Patents

Literature

32results about How to "Increase axial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

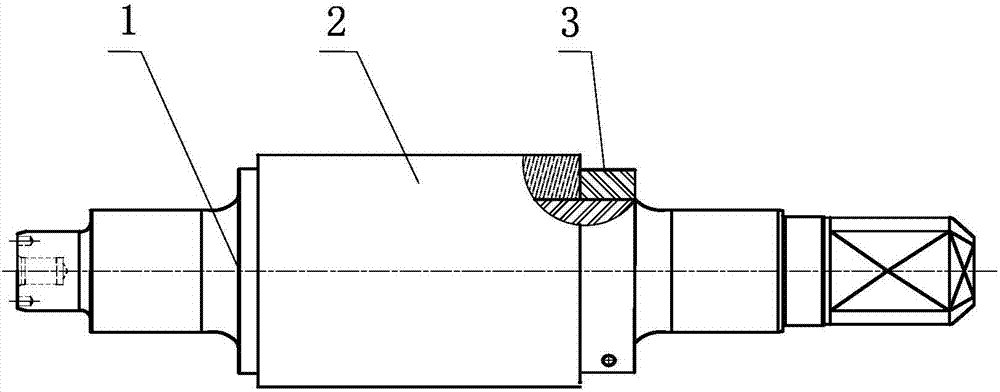

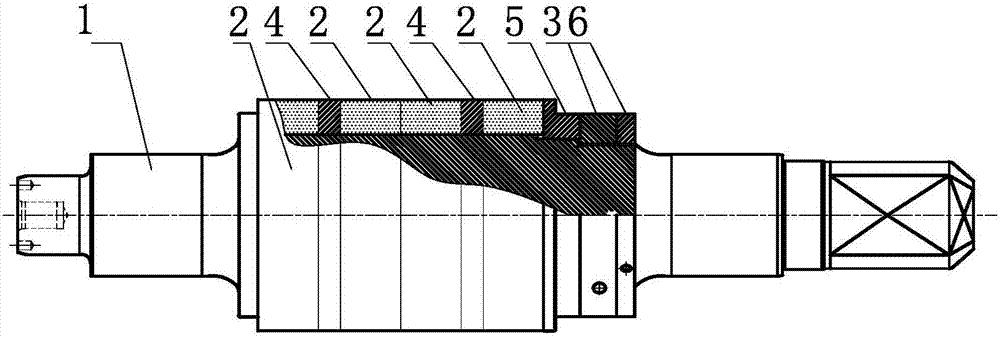

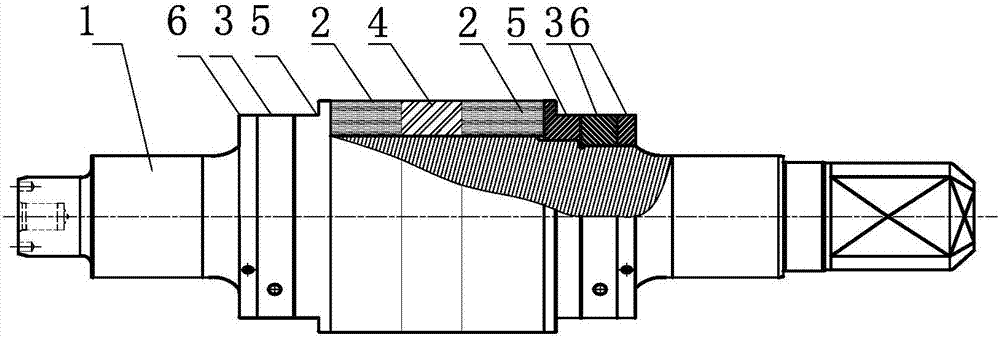

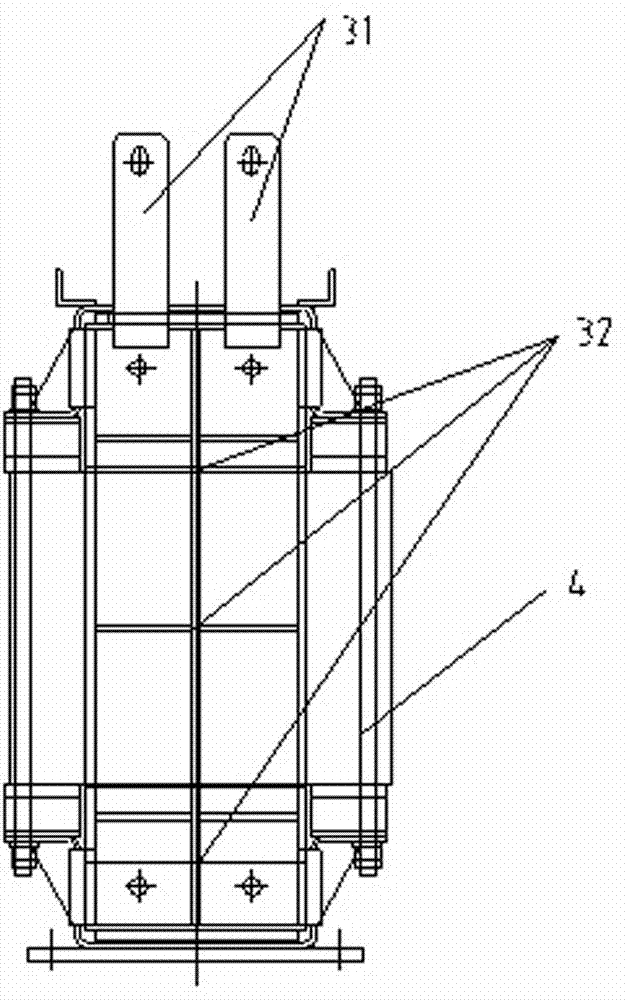

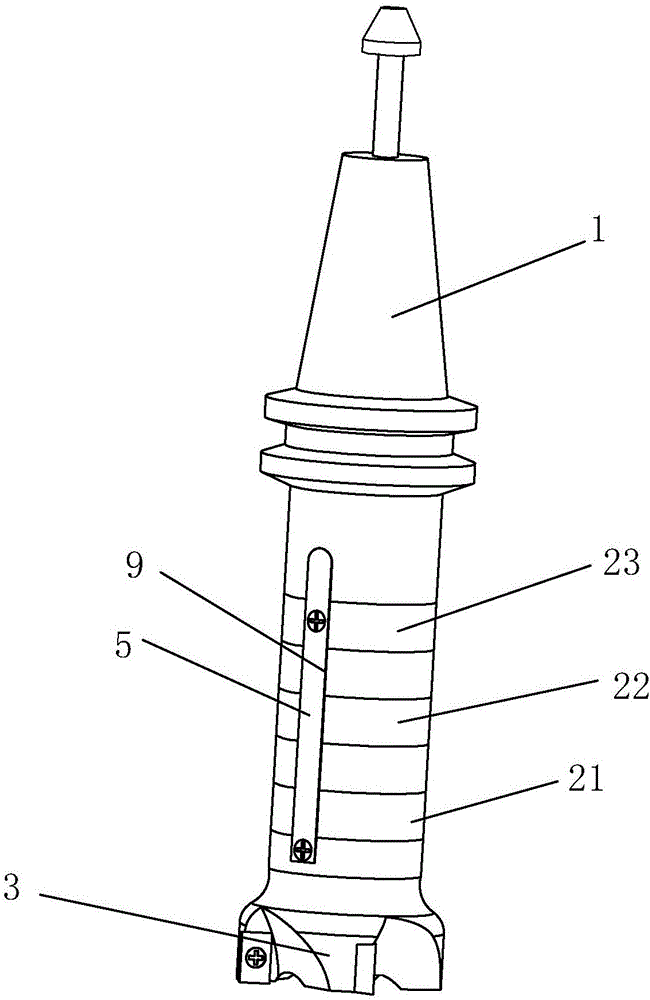

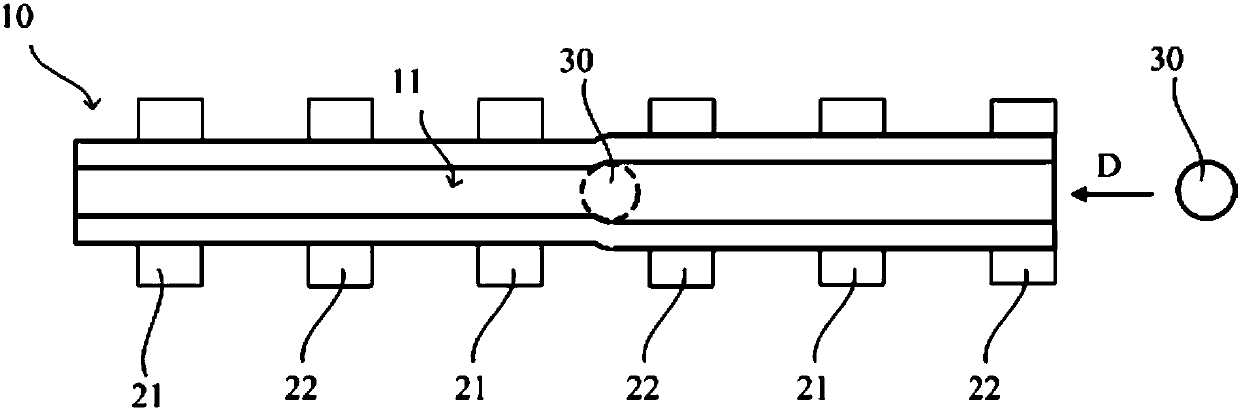

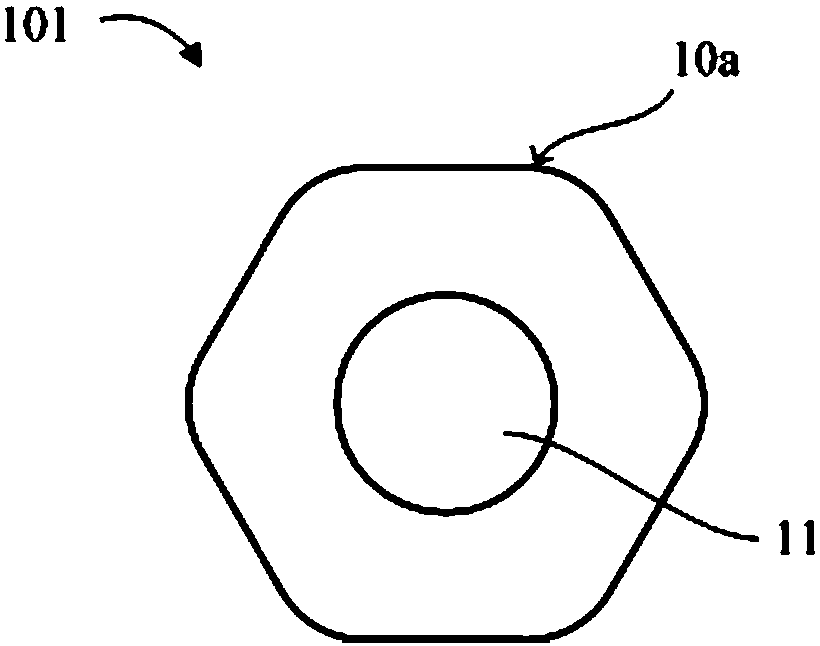

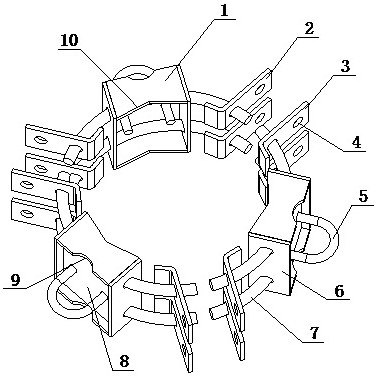

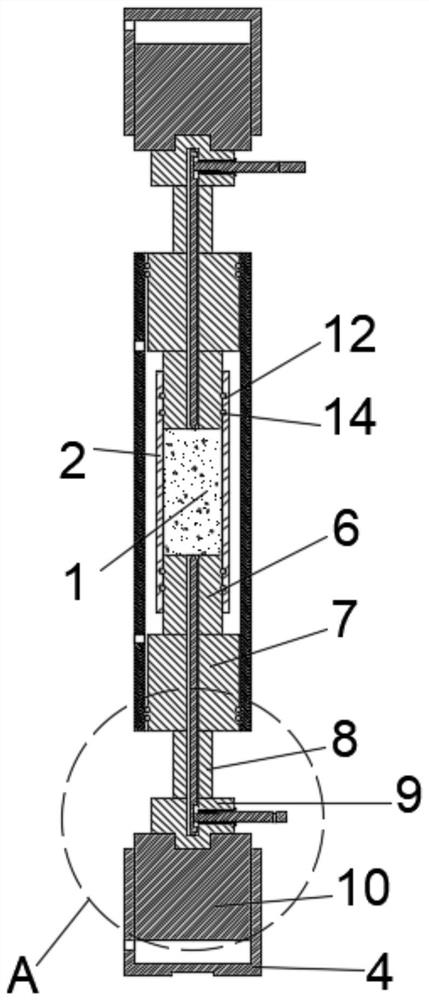

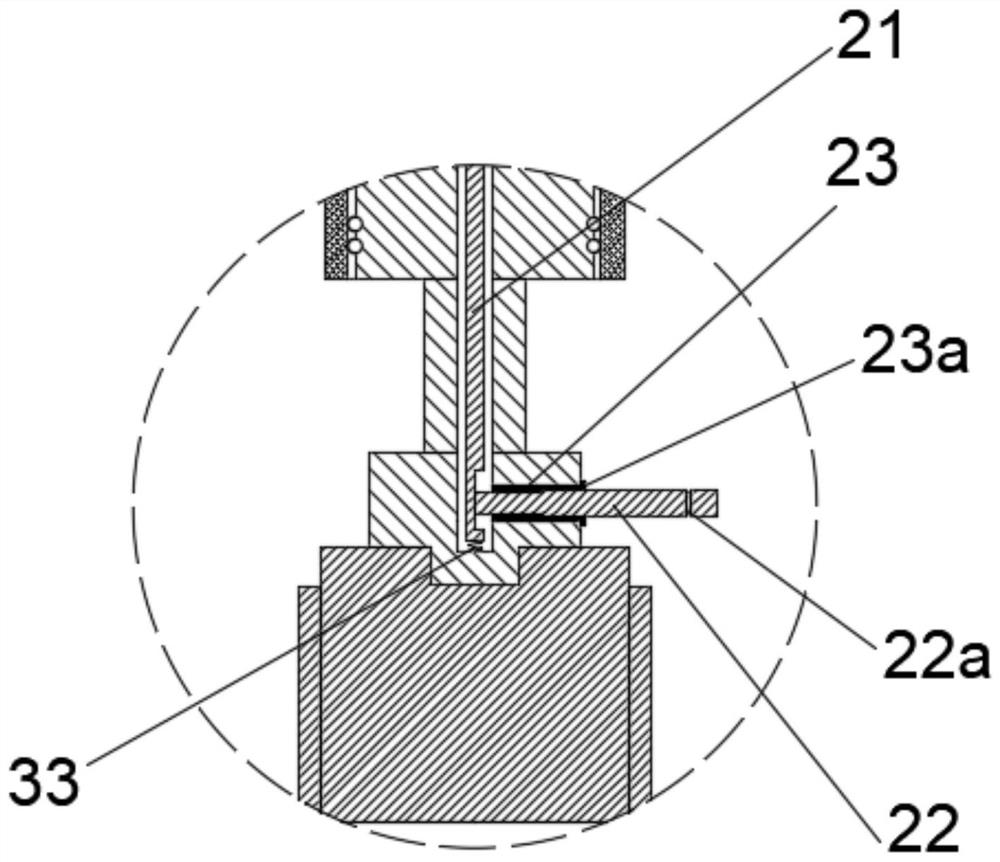

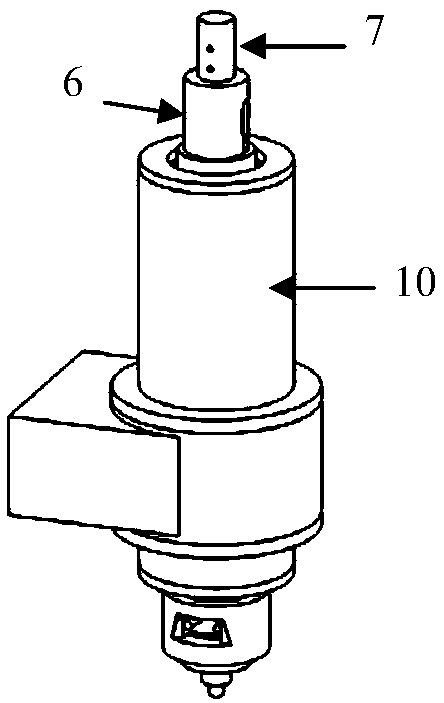

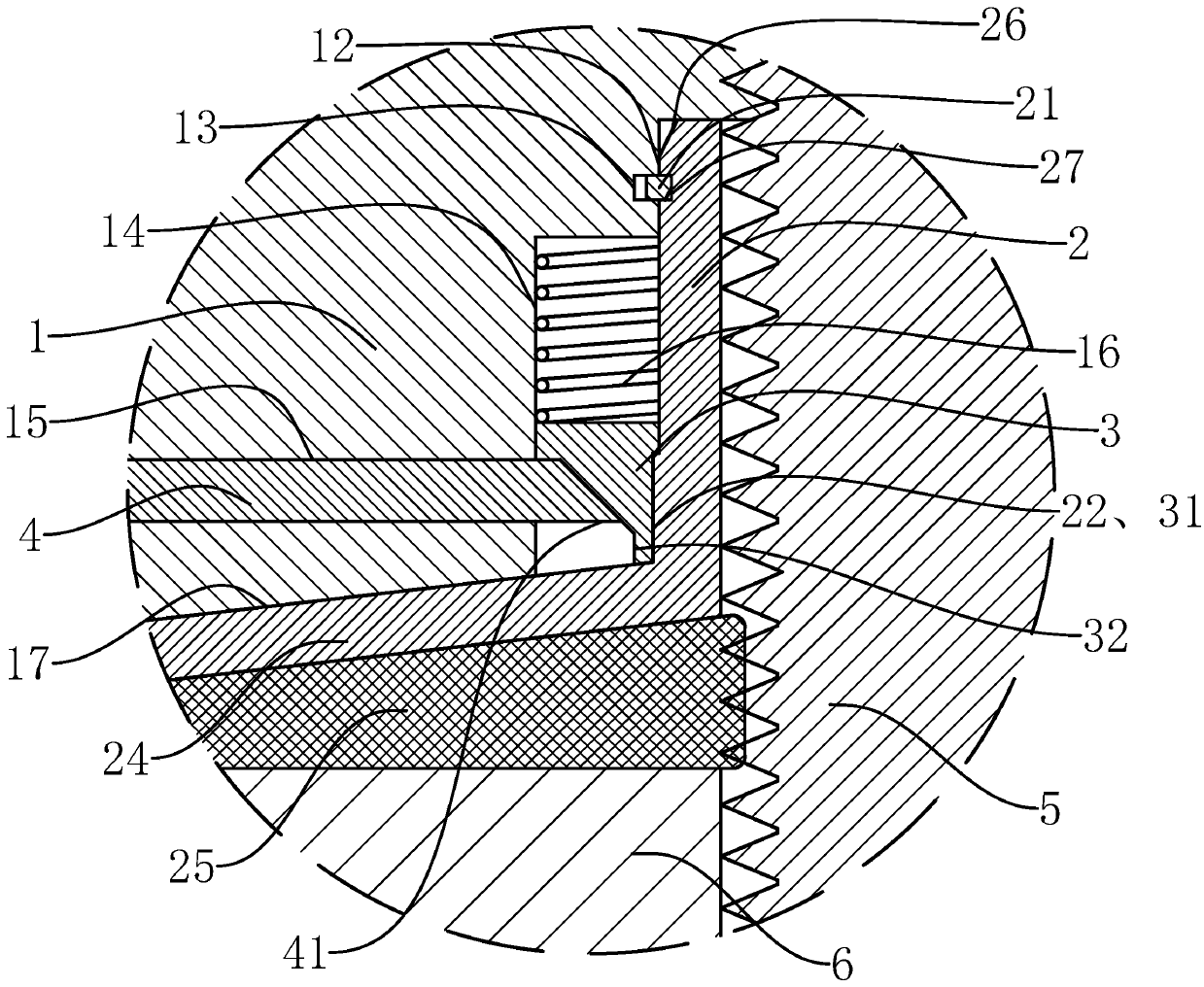

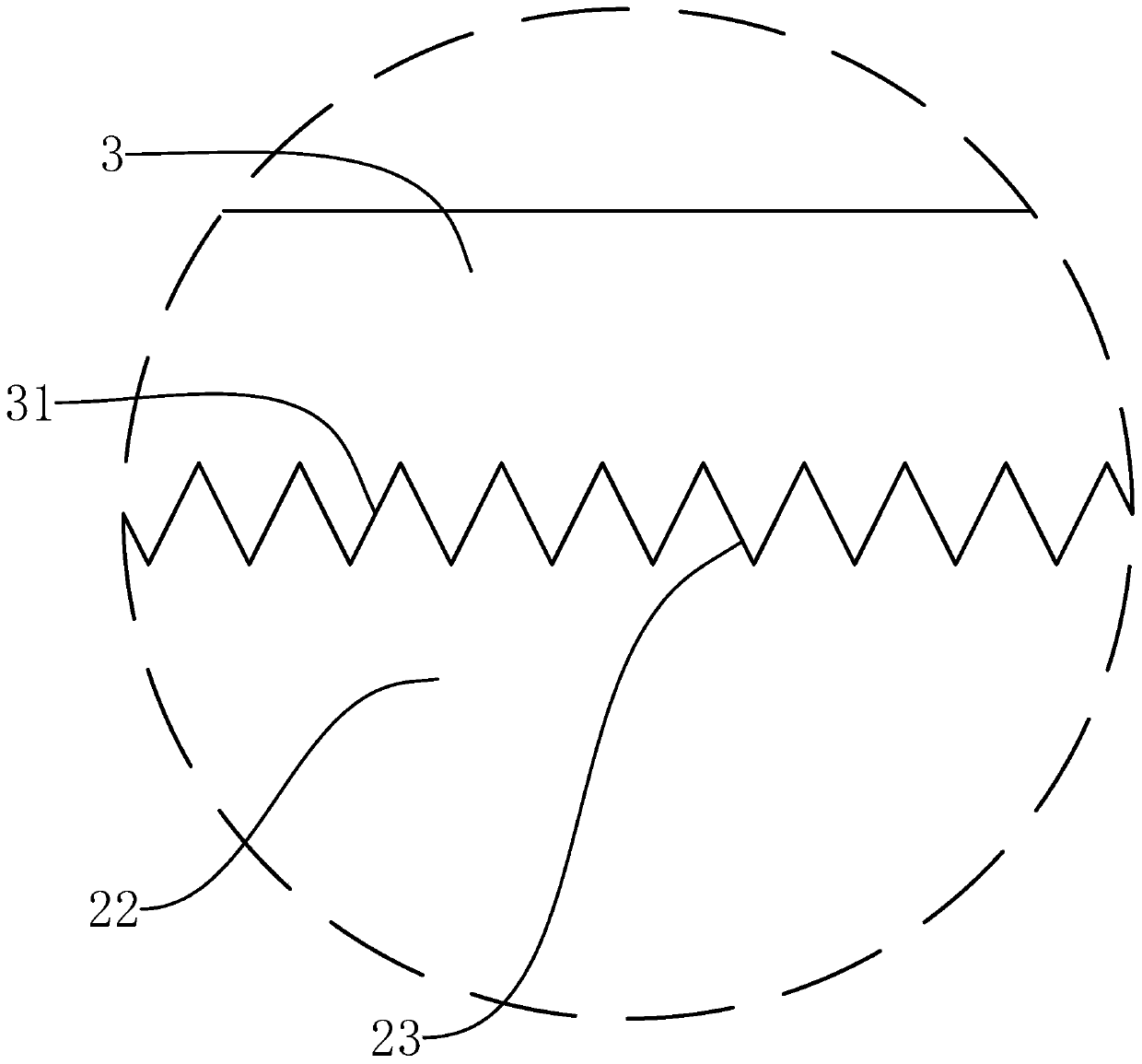

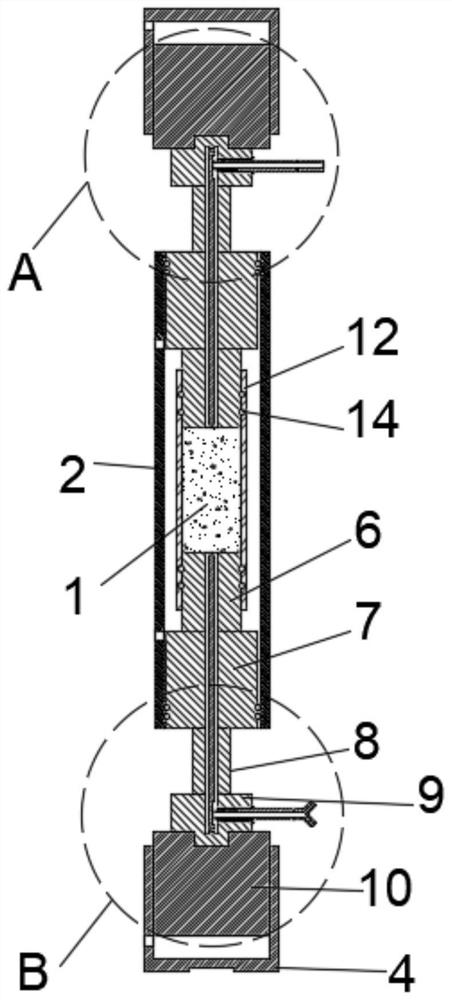

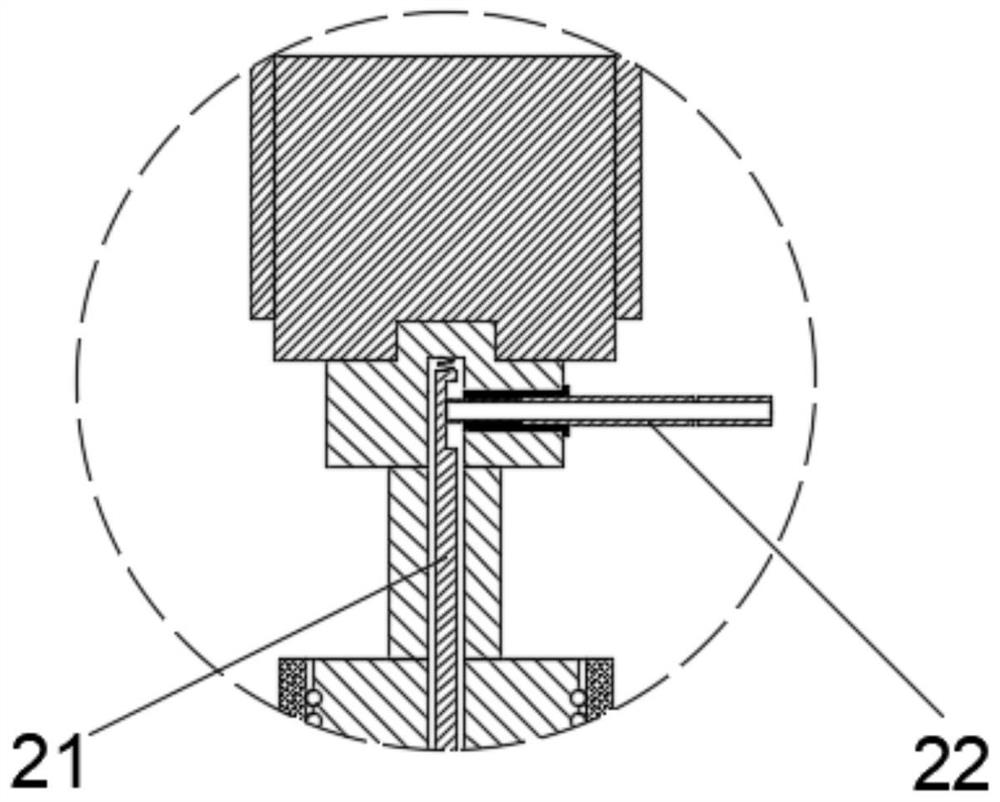

Spindle system for realizing friction surfacing with shaft shoulder

ActiveCN107052560AGeneration of restrictionsIncrease profitNon-electric welding apparatusSurface layerSelf locking

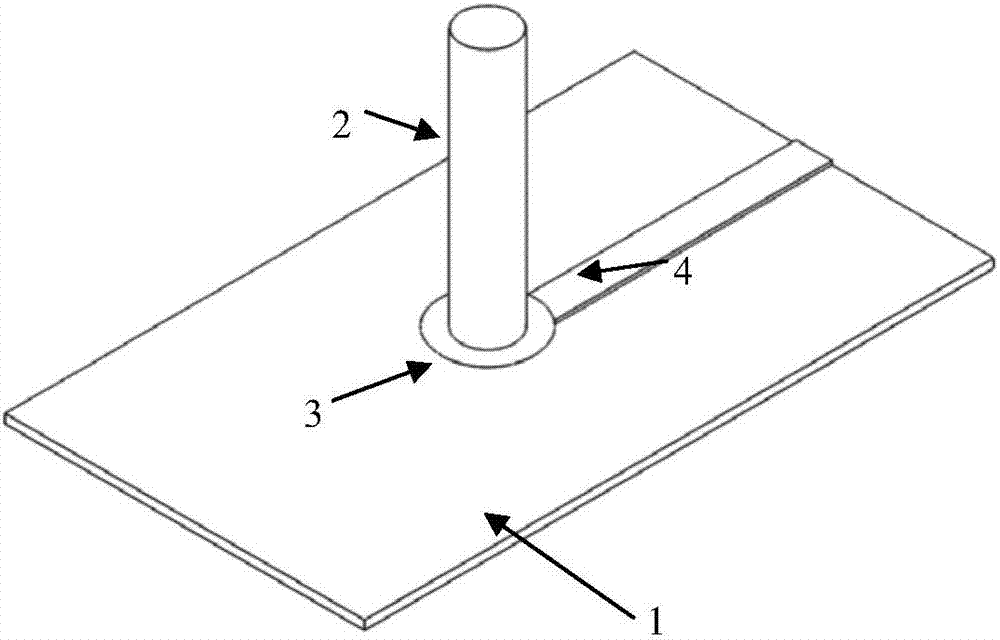

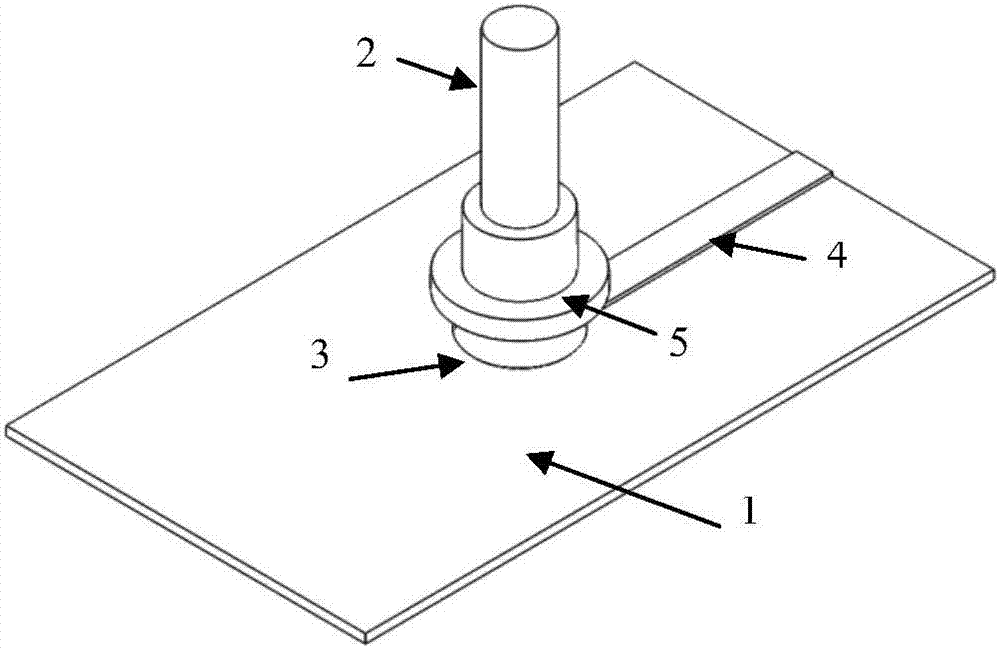

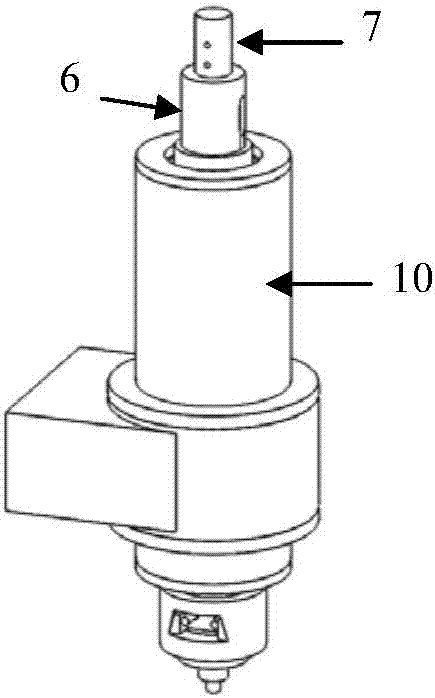

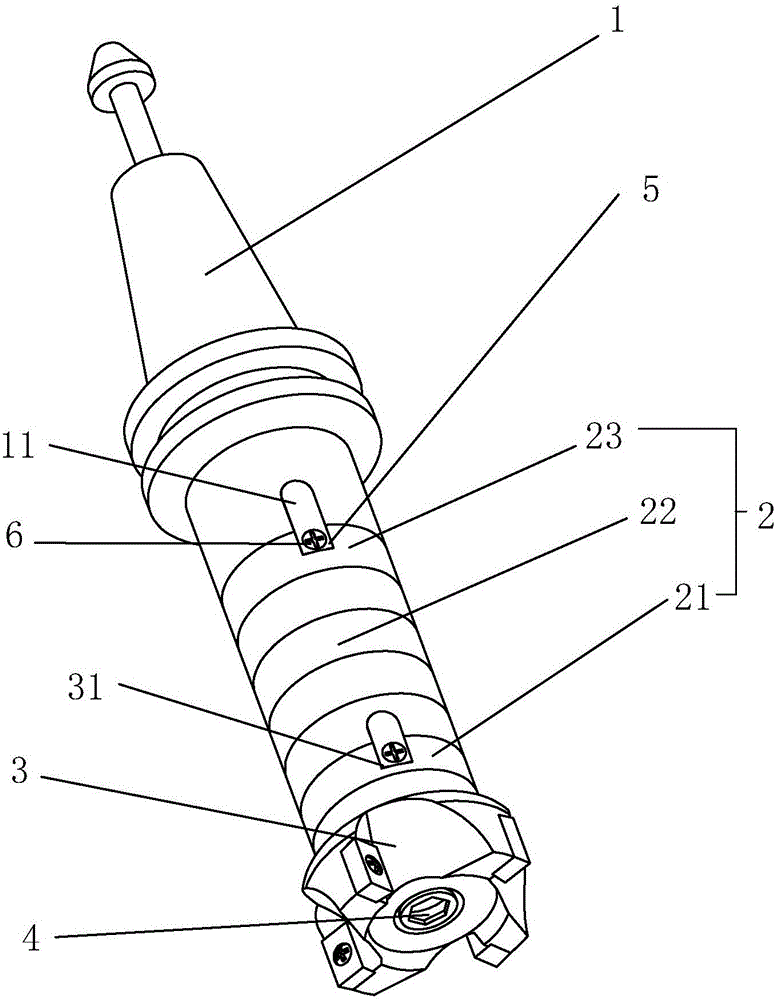

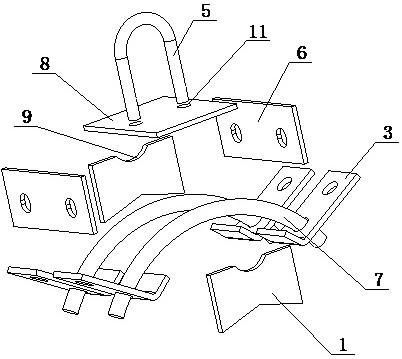

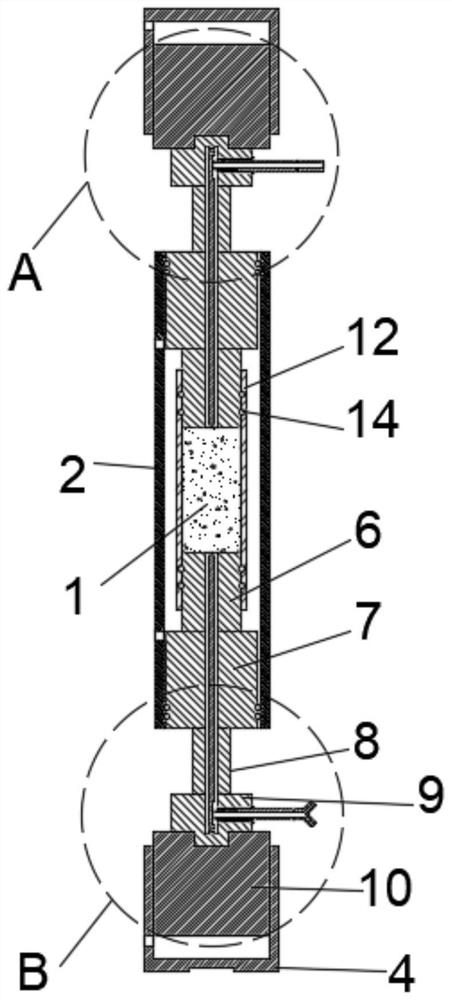

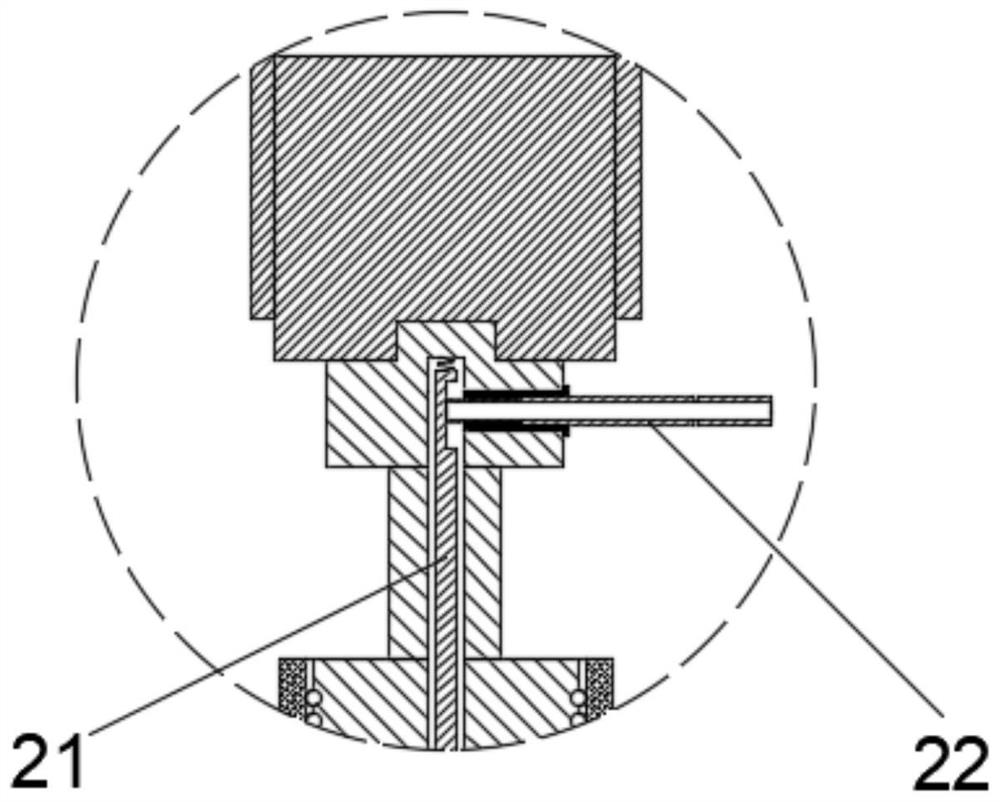

The invention discloses a spindle system for realizing friction surfacing with a shaft shoulder. The spindle system comprises a round bar consumable, a cylindrical shell, a hollow spindle, a shaft sleeve, a self-locking clamping mechanism and a rigid shaft sleeve, wherein the hollow spindle is coaxial with the cylindrical shell and is arranged in the cylindrical shell, and the shaft sleeve slides up and down along an inner hole of the hollow spindle; and the self-locking clamping mechanism is fixed to the lower end of the hollow spindle. The upper end of the round bar consumable is fixed to the shaft sleeve, and the lower end of the round bar consumable contacts with the surface of a workpiece through the self-locking clamping mechanism and the rigid shaft sleeve. When the hollow spindle rotates at high speed, the round bar consumable and the rigid shaft sleeve are driven by the shaft sleeve and the self-locking clamping mechanism at the lower end to rotate at high speed, and the shaft sleeve moves down along the hollow spindle at the same time, so that the round bar consumable rotates at high speed while can move down along the axial direction. The rigid shaft sleeve plays a role of friction and extrusion without consuming the shaft shoulder, and therefore the friction surfacing process with the shaft shoulder is realized. The spindle system can improve the use ratio of the round bar consumable and effectively eliminates the weak connection defect of the edge of a traditional friction surfacing layer, and thereby obtaining the friction surfacing layer with a good mechanical property.

Owner:TIANJIN UNIV

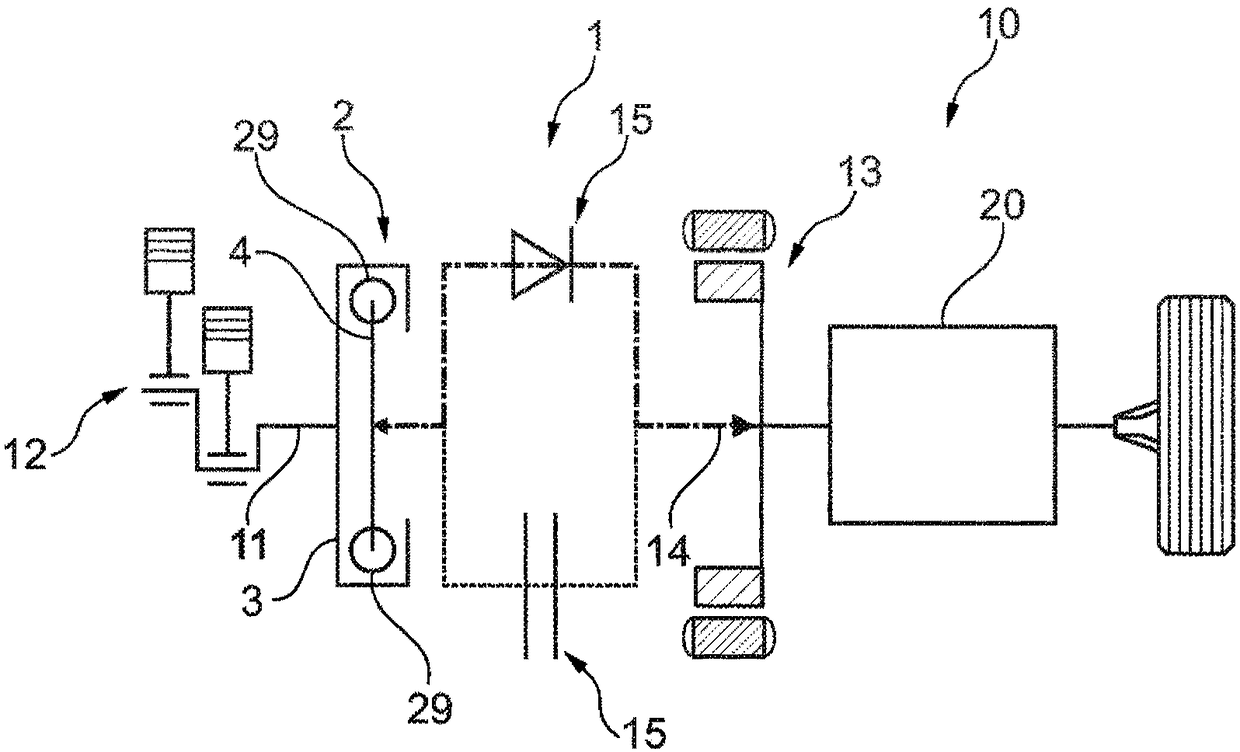

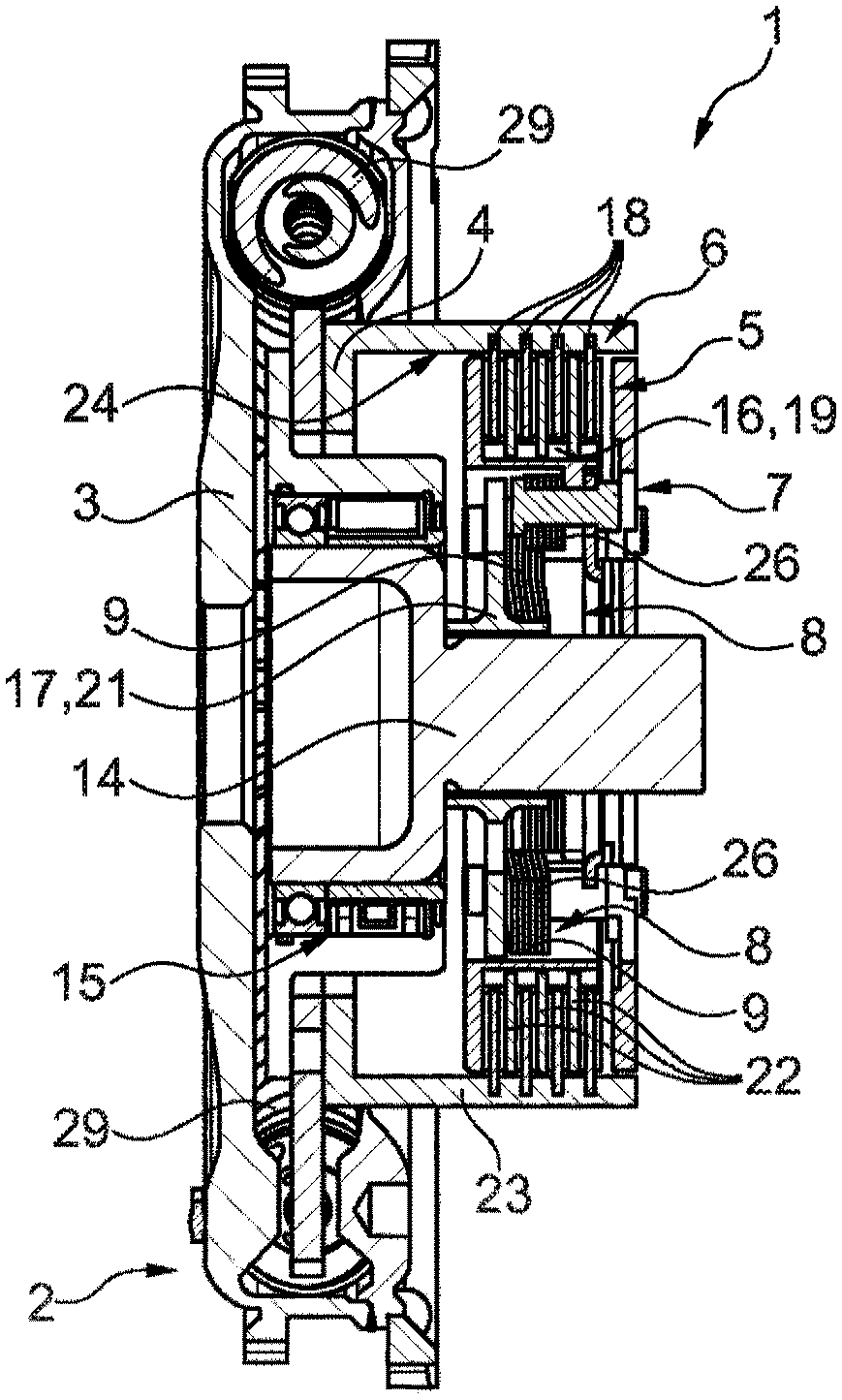

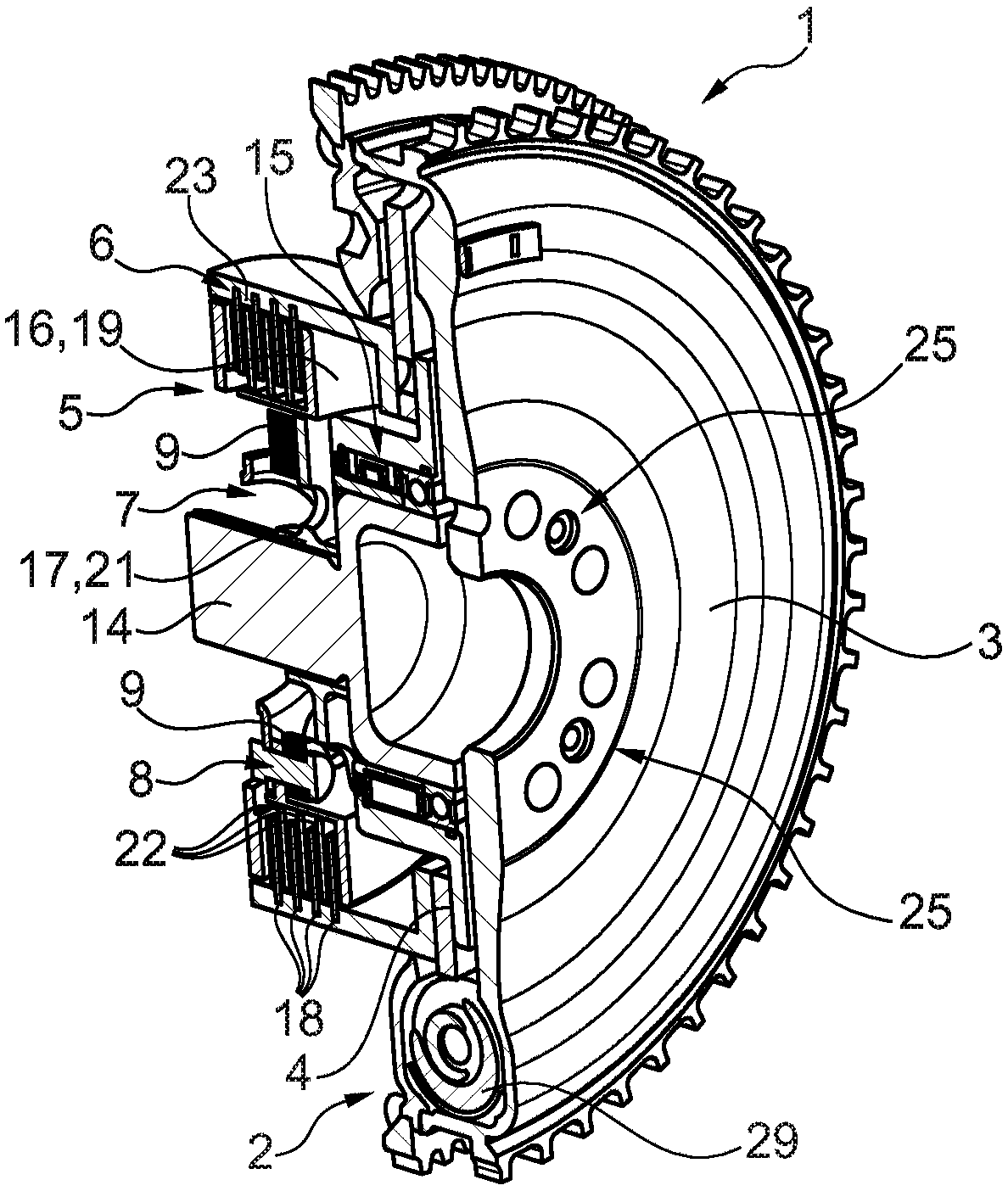

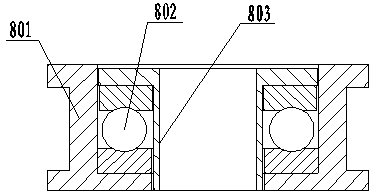

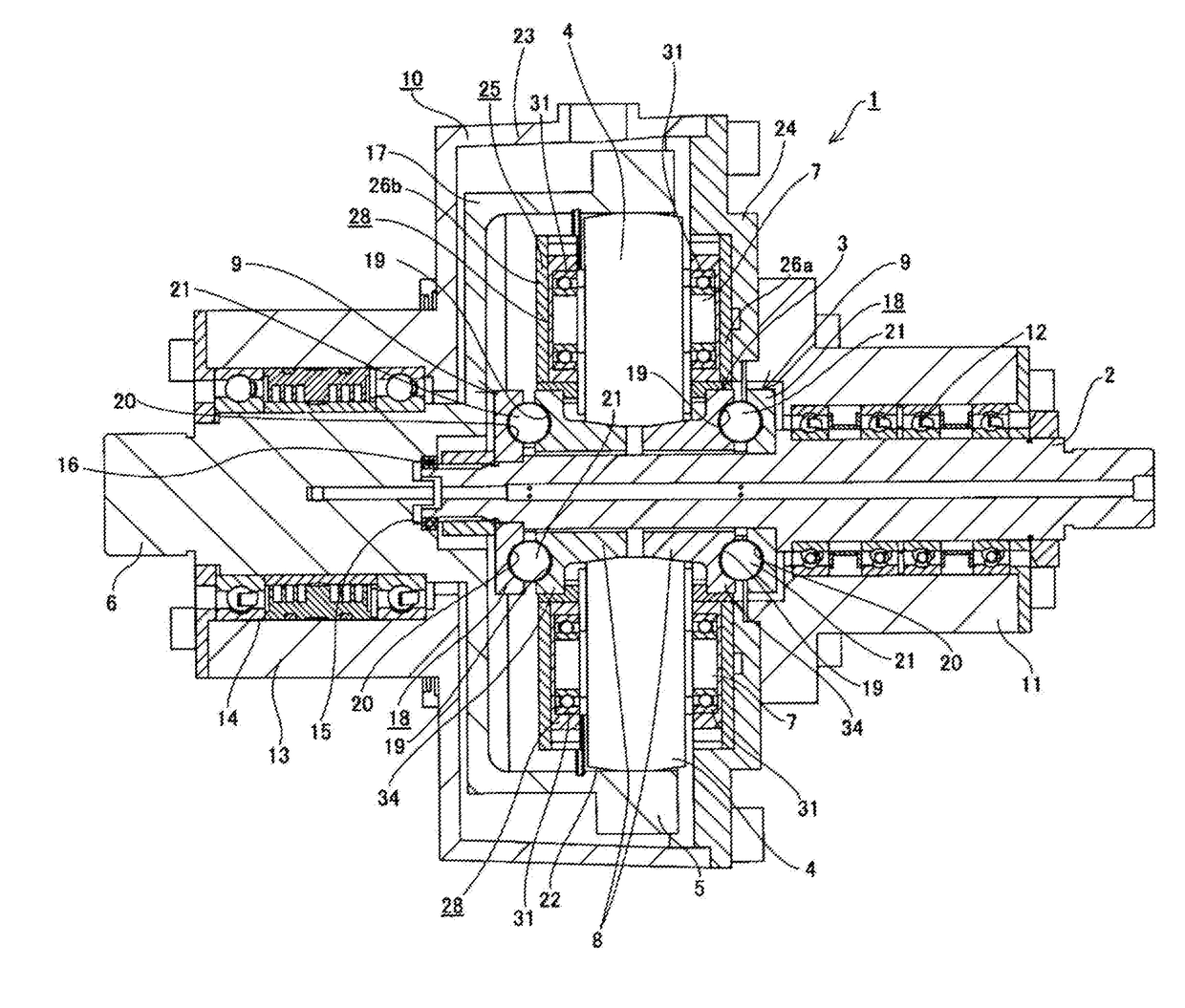

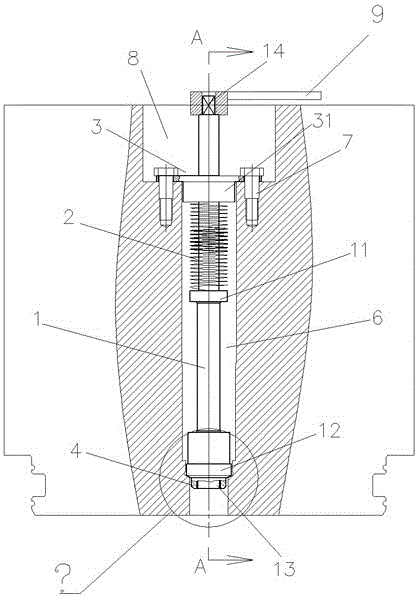

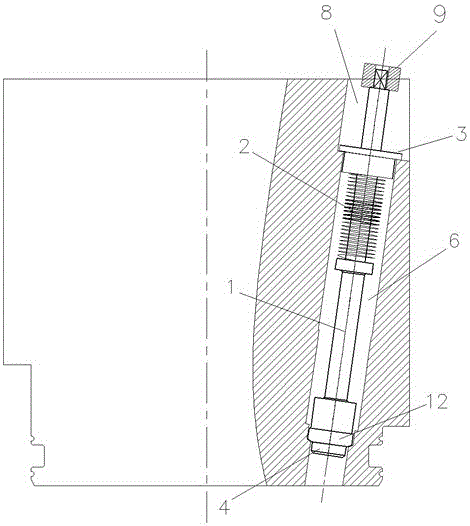

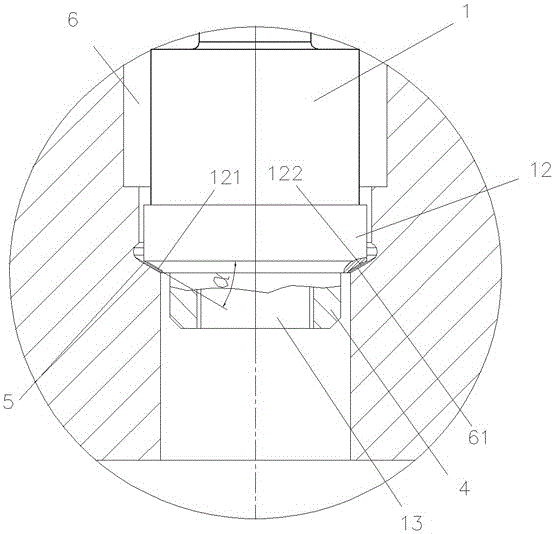

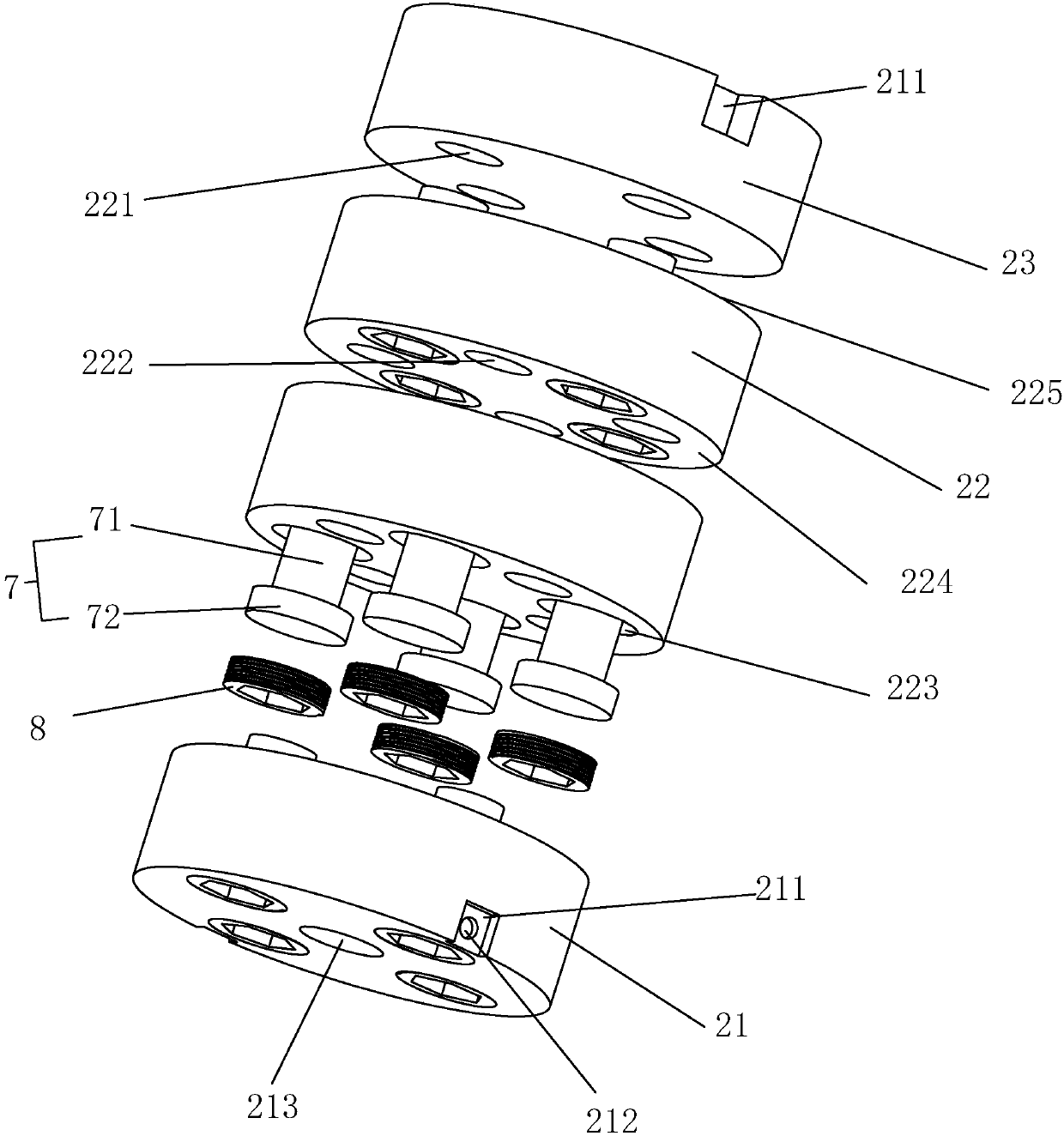

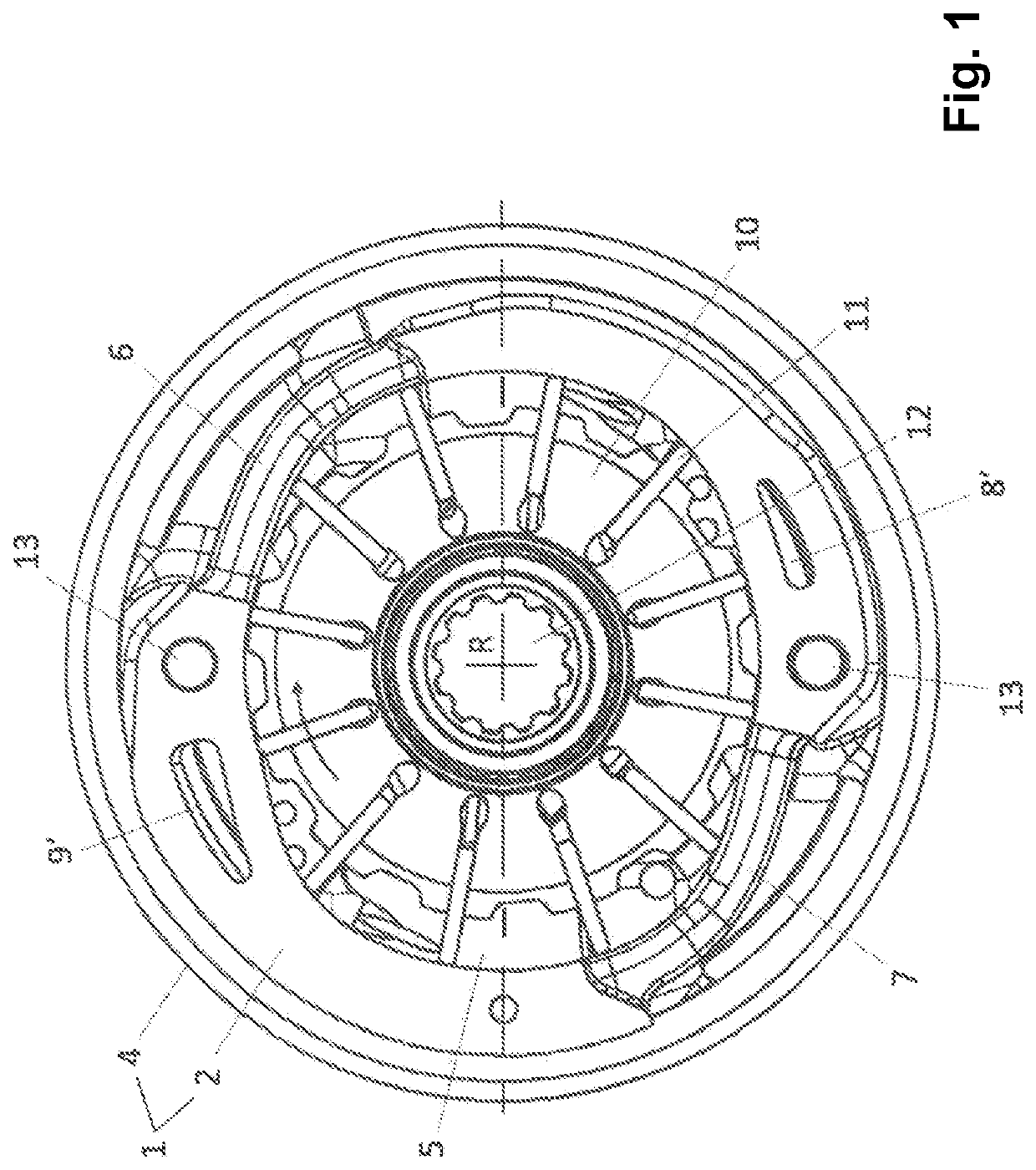

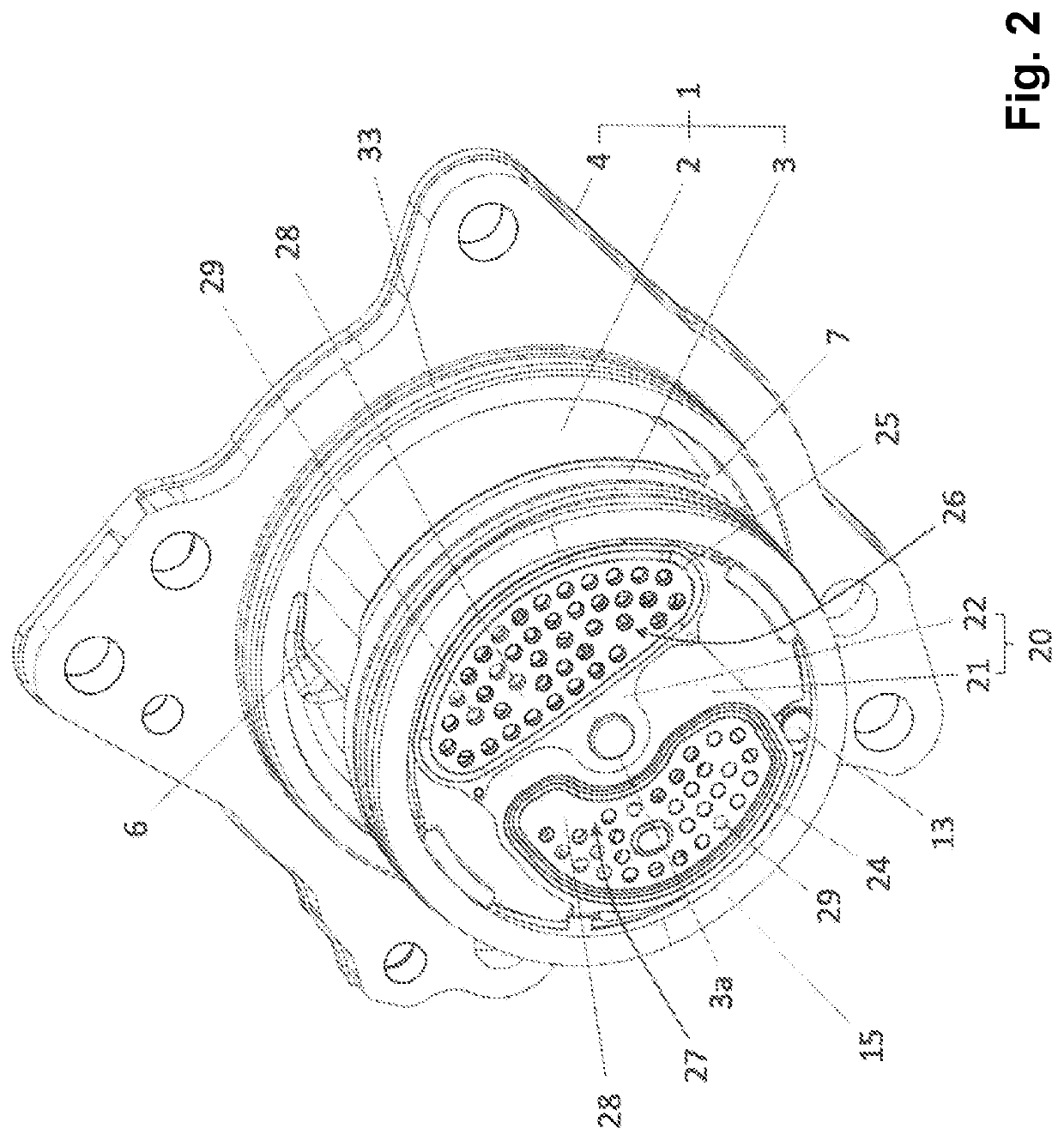

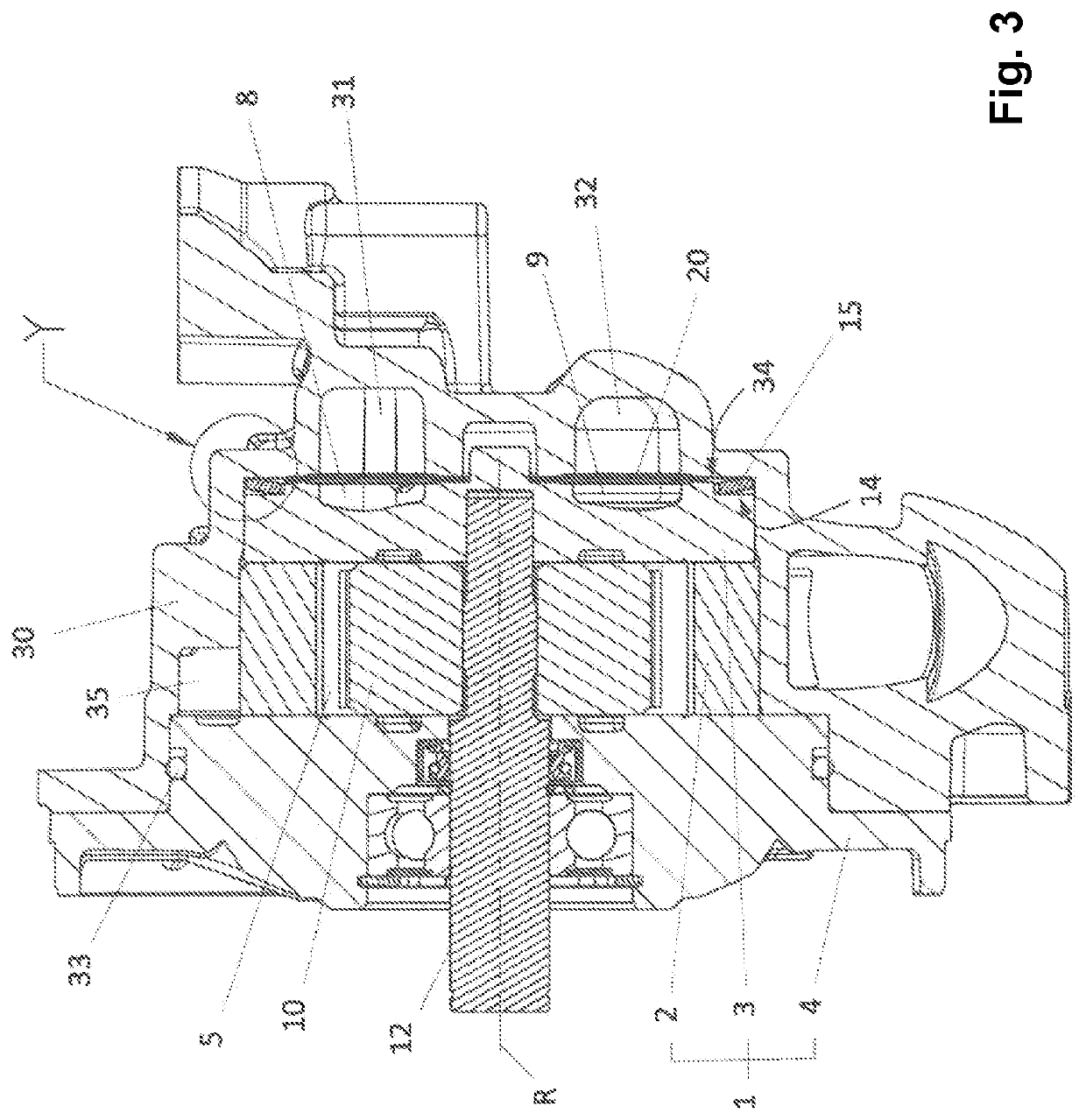

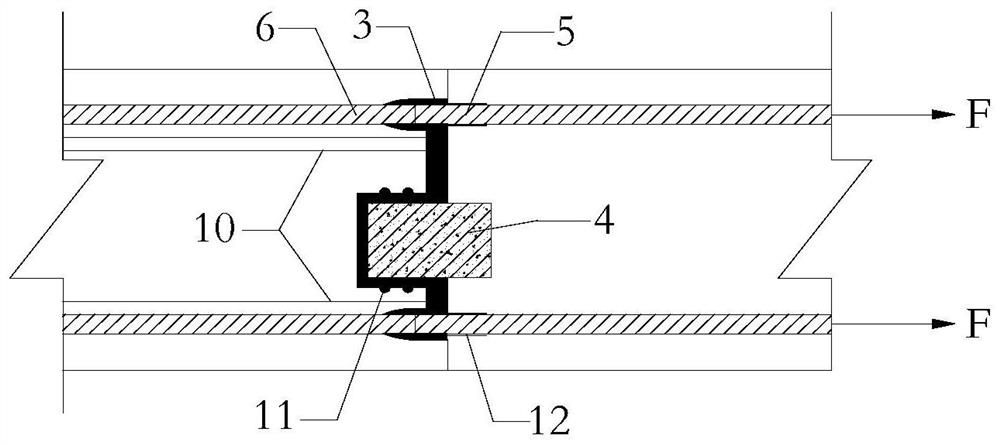

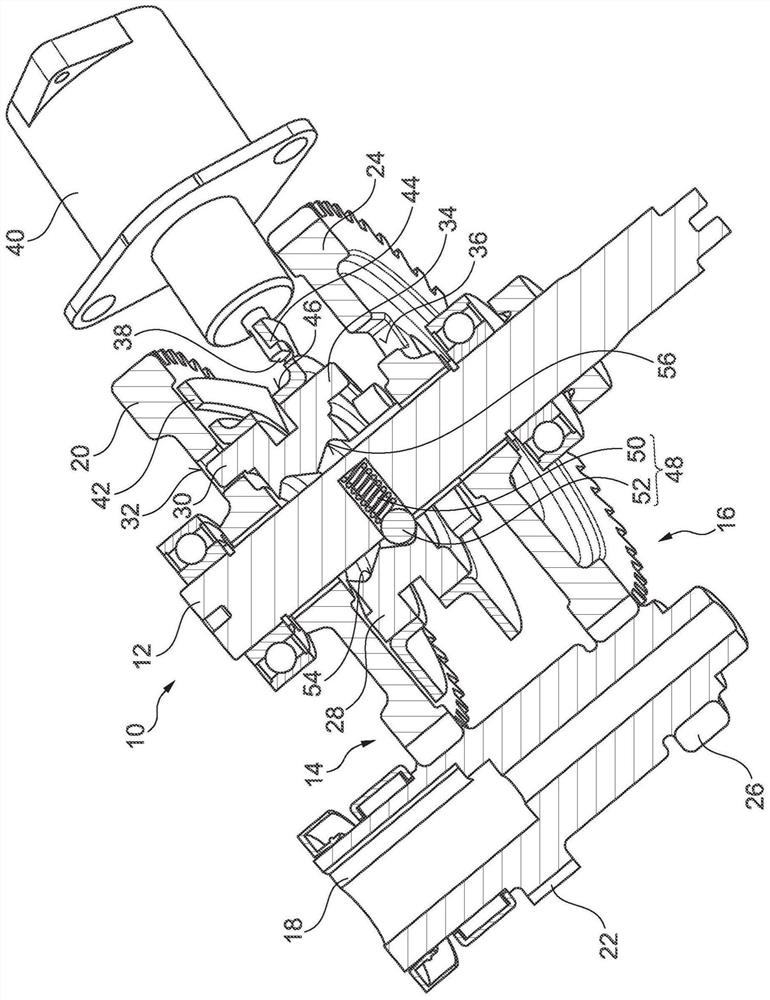

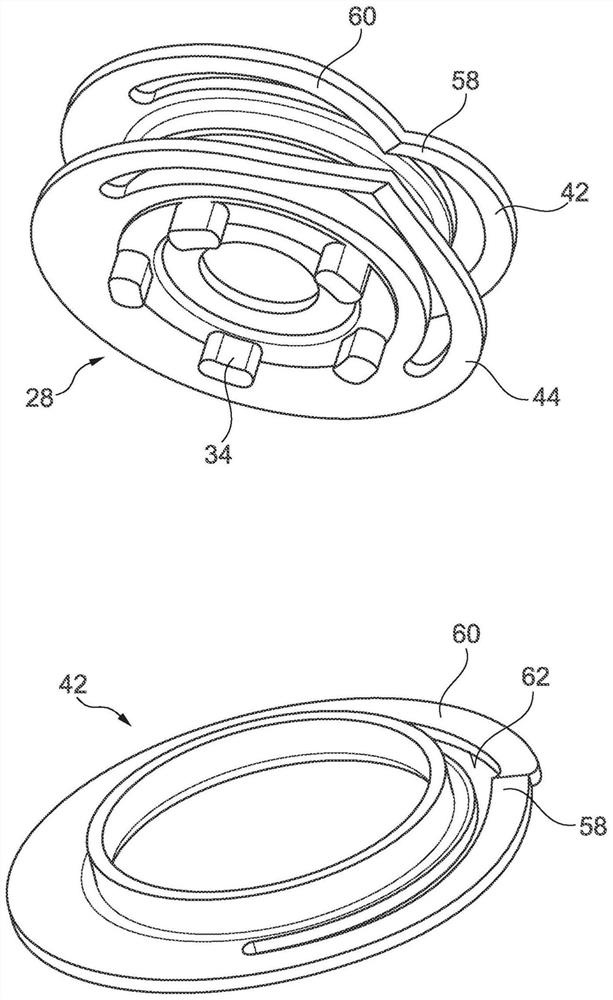

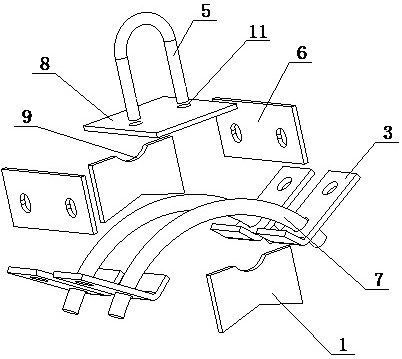

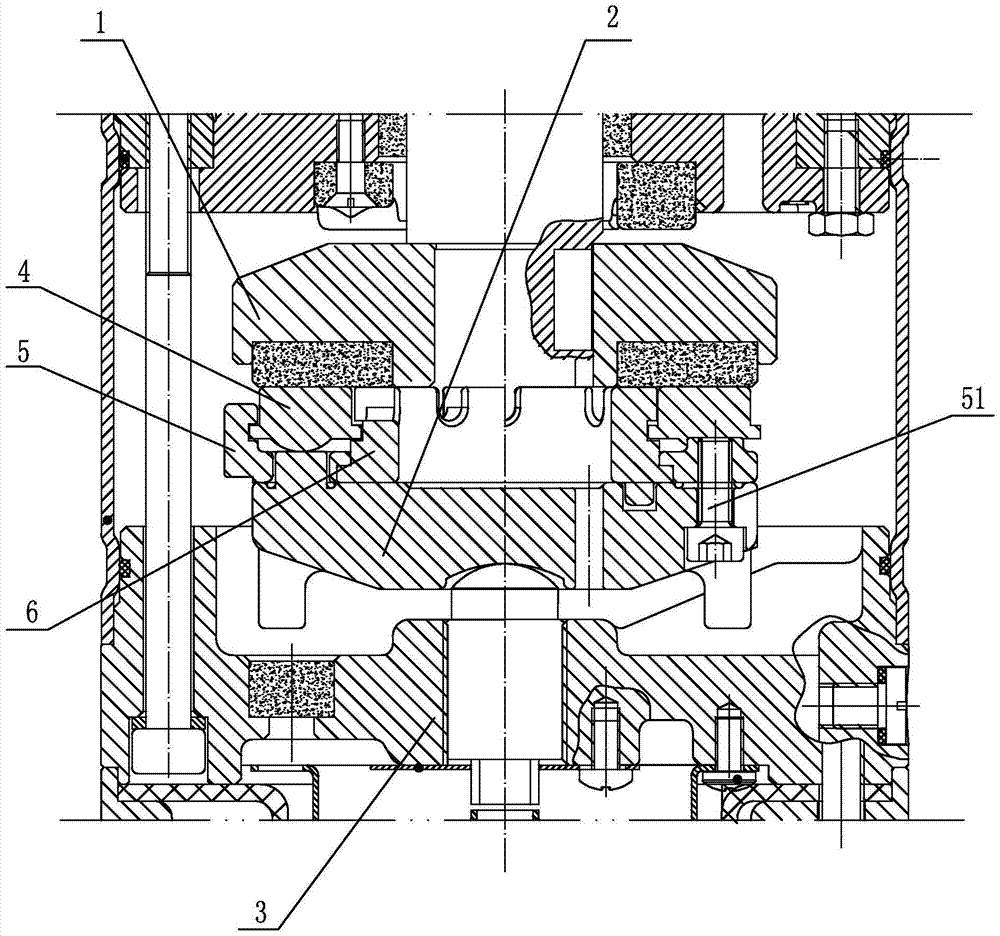

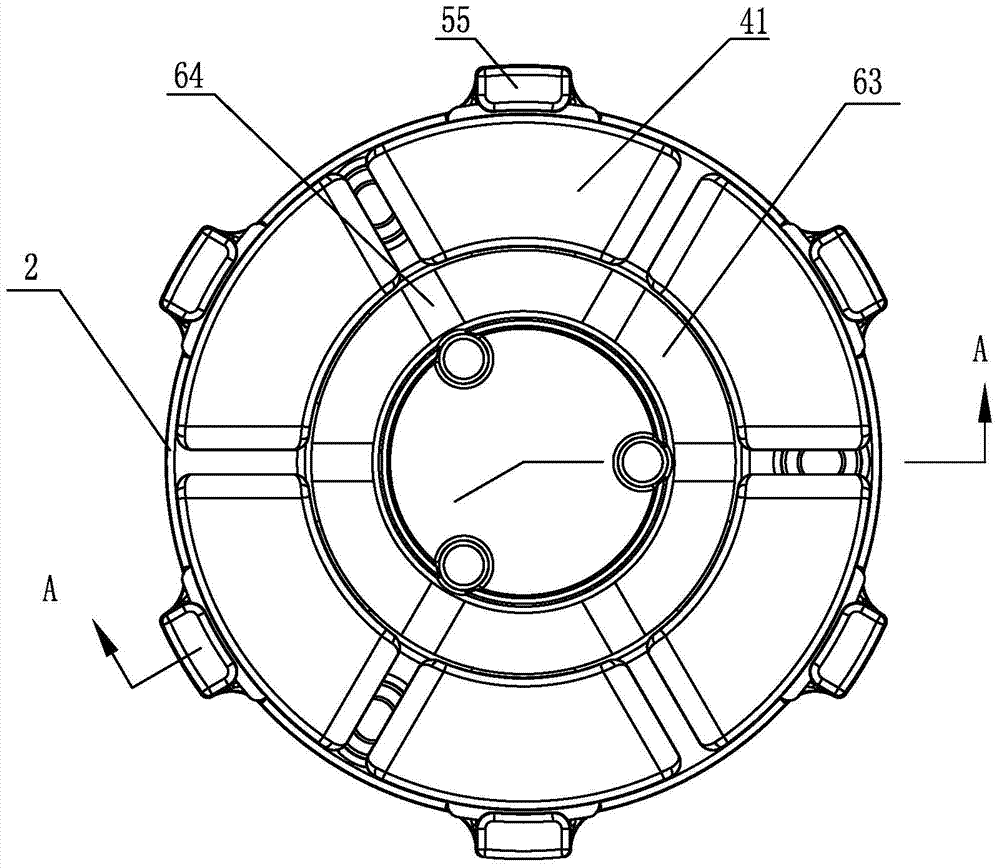

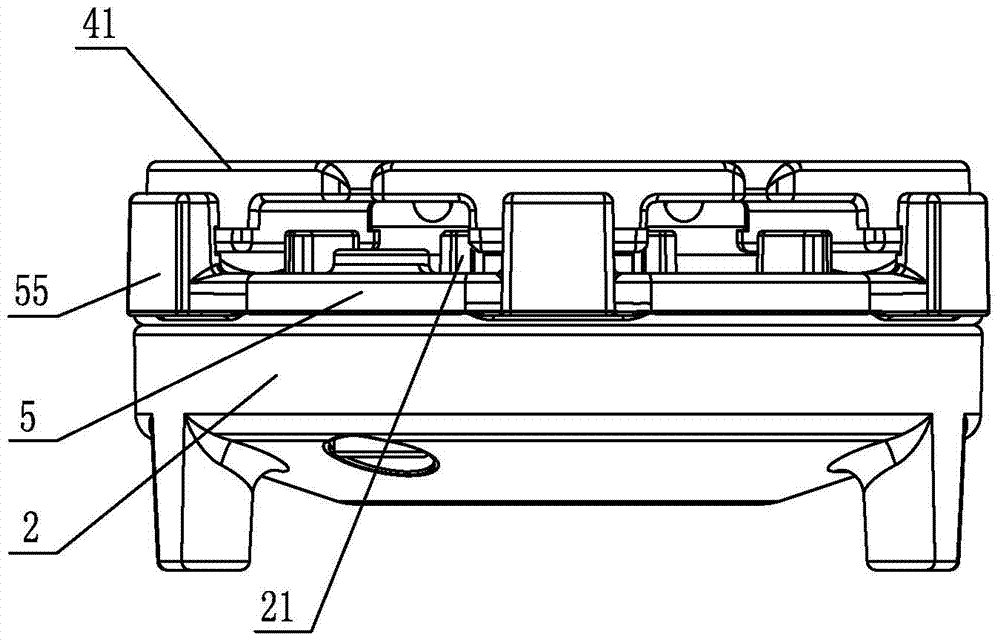

Clutch rotary vibration damper assembly having hybrid separating clutch integrated in rotating part of rotary vibration damper

ActiveCN108138869ACompact designSave spaceHybrid vehiclesFluid actuated clutchesTorsional vibrationVibration damper

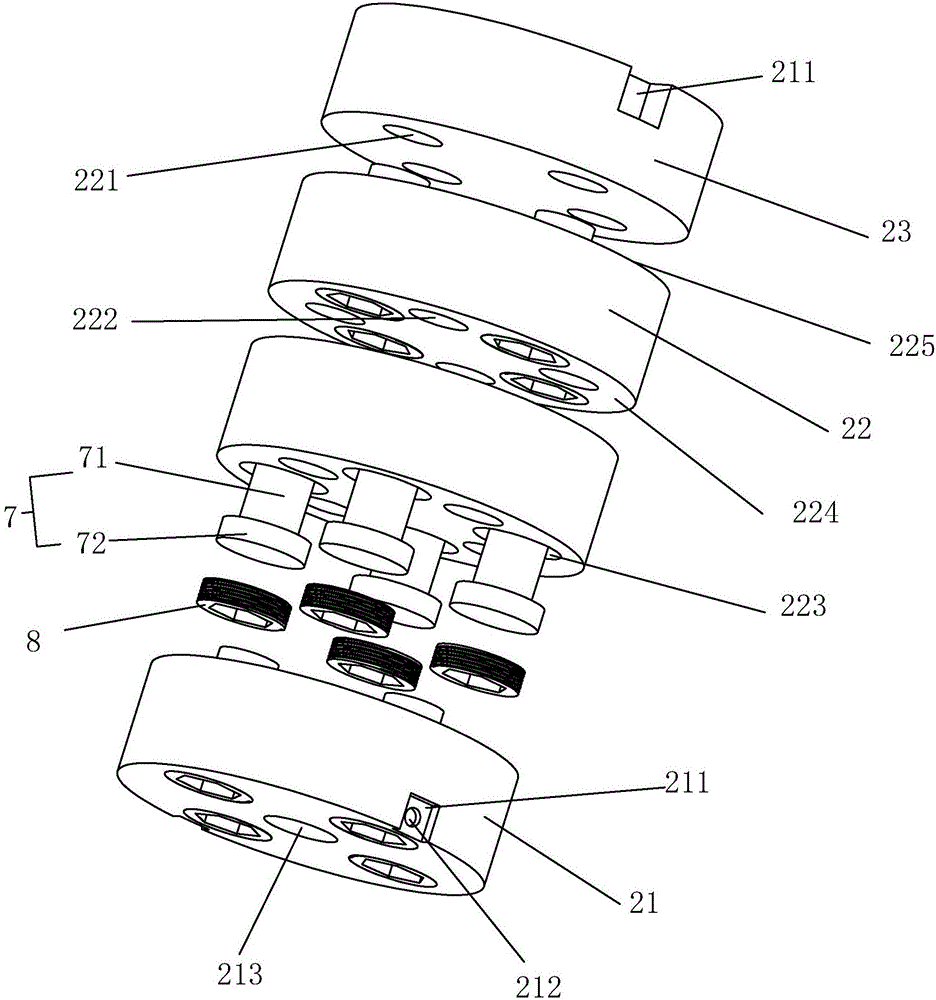

The invention relates to a clutch rotary vibration damper assembly (1) for a hybrid drive train (10) of a motor vehicle, having a rotary vibration damper (2) and a clutch device (5). The rotary vibration damper (2) comprises two rotating parts (3, 4) rotationally fixedly connected to each other, wherein the first rotating part (3) is prepared for the rotationally fixed connection to an output shaft (11) of an internal combustion engine (12), and the second rotating part (4) is arranged relative to the first rotating part (3) in a damped manner in a rotational movement. The clutch device (5) isfitted to the second rotating part (4) by a first clutch component (6), which, in an engaged position of the clutch device (5), is rotationally fixedly connected to the second clutch component (7). Aleaf spring unit (8) is fitted in the second clutch component (7) in such a way that, in a first direction of rotation of the first clutch component (6) relative to the second clutch component (7), said leaf spring unit (8) introduces an additional axial pressing force to press the clutch components (6, 7) against each other. The invention also relates to the drive train (10) of a motor vehicle,having the clutch rotary vibration damper assembly (1).

Owner:SCHAEFFLER TECH AG & CO KG

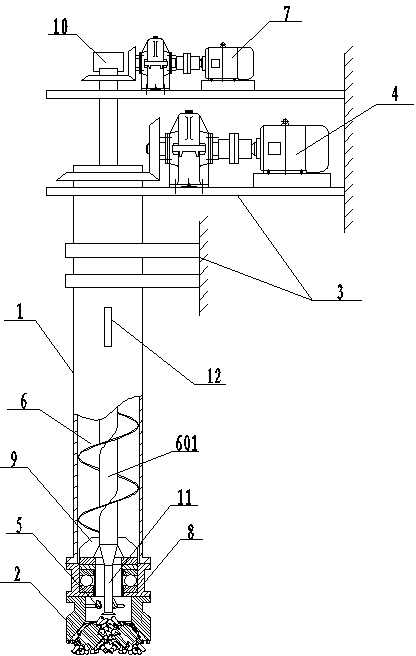

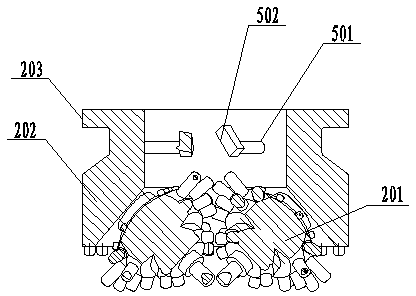

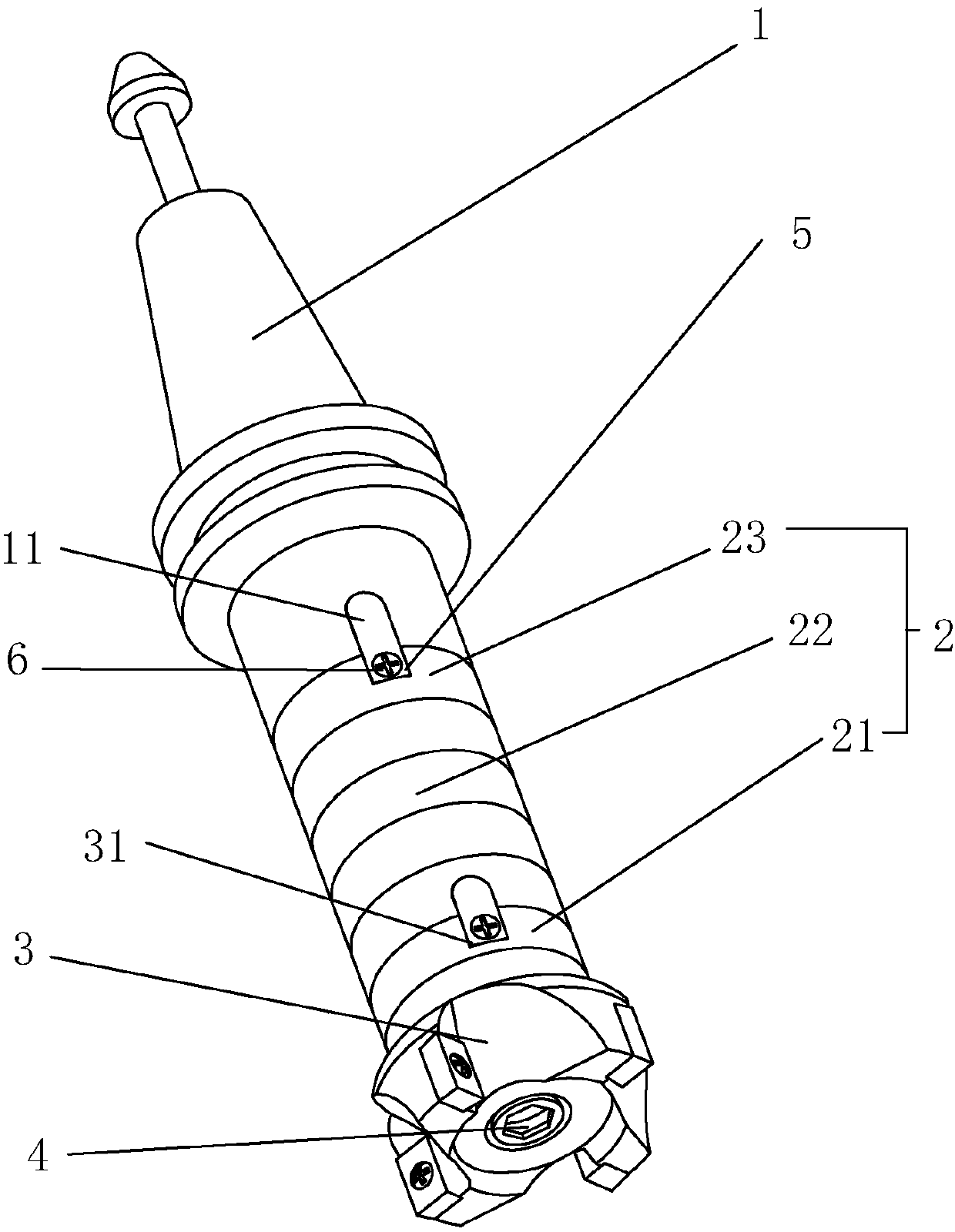

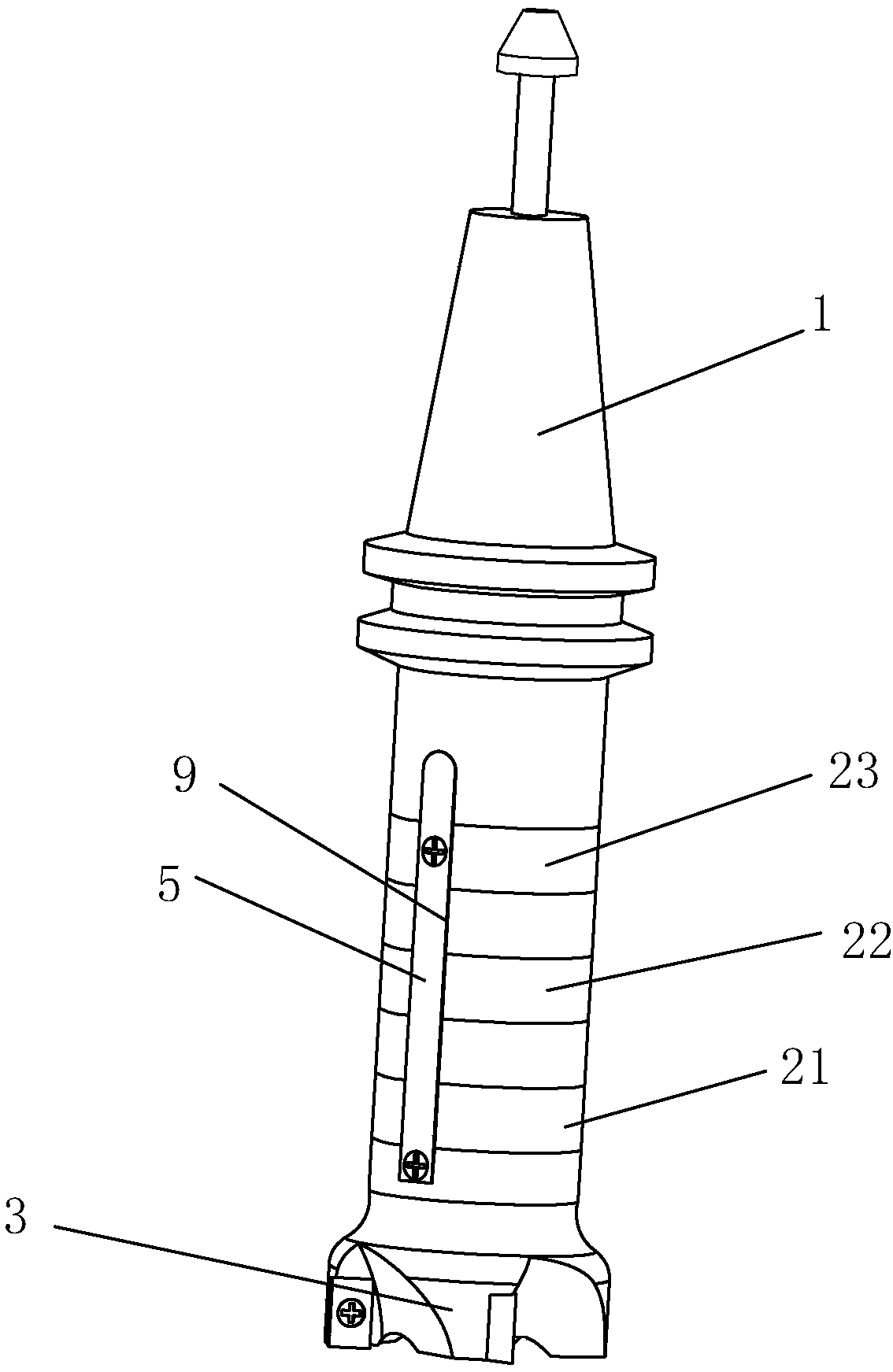

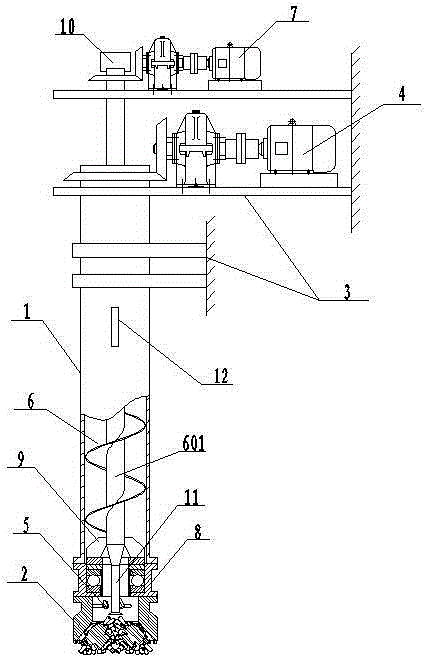

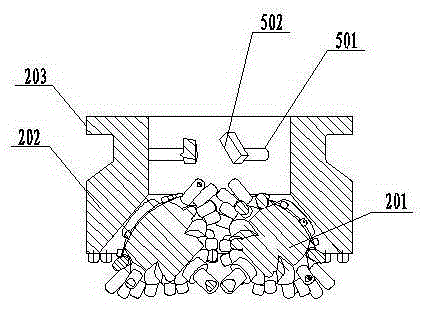

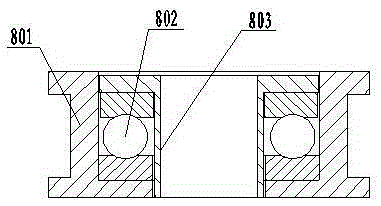

Drilling machine for exploiting shale gas

InactiveCN104120972AImprove securityPromote environmental protectionDrilling machines and methodsDrive motorOil shale gas

A drilling machine for exploiting shale gas comprises a drill stem, a drill bit, a power mechanism and a support. The drill bit is composed of a drill bit body and a plurality of cones arranged on the drill bit body, the drill bit body comprises a cylindrical sleeve and a flange connecting end, the flange connecting end is connected with one end of the drill stem through a connecting module, the drill stem is of a hollow shaft structure, a spiral mechanism is arranged in an inner cylindrical hole in the drill stem, one end of a main shaft of the spiral mechanism is connected with an output shaft of a drive motor through a transmission component, the other end of the main shaft is arranged in the inner cylindrical hole in the drill stem through a supporting mechanism, the main shaft is of a hollow shaft structure, and a cooling liquid injection device and a cooling liquid sprayer are arranged on the main shaft. According to the drilling machine, the drill bit mechanism and the connecting module of the drill bit and the drill stem are precisely designed, the spiral mechanism is arranged in the inner cavity of the vertical drill stem, rock debris is discharged through sliding friction, high-pressure flushing liquid is of no need, a large amount of energy is saved, and safety and environment friendliness of the drilling machine are greatly improved.

Owner:董书朋

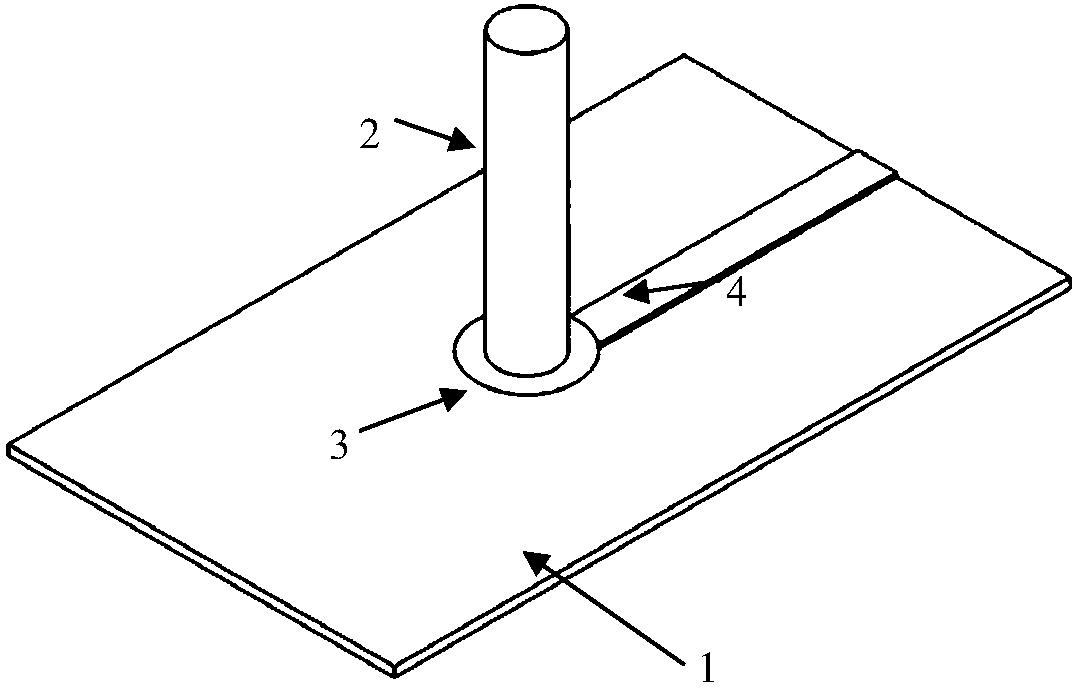

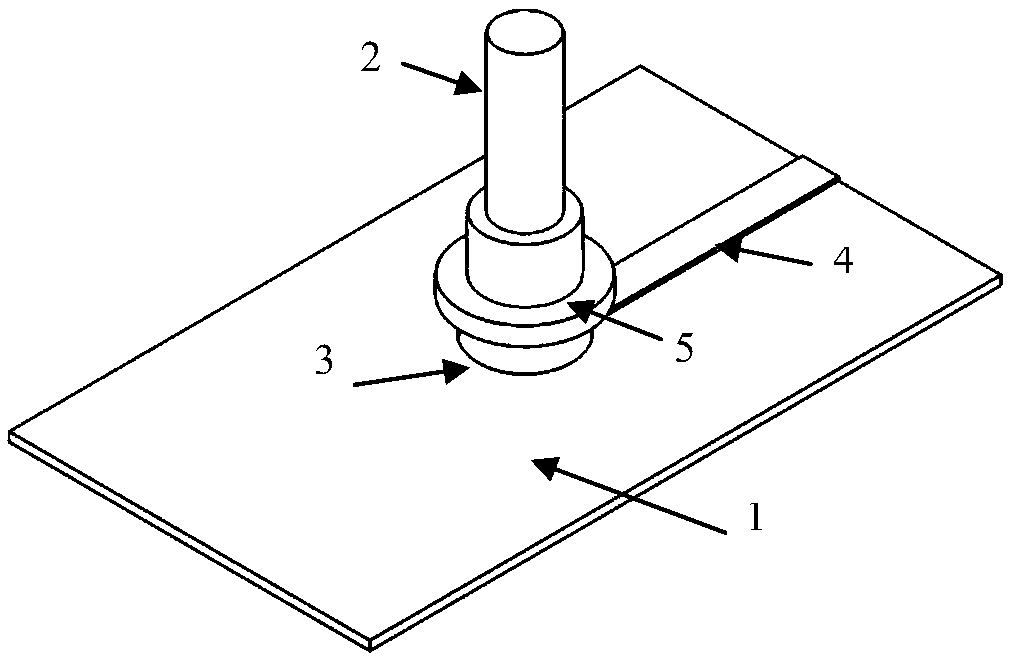

Composite roll and preparation method thereof

InactiveCN107225152AEasy accessIncrease axial pressureRollsMetal rolling arrangementsAxial pressureEngineering

The invention provides a composite roll. The composite roll comprises a roll shaft and roll rings arranged on the roll shaft in a sleeving manner. The roll shaft and the roll rings are in clearance fit. A nut is arranged at the position, on one side of each roll ring, of the roll shaft and is closely attached to the corresponding roll ring, and axial pressing force is applied to the roll rings by the nut. The invention further relates to a preparation method of the above composite roll. The preparation method comprises the following steps that A, the roll rings are arranged on the roll shaft in the sleeving manner, and the roll rings and the roll shaft are in clearance fit; B, the nuts are screwed in and mounted on one side of the roll shaft, and the nuts are attached to the roll rings in the axial direction; C, axial pressure is applied to the end faces of the roll rings, the roll rings can move in the axial direction, and the distance between each nut and the corresponding roll ring is increased; D, each nut is rotated to move towards the corresponding roll ring and is closely attached to the corresponding roll ring; E, the axial pressure is removed; and F, the nuts apply the axial pressing force to the end faces of the roll rings, and the roll rings are fixed to the roll shaft. The rolling torque is transmitted.

Owner:ZIGONG CEMENTED CARBIDE CORP

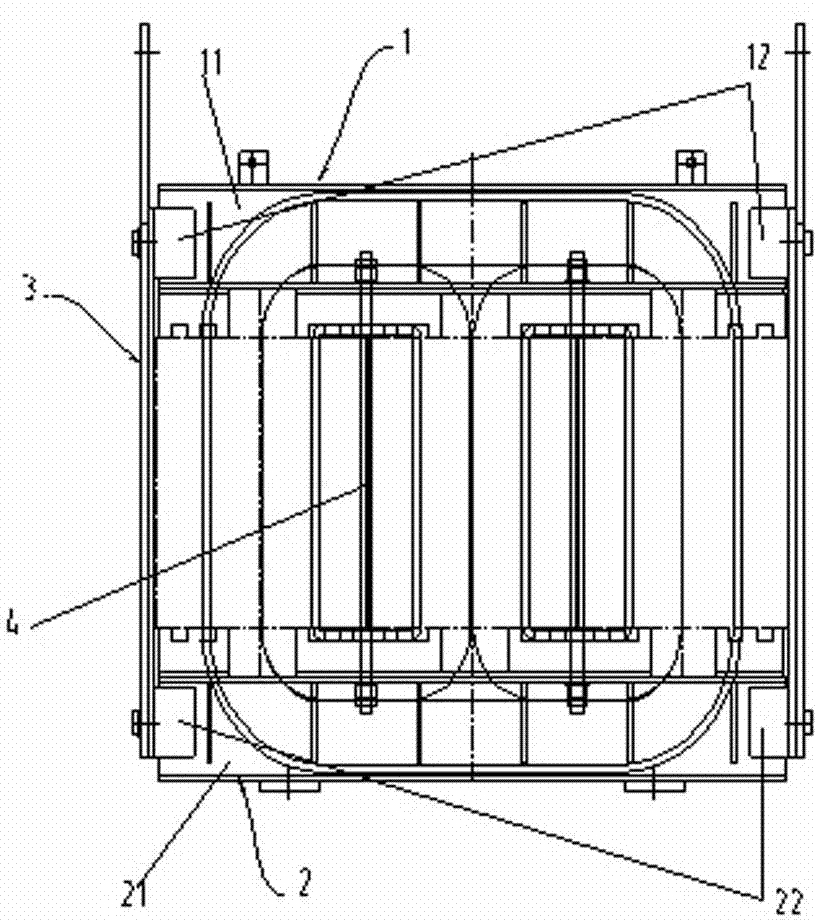

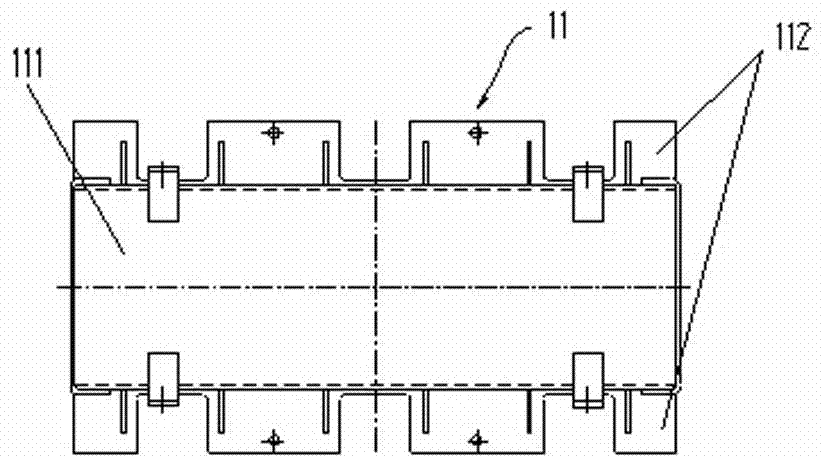

Transformer body structure

InactiveCN103050236AAchieve axial compressionIncrease axial pressureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerFlux loop

The invention relates to a transformer body structure, in particular to a body structure of an open type winding iron core transformer. The transformer body structure comprises a magnetic flux loop formed by splicing multiple silicon steel sheets, an upper clamping part arranged on the upper portion of the magnetic flux loop, a lower clamping part arranged on the lower portion of the magnetic flux loop and two side plates positioned on the left and right sides of the body structure, the upper clamping part comprises an upper body and upper fixed plates fixedly arranged on the left and right sides of the upper body, the lower clamping part comprises a lower body and lower fixed plates fixedly arranged on the left and right sides of the lower body, the side plates are detachable and connected with the upper fixed plates and the lower fixed plates respectively, a storage space of the magnetic flux loop is formed among the upper clamping part, the two side plates and the lower clamping part, and a connecting mechanism capable of being in detachable connection is arranged between the upper clamping part and the lower clamping part. The transformer body structure is compact in structure, high in strength, small in noise and high in short-circuit resistance.

Owner:WUJIANG TRANSFORMER CO LTD

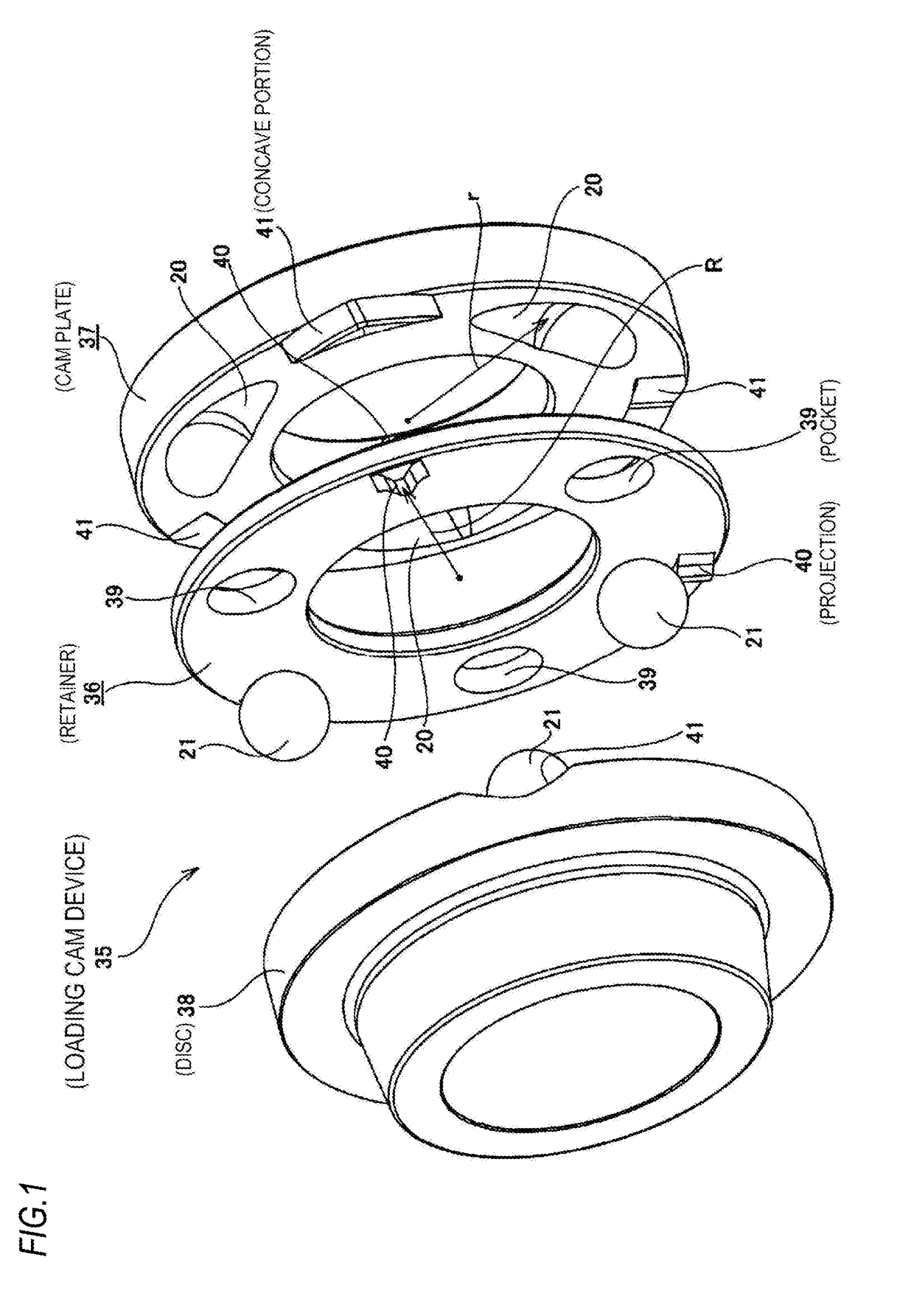

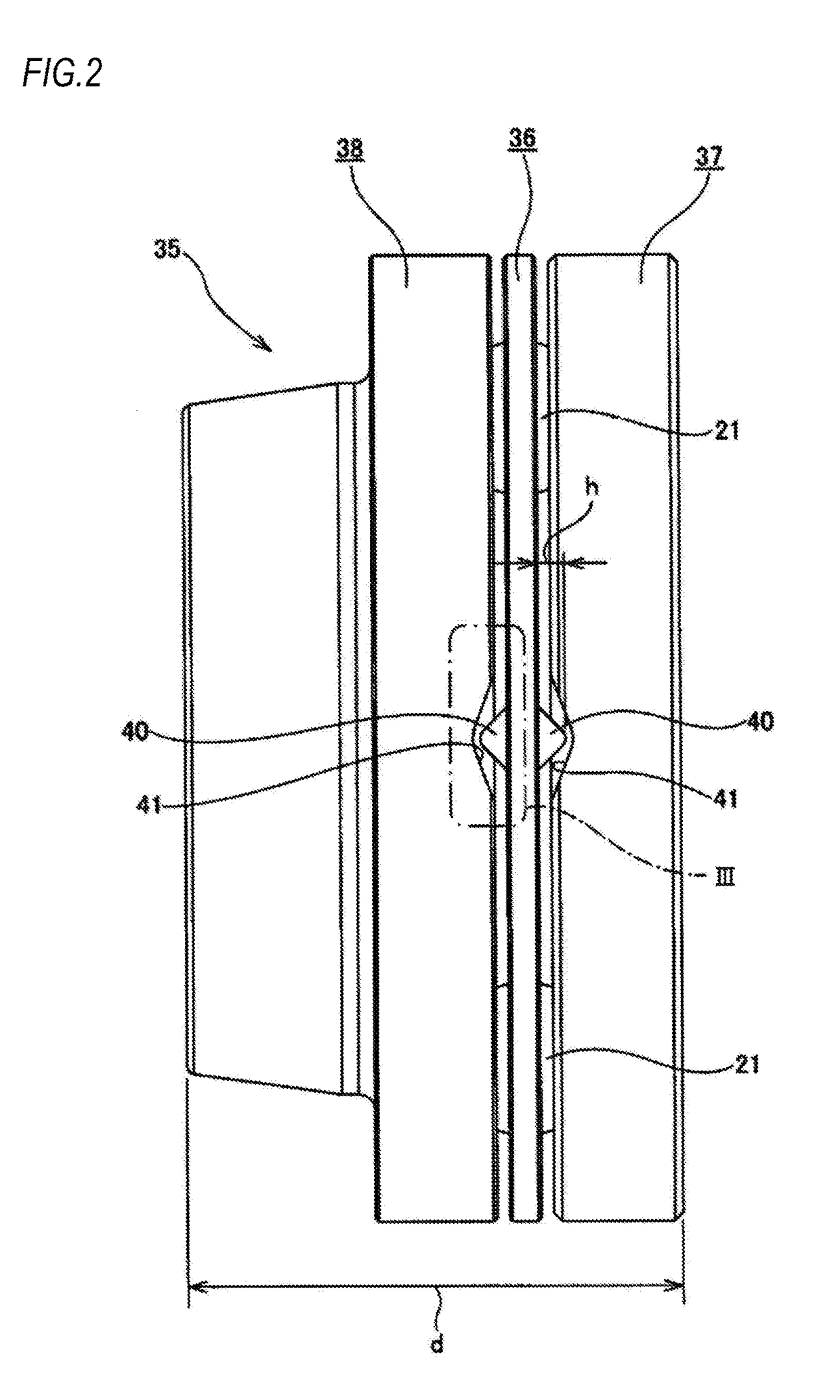

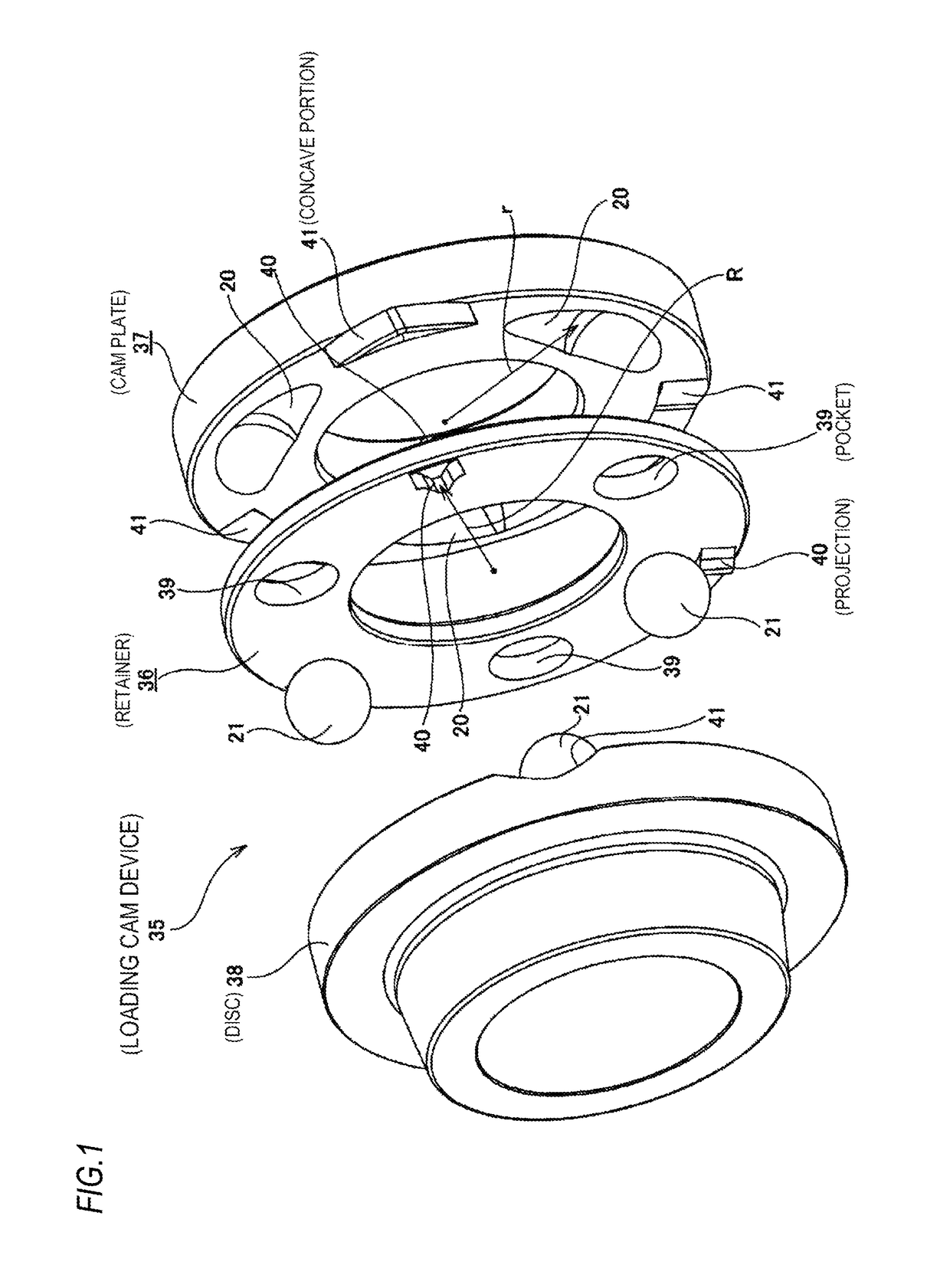

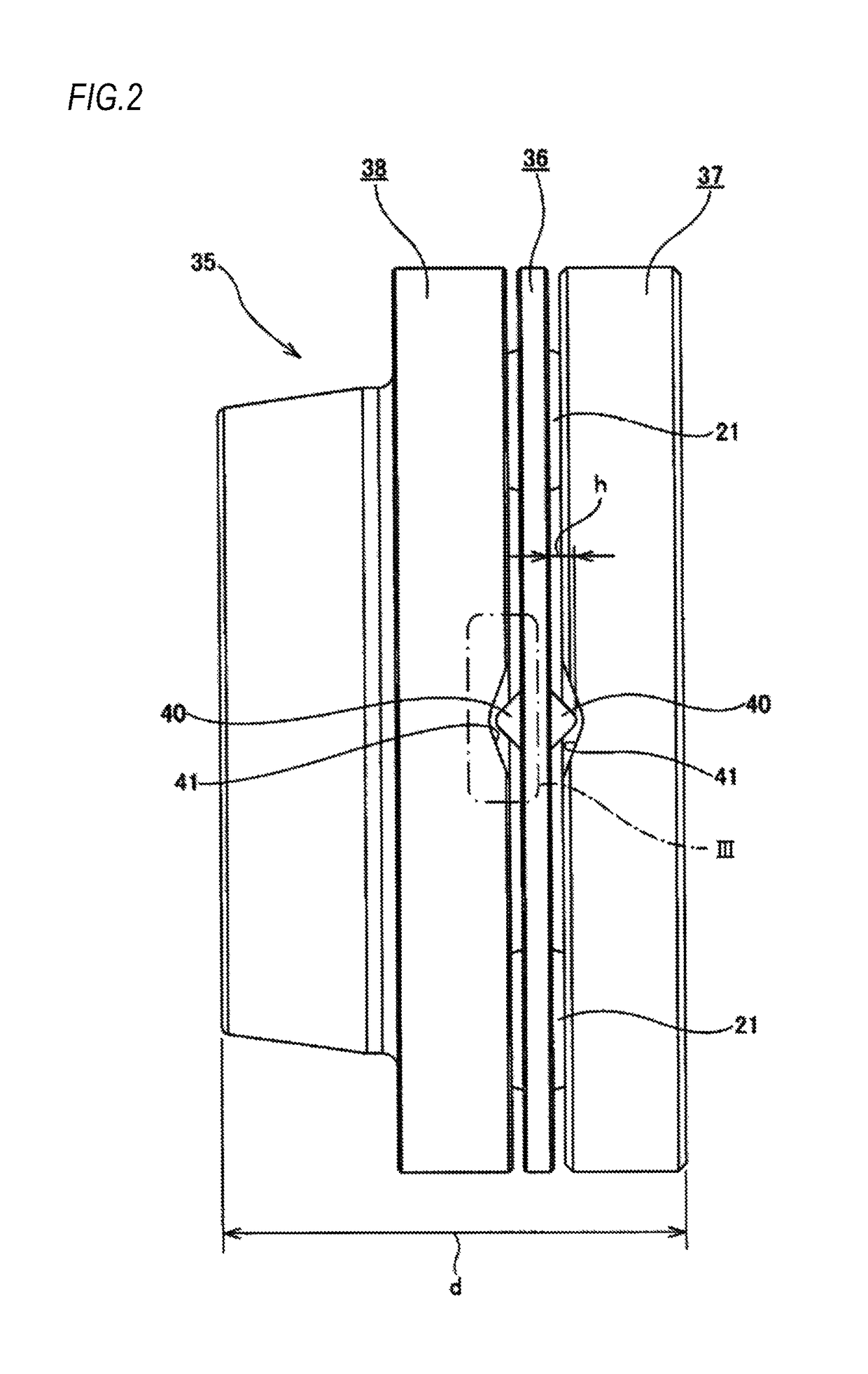

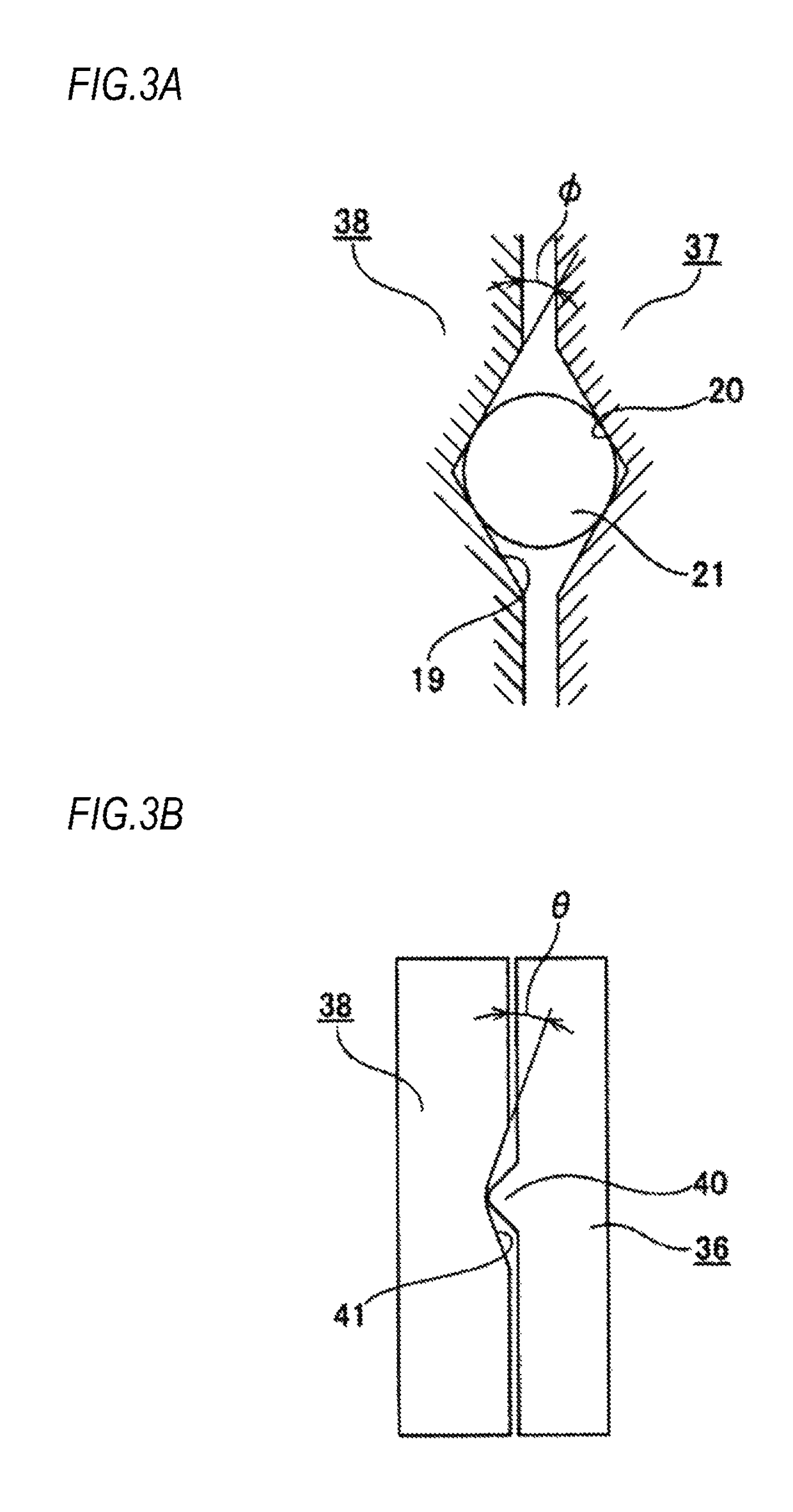

Loading cam device and friction roller-type speed reducer

Projections protruding towards a cam plate and a disc are provided on both axial side surfaces of the retainer at a plurality of positions at which phases of the projections in the circumferential direction are offset from pockets. One axial direction surface of the cam plate and the disc are formed with concave portions at portions facing the respective projections. The concave portions have an axial depth deepest at a center portion thereof in the circumferential direction and becoming shallower towards both end portions thereof.

Owner:NSK LTD

Milling cutter special for numerical control milling machine

The invention discloses a milling cutter special for a numerical control milling machine. The milling cutter comprises a cutter handle and a cutter bit. The cutter bit is provided with a connecting groove. A threaded hole is formed in the connecting groove. A clamping connecting groove is formed in the cutter handle. An extension section is arranged between the cutter handle and the cutter bit. The two end portions of the extension section are provided with matching grooves. A connecting block is arranged between the corresponding matching groove and the connecting groove, and a connecting block is arranged between the corresponding matching groove and the clamping connecting groove. The connecting blocks are provided with installation holes matched with the threaded hole. The corresponding connecting block and the cutter handle are connected through a first fastener matched with the threaded hole, and the corresponding connecting block and the cutter bit are connected through a first fastener matched with the threaded hole. The extension section is provided with a center hole used for being connected with the cutter bit. The extension section and the cutter bit are connected by arranging a second fastener matched with the center hole. According to the purpose, the milling cutter special for the numerical control milling machine is provided, it is ensured that small parts can still be machined in the situation that the distance between a main shaft and a clamp is increased by increasing the overall length of the milling cutter, the position of the main shaft does not need to be repeatedly adjusted, the machining process is simplified, and the work efficiency is improved.

Owner:浙江海拓环宇传动科技有限公司

Grinding tool for starting valve hole of diesel engine cylinder head

The invention discloses a grinding tool for a starting valve hole of a diesel engine cylinder head. The grinding tool comprises a grinding main shaft, a spring, a pressure plate and a locking nut; the lower end of the grinding main shaft extends out of a grinding head in a radial direction; the lower end of the grinding head downwards extends out of a stud; a locking nut is screwed on the stud; a bottom conical ring surface of the grinding head is matched with a to-be-ground conical ring surface on the bottom of the starting valve hole; the spring is arranged on the middle part of the grinding main shaft in a sleeved manner; the bottom of the spring abuts against a spring supporting table shoulder; a pressure plate is arranged on the upper part of the grinding main shaft in a sleeved manner; the two ends of the pressure plate are fixedly arranged on a cylinder head settling table; and the top of the spring abuts against a lug boss at the lower side of the pressure plate. The grinding tool is simple in structure, is low in cost, is convenient to operate, and solves the problem that the bottom surface of an inclined deep hole cannot be ground by a machine tool; and moreover, the cylinder head does not need to be dismounted, and is specially put to a perpendicular position of the starting valve hole, so that processing time is greatly shortened, production efficiency is improved, and processing quality for the starting valve hole of the diesel engine cylinder head is greatly improved.

Owner:CSSC MARINE POWER

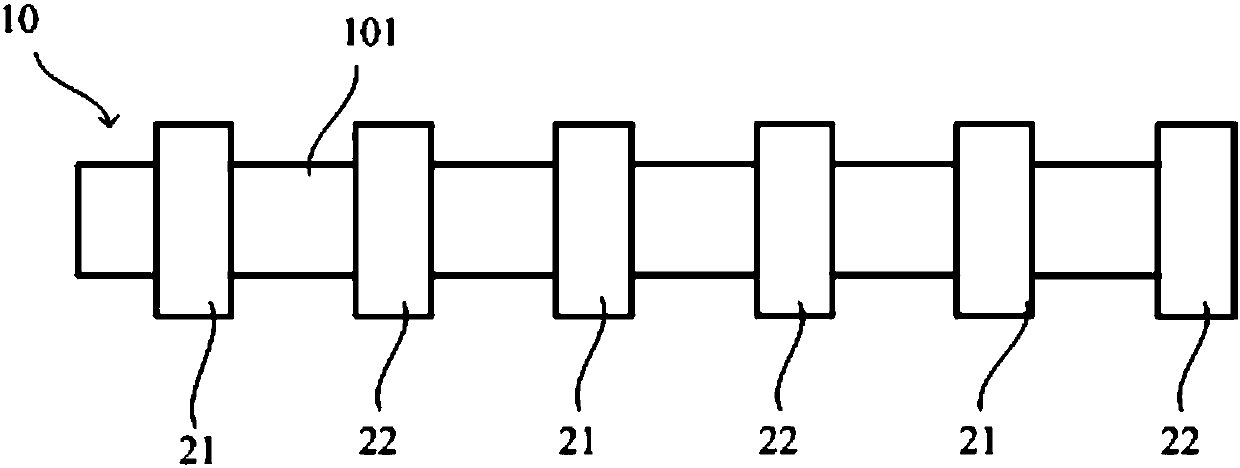

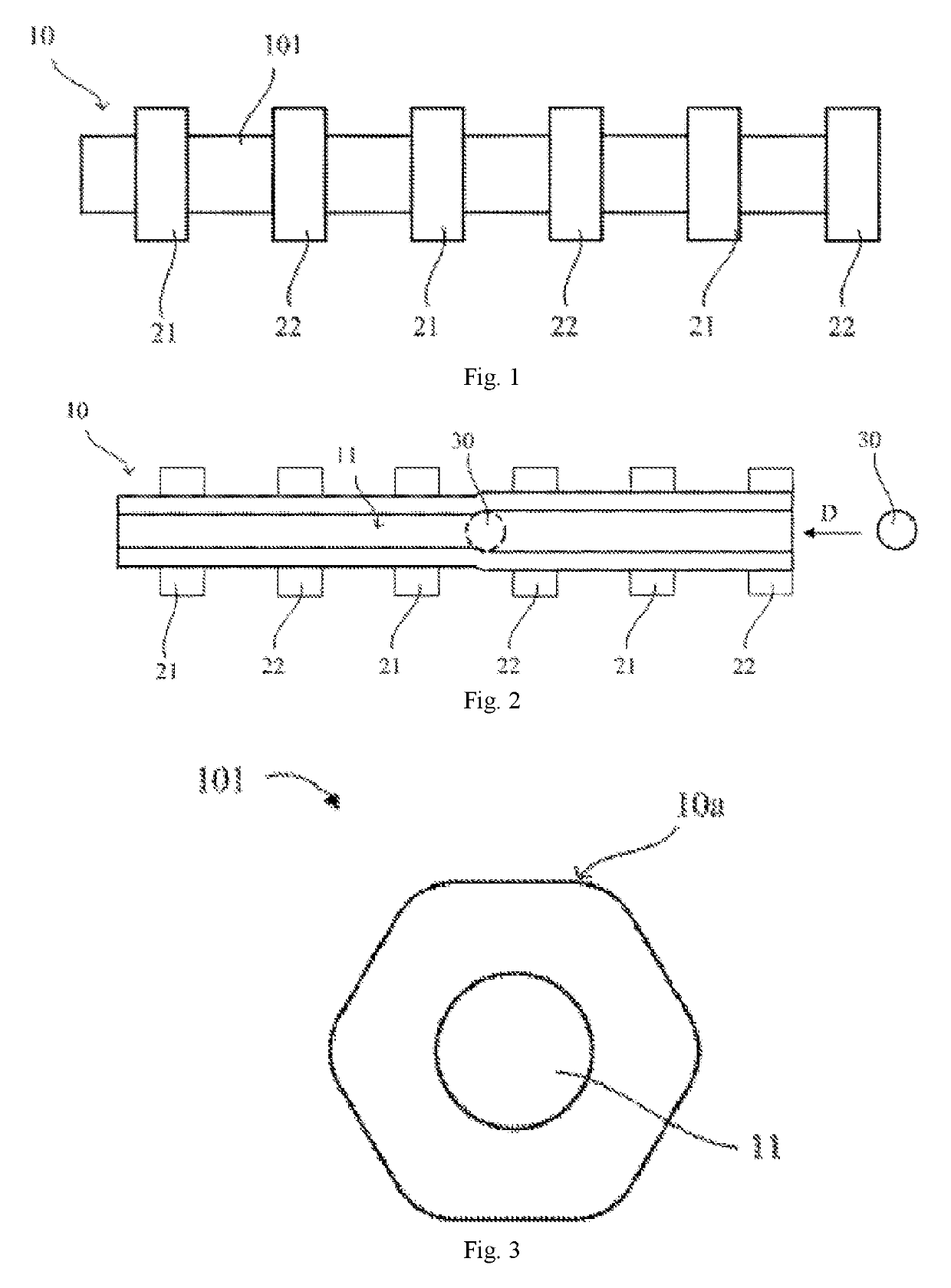

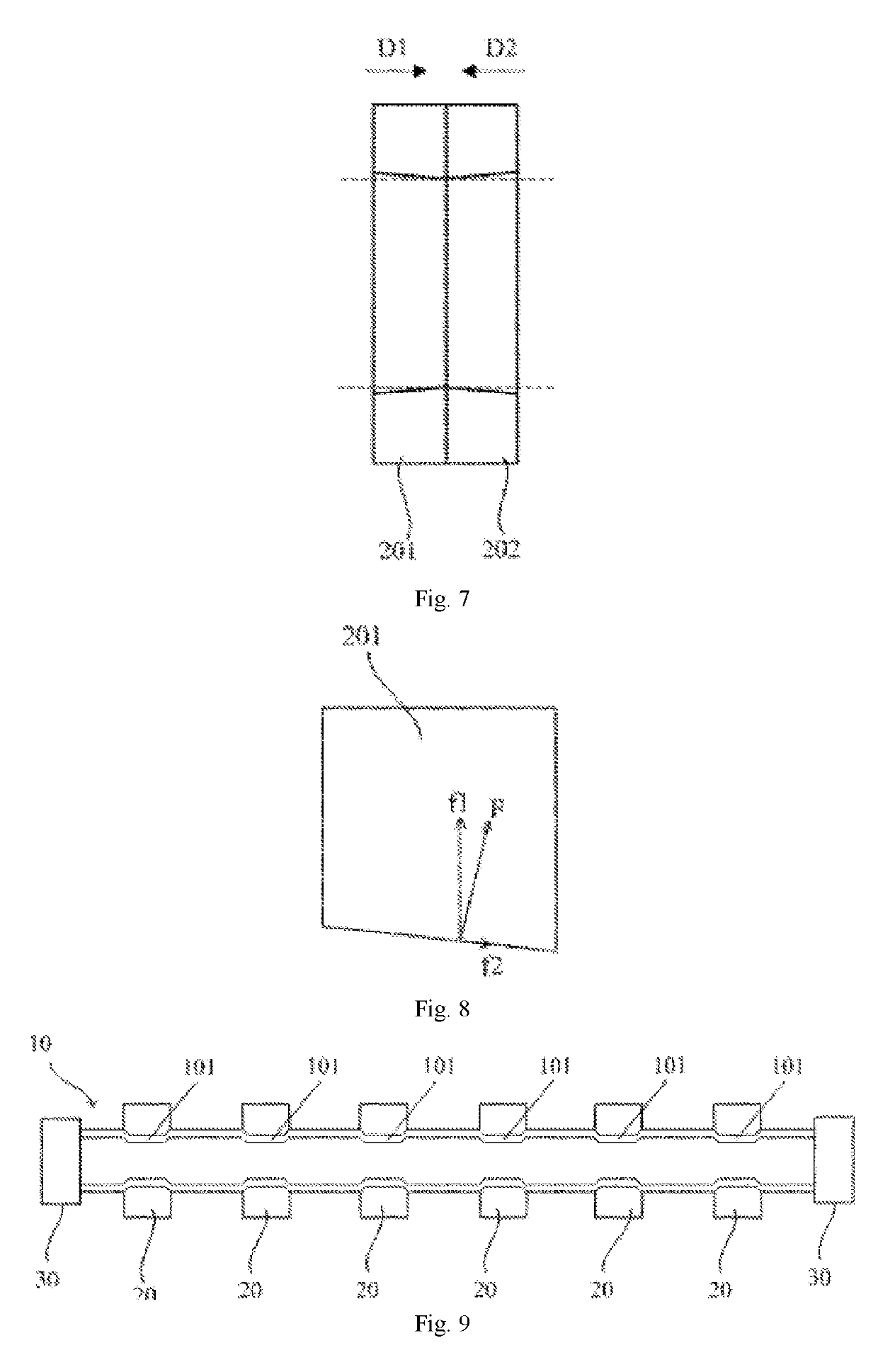

Engine and cam shaft thereof and manufacturing method of cam shaft

InactiveCN107587908AHigh torqueSimple structureValve arrangementsMachines/enginesManufacturing technologyEngineering

Provided are an engine and a cam shaft thereof and a manufacturing method of the cam shaft. The cam shaft comprises a central spindle, first cams and second cams, wherein the central spindle is provided with axial holes and matching segments, and the outer peripheral cross section of the matching segment at any axial position is polygonal; the first cams and the second cams are axially arranged onthe matching segments of the central spindle in a sleeving mode at intervals, the cross sections of the inner periphery surfaces of the first cams and the second cams are both polygonal, and each matching segment axially extends at least from the corresponding first cam to the corresponding second cam. Compared with existing cam shafts connected by adopting splines, the cam shaft can transmit larger torque and is simpler in structure, the manufacturing technology of the cam shaft is simplified, the manufacturing time consumption is reduced, and the cost is lowered.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

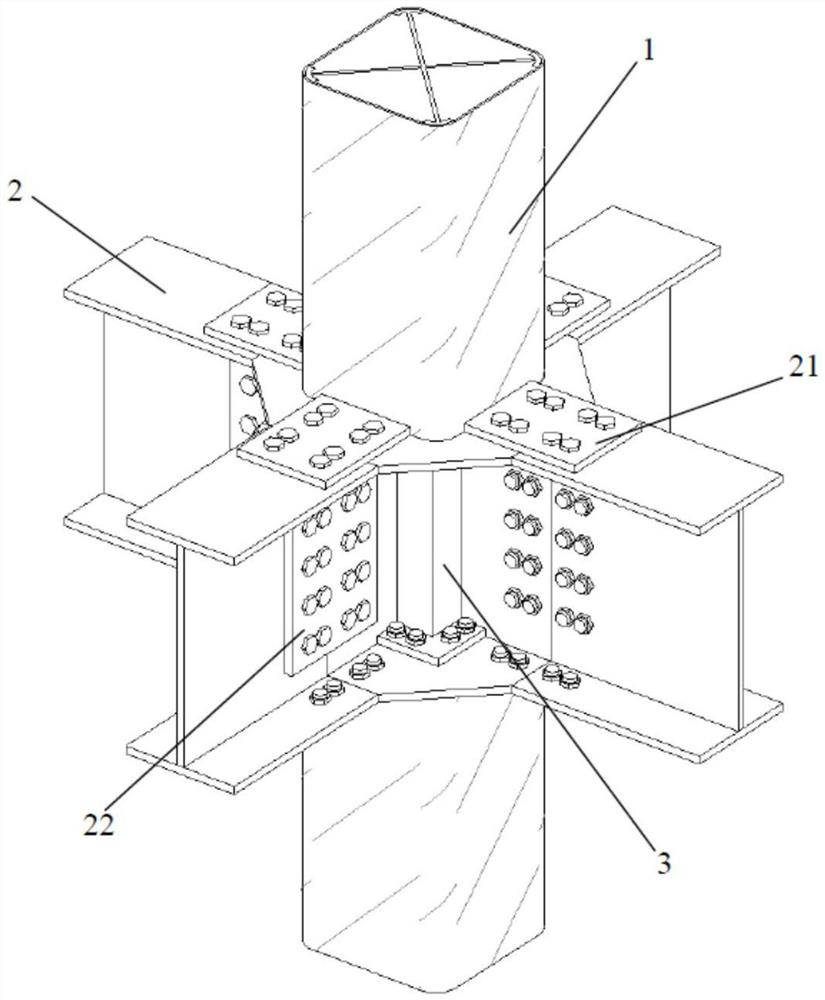

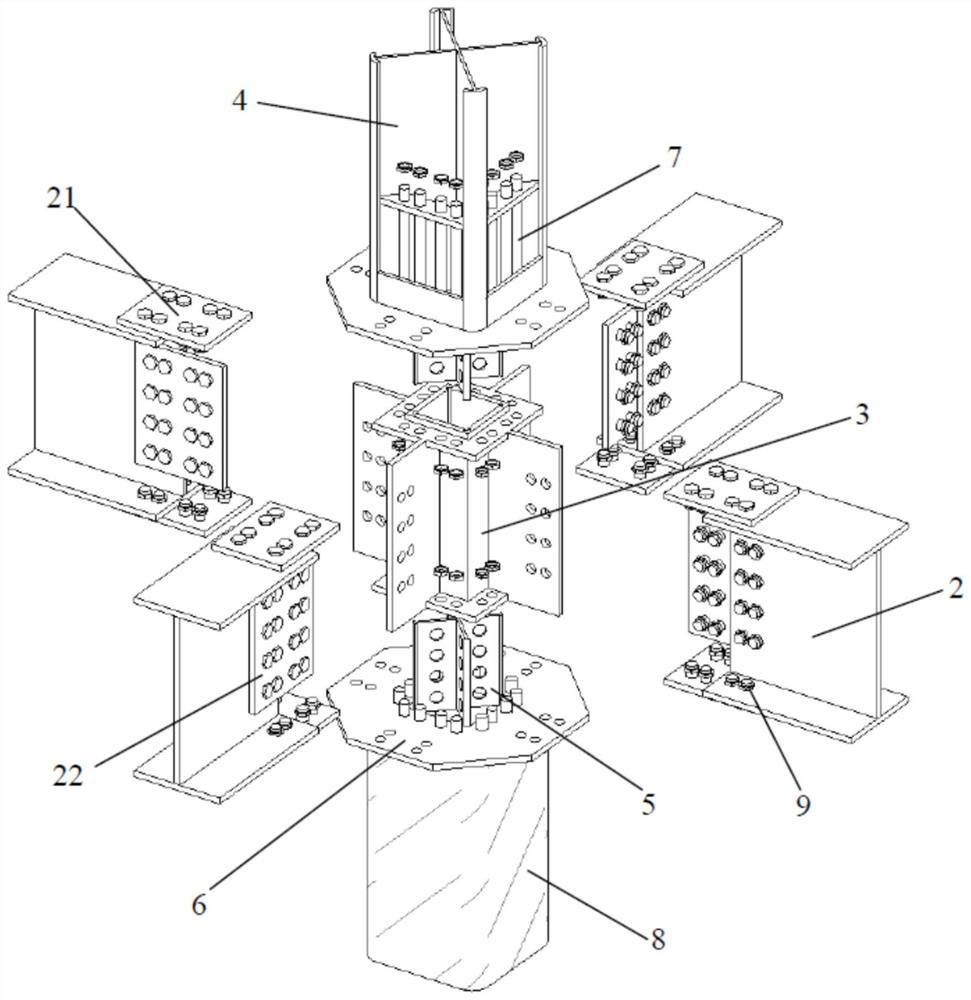

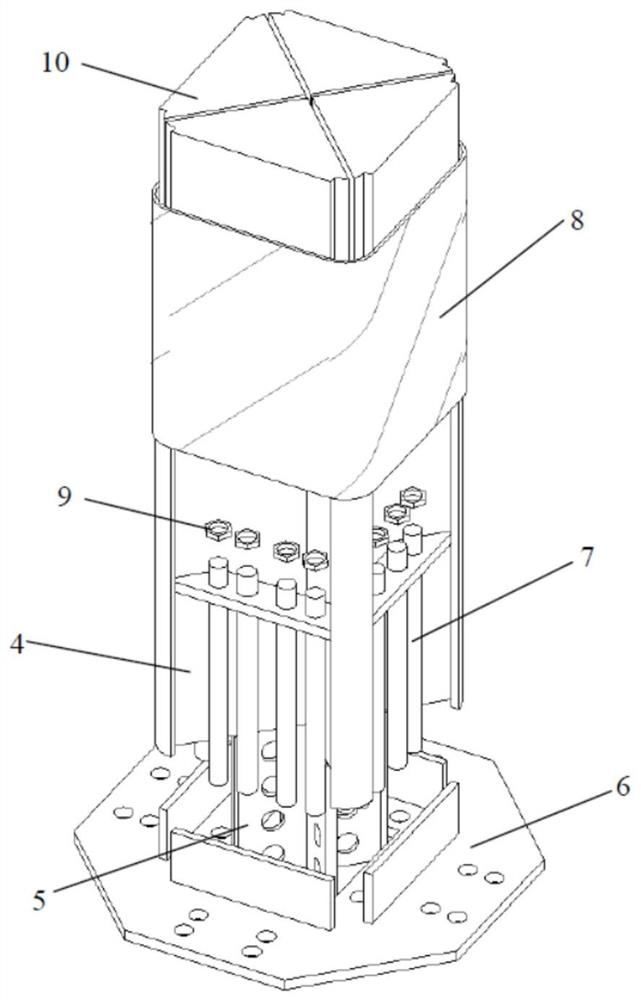

FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint and mounting method

ActiveCN113513089AImprove quality and efficiencyImprove construction efficiencyStrutsClimate change adaptationReinforced concrete columnEngineering

The invention relates to an FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint and a mounting method, and belongs to the field of design of a building structure beam-column joint. The FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint comprises an FRP externally-wrapped cross-shaped steel reinforced concrete column, an H-shaped steel beam and a square joint connecting sleeve, the FRP externally-wrapped cross-shaped steel reinforced concrete column comprises an upper column and a lower column, the square joint connecting sleeve is located between the upper column and the lower column, and the upper column and the lower column are connected with the square joint connecting sleeve through column end opening connecting plates correspondingly; and the H-shaped steel beam is fixedly connected with the column end opening connecting plates and the square joint connecting sleeve. By adopting the design of vertical force transfer of steel bars, the vertical connection of the joint is greatly enhanced, and the overall structural performance of the joint is enhanced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Special milling cutter for CNC milling machine

The invention discloses a milling cutter special for a numerical control milling machine. The milling cutter comprises a cutter handle and a cutter bit. The cutter bit is provided with a connecting groove. A threaded hole is formed in the connecting groove. A clamping connecting groove is formed in the cutter handle. An extension section is arranged between the cutter handle and the cutter bit. The two end portions of the extension section are provided with matching grooves. A connecting block is arranged between the corresponding matching groove and the connecting groove, and a connecting block is arranged between the corresponding matching groove and the clamping connecting groove. The connecting blocks are provided with installation holes matched with the threaded hole. The corresponding connecting block and the cutter handle are connected through a first fastener matched with the threaded hole, and the corresponding connecting block and the cutter bit are connected through a first fastener matched with the threaded hole. The extension section is provided with a center hole used for being connected with the cutter bit. The extension section and the cutter bit are connected by arranging a second fastener matched with the center hole. According to the purpose, the milling cutter special for the numerical control milling machine is provided, it is ensured that small parts can still be machined in the situation that the distance between a main shaft and a clamp is increased by increasing the overall length of the milling cutter, the position of the main shaft does not need to be repeatedly adjusted, the machining process is simplified, and the work efficiency is improved.

Owner:浙江海拓环宇传动科技有限公司

A drilling rig for mining shale gas

InactiveCN104120972BImprove securityPromote environmental protectionDrilling machines and methodsSprayerDrive motor

A drilling machine for exploiting shale gas comprises a drill stem, a drill bit, a power mechanism and a support. The drill bit is composed of a drill bit body and a plurality of cones arranged on the drill bit body, the drill bit body comprises a cylindrical sleeve and a flange connecting end, the flange connecting end is connected with one end of the drill stem through a connecting module, the drill stem is of a hollow shaft structure, a spiral mechanism is arranged in an inner cylindrical hole in the drill stem, one end of a main shaft of the spiral mechanism is connected with an output shaft of a drive motor through a transmission component, the other end of the main shaft is arranged in the inner cylindrical hole in the drill stem through a supporting mechanism, the main shaft is of a hollow shaft structure, and a cooling liquid injection device and a cooling liquid sprayer are arranged on the main shaft. According to the drilling machine, the drill bit mechanism and the connecting module of the drill bit and the drill stem are precisely designed, the spiral mechanism is arranged in the inner cavity of the vertical drill stem, rock debris is discharged through sliding friction, high-pressure flushing liquid is of no need, a large amount of energy is saved, and safety and environment friendliness of the drilling machine are greatly improved.

Owner:董书朋

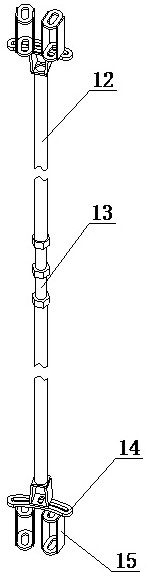

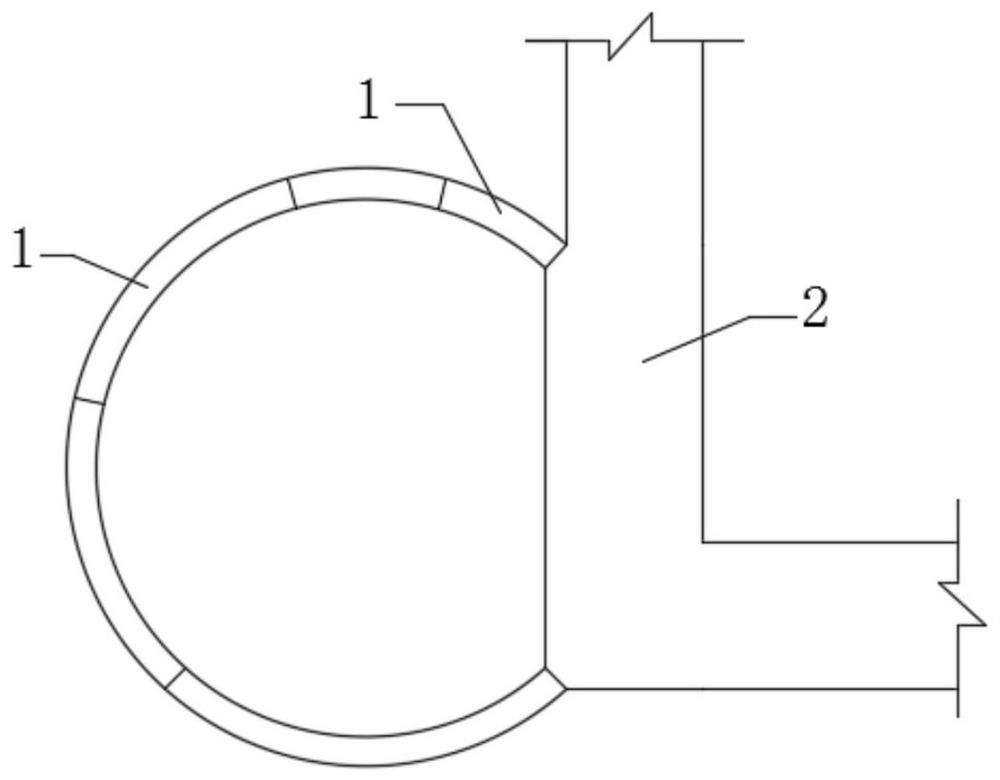

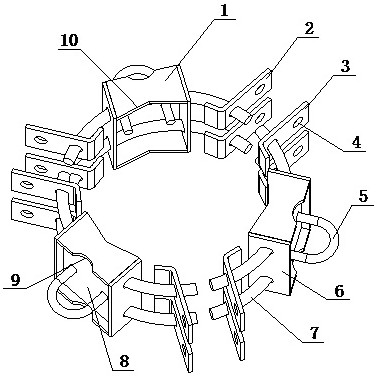

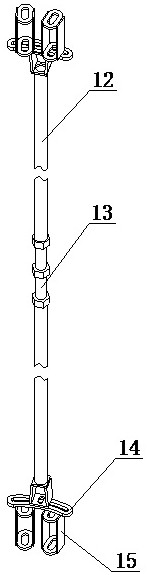

Communication signal tower reinforcing device and reinforcing method

ActiveCN113775201AImprove connection stabilityEnhanced axial compression and axial tension bearing capacityBuilding repairsTowersMechanical engineeringTower

The invention relates to a communication signal tower reinforcing device and a reinforcing method, and discloses the reinforcing device and the reinforcing method for improving the connection stability of a reinforcing rod through a double-layer holding structure, enabling the reinforcing rod to be better attached to the holding structure through a U-shaped clamping rod and preventing an adapter from twisting through the adapter of a double-supporting structure. The communication signal tower reinforcing device is characterized by comprising a length-adjustable reinforcing assembly, switching assemblies arranged at the two ends of the reinforcing assembly and used for connecting the reinforcing assembly to a signal tower main pipe flange, and a holding assembly used for fastening the reinforcing assembly, and is characterized in that the holding assembly can improve the connection stability of the reinforcing assembly; a switching assembly is provided with the double-supporting structure, so that the switching assembly can be prevented from twisting.

Owner:XI AN JIAOTONG UNIV

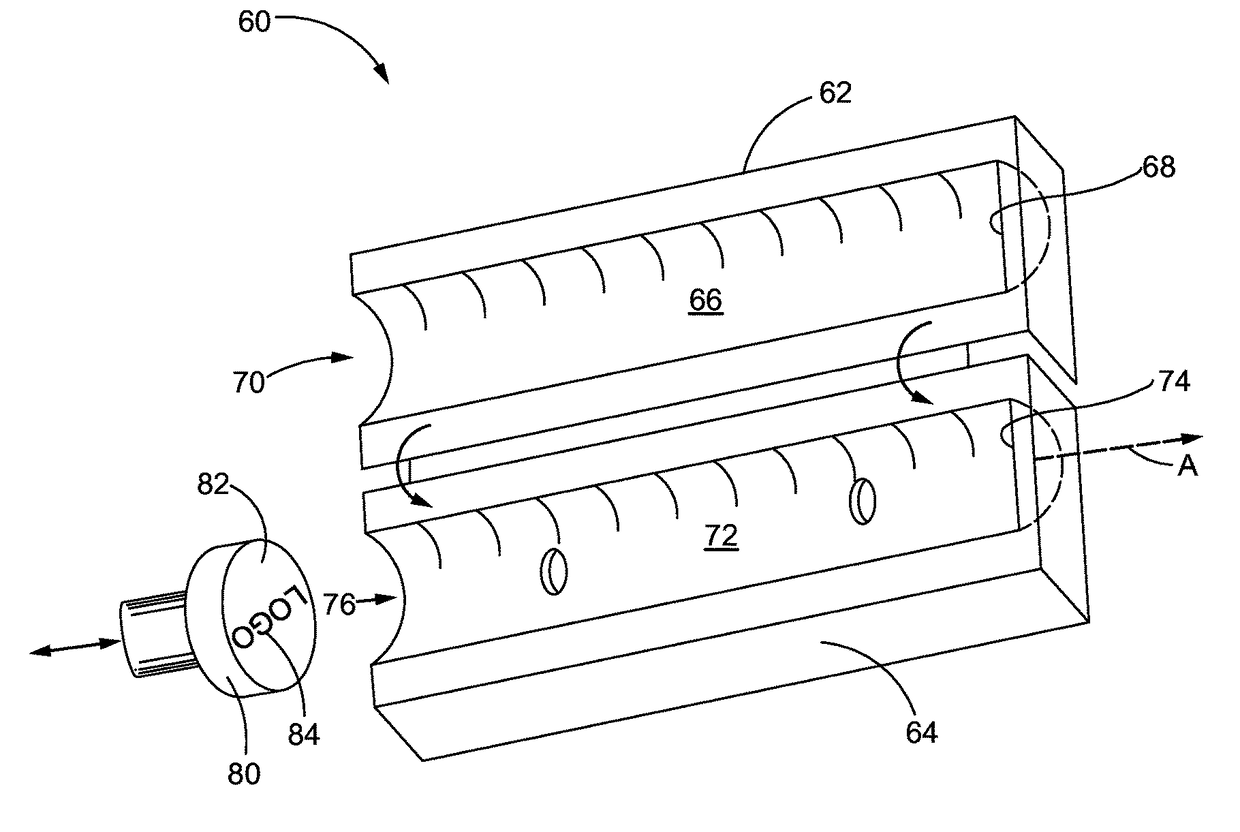

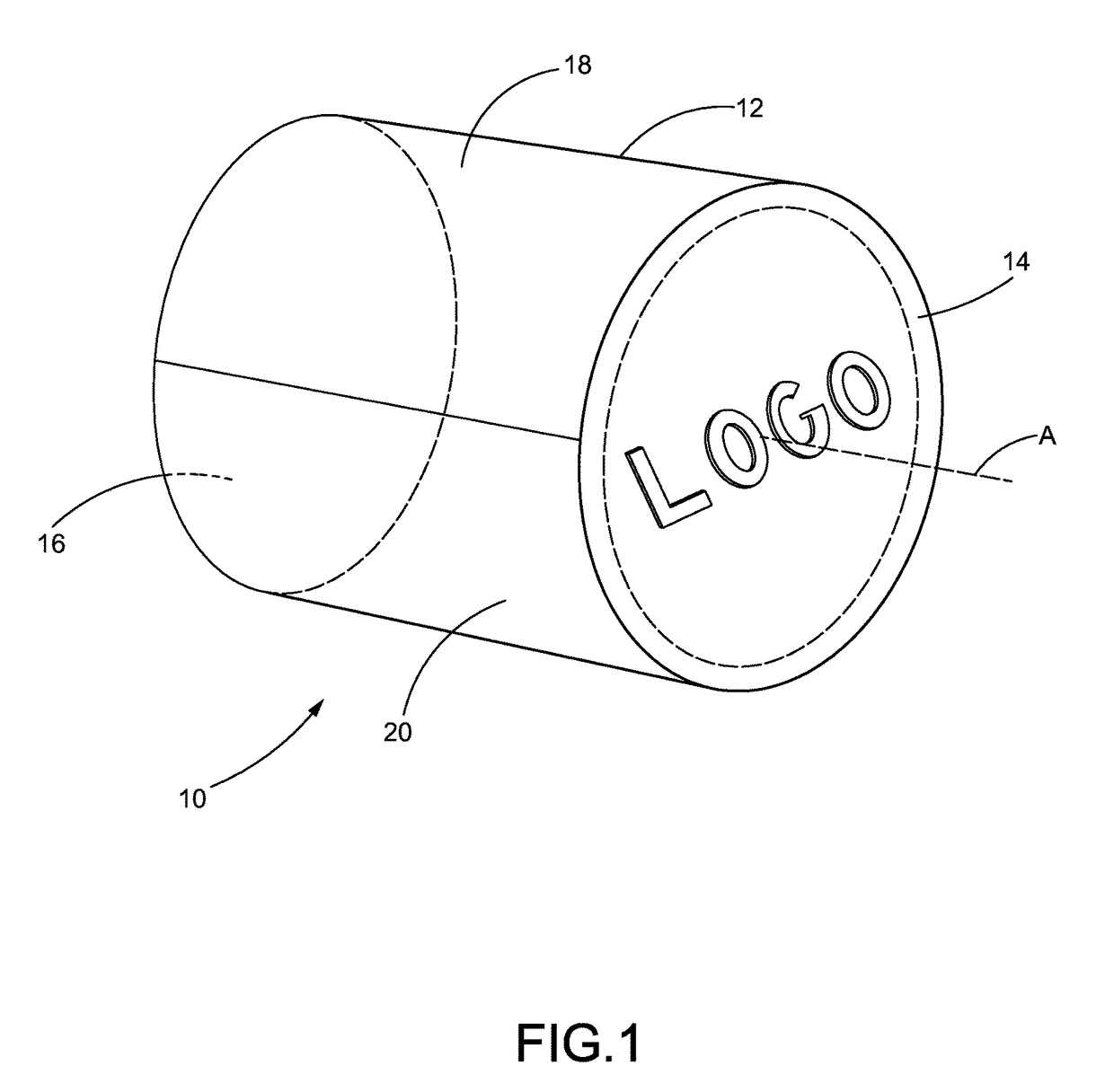

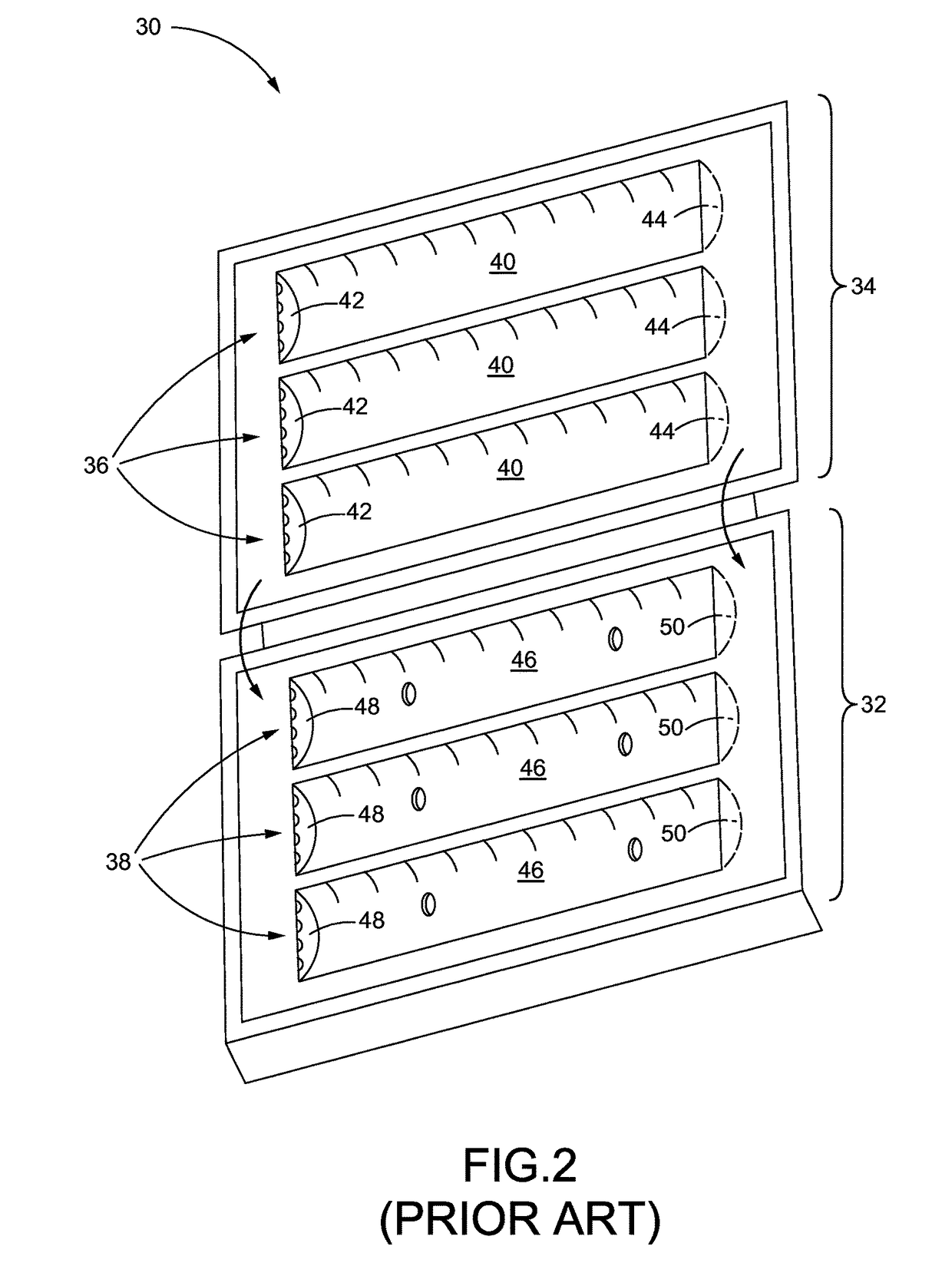

Apparatus and Method for Forming a Design on an Expanded Bead Foam Article

ActiveUS20150298370A1Increase axial pressureSemi-permeable membranesEngineeringBiomedical engineering

Owner:SONOCO DEV INC

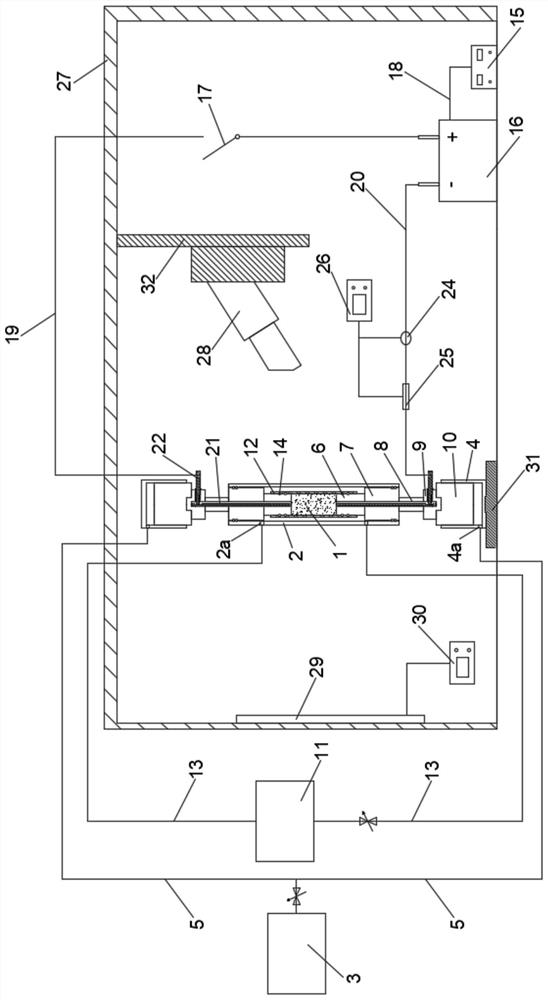

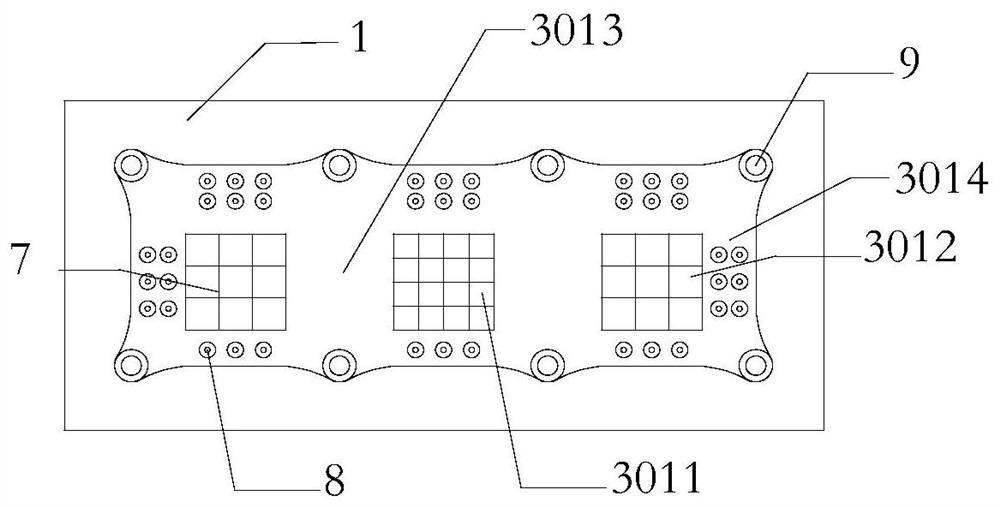

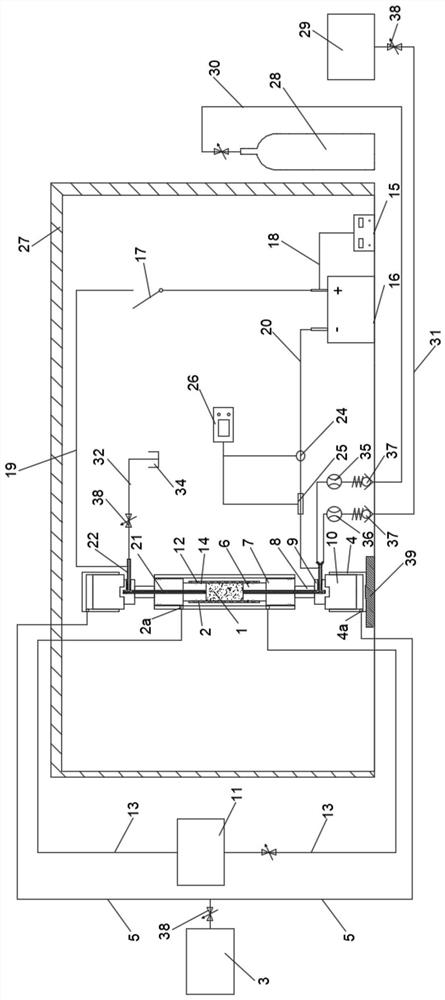

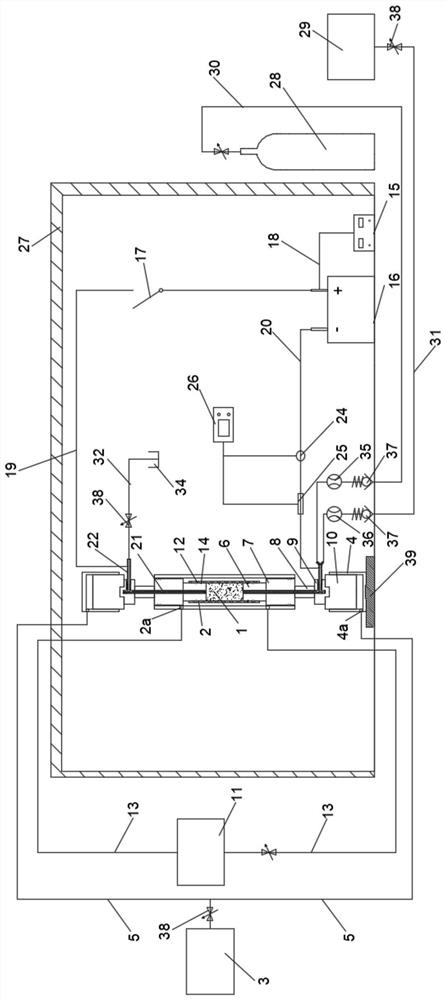

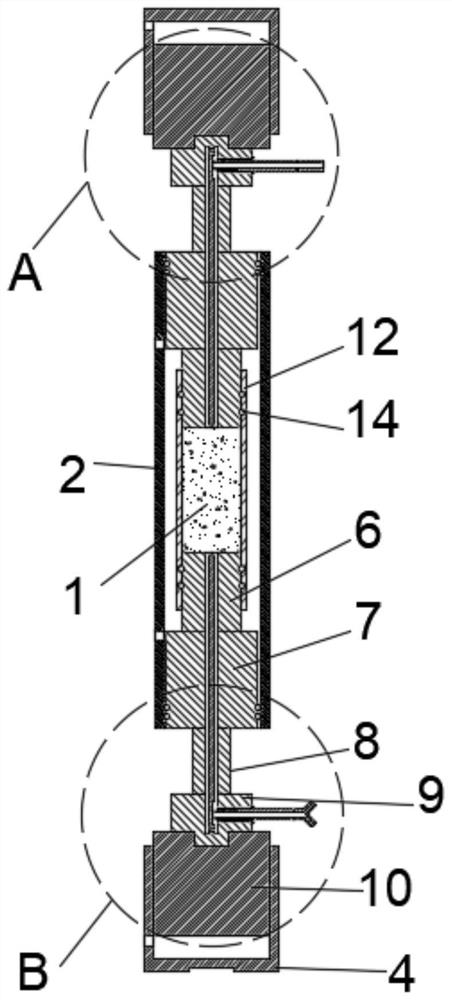

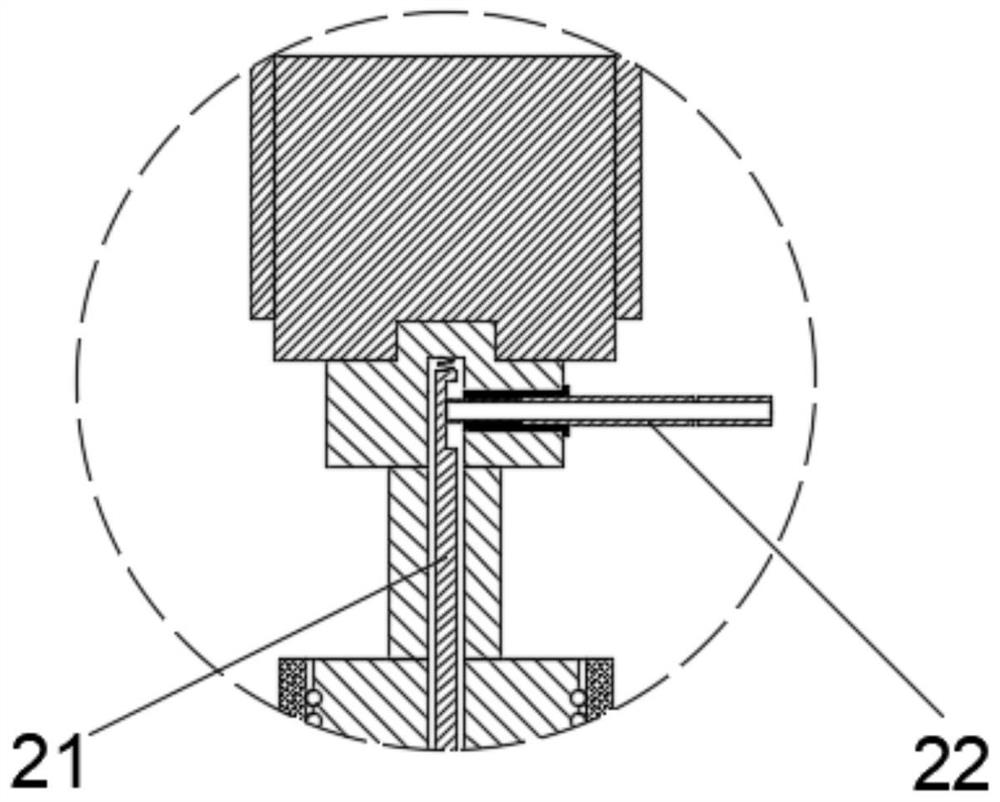

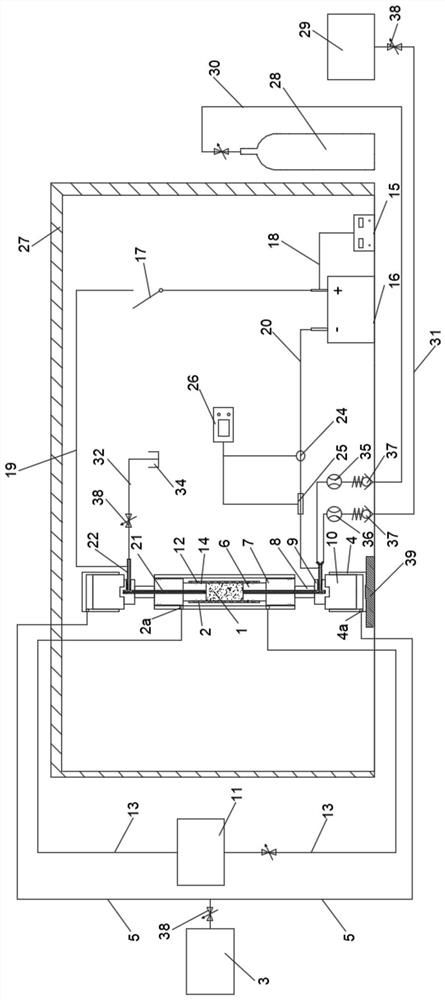

Test method for high-voltage electric pulse in-situ fracturing of coal seam cracks and real-time nondestructive observation

ActiveCN114076715AAffect interference test resultsAccurate macro and micro analysisMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesThermodynamicsVoltage pulse

The invention discloses a test method for high-voltage electric pulse in-situ fracturing of coal seam cracks and real-time nondestructive observation. The test method comprises the following steps: a manufacturing a cylindrical test piece; b installing the test piece in a circular-tube-shaped pressure chamber, connecting pipelines between systems, including a confining pressure loading module and an axial pressure loading module; c operating the axial pressure loading module and the confining pressure loading module in sequence, and applying axial pressure and confining pressure to the test piece; d operating a high-voltage electric pulse fracturing operation system to perform high-voltage pulse discharge, and fracturing the test piece; and e operating an in-situ CT scanning system, performing in-situ scanning on the test piece, and monitoring the internal change of the test piece. The step e can be randomly selected to be carried out after one or more of the steps b, c and d, the in-situ real-time lossless scanning monitoring of the same test piece is realized by operating the step e for many times in the test process, and the real-time lossless observation of the high-voltage electric pulse in-situ fracturing coal seam cracks can be carried out.

Owner:CHONGQING UNIV

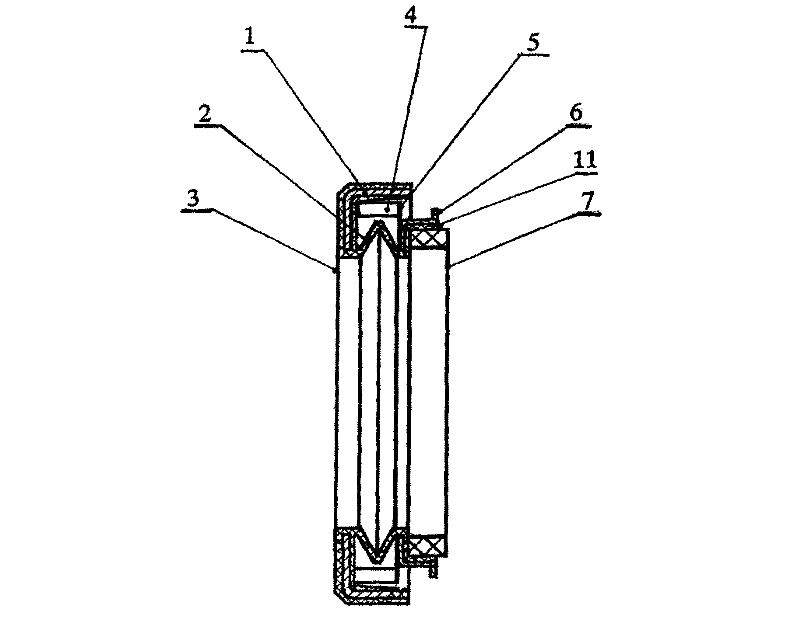

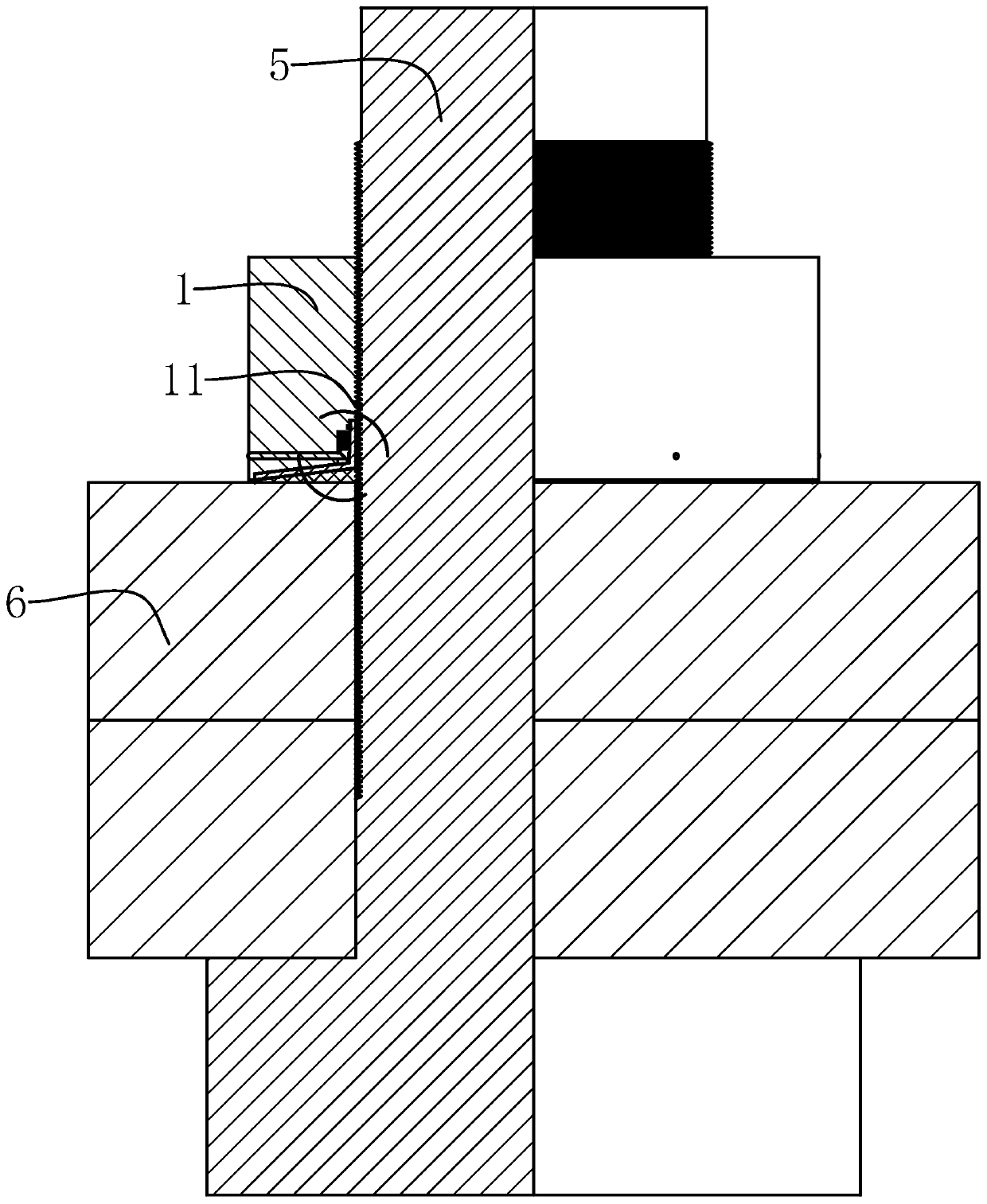

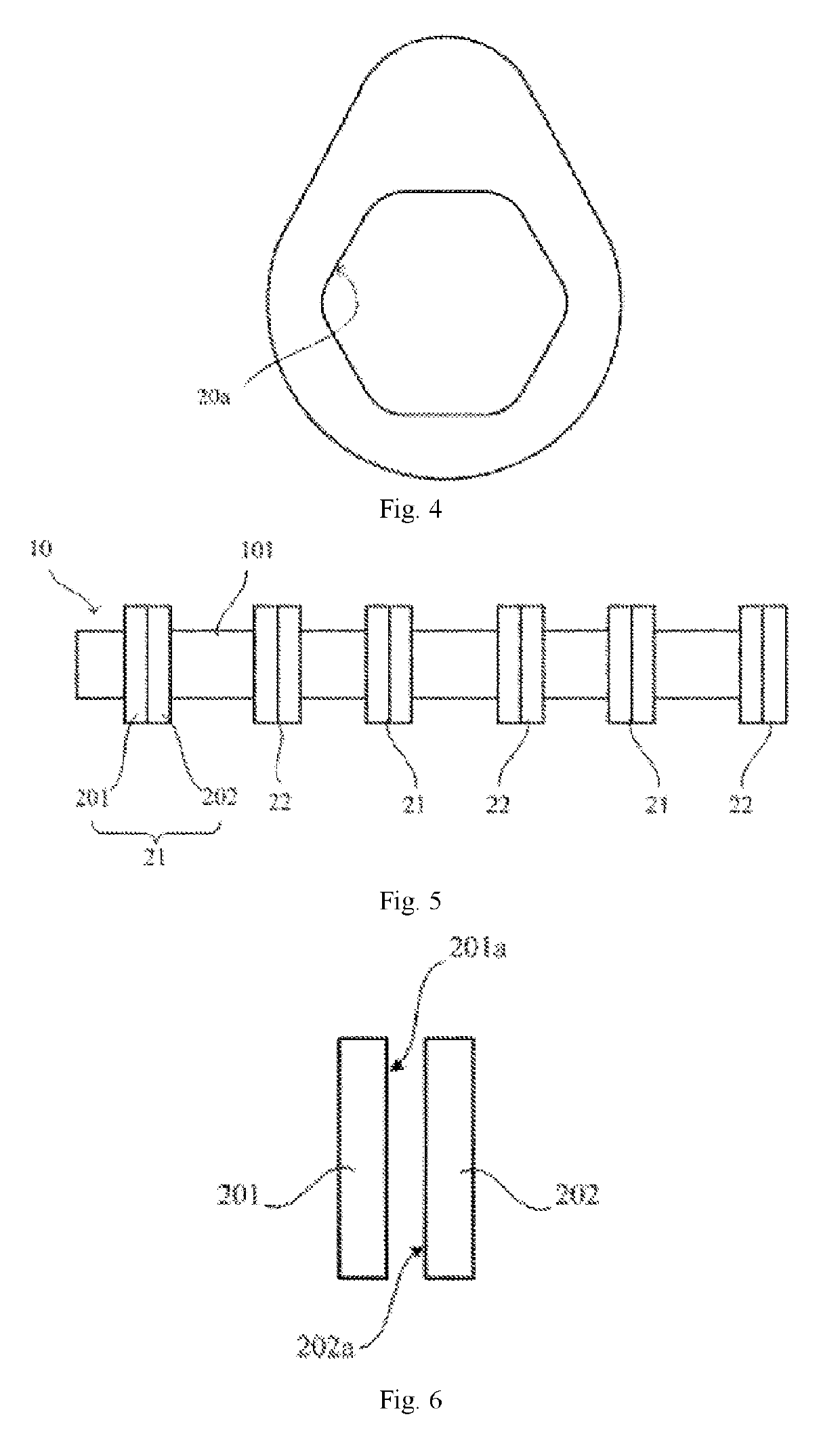

Pressure-bearing contact type shaft seal ring

The invention discloses a pressure-bearing contact type shaft seal ring which comprises an outer ring metal framework, an inner ring metal framework, a seal ring main body and a seal ring, wherein the seal ring main body is made of an elastomeric material. The pressure-bearing contact type shaft seal ring is characterized in that a corrugated structural segment is arranged between the outer ring metal framework and a central inner ring, an annular raised-tooth spring is installed on the end surface of an inner flange of the inner ring metal framework or a cylindrical spring is installed on the end surface of an outer flange, the seal ring or a combined seal ring is installed in the central inner ring of the seal ring main body, and the corrugated structural segment is an M-shaped corrugated structural segment or an S-shaped corrugated structural segment. The seal ring still has good sealing performance under a pressure environment and also has simple manufacture, easy installation andlong working and use life.

Owner:谢晓山 +1

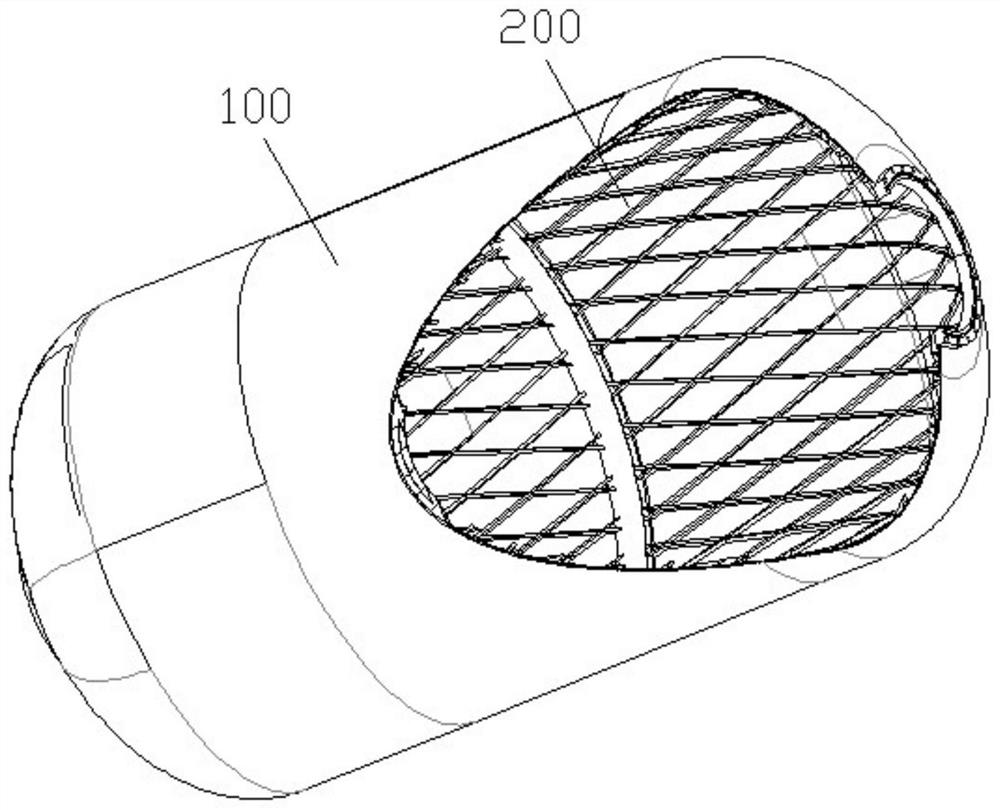

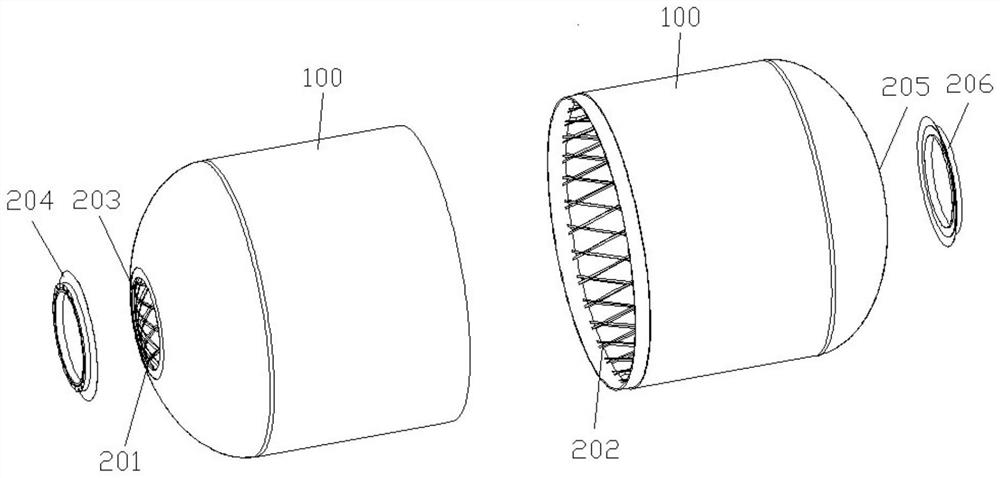

Winding forming method of composite material gas cylinder with inner grid ribs

ActiveCN111947018BAchieve weight reductionImprove axial compressive capacityVessel manufacturingVessel geometry/arrangement/sizeGas cylinderAxial compression

The invention discloses a winding forming method of a composite material gas cylinder with inner grid ribs, and belongs to the technical field of gas cylinder structures. Composite material gas cylinder with inner grid ribs, including the outer layer of the gas cylinder and the inner layer of the grid; the outer layer of the gas cylinder and the inner layer of the grid are made of composite materials; the inner layer of the grid is in the shape of a bottle liner, and the grid The inner layer is a grid rib structure; the outer layer of the cylinder is wound and connected to the outside of the inner layer of the grid. It solves the technical problem that in the prior art, the gas cylinder adopts a plastic liner, resulting in a relatively thin overall structure and weak axial compression resistance; the gas cylinder adopts a metal liner, resulting in heavy overall weight and unable to meet the use requirements. In the present invention, a grid inner layer is arranged inside the outer layer of the gas cylinder, and the grid inner layer is a dense inner grid rib structure, which improves the axial compression resistance of the entire gas cylinder, and is made of composite materials to realize the gas cylinder lightweight.

Owner:TIANJIN ISTAR ADVANCED MATERIAL TECH CO LTD +1

A Spindle System Realizing Friction Overlay Welding with Shaft Shoulder

ActiveCN107052560BGeneration of restrictionsIncrease profitNon-electric welding apparatusFriction weldingSurface layer

The invention discloses a spindle system for realizing friction surfacing with a shaft shoulder. The spindle system comprises a round bar consumable, a cylindrical shell, a hollow spindle, a shaft sleeve, a self-locking clamping mechanism and a rigid shaft sleeve, wherein the hollow spindle is coaxial with the cylindrical shell and is arranged in the cylindrical shell, and the shaft sleeve slides up and down along an inner hole of the hollow spindle; and the self-locking clamping mechanism is fixed to the lower end of the hollow spindle. The upper end of the round bar consumable is fixed to the shaft sleeve, and the lower end of the round bar consumable contacts with the surface of a workpiece through the self-locking clamping mechanism and the rigid shaft sleeve. When the hollow spindle rotates at high speed, the round bar consumable and the rigid shaft sleeve are driven by the shaft sleeve and the self-locking clamping mechanism at the lower end to rotate at high speed, and the shaft sleeve moves down along the hollow spindle at the same time, so that the round bar consumable rotates at high speed while can move down along the axial direction. The rigid shaft sleeve plays a role of friction and extrusion without consuming the shaft shoulder, and therefore the friction surfacing process with the shaft shoulder is realized. The spindle system can improve the use ratio of the round bar consumable and effectively eliminates the weak connection defect of the edge of a traditional friction surfacing layer, and thereby obtaining the friction surfacing layer with a good mechanical property.

Owner:TIANJIN UNIV

Pump comprising an axially acting spring gasket

PendingUS20210404466A1Cost-effective and reliableCost-effectiveEngine sealsSealing arrangements for enginesStructural engineeringMechanics

A pump for applying fluid to an assembly, the pump including: a pump housing featuring a circumferential wall surrounding a delivery chamber of the pump, an end-facing housing wall including an outer end-facing surface of the housing which faces axially away from the delivery chamber, an inlet and an outlet for the fluid which emerges on the outer end-facing surface of the housing; a delivery member, moveable within the delivery chamber, for delivering the fluid from a low-pressure side of the pump which includes the inlet to a high-pressure side of the pump which includes the outlet; and an axial gasket which fully surrounds the outlet, in order to separate it from the low-pressure side, in an axial view onto the end-facing wall of the housing. The axial gasket is a spring gasket in the form of a disc spring or hollow-profile spring or V-profile spring or bellows spring.

Owner:SCHWABISCHE HUTTENWERKE AUTOMOTIVE CMBH

Steel bar surface type connecting joint adopting nodular cast iron member

ActiveCN112814286AImprove connection strengthImprove energy consumptionBuilding reinforcementsRebarEarthquake resistant

The invention discloses a steel bar surface type connecting joint adopting a nodular cast iron member. The steel bar surface type connecting joint comprises a shield segment and a subway station wall column, the shield segment and the subway station wall column are connected through the nodular cast iron member, a tooth groove shear-resistant member and a non-bonding section prestressed steel bar, and the nodular cast iron member comprises a belly part, an upper wing and a lower wing. The belly part is connected with the tooth groove shear-resistant member, a longitudinal tensile steel bar is arranged in the shield segment, the non-bonding section prestressed steel bar is arranged in the subway station wall column, and the longitudinal tensile steel bar and the non-bonding section prestressed steel bar are connected through a longitudinal steel bar connecting sleeve. The steel bar surface type connecting joint has high connection strength and energy dissipation performance, is suitable for complex underground engineering construction, can bear large bending moment and shearing force at the same time, and is good in anti-seismic performance; and the duct piece section embedded nodular cast iron member is adopted, so that an embedded member is coordinated with concrete deformation, concentrated stress of longitudinal connecting steel bars is avoided, the integrity of the longitudinal connecting steel bars is enhanced, and a surface type connecting mode of the steel bars is formed.

Owner:JIANGSU UNIV OF SCI & TECH

Anti-skid nut and assembling method thereof

The invention provides an anti-skid nut and an assembling method thereof, belongs to the field of mechanical fasteners and solves the problem that an existing nut is poor in anti-loosening effect. Theanti-skid nut comprises a thread insert provided with a threaded hole, a rotation groove is formed in the hole wall at the bottom end of the threaded hole, a rotation sleeve is arranged in the rotation groove, a sliding groove is formed in the groove wall of the rotation groove, a sliding ring is arranged on the outer wall of the rotation sleeve, an axial moving groove is formed in the groove wall at the bottom end of the rotation groove, an axial moving sleeve is arranged in the axial moving groove, the outer wall of the rotation sleeve is sleeved with the inner wall of the axial moving sleeve, and the inner wall of the axial moving sleeve and the outer wall of the rotation sleeve are provided with a locating groove and a locating sleeve. The anti-skid nut further comprises a spacer anda gasket, the inner edge of the spacer is fixed to the outer wall at the bottom end of the rotation sleeve, radial moving holes are formed in the thread insert, radial moving rods penetrate through the radial moving holes, limiting grooves are formed in the outer wall of the axial moving sleeve, limiting blocks located in the limiting grooves in a sliding mode are arranged at the inner ends of theradial moving rods, and a reset spring with the two ends abutting against the top end of the axial moving sleeve and the axial moving groove is arranged in the axial moving groove. The anti-skid nutis better in anti-loosening and anti-skid effects.

Owner:NINGBO ZHENHAI HEXIN STANDARD PARTS

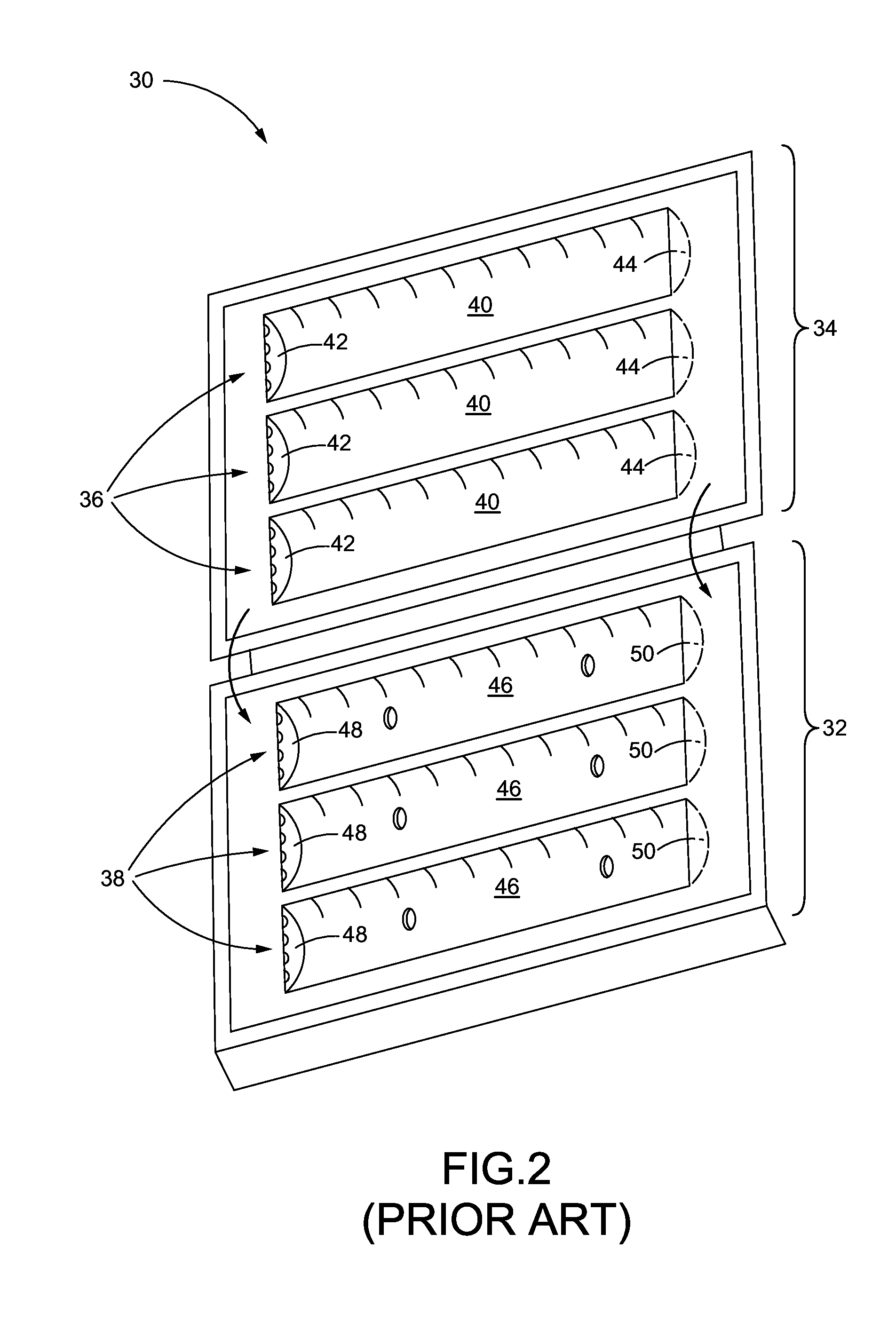

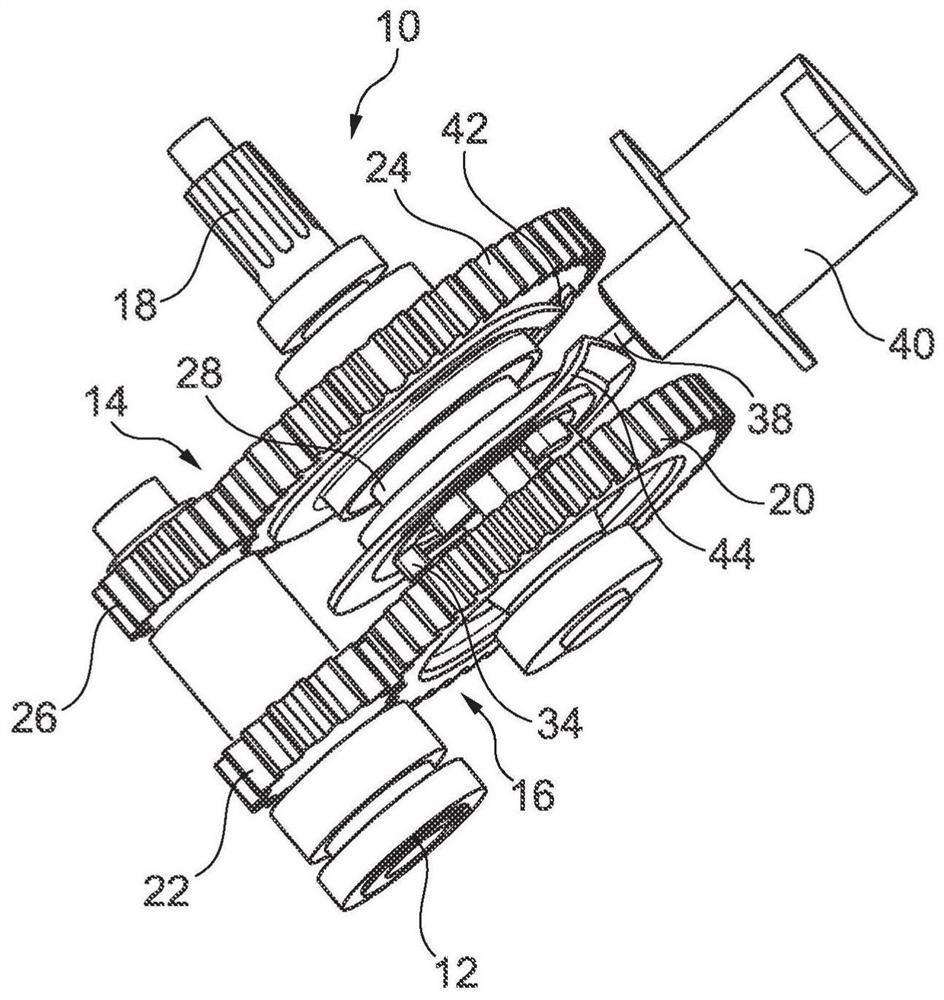

Two-speed transmission for an electrically driven motor vehicle

PendingCN112119244ASmall rotation speed rangeShift quicklyMechanical actuated clutchesToothed gearingsRadial planeGear wheel

Provided is a two-speed transmission (10) for an electrically driven motor vehicle, in particular an electric motor scooter. The transmission is provided with an input shaft (12) for introducing torque, an output shaft (18) for outputting torque, a first gear (14), a second gear (16), a slider sleeve (28) which is guided on the input shaft (12) or on the output shaft (18) in an non-rotatable but axially displaceable manner, for establishing a positively locking connection with a first gearwheel (20) of the first gear (14) and / or with a second gearwheel (24) of the second gear (16), and an actuating actuator (40) which has an extendable actuating finger (38) for axially moving the slider sleeve (28), wherein the slider sleeve (28) has a sliding ramp (42, 44) which runs in the circumferential direction and is bevelled with respect to a radial plane for the output at the extended actuating finger (38) of the actuating actuator (40). In order to prevent damage or noises occurring during switching, the sliding ramp (42, 44) is designed to be axially resilient, so that a comfortable power transmission is made possible in the case of an electrically driven motor vehicle.

Owner:SCHAEFFLER TECH AG & CO KG

Apparatus and method for forming a design on an expanded bead foam article

Owner:SONOCO DEV INC

Two-phase seepage test device for high-voltage electrical pulse in-situ permeability-enhancing gas-bearing reservoir

ActiveCN114062143BAccurate macro and micro analysisAvoid affecting the interference test resultsMaterial strength using tensile/compressive forcesPermeability/surface area analysisThermodynamicsData acquisition

The invention discloses a high-voltage electric pulse in-situ anti-permeability gas-bearing reservoir two-phase seepage test device, comprising a stress loading system, a high-voltage electric pulse fracturing operating system and a water-gas two-phase seepage system; the stress loading system It includes a pressure chamber, an axial pressure loading module and a confining pressure loading module; the high-voltage electric pulse fracturing operation system includes a high-voltage electric pulse generation module, a high-voltage electric pulse signal monitoring module and a protection module; the water-gas two-phase seepage flow The system includes a water-gas pressure loading module and a flow data acquisition module. By simulating the coal body test of electric pulse under different ground stress, different voltage and other conditions, and simulating the physical test of high-voltage electric pulse fracturing coal body under the action of multi-physics coupling, the in-situ permeability enhancement of high-voltage electric pulse can be carried out. Reservoir two-phase seepage test.

Owner:CHONGQING UNIV

Motor and camshaft thereof, and manufacturing method for camshaft

ActiveUS20190226569A1High torque transmissionSimple structureCamsValve drivesTorque transmissionHigh torque

Engine and its camshaft, camshaft manufacturing method, the camshaft comprises a central shaft having an axial hole, the central shaft has a fitting section, the outer circumference of a cross section at any axial position of the fitting section is a polygon; a first cam and a second cam, the first cam and second cam are respectively installed on the fitting section of the central shaft and are spaced axially. Such a structure has the advantages of higher torque transmission, simpler structure, simplified manufacturing process, shorter manufacturing time consumption and reduced cost.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

A kind of communication signal tower reinforcement device and reinforcement method

ActiveCN113775201BImprove connection stabilityIncrease axial pressureBuilding repairsTowersTowerMechanical engineering

The invention discloses a communication signal tower reinforcement device and reinforcement method. Disclosed is a method for improving the connection stability of reinforcement rods through a double-layered clamping structure, and using U-shaped clamping rods to make the reinforcement rods more closely fit the clamping structure. A reinforcing device and a reinforcing method for a structural adaptor to avoid torsion of the adaptor, characterized in that it comprises a length-adjustable reinforcing assembly, which is arranged at both ends of the reinforcing assembly and is used for connecting the reinforcing assembly to the main pipe flange of a signal tower. The connecting assembly and the tightening assembly for fastening the reinforcing assembly are characterized in that the tightening assembly can improve the connection stability of the reinforcing assembly, and the adapting assembly has a double support structure, which can prevent the adapting assembly itself from being twisted.

Owner:XI AN JIAOTONG UNIV

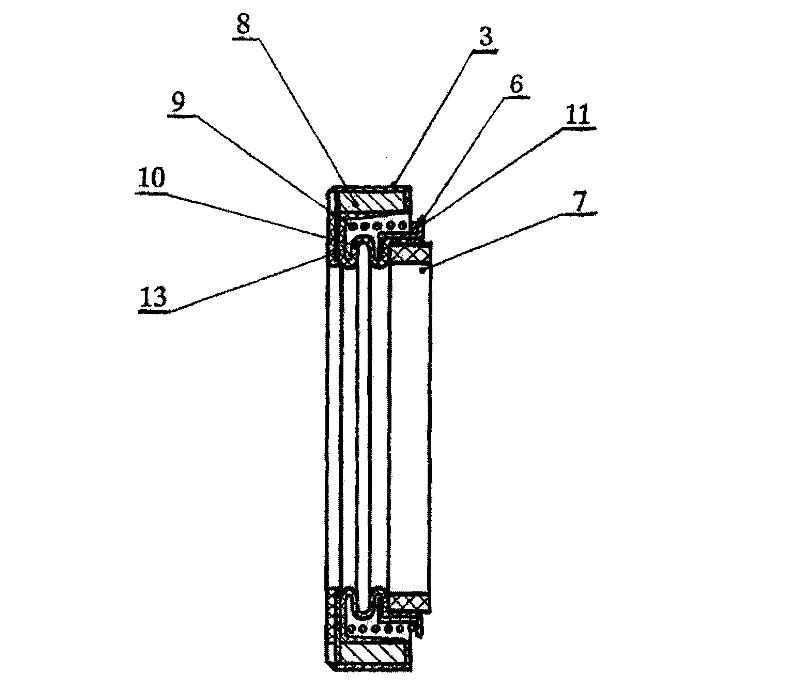

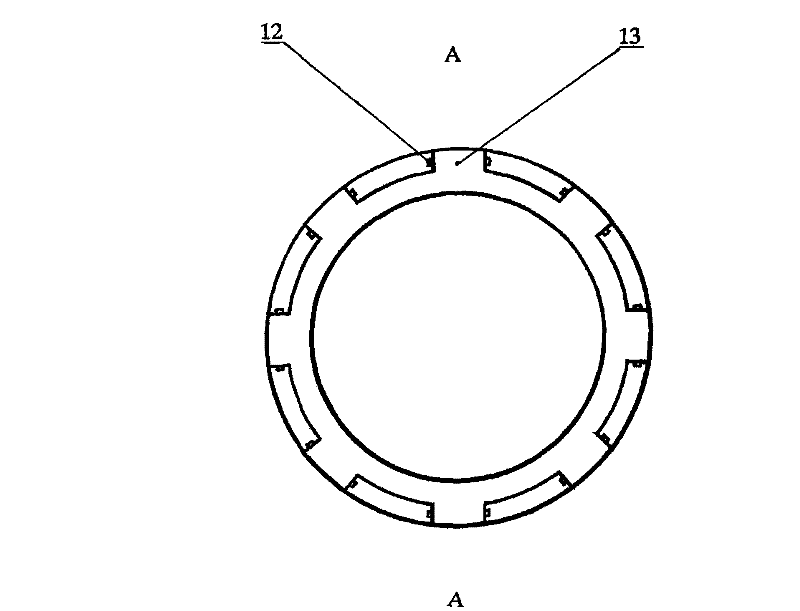

Water-lubricated thrust bearing of submersible motor for well

ActiveCN105443571BImprove the lubrication effectIncrease pressureBearing componentsSliding contact bearingsCircular discThrust bearing

The invention discloses a water-lubricating thrust bearing of submersible motors for wells. The water-lubricating thrust bearing comprises a thrust plate, a disc bearing base, a bearing base support, a bearing bush, a bearing plate and a plastic inner grinding ring; the bearing plate is fixed to the disc bearing base through a double-screw bolt; the bearing bush is composed of a plurality of independent fan-shaped bearing slide blocks, the upper planes of the fan-shaped bearing slide blocks are smooth, spherical crown-shaped protrusions are arranged at the middle parts of the bottom surfaces of the fan-shaped bearing slide blocks, side wings extending out symmetrically are arranged on the straight sides of the two sides of each fan-shaped bearing slide block, a pair of slide block limiting columns and a slide block supporting column in the bearing plate limit and support the fan-shaped bearing slide blocks respectively, and the slide blocks can be flexible but cannot be separated through cooperation with the plastic inner grinding ring; the upper surfaces and the lower surfaces of the side wings of the fan-shaped bearing slide blocks have temperature difference when the side wings work and generate frictional heating, and therefore the edges of the side wings are slightly bent and generate gaps with the thrust plate, and maintenance of a lubricating water film can be reinforced; through the plastic inner grinding ring, the axial bearing capacity is high, the material cost is low, the water lubrication capacity is improved, the service life is prolonged, and the product quality is improved.

Owner:GUANGDONG RUIRONG PUMP IND

High-voltage electric pulse in-situ anti-reflection gas-bearing reservoir two-phase seepage test method

ActiveCN114062142AAccurate macro and micro analysisAvoid affecting the interference test resultsNuclear energy generationMaterial strength using tensile/compressive forcesSteam pressureVoltage pulse

The invention discloses a high-voltage electric pulse in-situ anti-reflection gas-bearing reservoir two-phase seepage test method. The method comprises the following steps: step a, manufacturing a cylindrical test piece; b, installing the test piece is installed in a circular-tube-shaped pressure chamber, and connecting pipelines between systems; c, operating the axial pressure loading module and the confining pressure loading module in sequence; d, operating the water-gas two-phase seepage system; the sum of the steam pressure applied to the test piece in the step d is constantly smaller than the axial pressure and the confining pressure applied to the test piece in the step c; e, operating a high-voltage electric pulse fracturing operation system to perform high-voltage pulse discharge, and fracturing the test piece; and f, detecting a water and gas fluid flow change curve of the test piece in the pressure maintaining stress environment through a flow data acquisition module, implementing the step f before and after the step e respectively, and judging the effect of the high-voltage electric pulse fracturing test piece by comparing water and gas fluid flow data measured by the liquid flow meter and the gas flow meter before and after the step e, so that a high-voltage electric pulse in-situ anti-reflection gas-bearing reservoir two-phase seepage test can be carried out.

Owner:CHONGQING UNIV

High-voltage electric pulse in-situ anti-reflection gas-bearing reservoir two-phase seepage test device

ActiveCN114062143AAccurate macro and micro analysisAvoid affecting the interference test resultsMaterial strength using tensile/compressive forcesPermeability/surface area analysisThermodynamicsData acquisition

The invention discloses a high-voltage electric pulse in-situ anti-reflection gas-bearing reservoir two-phase seepage test device which comprises a stress loading system, a high-voltage electric pulse fracturing operation system and a water-gas two-phase seepage system; the stress loading system comprises a pressure chamber, an axial pressure loading module and a confining pressure loading module; the high-voltage electric pulse fracturing operation system comprises a high-voltage electric pulse generation module, a high-voltage electric pulse signal monitoring module and a protection module; the water-gas two-phase seepage system comprises a water-gas pressure loading module and a flow data acquisition module. The high-voltage electric pulse in-situ anti-reflection gas-bearing reservoir two-phase seepage test can be carried out by simulating an electric pulse action coal body test under the conditions of different ground stress, different voltages and the like and simulating a high-voltage electric pulse cracking coal body physical test under the multi-physical field coupling action.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com