Multi-head miniature test specimen creep experiment device and test method

A creep test and micro-sample technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of increasing the number of system error variables, unable to ensure the consistency of the sample environment, and lack of material high-temperature performance data. , to avoid load fluctuations, reduce manual recording workload, and reduce the number of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

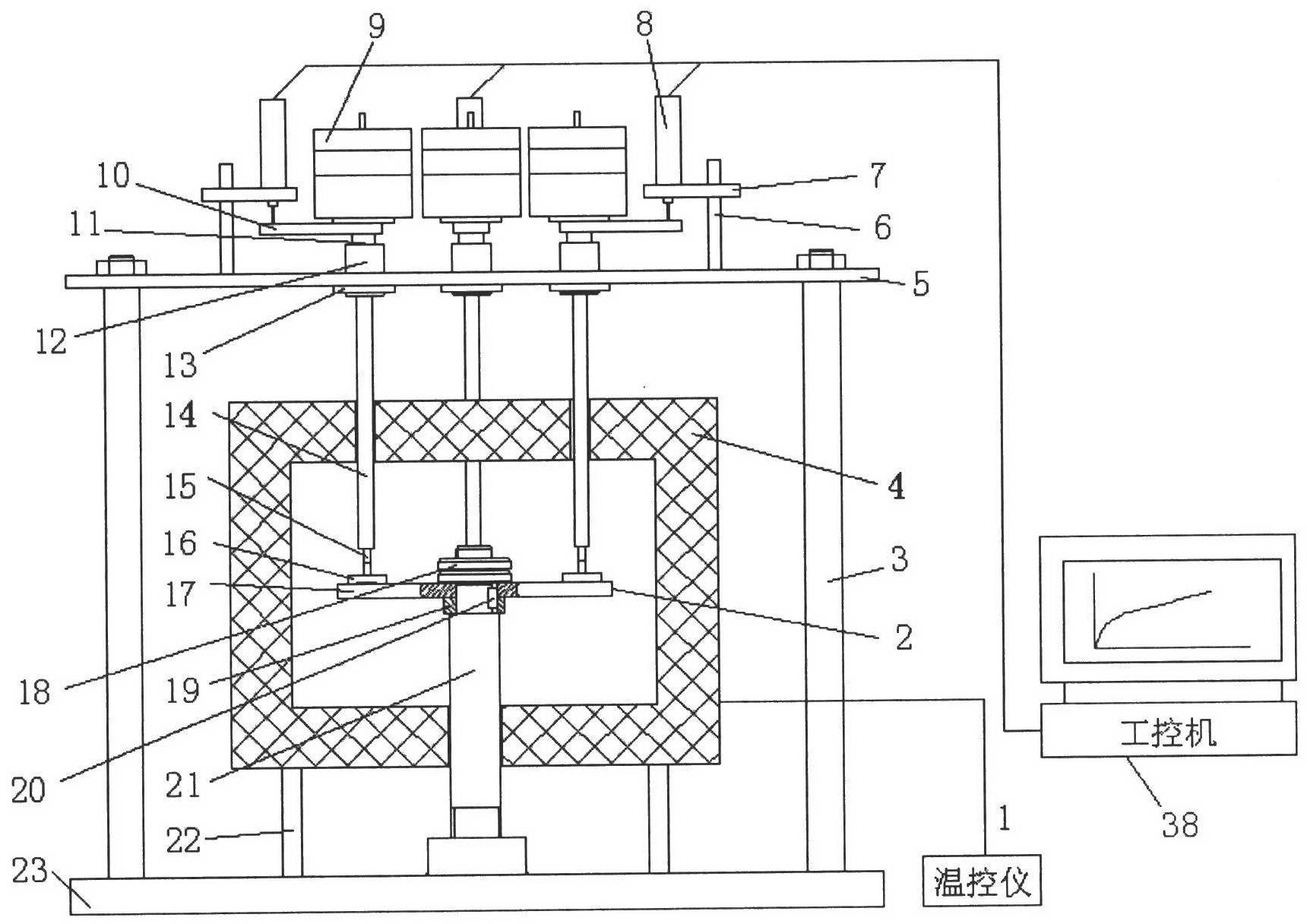

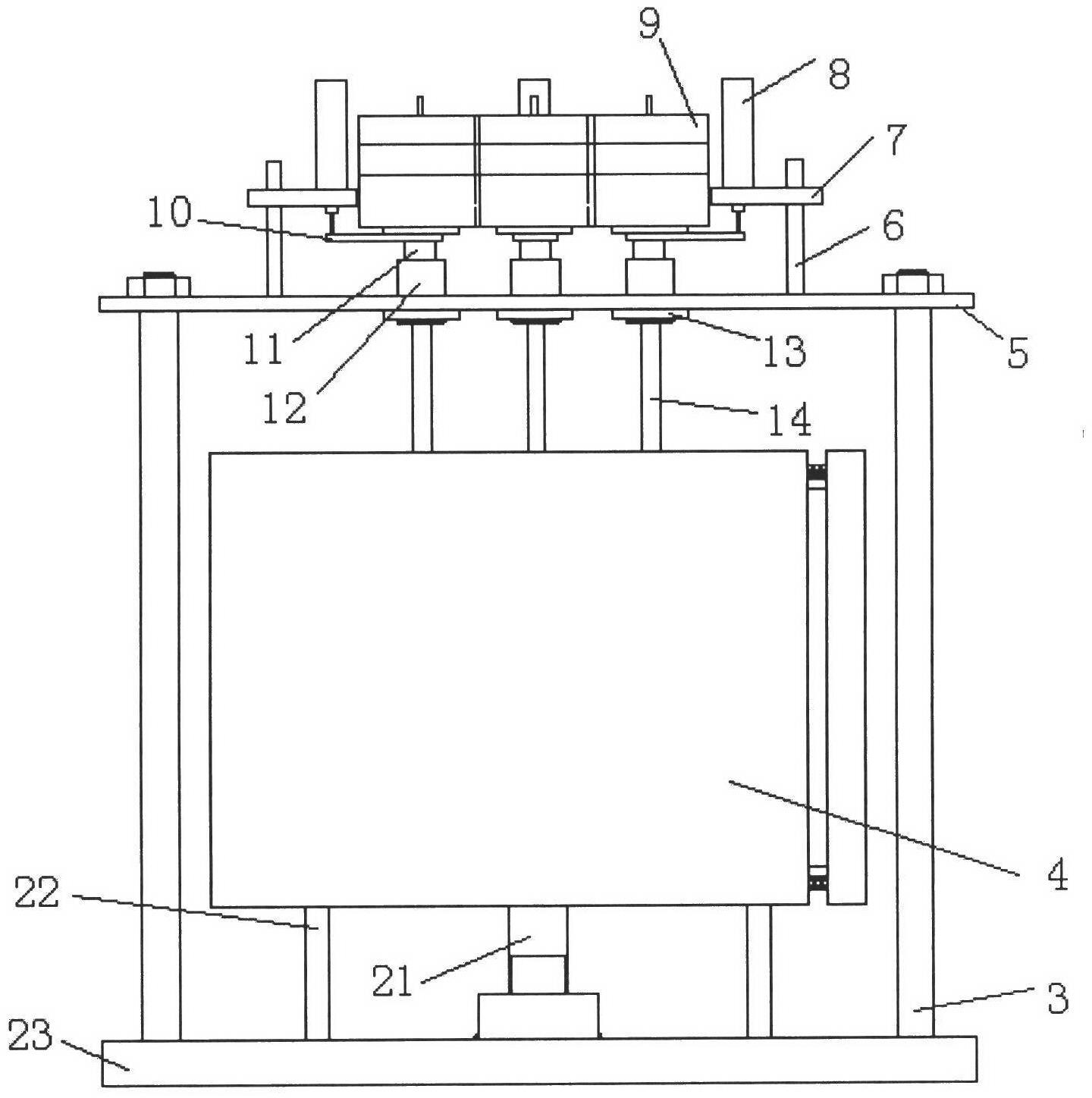

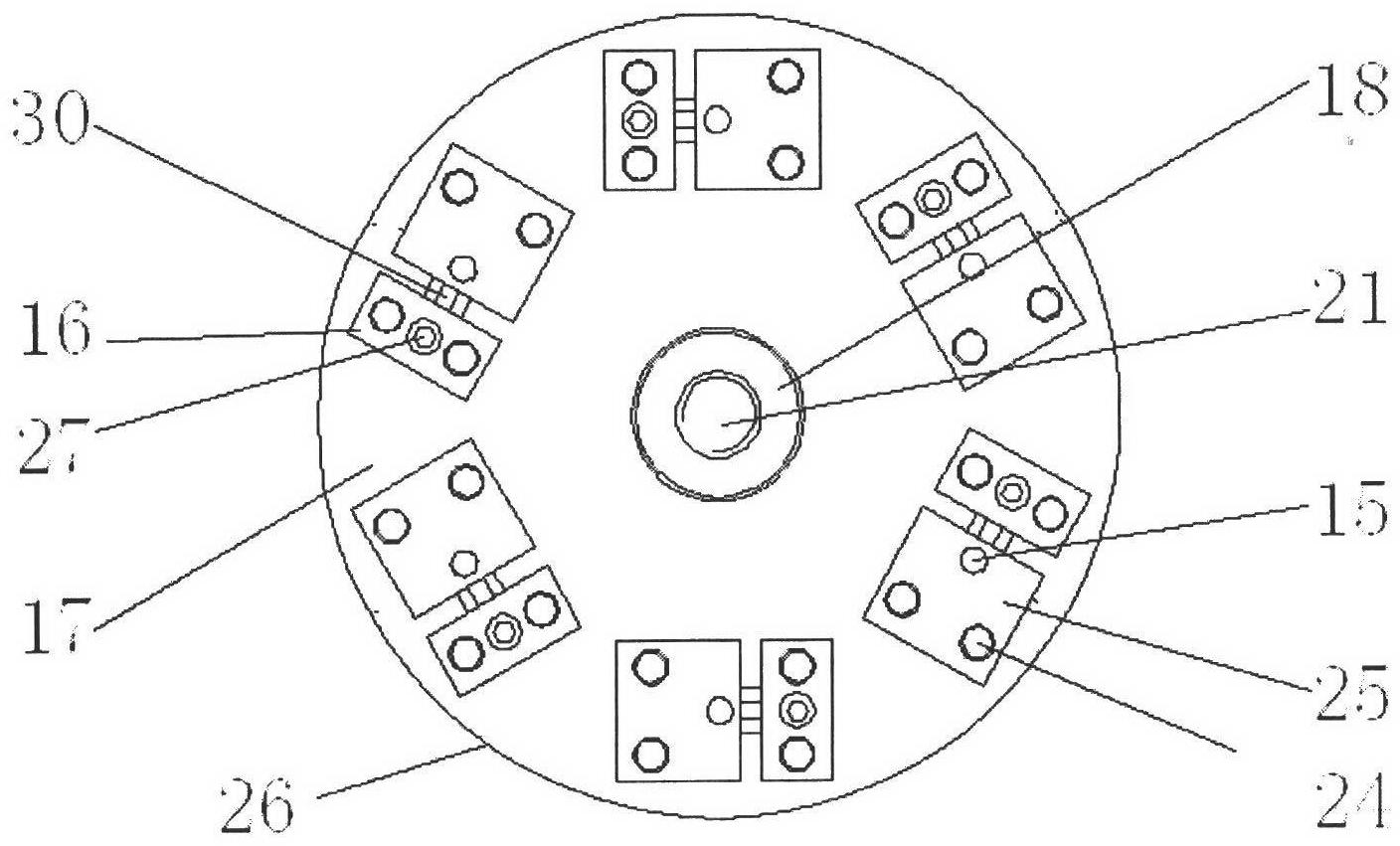

[0072] Example 1: Creep test of three-point bending micro-specimen under the same temperature and different loads

[0073] Three-point bending micro-sample 30 (size is 20 * 5 * 1.5mm) is packed in the chassis groove 35 of chassis 17, and guide upper mold 25 is installed, and after six micro-samples are all loaded into combined fixture 26, Connect it to the column 21 with two column lock nuts 18, and install the thermocouple 2. Weigh the weight of the indenter 15, the pressing rod 14 and the weight tray 11, and use this weight as the preload of the creep test. Install the pressure head 15, screw the pressure rod 14 into the bottom of the weight tray 11, and pass through the guide sleeve 12 from top to bottom. After the installation is completed, turn the column slightly to make the indenter of each micro-sample contact with the pressure rod and adjust to the same axis direction, but no weight load is applied at this time. The displacement sensor 8 is installed on the sensor c...

Embodiment 2

[0089] Example 2: Creep test of small punch and three-point bending micro-specimen under the same temperature and different loads

[0090] Put the micro-sample 30 (the size of the small punch micro-sample is Φ10×0.5mm, the size of the three-point bending micro-sample is 20×5×1.5mm) into the chassis 17, install the guide upper mold 25, and lock the screw 24 is fixed, after the two micro-samples are all loaded into the combination fixture 26, the combination fixture 26 is connected to the column 21 with two column lock nuts 18, and then the thermocouple 2 is installed. Weigh the weight of the indenter 15, the pressing rod 14 and the weight tray 11, and use this weight as the preload of the creep test. Install the pressure head 15, screw the pressure rod 14 into the bottom of the weight tray 11, and pass through the guide sleeve 12 from top to bottom. After the pressure rods and pressure heads of the two samples are installed, turn the column 21 slightly, so that the pressure he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com