Flip-chip integrated encapsulation structure of LED and method thereof

A light-emitting diode and integrated packaging technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., to achieve the effects of improving connection reliability, realizing automation and mass production, and solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

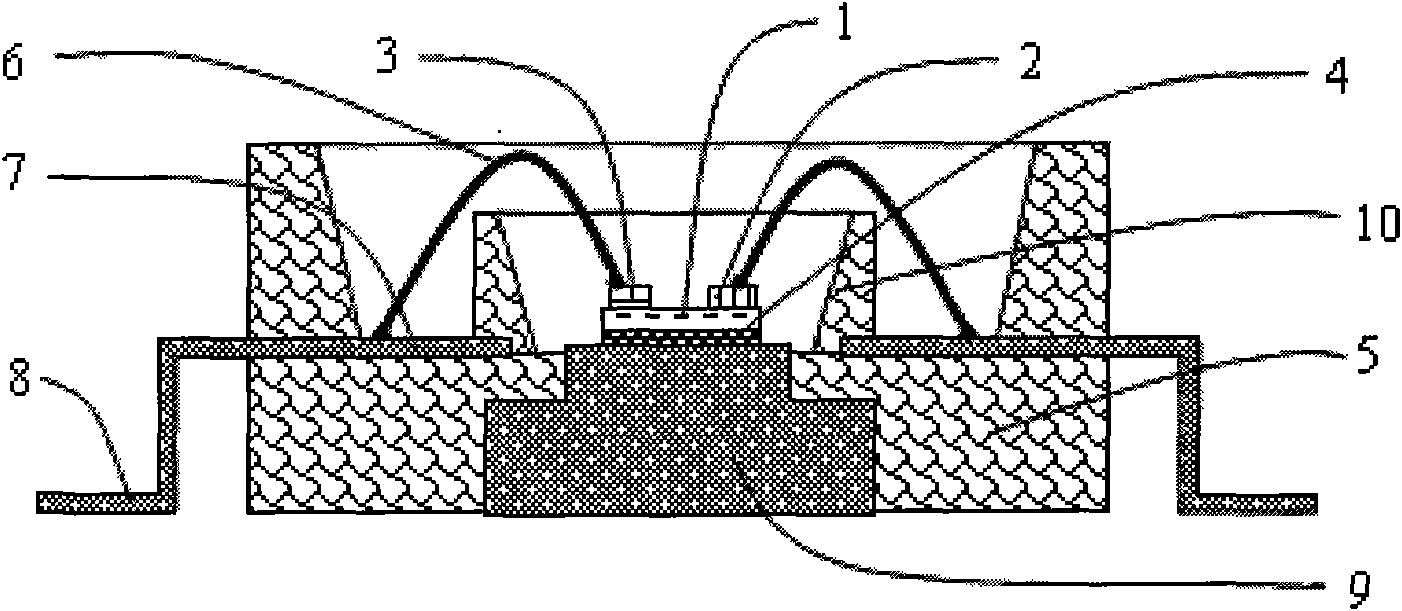

[0050] Such as Figure 2-1a and Figure 2-1b As shown, the light-emitting diode flip-chip integrated packaging structure uses the silicon wafer substrate 18 directly as the surface mount (SMD) support and heat dissipation channel for the entire structure of the LED chip 1 . A reflective cup is formed on the silicon wafer substrate 18, and the front side of the silicon wafer substrate 18 is provided with a front electrode connection layer 15, and at least one LED chip 1 is directly welded on the silicon wafer substrate with the reflective cup through metal bumps 14. 18 on the front electrode connection layer 15 to realize electrical connection. The front electrode connection layer 15 of the silicon substrate 18 is connected to the electrode metal pads 20 provided on the side and the back of the silicon substrate 18 through wiring on the side wall of the silicon groove. The front electrode connection layer 15 is electrically connected to the electrode metal pad 20 on the side ...

Embodiment 2

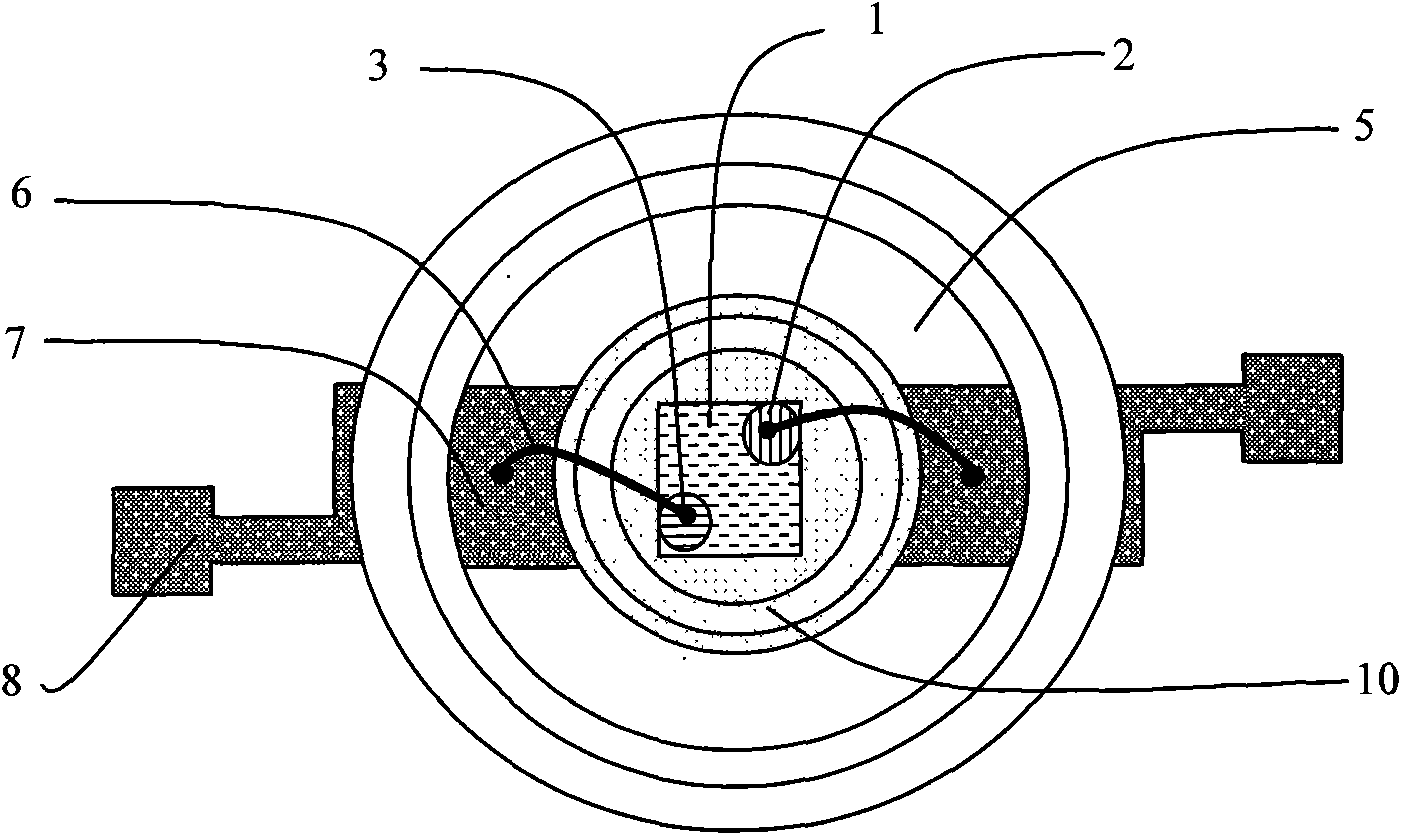

[0053] Such as Figure 2-2a and Figure 2-2b As shown, the light-emitting diode flip-chip integrated packaging structure uses the silicon wafer substrate 18 directly as the surface mount (SMD) bracket and heat dissipation channel supported by the entire structure of the LED chip 1, and a reflector cup is formed on the silicon wafer substrate 18. , the front surface of the silicon wafer substrate 18 is provided with a front electrode connection layer 15 . At least one LED chip 1 is directly flip-chip welded on the front electrode connection layer 15 of the silicon wafer substrate 18 with a reflective cup through the metal bump 14 to realize electrical connection. The front electrode connection layer 15 is connected to the electrode metal pad 20 provided on the back side of the silicon substrate 18 by means of through-hole wires in the silicon wafer substrate. The reflective cup can be formed by directly forming a silicon groove 21 on the silicon wafer substrate 18 as a reflec...

Embodiment 3

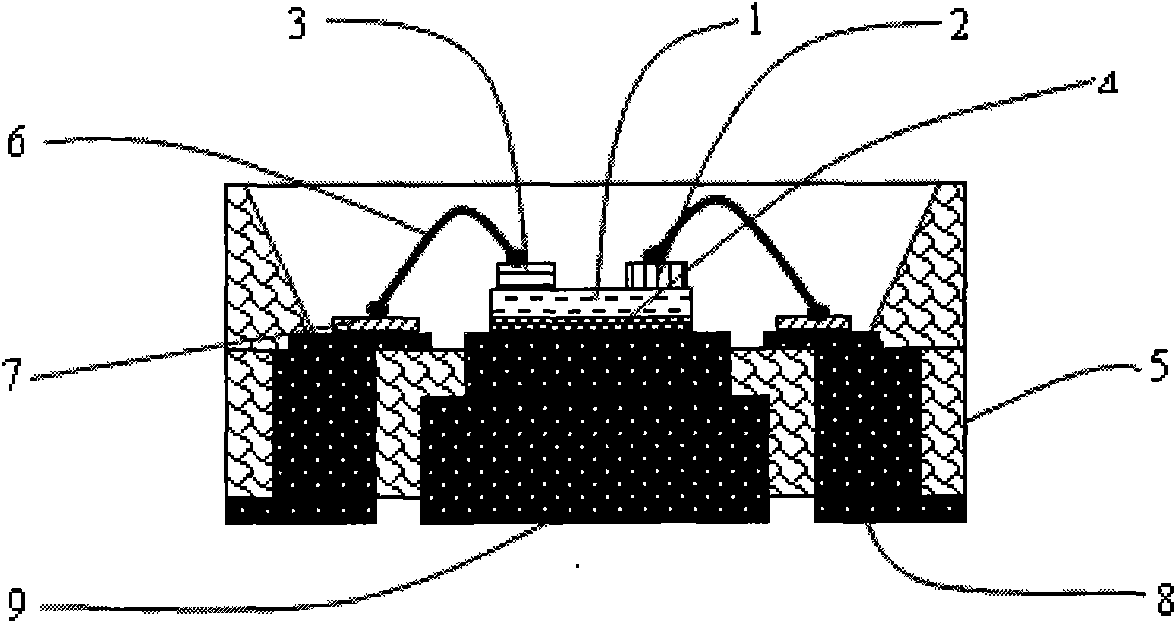

[0058] Such as Figure 3-1a , Figure 3-1b , Figure 3-1c , Figure 3-1d and Figure 3-1e As shown, here the connection between the front electrode connection layer 15 and the electrode metal pad 20 is mainly realized through the structure of the silicon groove side wall leads. The production steps are as follows:

[0059] (1) The LED chip 1 is manufactured. LED chip 1 is an epitaxial wafer grown on a sapphire substrate with multiple layers of gallium nitride. After a series of process steps such as photolithography, etching, metal layer deposition and passivation layer protection, the P electrode 2 and The N electrode 3 is fabricated.

[0060] (2) Fabricate a silicon wafer substrate 18 and form a reflective cup on the silicon wafer substrate 18 . The manufacturing steps are as follows: a, firstly fabricate the silicon wafer substrate 18 and the reflective cup wafer 16; b, then align the reflective cup wafer with the same characteristic size with the silicon wafer subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com