Device and method for detecting mechanical parameters of hydrate-containing sediments based on X-CT

An X-CT and hydrate-containing technology, applied in the field of equipment, can solve problems such as insufficient temperature control efficiency, uneven temperature control methods, and affecting measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

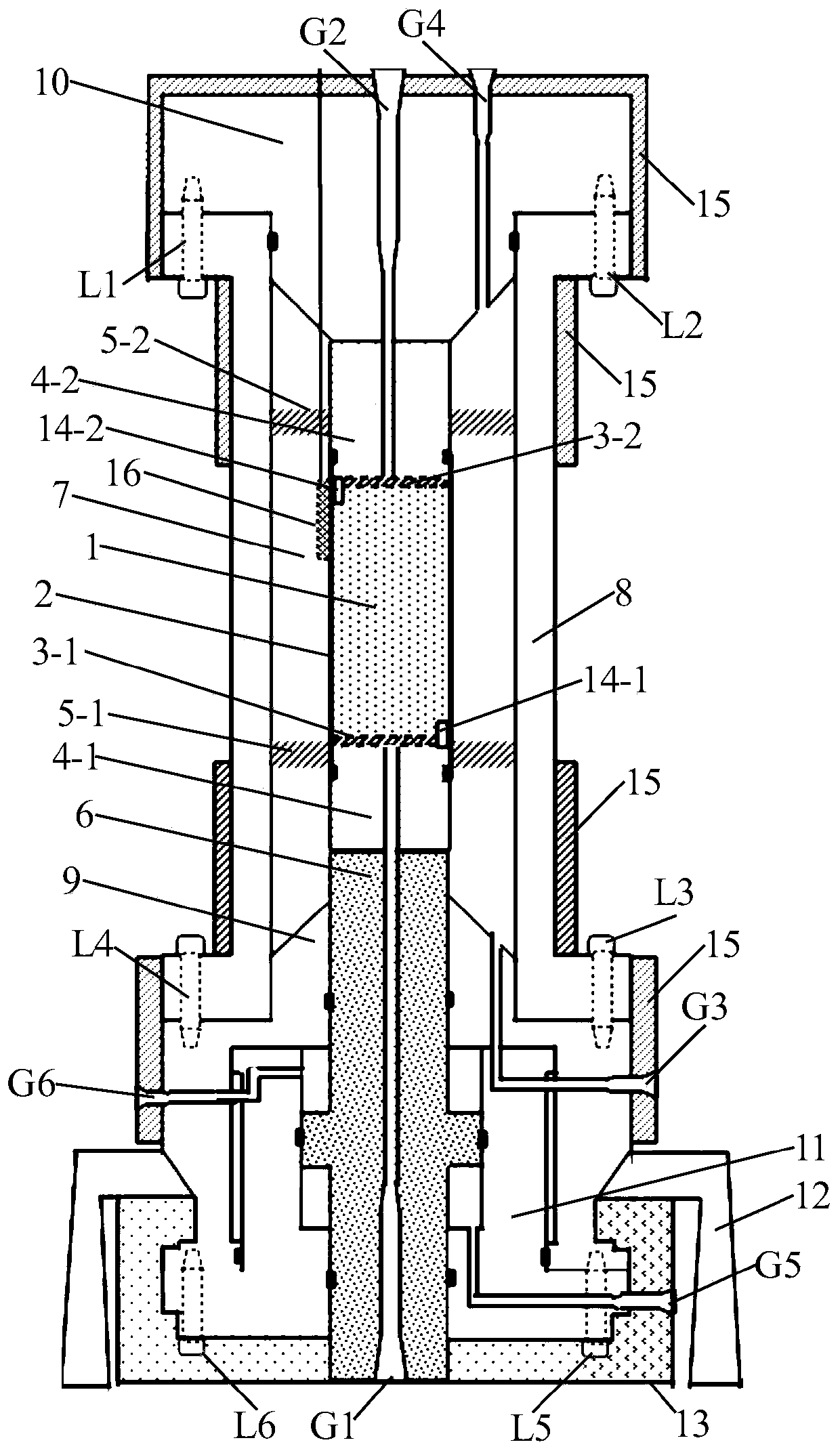

[0040]Embodiment 1. This embodiment proposes a set of pore-scale microscopic observation-triaxial shear comprehensive test system suitable for natural gas hydrate deposits, which can realize precise control of temperature, inlet pressure, outlet pressure, confining pressure and axial pressure. The main body of the reactor of the experimental system is made of beryllium, which is permeable to X-rays and meets the requirements of X-CT 3D scanning imaging tests. The system can simultaneously realize the micro-nano-scale scanning and macroscopic stress-strain curve testing of natural gas hydrate deposits.

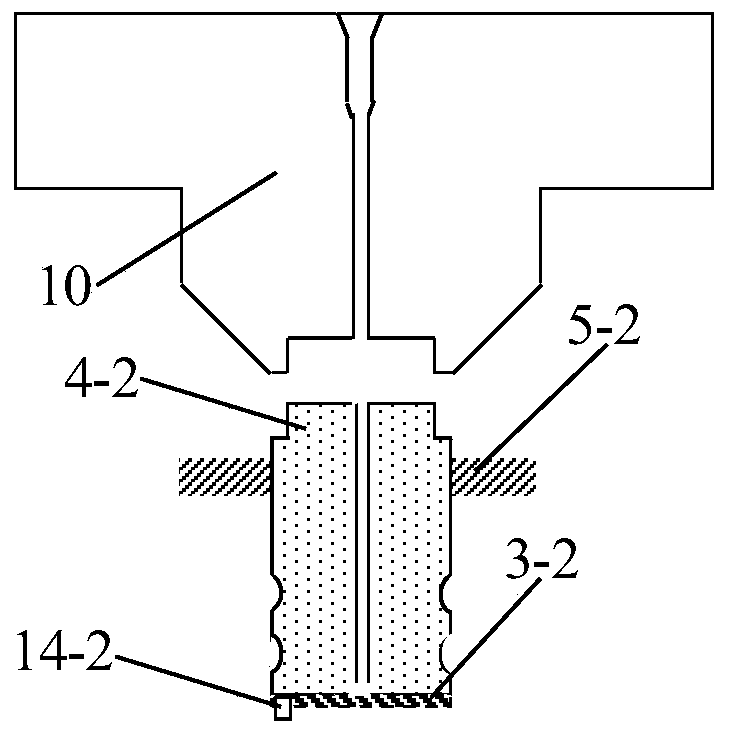

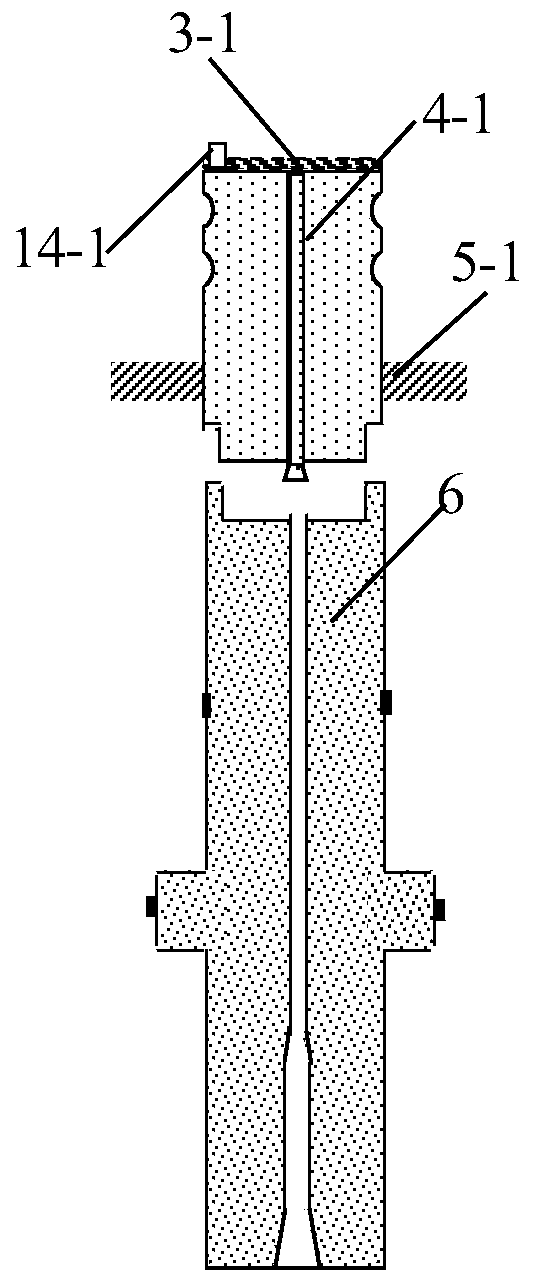

[0041] Specifically, refer to figure 1 , Figure 2, a device based on X-CT to detect the mechanical parameters of hydrate-containing sediments, including a micro-reactor, and the body of the reactor is made of beryllium or carbon fiber pressure-resistant pipe. Among them, the beryllium pressure tube is a beryllium pressure tube formed by forging beryllium powder under high tempe...

Embodiment 2

[0056] Embodiment 2. This embodiment proposes a method for detecting mechanical parameters of hydrate-containing sediments based on X-CT, including:

[0057] Step (1), install the sample

[0058] Saturate a certain amount of sediment sample with water and mix it thoroughly, put the mixed sand sample into the rubber sleeve and fully compact it; then put the sample adjustment block into the rubber sleeve, install the ballast centralizing ring on the rubber sleeve, The outside of the coincident portion of the sample conditioning spacer. Install the upper end cover and the lower end cover of the reaction kettle, install the axial pressure loading piston and the axial pressure loading reaction force mechanism, place the core holder on the CT scanner stage and fix it.

[0059] Step (2) Adjust the confining pressure and pore pressure so that the sample is consolidated for more than 24 hours

[0060] Open the outlet valve of the confining pressure liquid on the upper end cover of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com