A Dispersion Method for Precisely Controlling the Aspect Ratio of Alumina Whiskers

A technology of alumina whiskers and aspect ratio, which is applied in the field of alumina whiskers, can solve the problems that affect the molding and sintering of composite materials, affect performance parameters, and cannot improve product density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

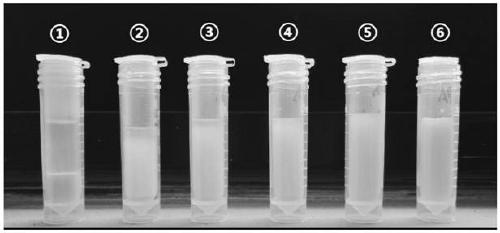

Examples

Embodiment 1

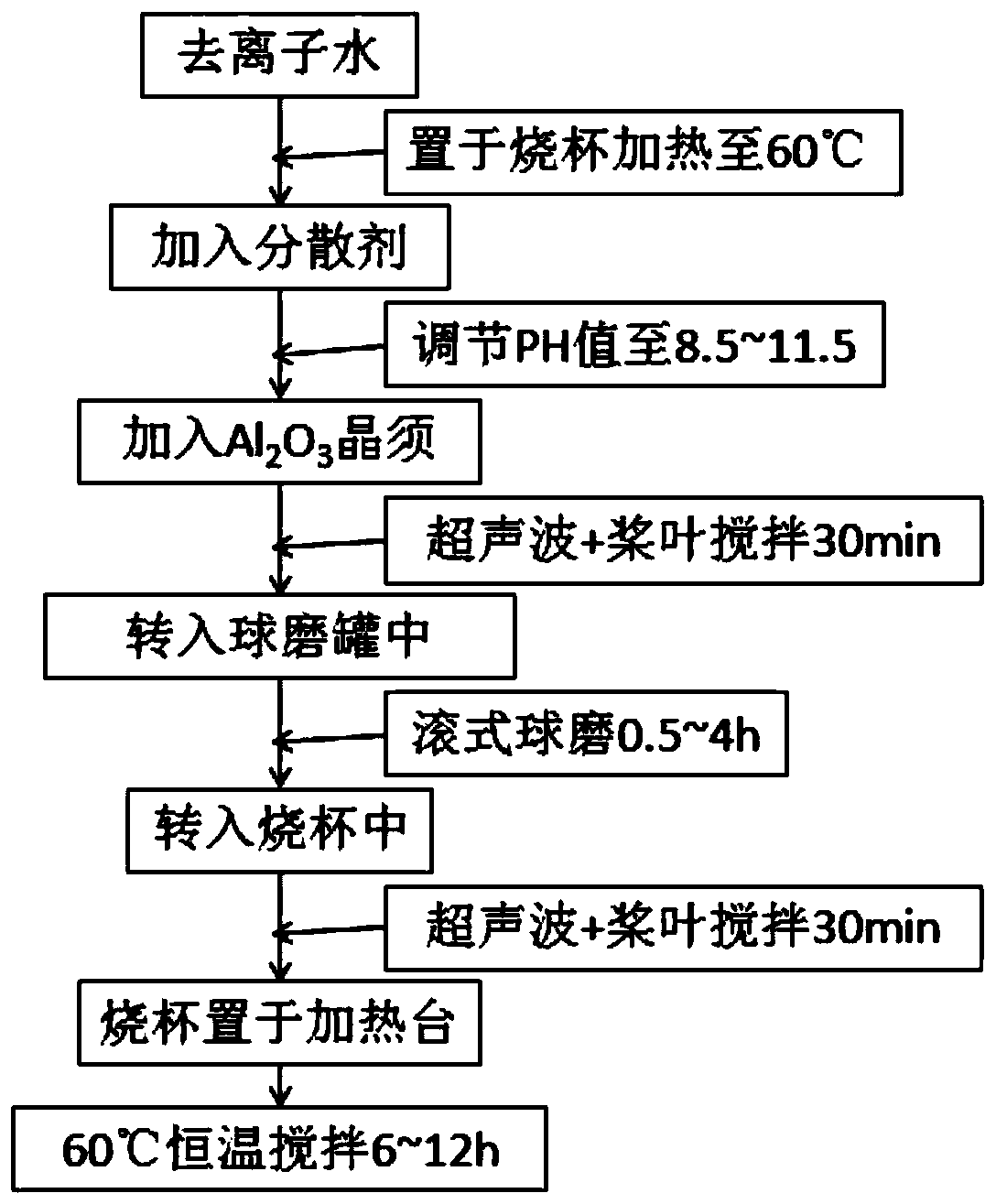

[0078] according to figure 1 The flow chart shown is for dispersion of alumina whiskers:

[0079] Add 100g of deionized water into the beaker, and heat the beaker to 60°C;

[0080] Add 0.2g polyethylene glycol and 0.1g 2-amino-2-methyl-propanol to the beaker to form a dispersant;

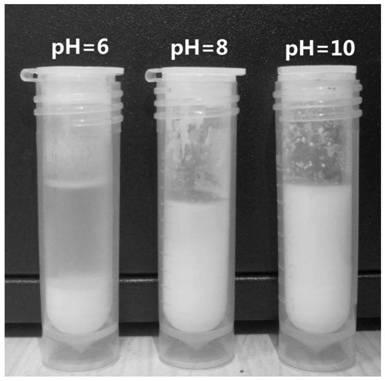

[0081] Adopt ammonia liquor and nitric acid to adjust the pH value of the mixed solution in the beaker to be 8.5;

[0082] Add the aluminum oxide whisker of 10g in the beaker;

[0083] Place the beaker in an ultrasonic cleaning agent and place paddles inside the beaker for stirring while ultrasonically dispersing; the output power of the ultrasonic cleaning machine is 100W, and deionized water is used as the ultrasonic solvent. The page of deionized water in the ultrasonic cleaning machine reaches 2 / 3 of the beaker; the speed of paddle stirring is 200 rpm; carry out ultrasonic dispersion and paddle stirring for 30 minutes to obtain the first dispersion;

[0084] Pour the first dispersant into a ...

Embodiment 2

[0088] The aluminum oxide whiskers were dispersed according to the method of Example 1. The difference from Example 1 was that polyacrylic acid was used instead of 2-amino-2-methyl-propanol, and the rolling ball milling time was 1 hour.

Embodiment 3

[0090] The aluminum oxide whiskers were dispersed according to the method of Example 1, the difference from Example 1 was that the rolling ball milling time was 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com