Omni-wheel based drive mechanism

a technology of drive mechanism and omni-wheel, which is applied in the direction of endless track vehicles, vehicle components, vehicles, etc., can solve the problems of inability to move smoothly when being used indoors, affecting the driving efficiency of the drive roller, and narrow paths available in the house for the robots. achieve good driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

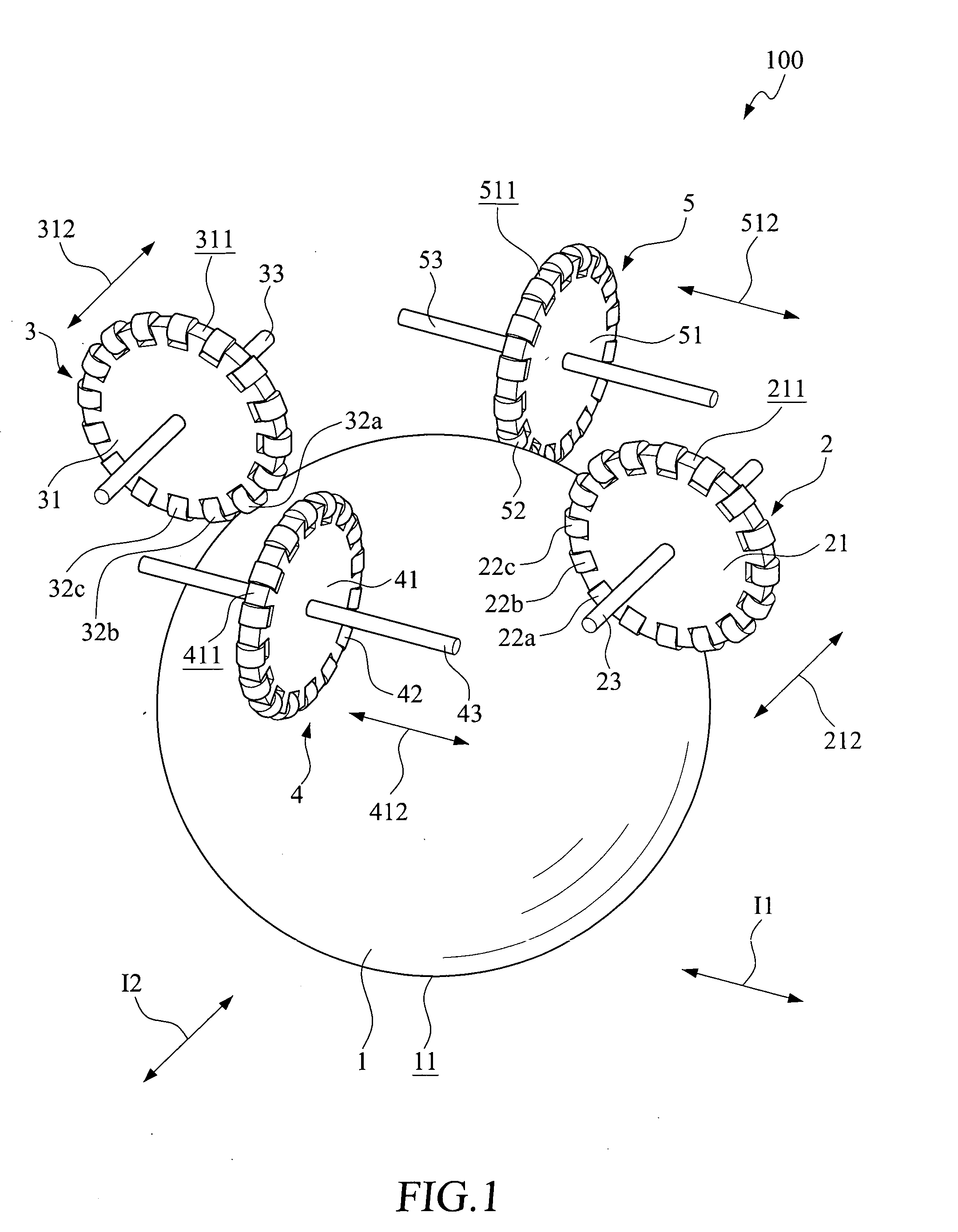

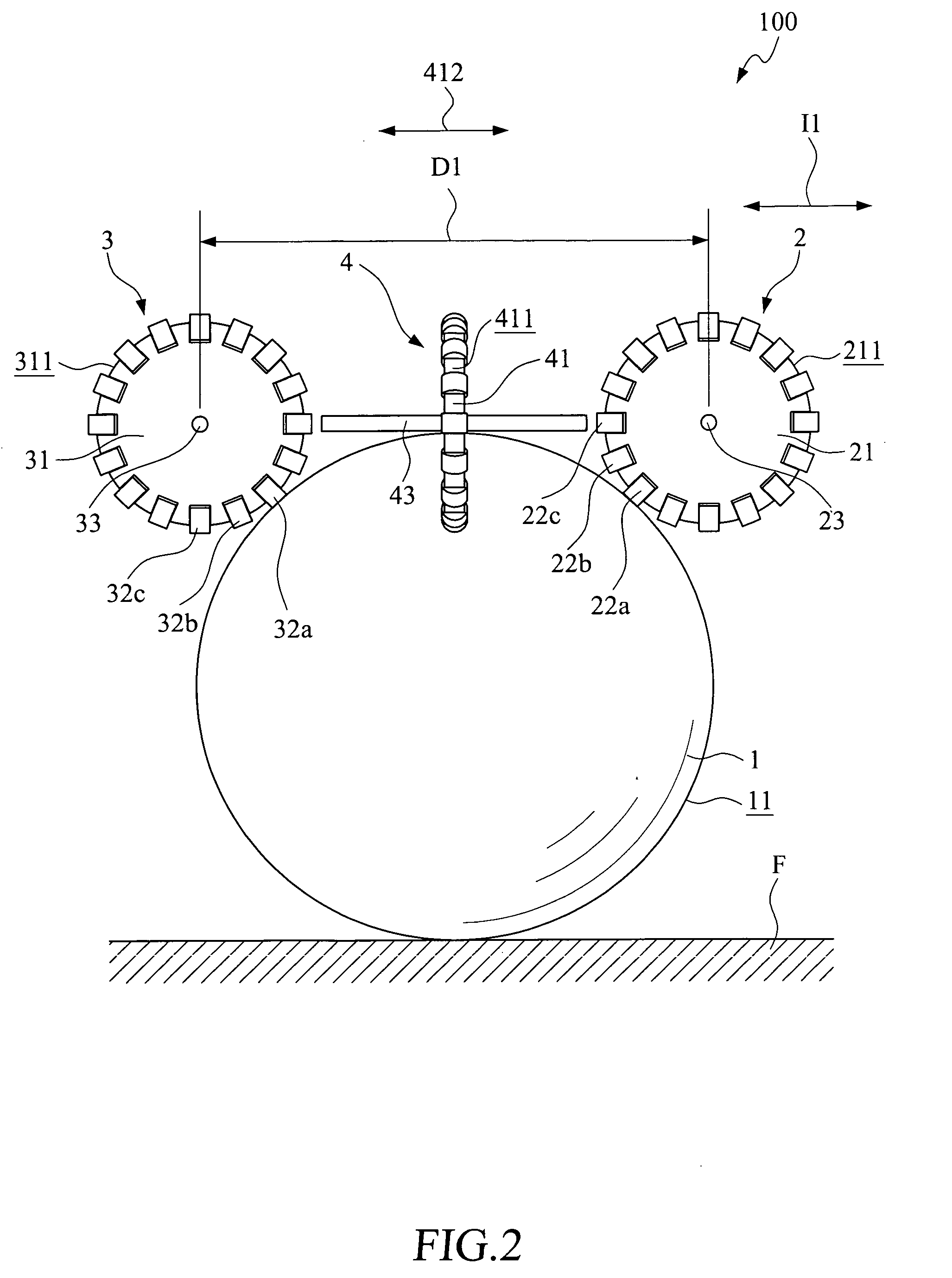

[0031]In the first embodiment, the first direction I1 and the second direction I2 are orthogonal to each other. The spherical wheel 1 is positioned among the first omni wheels 2, 3 and the second omni wheels 4, 5. Of course, the first and the second direction I1, I2 are not necessarily orthogonal to each other, but can contain other different angles between them, depending on actual design and intended use of the drive mechanism.

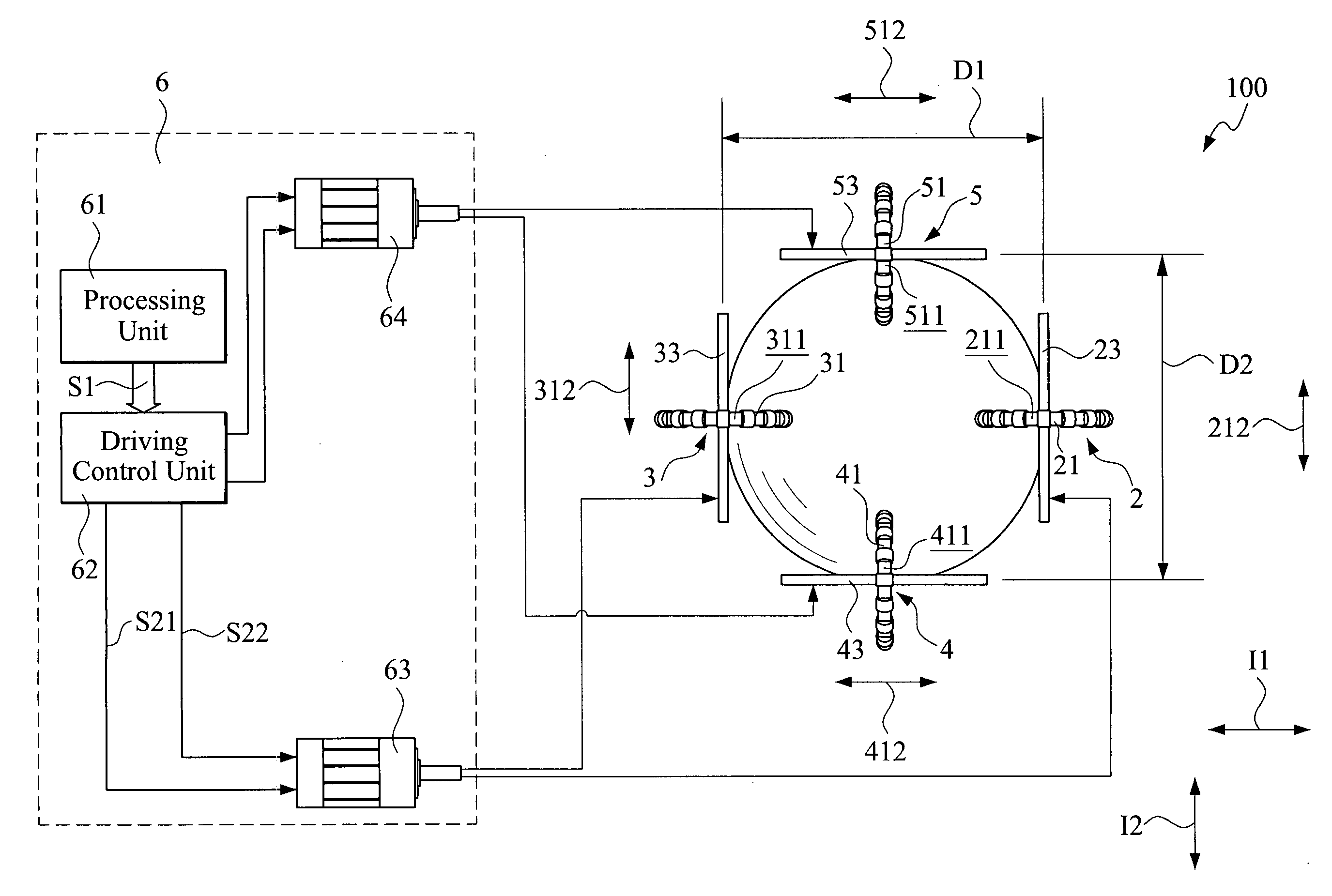

[0032]The control circuit 6 includes a processing unit 61, a driving control unit 62, a first driving unit 63, and a second driving unit 64. The driving control unit 62 is electrically connected to the processing unit 61; and both of the first and the second driving unit 63, 64 are electrically connected to the driving control unit 62. The first driving unit 63 is used to drive the first omni wheels 2, 3, to rotate and the second driving unit 64 is used to drive the second omni wheels 4, 5 to rotate. In the first embodiment, the first and the second driving ...

third embodiment

[0039]FIG. 7 is a side view showing an omni-wheel based drive mechanism 100a according to the present invention. FIG. 8 is a fragmentary and enlarged side view of a link for a chain used in the omni-wheel based drive mechanism. The omni-wheel based drive mechanism 100a is generally structurally similar to the previous embodiments, and includes a plurality of omni wheels 8. Each of the omni wheels 8 includes a main wheel 81, a plurality of guide rollers 82a, 82b, and a drive axle 83.

[0040]The third embodiment is different from the previous embodiments in that the main wheel 81 of the omni wheel 8 includes a driving wheel 811, a guide rail 812, and a driving belt. The driving belt is wound around the driving wheel 811 and the guide rail 812. The guide rollers 82a, 82b are rotatably mounted on and spaced along the driving belt. When the driving wheel 811 brings the driving belt to move, the guide rollers 82a, 82b on the driving belt sequentially contact with the spherical face 11 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com