Phase-change-material-based thermal management material, preparation method and applications thereof

A phase-change material and thermal management technology, applied in the field of phase-change material-based thermal management materials and their preparation, can solve the problems of poor shape stability and cycle stability of components, decreased output power of battery packs, and poor flame retardant performance, etc. Achieve good thermal conductivity and temperature control function, stable temperature adjustment and control, and ensure the effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

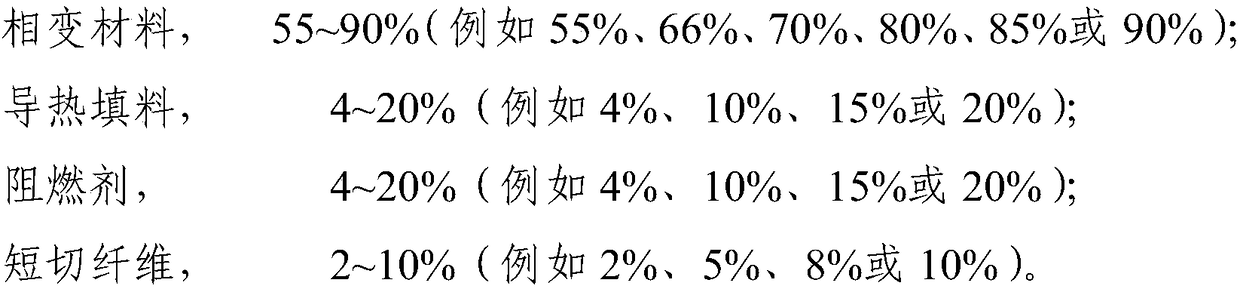

Method used

Image

Examples

Embodiment 1

[0061] ① Weigh 80g of alkane-type paraffin wax with a melting point of 45°C and heat it to melt, add 5g of oil absorbent and stir evenly; the oil absorbent is made of SEBS and HDPE at a mass ratio of 1:2.

[0062] ②Add 6g of graphene and 3g of chopped glass fiber to the material in step ① and stir and mix evenly; wherein the diameter of the chopped glass fiber is 10 μm and the length is 3mm.

[0063] ③ Add 6g of flame retardant to the material in step ② and stir evenly; the flame retardant is prepared from decabromodiphenyl ether, antimony trioxide and terpene resin in a mass ratio of 3:1:1.

[0064] ④ Cool to normal temperature after discharge, and then use a screen to dry out larger agglomerates to obtain the heat management material.

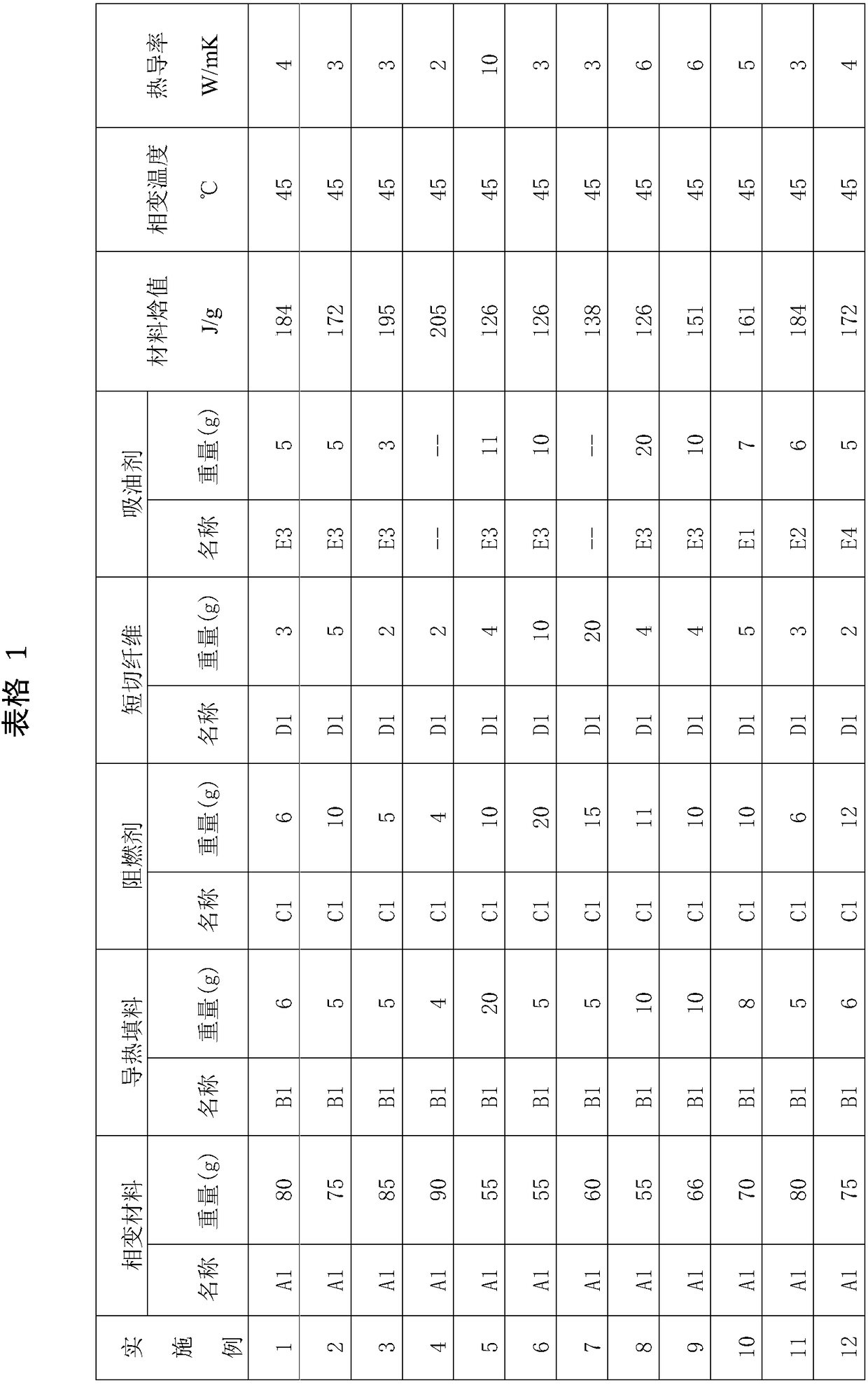

Embodiment 2 to 30

[0066] Examples 2 to 30 were performed in the same manner as in Example 1 except for the contents shown in Table 1 below. The enthalpy value, phase transition temperature and thermal conductivity of the thermal management material were detected, and the detection results are shown in Table 1.

[0067]

[0068]

[0069] In Table 1: A1 represents alkane type paraffin wax with a melting point of 45°C, A2 represents alkane type paraffin wax with a melting point of 55°C, A3 represents a higher aliphatic hydrocarbon with 18 carbon atoms, and A4 represents a higher aliphatic hydrocarbon with a carbon number of 22, A5 represents a higher aliphatic hydrocarbon with 26 carbon atoms, A6 represents a higher aliphatic alcohol with a carbon number of 12, A7 represents a higher aliphatic alcohol with a carbon number of 18, A8 represents polyethylene glycol with a molecular weight of 10,000, and A9 represents a molecular weight 20,000 polyethylene glycol, A10 represents higher fatty aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com