Shaped heat storage material and preparation method thereof

A technology of heat storage materials and composite heat storage materials, applied in the field of formed heat storage materials and their preparation, can solve problems such as exacerbating climate change and environmental pollution, achieve high heat storage capacity, rapid charge and discharge capacity, and high convenience of use , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of reduced graphene oxide / carbon nanotube / paraffin / concrete shaped heat storage material, comprising the following steps:

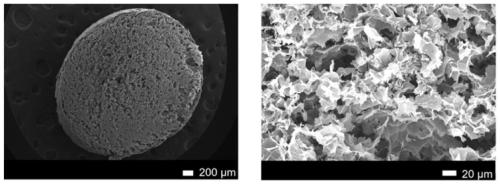

[0048] Mix 75g carbon nanotube water dispersion (1% by mass) and 150g graphite oxide water dispersion (2% by mass) by mechanical stirring and ultrasonic treatment for 1h, and pass the slurry through the diameter of the peristaltic pump or extrusion pump. It is extruded and dropped into the coagulation bath of cetyl trimethyl ammonium bromide (the mass fraction of cetyl trimethyl ammonium bromide is 1%, the mass fraction of water is 95%, and the mass fraction of ethanol is 95%). 4%) to obtain spherical graphene oxide / carbon nanotube hydrogels, which were washed and freeze-dried to obtain graphene oxide / carbon nanotube aerogels, which were heated in an oven at 200 °C Reduction for 2-4h to obtain reduced graphene oxide / carbon nanotube aerogel; figure 1 SEM image of its cross-section;

[0049] Using the vacuum-assisted vacuum im...

Embodiment 2

[0056] A preparation method of reduced graphene oxide / paraffin / concrete shaped heat storage material, comprising the following steps:

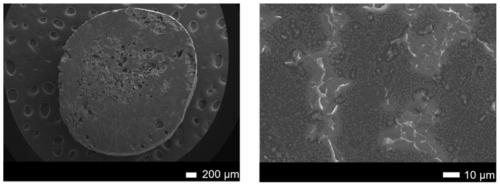

[0057] 240 g of graphite oxide water dispersion (mass fraction of 1%) was extruded into a polyethyleneimine coagulation bath (polyethyleneimine mass fraction of 1 %, the water mass fraction is 99%) to obtain granular graphene oxide hydrogel, which is washed and freeze-dried to obtain graphene oxide aerogel, which is heated and reduced in a 200 ° C oven for 2 h to obtain reduction and oxidation Graphene aerogel; Image 6 SEM image of its cross-section;

[0058] Using the vacuum-assisted vacuum impregnation loading method, the molten paraffin is adsorbed into the reduced graphene oxide foam by capillary action to obtain the reduced graphene oxide / paraffin shaped composite heat storage material; Figure 7 SEM image of its cross-section;

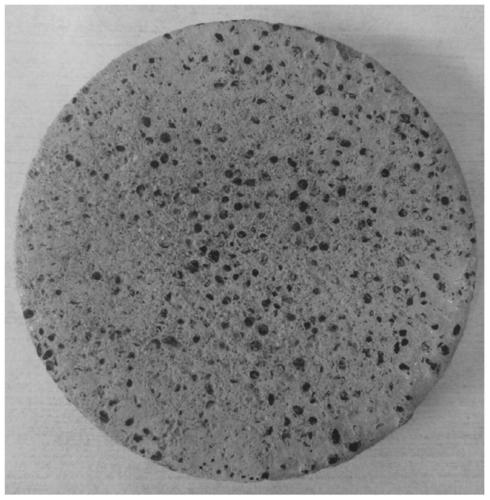

[0059] According to the mixing ratio of cement: river sand: water: graphene oxide = 10:20:4:1, and adding ...

Embodiment 3

[0063] A preparation method of reduced graphene oxide / carbon nanotube / paraffin / concrete shaped heat storage material, comprising the following steps:

[0064] 70g carbon nanotube water dispersion (mass fraction of 1%) and 140g graphite oxide water dispersion (mass fraction of 2%), through peristaltic pump or extrusion pump, squeeze the slurry through a needle with a diameter of 0.5mm to drip. In a polyethyleneimine coagulation bath (the mass fraction of polyethyleneimine is 1% and the mass fraction of water is 99%), granular graphene oxide / carbon nanotube hydrogels are obtained, and graphite oxide is obtained after washing and freeze drying. The graphene / carbon nanotube aerogel was heated and reduced in a 200°C oven for 2 h to obtain reduced graphene oxide / carbon nanotube aerogel;

[0065] Using the vacuum-assisted vacuum impregnation loading method, the melted paraffin is adsorbed into the reduced graphene oxide / carbon nanotube aerogel through capillary action to obtain the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com