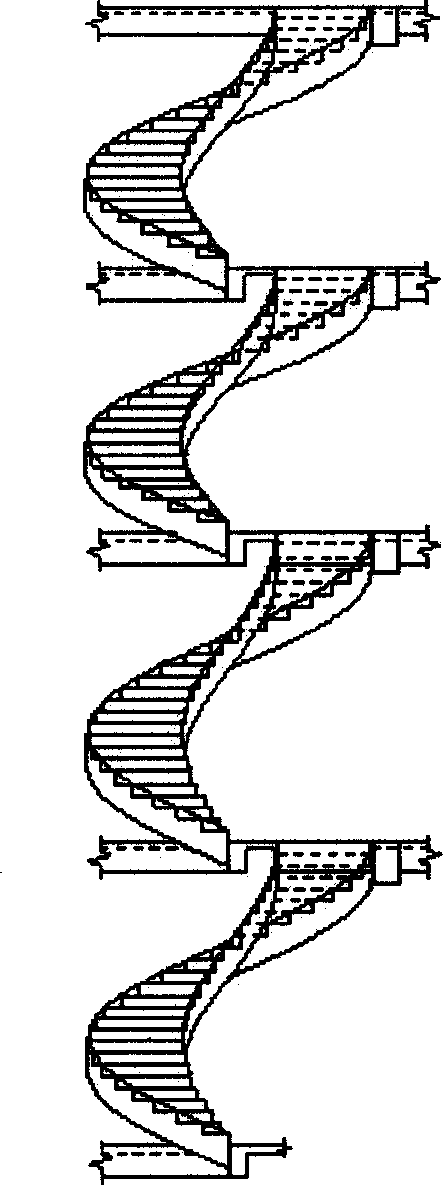

Integrally assembling staircase and method for fabricating same

A production method and integral technology, applied in the direction of ladder-like structure, building structure, construction, etc., can solve the problems of poor architectural effect, increase the geometric size and material consumption of supporting structures, and high production costs, so as to reduce production costs, The effect of shortening the production period and shortening the production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

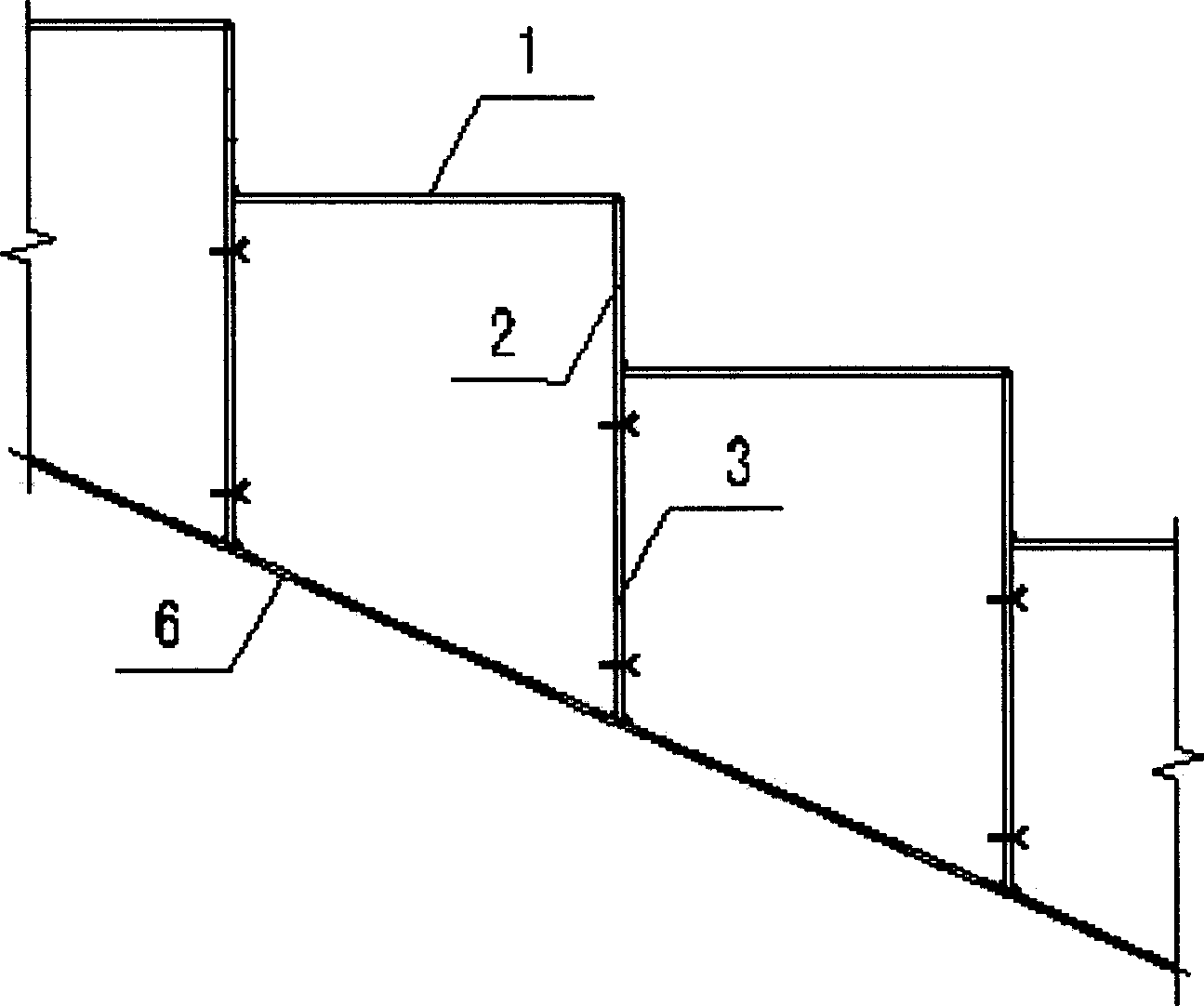

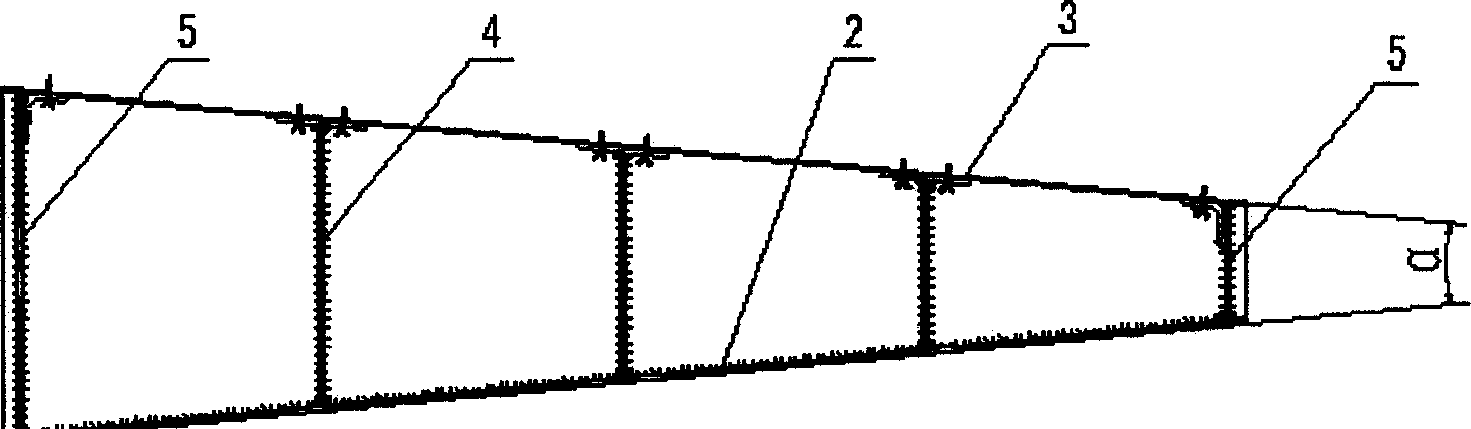

[0022] Embodiment of the present invention: Each step is made into a box-shaped structure in advance, and steps at all levels can be used with step panels (1), front radial connecting plates (2), rear connecting plates (3), and inner circumferential supports Plate (4), side ring support plate (5) and bottom panel (6) form a box-shaped body. When making, its step panel (1), front ring connection plate (2), rear connection Circumferential support plate (4), side circumferential support plate (5) can adopt materials such as steel plate material, wood, plastic plate to make, but preferably adopt steel plate to make large-scale straight staircase or spiral staircase; The step panel (1), the front radial connecting plate (2), the rear connecting plate (3), the inner circumferential support plate (4), the side circumferential support plate (5) and the bottom plate (6) of the physical structure are connected to each other The connection between can adopt the mode of screw connection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com