Patents

Literature

114results about How to "Easy to achieve productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible pressure sensor and preparation method thereof

ActiveCN106197772AHigh sensitivityImprove reliabilityForce measurement using piezo-resistive materialsElectrical resistance and conductanceIsolation layer

The invention discloses a flexible pressure sensor which comprises an induction layer, a substrate layer, an isolation layer and electrodes. The isolation layer is positioned between the induction layer and the substrate layer and bonded to the induction layer and the substrate layer, and enables electric contact between the induction layer and the substrate layer to be isolated discontinuously; the surface of the induction layer is provided with a first conductive layer, the surface of the substrate layer is provided with a second conductive layer, and the first and second conductive layers are bonded to the isolation layer in opposite directions; and the electrodes are led out of the first or second conductive layer and connected with an external circuit. The flexible pressure sensor is used to detect the size and fluctuation of pressure, a flexible conductive material on the specific substrate is bonded to other conductive substrate, the electrodes are led out, change of resistance between the electrodes is measured, and the size and fluctuation of the pressure is detected in directly. The pressure sensor of high flexibility and high reliability can be applied to a flexible bearing body, technology is simple, and the sensor can be compatible with a present processing technology of a resistant screen to realize scaled production and application.

Owner:常州第六元素半导体有限公司

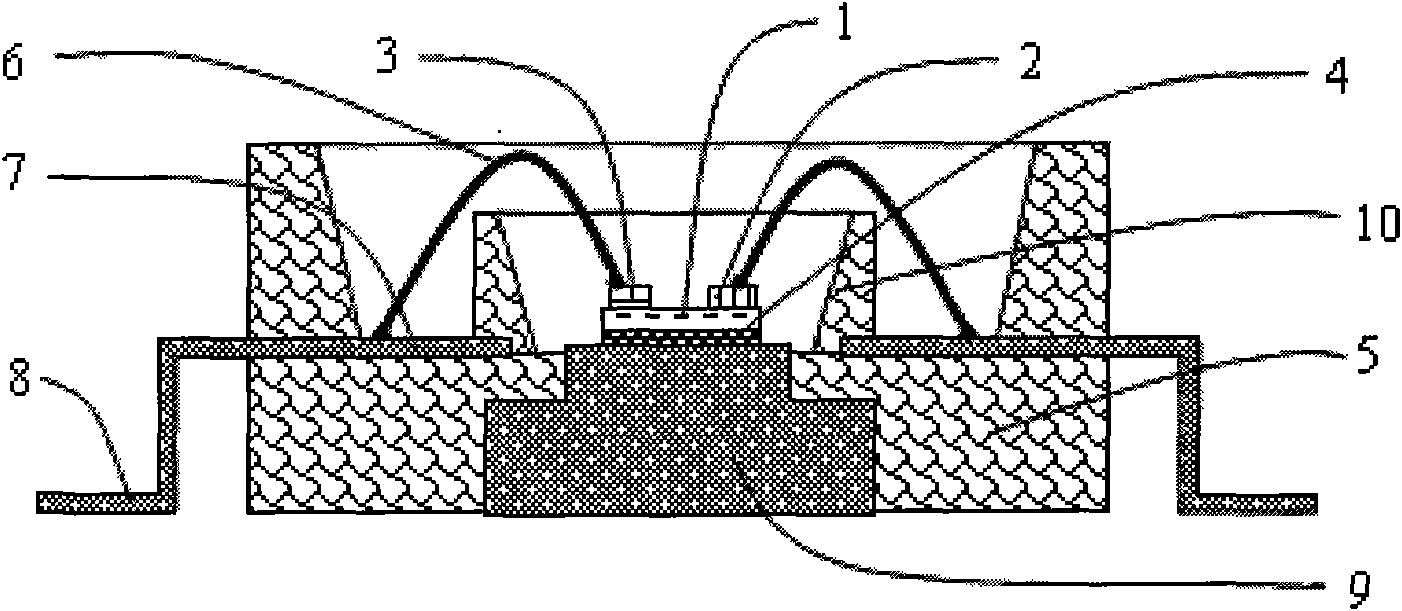

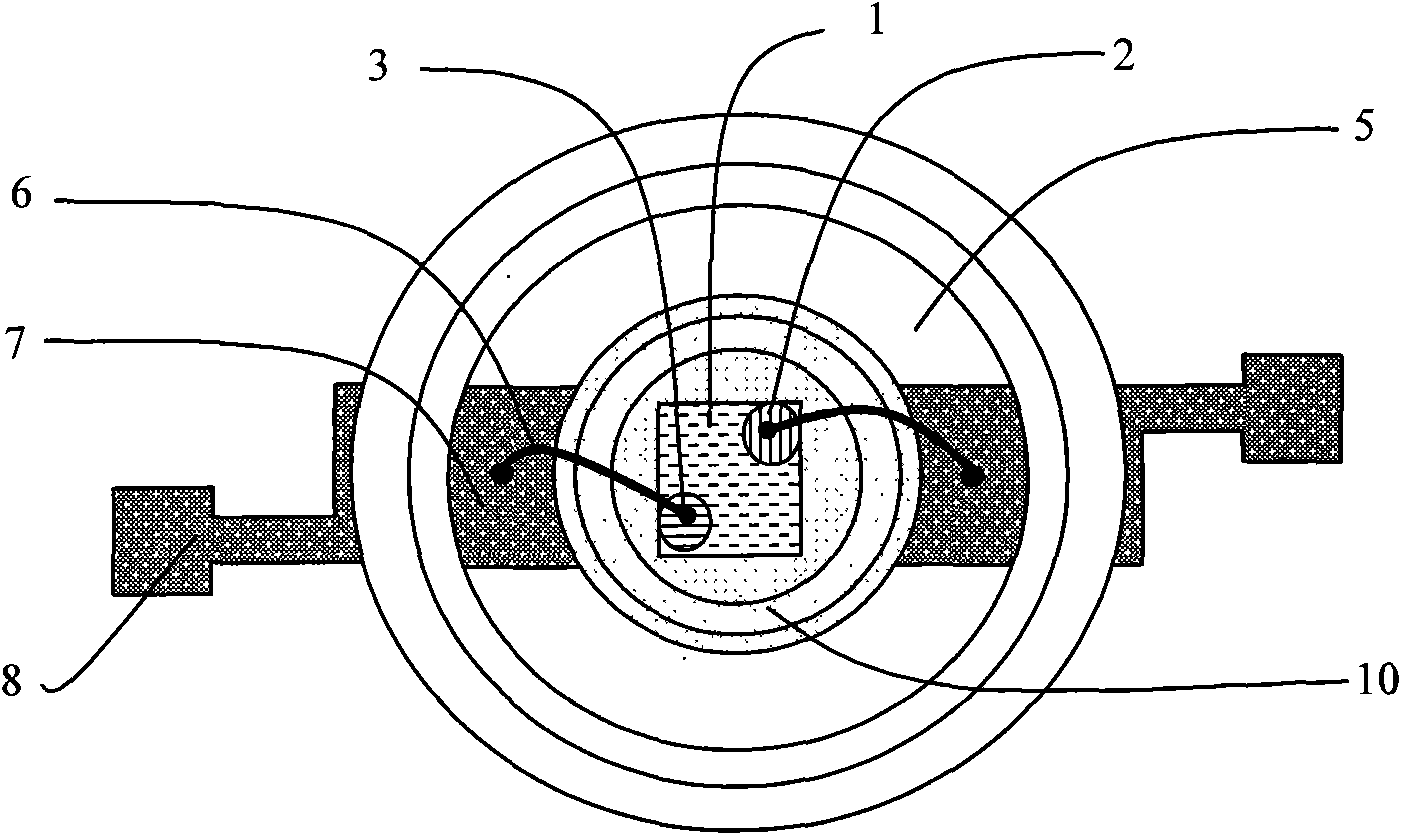

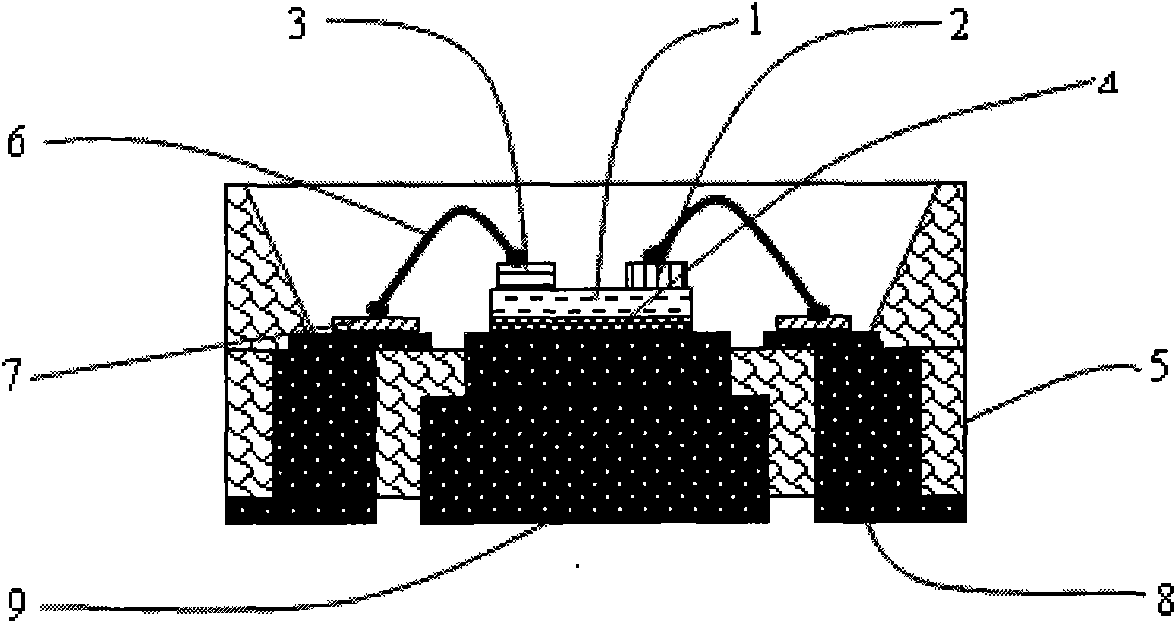

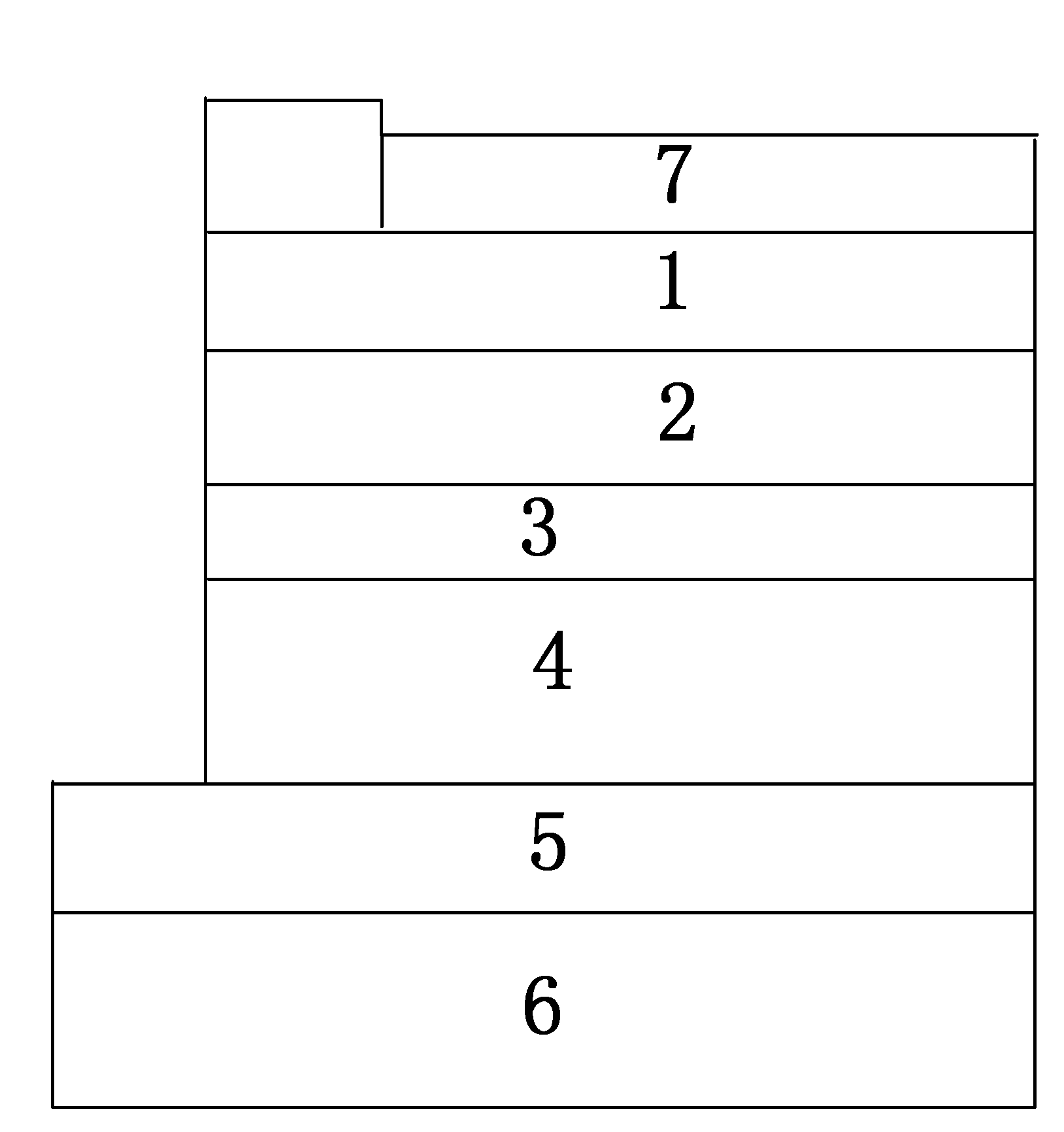

Flip-chip integrated encapsulation structure of LED and method thereof

InactiveCN101567411ABroaden applicationSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingMiniaturization

The invention provides a novel light emitting diode (LED) encapsulation structure which directly adopts a silicon dice substrate as both a surface mounting bracket and a radiation channel of an integrated structure support of an LED chip; a front electrode connecting layer is arranged on the front surface of the silicon dice substrate; the front electrode connecting layer on the front surface of the silicon dice substrate is connected with an electrode metal bonding pad at the back of the silicon dice substrate through a lead of a silicon groove side-wall or a lead of a through-hole of the silicon dice substrate; and at least one LED chip is welded directly by flip-chip on the front electrode connecting layer of the silicon dice substrate with an optical source through a metal bump. The invention also provides a method for manufacturing the LED encapsulation structure. The invention avoids steps of die bonding and gold-wire welding and enhances the connection reliability of chips and especially the connection reliability of multi-chip modules; and the invention leads the encapsulation of high-power LED and especially the encapsulation of multi-chip module to be miniaturized and also leads power-supply drive and circuits of LED protection and the like to be integrated on the silicon dice so as to provide a systematic and integrated encapsulation proposal for high-power LED illumination.

Owner:APT ELECTRONICS

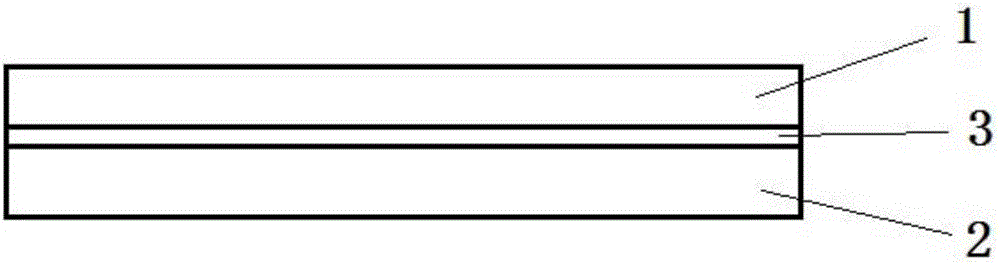

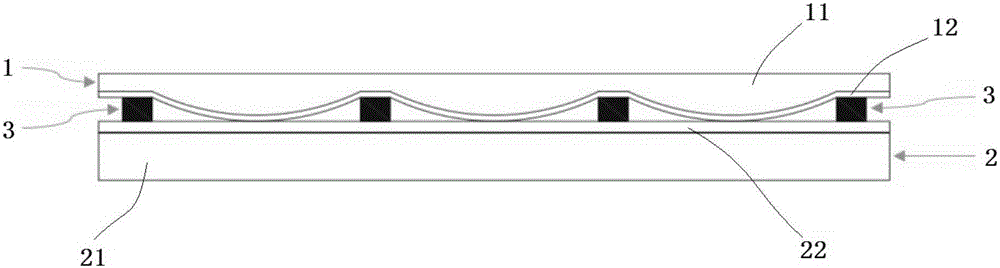

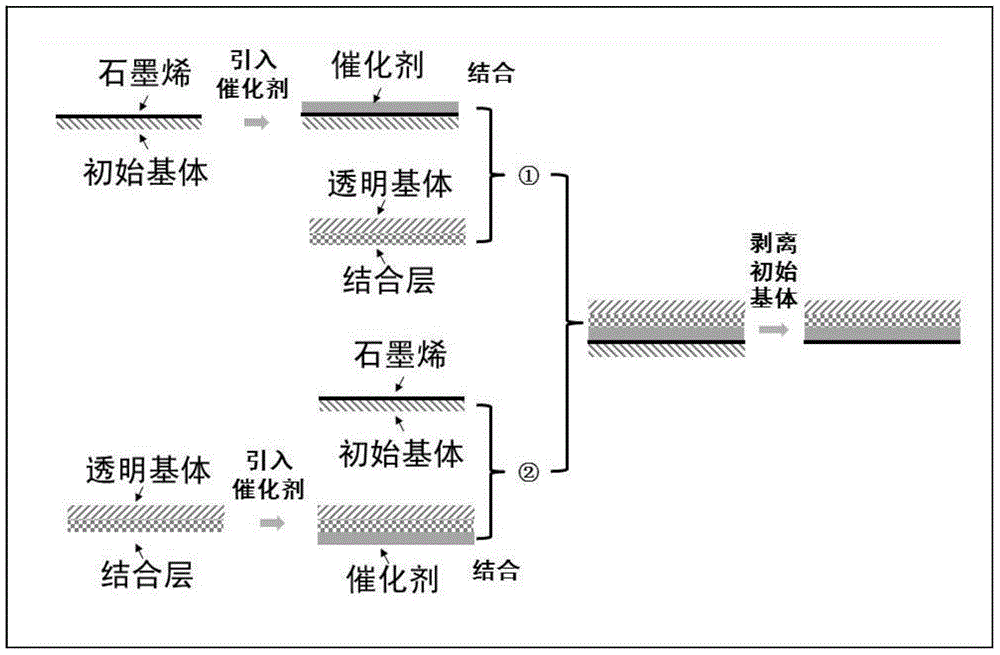

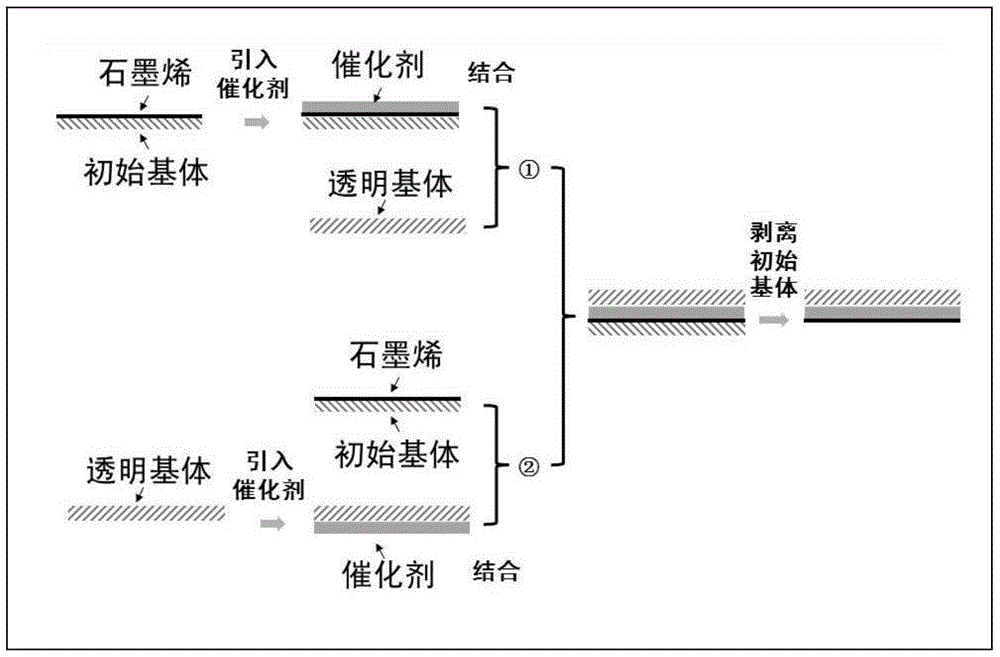

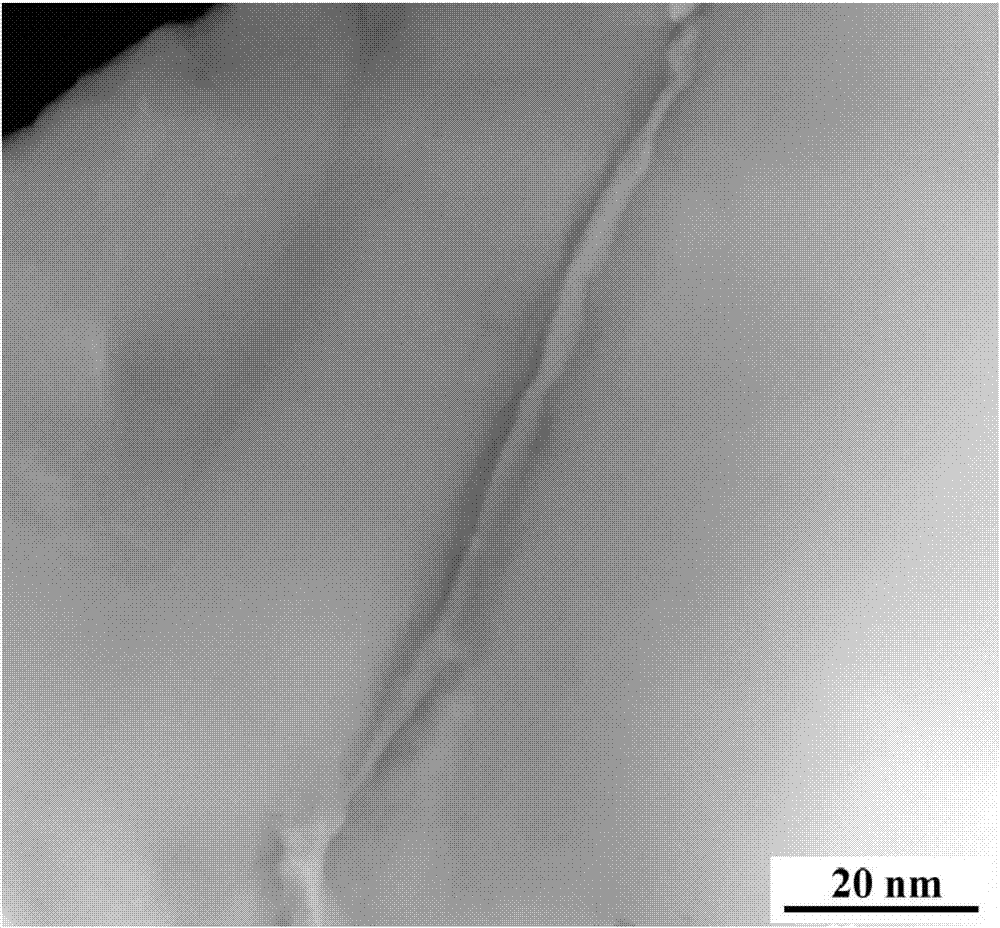

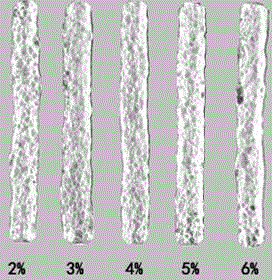

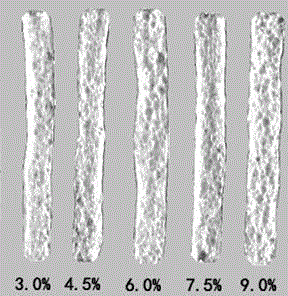

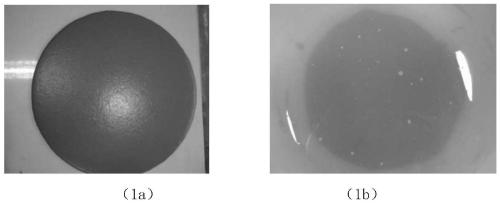

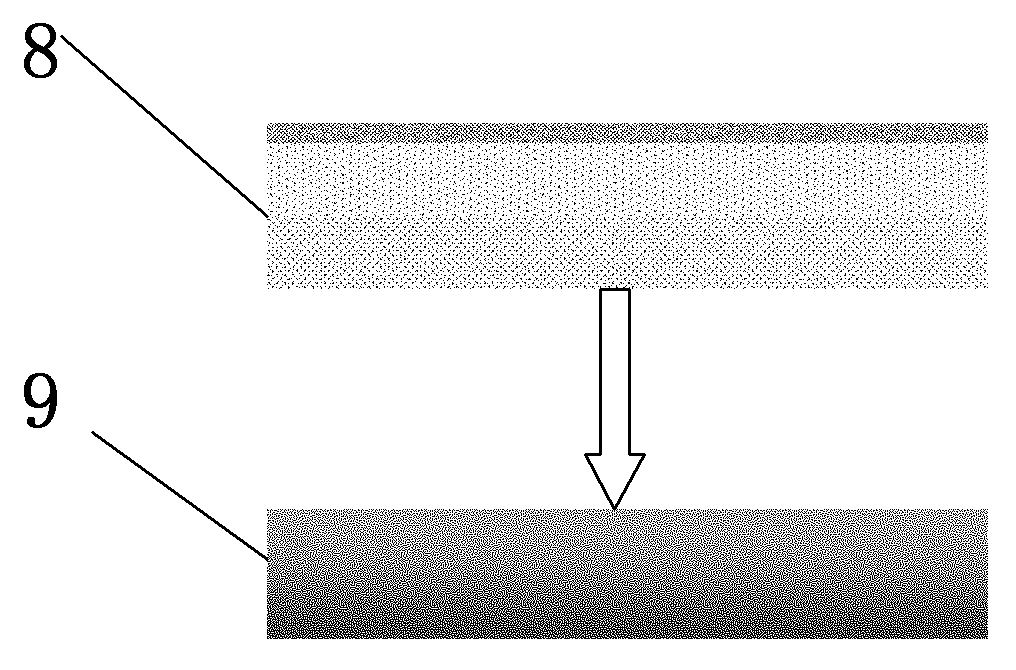

Large-scale preparation method for stably-doped large-area graphene transparent conductive films

ActiveCN104409177AImprove doping effectImprove stabilityCable/conductor manufactureDopantTransparent conducting film

The invention relates to a preparation technology for graphene transparent conductive films, in particular to a large-scale preparation method for stably-doped large-area graphene transparent conductive films. According to the method, the doping effect and stability of the graphene transparent conductive films are improved through a sandwich structure, and a doping agent is in direct contact with the intrinsic surface of graphene and positioned between the graphene and a transparent substrate. The method comprises the following steps: firstly, forming the doping agent on the surface of the graphene or the transparent substrate on an initial substrate; secondly, combining the graphene, the doping agent and the transparent substrate; finally, separating the graphene from the initial substrate so as to prepare the stably-doped large-area graphene transparent conductive films. The graphene serves as an outer-layer protection film of the doping agent, so that the doping stability can be improved; the intrinsic surface of the graphene is in direct contact with the doping agent, so that the pollution of an interface between the graphene and the doping agent by impurities can be avoided, the doping effect of the doping agent can be improved, and the conductivity of the film can be enhanced; the transferring and doping processes of the graphene are combined, so that the large-scale preparation can be easily realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

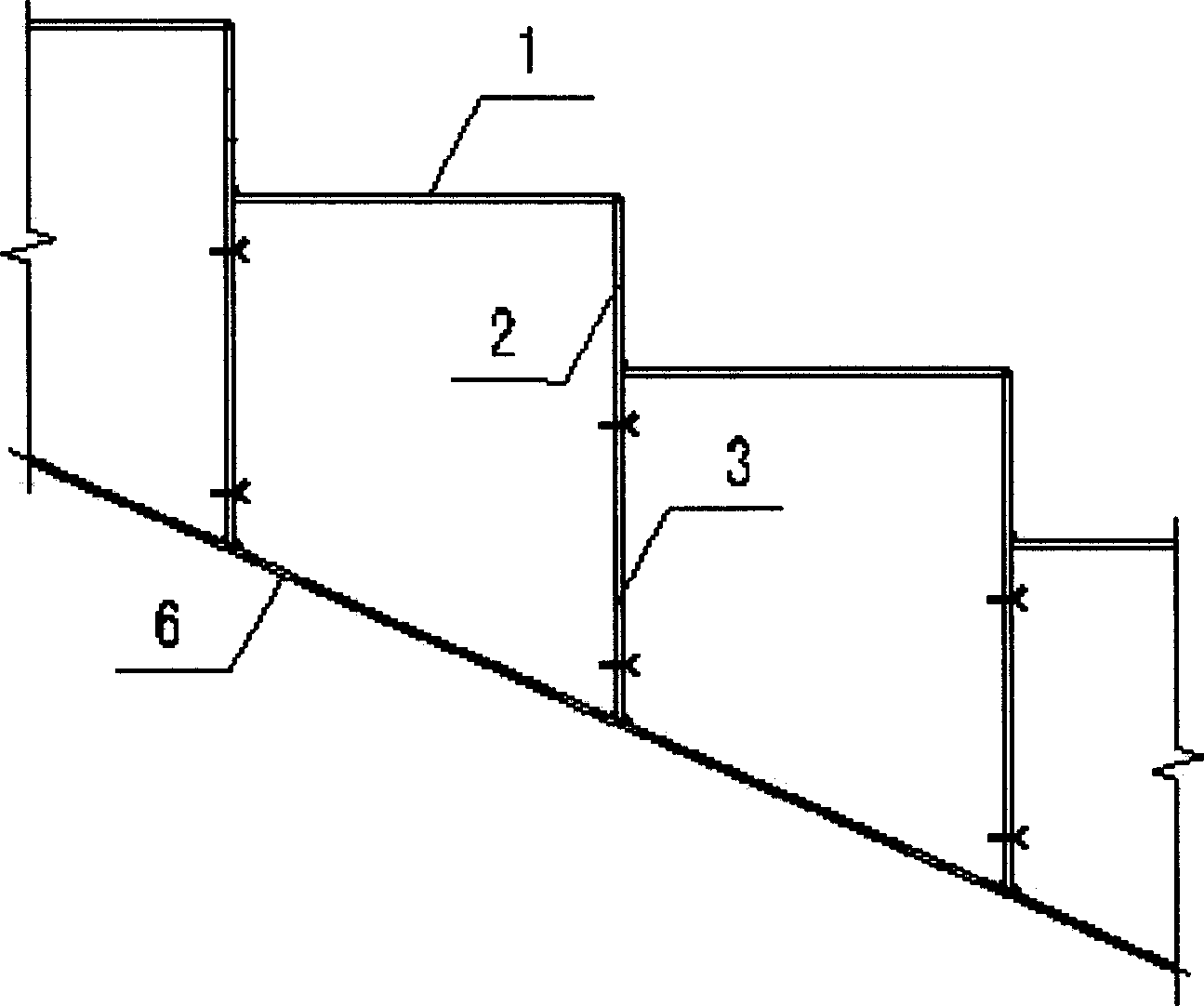

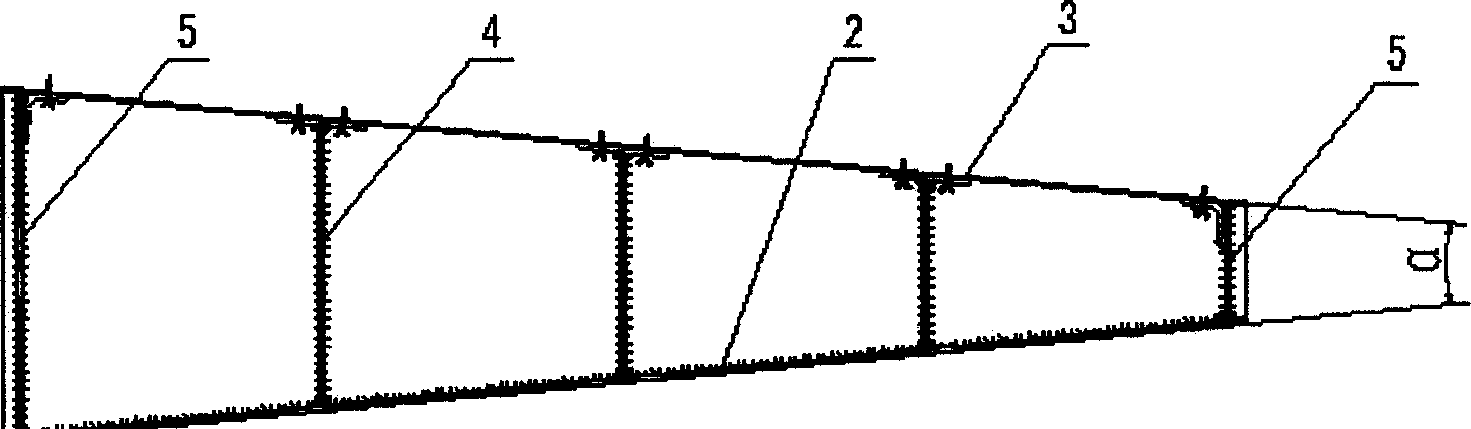

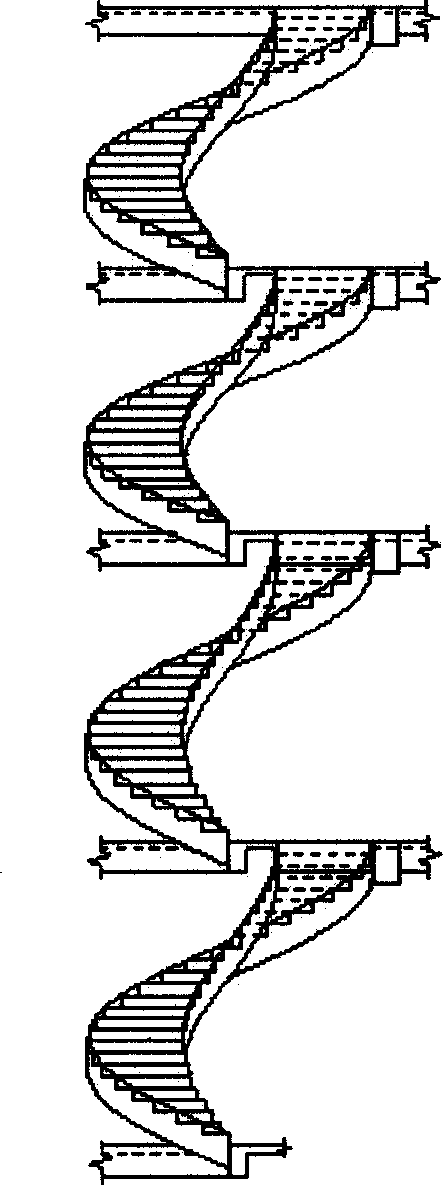

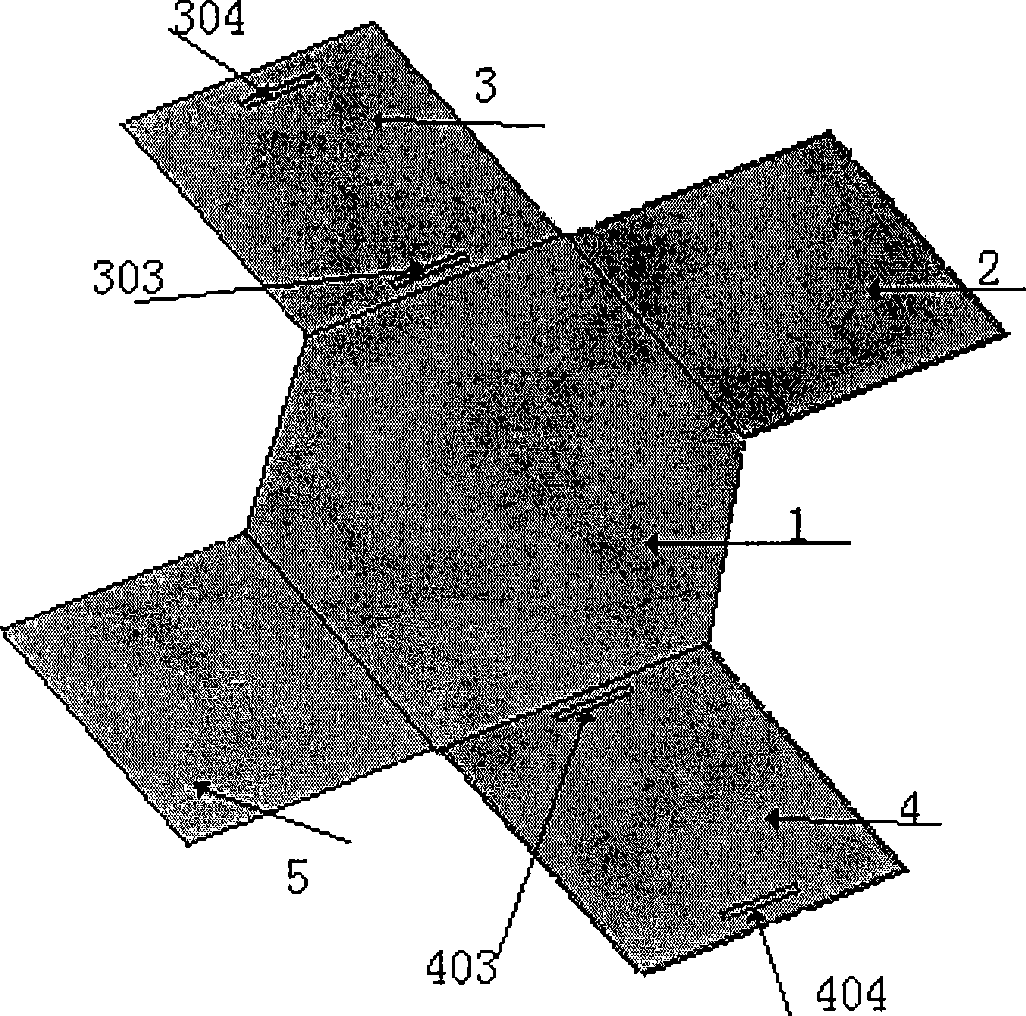

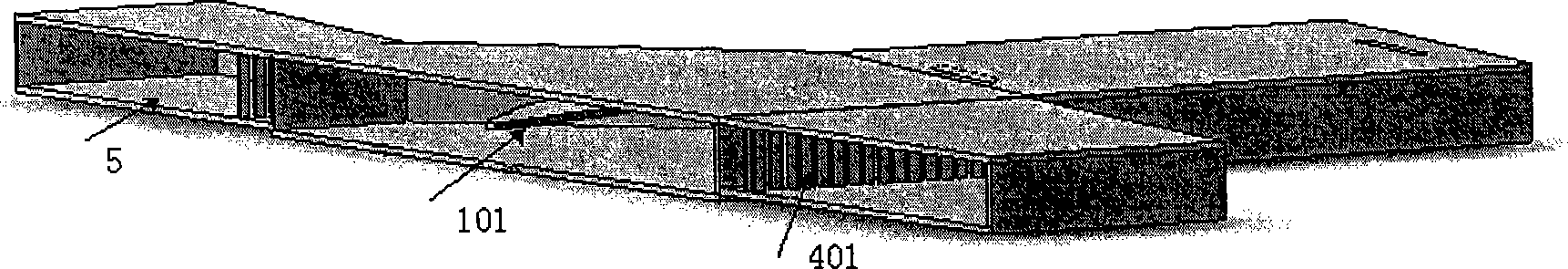

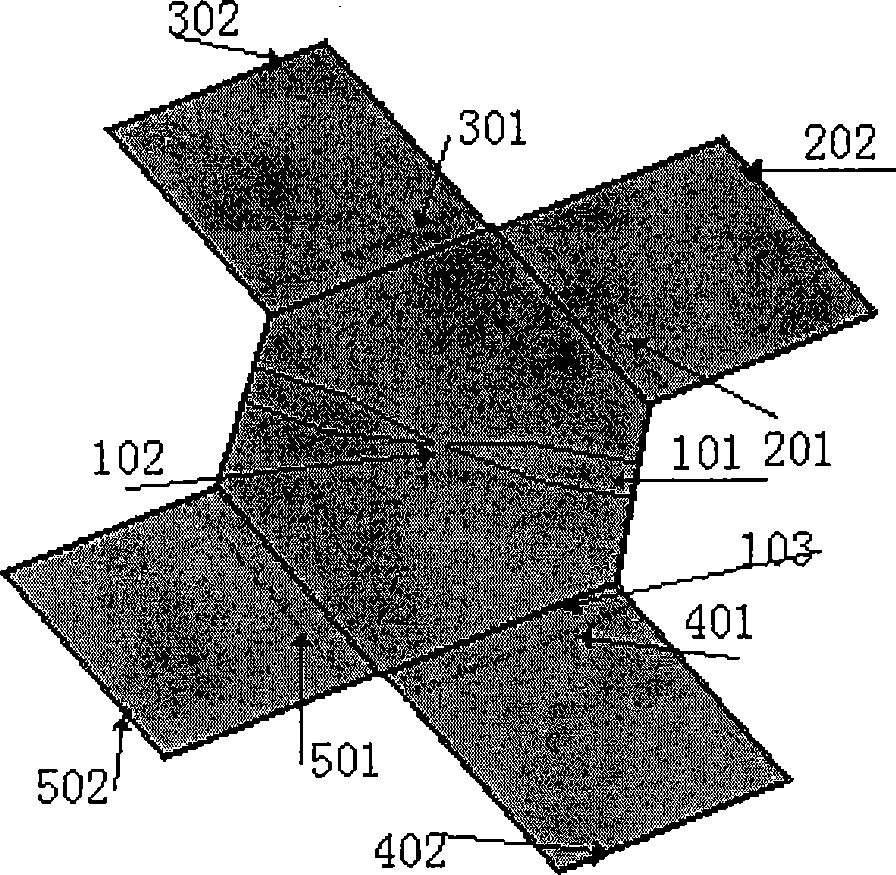

Integrally assembling staircase and method for fabricating same

The invention discloses an installation entire stair and the manufacturing method, especially an installation entire helix stair. The process is that: making every step to box structure and joining the steps into an entire stair by the method of bolt or joint. The shape of the stair could be straight stair or helix stair. The invention sharply decreases the time limit for a project and the cost. Moreover, it has advantages of simple structure, low cost and easy to realize mass production.

Owner:GUIZHOU UNIV

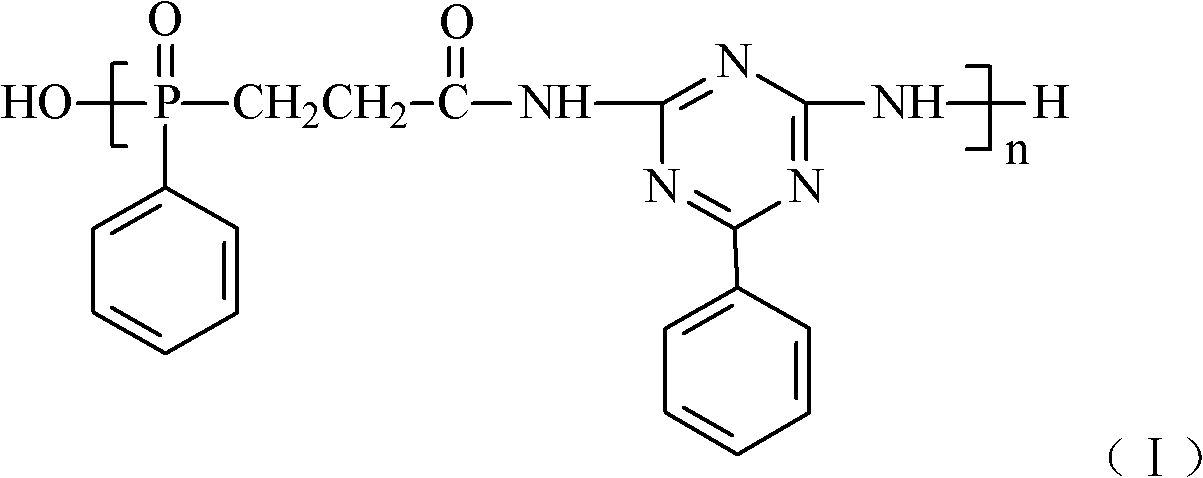

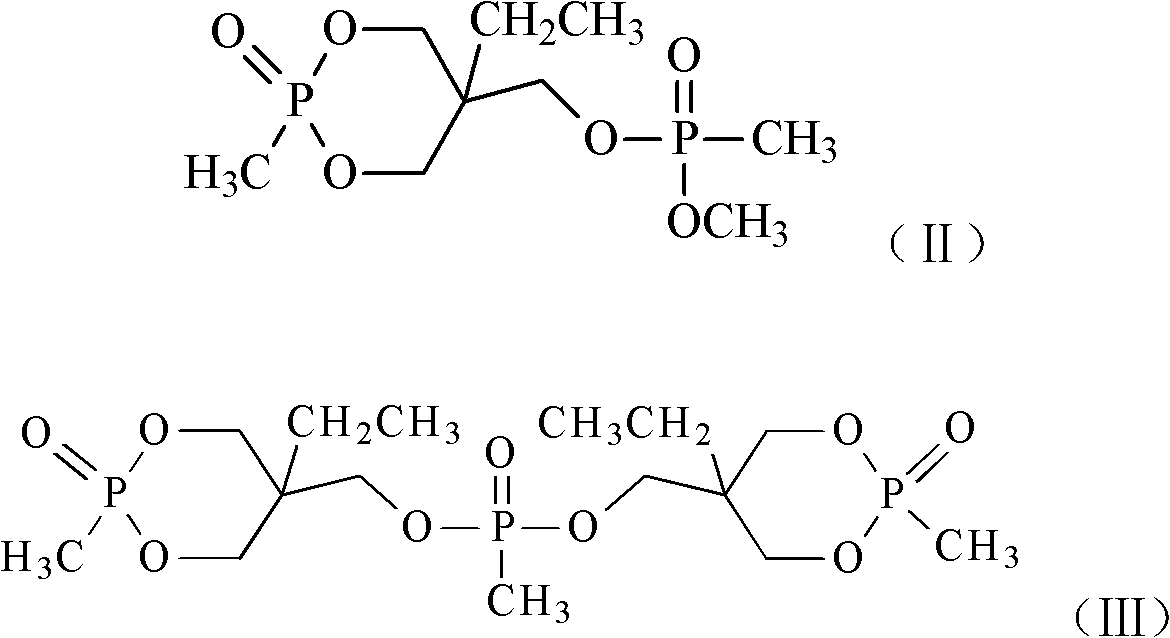

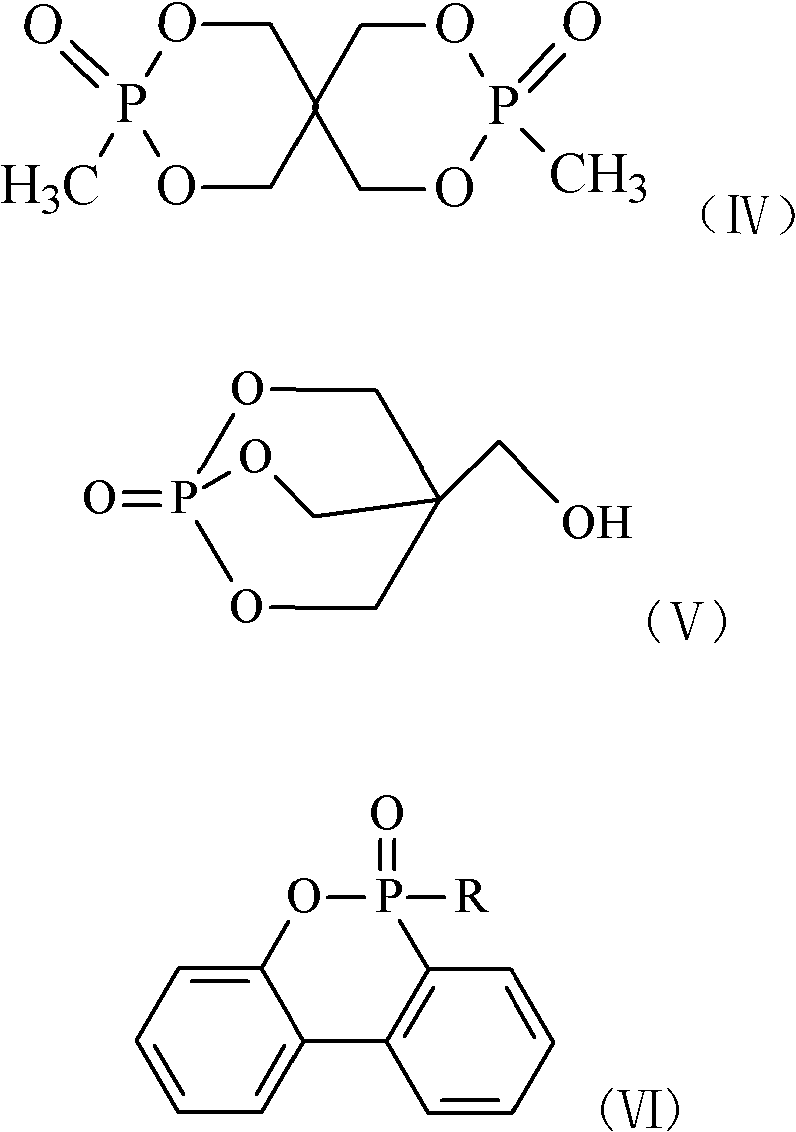

Halogen-free high-efficiency flame retardant composition and preparation method thereof

InactiveCN102337034AImprove thermal stabilityImprove liquidityFibre treatmentPolyolefinPolymer science

The invention discloses a halogen-free high-efficiency flame retardant composition and a preparation method thereof. The halogen-free high-efficiency flame retardant composition is prepared from the following components in percentage by mass: 10-80% of phenyl melamine carboxyethyl phenyl phosphinic acid condensation compound, 15-70% of melamine and / or derivative thereof and 5-20% of organic phosphate. The halogen-free flame retardant composition can be used for flame retarding of various polyolefin, nylon, polyurethane, polyester and other synthetic materials and textiles, and is particularly suitable for polyester and nylon engineering plastic; and by the addition of 12wt% of the flame retardant composition to polybutylene terephthalate (PBT) resin, the flame-retarding level can reach UL 94 V-0 (1.6 mm). The flame retardant composition has the characteristics of high flame retarding efficiency, good fluidity, no precipitation and the like, and can meet the use requirements of flame-retardant resin for electric appliance shells and supports, electronic and electric device connectors and the like.

Owner:DONGHUA UNIV

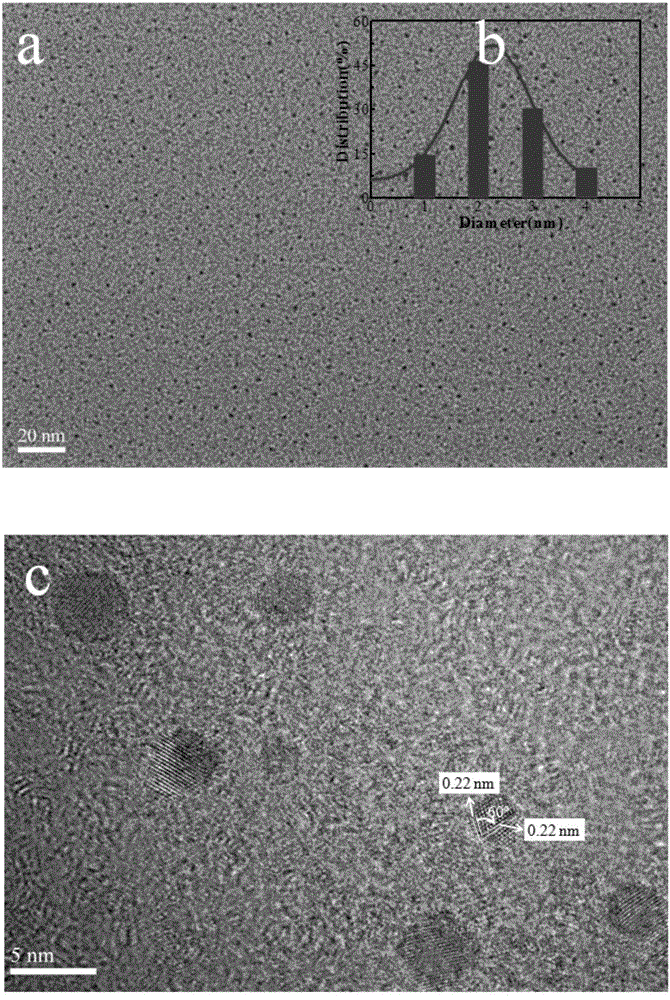

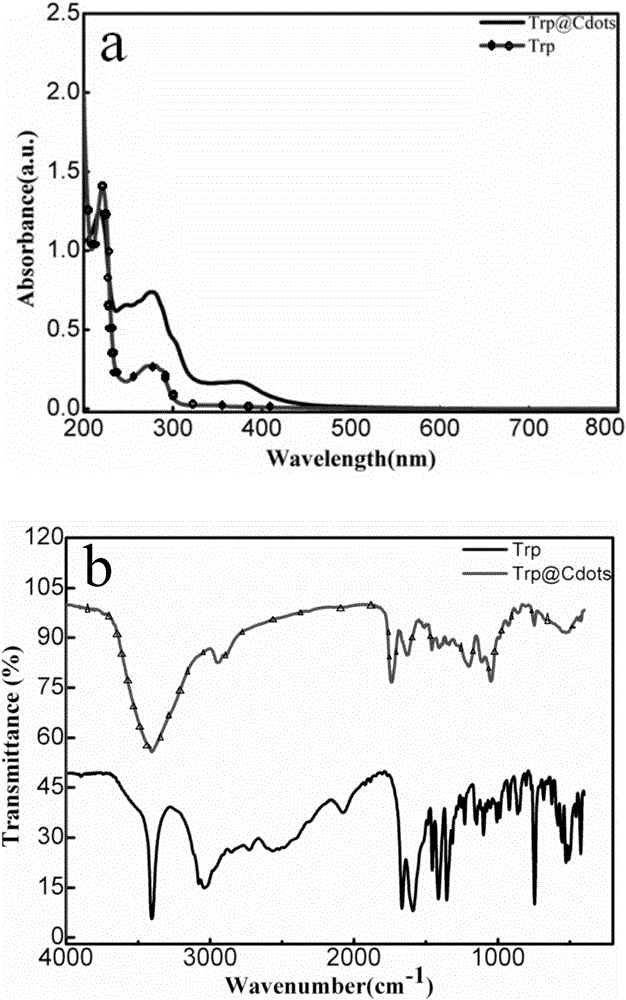

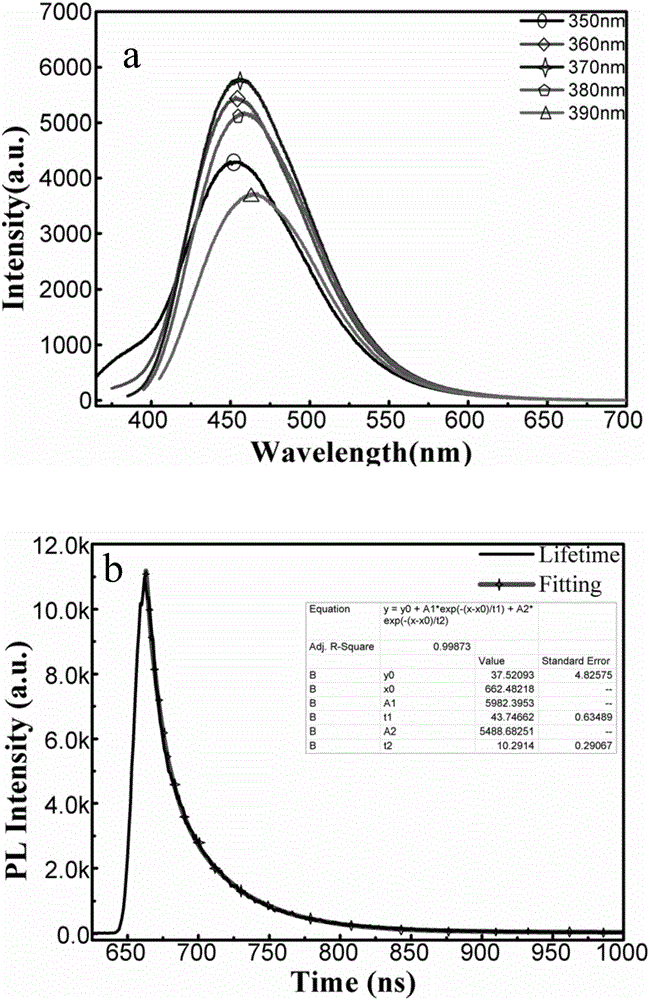

Method for batch green synthesis of nitrogen and phosphorus doped fluorescent carbon dots

ActiveCN106381143ALow costEasy to realize batchMaterial nanotechnologyNano-carbonQuantum yieldReaction temperature

The invention provides a method for batch green synthesis of nitrogen and phosphorus doped fluorescent carbon dots, wherein the method comprises the following steps: a first step, adopting a high-boiling-point polar organic solvent as a reaction medium, wherein the boiling point of the high-boiling-point polar organic solvent is greater than 180 DEG C; a second step, adopting organic small molecules as a carbon dot precursor, and adopting an auxiliary combination synthesis reagent; a third step, by a solvothermal reaction, mixing and dissolving the carbon dot precursor, phosphoric acid and the auxiliary combination synthesis reagent in the high-boiling-point polar organic solvent, controlling the reaction temperature and the reaction time, and preparing nitrogen and phosphorus doped fluorescent carbon dots; and a fourth step, purifying the mixed solution after the reaction of the third step, to obtain the high-purity fluorescent carbon dots. The water-soluble carbon dots with high fluorescence quantum yield can be further prepared in batch, and the fluorescent emission wavelength of the fluorescent carbon dots is controlled by controlling the reaction temperature and the reaction material ratio; the preparation process is green and pollution-free, has no need of special equipment, has the cost reduced, and is prone to realization of batching and scaling production.

Owner:SHANGHAI JIAO TONG UNIV

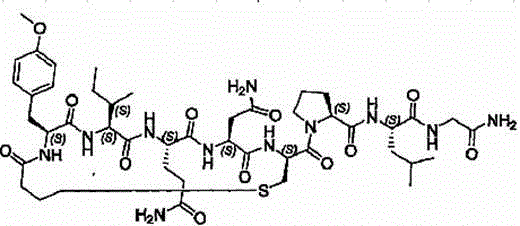

Synthesis process of carbetocin

InactiveCN104592362AHigh purityReduced operating requirementsOxytocins/vasopressinsPeptide preparation methodsSide chainCarbetocin

The invention provides a synthesis process of carbetocin. The synthesis process comprises the following steps: performing a coupling reaction on Fmoc-Gly-OH with Rink Amide-AM Resin obtained in the first step to obtain Fmoc-Gly-Rink Amide-AM Resin; performing deprotection (20% piperidine) with DBLK to obtain H-Gly-Rink Amide-AM RFesin, and orderly completing the coupling of the H-Gly-Rink Amide-AM Resin with Fmoc-Leu-OH, Fmoc-Pro-OH, Fmoc-Cys(Trt)-OH, Fmoc-Asn(Trt)-OH, Fmoc-Gln(Trt)-OH, Fmoc-Ile-OH, Fmoc-Tyr(Me)-OH and tetrachlorobutyric acid until carbetocin linear peptide resin is synthesized; mixing a cracking agent with the carbetocin linear peptide resin obtained in the fourth step to have a cracking reaction, thereby removing the Rink Amide-AM Resin and side chain protecting groups; cyclizing the carbetocin linear crude peptide into a carbetocin crude product, and separating and purifying the carbetocin crude product to obtain the carbetocin. The synthesis process has the advantages that the polymerization side reaction is prevented, the process route is greatly simplified, the production cost is reduced and the synthesis efficiency is improved; in addition, the purity of the finished product is high; in short, the synthesis process is convenient for large-scale production, and meanwhile, advantageous for environmental protection, and has remarkable economic and social benefits.

Owner:苏州天马医药集团天吉生物制药有限公司

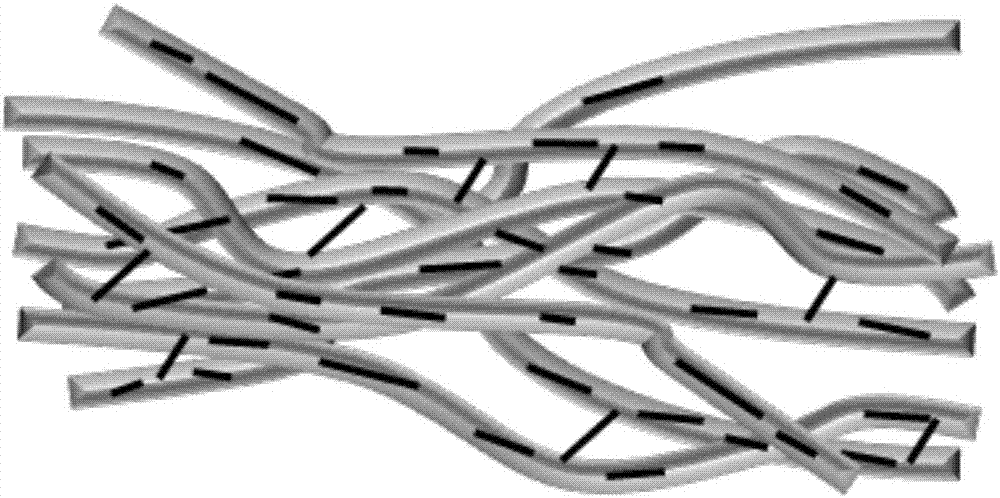

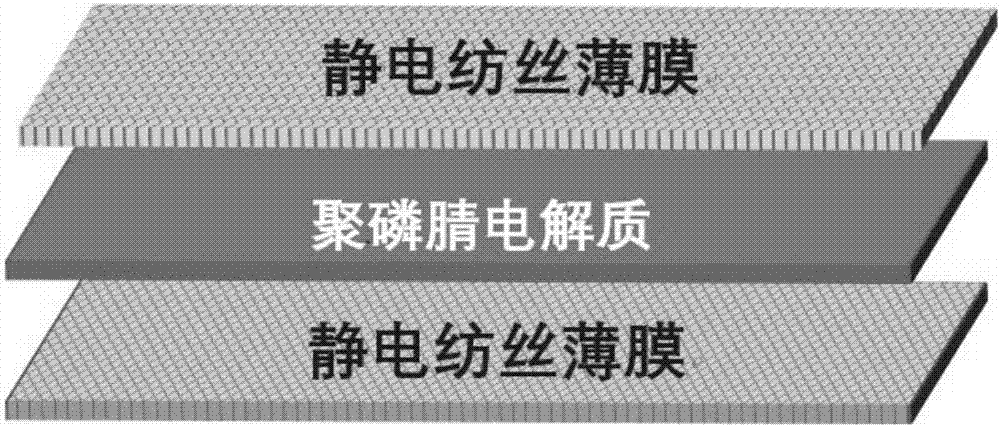

Solid electrolyte with double conducting ion networks and preparation method of solid electrolyte

ActiveCN106898811AImprove mechanical propertiesImprove film formationSolid electrolytesSecondary cellsSolid state electrolytePolyphosphazene

The invention relates to solid electrolyte with double conducting ion networks and a preparation method of the solid electrolyte, and solves the technical problem that existing polyphosphazene solid electrolyte is poor in mechanical property and low in conductivity. The solid electrolyte consists of a porous film and a polyphosphazene electrolyte material, wherein the porous film consists of a polymer, inorganic solid electrolyte and lithium salt; the porous film is a framework of the polyphosphazene electrolyte; and the polyphosphazene electrolyte is a carrier of lithium ions. The invention simultaneously provides a preparation method of the solid electrolyte. The solid electrolyte can be widely used in the field of preparation of the electrolyte.

Owner:BEIJING UNIV OF CHEM TECH

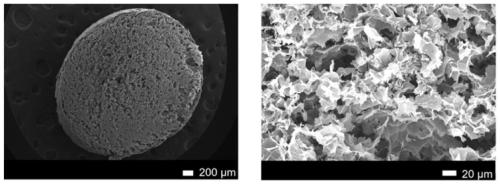

Shaped heat storage material and preparation method thereof

ActiveCN110305635AImprove heat storage capacityHigh heat storage capacityHeat-exchange elementsConductive materialsHeat storage material

The embodiments of the invention relate to the field of heat storage materials, in particular to a shaped heat storage material and a preparation method thereof. The preparation method comprises the steps that a high thermal conductive material is prepared into porous foam or an aerogel, then a heat storage material is loaded to obtain a shaped composite heat storage material with a rapid heat charging and discharging capacity; and then the shaped composite heat storage material is mixed with concrete to be poured and hardened to obtain the shaped heat storage material suitable for various shapes, sizes and occasions, so that the operational performance of the heat storage material is greatly improved, and the application range of the heat storage material is expanded. The preparation method can be used for preparing the shaped heat storage material with high heat storage capacity, the rapid heat charging and discharging capacity, shaping heat storage capacity and high convenience of use, and can be widely applied to the fields such as heat energy storage, heat supply, heating and industrial waste heat recycling.

Owner:TIANJIN POLYTECHNIC UNIV

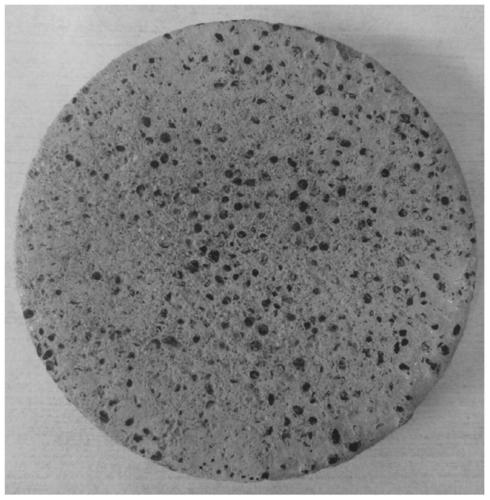

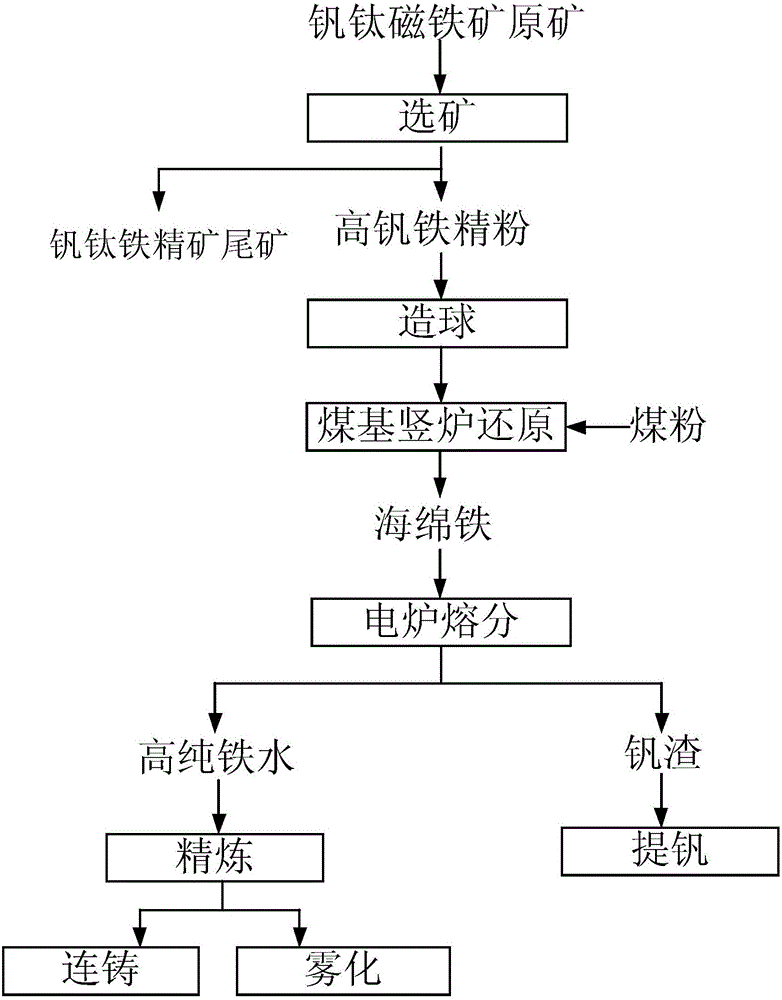

Process for comprehensively utilizing vanadium-titanium magnetite

The invention relates to a process for treating and comprehensively utilizing a vanadium-titanium magnetite. The process is characterized by comprising the following steps: (1) treating a raw vanadium-titanium magnetite by crushing, tailings discarding, fine grinding, low-intensity magnetic separating, high-intensity magnetic separating, and separating by a shaking table, so as to obtain a titanium concentrate and a high-vanadium-ferrum concentrate; (2) adding an adhesive to the high-vanadium-ferrum concentrate; uniformly mixing and pelletizing; drying; uniformly mixing with pulverized coal or coke powder; distributing; performing controlled reduction that V is not reduced through a coal based shaft furnace so as to obtain sponge iron, wherein the amount of used reducing agents such as the pulverized coal is 30 to 70% of the weight of high-vanadium-ferrum concentrate powder, and the reduction is performed for 10 to 18 hours at the temperature of 850 to 1060 DEG C; (3) heating the obtained sponge iron for 0.5 to 1.0 hour at the temperature less than 1050 DEG C through an intermediate frequency / main frequency furnace under a weak reduction atmosphere; then heating until the temperature is more than 1500 DEG C; performing melt separation to enable vanadium to enter slag, thus obtaining high-grade vanadium slag and high-purity molten iron. With the adoption of the process, a plurality of valuable elements in the vanadium-titanium magnetite can be effectively separated and utilized with high additional value.

Owner:WUHAN COSRED SCI & TECH LTD

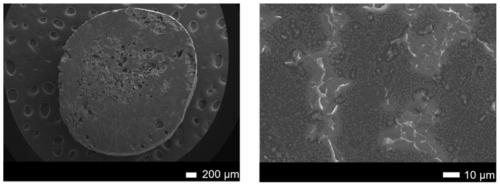

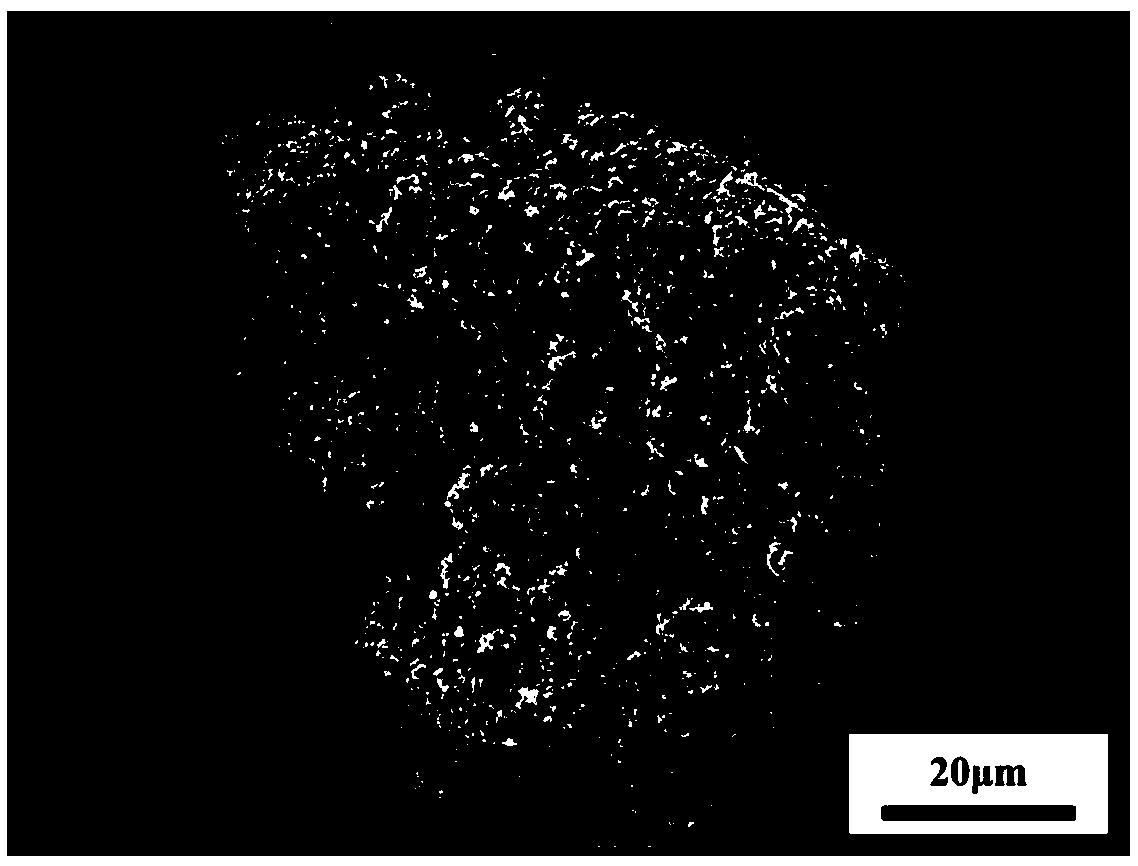

Preparation method of graphene/aluminum composite material

The invention discloses a preparation method of a graphene / aluminum composite material. The preparation method specifically includes the following steps that graphene oxide powder is evenly dispersed in an alcohol solution, and a graphene oxide alcoholic solution is prepared after emulsification and ultrasonic treatment; aluminum powder is slowly added under stirring, temperature is controlled to be not higher than room temperature, stirring speed is controlled to be 100-1000 r / min, stirring time lasts for 1-5 h, and the uniform graphene oxide alcoholic solution containing the aluminum powder is obtained; solid and liquid separation is performed through the filtering technology and the centrifugal technology, and graphene oxide / aluminum dry powder is obtained after separated paste solid is frozen and dried; and the dry powder is subjected to heat reduction under Ar / H2 mixed atmosphere, and finally the graphene / aluminum composite material is prepared. The graphene / aluminum composite material prepared through the method has the beneficial effects of being high in strength, low in heat expansion coefficient and the like, and the specific stiffness coefficient and the special strength coefficient are remarkably increased. The method is simple in technology and efficient, industrialized production and application can be easily achieved.

Owner:TANGSHAN JIANHUA TECH DEV

Preparation method for single-layer graphene-enhanced aluminium-based composite material

The invention discloses a preparation method for a single-layer graphene-enhanced aluminium-based composite material, relates to a preparation method for an aluminium-based composite material, and aims to solve the problems of high cost and great dispersing difficulty in the application of a single-layer graphene-enhanced aluminium-based composite material field at present. The preparation method comprises the following steps: firstly, weighing multi-layer graphene micro-flake aluminium metal powder, and weighing industrial pure aluminium block bodies, wherein the industrial pure aluminium block bodies and the multi-layer graphene micro-flake aluminium metal powder are in the weight ratio of (3-10):1; secondly, dispersing multi-layer graphene micro-flakes and moulding a precast block; thirdly, performing aluminium metal infiltration; fourthly, performing large plastic deformation; fifthly, performing high-temperature fusion treatment; sixthly, performing repeated plastic deformation and high-temperature fusion treatment. According to the preparation method for the single-layer graphene-enhanced aluminium-based composite material, the low-cost multi-layer graphene micro-flakes are taken as a raw material of an enhanced body, so that the cost is low; the content of single-layer graphene in the obtained composite material can reach 4 weight percent at most. The preparation method is applicable to preparing the single-layer graphene-enhanced aluminium-based composite material.

Owner:HARBIN INST OF TECH

MEMS spectrum gas-sensitive sensor

InactiveCN101470074AImprove performanceSolve poisoningColor/spectral properties measurementsInterference resistanceGas detector

The invention discloses a MEMS optical spectrum gas sensor, which utilizes optical spectrum to realize qualitative and quantitative analysis of object gas. The sensor obtains the concentration of object gas via the adsorbed amount of infrared light emitted by the discharge of the target gas in the object, while the adsorbed amount is determined by the light intensity difference between the infrared light of a reference chamber and a measurement chamber. The sensor is mainly composed of a radio frequency luminous tube, a target gas characteristic adsorption reference chamber (a main reference chamber), a target gas characteristic adsorption measurement chamber (a main measurement chamber), a non-characteristic adsorption measurement (an auxiliary measurement chamber) and a non-characteristic adsorption reference chamber (an auxiliary reference chamber). The main reference chamber and the main measurement chamber are used for detecting the concentration of target gas. The auxiliary reference chamber and the auxiliary measurement chamber are used for determining if the infrared adsorption in the main measurement chamber is caused by interference gas. The invention can resolve the defects of prior sensors such as low selectivity, low interference resistance and short service life, having low cost and wide application.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Culture medium for culturing dendrobium officinale tissue cultured seedling and method for preparing culture medium

ActiveCN104509440AShort training periodImprove transplant survivalHorticulture methodsPlant tissue cultureBiotechnologyPhosphate

The invention discloses a culture medium for culturing dendrobium officinale tissue cultured seedling and a method for preparing the culture medium, and belongs to the technical field of dendrobium officinale planting. The culture medium for culturing the dendrobium officinale tissue cultured seedling comprises the following components: mashed potatoes, applesauce, banana sauce, white sugar, ammonium nitrate, potassium nitrate, potassium dihydrogen phosphate, boric acid, amino acids, vitamins, IBA, GA, 6-BA and pure water. According to the invention, growth hormones IBA, GA and 6-BA are added to the culture medium for culturing dendrobium officinale tissue cultured seedling, so that the roots, buds and leaves can be promoted to grow quickly; and in addition, the culture medium is rational in component match and comprehensive in nutrition, and can shorten the culturing period of the dendrobium officinale and increase the survival rate of the transplanted dendrobium officinale to 98.75%. The method for preparing the culture medium for culturing the dendrobium officinale tissue cultured seedling, provided by the invention can shorten the disinfection time, improve the sterilization effect reliability and the industrialized production efficiency, and reduce the production cost. The method for preparing the culture medium for culturing the dendrobium officinale tissue cultured seedling is simple to operate and liable to realize the industrialized, normalized and standardized production.

Owner:翁源县天下泽雨农业科技有限公司

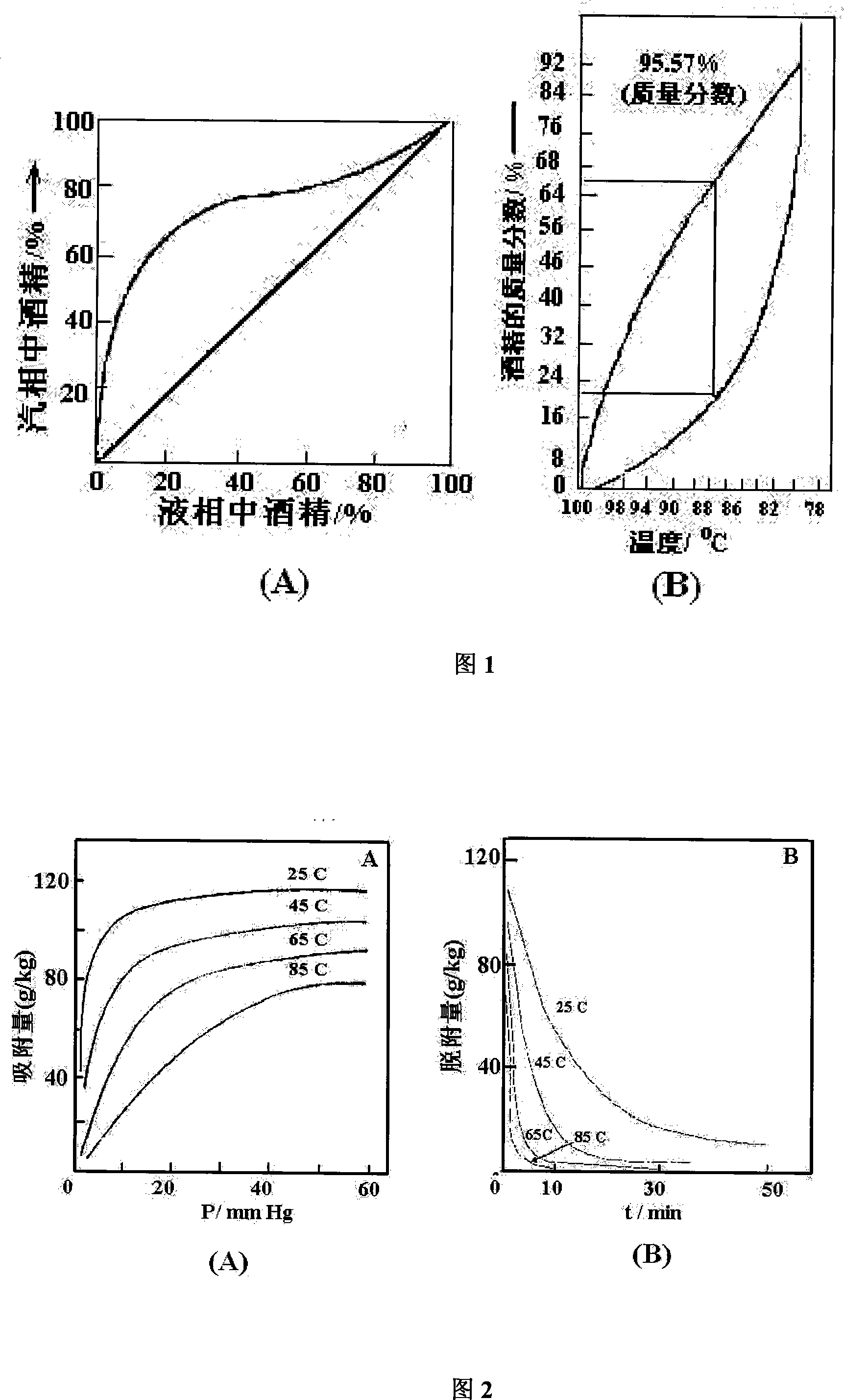

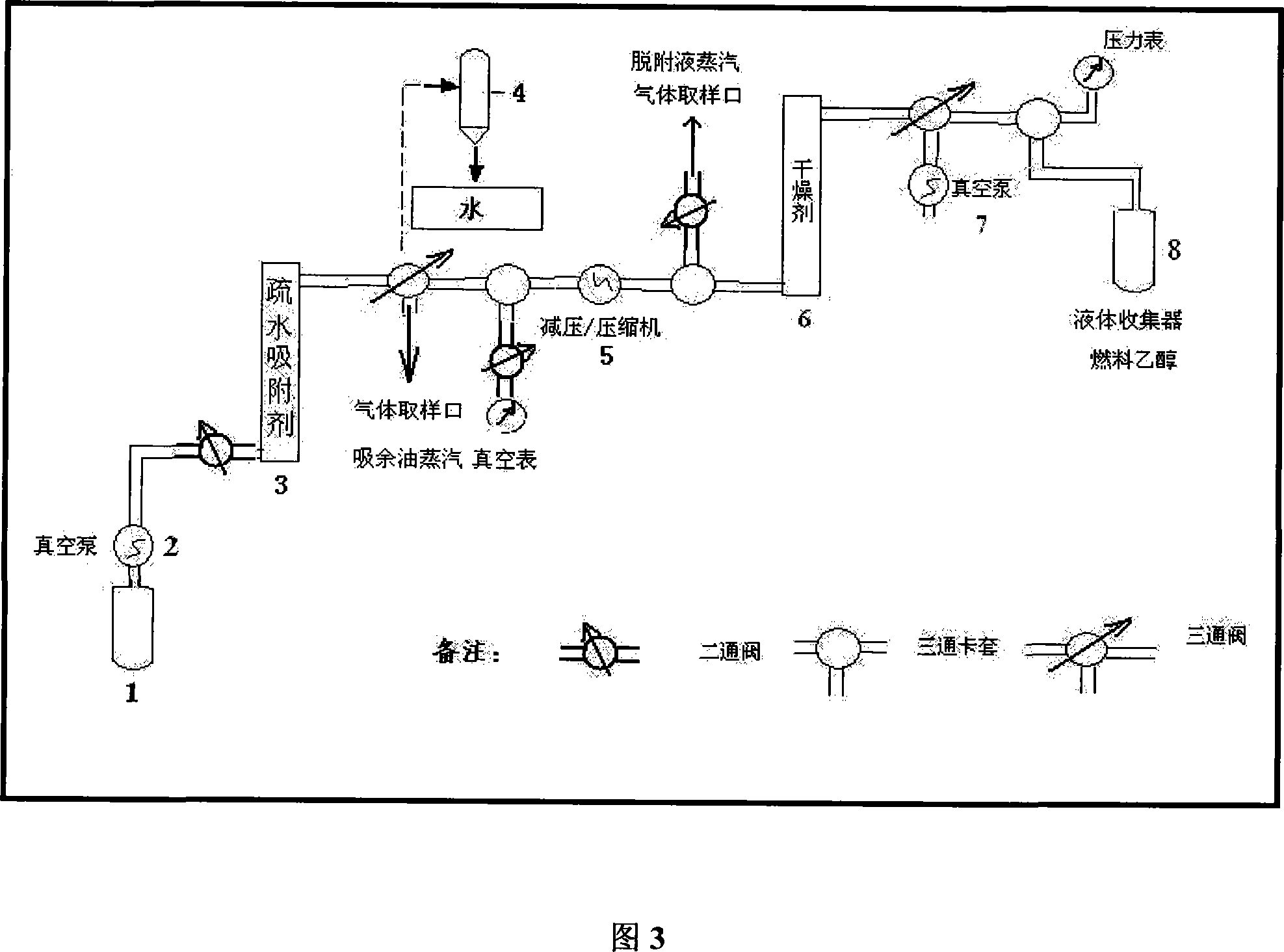

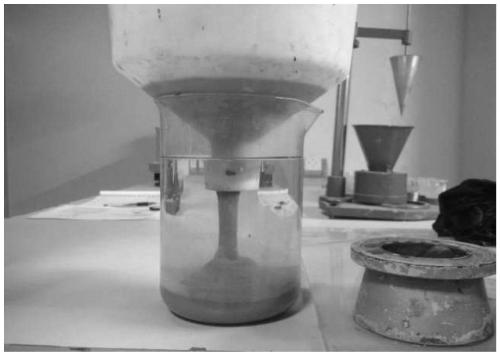

Method and device for producing fuel alcohol by fermentation liquor distillation-free whole molecular sieve adsorptive separation

InactiveCN101225017ASimple structureEfficient use ofOrganic compound preparationHeat recovery systemsHigh concentrationChemical industry

The invention belongs to the technical field of chemical industry, in particular to a preparation method and device of fuel alcohol through distill-free fermentation and molecular sieve adsorption and separation. The method and steps are as follows: extracting directly of the mixture of ethyl alcohol and water above the fermentation fluid raw material (unclear wine fluid, ethyl alcohol comprising 1 to 15 percent) with a temperature of 20 to 40 degrees, and leading into the sparse water silicon zeolite absorbent bed level after heating to 100 to 120 degrees C. Then the ethyl alcohol is absorbed by sparse water absorbent, and the water is discharged. Afterward pressure reducing desorption or gas carrying desorption are adopted to enable the high-concentration alcohol desorption absorbed by the sparse water silicon zeolite absorbent to get highly concentrated ethyl alcohol vapor with a concentration of more than 95 percent, which can be fuel alcohol with a concentration of more than 99.2 percent after the dehydration through the 3A molecular sieve or dry dehydration by other drying agents. Compared with traditional multiple-effect rectification method, the method can save energy by above 50 percent. The preparation method and device of fuel alcohol through distill-free fermentation and molecular sieve adsorption and separation has the advantages of the realization of continuous production, simple equipment, small occupying area, high efficiency, low energy consumption, and extensive application prospect in the concentration production of the organic solvents of the biomass fermentation high volatile molecules.

Owner:FUDAN UNIV

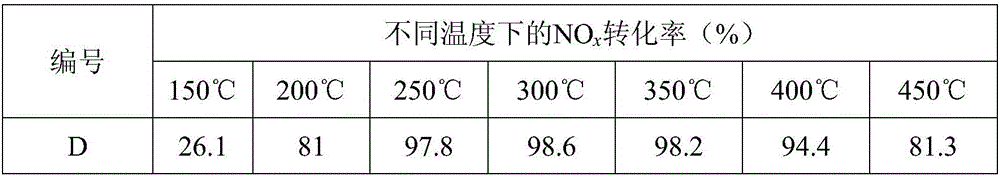

Method for preparing monolith catalyst

InactiveCN106076318ALow investment costFlexible approachGas treatmentHeterogenous catalyst chemical elementsProduction lineAdhesive

The invention provides a method for preparing a monolith catalyst. The method includes the following steps that firstly, catalyst powder is mixed with an adhesive, surfactant and a solvent to obtain slurry; secondly, a carrier is washed with water and dried to obtain a preprocessed carrier; thirdly, the carrier is soaked in the slurry and taken out, and the slurry in channels of the carrier is blown out by means of compressed air; fourthly, the carrier obtained in the third step is dried and baked, and the monolith catalyst is obtained. The monolith catalyst produced through the method is good in catalytic activity, investment cost for catalyst industrial production can be greatly reduced, investment is only 5-10% that of a complete production line under the same productivity condition, and the method can be used for preparing monolith catalysts of different types, particularly SCR monolith catalysts.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

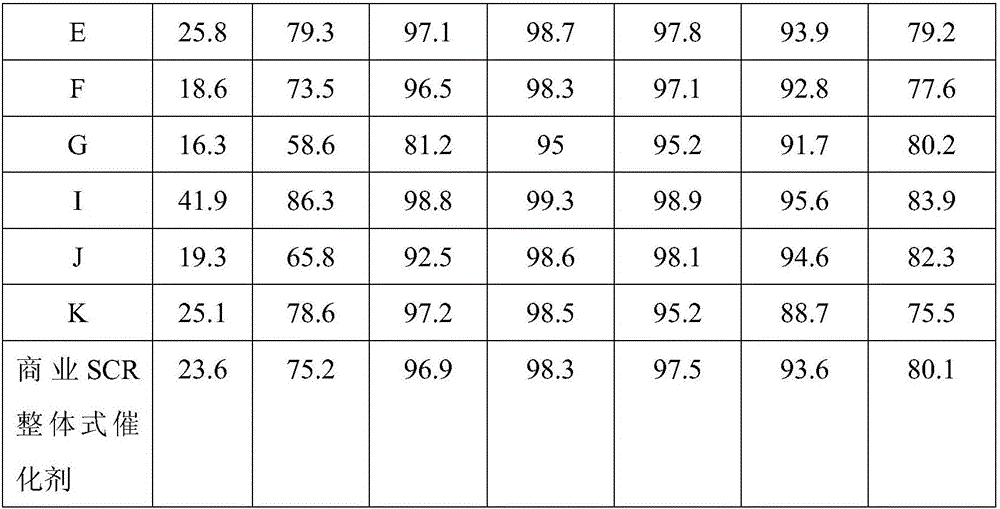

Whole grain hulless oat gluten and preparation method thereof

ActiveCN104543720AStrong water absorptionInhibit or delay absorptionFood ingredient functionsFood preparationAdditive ingredientGluten

The invention discloses whole grain hulless oat gluten which comprises the following components in percent by mass: 2 to 6 percent of wheat dietary fiber flour, 3 to 9 percent of waxy wheat flour, 0.3 to 0.9 percent of Konjac powder, 3 to 15 parts of whole naked oats flour, 4 to 5 percent of salt, 4 to 4.5 percent of a sweetener, 20 to 25 percent of water, and the balance of wheat flour. The invention further discloses a preparation method of the whole grain hulless oat gluten. The preparation method of the whole grain hulless oat gluten comprises the steps of mixing, dough kneading, squeezing and curing, splitting, cooling, mixing and seasoning, packaging, sealing, boxing and the like. The whole grain hulless oat gluten prepared through the formula and the preparation method provided by the invention is low in salt and sugar, is not added with any chemical additives, tastes good, and is nutritional and healthy; the preparation method provided by the invention is simple and easy to control, is relatively low in cost, and is easy to achieve large scale promotion and production.

Owner:HUNAN YUFENG FOOD IND

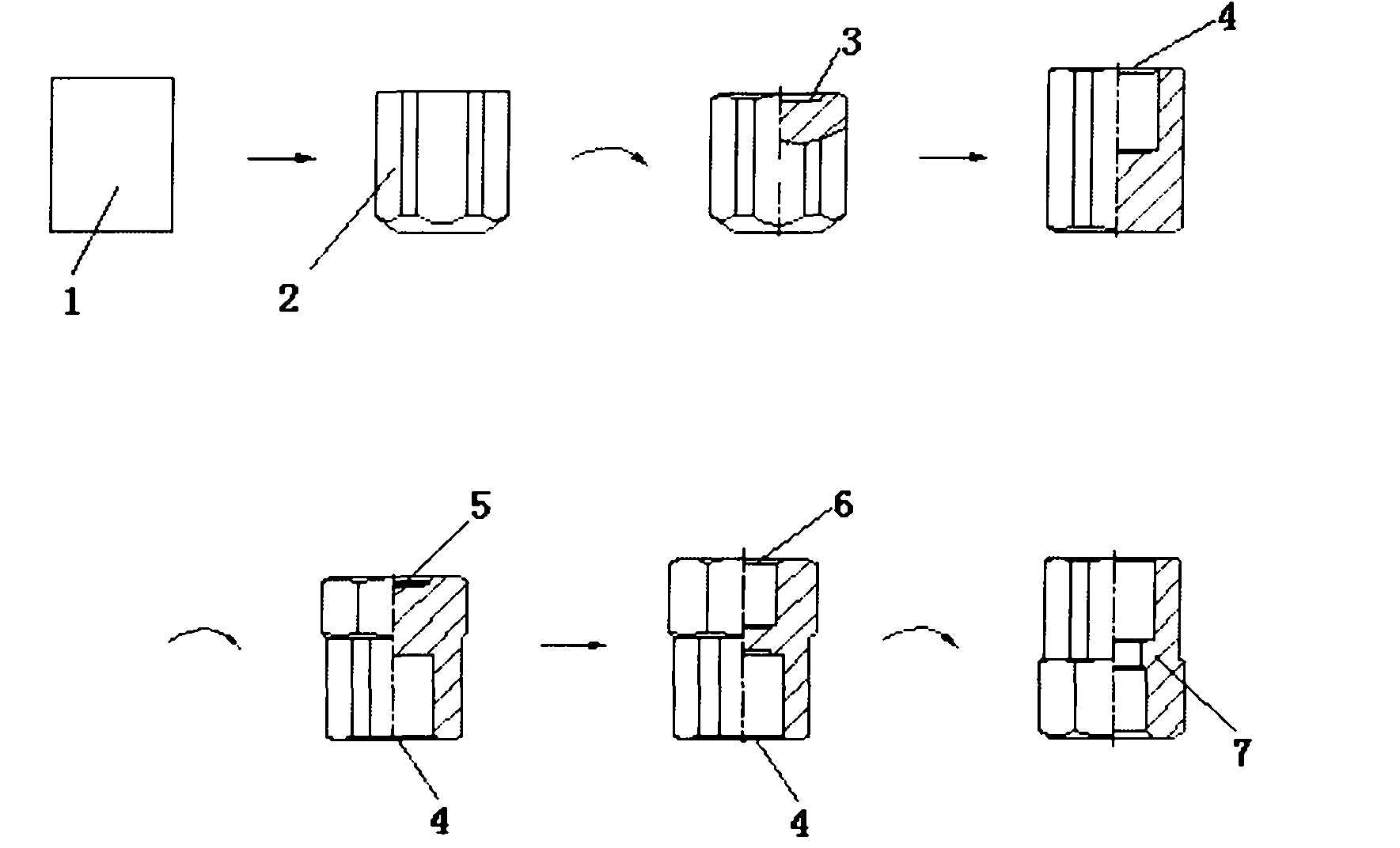

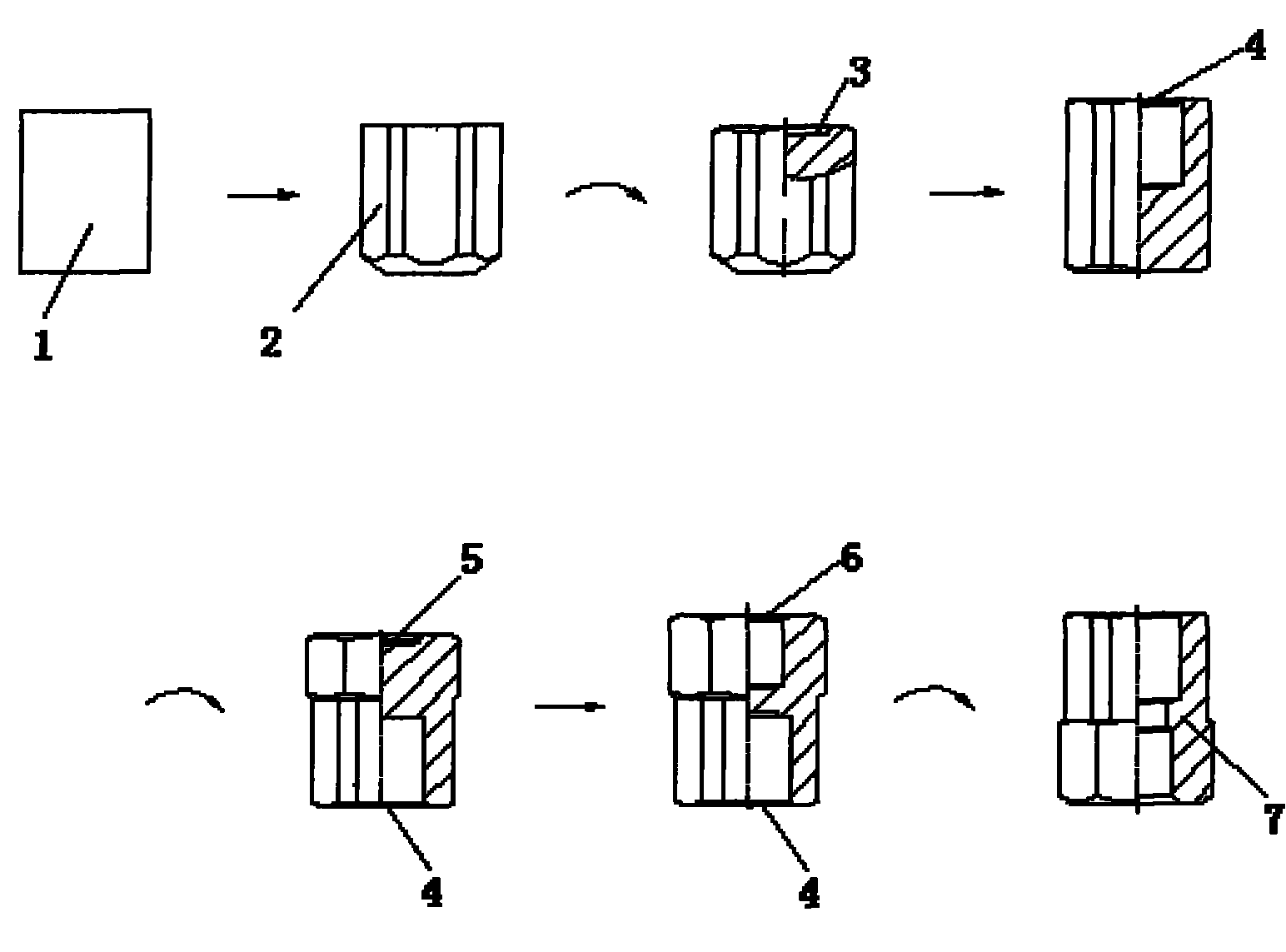

Process for manufacturing pneumatic inner and outer tooth joint blank

InactiveCN102152062AEasy to implement mechanicallyEasy to achieve productivityEngine componentsMaterials scienceRaw material

The invention discloses a process for manufacturing a pneumatic inner and outer tooth joint blank. The process comprises the following steps of: making a round disc material from a steel blank raw material, performing phosphate surface treatment on the round disc material, performing spheroidizing annealing, phosphate coating treatment and fine extraction and diameter fixing treatment on the round disc material subjected to rough extraction, and finally performing a forming procedure of the pneumatic inner and outer tooth joint blank in a cold forming header. The forming procedure of the pneumatic inner and outer tooth joint blank comprises the specific steps of: breaking the material; forming and heading the material into a hexagonal shape with circular beads; turning the material, forming and heading a first location hole at the upper end and an inner chamfer at the lower end; translating the material and heading a first counter bore at the front end; heading the other end of the turned material into a hexagonal shape with inclination angles, and heading a second location hole; translating the material and heading a second counter bore at the front end; and removing residual scrap iron in a middle hole so as to manufacture the final blank. The cold header is used for forming at one time, so the production efficiency and the quality of the pneumatic inner and outer tooth joint blank are improved, the raw materials are saved, and the production cost is reduced.

Owner:NINGBO ANCHOR FASTENERS INDAL

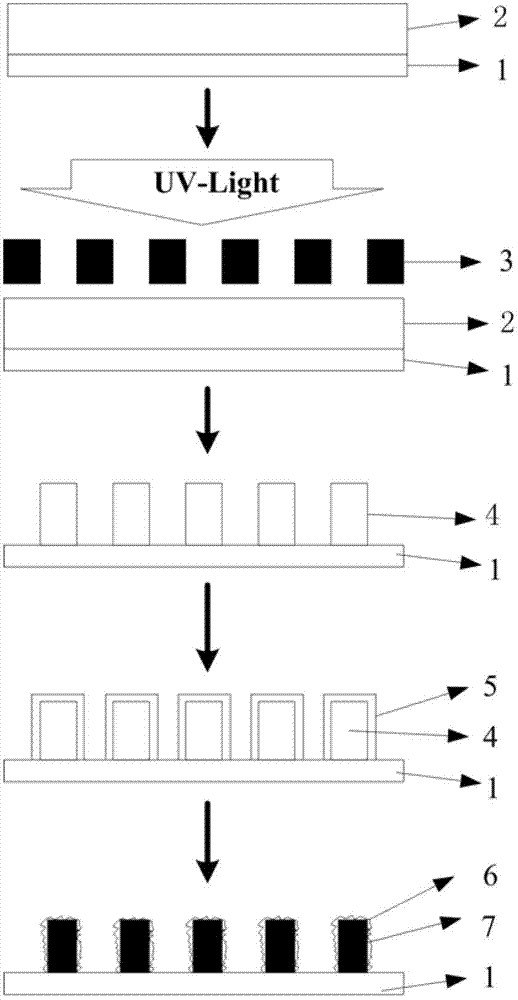

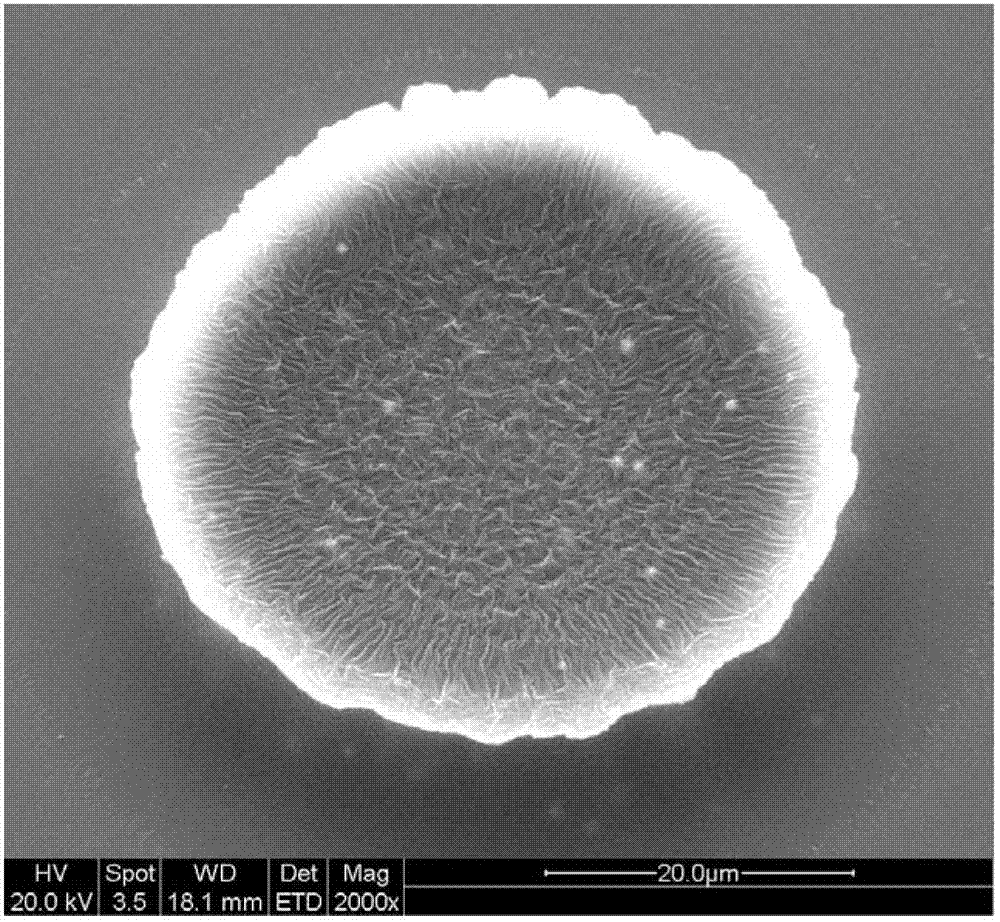

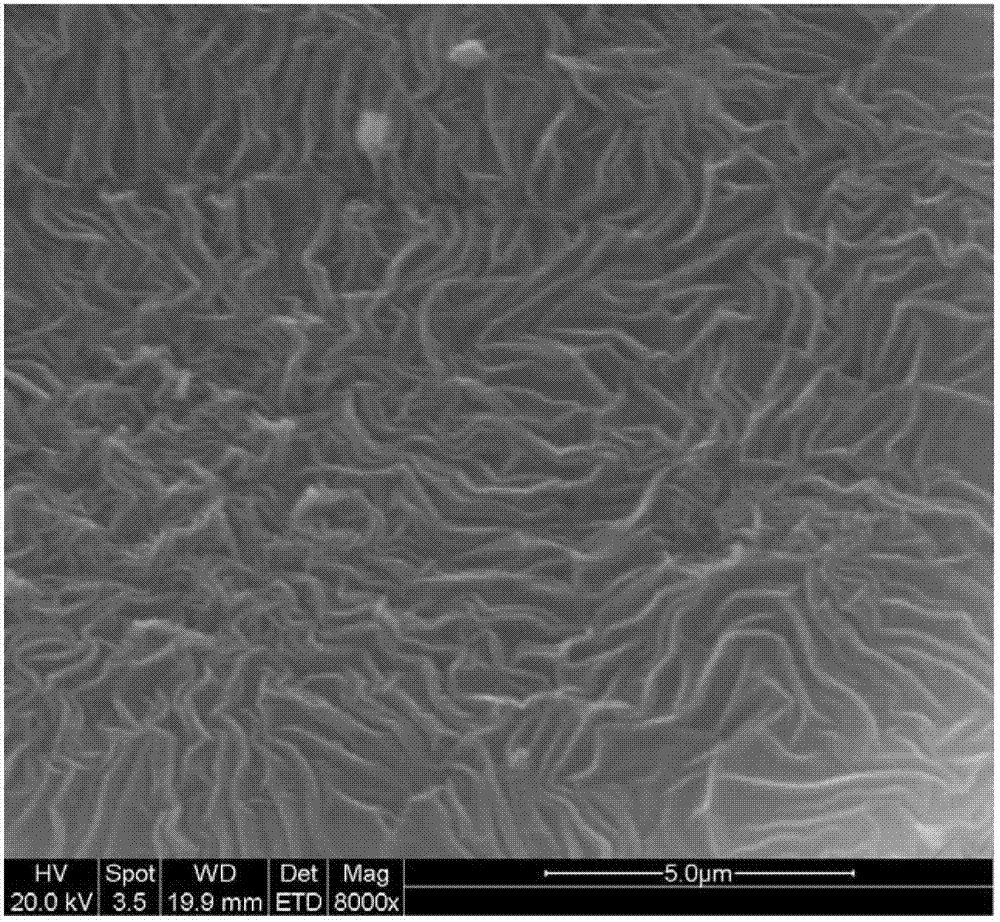

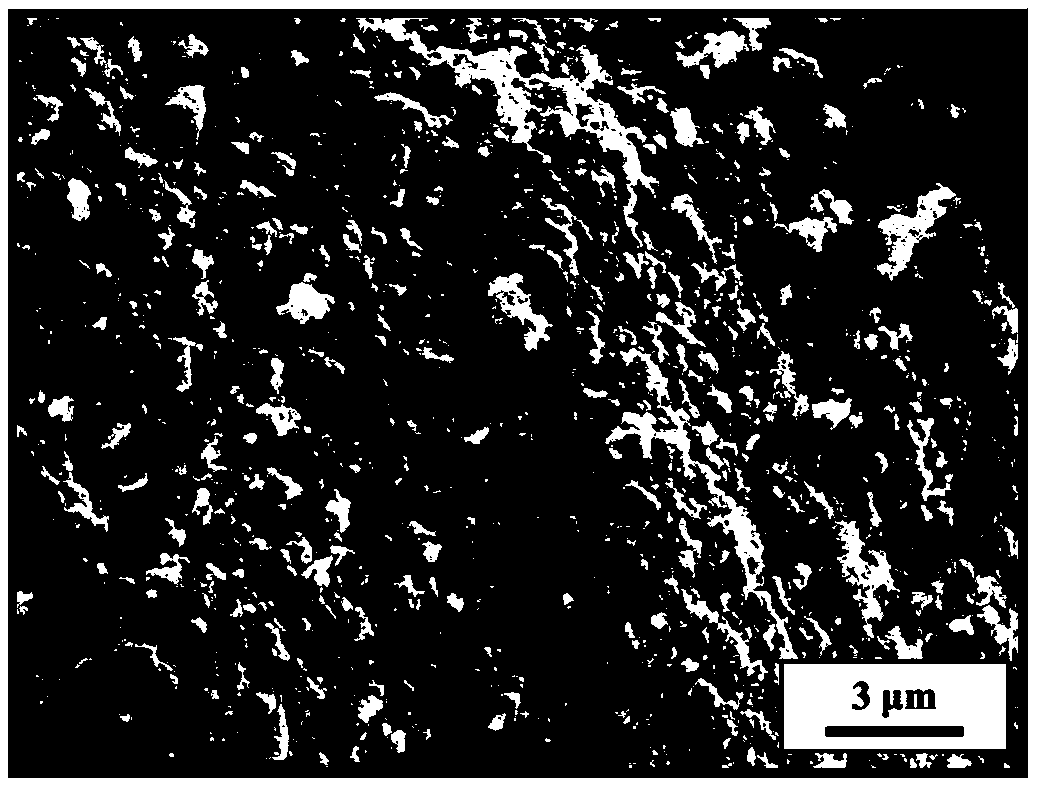

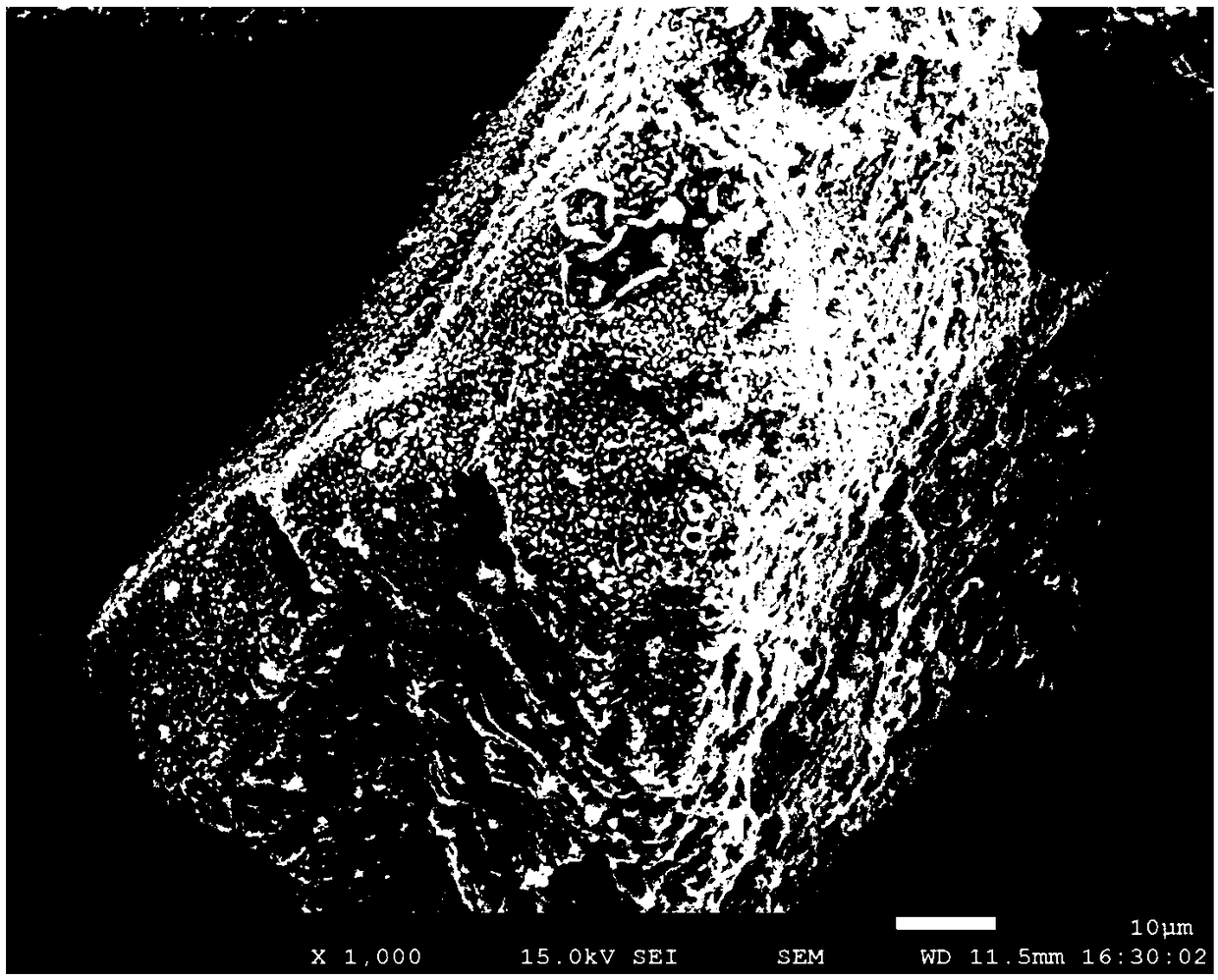

Preparation method for three-dimensional carbon micro-nano electrode array structure integrating carbon nano-drape

InactiveCN102757013AGood electrical conductivityImprove biological activityDecorative surface effectsChemical vapor deposition coatingCarbon filmMicro nano

The invention provides a preparation method for a three-dimensional carbon micro-nano electrode array structure integrating carbon nano-drape. The preparation method comprises the following steps: 1) photoetching to obtain a photoresist microstrucutre with an electrode pattern; 2) depositing a carbon film: depositing one layer of carbon film on the photoresist microstrucutre; and 3) performing pyrolysis: performing multi-step pyrolysis under the environment of inert gas or other mixed gas, wherein the pyrolysis temperature at each step is different. According to the preparation method, the carbon micro-nano integrated structure by combining the carbon nano-drape and the carbon microstructure and generating nano-drape on the surface of the microstructure. Due to integration of the biologically compatible nano-drape carbon film, the specific surface area of the carbon micro-nano electrode array is greatly increased and the bioactivity and the stability of the enzyme are improved. The method is applied to a micro-electro-mechanical system and has the characteristics of simple and convenient process, firm structure and high biocompatibility. The prepared carbon microstructure can serve as a microelectrode and can be applied to the micro-electro-mechanical fields of biological fuel cells, biological chips, micro-electrochemical sensors and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

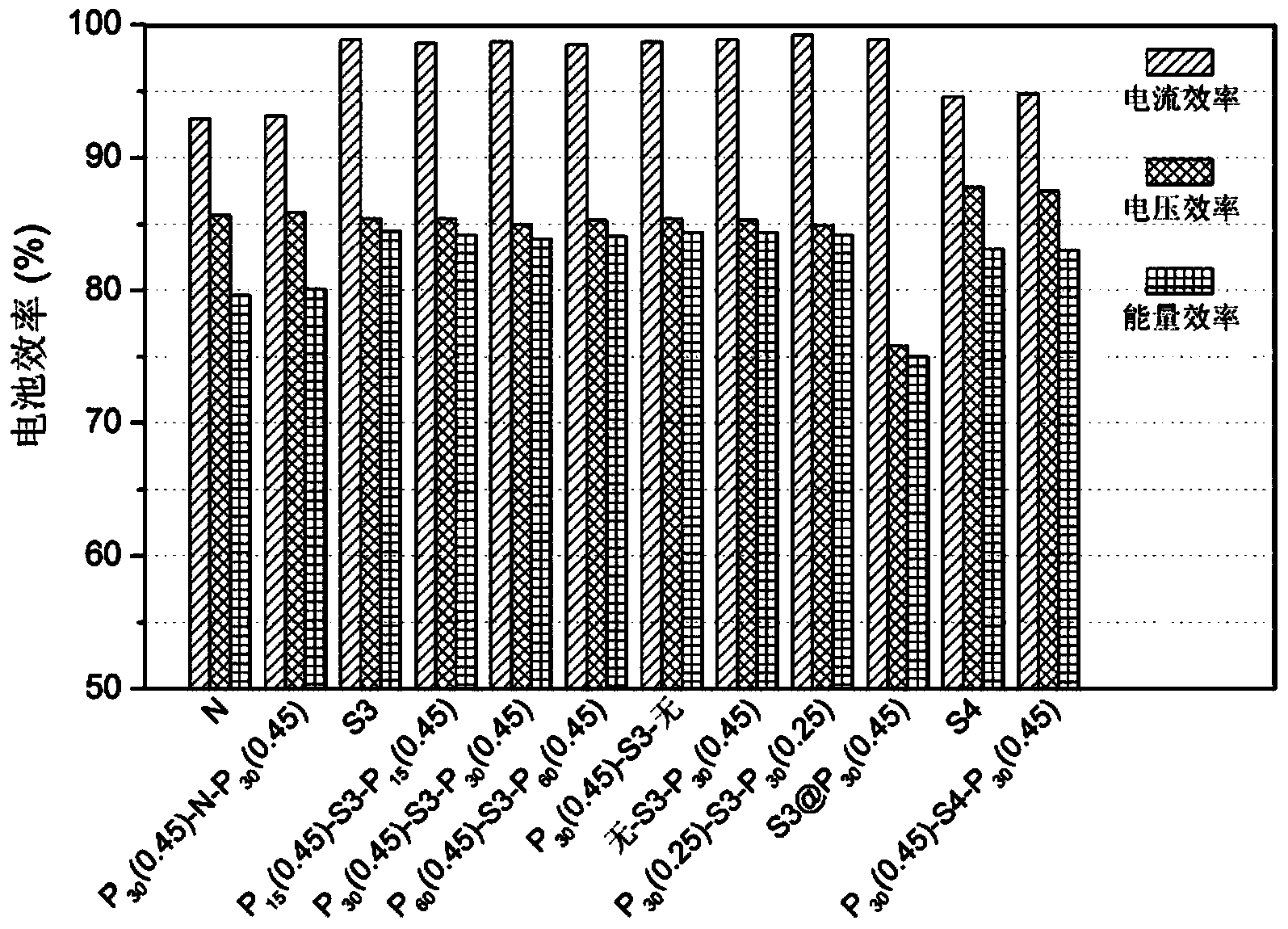

Polyfluortetraethylene sandwich layer protective ion exchange membrane, preparation method of membrane and liquid flow battery

ActiveCN103762375AHigh strengthUniform pore size distributionCell electrodesSynthetic resin layered productsTectorial membranePhysical chemistry

The invention discloses a polyfluortetraethylene sandwich layer protective ion exchange membrane. The polyfluortetraethylene sandwich layer protective ion exchange membrane comprises a sulfonation polymer ion exchange membrane basic membrane, and also comprises a polyfluortetraethylene microporous membrane(s) which is / are used as a sandwich layer protective membrane and attached to one side or two sides of the basic membrane. The invention also discloses a preparation method of the polyfluortetraethylene sandwich layer protective ion exchange membrane and a liquid flow battery adopting the polyfluortetraethylene sandwich layer protective ion exchange membrane. By adopting the polyfluortetraethylene sandwich layer protective ion exchange membrane, the high ion selectivity and high stability requirements can be simultaneously met, the efficiency of the liquid flow battery is improved, the cycling life is prolonged and especially the all-vanadium redox flow battery can be remarkably improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of graphene/aluminum composite material

The invention discloses a preparation method of a graphene / aluminum composite material. The preparation method comprises the following steps that a graphene oxide aqueous solution is subjected to ultrasonic treatment and is evenly dispersed; the obtained graphene oxide aqueous solution is cooled to be below 5 DEG C, aluminum power is slowly added in a stirring state, the temperature is controlled to be smaller than 5 DEG C, the stirring speed is 100-1,000 turns / min, the stirring duration is 1-2 hours, and the uniform graphene oxide aqueous solution with aluminum power is obtained; solid-liquid separation is carried out through a low-temperature centrifugal process, a pasty solid obtained after separation is treated through a freeze-drying process, and then graphene oxide / aluminum composite dry powder is obtained; and the graphene oxide / aluminum composite dry powder is subjected to heat reduction in Ar / H2 mixed gas, and finally the graphene / aluminum composite material is obtained. The prepared graphene / aluminum composite material has the advantages of being high in strength, low in heat expansion factor and the like, and the specific stiffness and specific strength factors are obviously increased; and the preparation method is simple and efficient, and industrial production and application can be achieved easily.

Owner:TANGSHAN JIANHUA TECH DEV

Preparation method for iron-coated ceramic composite powder of core-shell structure

ActiveCN108705077ASimple processReduce manufacturing costTransportation and packagingMetal-working apparatusCeramic compositeHydrogen

The invention discloses a preparation method for iron-coated ceramic composite powder of a core-shell structure. The preparing method comprises the following steps that (1) ceramic particles are selected to be placed into a fluidized bed, mixed fluidization gas of hydrogen and argon passes through a fluidized bed, and the ceramic particles are in the fluidized state; (2) the ceramic particles in the fluidized state are heated; (3) an iron precursor is heated, and the argon is used as carrier gas to carry iron precursor steam to enter a fluidized bed reaction section zone; (4) a chemical vapordeposition reaction is carried out in the fluidized bed reaction section zone; and (5) after the reaction is finished, argon shield cooling is carried out and the product temperature reaches to the room temperature, and the iron-coated ceramic composite powder of the core-shell structure is obtained. The composite powder has the advantages that the product is pure, impurities and pollution are avoided, the bonding force between an iron-coated layer and a ceramic base is high, iron is evenly distributed to the surface of the powder, and the content can be controlled. The preparation method foriron-coated ceramic composite powder has the advantages that the technological process is simple, the reaction condition is gentle, and large-scale and continuous production is facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing nutrition enrichment type bread by using ultra-fine defatted rice bran

The invention relates to a method for preparing a piece of nutrition enrichment type bread by using ultra-fine defatted rice bran. The method comprises the following steps: firstly, selecting the fresh rice bran; secondly, cleaning and removing sundries; thirdly, processing the cleaned rice bran stably by microwave; fourthly, defatting the rice bran; fifthly, drying the defatted rice bran; sixthly, coarsely crushing the defatted rice bran into defatted rice bran coarse powder with 60 meshes; seventhly, crushing the defatted rice bran coarse powder in an ultrafine way into defatted rice bran with d50 below 1mum, and eighthly, preparing the bread: adding 4g-10g of the ultra-fine defatted rice bran, 0.8g-1.2g of calcium lactate, 0.02g-0.025g of zinc lactate into 100g of bread powder and mixing uniformly, and then preparing the bread according to the common method for preparing bread. The prepared bread is good in quality, does not have peculiar smell, and is soft and elastic. The prepared nutrition enrichment type bread is rich in nutrition and delicious, can effectively supplement dietary fiber, calcium, zinc, vitamin and other nutrient substances needed by a human body, and particularly has a good health-care function to the crowds which are in middle and old age and easy to lose calcium and zinc.

Owner:HEFEI UNIV OF TECH

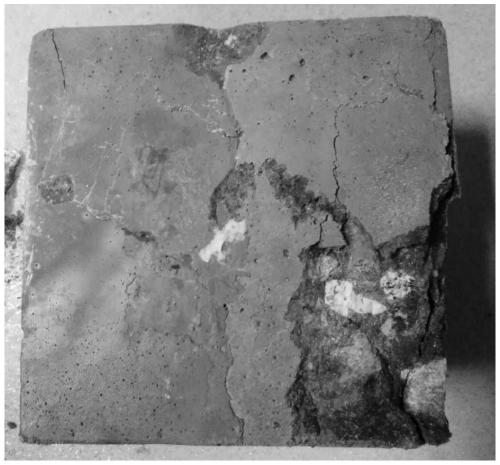

Nano modified cement-based underwater non-dispersible material and preparation method thereof

The invention belongs to the fields of water conservancy engineering, buildings, bridges, sea bank revetments, and the like, and particularly relates to a nano modified cement-based underwater non-dispersible material and a preparation method thereof. The material is prepared from cement, mineral powder, silica fume, a superplasticizer, a defoamer and other materials, a certain amount of nano-SiO2or CaCO3 and a preferred flocculant are added, the materials are mixed evenly through a mixer, and then quartz sand is added to obtain the nano modified cement-based non-dispersible material. According to the nano modified cement-based underwater non-dispersible material, the fluidity reaches 260 cm, the underwater self-leveling can be realized, good dispersion resistance is achieved while high fluidity is achieved, the content of suspended matter is lower than 80 mg / L, 1d strength is nearly 20 MPa, and 28 d strength is greater than 50 MPa, and the micro expansion effect is achieved. The nanomodified cement-based underwater non-dispersible material can be in the forms of dry powder, wet mixed mortar or concrete, and the like, can be made into dry powder materials, and can be directly used for underwater construction by being mixed with water added on site, large-scale production and application are achieved easily, and the application requirements of the fields of the water conservancy engineering, the buildings, the bridges, the sea bank revetments can be met.

Owner:闰镁科技(深圳)有限公司

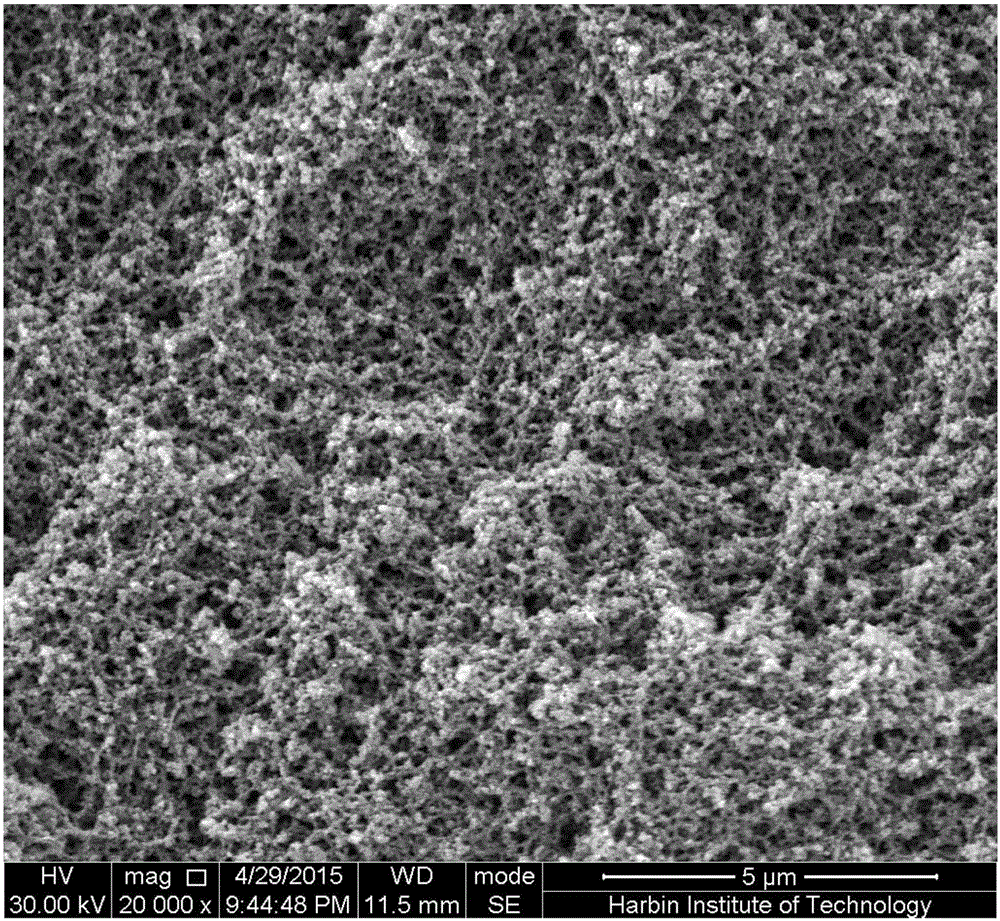

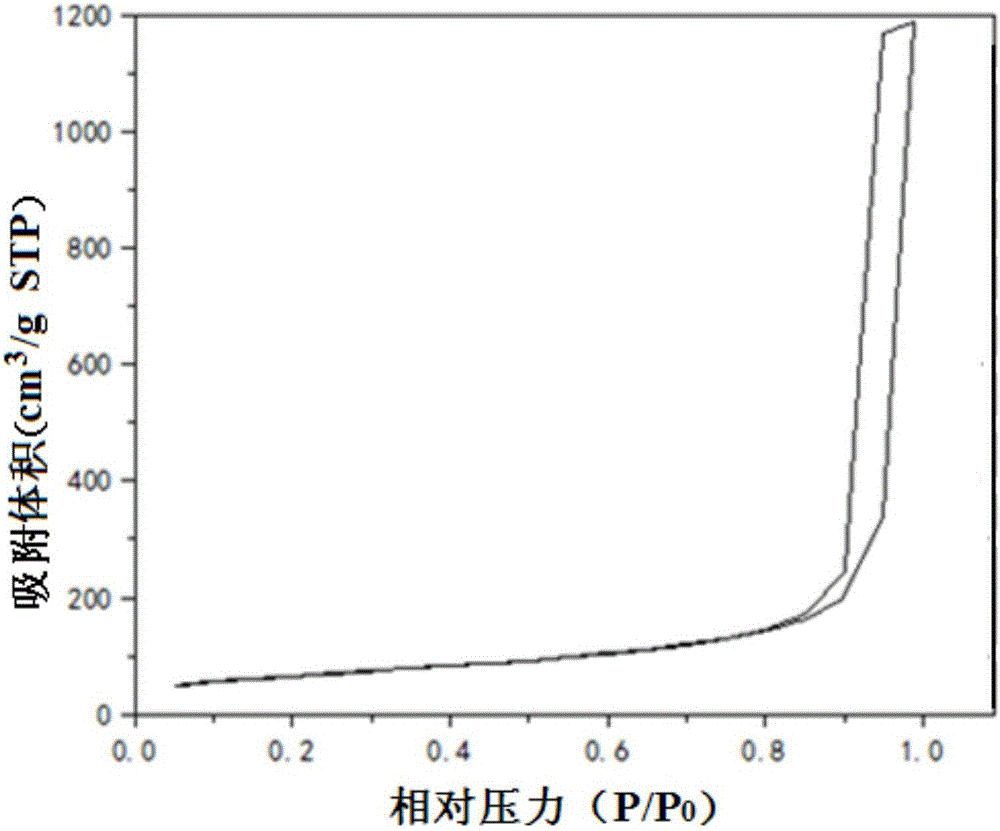

Preparation method of resorcinol-formaldehyde/silicon dioxide aerogel

The invention relates to an aerogel preparation method, and discloses a preparation method of resorcinol-formaldehyde / silicon dioxide aerogel. The preparation method is used for solving problems of conventional one-step sol method used for aerogel hybridization that the composition structure of a polymer prepared from sol can not be controlled, independence of hybridized aerogel components is lost, component performance is difficult to maintain. Two-step sol method is complicated, many catalysts are needed, and sol-gel time is relatively long. The preparation method comprises following step: 1, resorcinol-formaldehyde sol colloidal nucleuses are prepared; 2, a mixed soil precursor of the resorcinol-formaldehyde / silicon dioxide aerogel is prepared; and 3, the resorcinol-formaldehyde / silicon dioxide aerogel is prepared. Compared with the prior art, the preparation method is simple, and is convenient to control; the amount of needed catalyst is small; preparation time is shortened; sample strength is increased; cost is reduced; the preparation method is convenient for large-scale and industrialized production, and possesses significant importance on promotion of applications of hybridized aerogel.

Owner:HARBIN INST OF TECH

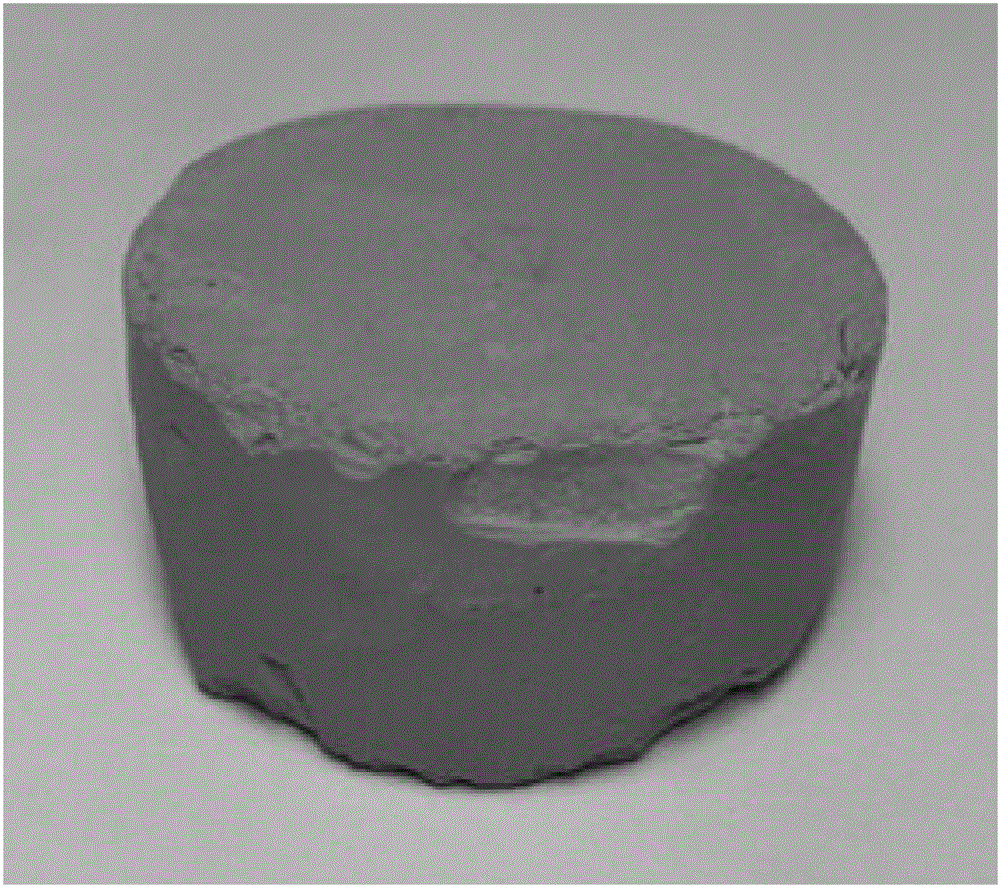

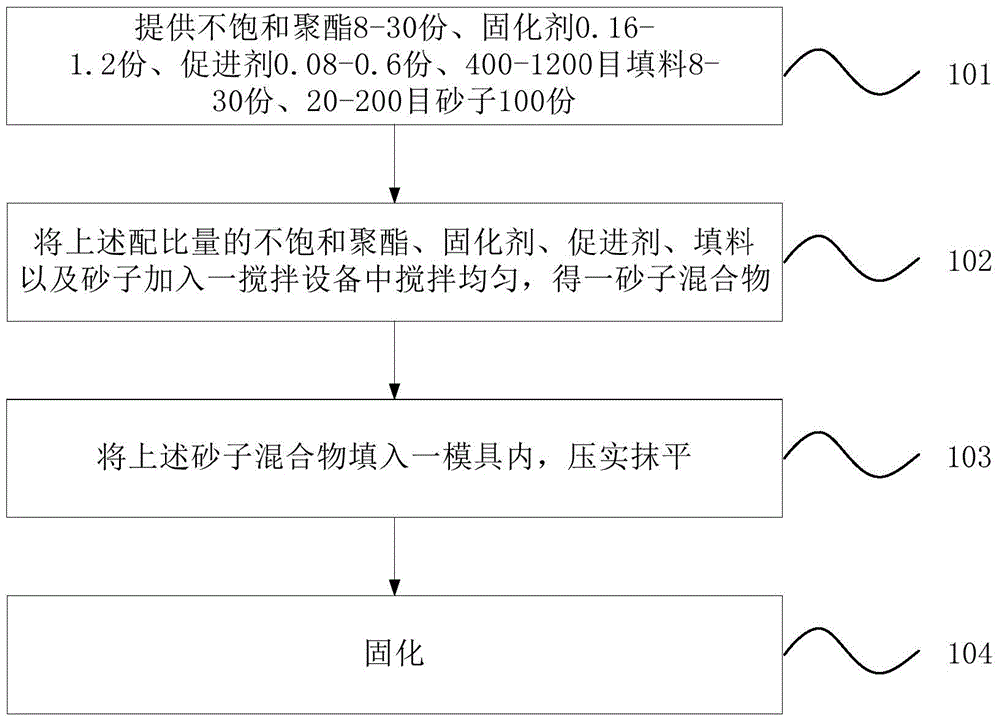

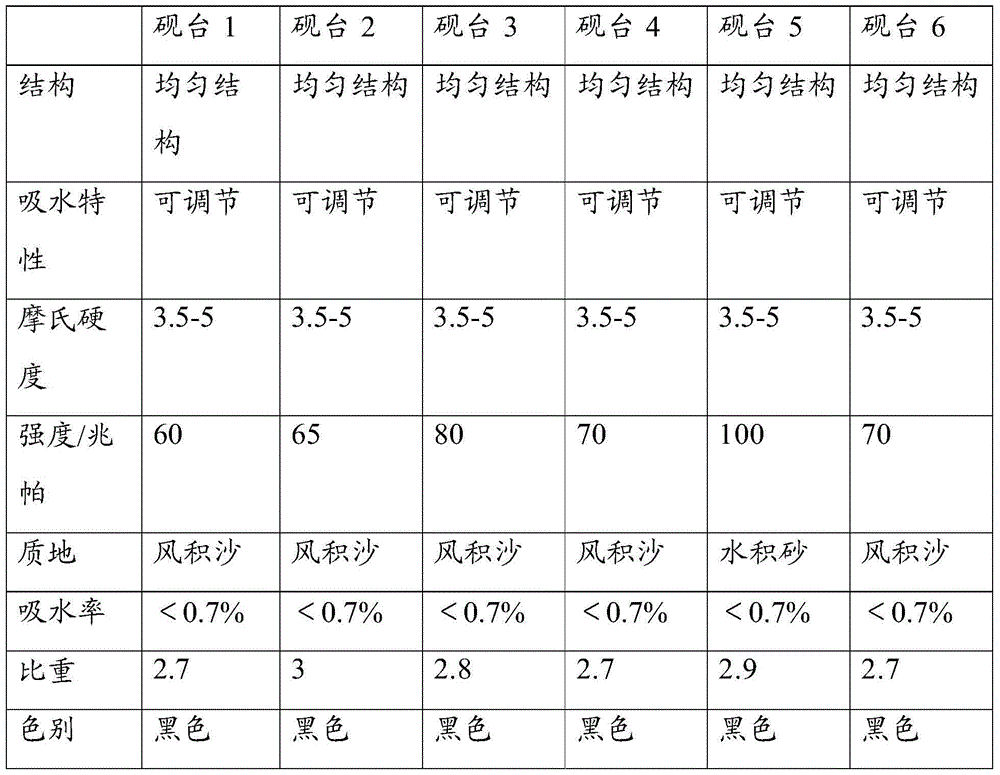

Silica sand inkstone and preparation method thereof

The invention discloses a silica sand inkstone and a preparation method thereof, and belongs to the field of inkstones. The silica sand inkstone comprises the following raw materials in parts by weight: 8-30 parts of unsaturated polyester, 0.16-1.2 parts of a curing agent, 0.08-0.6 part of an accelerant, 8-30 parts of 400-1200 mesh packing and 100-500 parts of 20-200 mesh sand. The preparation method of the silica sand inkstone comprises the following steps: adding the unsaturated polyester, the curing agent, the accelerant, the packing and the sand in the corresponding parts by weight to stirring equipment for uniformly stirring so as to obtain a sand mixture; filling the sand mixture after the treatment in a mold, compacting and smoothing; finally curing. The silica sand inkstone and the preparation method thereof provided by the invention have the advantages of simple production technology, low cost, good performance, no sinter molding, energy conservation and environmental protection and the like, and materials are seen everywhere and easily obtained at a low price.

Owner:北京仁创文化有限公司

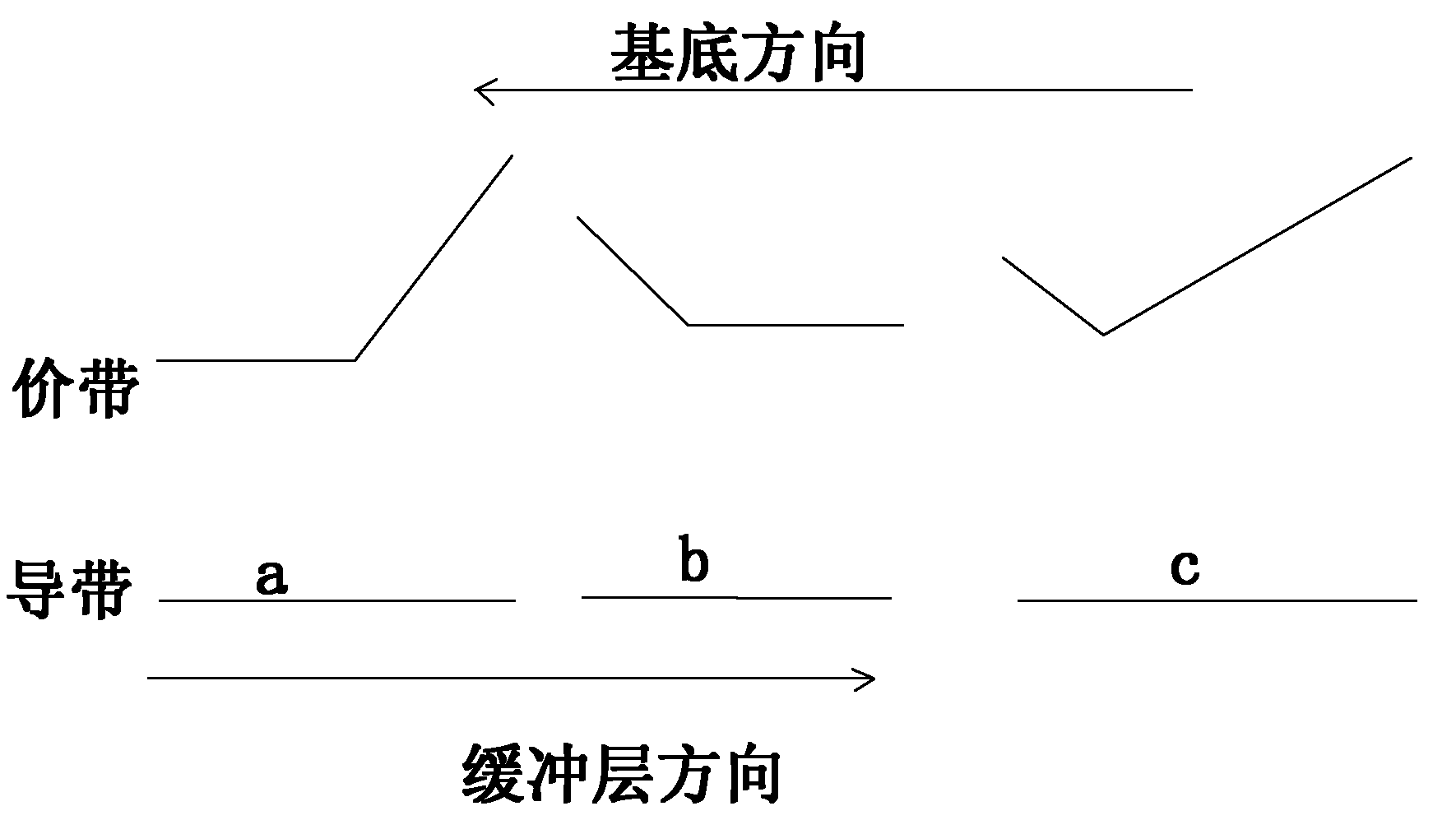

Preparation method of thin-film solar cell absorption layer with gradient gallium-indium atomic ratio distribution

InactiveCN101937943AImprove conversion efficiencyRealize ratio gradient distributionFinal product manufactureSemiconductor devicesIndiumNanoparticle

The invention discloses a preparation method of a thin-film solar cell absorption layer with gradient gallium-indium atomic ratio distribution. The preparation method is characterized in that a thin-film solar cell CIGS (Copper Indium Gallium Selenium) absorption layer is prepared from CIGS nano particles containing different gallium-indium content ratios by a simple multilayer spraying method. By using the CIGS nano particles containing different gallium-indium content ratios and utilizing the simple multilayer spraying method to prepare the thin-film solar cell CIGS absorption layer, the invention realizes the gradient distribution of the gallium-indium atomic ratios in the solar cell CIGS absorption layer so as to improve the conversion efficiency of the solar cell; in addition, the preparation method has the advantages of simple process and needed equipment and can easily realize large-area evenness and continuous production.

Owner:ZHEJIANG SHANGYUE OPTOELECTRONICS TECH

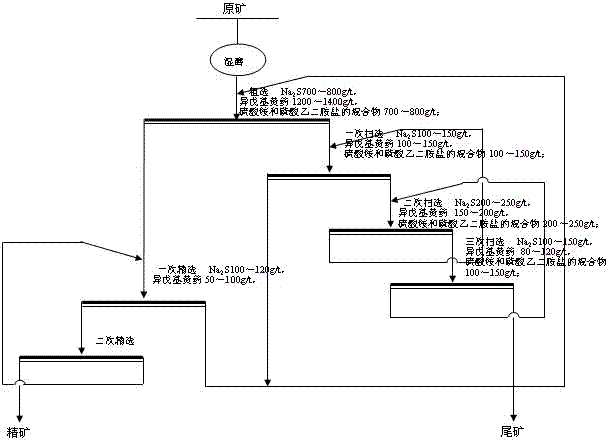

Flotation method of highly argillaceous alkaline gangue copper oxide ore

The invention provides a flotation method of highly argillaceous alkaline gangue copper oxide ore. loatability of the highly argillaceous alkaline gangue copper oxide ore is utilized to improve a conventional sulfating flotation technique, and a flotation process of foaming agent absence-powerful activation-mud dispersion-powerful collection to efficiently recycle the copper oxide ore. The method provided by the invention comprises the following steps: firstly grinding the highly argillaceous alkaline gangue copper oxide ore, then performing size mixing on the grinded ore, and finally carrying out flotation to produce copper concentrate, wherein no foaming agent is added in the whole flotation process. Compared with the conventional sulfating flotation technique, with the adoption of the method, the recycling rate of copper is improved by more than 15% based on accordant concentrate grade, not only the influence of ore mud on the flotation process is eliminated, the efficient recovery of the copper oxide ore is guaranteed, but also the convenient flotation operation and stable index are achieved; and the method is suitable for realizing further industrial and large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

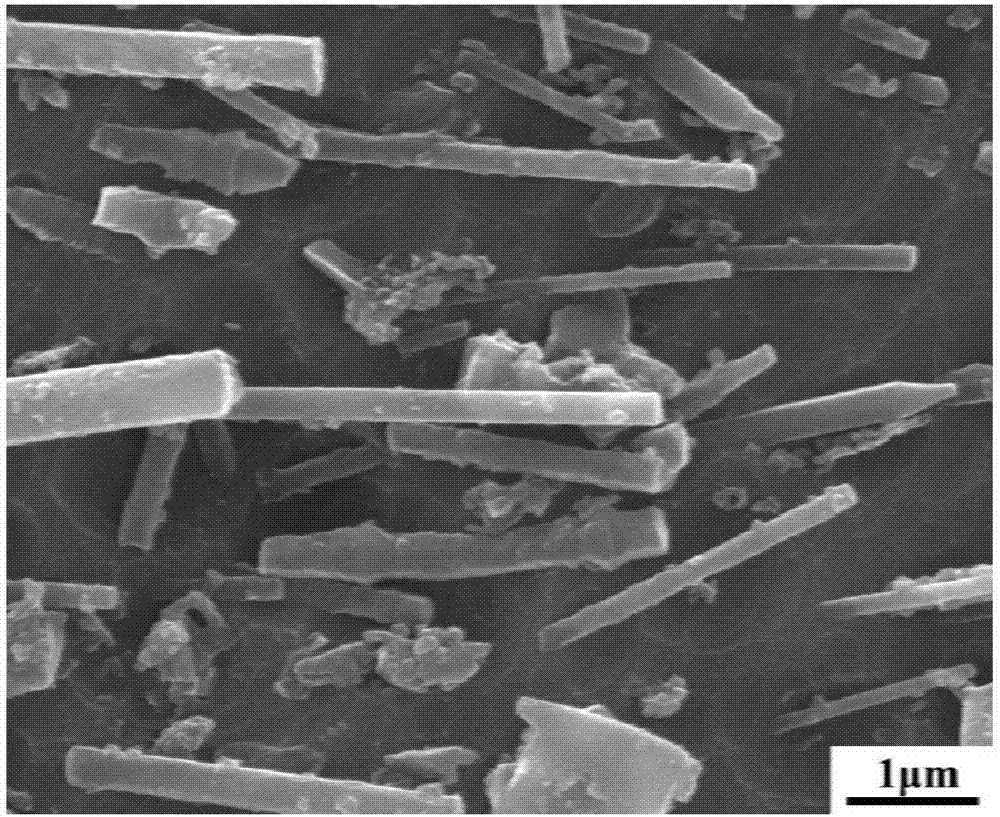

Method for preparing directionally-arranged SIC nanowire reinforced aluminum matrix composite material based on semi-solid extrusion

The invention relates to a method for preparing a directionally-arranged SIC nanowire reinforced aluminum matrix composite material based on semi-solid extrusion. The problem that by adopting conventional hot extrusion treatment, damage to SIC nanowires is serious in the directional arrangement process of the SIC nanowires is solved. The method comprises the steps that firstly, a non-directional SIC nanowire reinforced aluminum matrix composite material is prepared; secondly, the non-directional SIC nanowire reinforced aluminum matrix composite material and a hot extrusion die are preheated; and thirdly, the directionally-arranged SIC nanowire reinforced aluminum matrix composite material is prepared through semi-solid extrusion. According to the method, the SIC nanowire reinforced aluminum matrix composite material is subjected to hot extrusion treatment above a solid phase line and below a liquid phase line; the grain boundary of an aluminum matrix is melted, the aluminum matrix is located in the solid-liquid mixing state, constraining force to the SIC nanowires is small, and the SIC nanowires can achieve low-damage directional arrangement.

Owner:HARBIN INST OF TECH

Method for producing pineapple vinegar by utilizing full pineapple fruit

InactiveCN103789191AFruityMild sourMicroorganism based processesVinegar preparationBiotechnologyNutrition

The invention relates to a method for producing pineapple vinegar by utilizing full pineapple fruits. The method particularly comprises the following steps of washing fresh and mature pineapple fruits, and then crushing and squeezing the full pineapple fruits with peel residues and sarcocarp to obtain juice; filtering the pineapple juice; removing residues to obtain full fruit pineapple juice; adding sweet fermented glutinous rice fermented for 2-3 days to the pineapple juice according to the weight ratio of 1:(0.5-0.8) for alcoholic fermentation to improve the mouthfeel and quality of a finished product; carrying out acetic fermentation by mixing double acetic bacteria, fermenting at 30-35 DEG C for 6-8 days to obtain fermented original vinegar; filtering to remove sediments, and precipitating; indirectly heating the clarified fermented original vinegar to 50-55 DEG C, and keeping for 15-20 minutes; closely standing at ordinary temperature, and ageing for about 3 months. The pineapple fruit vinegar brewed through the method is strong in fruit flavour, gentle in sourness, mellow in mouthfeel and rich in nutrition, is easy and convenient to operate by obtaining the juice by crushing and squeezing the full pineapple fruits and can effectively increase the production efficiency and conveniently realize the large-scale production.

Owner:GUANGDONG OCEAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com