Preparation method for three-dimensional carbon micro-nano electrode array structure integrating carbon nano-drape

A technology of electrode array and carbon nanometer, which is applied in the field of preparation of three-dimensional carbon micro-nano electrode array structure, to achieve the effect of enhancing stability and activation, enhancing electrical conductivity, and mature manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

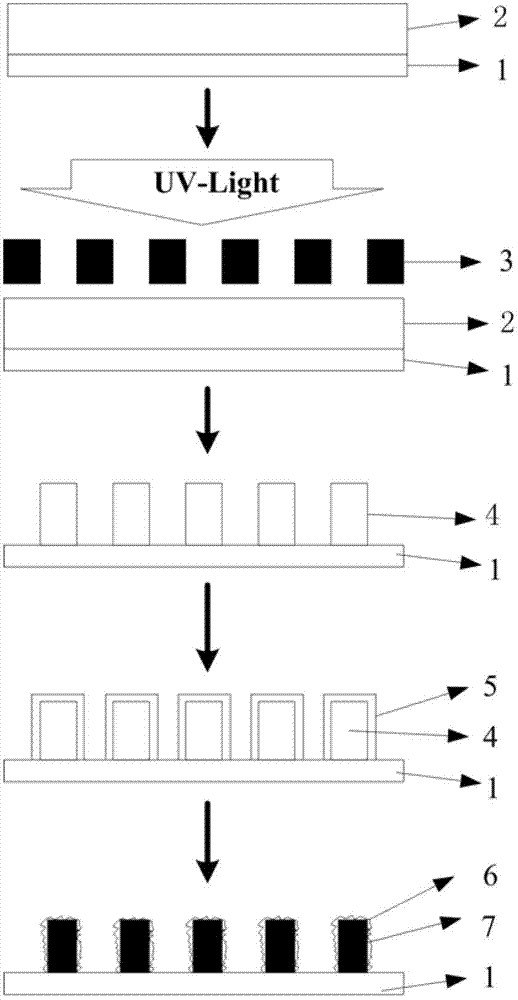

Method used

Image

Examples

Embodiment 1

[0032] (1-1) Pretreatment steps: After rinsing with deionized water, place the silicon wafer in acetone for 10 minutes, then put it into SPM solution (concentrated sulfuric acid: hydrogen peroxide = 2:1), and heat it on a hot plate at 120°C for 10 minutes , after rinsing with deionized water, dry the substrate and cool to room temperature;

[0033] (1-2) Coating step: use the KW-4A type coagulation machine to homogenize the pretreated silicon substrate, and take two steps to apply the glue. The first step is to rotate at 500r / min for 50s, and then at a high speed of 1000r / min rotation 100s; pre-baking the obtained substrate after homogenization, heating on a hot plate at 65°C for 30min, and then heating at 120°C for 5min;

[0034] (1-3) Exposure step: Expose the pre-baked silicon substrate, the photolithography machine model is KarlSuss MA6, and the exposure dose is 5-7mW / cm 2 , the light wavelength is 365nm, and the exposure time is 100s; after the exposure, the substrate i...

Embodiment 2-7

[0052]

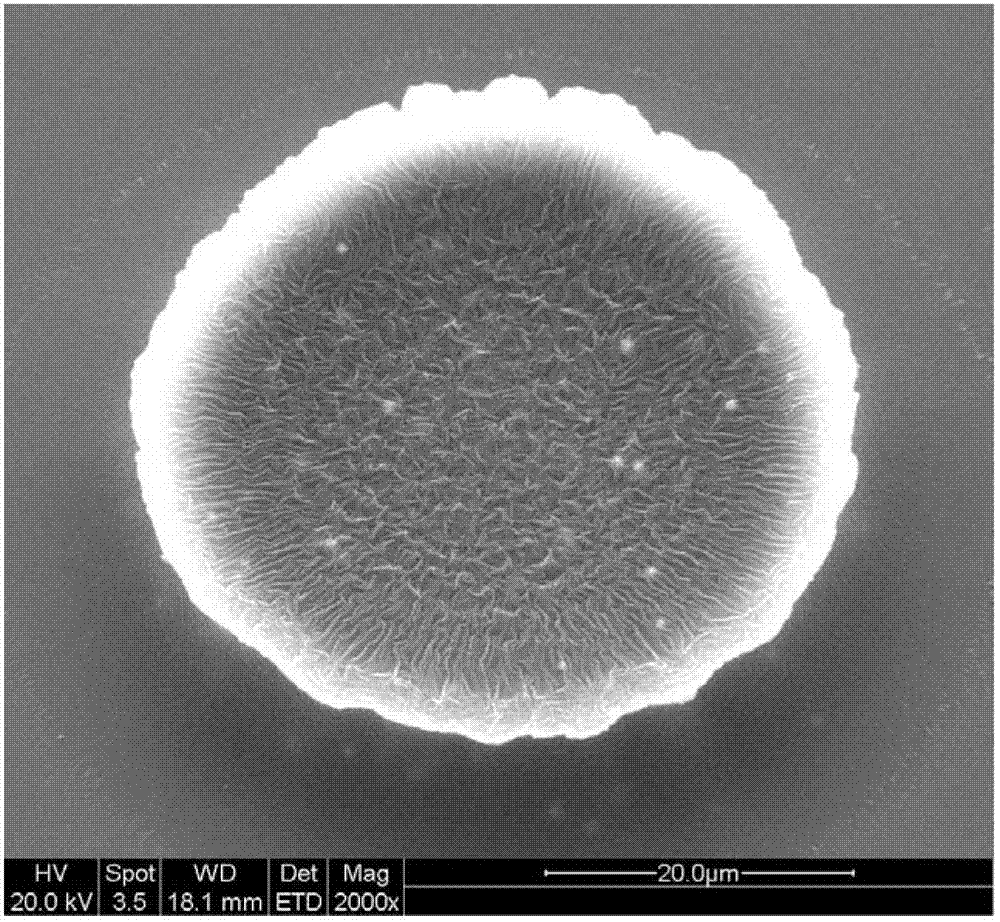

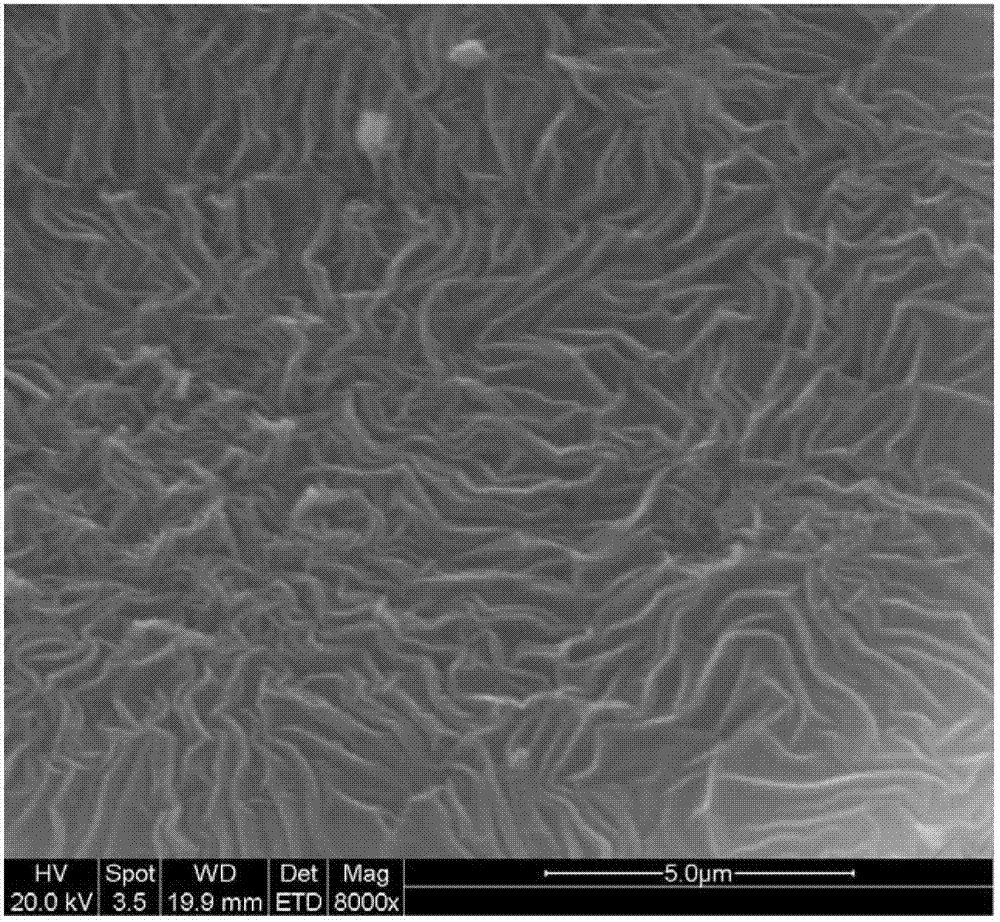

[0053] The results show that the thickness of the carbon film has an important influence on the formation of carbon wrinkles and the size of carbon wrinkles. The larger the thickness of the carbon film, the larger the size of the wrinkles. The maximum temperature has little effect on the formation of wrinkles, but since the minimum temperature required for complete carbonization of the photoresist needs to be achieved, the maximum temperature is required to be greater than 600°C. The heating rate from room temperature to 300 °C has little effect on the experiment, mainly because the photoresist does not react at this stage. The lower the heating rate from 300°C to 1000°C, the more conducive to the full shrinkage of carbon columns, which is also conducive to the formation of wrinkles. The carbonization process of the photoresist mainly occurs at this stage. At the same time, the photoresist (carbon column) shrinks. Since the Young's modulus of the deposited carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com