Engine and cam shaft thereof and manufacturing method of cam shaft

A manufacturing method and camshaft technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex camshaft structure, complicated manufacturing process, limited transmission torque, etc., and achieve reduced manufacturing time and improved manufacturing process Effects of simplification, axial size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

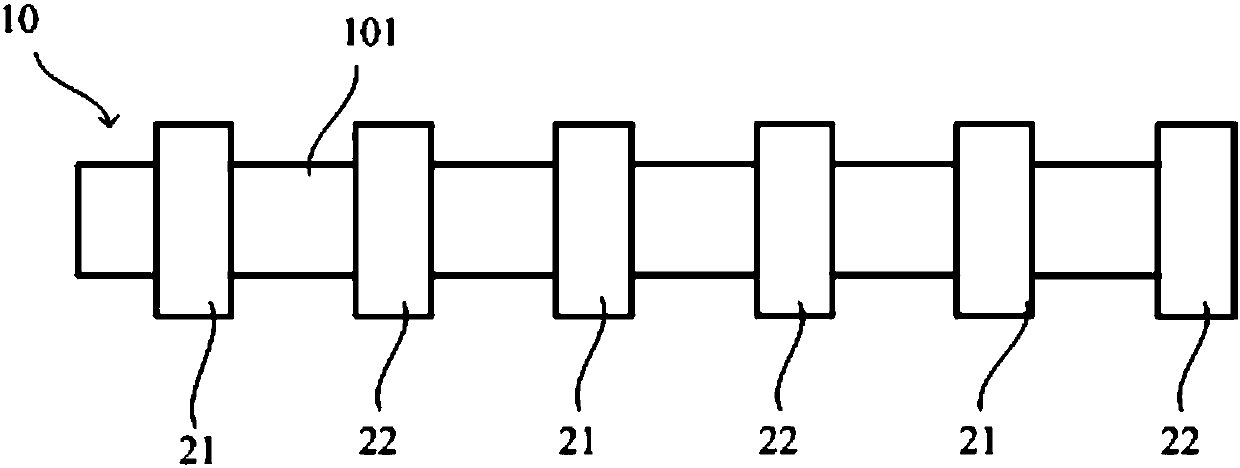

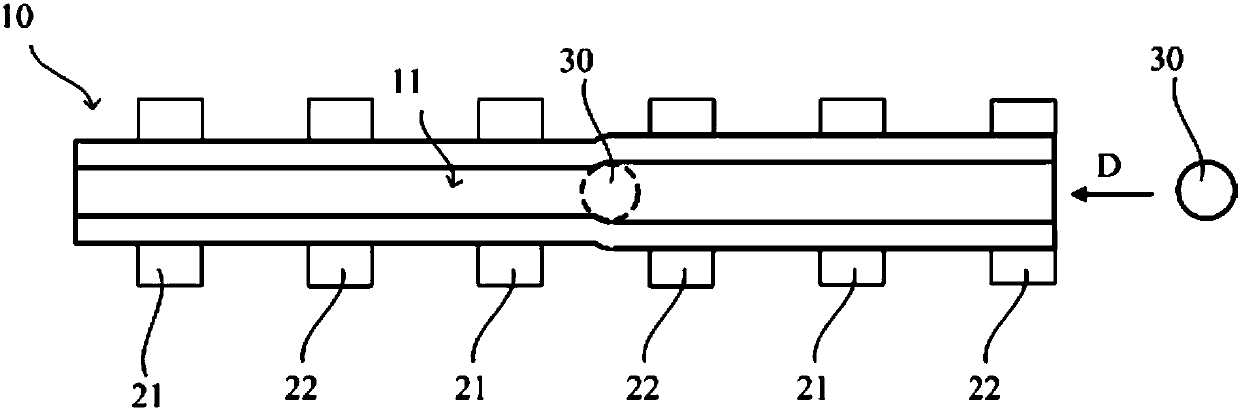

[0074] Embodiments of the present invention provide a camshaft, such as figure 1 As shown, it includes a mandrel 10 and a plurality of cams sleeved on the mandrel 10 . The plurality of cams include a first cam 21 and a second cam 22 . Wherein, the first cam 21 and the second cam 22 are sleeved on the outside of the core shaft 10 and arranged at intervals along the axial direction.

[0075] Such as figure 1 A camshaft with six cams is exemplarily shown, and each cam on the camshaft corresponds to a cylinder. The first cam 21 and the second cam 22 are connected to the core shaft 10 in a rotationally fixed manner, and both rotate synchronously. The first cam 21 and the second cam 22 are respectively used to drive different valves. figure 1 In the illustrated embodiment, the first cam 21 and the second cam 22 are adjacent without other cams in between. In other embodiments, other cams may also be provided between the first cam 21 and the second cam 22 .

[0076] The mandrel 1...

no. 2 example

[0085] This embodiment provides a camshaft. The camshaft of this embodiment changes the structures of the first cam 21 and the second cam 22 on the basis of the first embodiment.

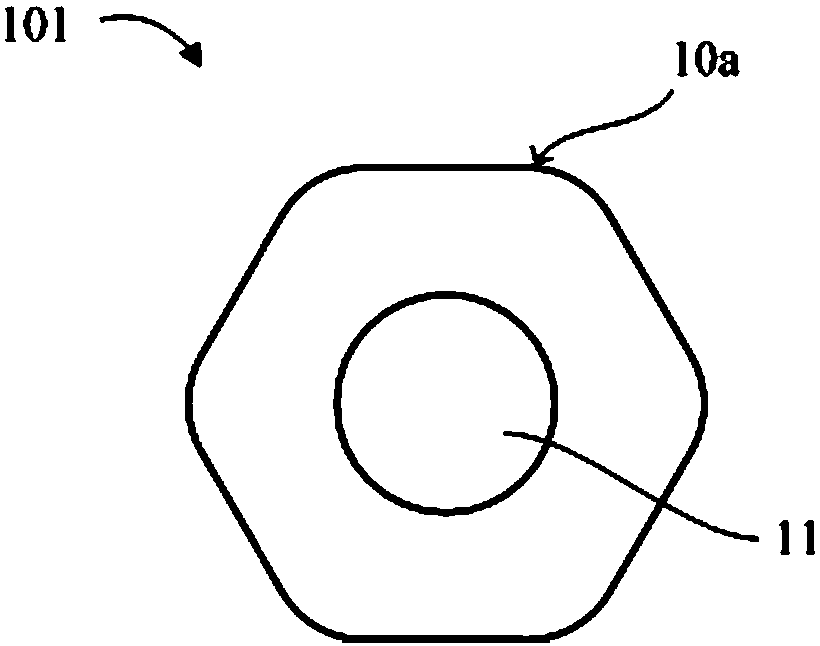

[0086] refer to Figure 5 As shown, at least one of the first cam 21 and the second cam 22 includes a first part 201 and a second part 202 arranged in the axial direction. direction, radial direction and axial direction are all fixed on the mandrel 10, that is, the first part 201, the second part 202 and the mandrel 10 are completely fixed. Relative movement occurs between 10. Wherein, it can be set that all the cams sleeved on the mandrel 10 include the first part and the second part; it can also be set that some cams sleeved on the mandrel include the first part and the second part, and The rest of the cams can be integrally formed cams.

[0087] exist Figure 5 In the shown embodiment, the first cam 21 and the second cam 22 sleeved on the mandrel 10 both include the first part 201 and the sec...

no. 3 example

[0101] This embodiment provides an engine, including the camshaft described in the above-mentioned first embodiment or the second embodiment, and the first valve and the second valve, wherein the first cam 21 is used to drive the first valve but not drive the second valve. Two valves, the second cam 22 is used to drive the second valve but not the first valve.

[0102] The first valve and the second valve may be valves of the same cylinder, or valves of different cylinders.

[0103] When the cam includes the first part 201 and the second part 202, the first part 201 and the second part 202 of the same cam drive at least the same valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com