Patents

Literature

171 results about "Creep testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Creep testing (creep-rupture, stress-rupture, stress-relaxation) is conducted to determine the deformation (creep) of a material when subjected to a prolonged load at a constant temperature. A creep test has the objective of measuring creep and creep rates occurring at stresses usually well below those which would result in fracture.

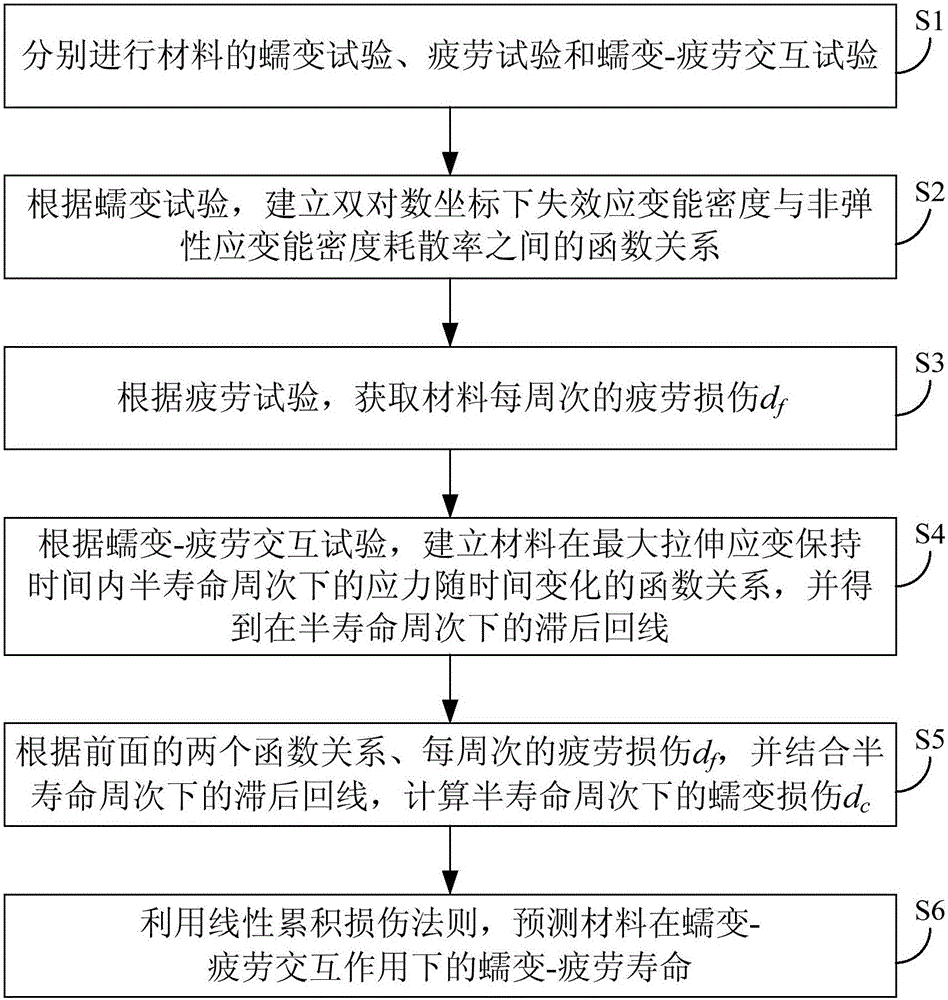

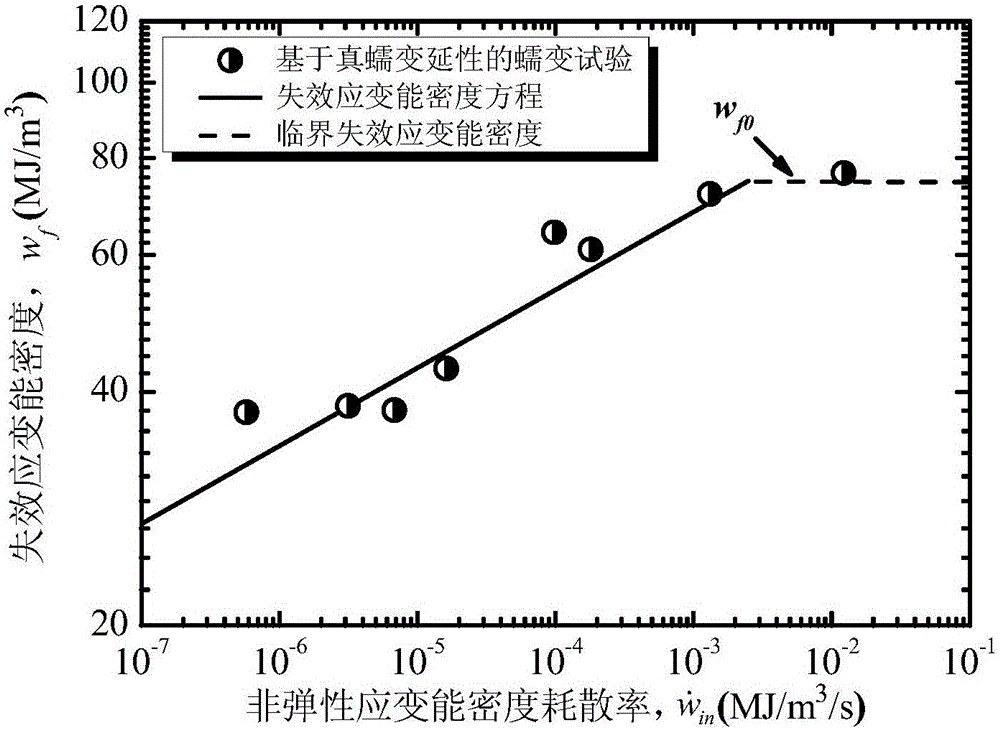

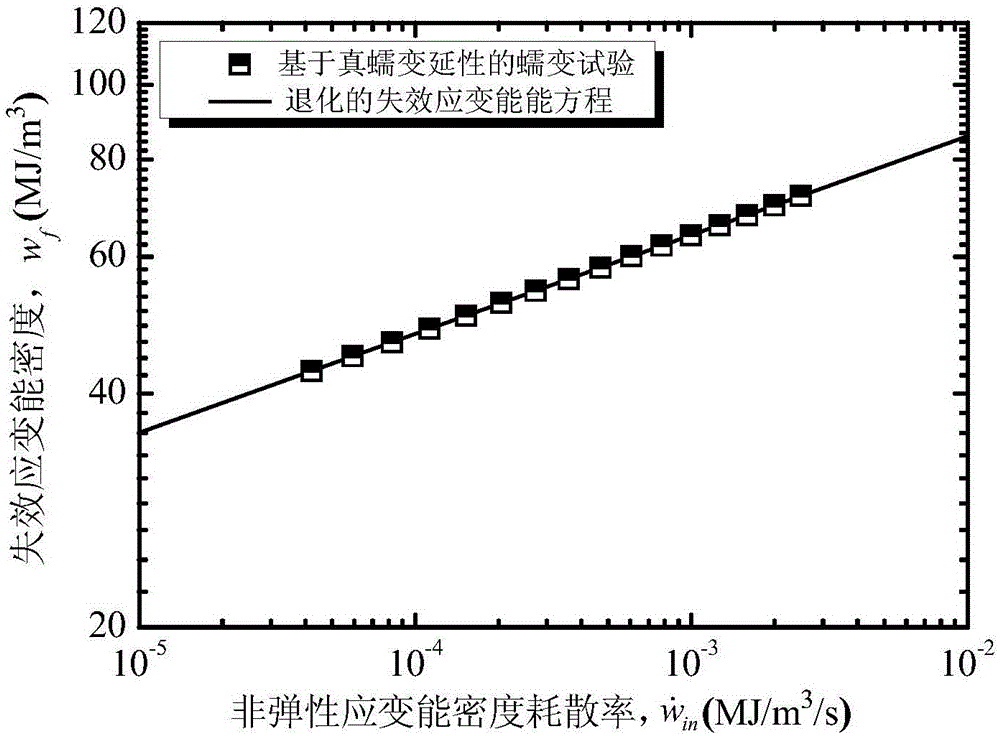

Forecasting method for creep-fatigue life of material

ActiveCN105158084ALife expectancyReal-time Damage DetectionMaterial strength using tensile/compressive forcesFatigue damageHysteresis

The invention provides a forecasting method for creep-fatigue life of a material. The method comprises the following steps: respectively performing a creep test, a fatigue test and a creep-fatigue interaction test for the material at a same test temperature; establishing a relation between the failure strain energy density wf and a non-elastic strain energy density dissipation rate of the material under a log-log coordinate according to the creep test; acquiring the fatigue damage df of the material per period according to the fatigue test; acquiring a hysteresis loop under a half-life period according to the creep-fatigue interaction test and establishing a function relation of the change of the stress Sigma (t) of the material under the half-life period within the maximum tensile strain maintaining time along with the change of time t; calculating the creep damage dc under the half-life period by combining with the hysteresis loop and based on the relation between wf and the function as shown in the specification and the relation of change of the fatigue damage df and the stress Sigma (t) along with the change of time t; and utilizing a linear accumulating damage rule to forecast the creep-fatigue life of the material under a creep-fatigue interaction. According to the method provided by the invention, the life of the material under the creep-fatigue interaction can be accurately forecasted.

Owner:EAST CHINA UNIV OF SCI & TECH

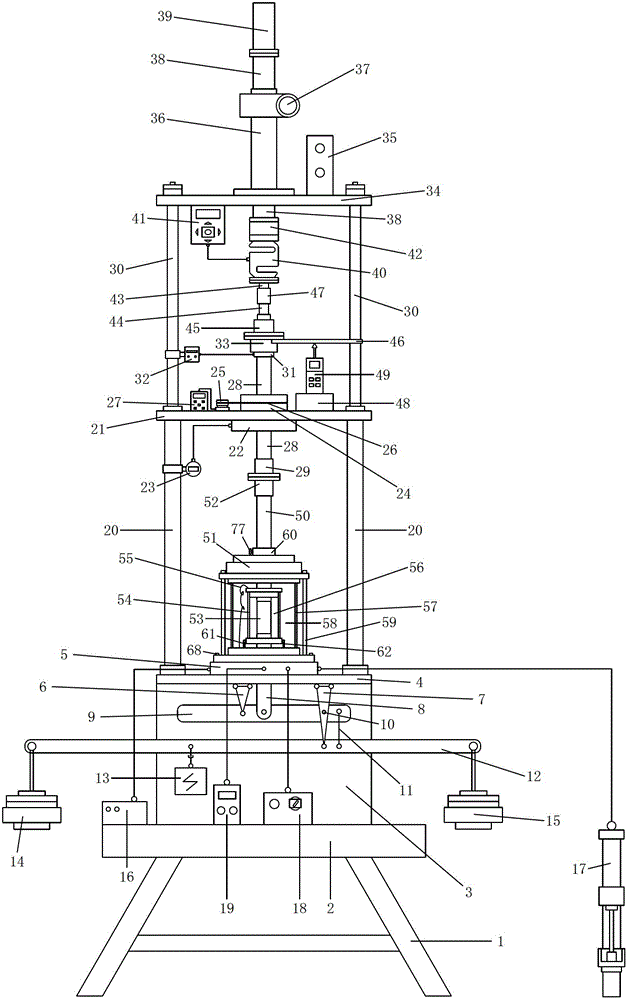

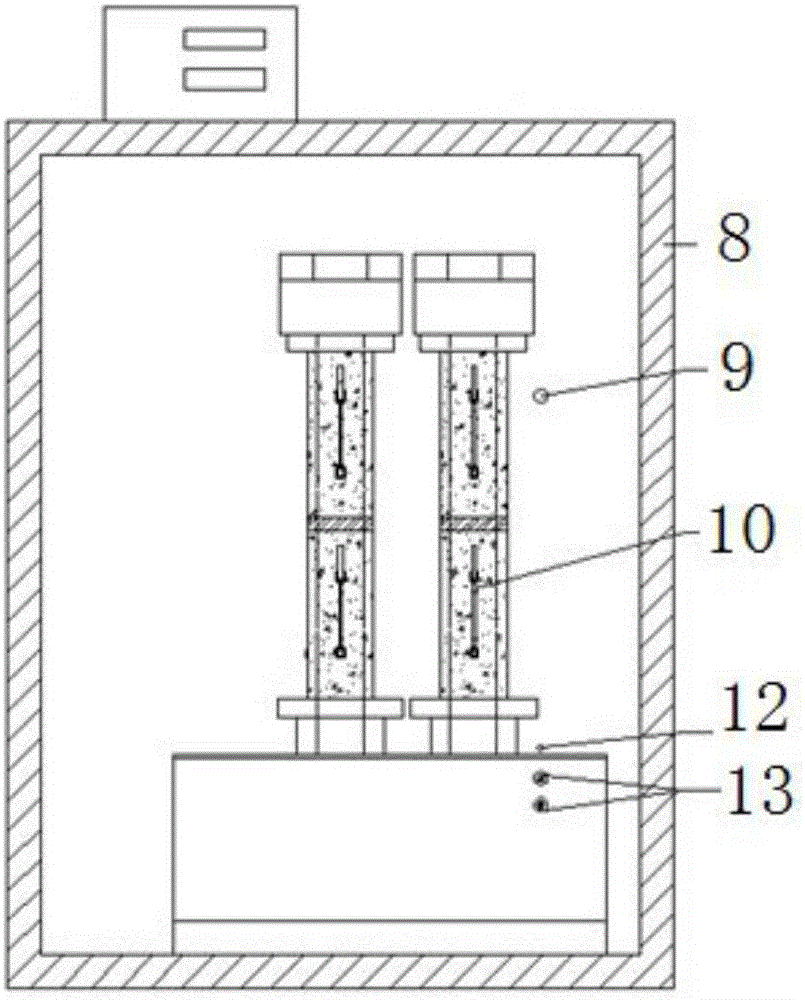

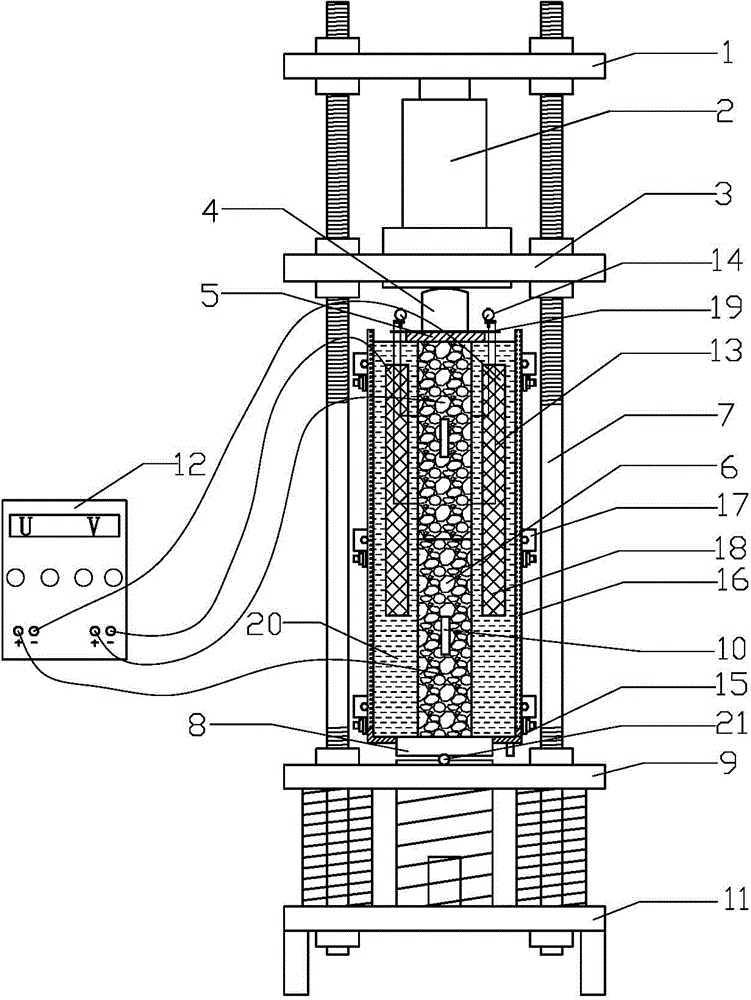

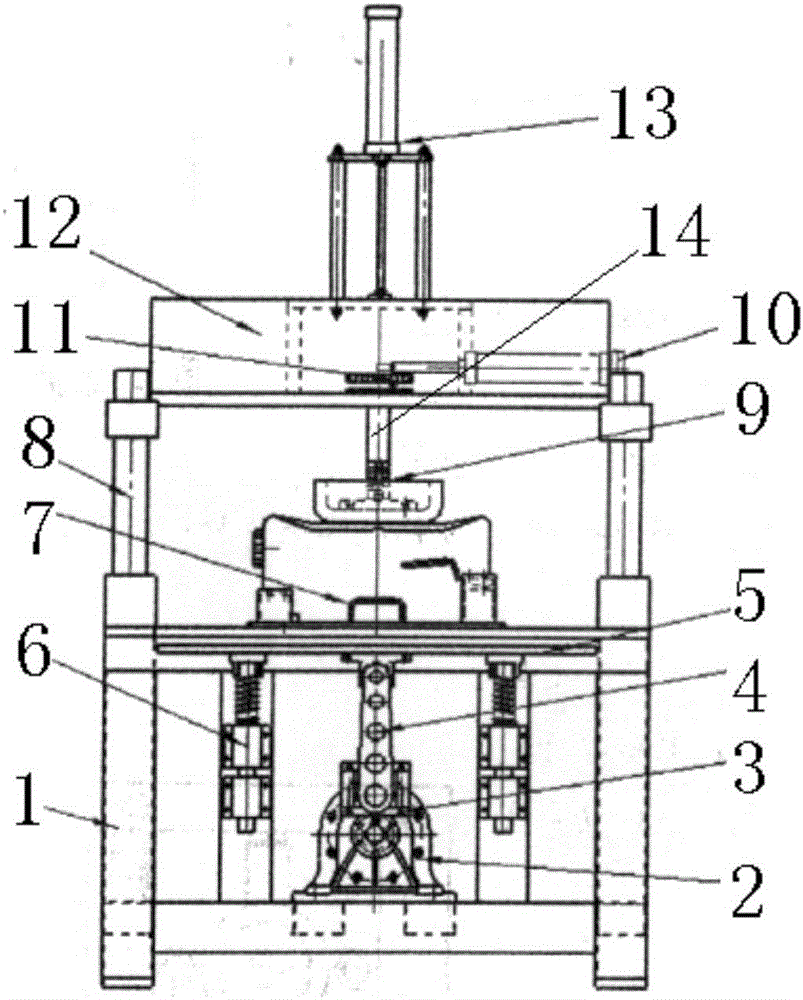

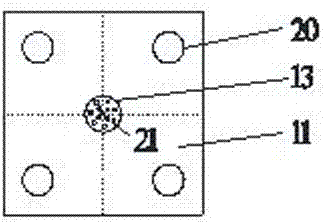

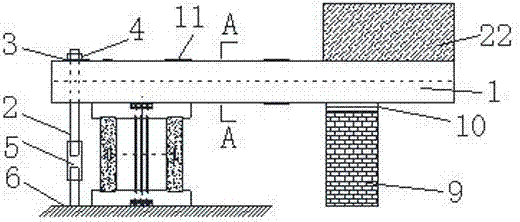

Multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions

InactiveCN103149101AStable controlCode of PracticeInvestigating material ductilityAxial displacementAmbient pressure

The invention discloses multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions, which structurally comprises a main body part, power supply equipment, an axial loading and measuring mechanism, a torque loading and measuring mechanism, a volume-changed water level controlling and measuring mechanism, an ambient pressure loading and measuring mechanism, a pore pressure measuring mechanism, a creeping and loading mechanism, an axial displacement measuring mechanism and a lubricating mechanism. A torque separator can apply any combined axial action and torque action; a multifunctional lever part not only can apply a tension action to a sample through a lever, but also can apply a pressure action to the sample through the lever; and a detachable split volume-changed measuring water jacket structure is remarkably changed on the aspect of soil body sample body-changed measurement. The machine provided by the invention is simple in structure, convenient to operate and high in accuracy rate and success rate.

Owner:XIAN UNIV OF TECH

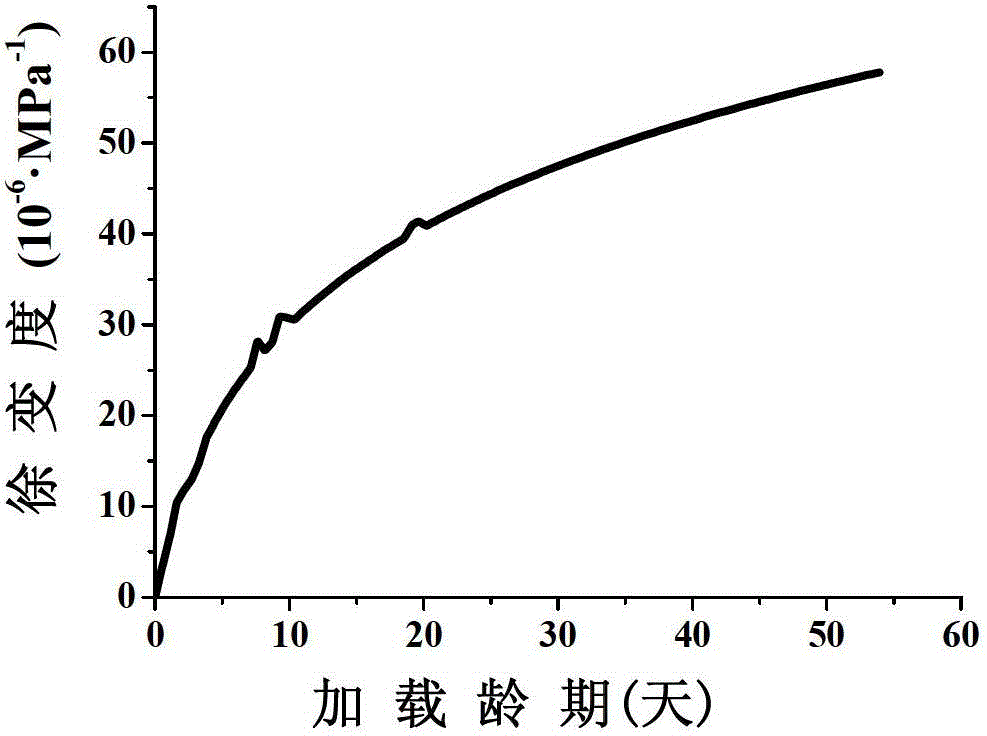

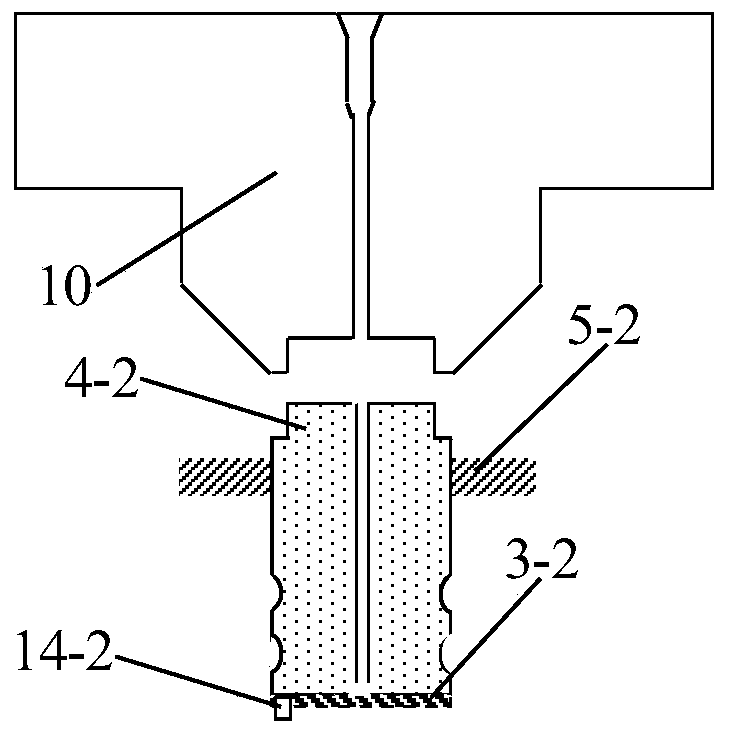

Concrete tensile creep testing device and concrete shrinkage stress creep testing method

The invention discloses a concrete tensile creep testing device which comprises a bracket, an upper perforated-articulated chuck, a lower perforated-articulated chuck, a perforating test piece, a deformation gauge and a balance weight load, wherein the two perforated-articulated chucks which are connected with the perforating test piece are respectively hung on the bracket and are connected with the balance weight load, so that the testing device can be formed. A concrete shrinkage stress creep testing method adopts a standard creep chamber and natural environmental condition, is restrained by complete or non-complete constraint stiffness, adopts loading ways of 'step loading' and 'follow-up loading', is carried out under the shrinkage threshold value and fixed age period loading control condition, and can be used for testing the concrete shrinkage stress creep. After the testing device and the testing method are adopted, the problems of connection between the concrete test piece and the chucks, physical alignment and load loss can be solved, and the test operability can be improved; furthermore, creep and strain can be tested gradually, so that more creep behaviors and performance problems can be researched; particularly, the concrete shrinkage stress creep test can be realized in the natural environment.

Owner:CENT SOUTH UNIV

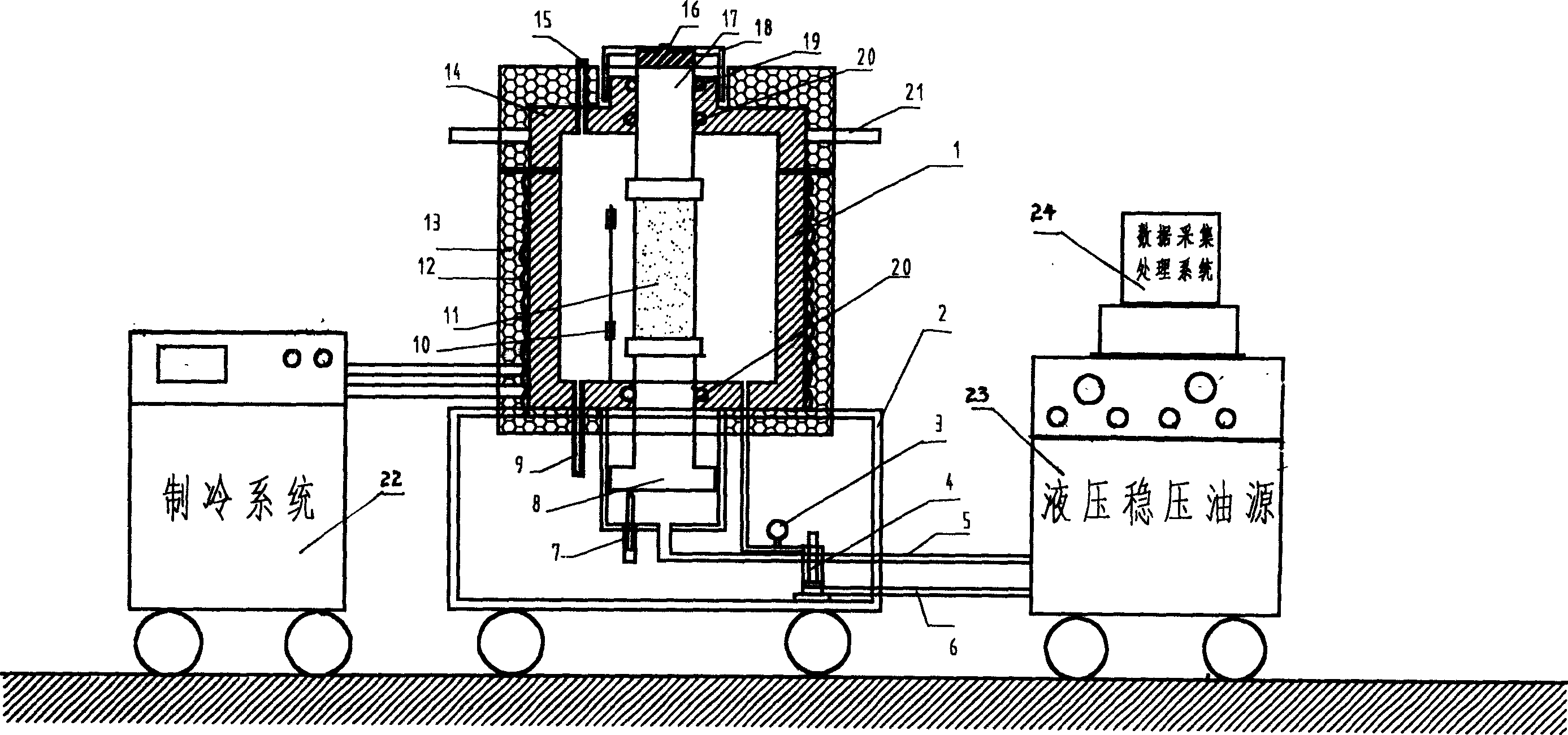

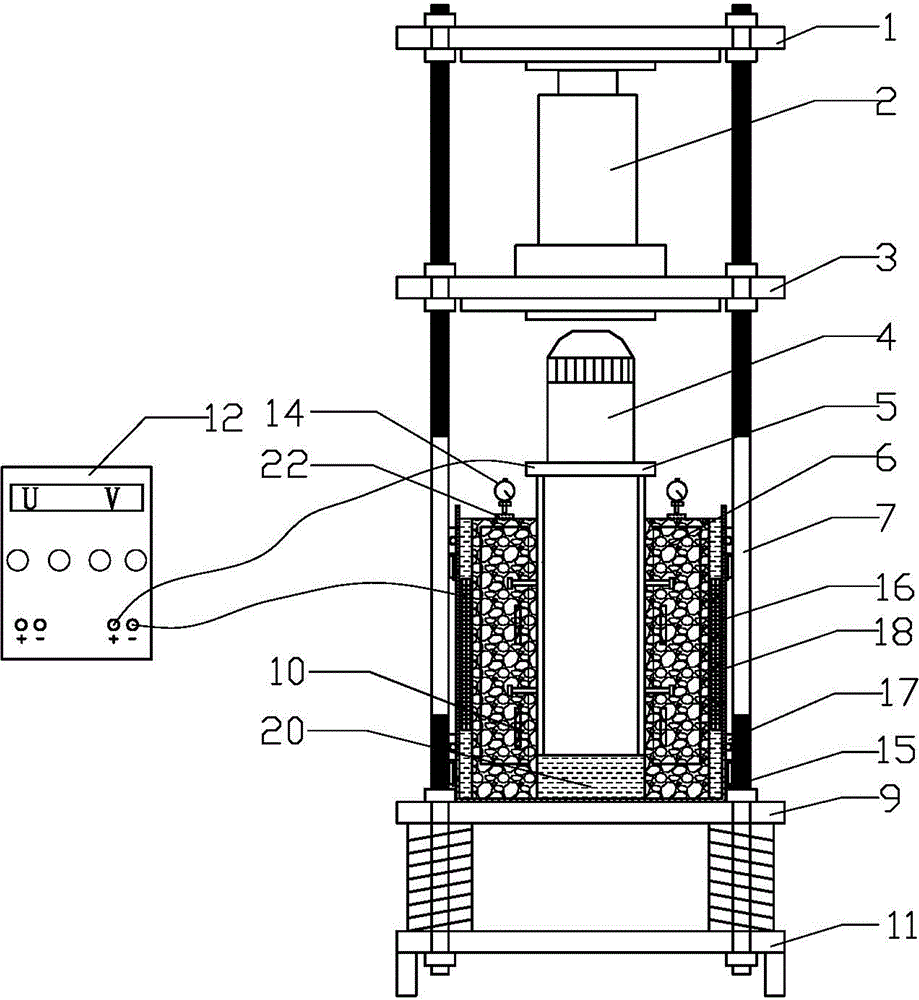

Low-temperature high-pressure three-axle creep testing instrument

InactiveCN1609587ALow costReduce volumeMaterial strength using tensile/compressive forcesAxial pressureRoom temperature

The present invention relates to engineering material test instrument, and is especially one kind of low temperature high pressure three-axis creepage test instrument. The instrument includes system unit, refrigerating system, stable pressure hydraulic oil source system and data acquisition and processing system. The test tank of the system unit set on support has inside upper pressure rod, lower axial pressurizing piston with lower part communicated with the stable pressure hydraulic oil source system via the axial pressure loader, inside communicated with the stable pressure hydraulic oil source system via the peripheral pressure loader, and refrigerating compressing tube connected with refrigerating system. All the measuring sensors are connected separately with the data acquisition and processing system. The present invention may be used in completing single- and three-axis creepage and strength test at normal or low temperature.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

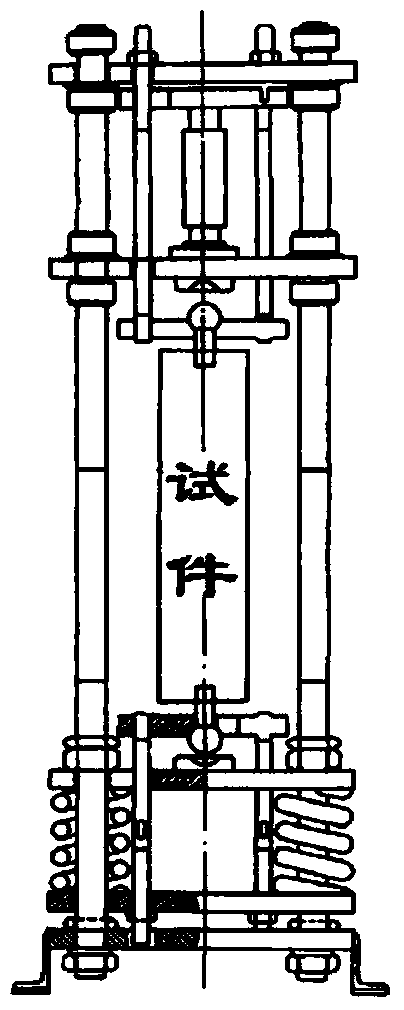

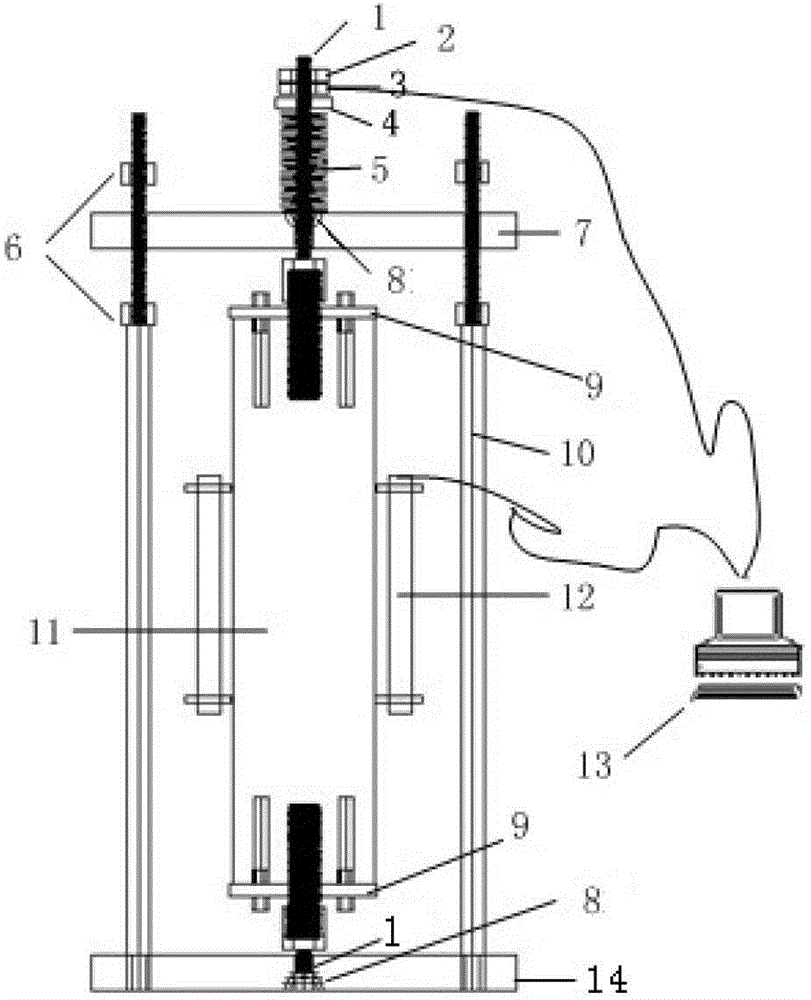

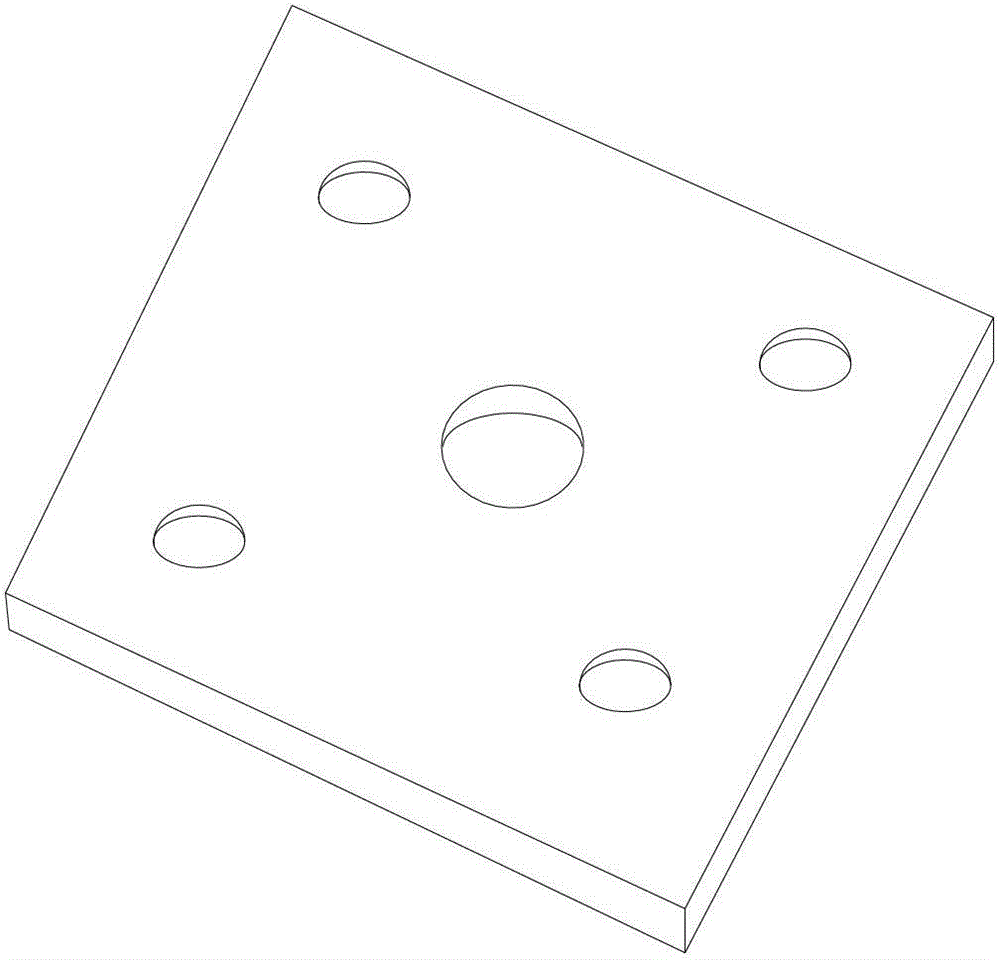

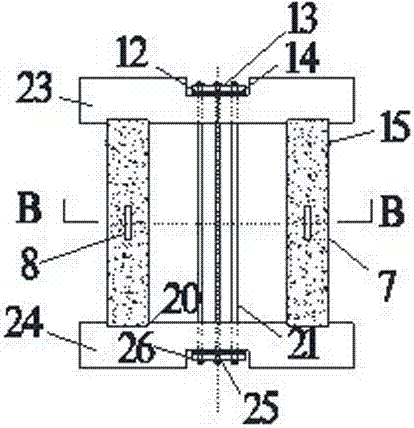

Concrete axis stretching creep tester and test method thereof

InactiveCN103149100AImprove continuityRealize acquisitionInvestigating material ductilityStress concentrationConstant stress

The invention discloses a concrete axis stretching creep tester and a test method thereof. The tester comprises an upper pulling plate, a lower pulling plate, pulling bars, screws, a spring, a stress sensor and vibrating string extensometers, the pulling bars are fixed on the lower pulling plate, and the upper ends of the pulling bars are provided with thread ends; the upper pulling plate traverses the upper ends of the pulling bars and is sleeved on the thread ends, and the thread ends at the upper and lower sides of the upper pulling plate are provided with nuts to fix the upper pulling plate; the upper and lower pulling plates are provided with the screws respectively and are used for the fixed connection of the upper and lower end of a concrete test piece, and the vibrating string extensometers are arranged at two sides of the concrete test piece; and the screw on the upper pulling plate stretches out of the upper pulling plate, the spring is sleeved on the stretching end of the screw, the stretching screw is also sequentially sleeved with a pad and a nut, and the stress sensor is arranged between the pad and the nut. The tester and the method realize the continuous automatic detection and acquisition of deformation; and no eccentricity, concentrated stress and constant stress are realized in the stretching process, so the test accuracy is improved.

Owner:SOUTHEAST UNIV

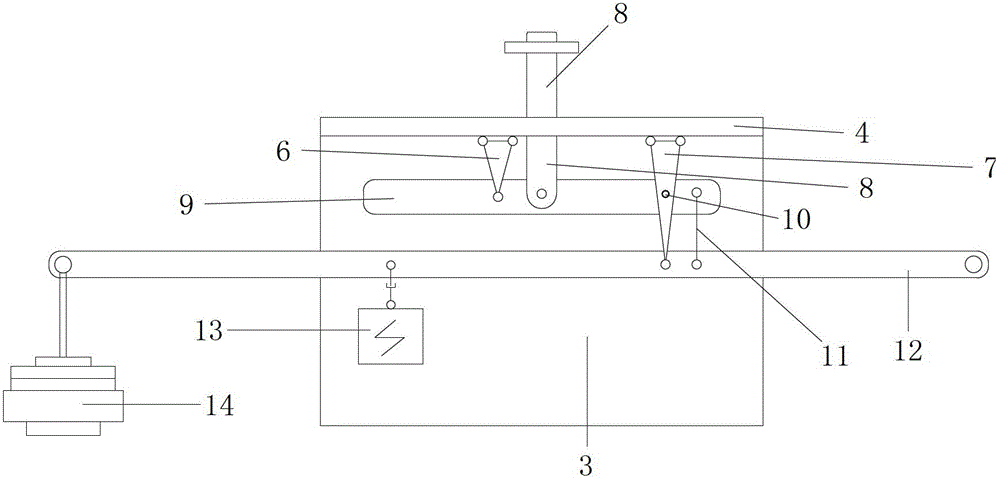

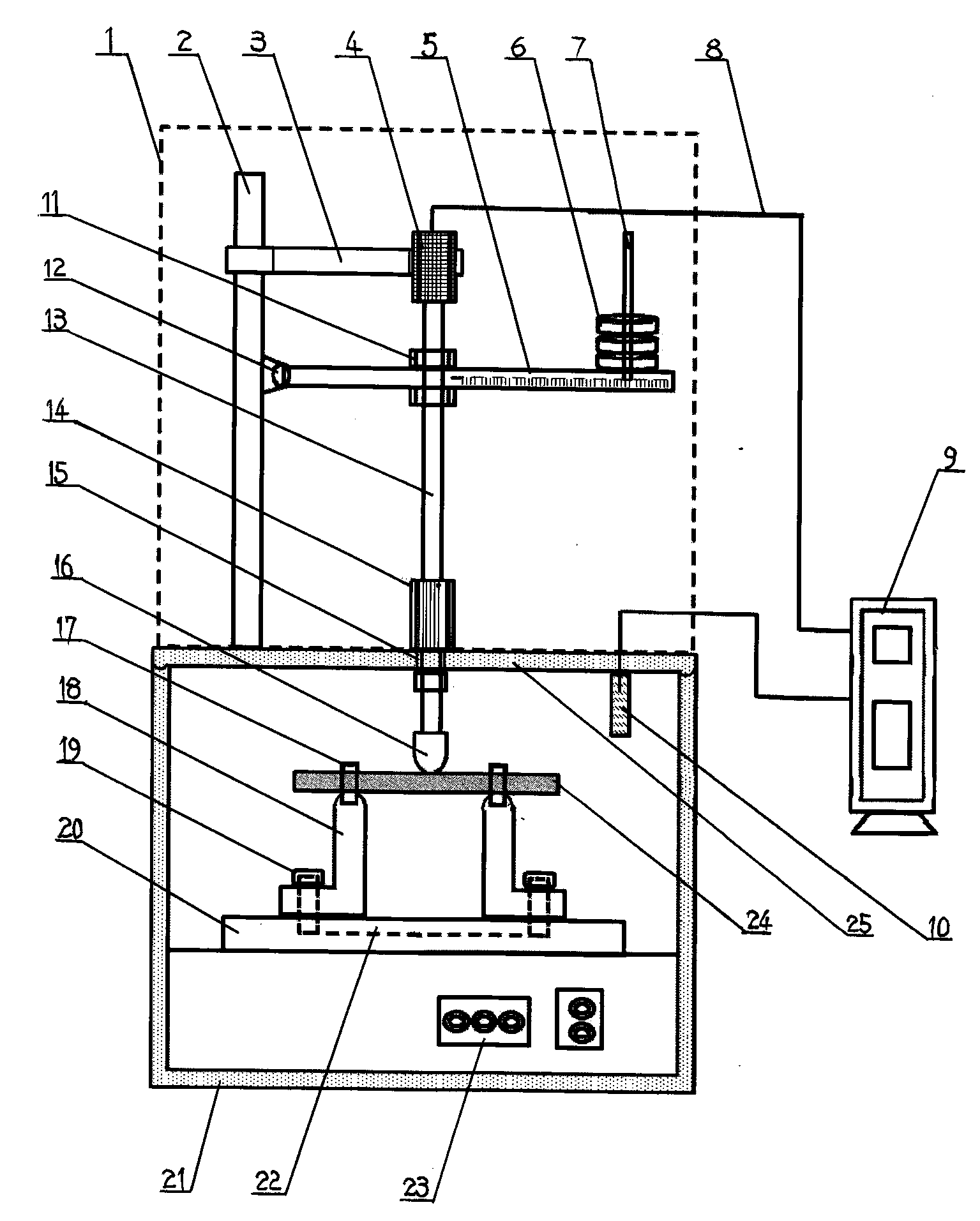

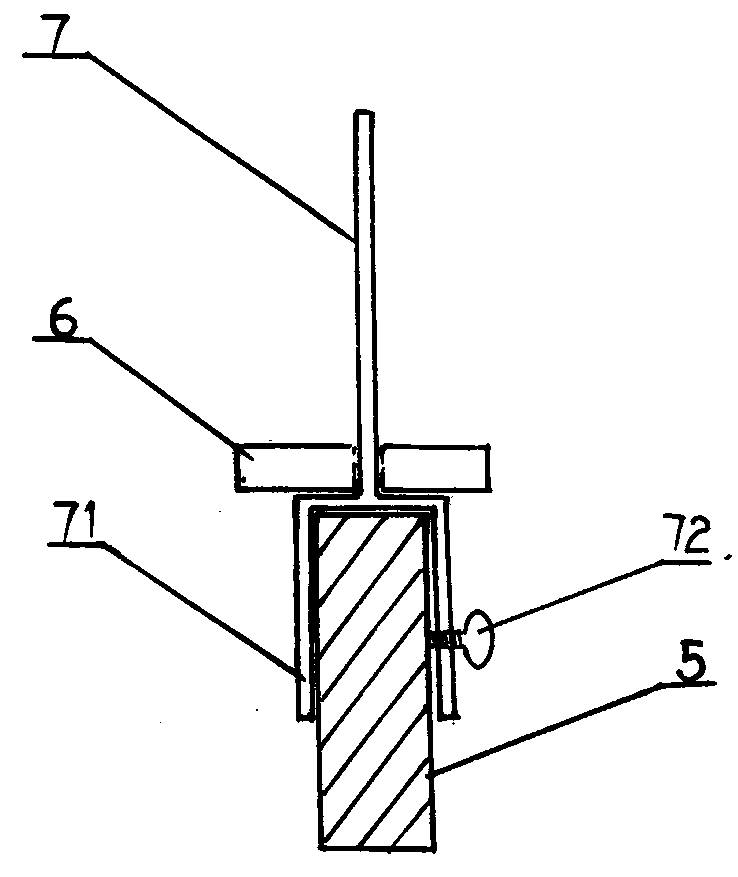

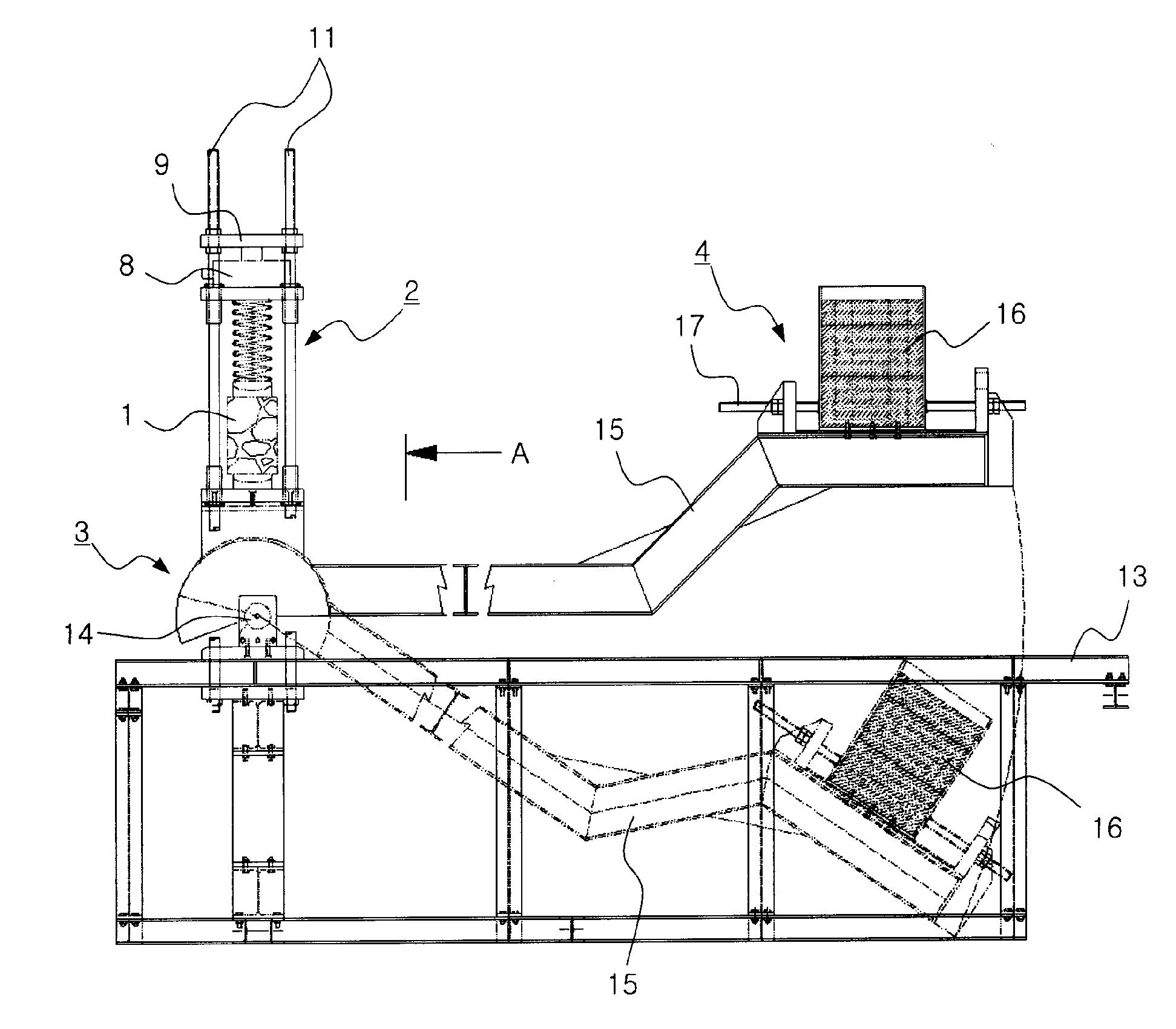

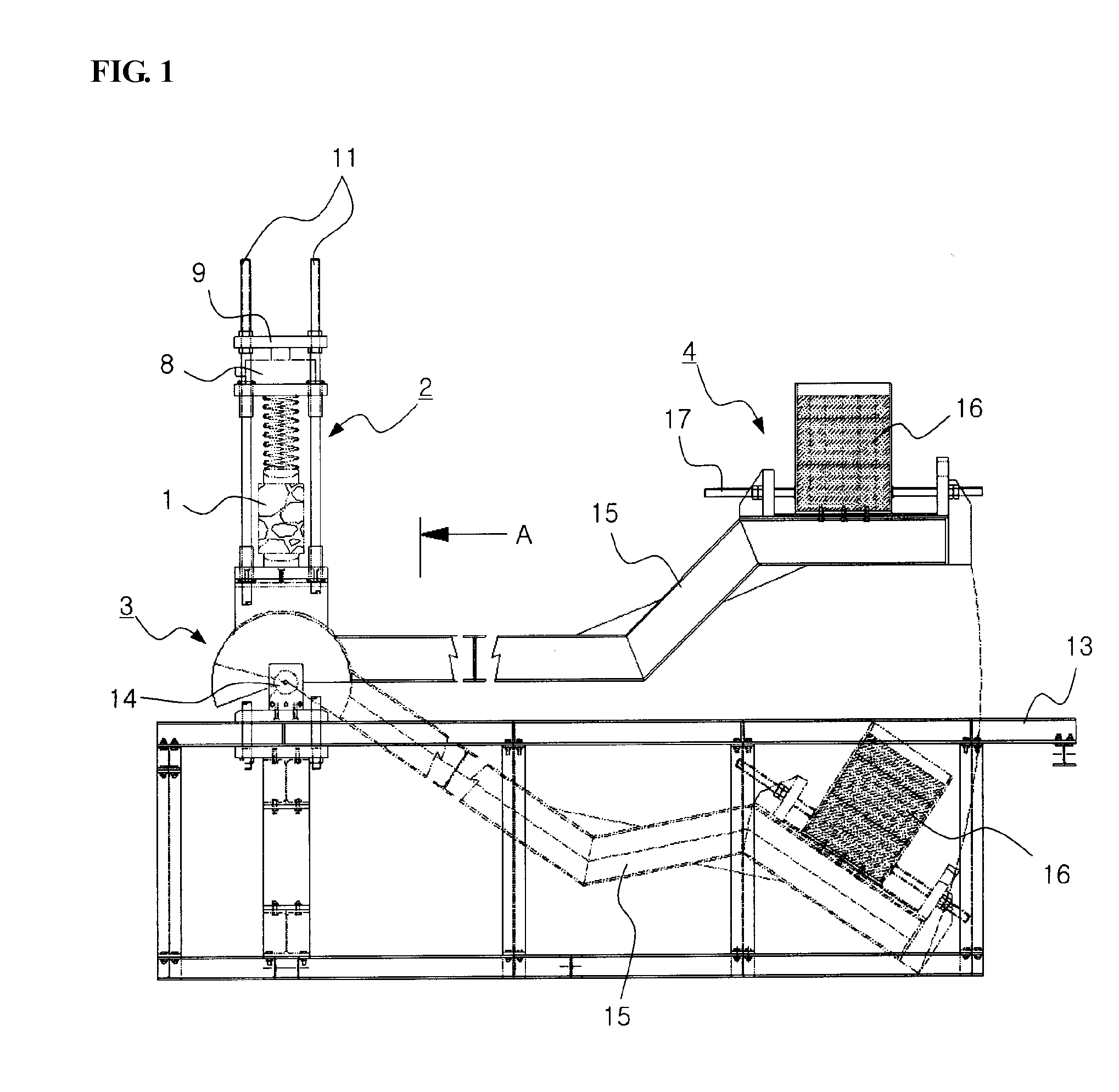

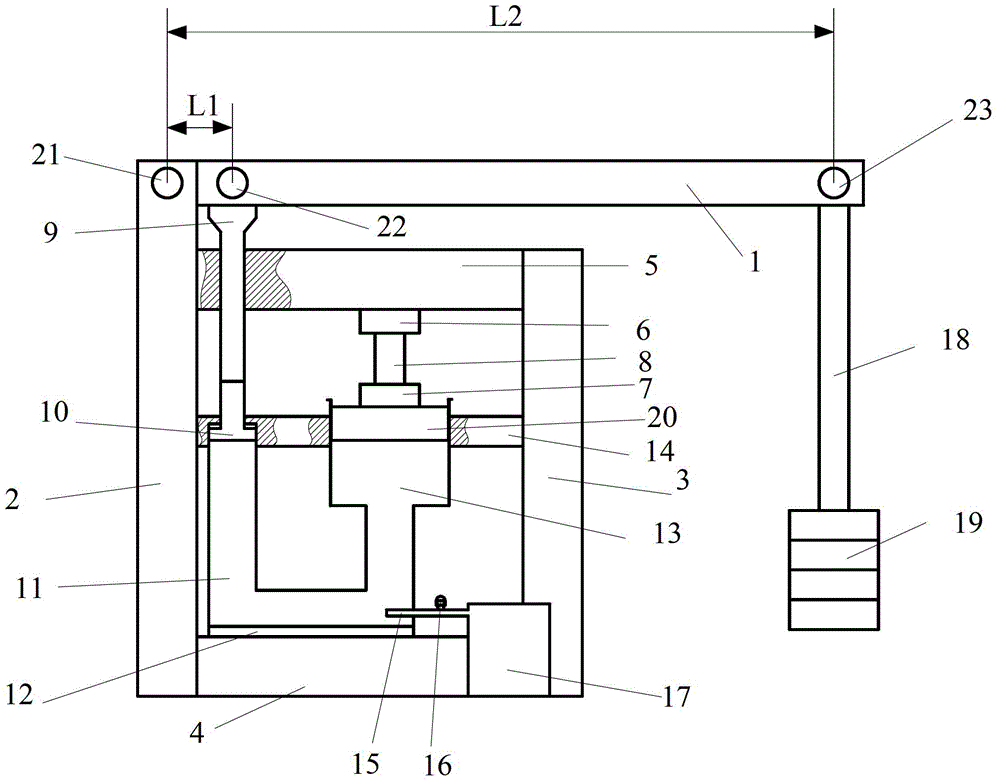

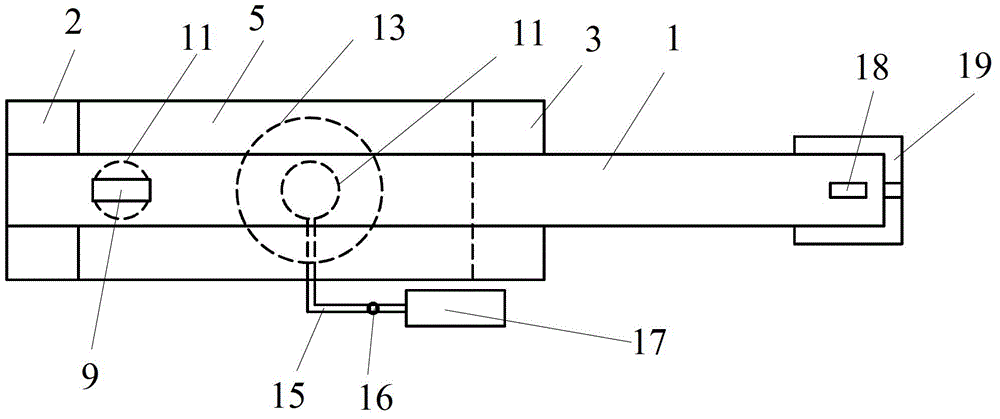

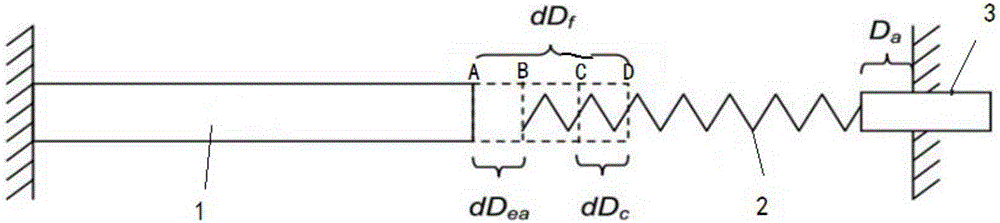

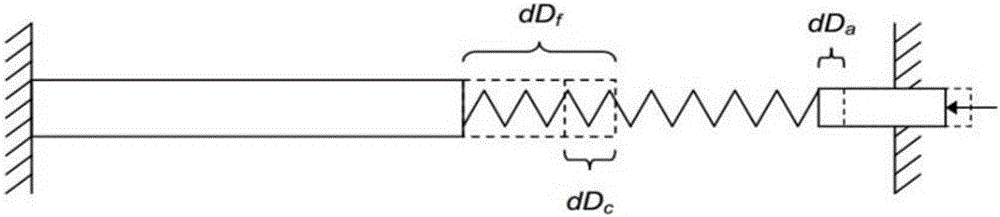

Simple method for various creepage tests and device thereof

InactiveCN103808572AGuaranteed Creep Test AccuracyGuaranteed stabilityMaterial strength using steady bending forcesEngineeringStress sensor

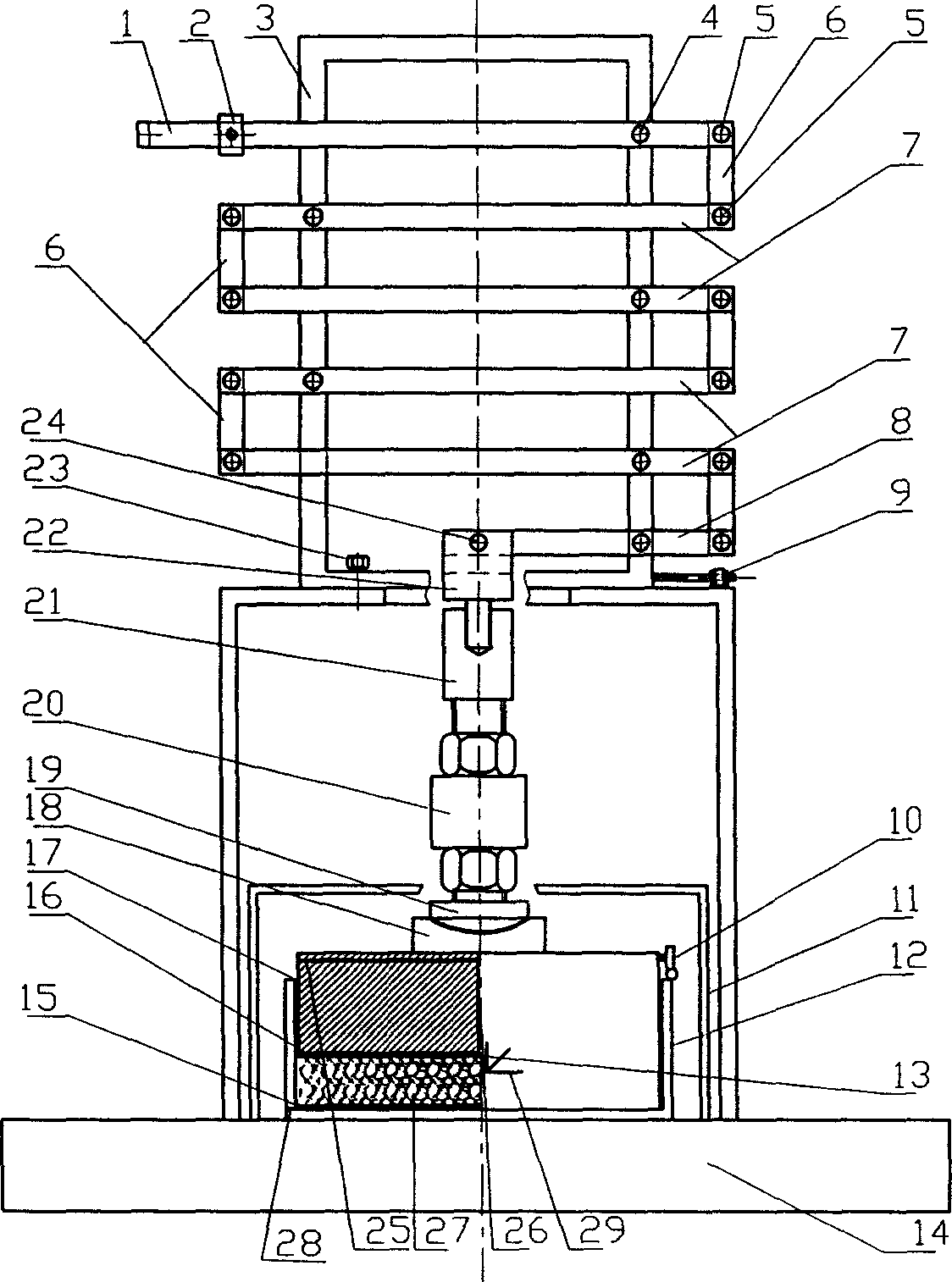

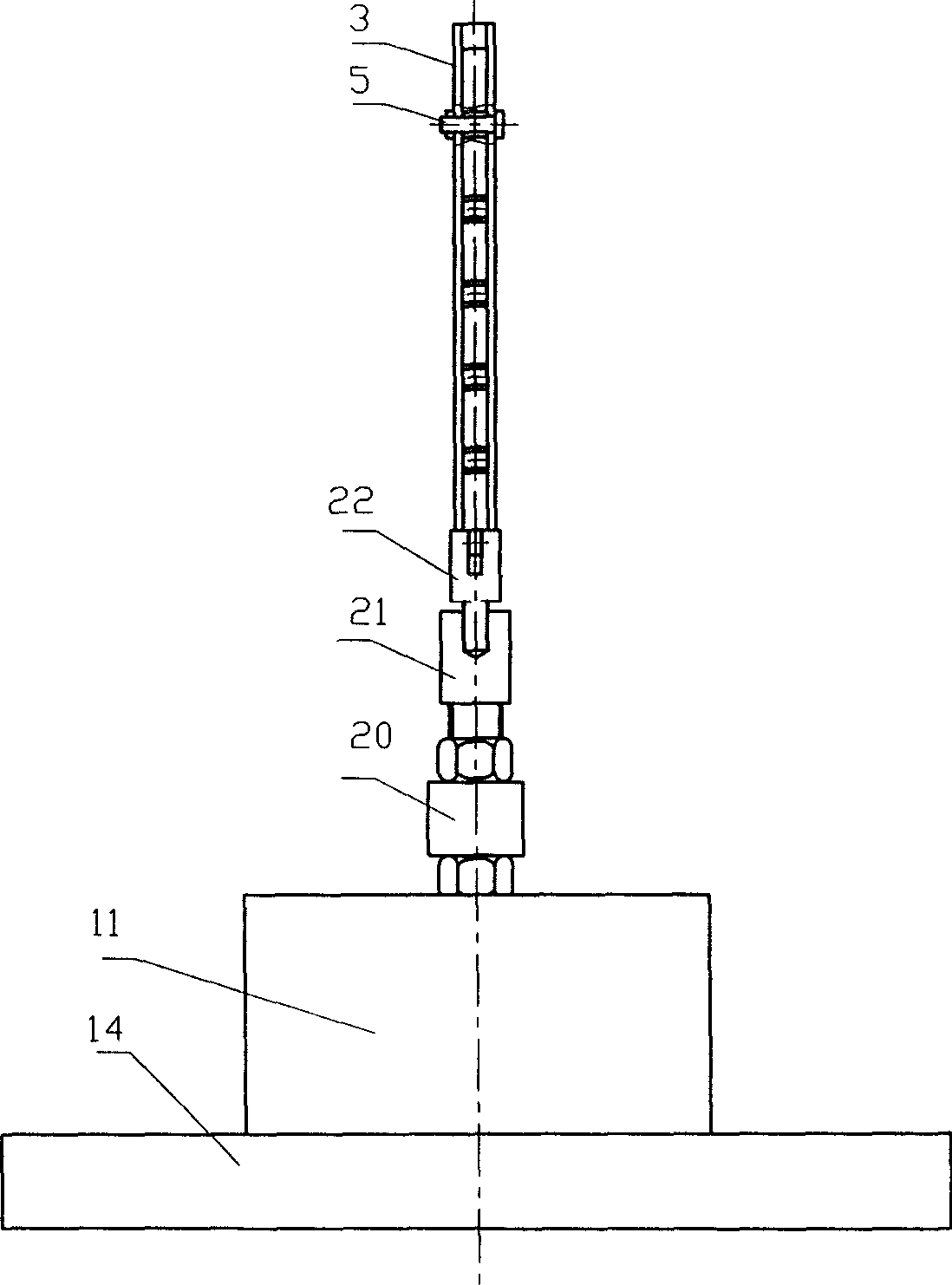

The invention belongs to a simple method for various creepage tests and a device thereof. According to the method, an experiment environment in which an experiment material is positioned and a device for applying pressure to the experiment material are arranged in separated spaces; the device for applying the pressure is a mechanically manual pressure applying adjustment device; force is loaded to a loading lever through a weight; the loading force is transmitted to a force transmission rod through a loading force application point by the loading lever; a pressure head on the force transmission rod applies pressure to the experiment material for experiment; a stress sensor and a displacement sensor are used for acquiring experiment data in real time and the experiment data are transmitted into a computer through a data wire; system software is used for processing the data and drawing a creepage curve. The device consists of an experiment box, an operating platform and the pressure applying adjustment device. The method disclosed by the invention can be suitable for long-time experiment, and guarantees the creepage test precision and the test running cost can be greatly lowered. The device has the advantages of simple structure, low manufacturing cost, convenience in operation and maintenance, high loading stabilization precision, low experiment cost and good effect.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

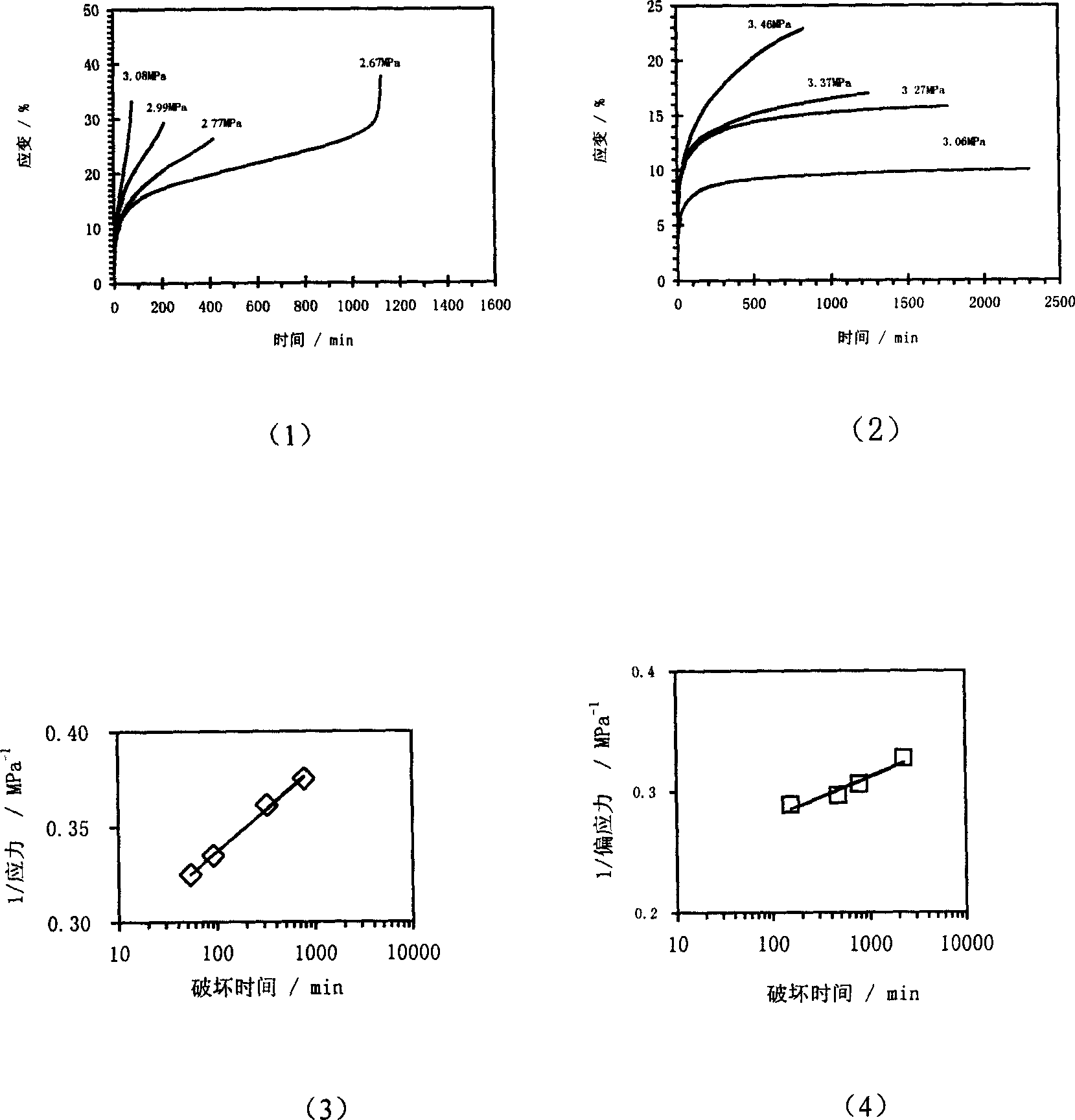

Testing method of polyphase coupling creep of fragmented rock body and equipment thereof

InactiveCN1687739ABulkyHigh precisionEarth material testingInvestigating material ductilityCouplingEngineering

The invention is the multi-phase couple creep testing method of the broken rock and the equipment. The invention adopts the multi-phase lever driving device, the loading device connecting the driving device and the compressing device under the loading device. The lever loading makes the beam wind the hinge of the framework; add the charge conveyed by the lever system on the samples through the adjusting screw, the force sensor, the ball hinge pressing head and the infiltrator; implement worm misshaping test to the sample in the high-low temperatures. The invention is stable, simple, small, convenient and precise.

Owner:CHINA UNIV OF MINING & TECH +1

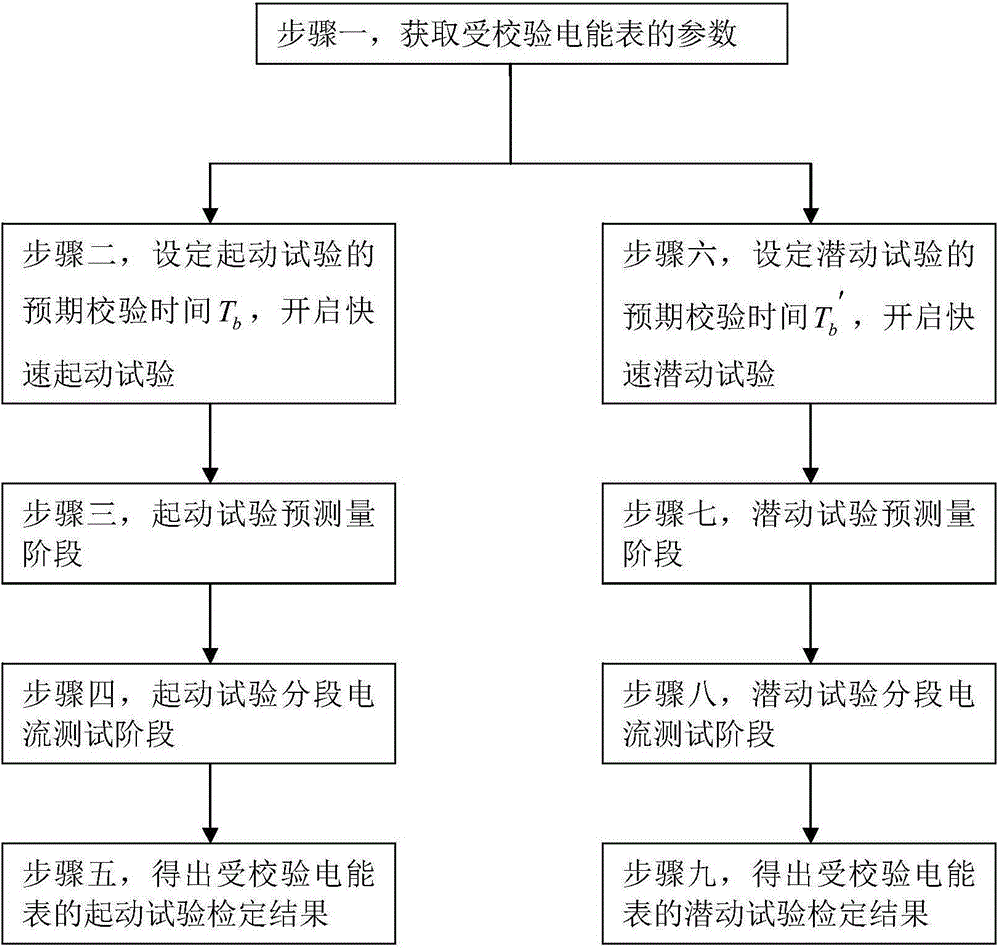

Rapid electric energy meter verification method based on segmented current technology

The invention discloses a rapid electric energy meter verification method based on segmented current technology. The method comprises a start testing process and a creep testing process; and each of the start testing process and the creep testing process comprises a pre-test phase, a first segmented current test phase and a second segmented current test phase. On the premise that national metering detection rules and prescriptions are satisfied, time of the start test and creep test of the electric energy meter is reduced, and the aim of rapid verification for the electric energy meter is achieved; and it is proved that the verification time of the rapid electric energy meter verification method of the invention is shorted for tens of times compared with a routine electric energy meter verification method.

Owner:广州市格宁电气有限公司 +1

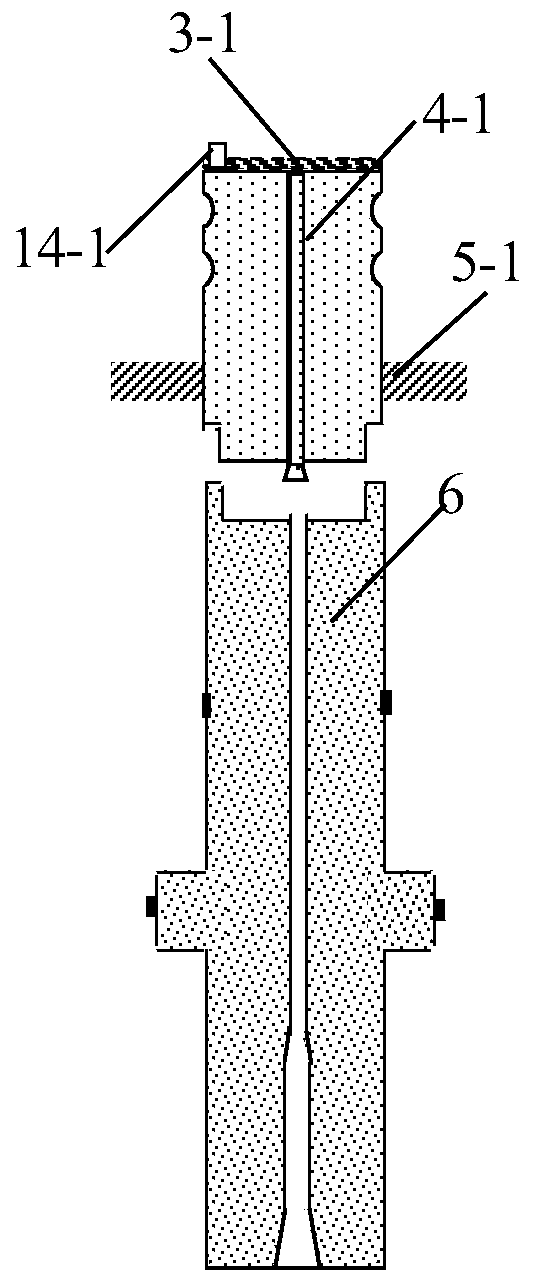

Uniaxial creep testing device and method for frozen earth with temperature gradient

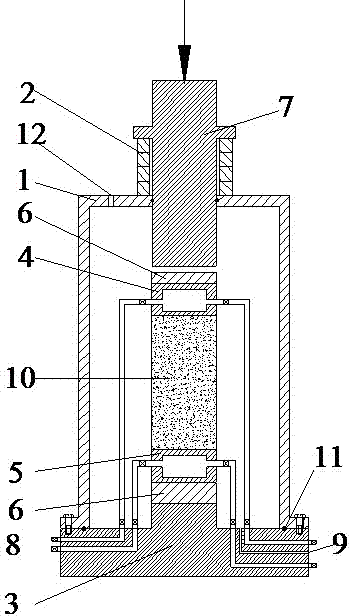

ActiveCN103091180AHigh temperature control accuracyFacilitate the study of scale effectsInvestigating material ductilityEngineeringStressed state

The invention discloses a uniaxial creep testing device and a uniaxial creep testing method for frozen earth with a temperature gradient. The device consists of a pressure cover, a height adjusting cushion block, a convex pedestal, an upper refrigerating plate, a lower refrigerating plate and heat insulation plates, wherein a piston and a vacuumizing channel are arranged at the upper part of the pressure cover in a sliding way, and refrigerating fluid circulating channels and a test lead wire channel are formed in the convex pedestal. In the testing process, the heat insulation plate, the lower refrigerating plate, a sample, the upper refrigerating plate, the heat insulation plate and the pressure cover are sequentially mounted on the convex pedestal, and the space between the convex pedestal and the pressure cover is sealed by an O-shaped seal ring; an adiabatic boundary condition required by the sample is realized by vacuumizing in the pressure cover; the vertical temperature gradient of the sample is realized by regulating cold medium temperatures in the upper refrigerating plate and the lower refrigerating plate; and a creep load required by the sample is realized by regulating the forced direction and size of the piston. According to the uniaxial creep testing device and the uniaxial creep testing method, a unidirectional stress state and the stable adiabatic boundary condition can be provided, and the device and the method are suitable for research of uniaxial creep characteristics of the frozen earth under the conditions of different temperature gradients and scales.

Owner:CHINA UNIV OF MINING & TECH

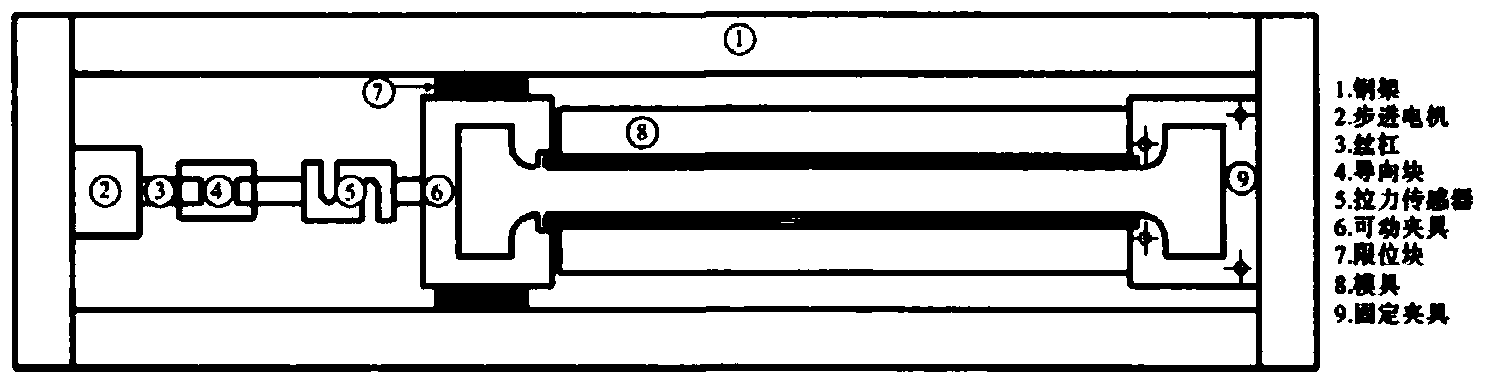

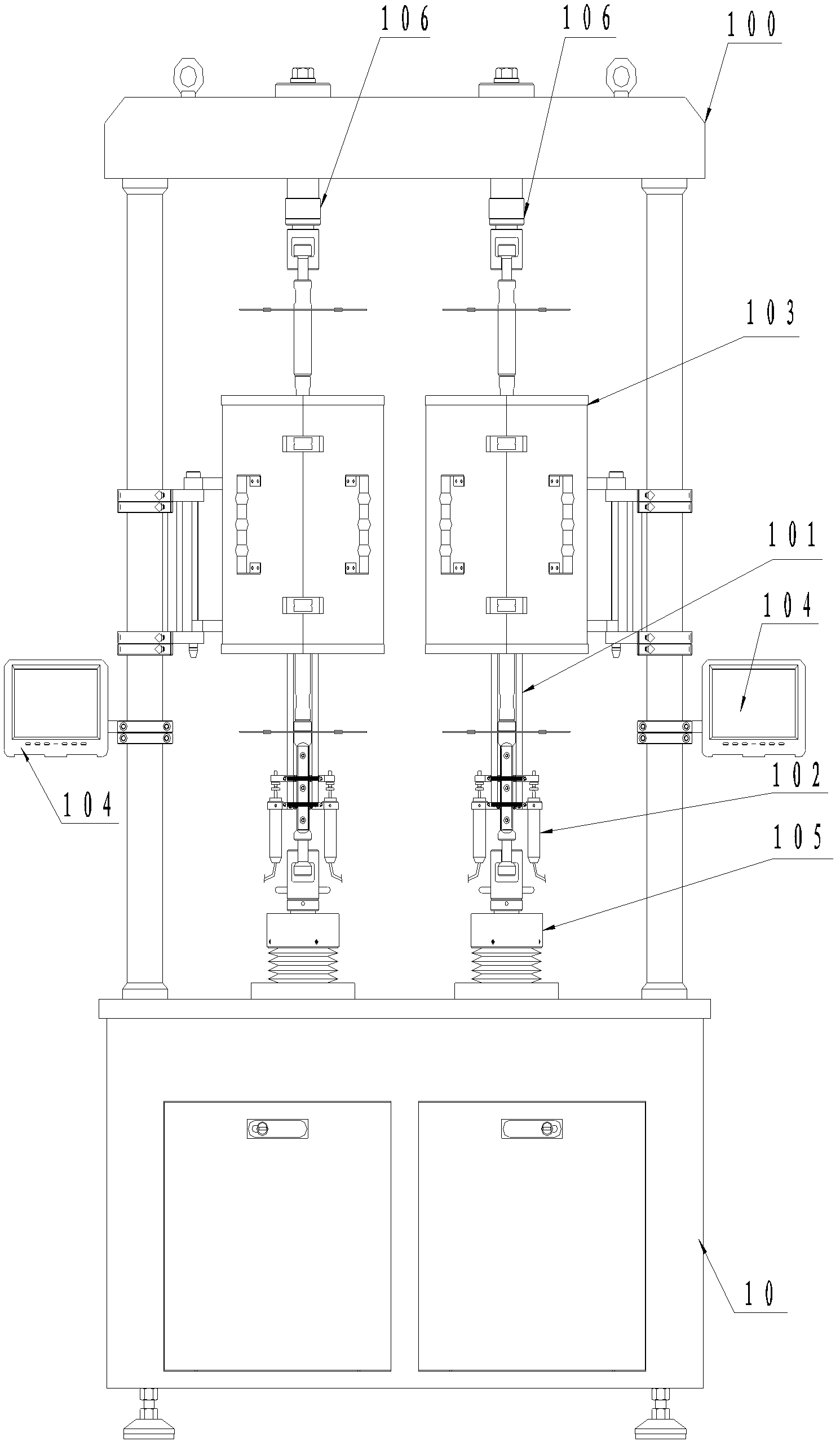

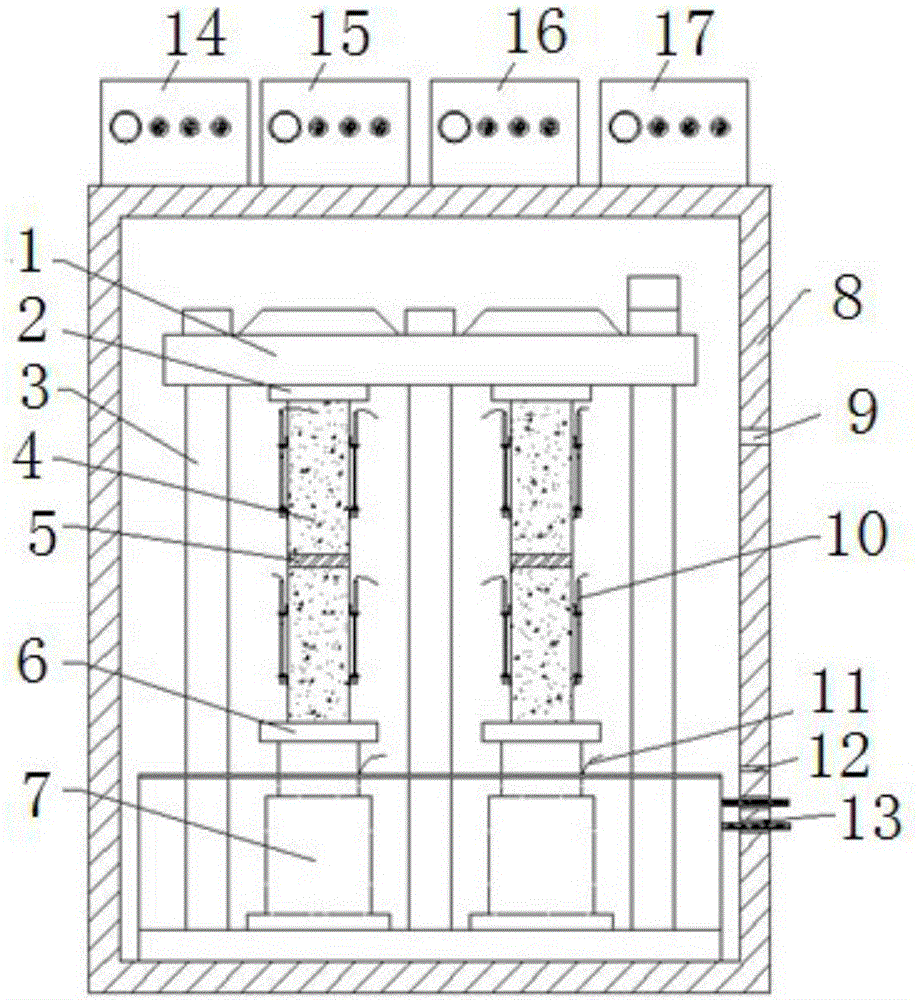

Multi-head electronic type high-temperature creep permanent strength testing machine

ActiveCN103175746AEasy to adjustIncreased Assay FlexibilityInvestigating material ductilityUltimate tensile strengthCreep testing

The invention discloses a multi-head electronic type high-temperature creep permanent strength testing machine. The testing machine comprises a rack with a door frame type structure, two or more tensile connecting devices for restraining a sample are arranged on the rack, the tensile connecting devices are parallel to on another, each tensile connecting device is configured with an independent displacement sensor and a high-temperature furnace, and the displacement sensor is connected with a distortion-measuring extraction device connected with a sample. The invention aims at providing the multi-head electronic type high-temperature creep permanent strength testing machine, each tensile connecting device of the testing machine is independently controlled to respectively perform the permanent or creep testing, the working efficiency of the equipment is greatly improved, and the cost performance of the product is improved, thereby improving the competition force of the product in the market.

Owner:珠海市三思泰捷电气设备有限公司

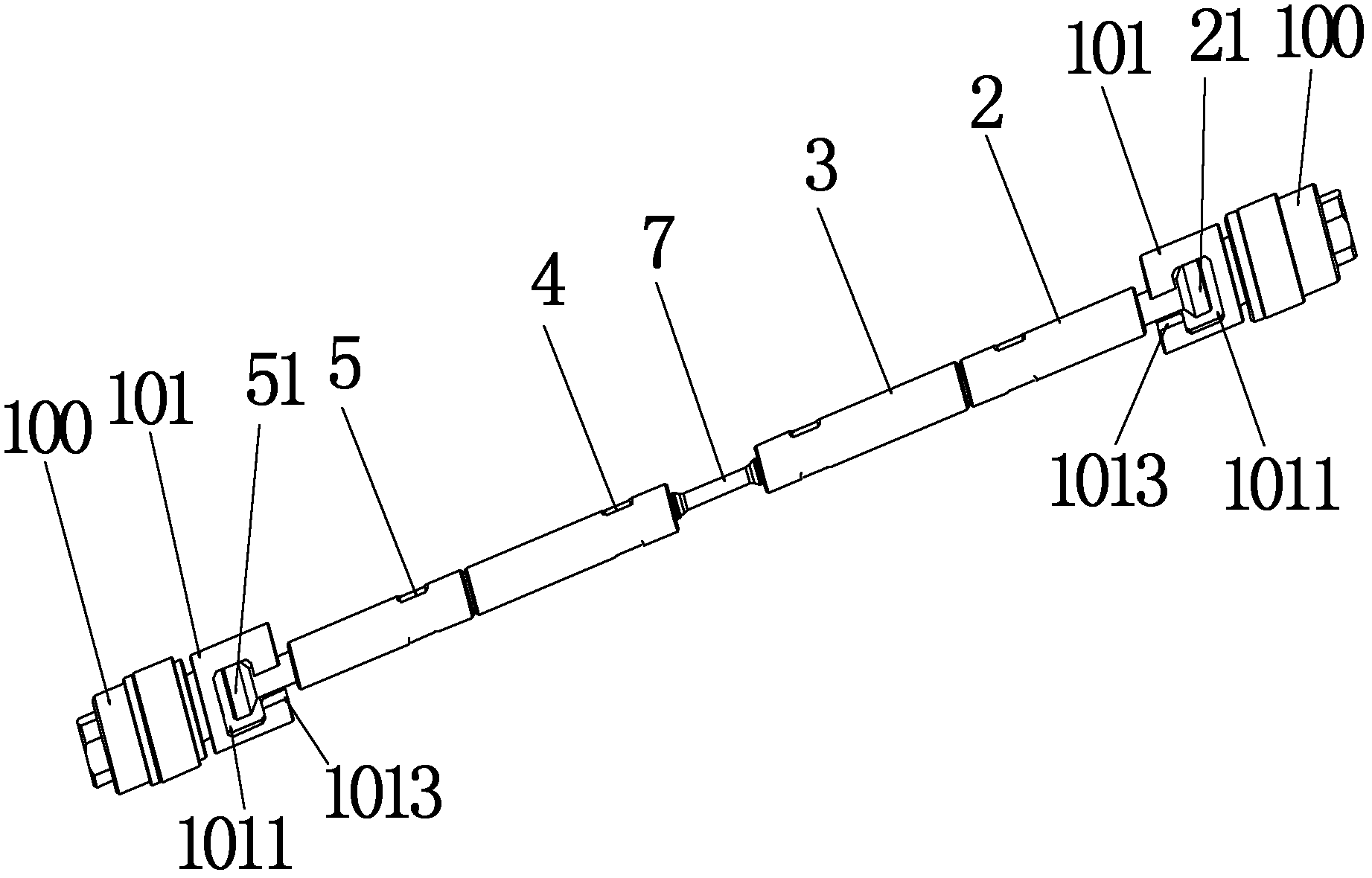

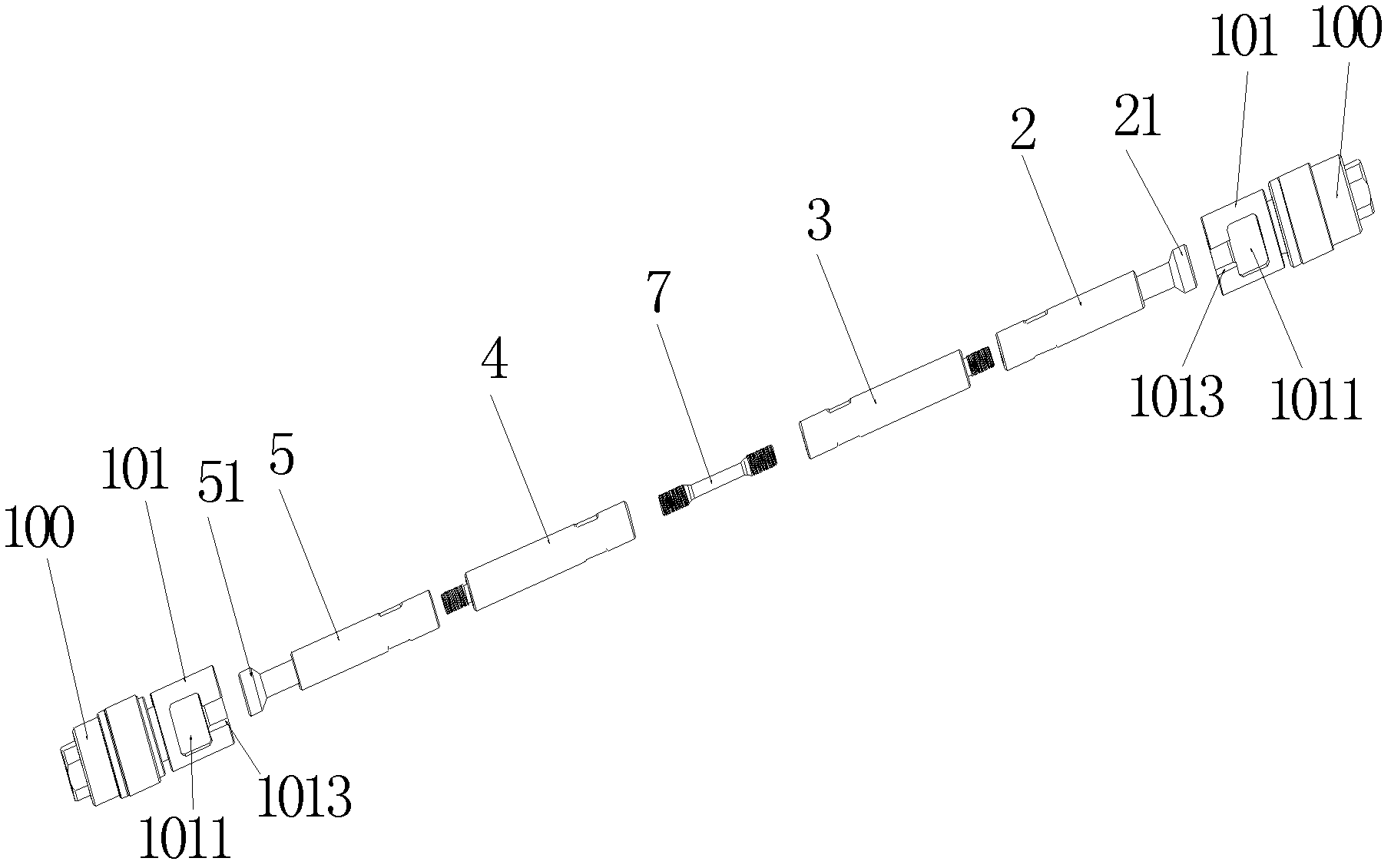

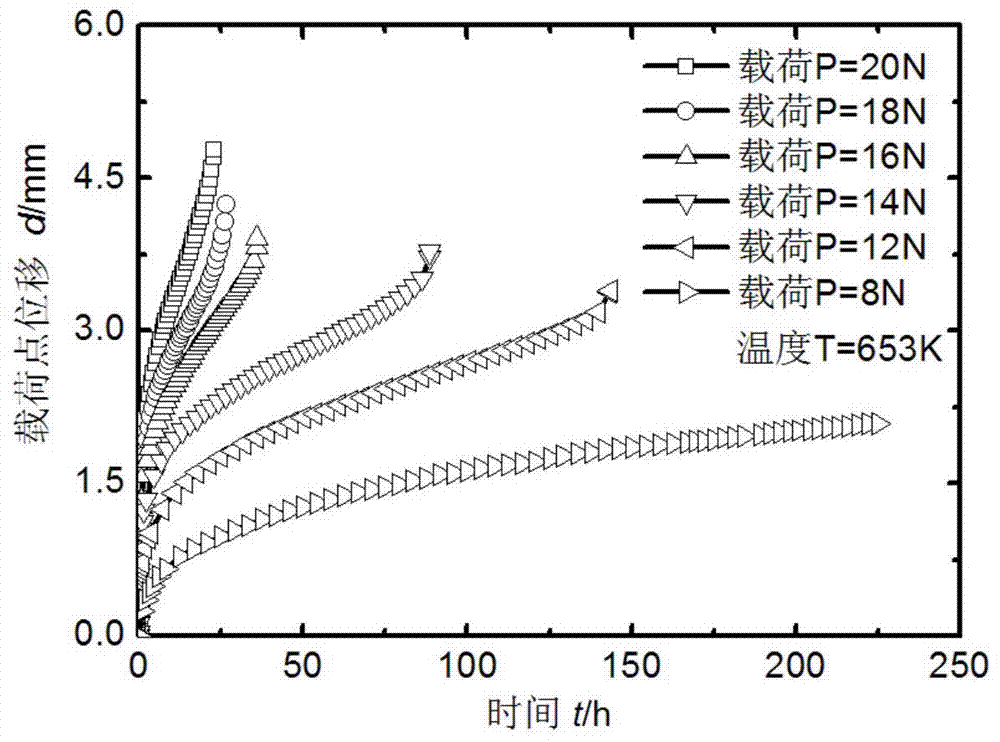

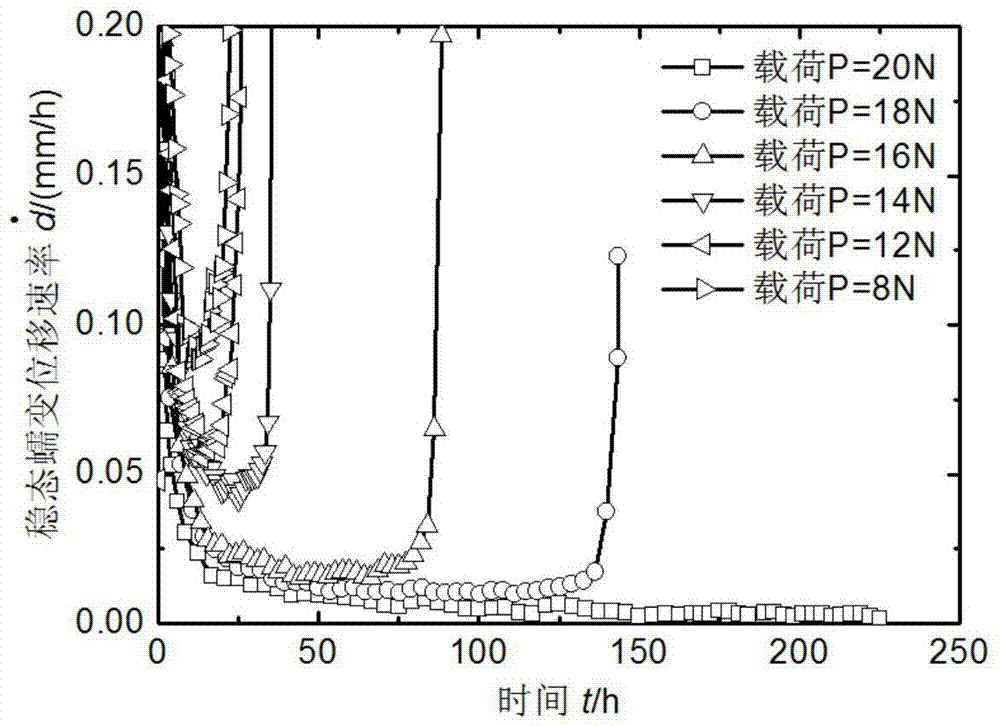

Clamped straight rod small sample creep testing method and apparatus thereof

InactiveCN103487336ASimple and fast operationImprove test accuracyInvestigating material ductilitySmall sampleComputer module

The invention provides a clamped straight rod small sample creep testing method and an apparatus thereof. The testing apparatus comprises a heating module, a loading module, a clamping module, a displacement measuring module and an external support; and the testing method comprises the following steps: designing and making a clamped straight rod small sample, carrying out multiple creep tests of a material at a same temperature under different loads, establishing a steady state creep rate curve, obtaining a Kachanov-Rabotnov creep damage constitutive equation, and adopting a finite element to carry out parameter optimization. The small sample creep testing method provided by the invention solves the problems of difficult data parse and many testing influence factors of present small sample technologies, has the advantages of simple operation, high testing precision and low cost, and provides basic data for the exploitation of a new material, the high-temperature integrity evaluation of a service member and the performance evaluation of an irradiated material.

Owner:EAST CHINA UNIV OF SCI & TECH

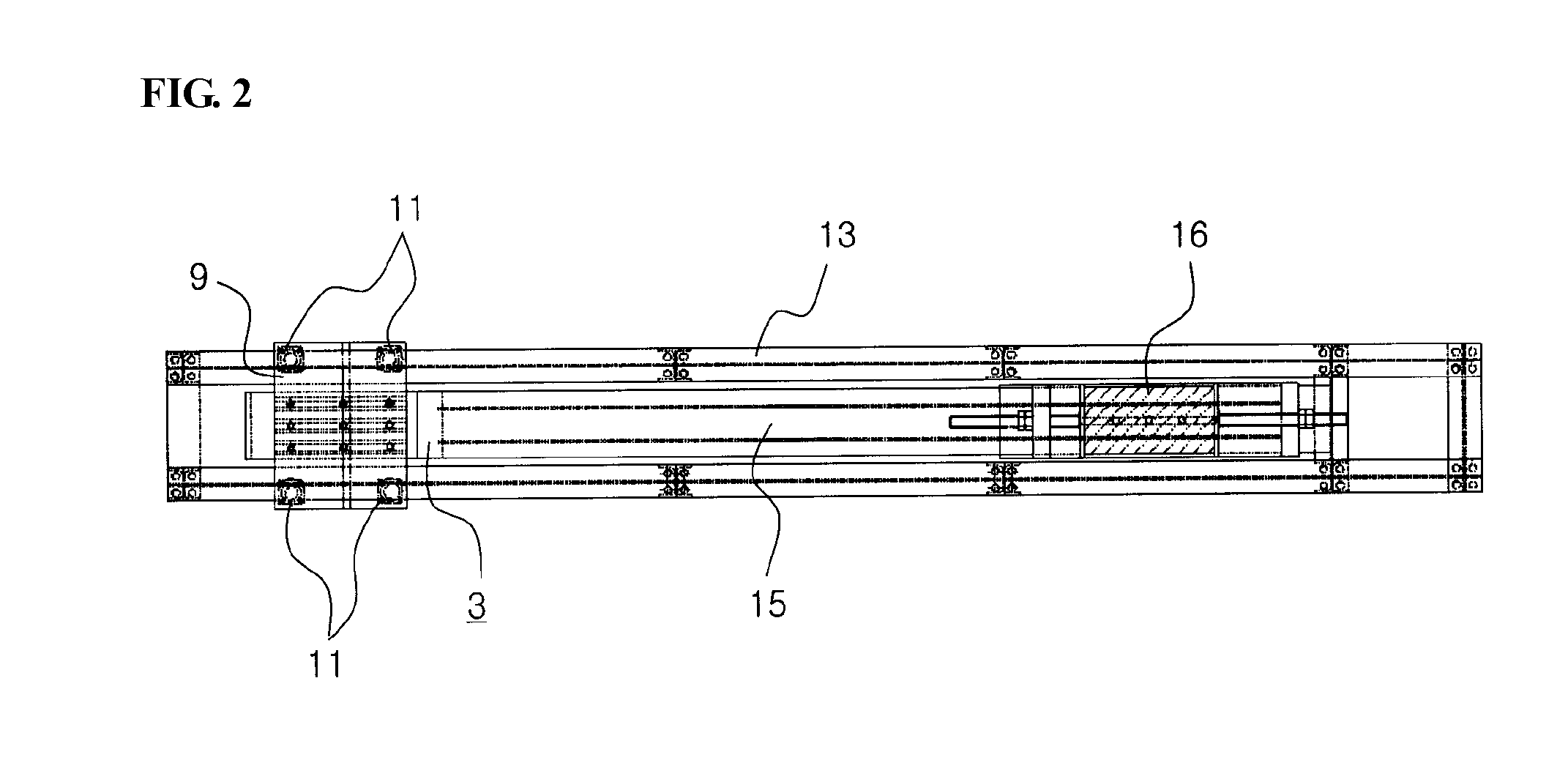

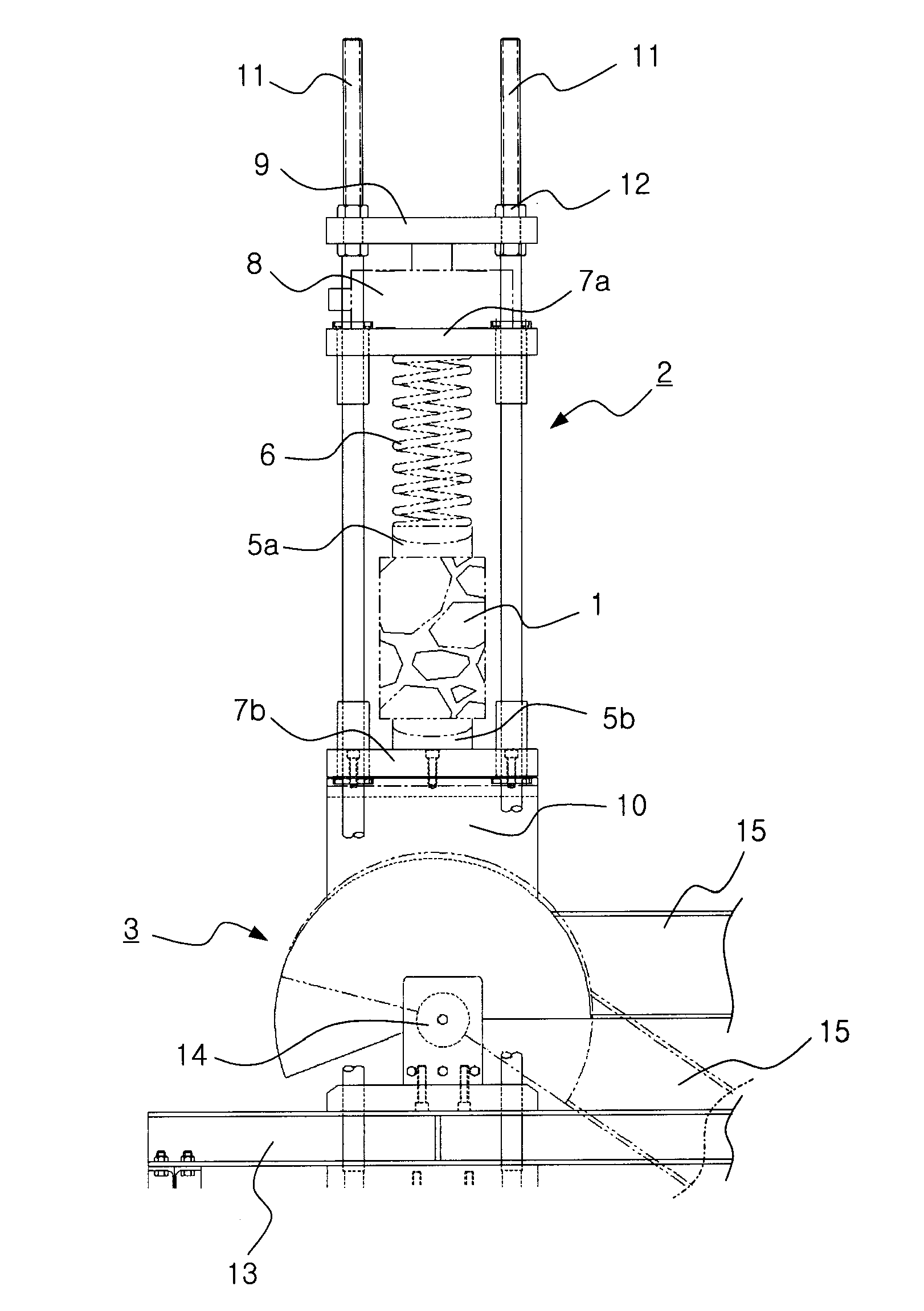

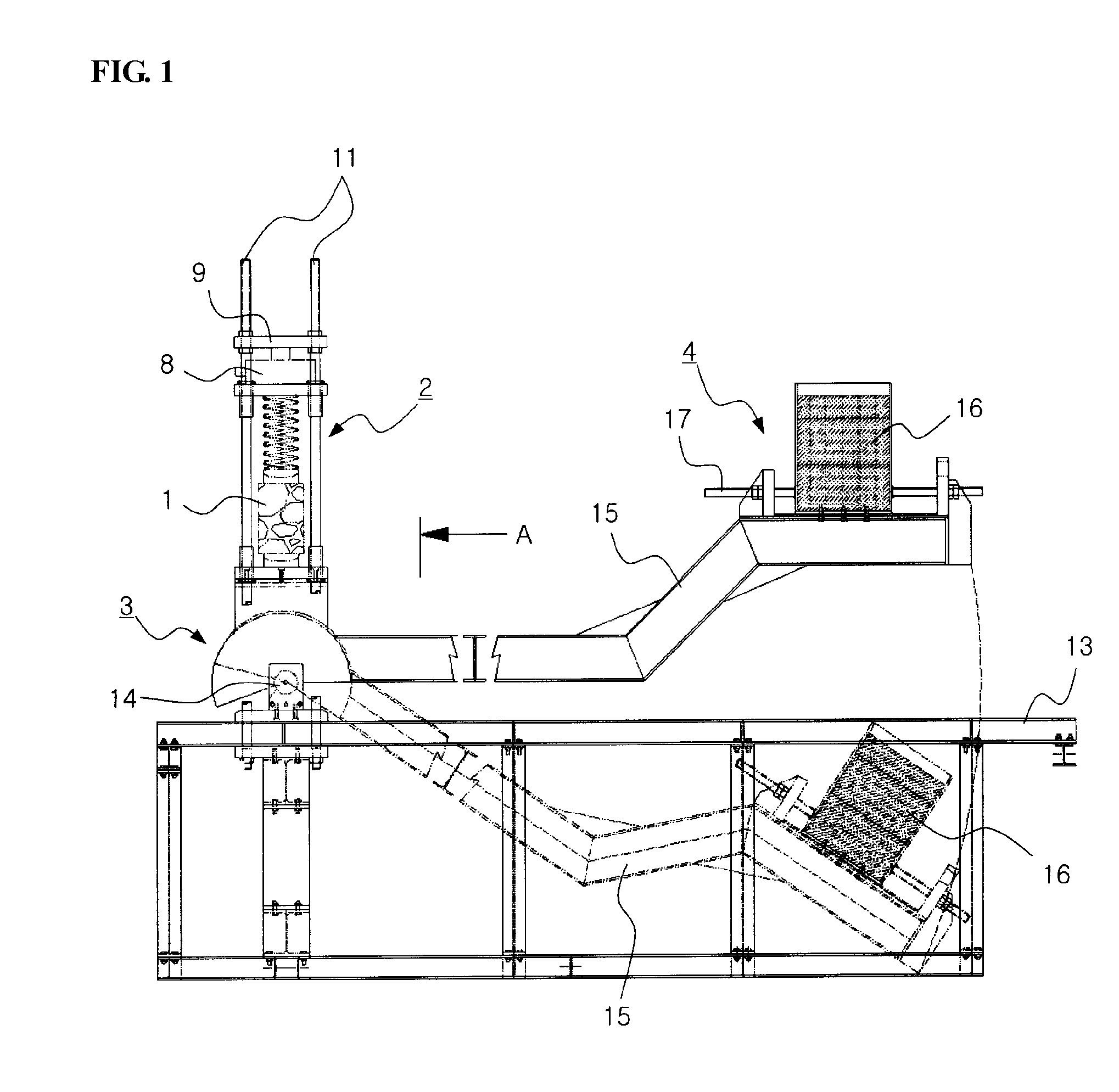

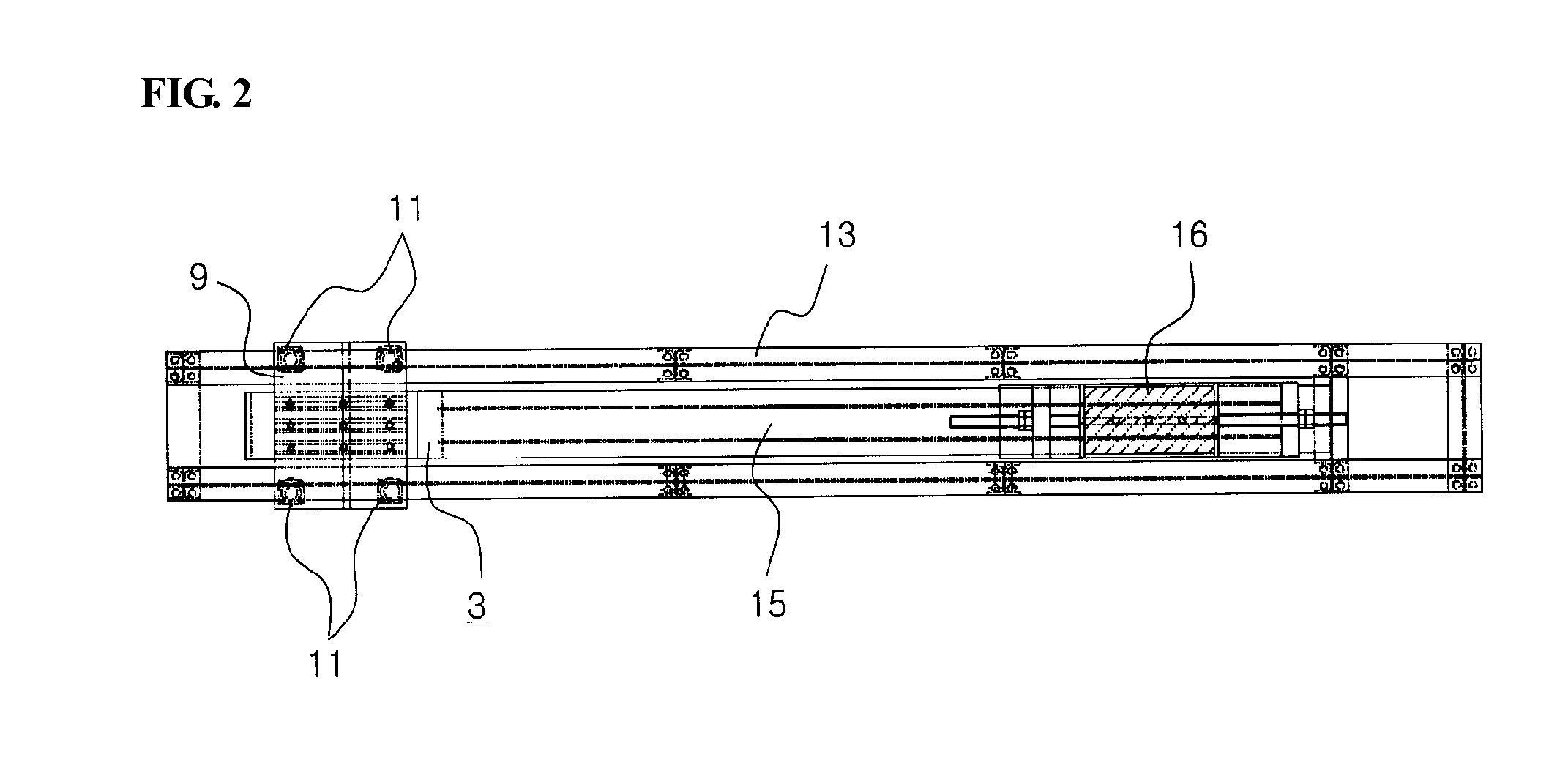

Creep tester for precision load control with weight

ActiveUS20090007691A1Flow propertiesMaterial strength using tensile/compressive forcesConstant loadSample length

A creep tester for a precise and accurate creep test includes a movable actuator capable of loading corresponding to change in length of a specimen, a cam actuator operated in association with the movable actuator, and a self weight actuator. The movable actuator includes upper and lower spherical adjusting seats to hold upper and lower portions of the specimen, a spring disposed on the upper spherical adjusting seat to correspond to a minute deformation of the specimen, upper and lower movable tables respectively contacting the spring and the lower spherical adjusting seat, a load cell and a stationary table disposed on the upper movable table, and a movable loading table disposed below the lower movable table to apply a predetermined load to the specimen. The creep tester can perform a precise creep test by continuously applying a constant load without supplementation of hydraulic pressure.

Owner:KOREA ELECTRIC POWER CORP

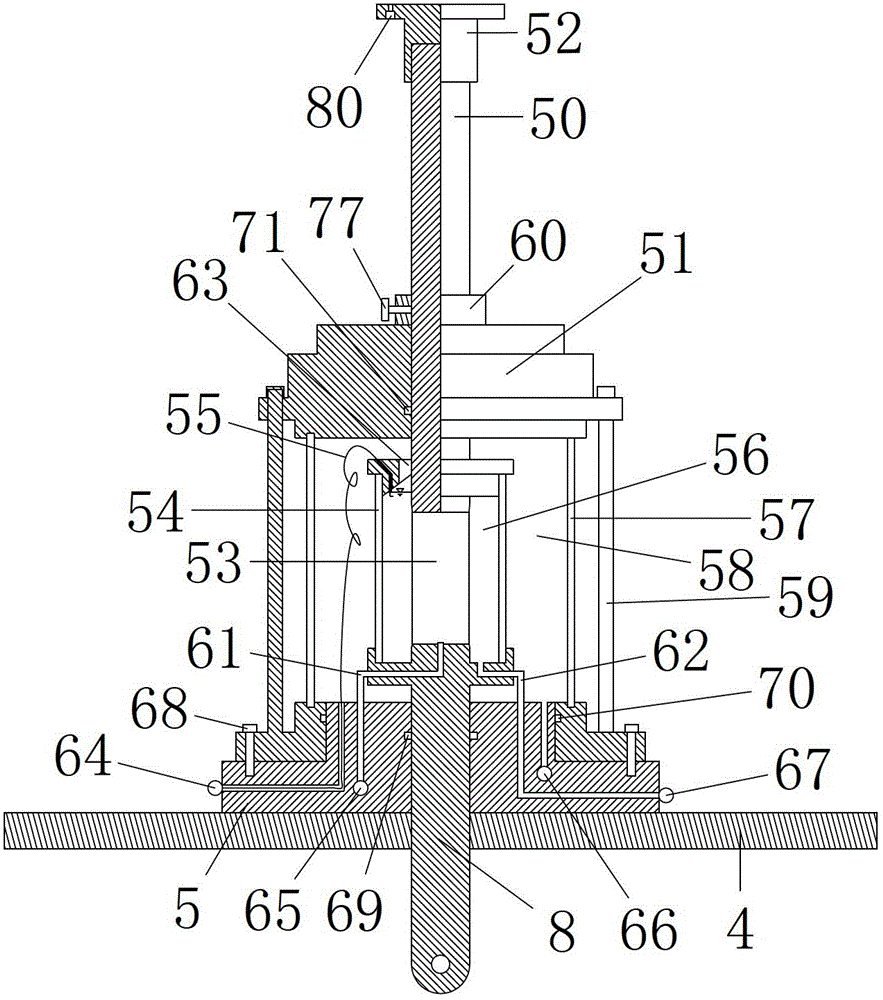

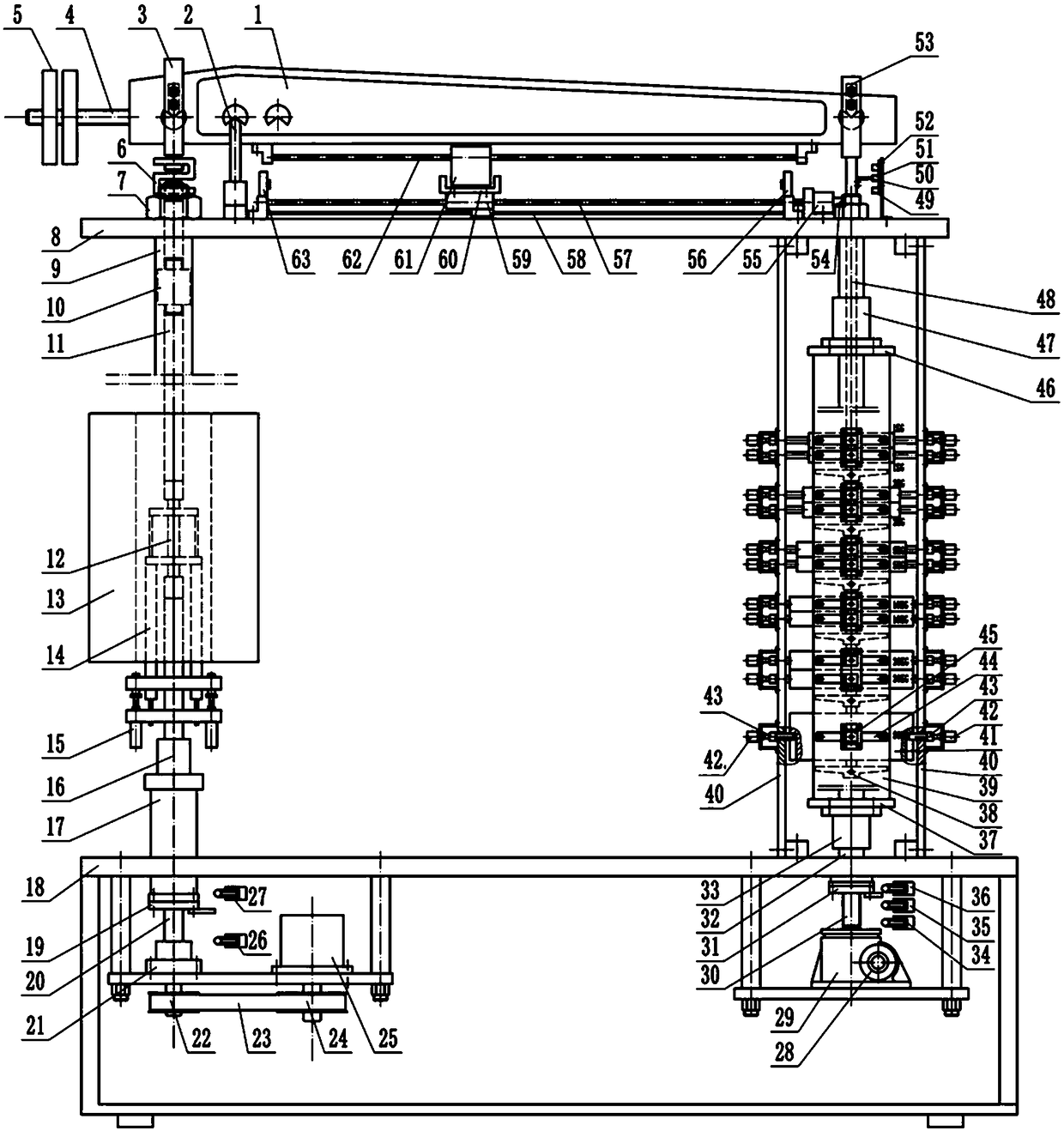

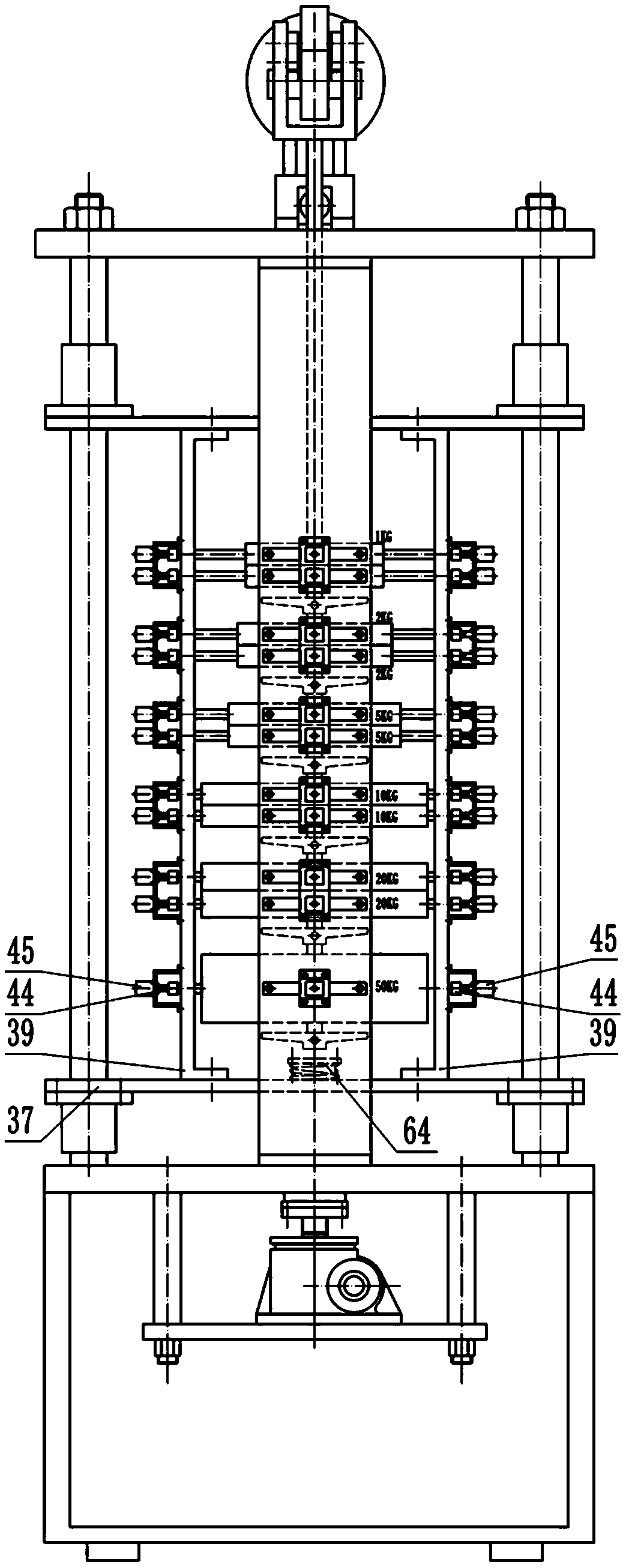

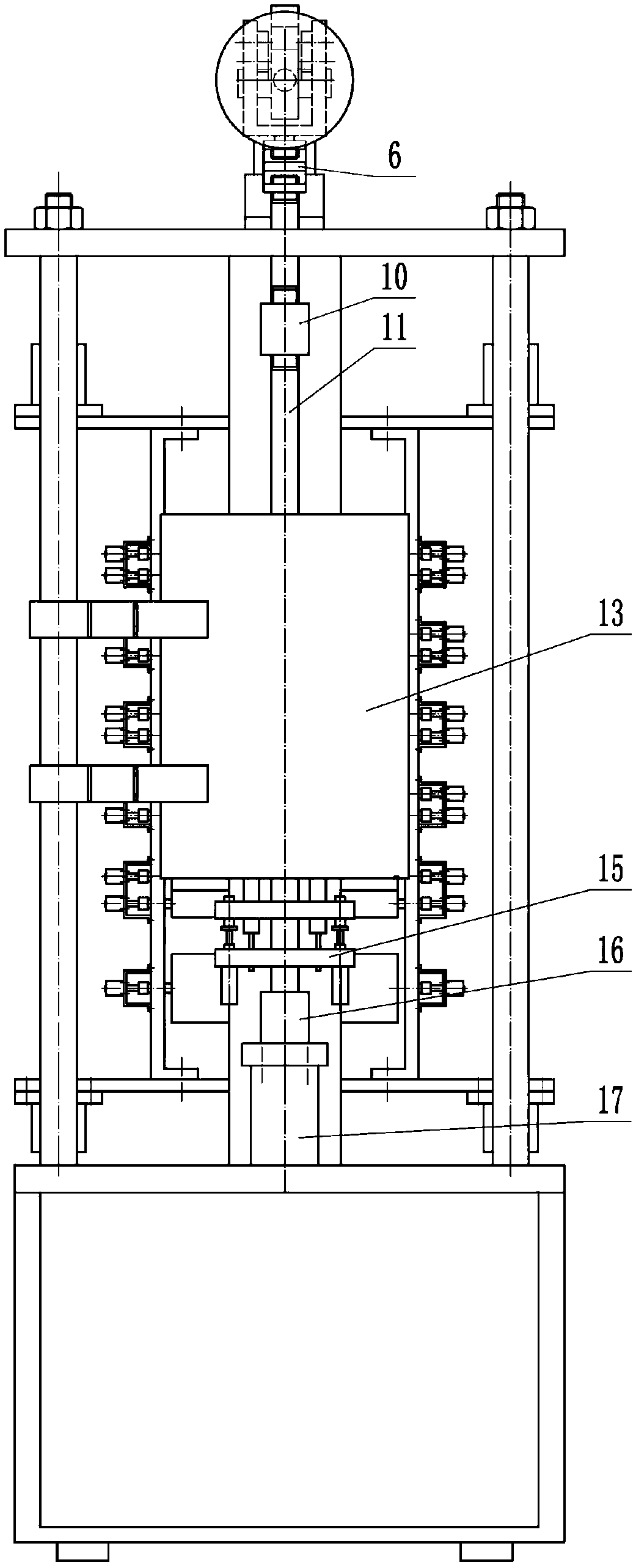

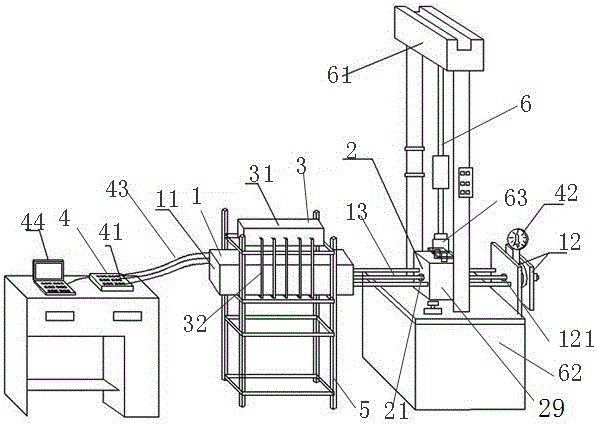

Mechanical high temperature creep testing machine capable of realizing automatic precise loading

InactiveCN109211684ATest creep limitHigh loading accuracyMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesManufacturing technologyLeveling mechanism

The invention discloses a mechanical high temperature creep testing machine capable of realizing automatic precise loading, belongs to the field of instruments of material science and machine manufacturing technologies and aims at solving the problems that when the existing mechanical creep testing machine employs a manual weight loading mode, cyclic load loading cannot be realized in the manual loading mode, when load is relatively high, the loading is relatively slow, labor intensity is relatively high, moreover, the load cannot be loaded continuously, and precision is relatively low. The mechanical high temperature creep testing machine is composed of a rack, a lever and connection mechanism, a weight automatic loading device, a rider precise fine-adjustment device, a lever self-leveling mechanism, a clamp and deformation measurement mechanism and a heating temperature control mechanism. Under the control of a control system, weight automatic loading and rider precise fine-adjustment can be realized, self-leveling can be carried out by a lever, and the problems that the existing manual loading mode is slow in loading and the cyclic load loading cannot be realized are solved; andmoreover, according to the mechanical high temperature creep testing machine, in a weight and rider combined loading mode, the continuous loading can be realized, so precision is relatively high.

Owner:JILIN UNIV

Concrete creep testing system

InactiveCN102235952ASafe and reliable engineering designEconomically reasonableInvestigating material ductilityServo actuatorElectro hydraulic

The invention provides a concrete creep testing system, which comprises a base, a lead screw, a top plate, an electro-hydraulic servo actuator, a strain gauge, a load sensor and a disc spring, wherein the bottom of the lead screw is fixed on the base; the top plate is fixed at the top of the lead screw; a movable lower pressure plate and a movable upper pressure plate are arranged on the lead screw; the disc spring is arranged between the upper pressure plate and the top plate; the load sensor is arranged at the bottom of the upper pressure plate; the strain gauge is embedded into a test piece; and the electro-hydraulic servo actuator is arranged between the base and the lower pressure plate. According to the embodiment, counterforce loading is realized by adopting the disc spring at the upper part of the test piece, and the electro-hydraulic servo actuator for loading is adopted at the bottom of the test piece, so that the creep property of the full-grade concrete can be directly measured, the creep property of the full-grade concrete is reflected truly, and the engineering design is safer and more reliable, economic and reasonable.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

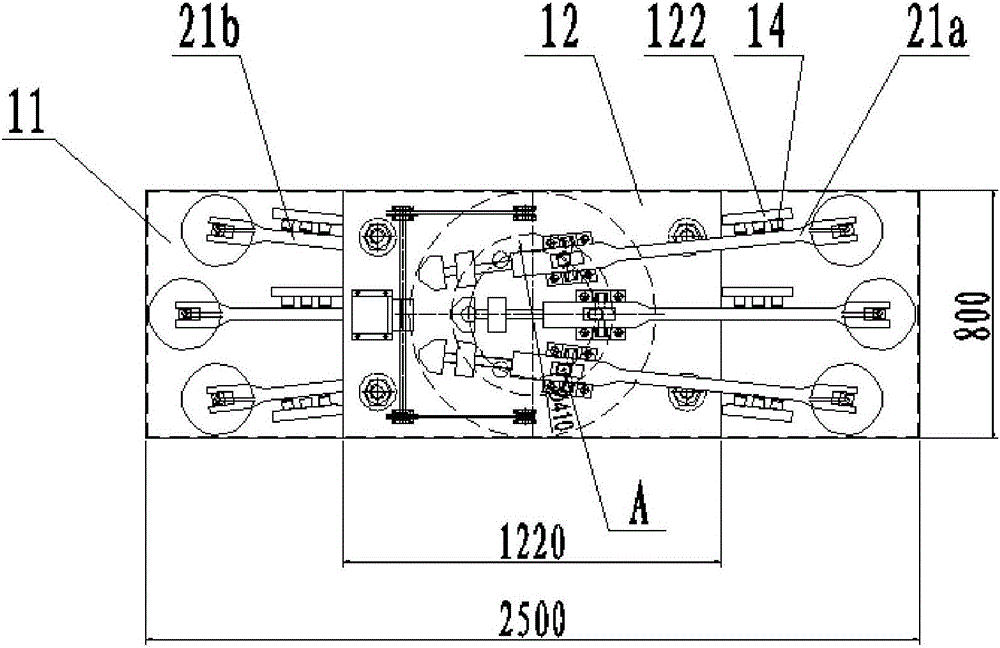

Cement-based material compression creep testing device

InactiveCN105784491AAccurate measurement dataImprove measurement efficiencyMaterial strength using tensile/compressive forcesAlkalinityControl system

The invention discloses a cement-based material compression creep testing device which comprises a double-station gate-type loading machine, wherein cement-based material cast test pieces which are connected in series through middle metal connecting discs are clamped between upper pressing discs and lower pressing discs on the double-station gate-type loading machine; load sensors are connected with the lower pressing discs; the load sensors are connected with a computer; the computer is connected with a control end of a hydraulic control part through a controller and a hydraulic servo system and is used for controlling the hydraulic driving part to act upwards and downwards to achieve load control; the double-station gate-type loading machine is mounted inside a sealed adiabatic box body; temperature, humidity, pH value and salt mist regulating equipment is mounted inside the box body. The acidity, the alkalinity and the salt mist can be adjusted. By improving a load control system of loading equipment, a stable and adjustable environment adjusting system can be provided, and the cement-based material compression creep testing device has the advantages of precise data measurement, high measurement efficiency and high automation degree.

Owner:TSINGHUA UNIV

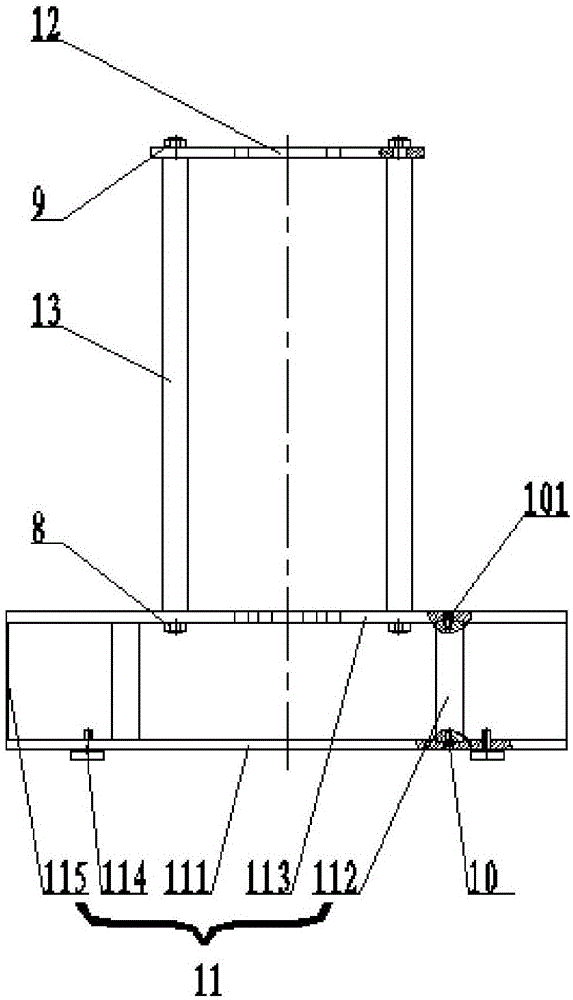

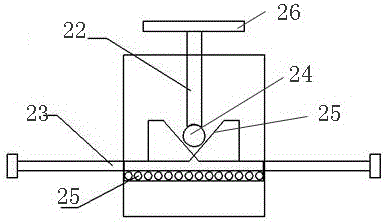

Uniaxial-creep testing machine

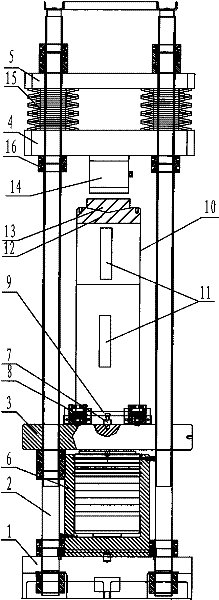

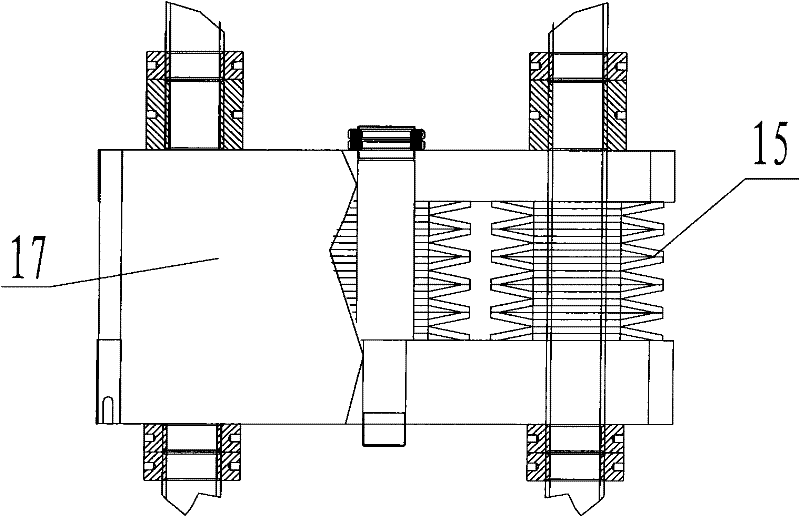

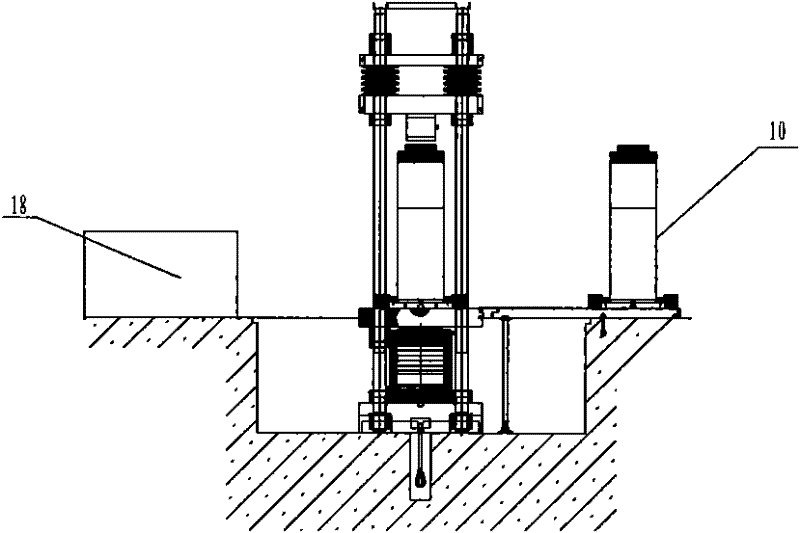

ActiveCN102749250AAchieve axial compressionAxial load remains constantMaterial strength using tensile/compressive forcesCylinder blockCreep testing

The invention discloses a uniaxial-creep testing machine, which comprises a rack, a loading mechanism and a test piece mounting assembly, wherein the rack comprises a first vertical beam, a second vertical beam, a first cross beam and a second cross beam; the loading mechanism comprises a lever arm, a loading counter weight, a counter weight hook, a force transferring arm, a first oil cylinder and a second oil cylinder; the first oil cylinder consists of two cylinder blocks and a pipe body, wherein the two cylinder blocks have the same diameters, the center lines of the cylinder blocks are mutually parallel, and the pipe body is used for communicating the two cylinder blocks; the first oil cylinder is fixed on the first cross beam; one cylinder block for forming the first oil cylinder is internally provided with a first piston; the other cylinder block for forming the first oil cylinder is connected and communicated with the second oil cylinder; the internal diameter of the second oil cylinder is more than the internal diameter of the first oil cylinder; the inside of the second oil cylinder is internally provided with a second piston; one end of the lever arm is hinged with a first hinge pin on the top of the first vertical beam; the counter weight hook is hinged with a third hinge pin installed on the end part of the lever arm; the loading counter weight is arranged on the counter hook; one end of the force transferring arm is connected with the first piston; and the other end of the force transferring arm is hinged with a second hinge pin installed on the lever arm.

Owner:SICHUAN UNIV

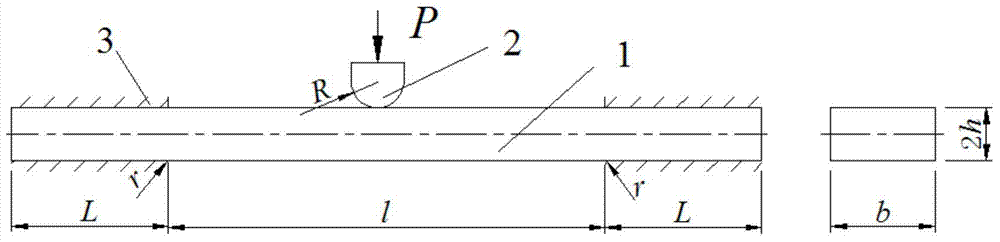

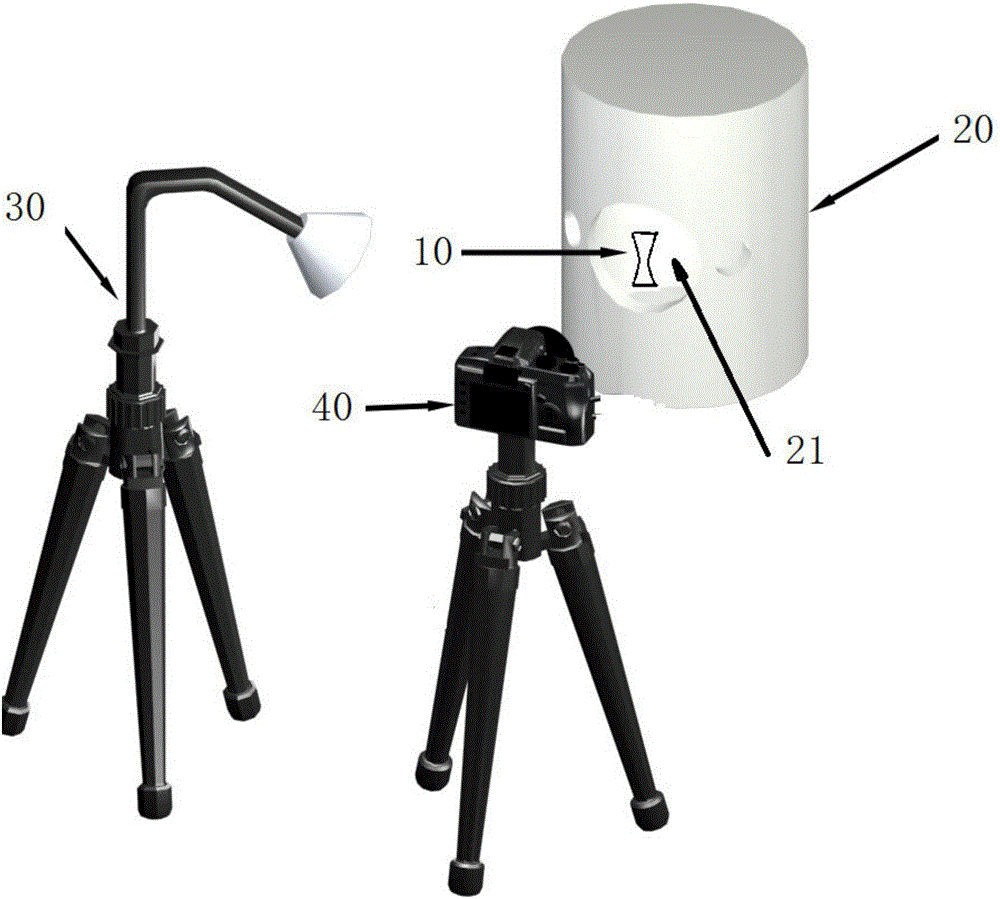

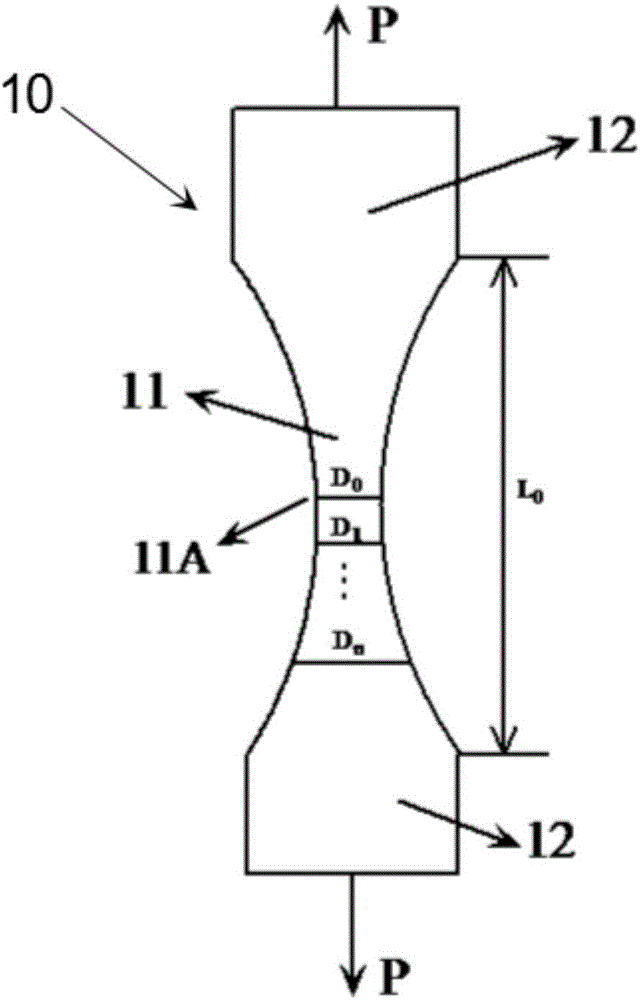

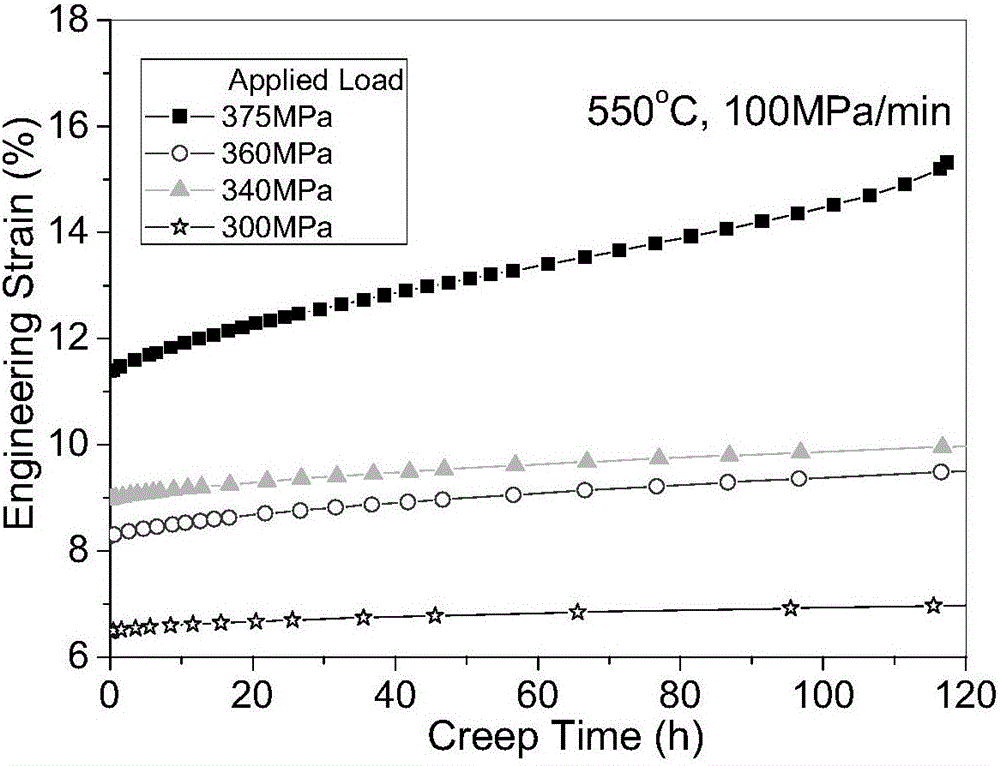

High-temperature creep property testing method based on section-variable test sample

InactiveCN106802258ATo achieve the purpose of multi-throughput measurementImprove test efficiencyMaterial strength using tensile/compressive forcesTest efficiencyStress level

The invention relates to a high-temperature creep property testing method based on a section-variable test sample. The high-temperature creep property testing method comprises the following steps: spraying high-temperature paint on the surface of a section-variable test sample in advance to form speckles; then putting the section-variable test sample into a heating furnace with a view window; arranging an illumination light source for illuminating the section-variable test sample and a camera for photographing the section-variable test sample on an outer side of the heating furnace; applying a certain fixed load P to two clamping ends of the section-variable test sample; carrying out continuous observation and photographing on a speckle pattern on the surface of the section-variable test sample through the camera; and finally, inputting the speckle pattern on the surface of the test sample, which is photographed by the camera, into a processing device, and obtaining full-field deformation of the surface of the section-variable test sample in a high-temperature creep testing process through computer image processing. The high-temperature creep property testing method has the advantages of high testing efficiency, good precision, low cost and the like; and a lot of data results under different stress level conditions can be obtained through one time of testing, so that time and cost for a high-temperature creep test are effectively saved.

Owner:HEFEI GENERAL MACHINERY RES INST

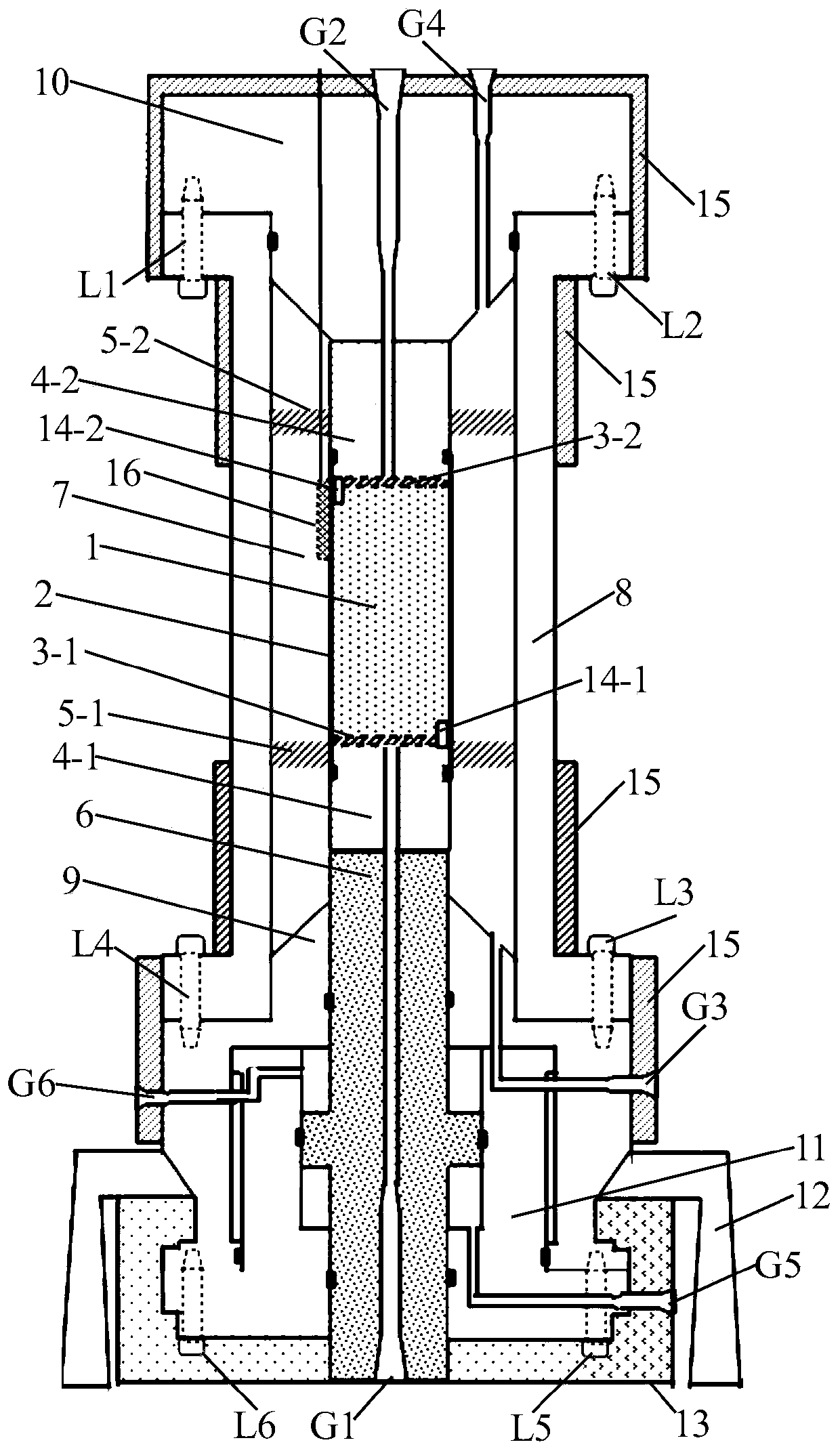

Device and method for detecting mechanical parameters of hydrate-containing sediments based on X-CT

ActiveCN111289385APrecise control of axial temperatureControl aspect ratioMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesFiberCarbon fibers

The invention provides a device and a method for detecting mechanical parameters of hydrate-containing sediments based on X-CT. The device comprises a reaction kettle, a shear loading unit, a back pressure control unit, an unloading pressure loading unit and a strain measurement unit, wherein the reaction kettle body is a beryllium or carbon fiber pressure-resistant pipe, and the two end are sealed with end covers; the outer side of the lower end cover is connected with an axial pressure loading counter-force mechanism; an upper sample adjusting cushion block, a sediment sample, a lower sampleadjusting cushion block and an axial pressure loading piston are arranged in the reaction kettle from top to bottom. According to the device and the method, high-pressure conditions required for synthesizing the methane hydrate are met, and the axial temperature of the sample can be precisely controlled, so that the sample is uniformly distributed; the sample preparation efficiency can be improved through the rapid temperature control, the sample size can be adjusted, and the purpose of controlling height-diameter ratios of the different samples is achieved; and the synchronous detection of astress-strain curve of the sediments containing the natural gas hydrate and the internal destructive microstructures of the sediments can be achieved, and the constant strain shearing and the constant stress creep tests can be realized.

Owner:QINGDAO INST OF MARINE GEOLOGY

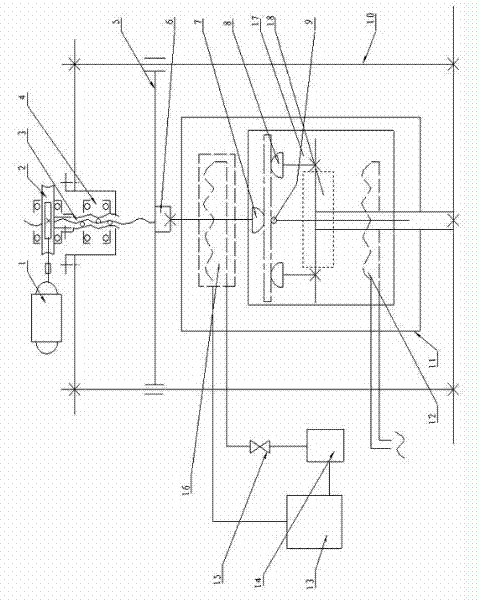

Single-linked low-temperature low-confining-pressure triaxial creep testing apparatus

InactiveCN104634666ANo need to worry about validityStable air pressureMaterial strength using tensile/compressive forcesGas cylinderAxial pressure

The invention discloses a single-linked low-temperature low-confining-pressure triaxial creep testing apparatus, and relates to the field of civil engineering material testing instruments. By adopting the creep testing apparatus, the problem of imperfect frozen soil creep tests under small stress and small confining pressure at present can be solved. A technical scheme adopted by the single-linked low-temperature low-confining-pressure triaxial creep testing apparatus is as follows: the single-linked low-temperature low-confining-pressure triaxial creep testing apparatus mainly comprises a host, a pressure chamber, a pneumatic servo system, an automatic data acquisition system and an automatic temperature control system, wherein a gas cylinder is fixedly arranged at the lower part of a reaction frame of the host, an axial load sensor is fixedly arranged at the lower part of a force transfer rod of the gas cylinder, a displacement sensor is fixedly arranged between the reaction frame and the gas cylinder, a double-helical copper pipe connected with the automatic temperature control system is arranged inside the pressure chamber, a temperature sensor is arranged on a top cover of the pressure chamber, the axial pressure and confining pressure of the pressure chamber are controlled by an axial pressure regulator and a confining pressure regulator of the pneumatic servo system, a confining pressure sensor is arranged at a confining pressure pipeline at the bottom end of the pressure chamber, and a heat preservation tank is arranged at the outer part of the pressure chamber. The single-linked low-temperature low-confining-pressure triaxial creep testing apparatus disclosed by the invention can be applied to uniaxial or triaxial creep tests of frozen soil under low temperature and low confining pressure and uniaxial or triaxial creep tests under normal temperature and low confining pressure.

Owner:HARBIN INST OF TECH

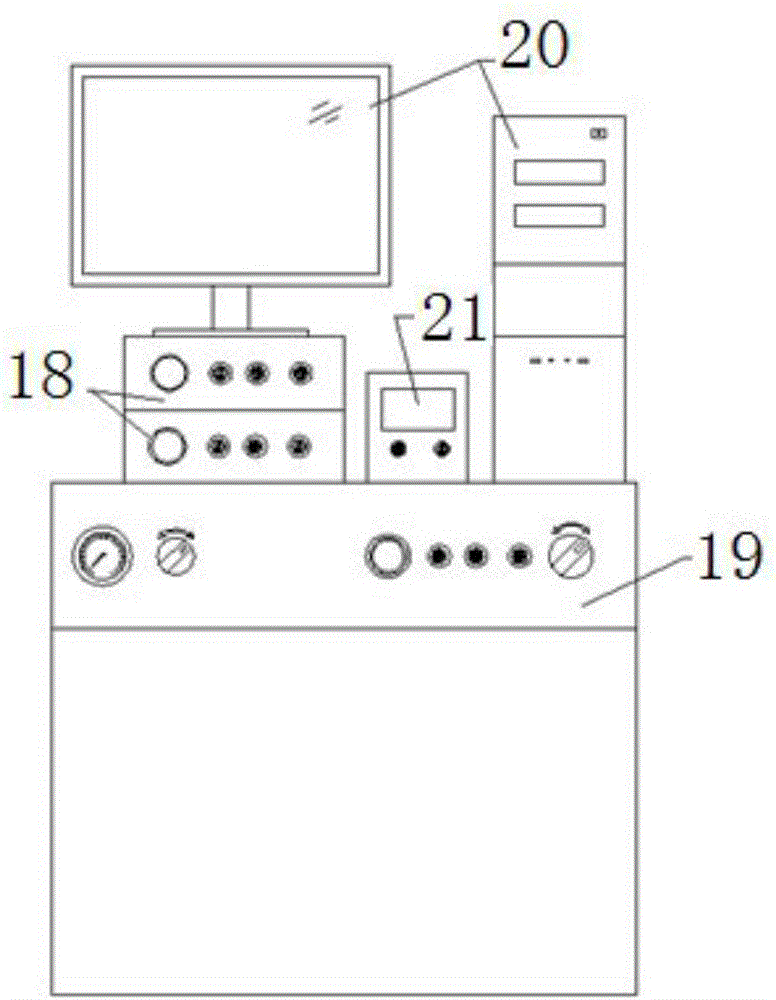

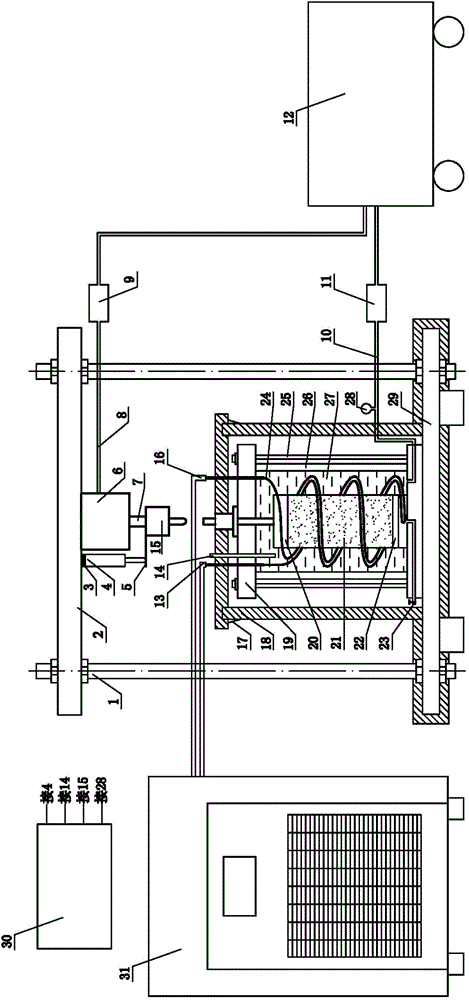

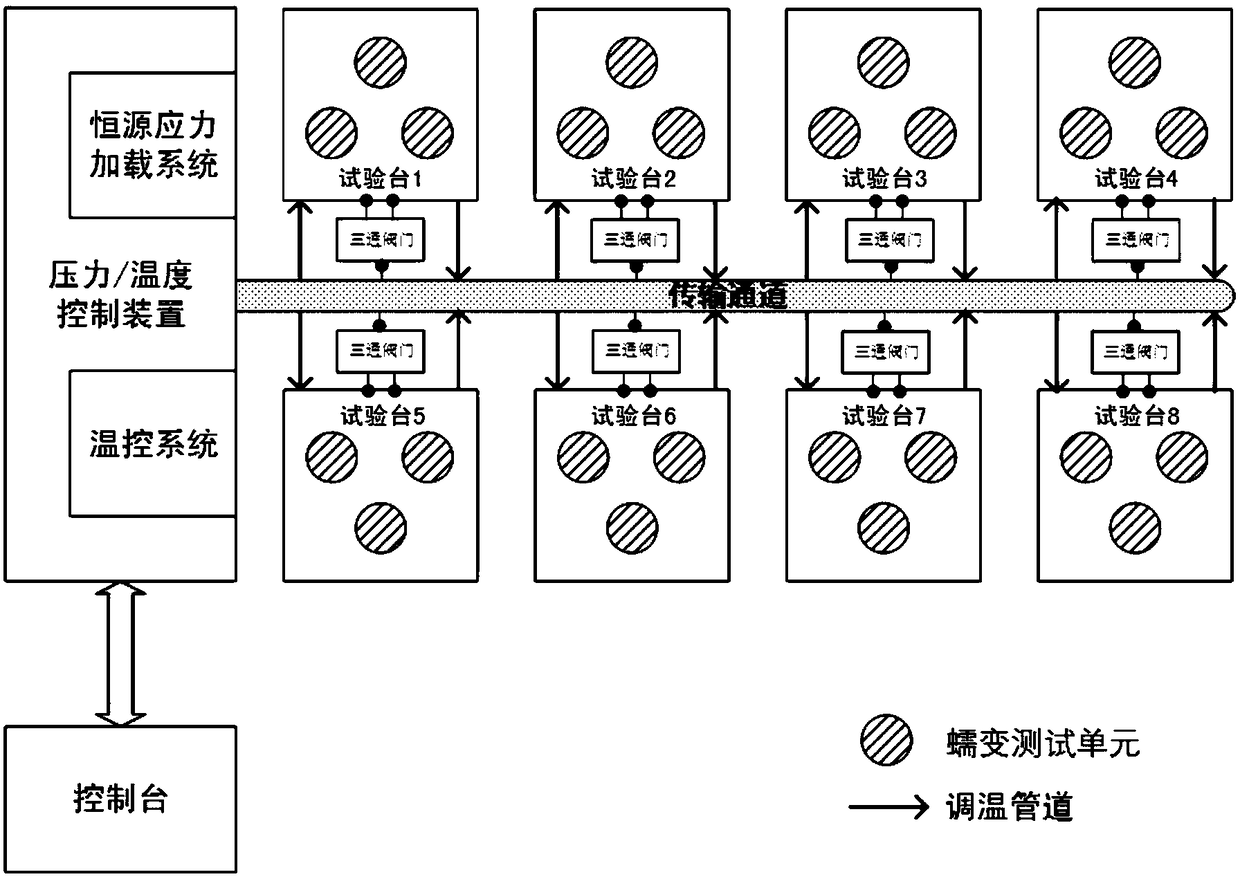

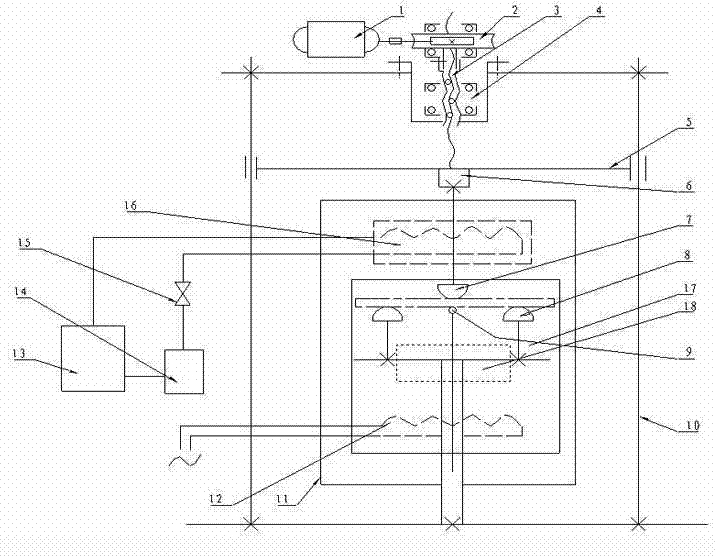

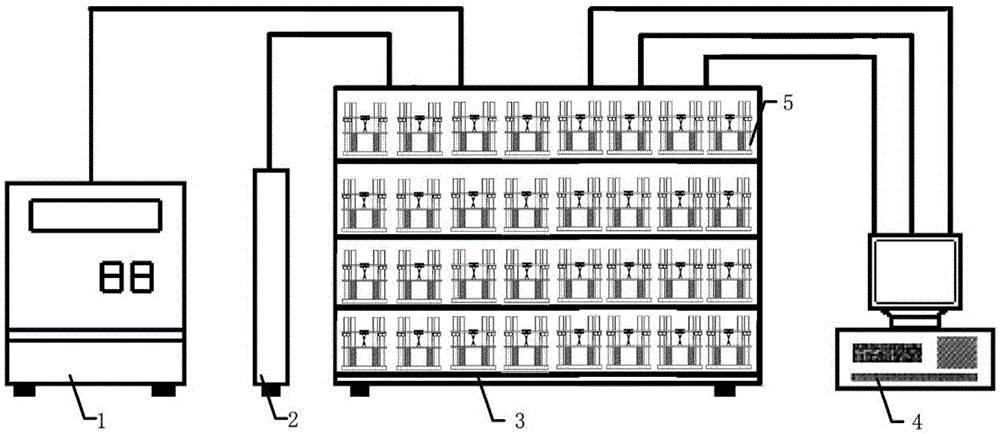

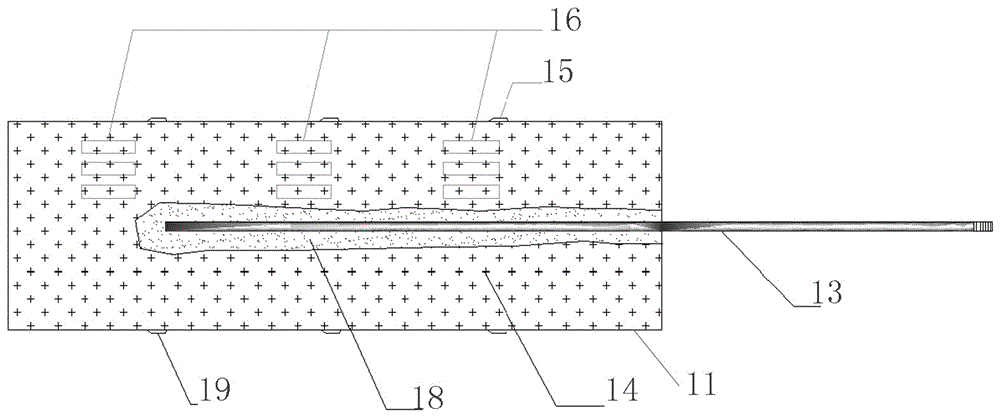

Testing system and testing method for long-time creep property of explosive

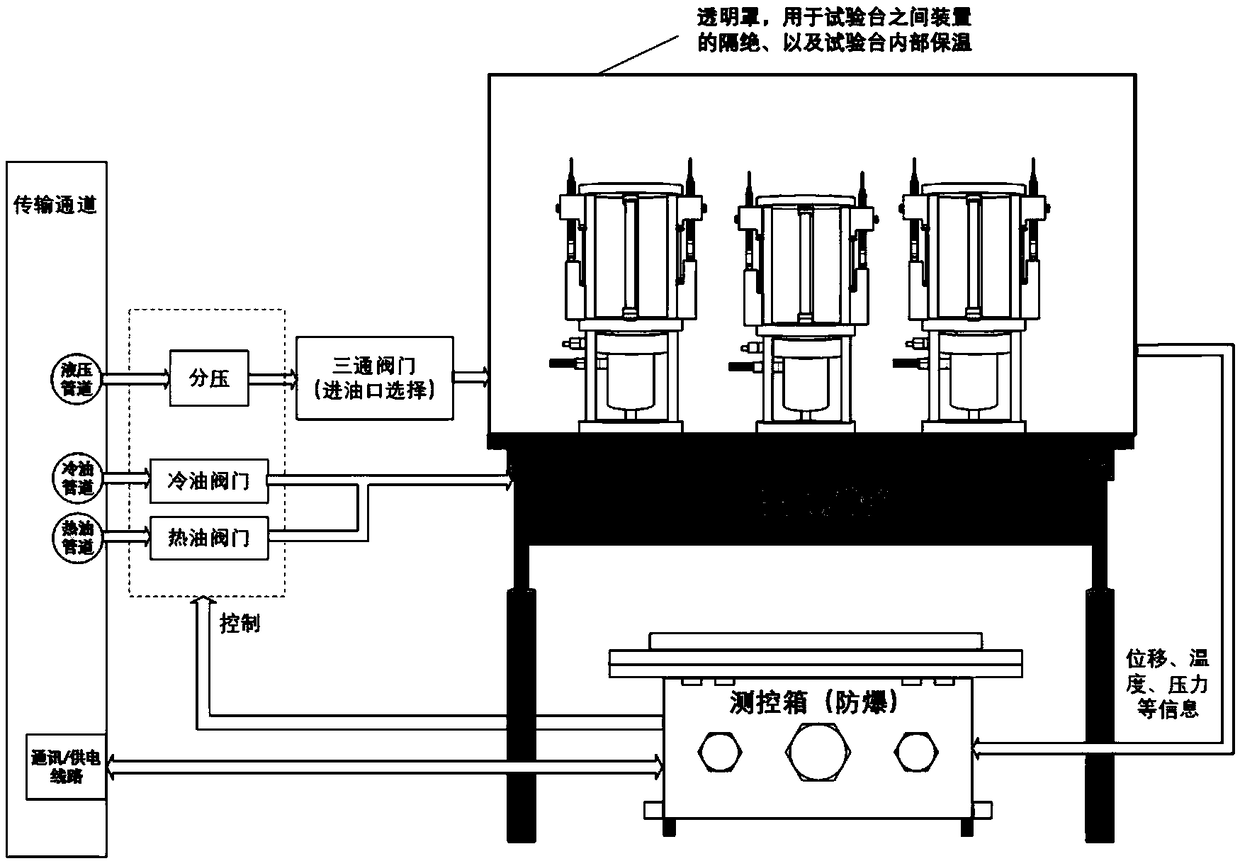

PendingCN109030234ALow costSave time and costMaterial strength using tensile/compressive forcesTemperature controlInformation transmission

The invention discloses a testing system for the long-time creep property of an explosive. The testing system comprises a control console, a temperature control system, a loading system and test beds,wherein the temperature system and the loading system are connected with the control console, and the test beds are connected with the temperature control system and the loading system; creep testingunits are arranged on the test beds and installed in a sealed transparent cover, and a temperature control device is arranged below the transparent cover and connected with the temperature control system; the creep testing units are further connected with the loading system; and a temperature sensor is arranged in the transparent cover, load sensors and displacement sensors are arranged on the creep testing units, the temperature sensor, the load sensors and the displacement sensors are all connected to a testing control box, and the testing control box controls temperature adjustment of thetemperature control device and pressure loading adjustment of the loading system and achieves information transmission with the control console through a communication line. The invention further provides a testing method for the long-time creep property of the explosive. According to the testing system and testing method for the long-time creep property of the explosive, the cost can be significantly reduced, the research cycle is shortened, and the huge application value is achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Testing mechanism for concrete creep under corrosion action, application and creep testing method

ActiveCN105890969AReduce volumeEasy to operateWeather/light/corrosion resistanceStrength propertiesCouplingRebar

The invention discloses a testing mechanism for concrete creep under the corrosion and load coupling action. The testing mechanism comprises a stress steel plate and a pressure sensor, wherein the stress steel plate is installed on the upper portion of a testing sample. The testing mechanism is characterized in that the testing sample is installed in the center of an open container containing a corrosion solution; a conductive metal net is arranged in the corrosion solution, a steel bar in the testing sample is connected with the positive electrode of a constant-voltage direct-current power source, the conductive metal net is connected with the negative electrode of the constant-voltage direct-current power source, and an electrochemical corrosion circuit is formed by the corrosion solution, the constant-voltage direct-current power source, the conductive metal net and the testing sample; a dial indicator is installed on the testing sample. The creep testing method of the testing mechanism comprises the first step of manufacturing of the testing sample, the second step of installation, the third step of loading and the like. The creep characteristics of concrete under the corrosion and load coupling action are taken into consideration and better conform to the environment state of practical engineering structures, tests have higher engineering value, and significant engineering application value and wide market application prospects are achieved.

Owner:HUNAN CITY UNIV

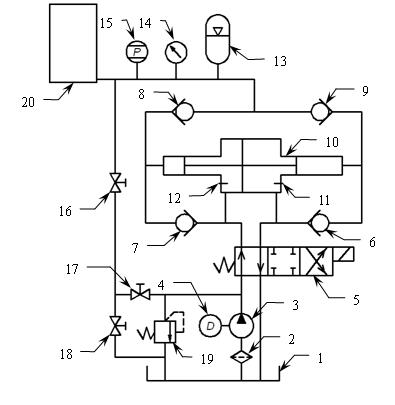

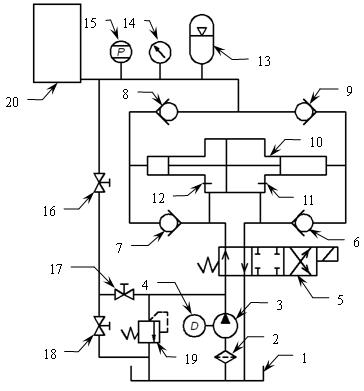

Confining pressure keeping system of rock triaxial creep testing machine

InactiveCN101936857AImprove protectionImprove efficiencyInvestigating material ductilityHydraulic pumpFuel tank

The invention discloses a confining pressure keeping system of a rock triaxial creep testing machine. In the system, a hydraulic pump is connected with a motor, an oil tank is connected with the inlet opening of the hydraulic pump via an oil filter, a relief valve is arranged between the outlet opening of the hydraulic pump and the oil tank, a servo change valve is respectively connected with the oil tank, the hydraulic pump, a double-stroke pressure cylinder and a check valve, the double-stroke pressure cylinder is internally provided with a limit sensor and is connected with the check valve in turn, the check valve and the oil line of the check valve connected with a triaxial chamber are respectively provided with an accumulator, a pressure gage and a pressure sensor, and the triaxial chamber is connected with the hydraulic pump via a stop valve and is connected with the oil tank via the stop valve. The invention has simple and convenient oil charging / discharging operations, and can maintain the pressure in the triaxial chamber to be constant in a long term, thus greatly improving the testing precision and effectively prolonging the service life of a hydraulic element.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

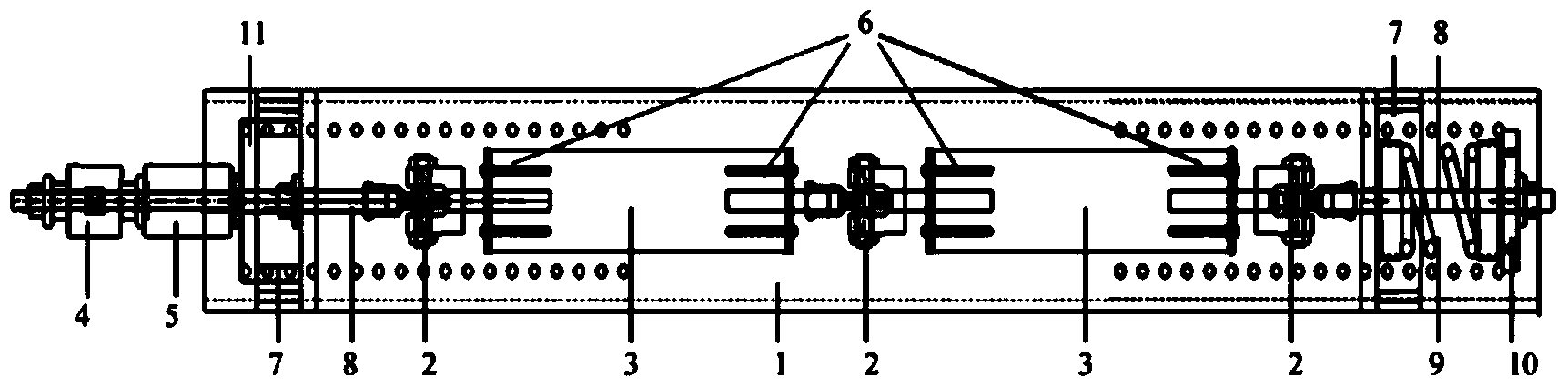

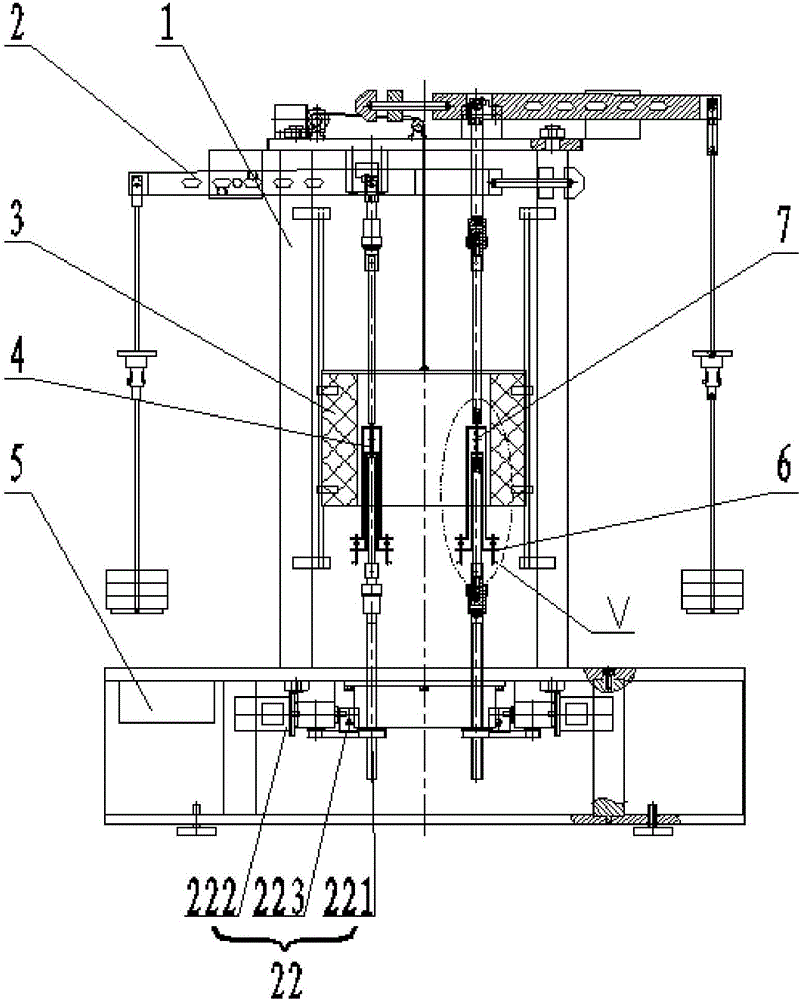

Circumferentially distributed type high-throughput permanent creep testing machine

ActiveCN106769422ASmall footprintGood for controlling uniformityMaterial strength using tensile/compressive forcesLeveling mechanismStress point

The invention provides a circumferentially distributed type high-throughput permanent creep testing machine, which comprises a rack, N sets of loading systems and a heating device, wherein the N sets of loading systems are arranged in the rack and are independent from one another, and the heating device are shared; the rack comprises a base and an upper horizontal plate supported by the base; each loading system comprises a lever loading mechanism, an upper pull rod mechanism and a lifting leveling mechanism. The N sets of loading systems comprise L sets of first lever loading mechanisms supported on the upper surface of the upper horizontal plate and M sets of second lever loading mechanisms suspended on the lower surface of the upper horizontal plate; the stressed points of the N sets of lever loading mechanisms are circumferentially distributed, and correspondingly, the N sets of upper pull rod mechanisms, lower pull rod mechanisms and N test samples are circumferentially distributed; the N test samples are circumferentially distributed in a cylindrical high-temperature furnace of the heating device evenly; N, L and M are all integers, N is greater than or equal to 2, L is greater than or equal to 1, and M is greater than or equal to 1. According to the circumferentially distributed type high-throughput permanent creep testing machine, the accuracy and consistency of testing data of a plurality of test samples can be guaranteed, and the testing machine is small in occupied area and low in testing cost.

Owner:上海航空材料结构检测股份有限公司

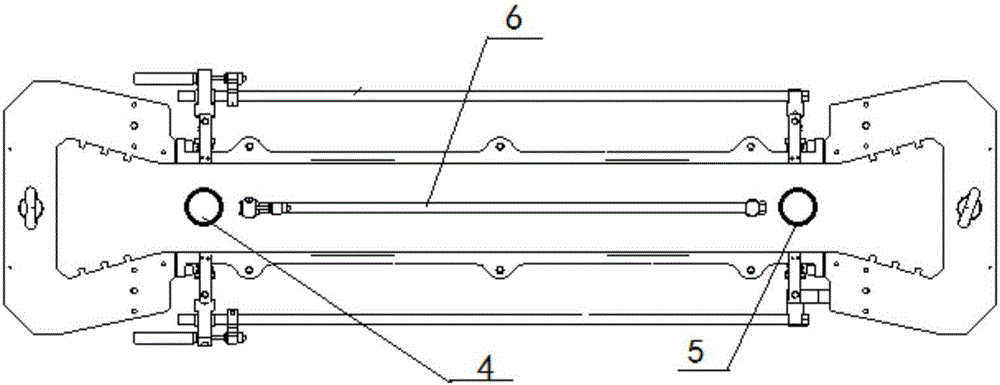

Vehicle seat bumpiness creeping testing device

PendingCN106644516AReasonable structural designThe test data is accurate and reliableVehicle testingVibration testingTest efficiencyEngineering

The invention discloses a vehicle seat bumpiness creeping testing device. The vehicle seat bumpiness creeping testing device comprises a lower support, an upper support, and a platform used for fixing a seat. The bottom part of the lower support is provided with a motor, and the rotating shaft of the motor is connected with the lower part of the platform by an eccentric mechanism and a connecting rod. A guiding mechanism is disposed between the lower part of the platform and the lower support, and the upper support is disposed on the lower support. The upper support is provided with a suspender, the lower end of which is provided with a hip-shaped module, and the suspender is provided with a rotating disc. The upper support is provided with a pushing cylinder, and the end part of the piston rod of the pushing cylinder is connected with the pin shaft of the eccentric mechanism disposed on the rotating disc in a hinged manner. The vehicle seat bumpiness creeping testing device is advantageous in that the structural design of the testing device is reasonable, and the eccentric mechanism is used to drive the platform and the seat disposed on the platform to bump upwards and downwards, and an actual vehicle state is simulated for testing, and therefore test data is accurate and reliable, and by adopting motor driving, testing efficiency is high.

Owner:WUHU RUITAI AUTO PARTS

Bending creep testing device for asphalt mixture

InactiveCN102589985AConstant accuracyConstant pressureMaterial strength using steady bending forcesLinear variable differential transformerAutomatic control

The invention discloses a bending creep testing device for an asphalt mixture. The device comprises a rack, wherein a servo motor, a speed reducer and an upper pressing head, which are in sequential transmission connection, are arranged on the rack; a high and low temperature environment testing box is arranged in the rack; the upper part of the upper pressing head extends into the high and low temperature environment testing box; the upper pressing head is provided with a load sensor; a lower supporting seat which is opposite to the upper pressing head is arranged in the high and low temperature environment testing box; the lower supporting seat comprises a left supporting head and a right supporting head; a linear variable differential transformer (LVDT) sensor is arranged between the two supporting heads; and the high and low temperature environment testing box is provided with a corresponding heating device and a corresponding refrigerating device. The bending creep testing device for the asphalt mixture has the advantages that the upper pressing head is driven by the servo motor, the motion accuracy of the pressing head and the constancy of pressure can be effectively kept, the high and low temperature environment testing box is relatively closed, refrigerating and heating functions are integrated on equipment, space can be saved, and waste is avoided; and the servo motor, the load sensor, the LVDT sensor, the refrigerating device and the heating device can be automatically controlled in a centralized mode through a circuit, and the degree of intelligence of operation of the equipment is improved.

Owner:SHANDONG LUDA TEST INSTR

Concrete temperature stress testing machine and creep testing method

ActiveCN106018094AThe test results are close to the actualEasy to operateMaterial strength using tensile/compressive forcesTemperature stressEngineering

The invention discloses a concrete temperature stress testing machine and a creep testing method. The concrete temperature stress testing machine comprises a free deformation testing machine and a restrained deformation testing machine; the restrained deformation testing machine comprises a bottom die plate, side die plates, two P wave sensors, two S wave sensors and a restrained deformation detection device; the bottom die plate and the side die plates are matched to form a restrained die cavity suitable for arranging a concrete restrained test piece, and two through holes are formed in the bottom die plates; the two P wave sensors are correspondingly arranged on the upper surface and the lower surface of the concrete restrained test piece, and the P wave sensor arranged on the lower surface of the concrete restrained test piece is located in one through hole; the two S wave sensors are correspondingly arranged on the upper surface and the lower surface of the concrete restrained test piece, and the S wave sensor arranged on the lower surface of the concrete restrained test piece is located in the other through hole. According to the concrete temperature stress testing machine, concrete creep can be accurately detected, and a detection result is closer to the actual condition.

Owner:TSINGHUA UNIV +1

Concrete-filled steel tube creep testing device considering initial stress of steel tube

ActiveCN107884268AReduce the difficulty of processing and manufacturingEasy to processMaterial strength using tensile/compressive forcesMaterials processingStrain gauge

The invention belongs to the technical field of concrete-filled steel tube compression resistance and creep tests and in particular relates to a concrete-filled steel tube creep testing device considering initial stress of the steel tube. The concrete-filled steel tube creep testing device comprises a steel tube initial stress loading device and a lever-type concrete creep loading device, whereinthe steel tube initial stress loading device is arranged on a rigid foundation, a concrete-filled steel tube test block provided with a vibration wire strain gauge is arranged in the steel tube initial stress loading device, the steel tube initial stress loading device is arranged at the lower side of the lever-type concrete creep loading device, a structure capable of applying a loading force isarranged at one end of the lever-type concrete creep loading device, and the other end of the lever-type concrete creep loading device is connected with ground by virtue of a structure with length adjustable. The concrete-filled steel tube creep testing device provided by the invention has the advantages that each part is low in manufacturing and processing difficulty, construction is convenient,materials can be directly selected from a construction site, cost is relatively low, and safety and reliability are realized, so that the concrete-filled steel tube creep testing device provided by the invention has relatively great popularization and application value and a relatively good application prospect.

Owner:TAIYUAN UNIV OF TECH

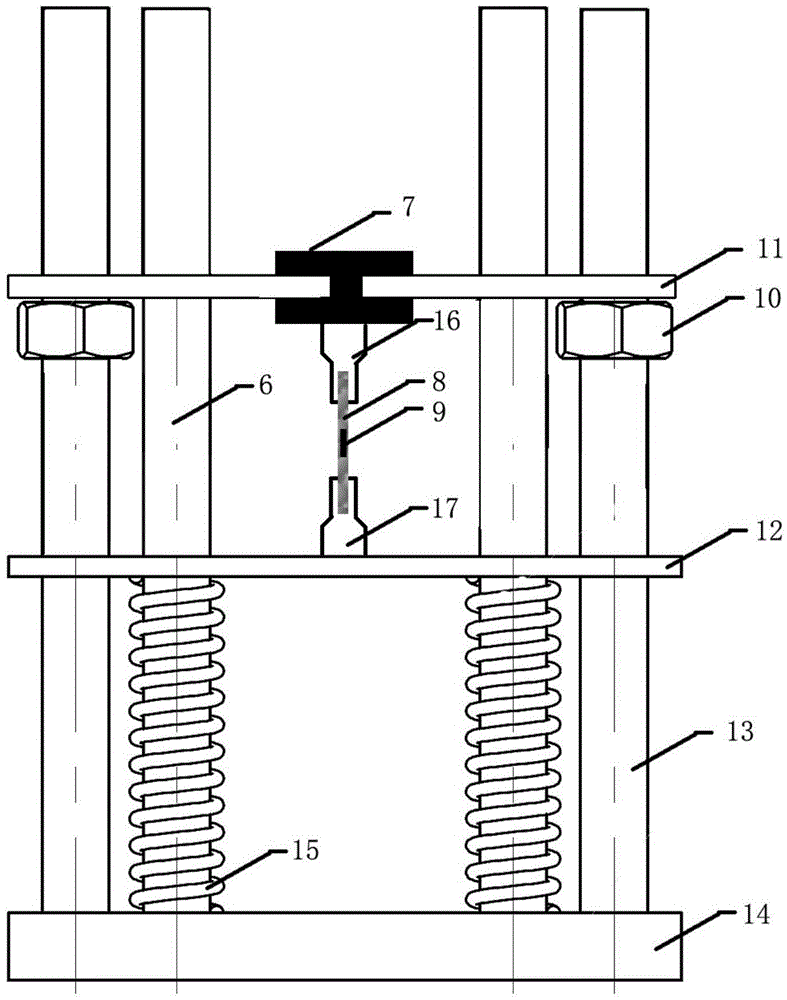

Tensile creep testing device capable of testing multiple groups of samples synchronously under temperature and humidity control condition

ActiveCN105571947AShort test cycleImprove test efficiencyMaterial strength using tensile/compressive forcesTemperature controlControl system

The invention provides a tensile creep testing device capable of testing multiple groups of samples synchronously under the temperature and humidity control condition. The tensile creep testing device comprises a temperature control system, a humidity control system, a sample chamber and a computer system. The computer system controls the temperature and the humidity of the sample chamber through the temperature control system and the humidity control system, a temperature sensor, a humidity sensor and tensile creep testing device bodies are arranged in the sample chamber, and the temperature sensor and the humidity sensor are connected with the computer system. Each tensile creep testing device body comprises guide rods, a dynamical sensor, a strain gage, bolts, a top plate, a middle plate, threaded rods, a bottom plate, an upper clamp and a lower clamp, wherein the dynamical sensor is arranged in the middle of the movable top plate, the upper clamp is arranged below the dynamical sensor, the lower clamp is fixed to the middle of the movable middle plate, a sample to be tested is arranged between the upper clamp and the lower clamp, the strain gage is pasted on the middle of the sample to be tested, and the strain gage and the dynamical sensor are connected with the computer system. The tensile creep testing device can precisely control the temperature and the humidity within a wide temperature range and a full humidity range and can also test the creep of multiple groups of samples synchronously, so that experimental time is saved.

Owner:NANJING NARI GROUP CORP +1

Creep tester for precision load control with weight

ActiveUS7784357B2Flow propertiesMaterial strength using tensile/compressive forcesConstant loadSample length

Owner:KOREA ELECTRIC POWER CORP

System and method for testing aging characteristics of bolt system on basis of creep testing machine

The invention discloses a system and a method for testing aging characteristics of a bolt system on the basis of a creep testing machine. The system comprises a sample preparation device, a sample loading device and a strain detection device, wherein the sample preparation device is fixed on a steel frame and comprises a sample fixture, fixed steel plates and bolts, a sample is mounted in the sample fixture, strain gauges are embedded in the sample, and the bolts are inserted in the central line of the sample and connected with the fixed steel plates; the sample loading device comprises the creep testing machine and a pressure switching device, a base of the pressure switching device is fixed on a worktable of the creep testing machine, and the upper part of the pressure switching device is connected with a pressure head of the creep testing machine; the bolts penetrate through holes I of the pressure switching device and connected with the fixed steel plates. The system simulates change of stress and strain of the bolt system along with time in an engineering environment and provides technical support for long stability of a bolt supporting body under the condition of stress-seepage coupling.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com