Composite roll and preparation method thereof

A composite roll and roll ring technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of complex hydraulic nut structure, high processing requirements of parts, and reduced axial pressing force, and is suitable for large-scale promotion. Application, fewer assembly parts, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

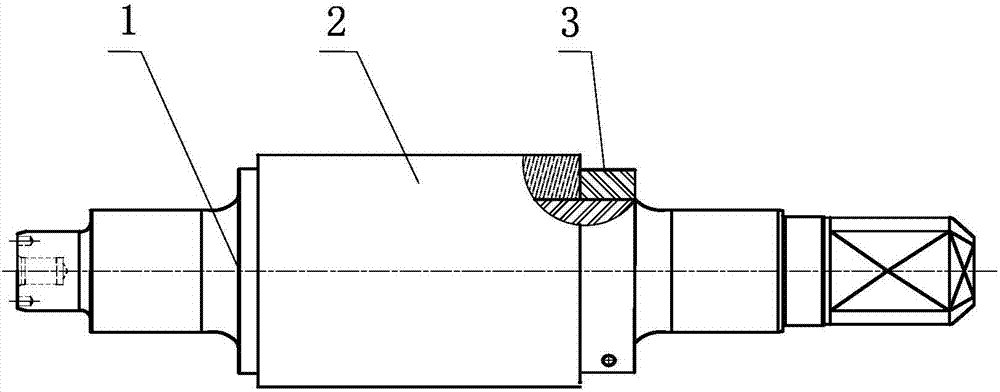

[0054] The cemented carbide composite roll with a lock nut at one end, the specific implementation steps are as follows:

[0055] 1. Set the roller ring 2 on the roller shaft 1, the gap between the roller ring and the roller shaft is matched, and one side of the roller ring is positioned by the roller shaft;

[0056] 2. Screw in the nut 3 and install it on the other side of the roller shaft, and the nut is close to the roller ring along the axial direction;

[0057] 3. Apply axial pressure to the end face of the roller ring, so that the roller ring moves in the axial direction, and the distance between the nut and the roller ring increases;

[0058] 4. The rotating nut moves to the roller ring and fits closely with the roller ring;

[0059] 5. Remove the axial pressure;

[0060] 6. The nut applies an axial compressive force of 100-200 MPa to the end face of the roller ring to fix the roller ring on the roller shaft. The obtained composite roll is as figure 1 shown.

[006...

Embodiment 2

[0063] The cemented carbide composite roll with a lock nut at one end, the specific implementation steps are as follows:

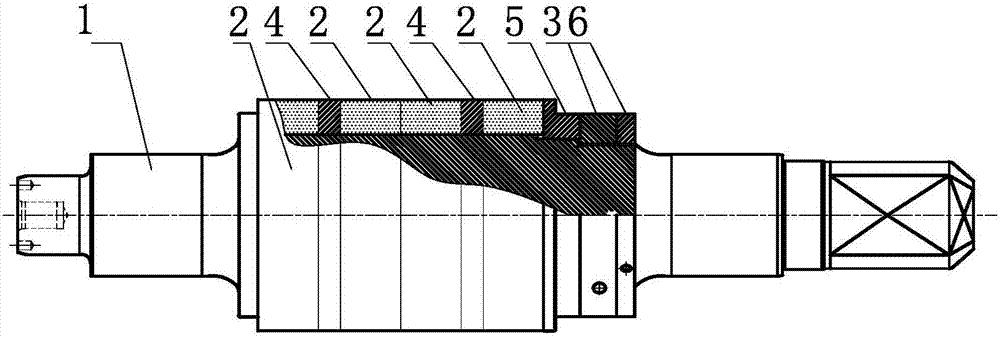

[0064] 1. If Figure 4 As shown, first put the cemented carbide roll ring 2 and the pressing ring 5 on the roll shaft 1 sequentially, and the gap fit is adopted between the roll ring, the pressing ring and the roll shaft. The above hard alloy roll ring can also be one or A plurality of roller rings, spacer rings 4 can be placed between a plurality of roller rings (such as figure 2 shown). One side of the roller ring (a plurality of roller rings refers to the outermost roller ring) is positioned by the roller shaft;

[0065] 2. Set the lock nut 3 on the other side of the roller shaft, and the nut is close to the compression ring along the axial direction, so that the nut and the compression ring are pre-locked.

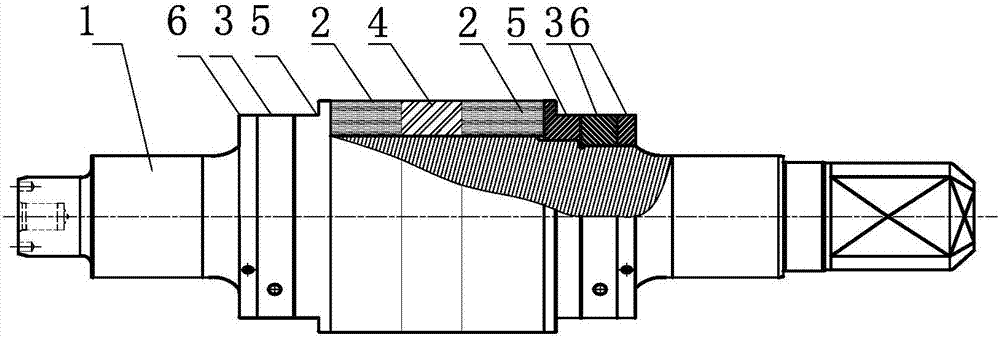

[0066] 3. If Figure 5 As shown, a pressurizing device 7 is installed behind the lock nut 3, and the pressurizing device is fixedly connected...

Embodiment 3

[0073] One end has the cemented carbide composite roll of locking nut, concrete implementation step 1-7 is the same as embodiment 2, also comprises the following steps:

[0074] 8. Install a stop nut 6 on the outside of the lock nut of the roller shaft and tighten it to form a double nut lock to prevent the lock nut from loosening during long-term service and further improve the reliability of use. The obtained easy-to-install and easy-to-unload composite rolls are as follows: figure 2 shown.

[0075] The disassembly method of the above embodiment is as follows: apply an axial pressure to the compression ring to create a gap between the lock nut and the compression ring; loosen the back nut, lock nut, remove the axial pressure, and then remove Back nuts, lock nuts, compression rings, roller rings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com