Testing system and testing method for long-time creep property of explosive

A creep performance and testing system technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of high cost of occupied materials, long time consumption, and many samples to be tested, so as to save costs and shorten the research cycle. , The effect of saving the cost of test materials and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

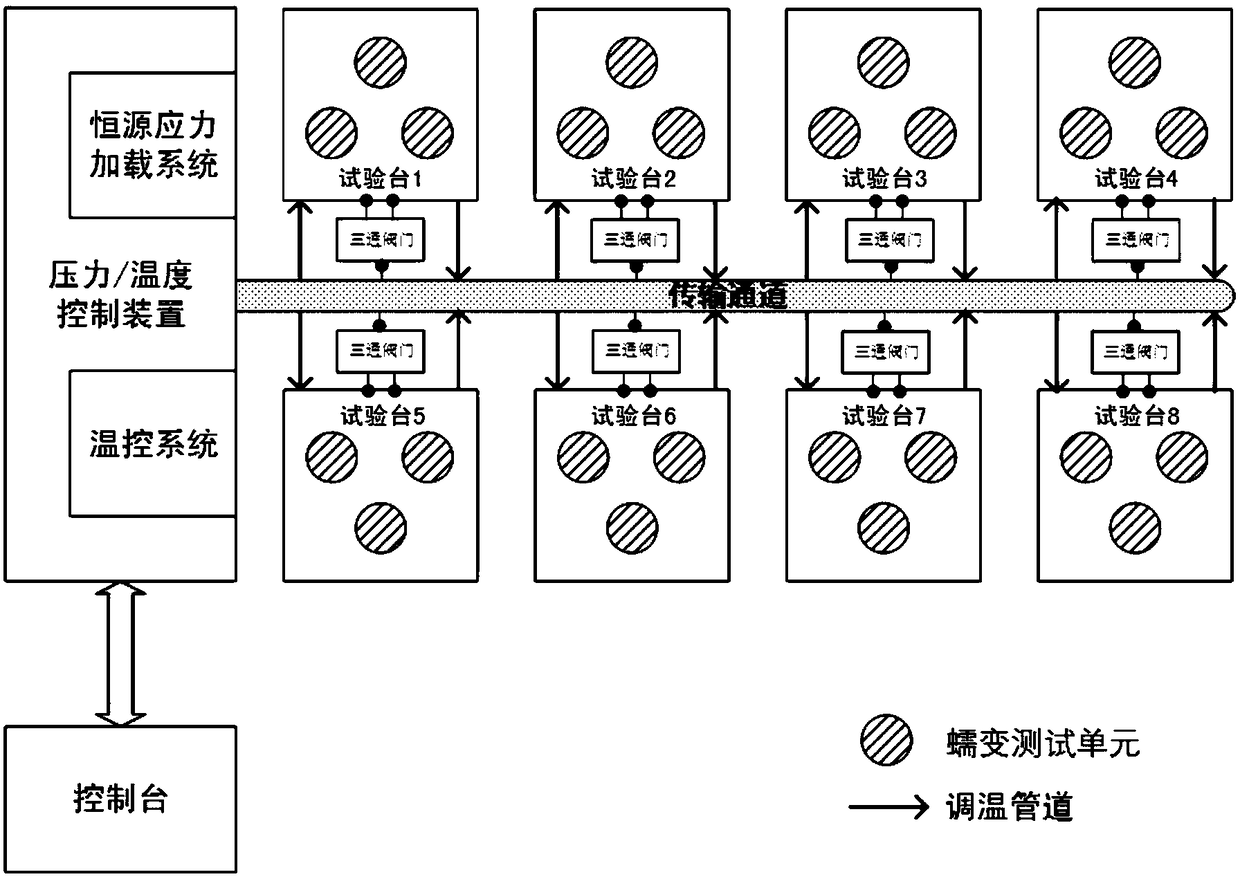

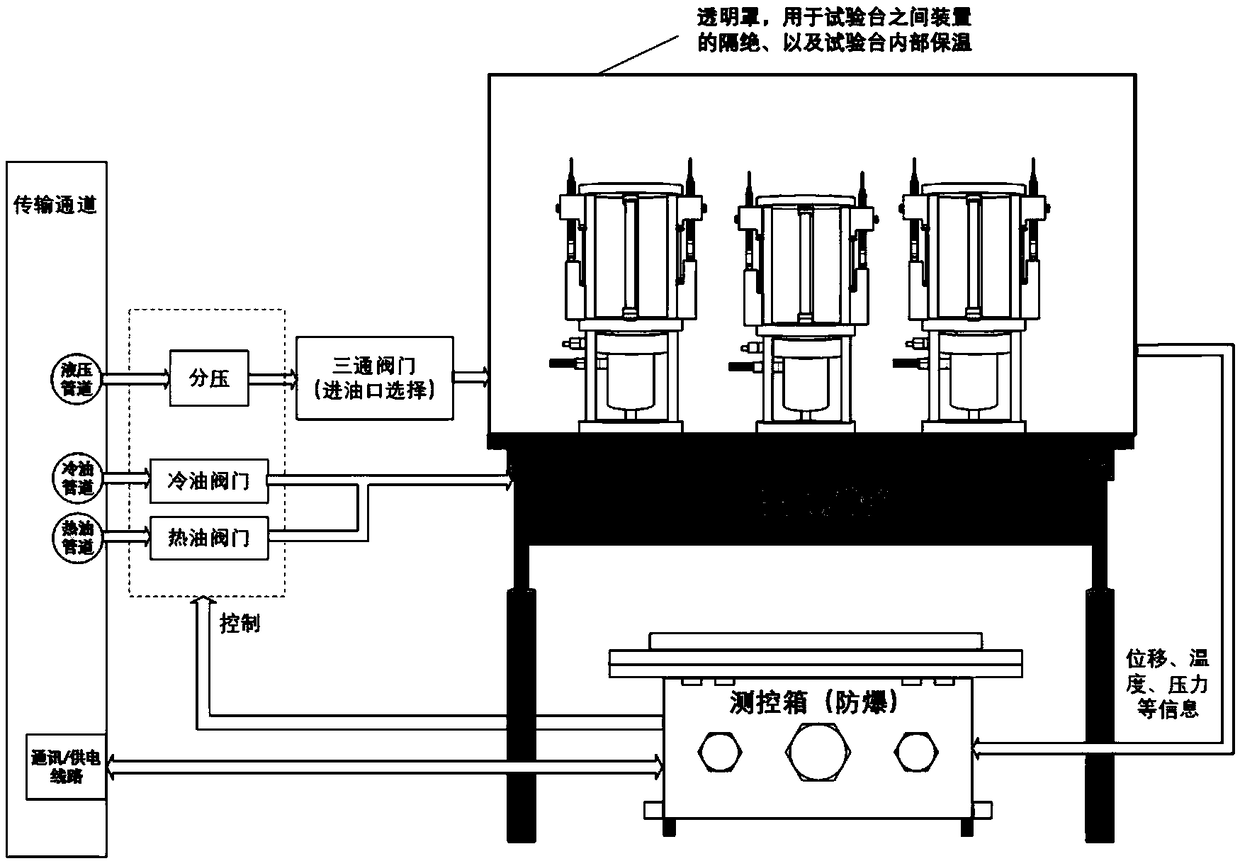

[0028] as attached figure 1 and 2 As shown, the test system for the long-term creep performance of explosives includes a console, a temperature control system and a loading system connected to the console, and a test bench connected to the temperature control system and the loading system respectively;

[0029] The test bench is provided with a creep test unit, the creep test unit is installed in a sealed transparent cover, and a temperature control device is provided under the transparent cover to provide stable temperature control for the creep test unit on the test bench. The control device is connected with the temperature control system; the creep test unit is also connected with the loading system to realize the creep pressure control of the creep test unit; a temperature sensor is also arranged in the transparent cover, and there is a load sensor and a load sensor on the creep test unit. The displacement sensor, temperature sensor, load sensor and displacement sensor a...

Embodiment 2

[0037] A method for testing the long-term creep performance of explosives mainly adopts the test system for the long-term creep performance of explosives provided by the present invention, and includes:

[0038]The explosive sample is fixed through the explosive connection device, and the transparent cover is set up. According to the different requirements of different test benches for temperature and pressure, the console sends instructions to the matching measurement and control box of the test bench through the communication line, and the measurement and control box sends control instructions to realize temperature control. And hydraulic pressure control, at this time, according to the magnitude of the hydraulic pressure and the displacement direction of the piston, the creep test of the explosive sample is realized. During the test, the displacement sensor, load sensor and temperature sensor are used to collect information and transmit it to the measurement and control box. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com