of wavelength division multiplexing (WDM) and optical transport network (OTN) equipment management. The method comprises the following steps of: 1, collecting and creating a unit disk management object dataset and an optical port management object dataset in an OTN; 2, collecting and creating an internodal optical fiber connection management object dataset; 3, collecting and creating an intra-node optical fiber connection management object dataset; 4, collecting and creating an optical channel management object dataset; 5, checking whether the same wavelength of different light source positions forms a wavelength conflict or not by analyzing an optical fiber connection object sequence and optical port information, and directly finishing the method if the same wavelength of the different light source positions forms the wavelength conflict; and 6, automatically searching for an optical port and wavelength information required by the configuration of a reconfigurable optical add-drop multiplexing optical cross processing unit disk by analyzing an optical fiber connection management object sequence, and creating optical cross connection configuration data. By the method and the device, errors caused by artificial memory, manual parameter collection and manual operation are avoided, and the running cost of a network is decreased.

Owner:FENGHUO COMM SCI & TECH CO LTD

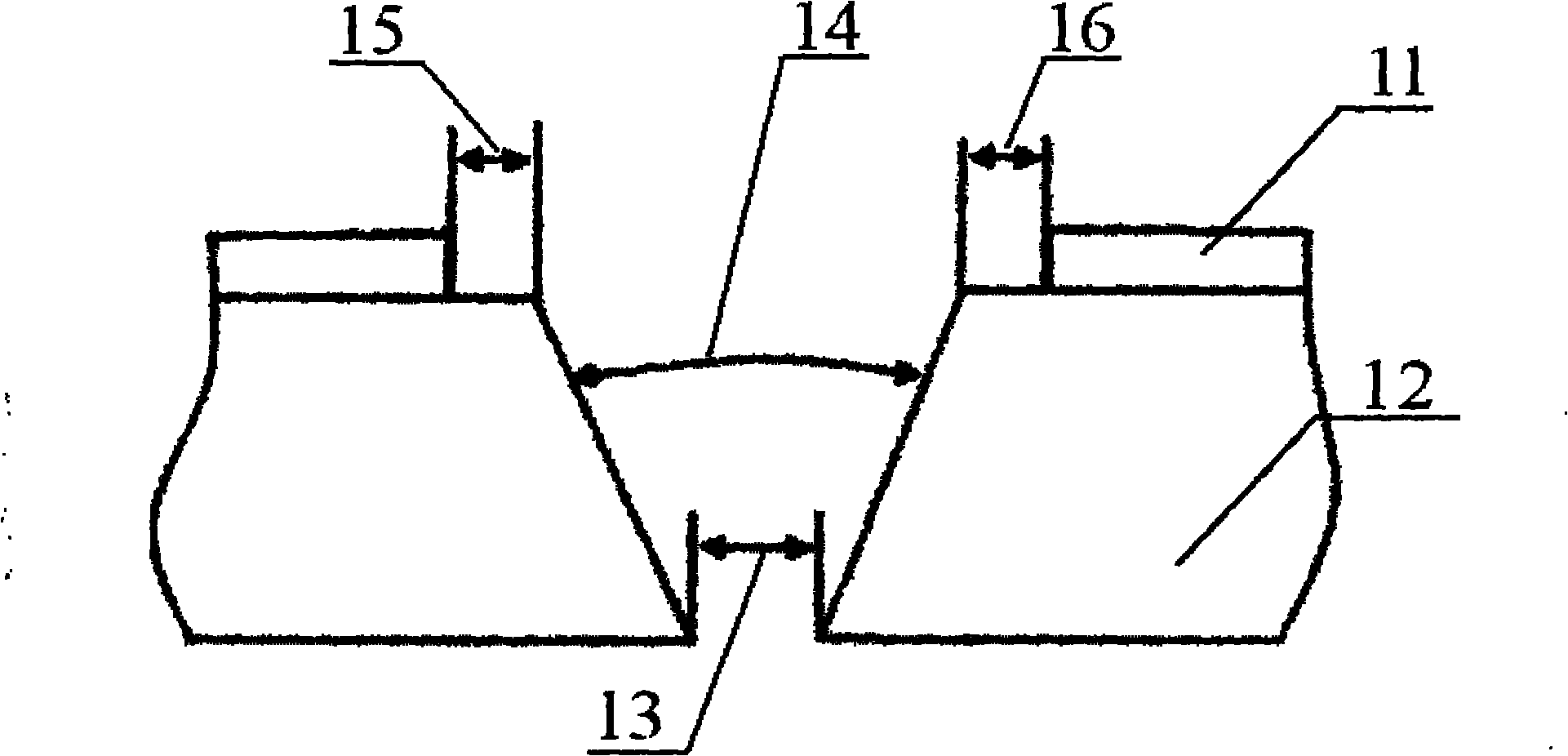

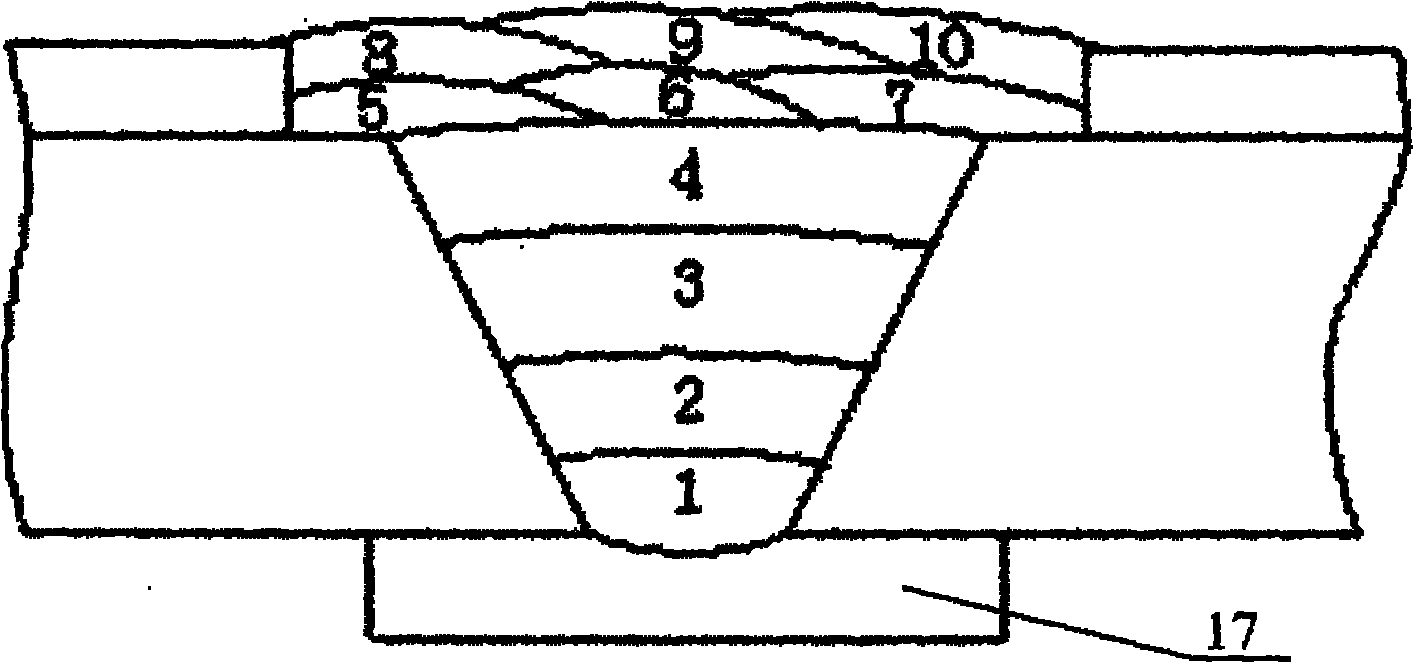

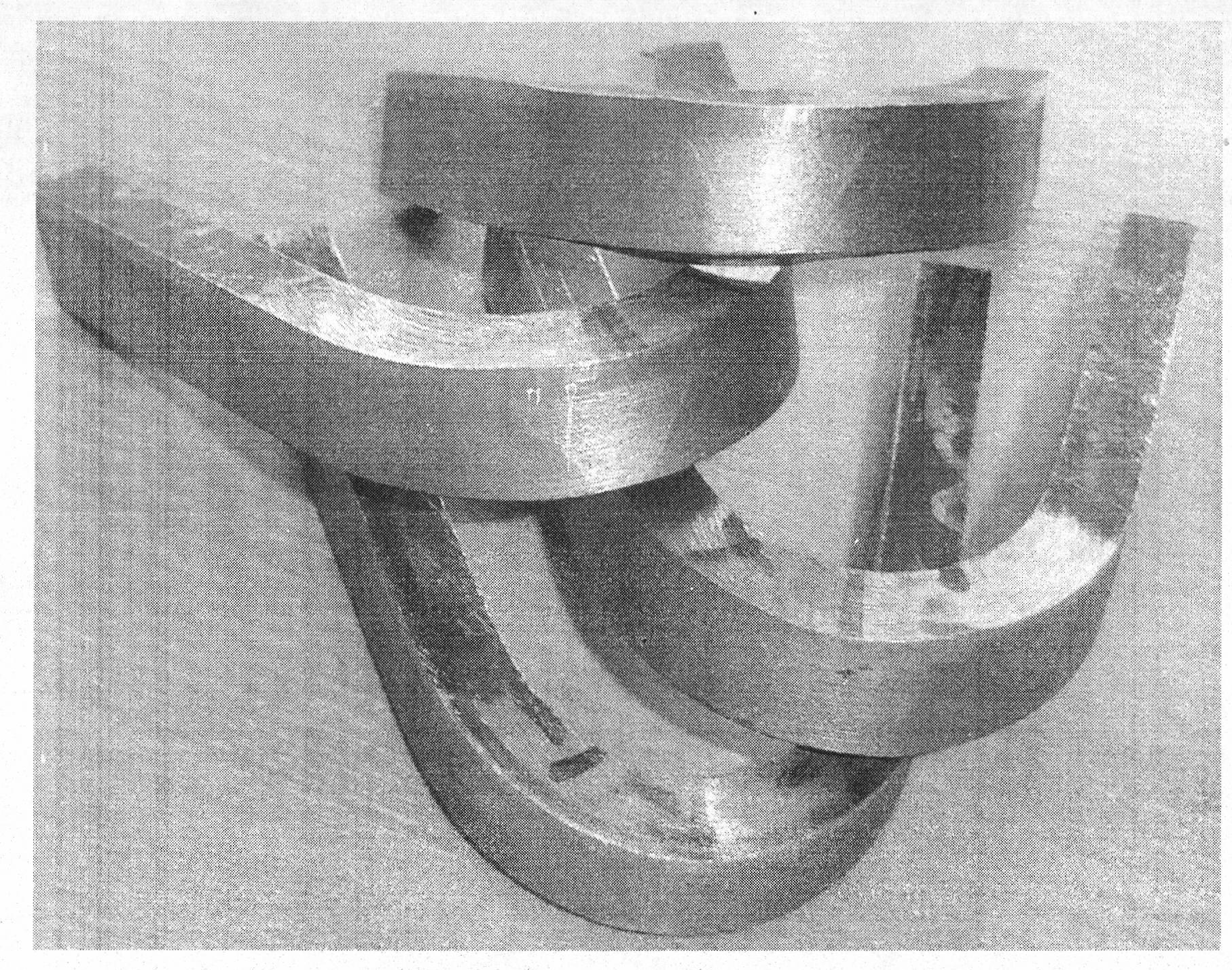

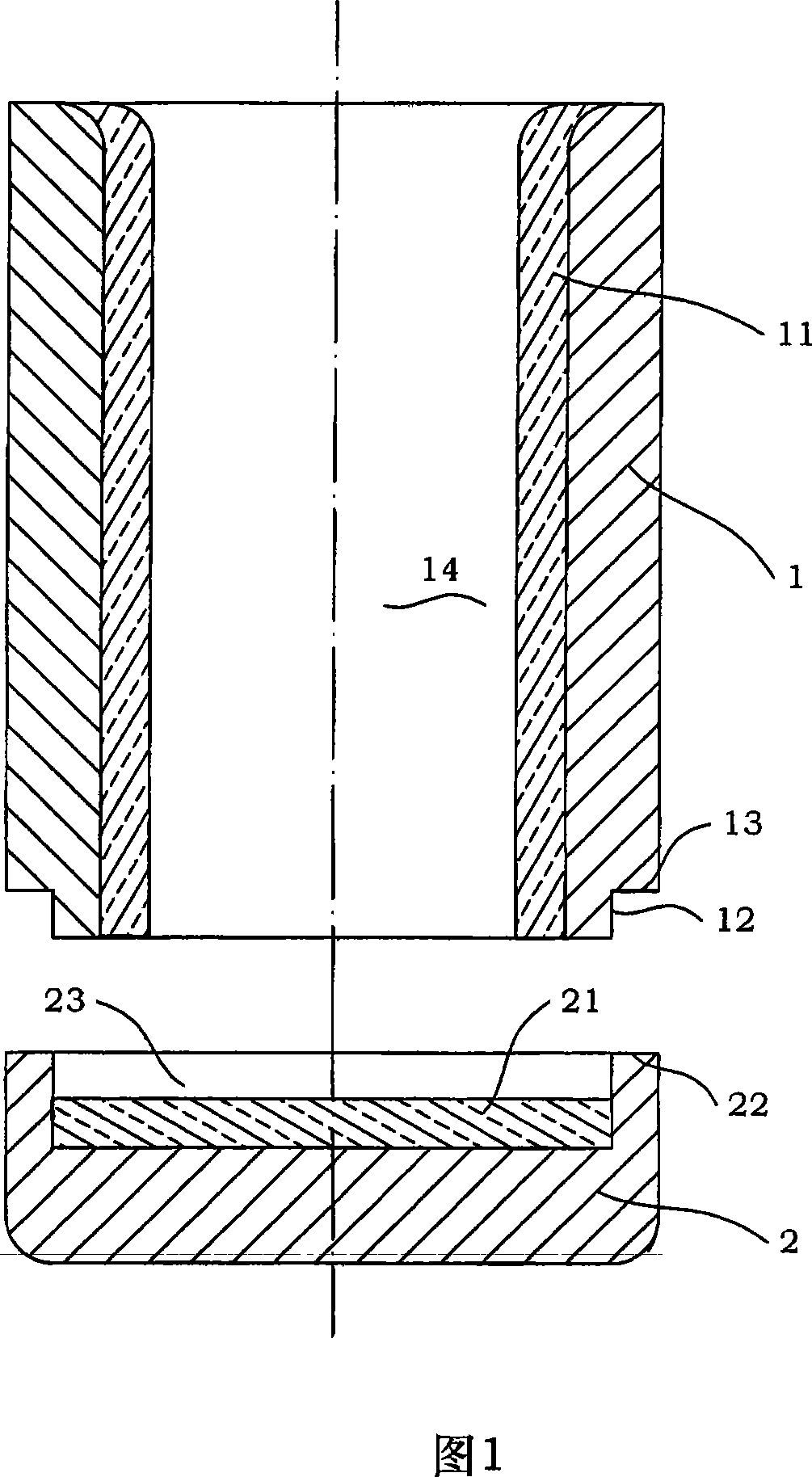

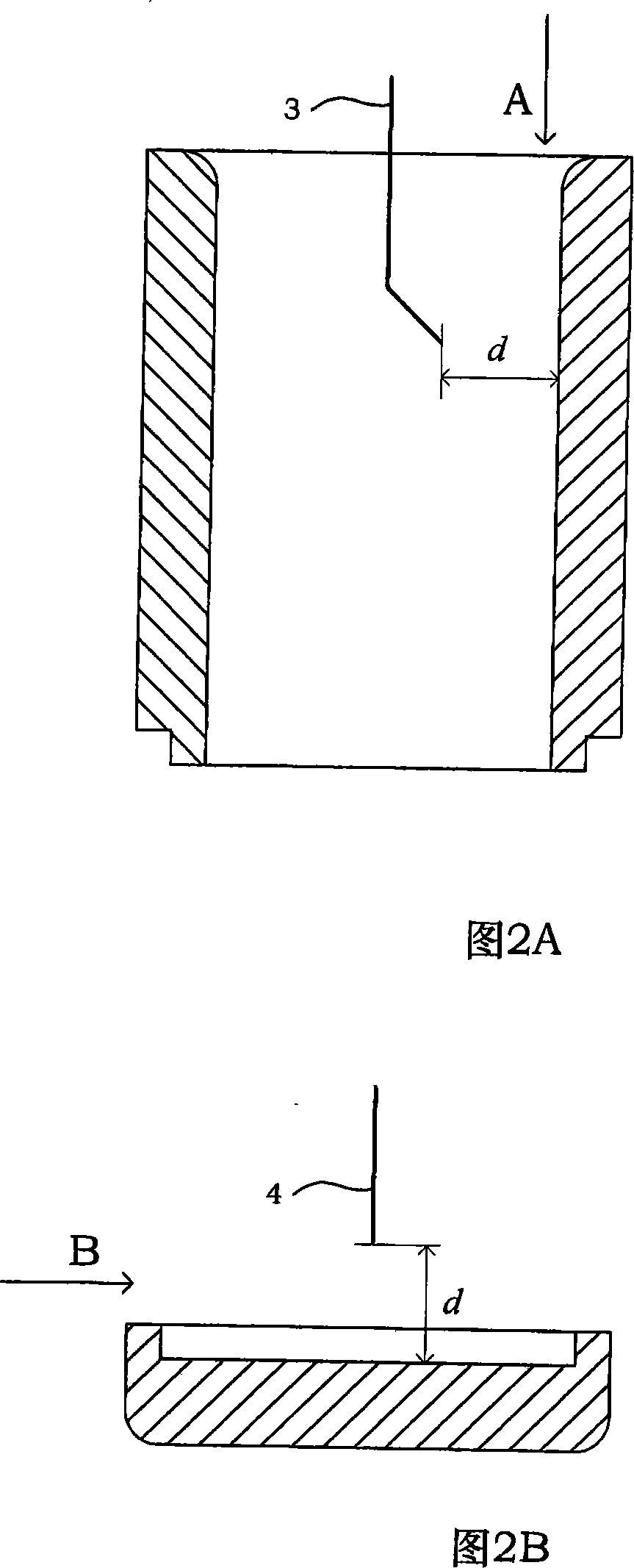

Split graphite crucible and method for preparing carbon coating inside the crucible

InactiveCN101162125ALittle thermal impactEasy to automateMolten spray coatingCrucible furnacesSpray methodZero resistance

The invention discloses a split type graphite crucible with a split structure and Y2O3 carbon coating with zero resistance in upper and lower crucible bodies, wherein, a lug boss (12) of the upper crucible body (1) of the split type graphite crucible is arranged inside a concave chamber (23) of the lower crucible body (2), the end surface of the lug boss (12) is in close joint with the bottom of the concave chamber (23) of the lower crucible body (2), a surface of the lug boss (12) of the upper crucible body (1) is in close joint with a concave support surface (22) of the lower crucible body (2); the wall of an inner chamber (14) of the upper crucible body (1) is provided with an A-type inner coating (11) with a thickness of 50-250 um, the bottom of the concave chamber (23) of the lower crucible body (2) is provided with a B-type inner coating (21) with a thickness of 50-250 um. Both the A-type inner coating (11) and the B-type inner coating (21) adopt the spraying method of air plasma to prepare Y2O3 inside the crucible body of the split type graphite crucible so as to form the carbon coating with zero resistance, which effectively stops the chemical reaction between carbon and metal fused mass in the melting process, thereby avoiding carbon pollution.

Owner:BEIHANG UNIV

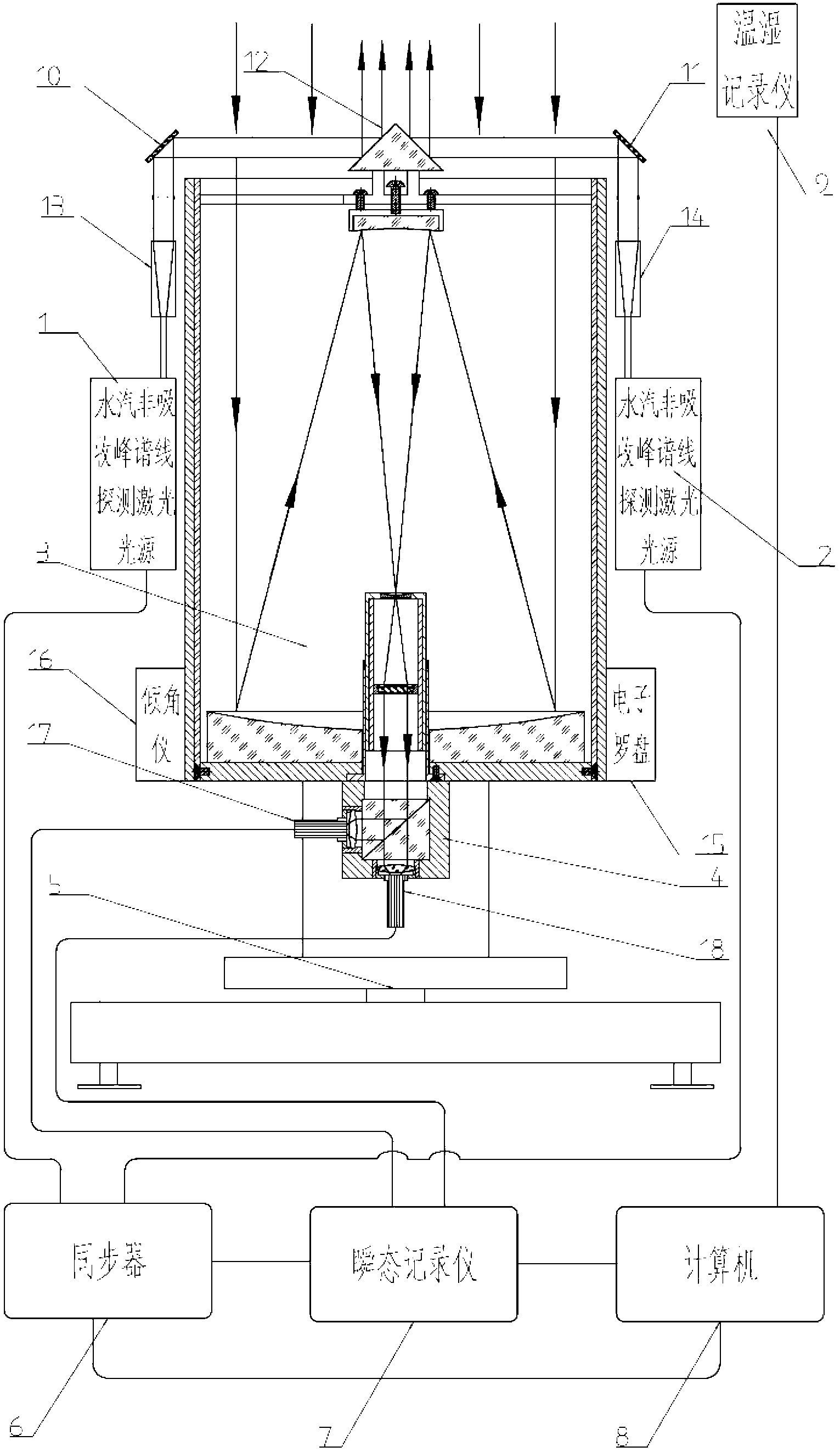

Automatic continuous detection device of micro-pulse differential absorption lidar water vapor spatial and temporal distribution

ActiveCN103293116AImprove stabilityImprove reliabilityColor/spectral properties measurementsDifferential absorption lidarOptical path

The invention discloses an automatic continuous detection device of micro-pulse differential absorption lidar water vapor spatial and temporal distribution. The device comprises dual wavelength detection light sources, a lidar receiving optical system, a signal detection system, a three dimensional rotating platform, a transient recorder, an automatic temperature and humidity recorder and the like. The wavelengths of the two detection light sources are respectively positioned on a water vapor absorption peak and a water vapor non-absorption peak, the detection light can be transmitted into atmosphere at any angle, water vapor absorption characteristic backward scattering signals in specific spectral lines are obtained, water vapor distance-distinguished relative humidity profiles in transmission paths of light are obtained by inversion, and after profiles being calibrated, high-resolution and high-precision water vapor relative humidity spatial and temporal distribution data in light paths is finally obtained. The automatic continuous detection device can carry out day and night all-weather observation for water vapor relative humidity stereo distribution, and has advantages of high time resolution, high spatial resolution and high detection precision.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

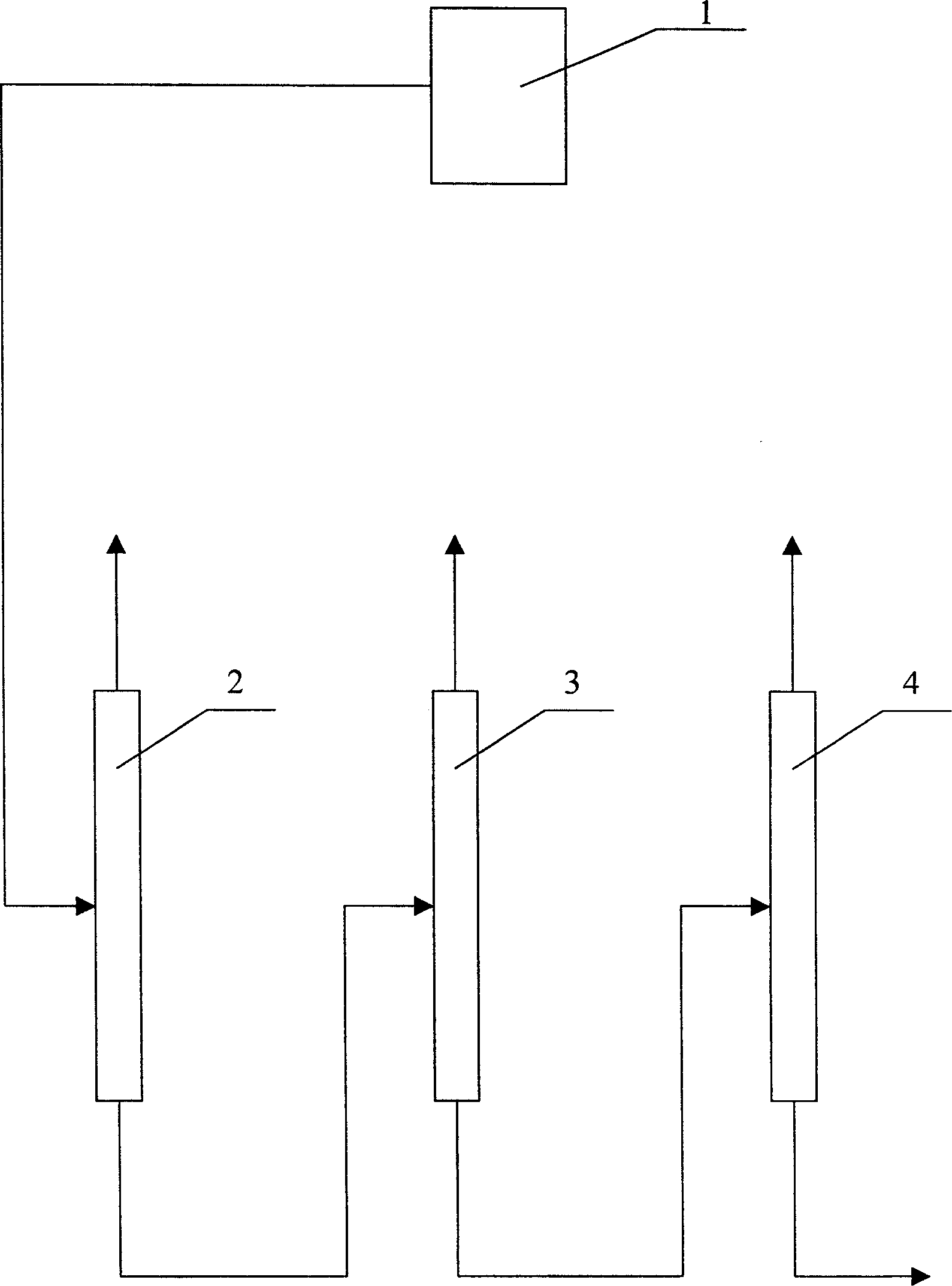

Process for extracting 1-methylnaphthalene and 2-methylnaphthalene from tar

InactiveCN1721380ASimple processEasy to automateDistillation purification/separationTar2-methylnaphthalene

The method of extracting 1-methyl naphthalene and 2-methyl naphthalene from tar includes adopting the production apparatus comprising one alkylating polymerization reactor and three serially connected rectification towers, and the production process, which comprises the alkylating polymerization reaction of material with methyl naphthalene content not lower than 60 %, solid acid and / or liquid acid catalyst and alkylation agent in 70-90 deg.c and 95-115 deg.c separately; the separation of the alkylating polymerization product in the first rectification tower to eliminate light distillation fraction from the tower top; the further separation in the second rectification tower to obtain 2-methyl naphthalene of 95 % over purity from the tower top; and the further separation in the third rectification tower to obtain 1-methyl naphthalene of 95 % over purity from the tower top. The present invention makes it possible to treat both tar scrubbing oil and coal tar scrubbing oil in the same apparatus.

Owner:TIANJIN UNIV

High-purify upper oxygen-free copper rod production method

The invention discloses a method for producing high-purity upward oxygen-free copper rods, which comprises the following steps: uniformly adding copper plates into a melting furnace in batches during melting of copper materials; adopting a Cu-RE intermediate alloy rod to continuously add single rare earth element or mischmetal element, realizing electromagnetic stirring in the melting furnace through induction heating coils, and making the rare earth element uniformly distributed in molten copper; and arranging a ceramic filtration baffle plate on the front of a sluice between the melting furnace and a heat-insulating furnace, making the ceramic filtration baffle plate completely cover the sluice, preventing rare earth oxide from being rolled into upward oxygen-free copper rods, and obtaining the high-purity upward oxygen-free copper rods. The method has the advantages of simple production technique, stable production process, less residual oxide inclusion formed by the rare earth element, good purification effect of the copper materials, and good product quality.

Owner:JIANGSU UNIV +1

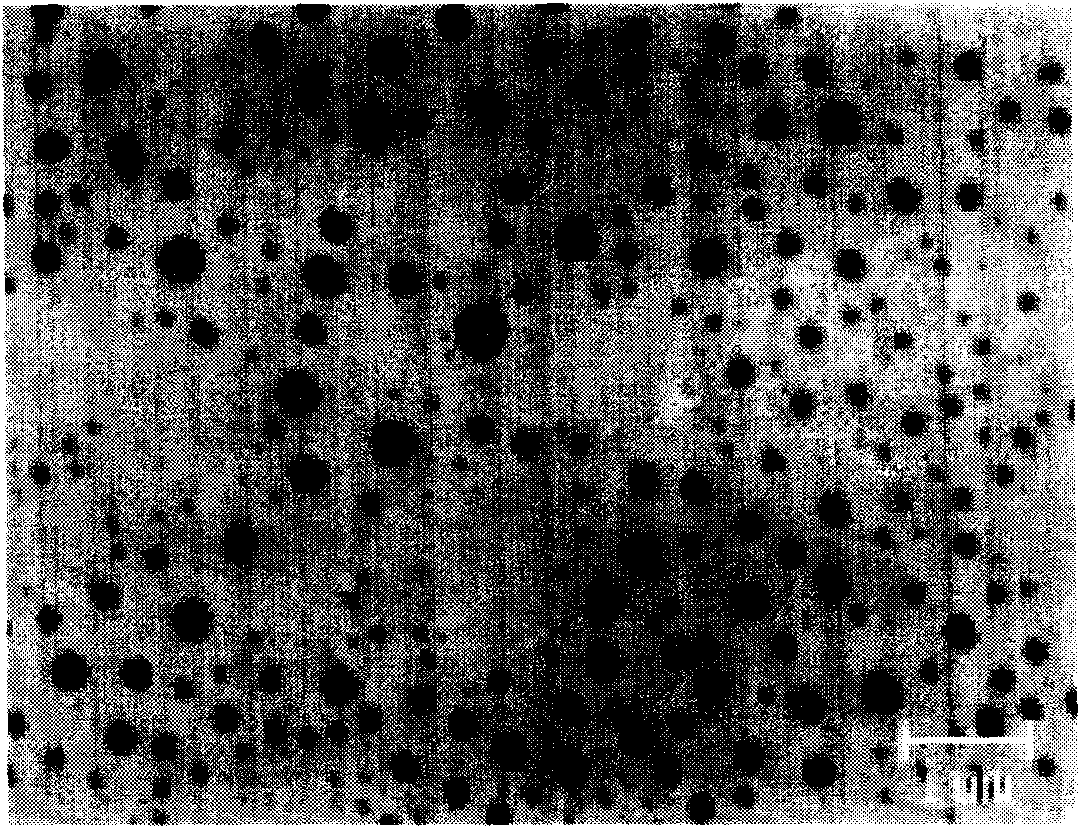

Antigen detection method and application thereof

InactiveCN101566626AEasy to store and transportHigh sensitivityMicrobiological testing/measurementMaterial analysisPsa antigenMicrosphere

The invention relates to an antigen detection method and application thereof. The method converts detection of an antigen signal into detection of a nucleic acid barcode label, and comprises the following operation steps: (1) labeling modified nano magnetic microspheres by using an antibody I of an antigen to be detected to prepare immune magnetic microspheres, and labeling nano-gold sol by using an antibody II of the antigen to be detected and a nucleic acid barcode fragment at the same time to prepare a double-labeled nano-gold probe; (2) fully combining the immune magnetic microspheres, the nano-gold probe and the antigen to be detected, removing combined aggregate, and leaving supernatant fluid for detection; and (3) detecting the nucleic acid barcode label in the supernatant fluid. The antigen detection method can be applied to the detection of clinical PSA antigen. The method has the advantages of simple operation, high sensitivity, good specificity, easy automation and wide application prospect.

Owner:SHENZHEN PEOPLES HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com