Mechanical high temperature creep testing machine capable of realizing automatic precise loading

A high-temperature creep and testing machine technology, applied in the direction of applying stable tension/pressure to test material strength, using applied repetitive force/pulsation force to test material strength, instruments, etc., can solve the problem of unrealistic cyclic load loading and weight weight Large, prone to impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

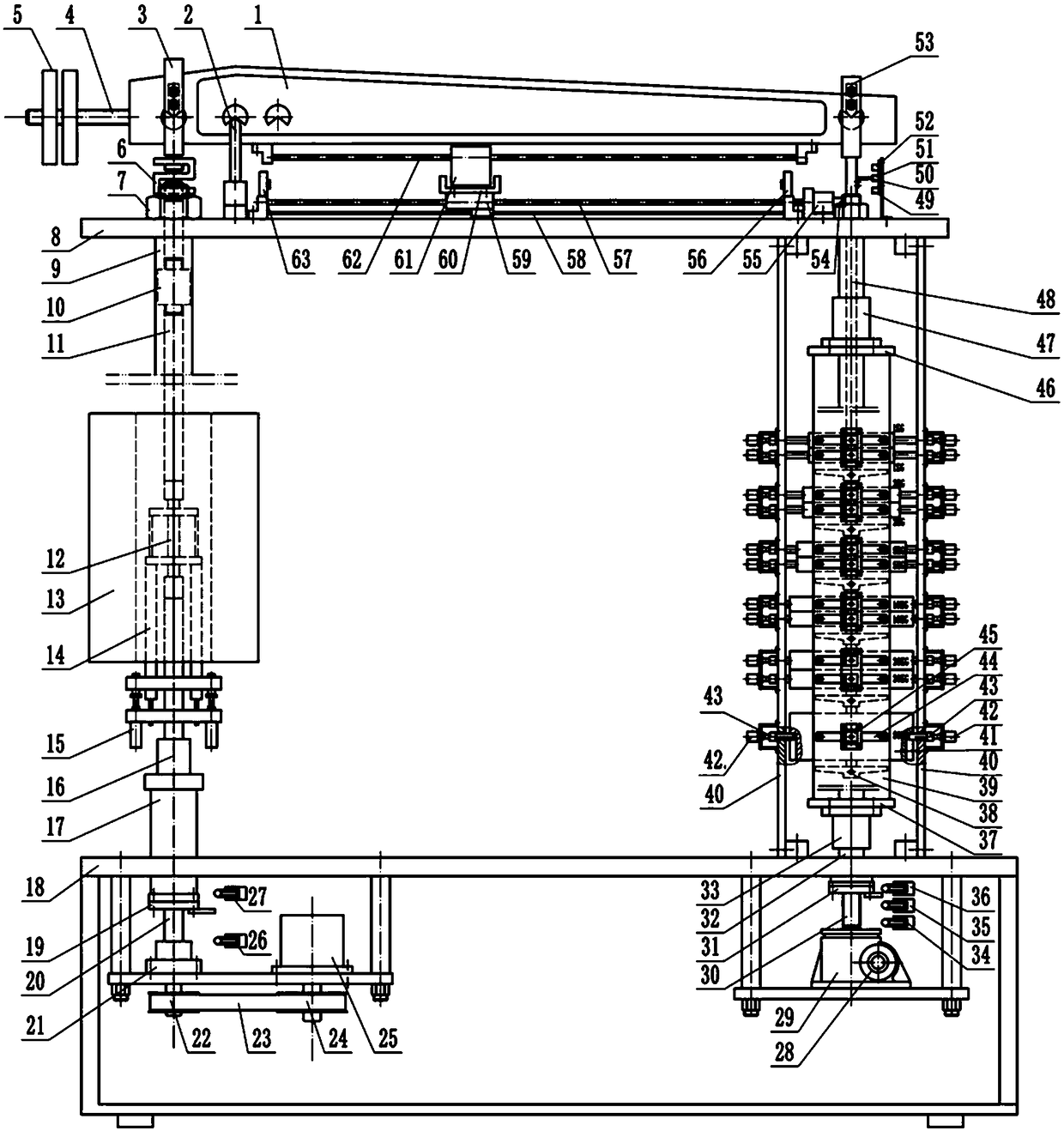

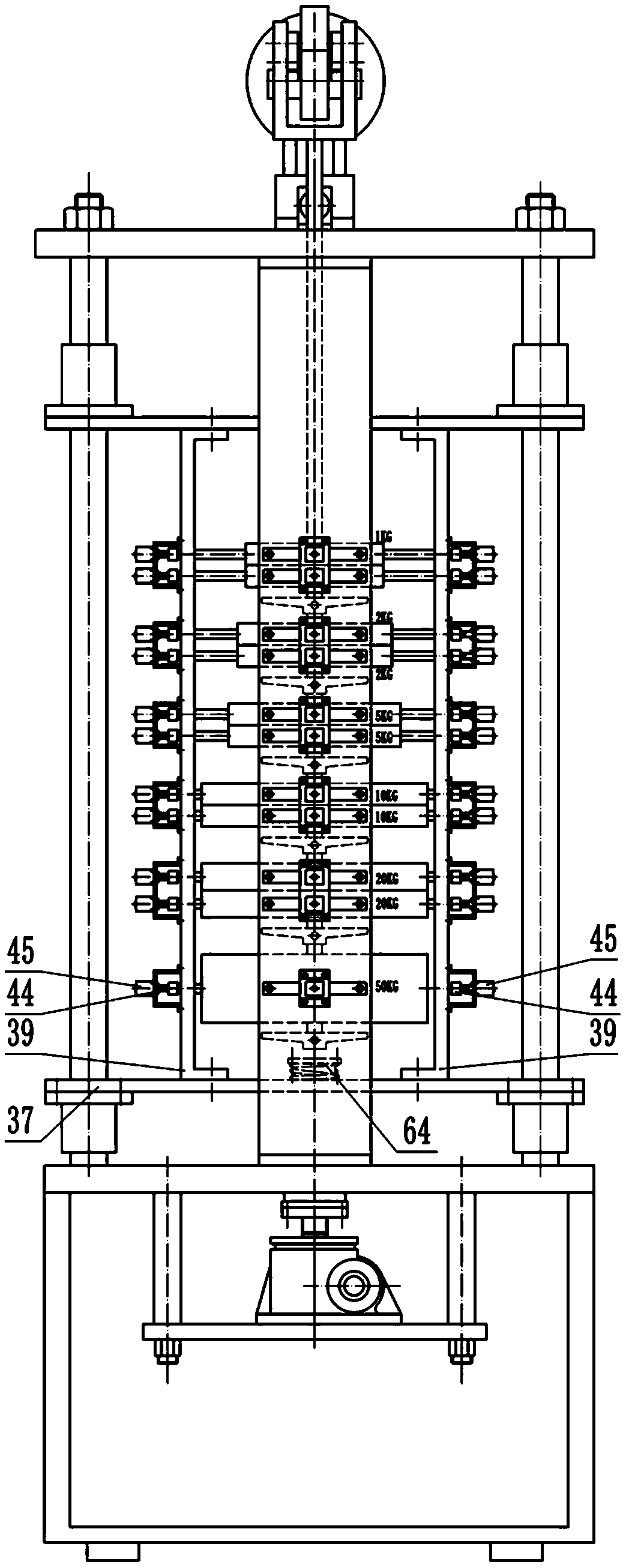

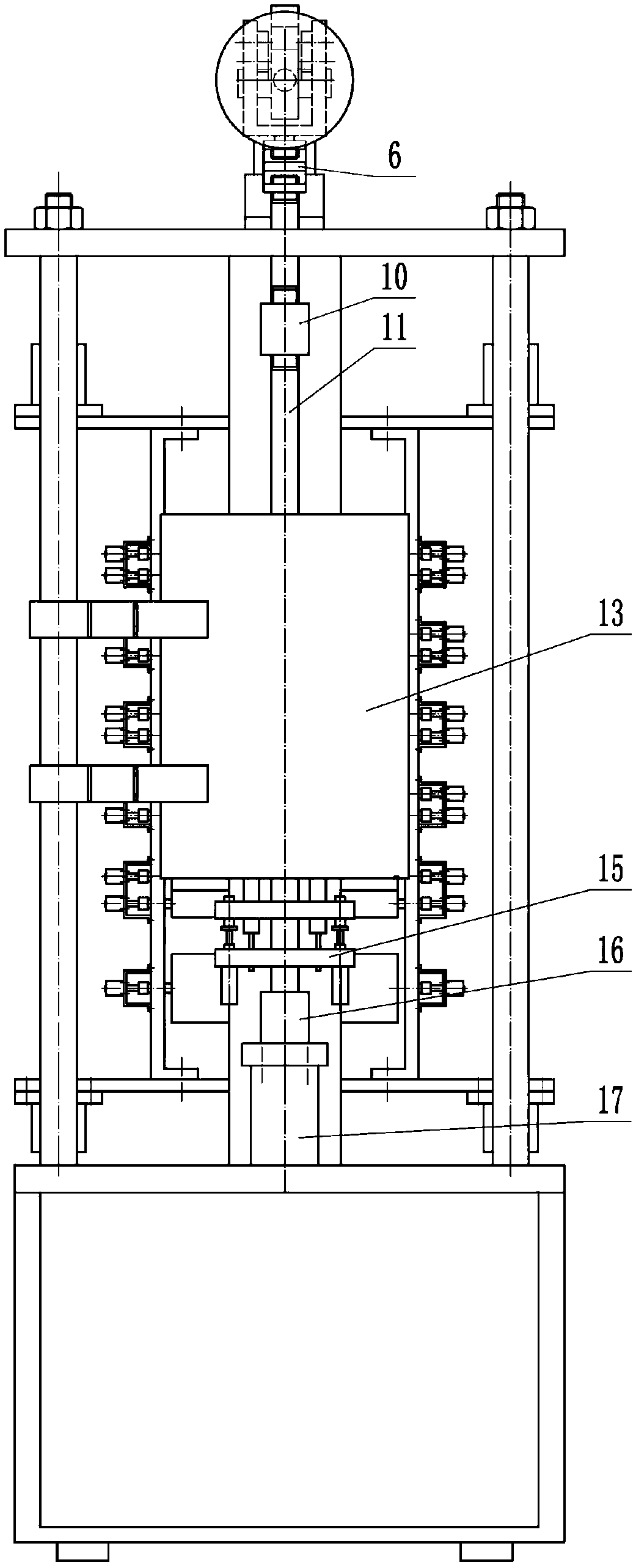

[0063] A mechanical high-temperature creep testing machine that can realize automatic and accurate loading. The technical scheme adopted is as follows:

[0064] The testing machine is composed of a frame, a lever and a connecting mechanism, a fixture and a deformation measuring mechanism, a lever self-leveling mechanism, a heating and temperature control mechanism, an automatic weight loading device and a precise fine-tuning device for a floating code.

[0065] Described frame is made up of upper crossbeam 8, column 9 and workbench 18, and described workbench 18 is placed on the level ground, and upper beam 8 and workbench 18 are supported by four uprights 9, is positioned at workbench 18 above;

[0066] The lever and connecting mechanism are mainly composed of lever 1, lever support 2, sample end connection seat 3, weight end connection seat 53, force sensor 6, and upper ball joint 10. The lever support 2 is supported and placed horizontally on the upper beam 8; the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com