A stirring method for preparing a crucible for particle reinforced metal matrix composites

A particle-reinforced and composite material technology, which is applied in the preparation of particle-reinforced aluminum-based composite materials, the preparation of crucibles for particle-reinforced metal-based composite materials by stirring method, and the field of vacuum air-conditioned pressure casting, which can solve the problem of high crucible replacement and maintenance costs, and external connections. Avoid problems such as road temperature rise and alloy liquid spillage, and achieve the effects of low cost, prevention of spillage, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

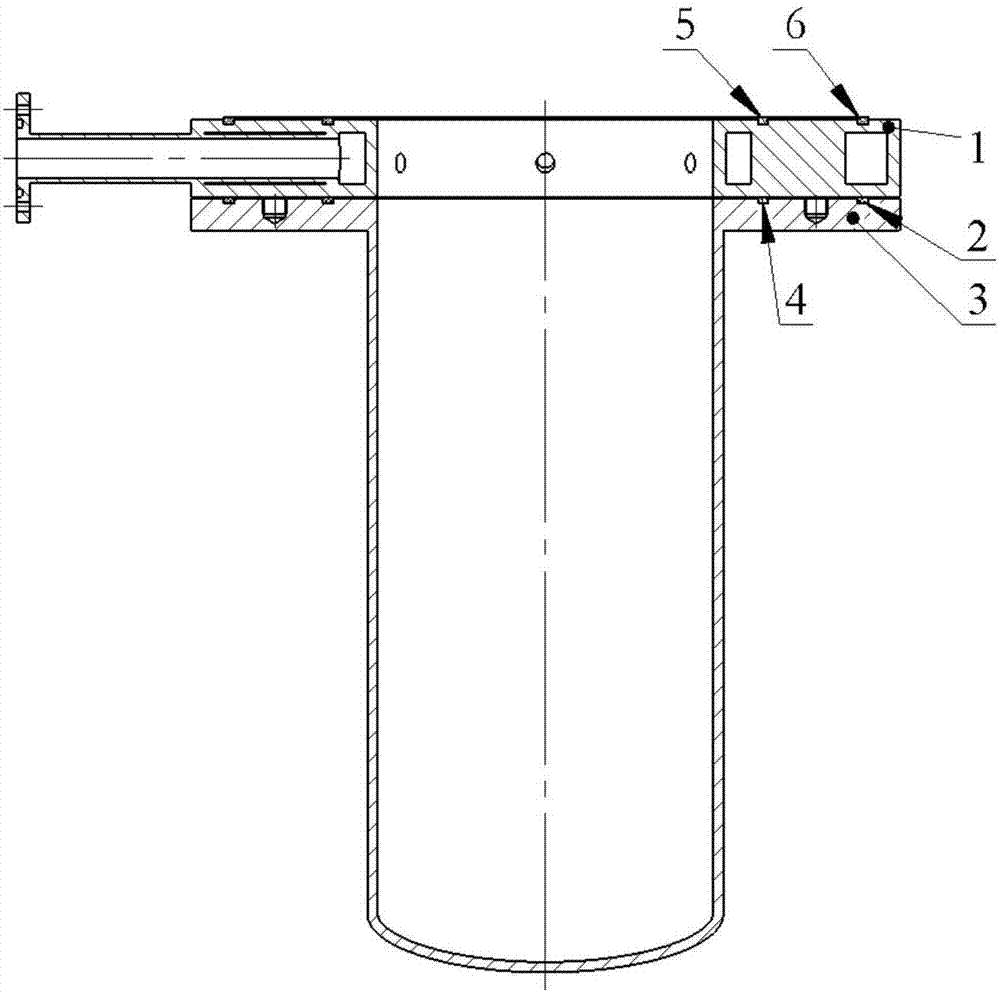

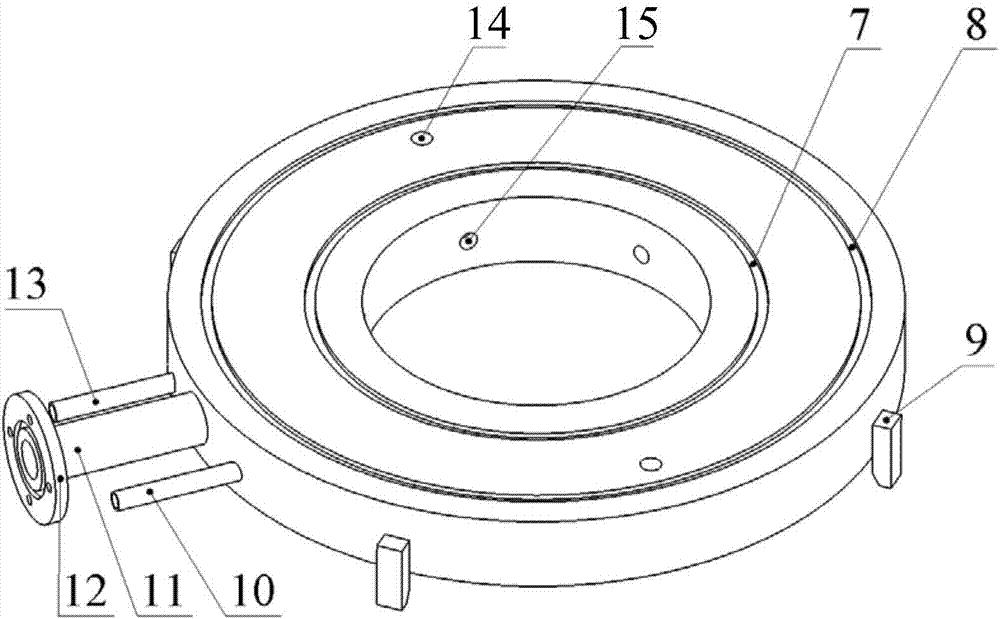

[0023] A crucible for preparing particle-reinforced metal matrix composites by stirring method, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the middle plate 1 of the crucible is welded by pipe and plate, and the material is stainless steel 304. The materials of the outer packing 2 and the inner packing 4 are asbestos and tetrafluoroethylene. The crucible body 3 is welded by stainless steel 304. Packing I5 and Packing II6 material is silicone rubber.

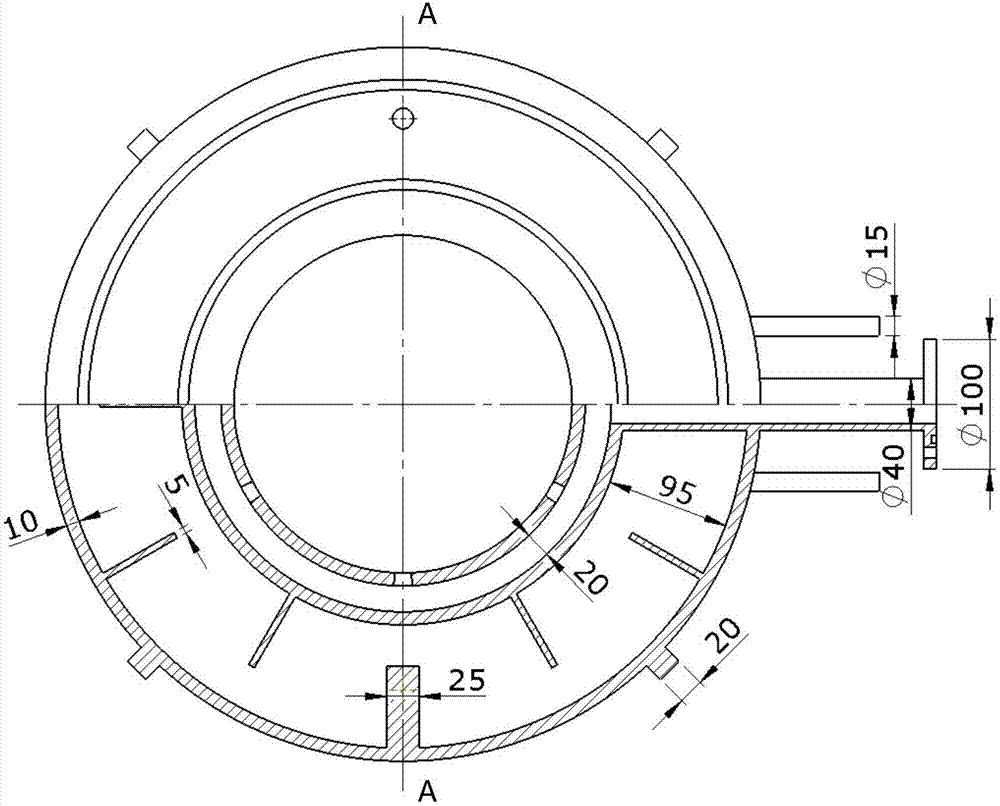

[0024] The intermediate plate 1 consists of an upper cover plate, a lower base plate, 3 layers of intermediate support plates, 9 water baffles, 2 thickened water baffles, water inlet pipe 10, return water pipe 13, air pipe 11, flange plate 12 and 4 positioning Block 9 is welded. The upper cover plate and the lower bottom plate are made of plates with a thickness of 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com