Pressure-bearing contact type shaft seal ring

A sealing ring and contact technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of loss of sealing performance and degradation of sealing performance, and achieve the effects of preventing leakage, strengthening sealing performance, and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

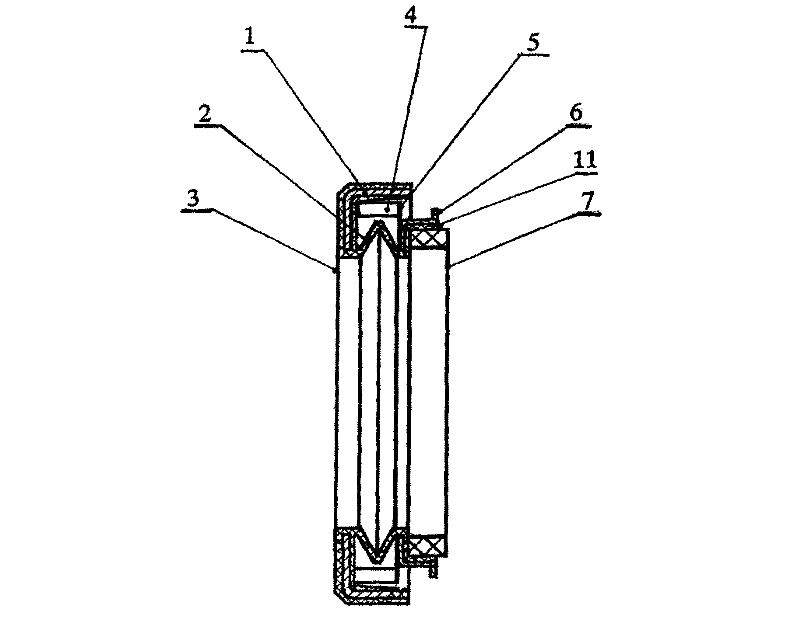

[0020] refer to figure 1 , a pressure-contact shaft seal ring, comprising an outer ring metal skeleton 1, a seal ring main body 3 made of elastomer material, an inner ring metal skeleton 6 and a seal ring 7, and the metal skeleton 1 of the outer ring and the seal ring main body 3 An M-shaped corrugated structural section 2 is arranged between the central inner rings 11, an inner ring metal skeleton 6 is installed on the outer diameter of the central inner ring 11, and an annular toothed spring 5 is installed on the end surface of the inner ring metal skeleton 6, and the central inner ring Sealing ring 7 is installed in the internal diameter of 11.

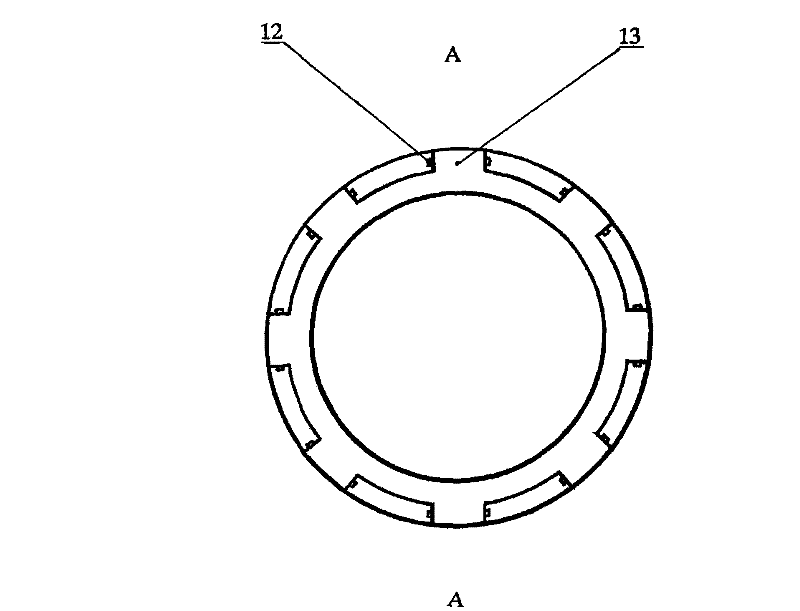

[0021] refer to image 3 Figure 4 , two ends of the combined stepped outer ring metal frame 8 are processed with grooved steps, and the pressure retaining ring 13 is processed with inner holes and outer teeth, and its outer teeth are embedded in the groove at one end of the combined stepped outer ring metal frame 8 The riveting...

Embodiment 2

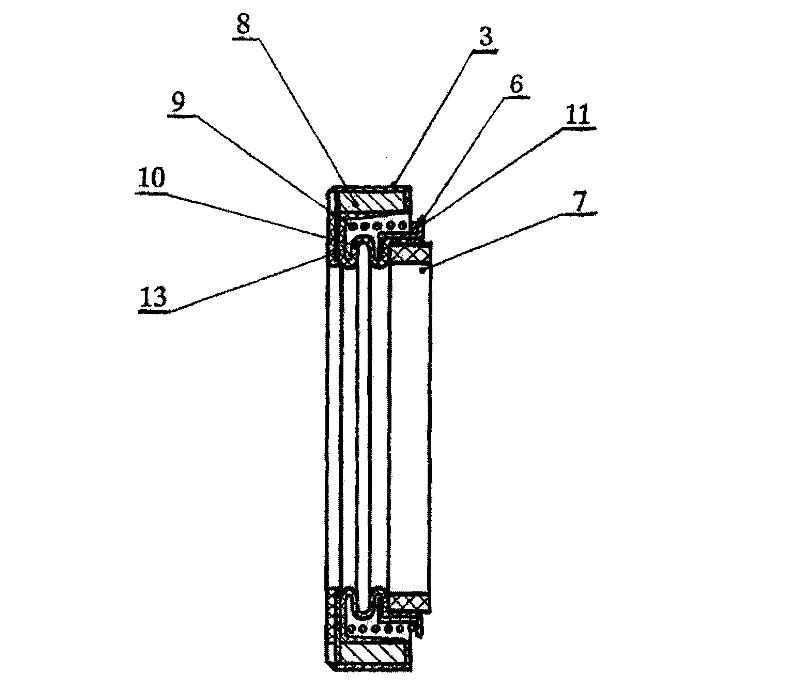

[0025] refer to figure 2 image 3 Figure 4 Another structural form of the pressure-bearing contact shaft seal ring of the present invention includes a seal ring main body 3 made of elastomer material, a combined stepped outer ring metal skeleton 8 and a seal ring 7, and the combined stepped metal skeleton 8 There is an S-shaped corrugated structural section 10 between the central inner ring 11 of the sealing ring main body 3, and the sealing ring main body 3 made of elastomer material wraps the combined stepped outer ring metal skeleton 8 and the pressure ring 13 riveted with it 1. The S-shaped corrugated structure section 10 continues to extend to the central inner ring 11 to form a whole, and a cylindrical spring 9 is installed on the outer flange end face of the inner ring metal skeleton 6 or an annular warping tooth is installed on the inner flange end face Spring, the sealing ring 7 is installed in the center inner ring 11.

[0026] The metal frame 8 of the combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com