Test method for high-voltage electric pulse in-situ fracturing of coal seam cracks and real-time nondestructive observation

A high-voltage electric pulse and non-destructive observation technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Research on the response mechanism of pulse fracturing coal body and other issues, to achieve the effect of easy processing and replacement, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

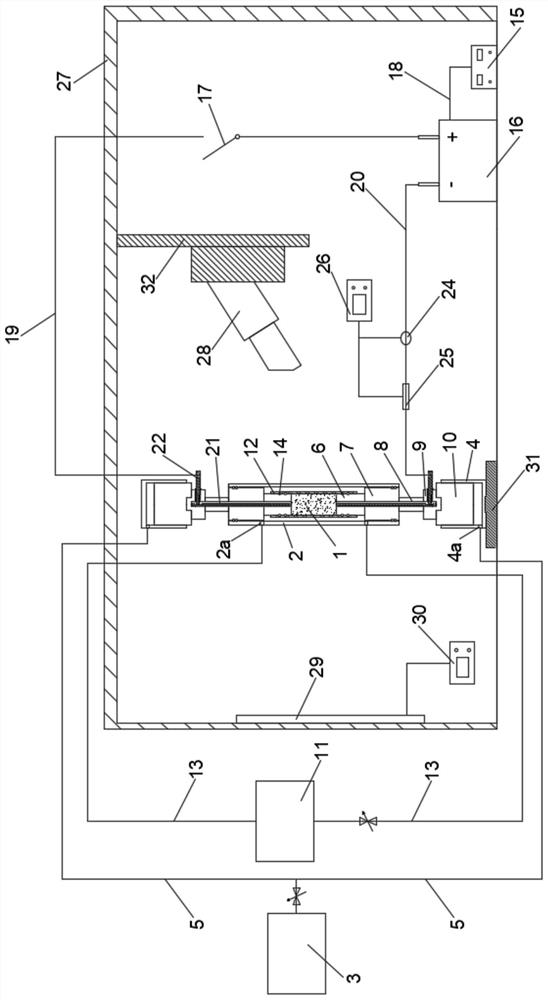

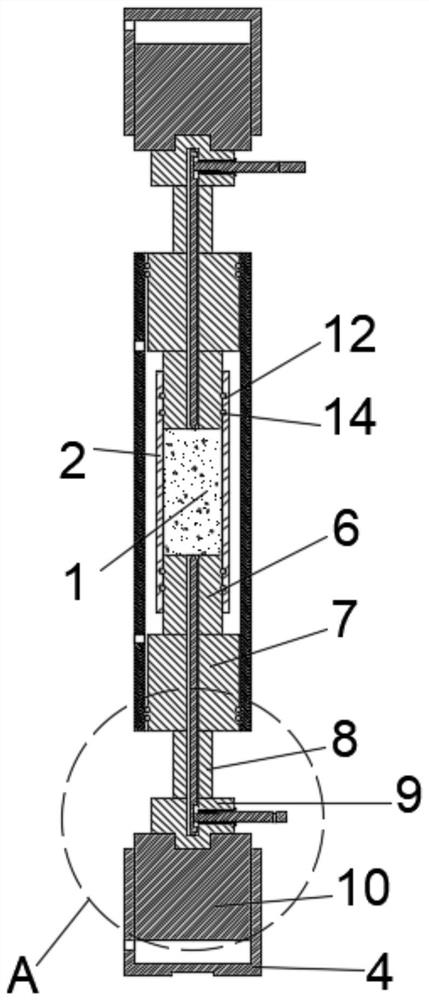

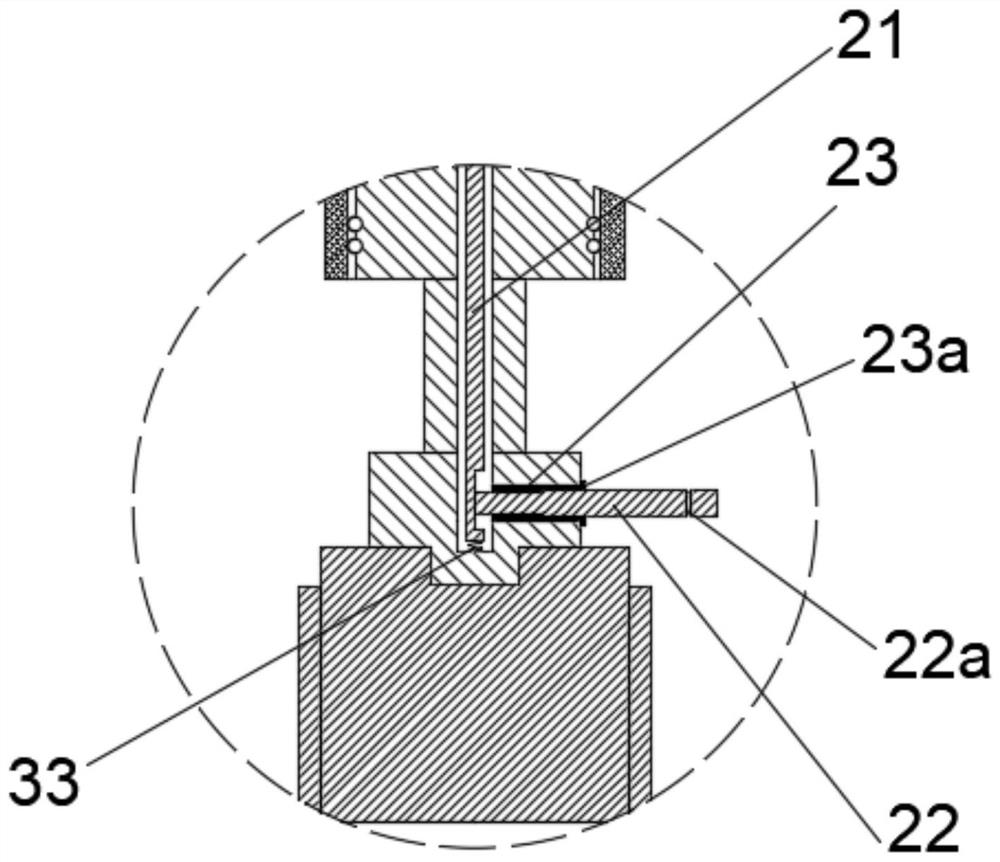

[0048] to combine figure 1 — image 3 As shown, a real-time non-destructive observation device for high-voltage electric pulse in-situ fracturing coal seam fractures is mainly composed of three parts: a stress loading system, a high-voltage electric pulse fracturing operating system, and an in-situ CT scanning system.

[0049] The stress loading system is mainly composed of a pressure chamber 2, an axial pressure loading module and a confining pressure loading module.

[0050] The pressure chamber 2 adopts a circular tube structure, and the test piece 1 is installed in the center of the pressure chamber 2 .

[0051] The axial pressure loading module consists of an axial pressure pump 3, and a first slide bar 6, a second slide bar 7, a third slide bar 8, a fourth slide bar 9, a Five sliding rods 10, an oil cylinder 4, and an axial pressure pipeline 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com