Transformer body structure

A transformer and body technology, which is applied to the body structure field of an open wound iron core transformer, can solve the problems of uncontrollable winding deformation, reduction of body strength, and inability to achieve axial compression of the body, and to improve the Short circuit resistance, compact structure, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

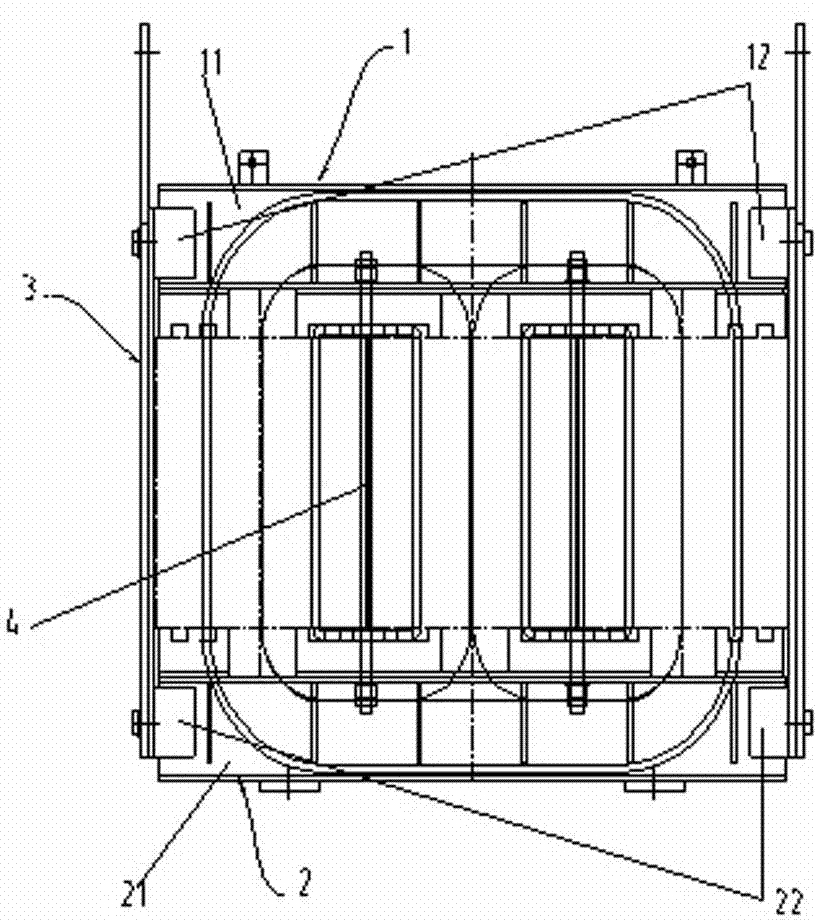

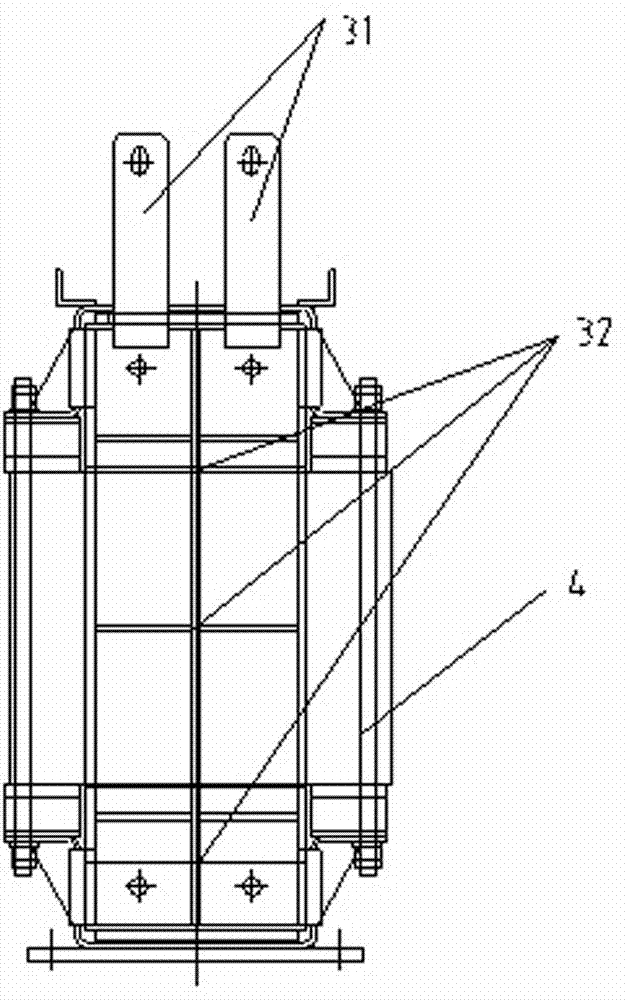

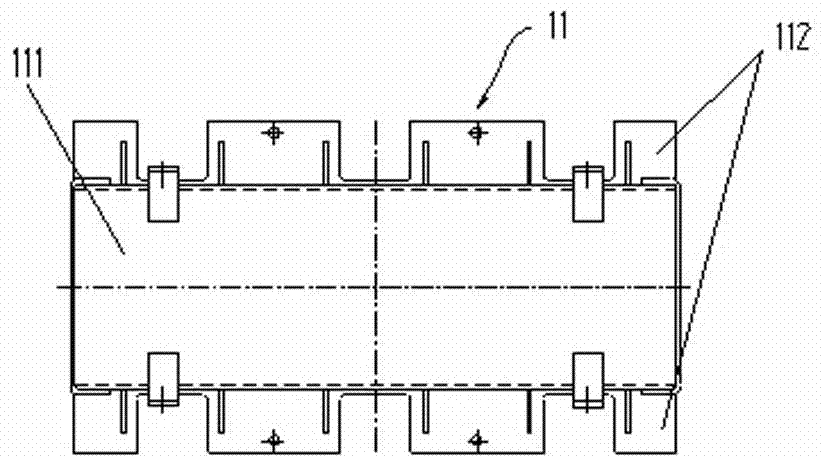

[0024] Refer to attached figure 1 , attached figure 2 As shown, a transformer body structure, which includes a magnetic flux circuit spliced by a plurality of iron chips, the transformer body structure also includes an upper clamp 1 arranged on the upper part of the magnetic circuit, and an upper clamp 1 arranged on the lower part of the magnetic circuit. The lower clamp 2, two side plates 3 located on the left and right sides of the body structure, the upper clamp 1 includes an upper body 11 and an upper fixing plate 12 welded on the left and right sides of the upper body 11, the lower clamp 2 includes a lower The body 21 and the lower fixing plate 22 welded on the left and right sides of the lower body 21, the upper fixing plate 12 and the lower fixing plate 22 are welded with mounting nuts, the side plate 3 has holes corresponding to the mounting nuts, and the side plate 3 passes through the nut assembly Detachable and respectively connected with the upper fixing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com