Uniaxial-creep testing machine

A creep test, uniaxial technique, applied in the direction of applying a stable tension/compression to test the strength of the material to ensure stability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

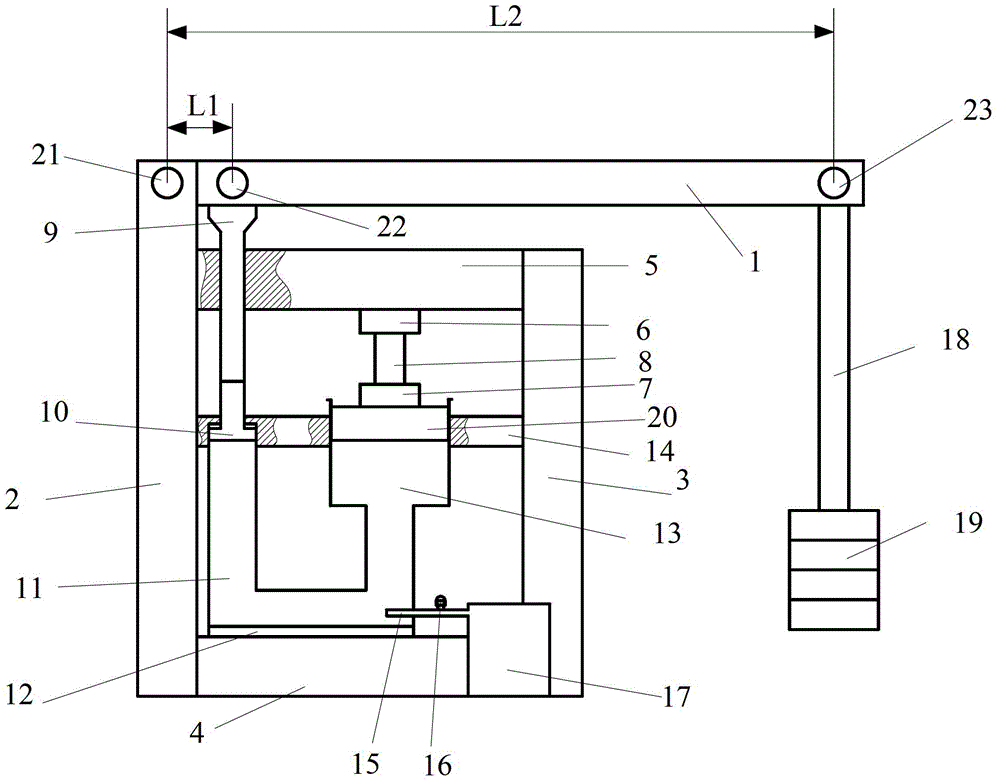

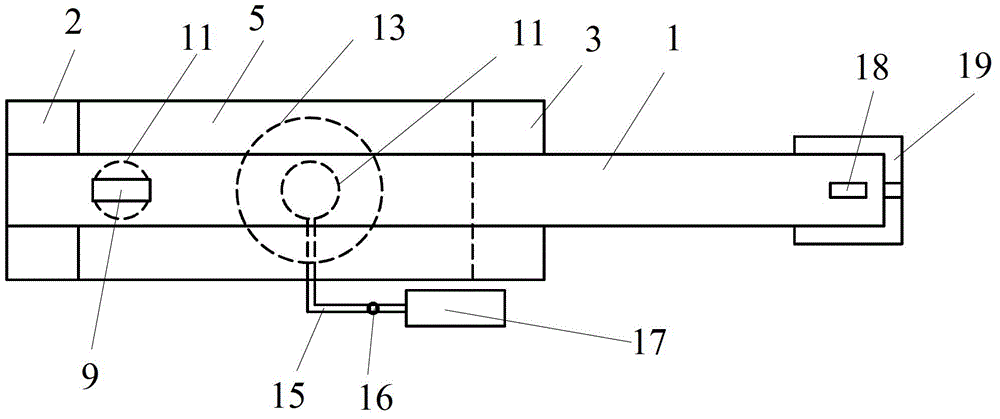

[0024] The structure of the uniaxial creep testing machine of the present invention will be further described below with reference to the accompanying drawings.

[0025] In this embodiment, the structure of the uniaxial creep testing machine is as follows figure 1 , figure 2 As shown, it consists of a frame, a loading mechanism, a specimen installation assembly and a manual oil pump 17.

[0026] Described frame is made up of the first vertical beam 2, the second vertical beam 3, the first crossbeam 4, the second crossbeam 5 and the third crossbeam 14; The first vertical beam 2 is higher than the second vertical beam 3, the first vertical beam 2 and the second vertical beam 3 are installed parallel to each other and separated by a distance; the first beam 4 is a lower beam, located between the first vertical beam 2 and the second vertical beam 3, and its bottom surface is flush with the bottom surface of the second vertical beam 3 , its two ends are fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com