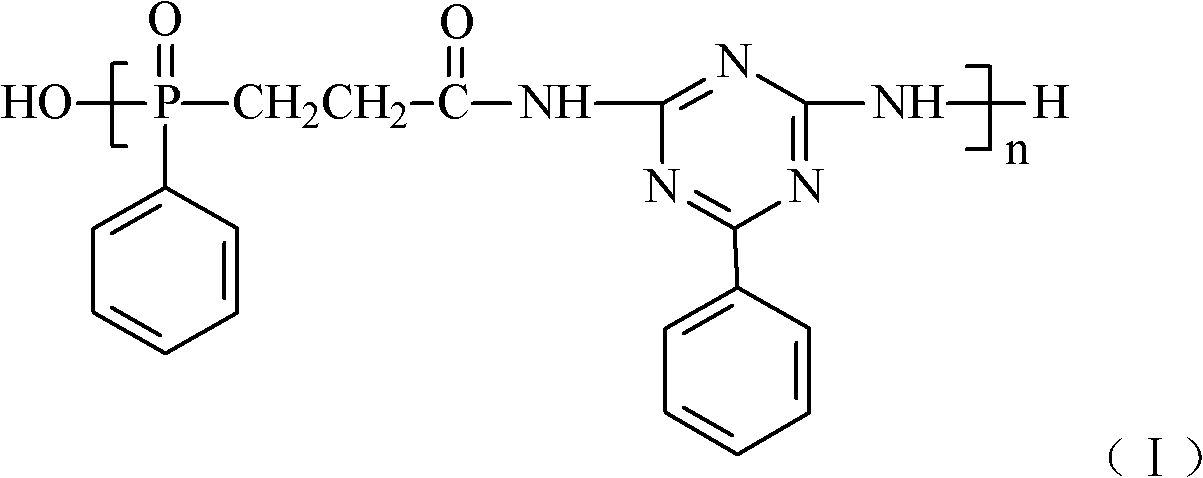

Halogen-free high-efficiency flame retardant composition and preparation method thereof

A composition and flame retardant technology, applied in the field of halogen-free high-efficiency flame retardant composition and its preparation, can solve the problems of unsatisfactory comprehensive performance of materials, limited practical application range, high addition of inorganic flame retardants, etc., and achieve excellent Synergistic flame retardant synergistic effect, easy industrial production and application, and the effect of improving char formation and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

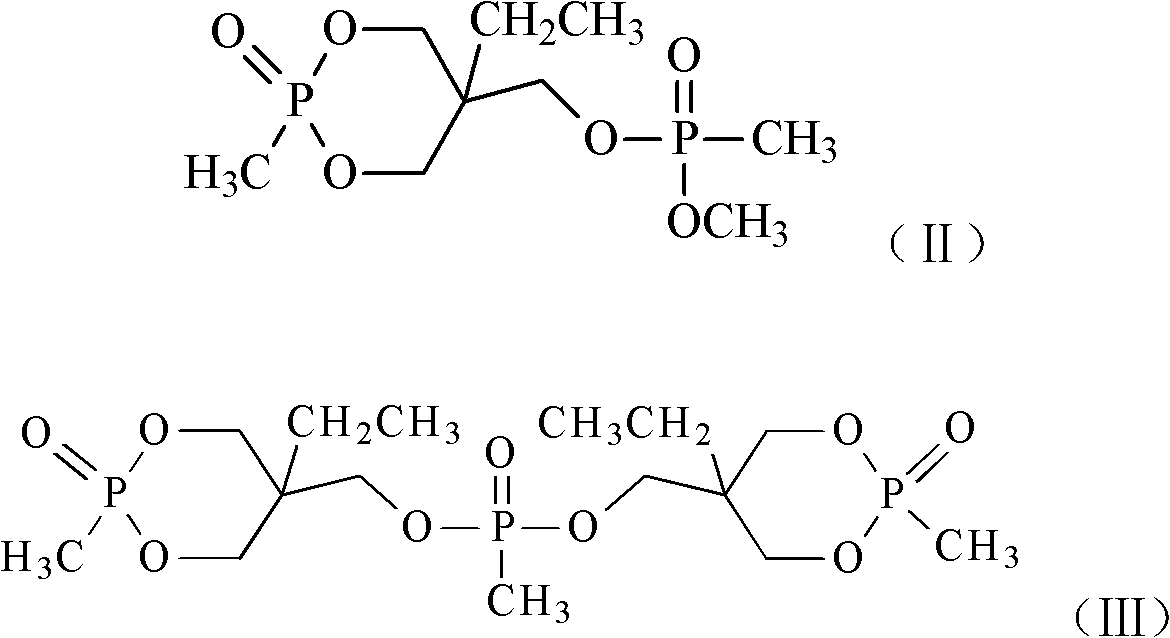

Method used

Image

Examples

Embodiment 1

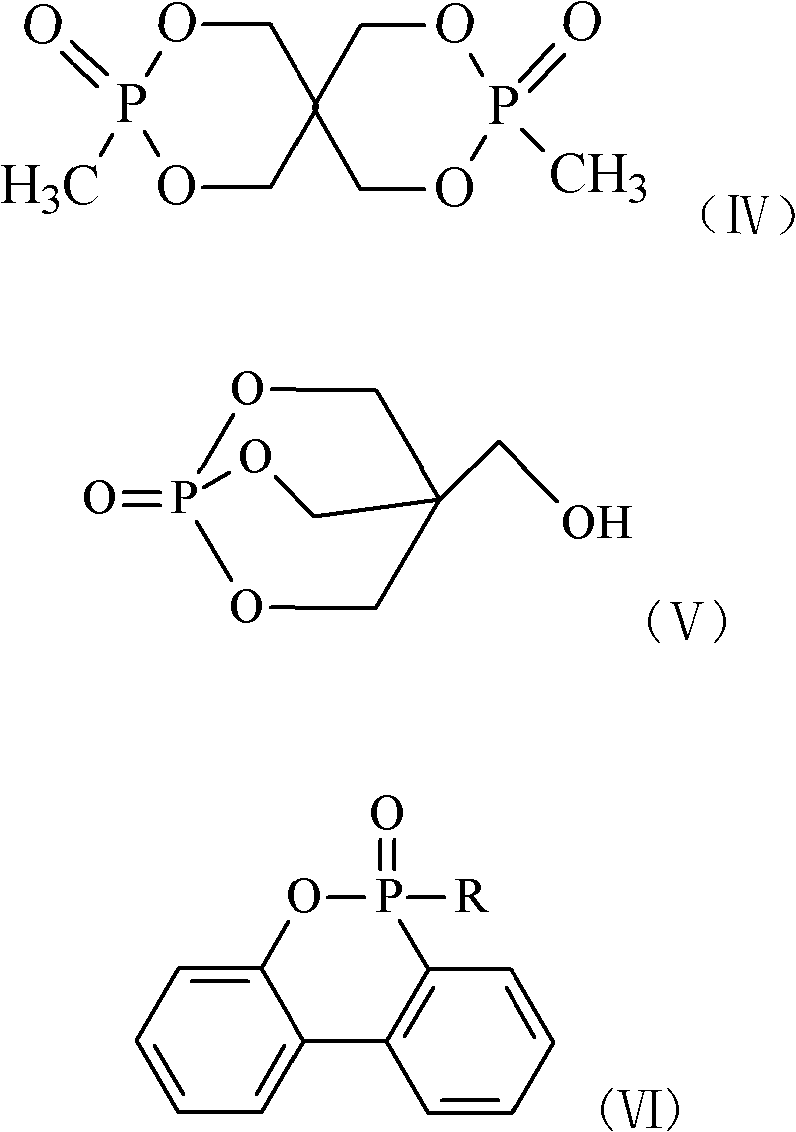

[0061] Add 65% of benzomelamine carboxyethylphenyl hypophosphorous acid condensate, 20% of melamine cyanurate, and 15% of cyclic phosphoric acid ester (VI) (R=H) into the mixture Mix evenly in a machine, and then pulverize with a pulverizer to obtain a halogen-free high-efficiency flame retardant composition with high flame retardant efficiency, good fluidity, and no precipitation.

[0062] The flame retardant composition accounting for 12% of the total mass percentage of the material is melt-blended with PBT resin, injected, cooled, and pelletized to obtain flame-retardant PBT pellets with a flame-retardant grade of up to UL94V-0 (1.6mm) .

Embodiment 2

[0064] Weigh 20% benzomelamine carboxyethylphenyl hypophosphorous acid condensate, 30% melamine cyanurate, 15% melamine phosphate, 25% melamine polyphosphate, 5% Triphenyl phosphate, mixed evenly, pulverized and put into the mixer, then added 5% tricumyl phosphate, mixed evenly, you can get high flame retardant efficiency, good fluidity, halogen-free high-efficiency flame retardant agent composition.

[0065] The flame retardant composition accounting for 15% of the total mass percentage of the material is melt-blended with nylon 6 resin, injected into a tape, cooled and pelletized to obtain flame-retardant nylon 6 grains with a flame-retardant grade of UL94V-0 (1.6mm) material.

Embodiment 3

[0067] Weigh 80% of benzomelamine carboxyethylphenyl hypophosphorous acid condensate, 5% of melamine cyanurate, and 10% of melamine polyphosphate, which account for 80% of the total mass percentage of the composition, mix them evenly, pulverize them and put them into a mixer , and then add 5% m-phenylene tetrakis (xylyl) bisphosphate and mix evenly to obtain a halogen-free high-efficiency flame retardant composition with high flame retardant efficiency and good fluidity.

[0068] The flame retardant composition, which accounts for 25% of the total mass percentage of the material, is melt-blended with PP resin, injected, cooled, and pelletized to obtain flame-retardant PP pellets with a flame-retardant grade of UL94 V-1 (1.6mm). material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com