Patents

Literature

234results about How to "Shift quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-clutch automatic transmission shift control method

ActiveCN102230532AOvercome limitationsSmooth shiftingGearing controlAutomatic transmissionSolenoid valve

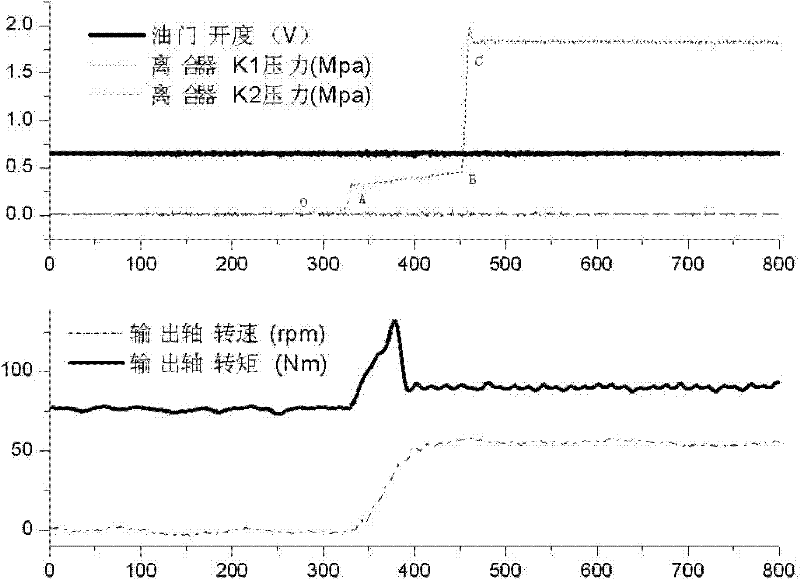

The invention belongs to an automotive transmission and in particular discloses a double-clutch automatic transmission shift control method. The method is characterized in that: a duty ratio of a solenoid valve for controlling the engagement and separation of clutches in a double-clutch automatic transmission is adjusted to control a matched timing sequence of two clutches and respective joint speed and joint pressure thereof in the shifting process, so that the sum of transmission torque of a front clutch and a subsequent clutch adapts to the torque of an engine in the shifting process; and a shifting moment and a corresponding shift method are determined according to an accelerator pedal position signal acquired by a sensor, the rotating speed of the engine, the rotating speed and a clutch pressure signal of an input shaft of the front clutch and the rotating speed and a clutch pressure signal of an input shaft of the subsequent clutch. By the method, the shifting process is stable and rapid, the shifting quality is high, and the riding comfort is improved.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

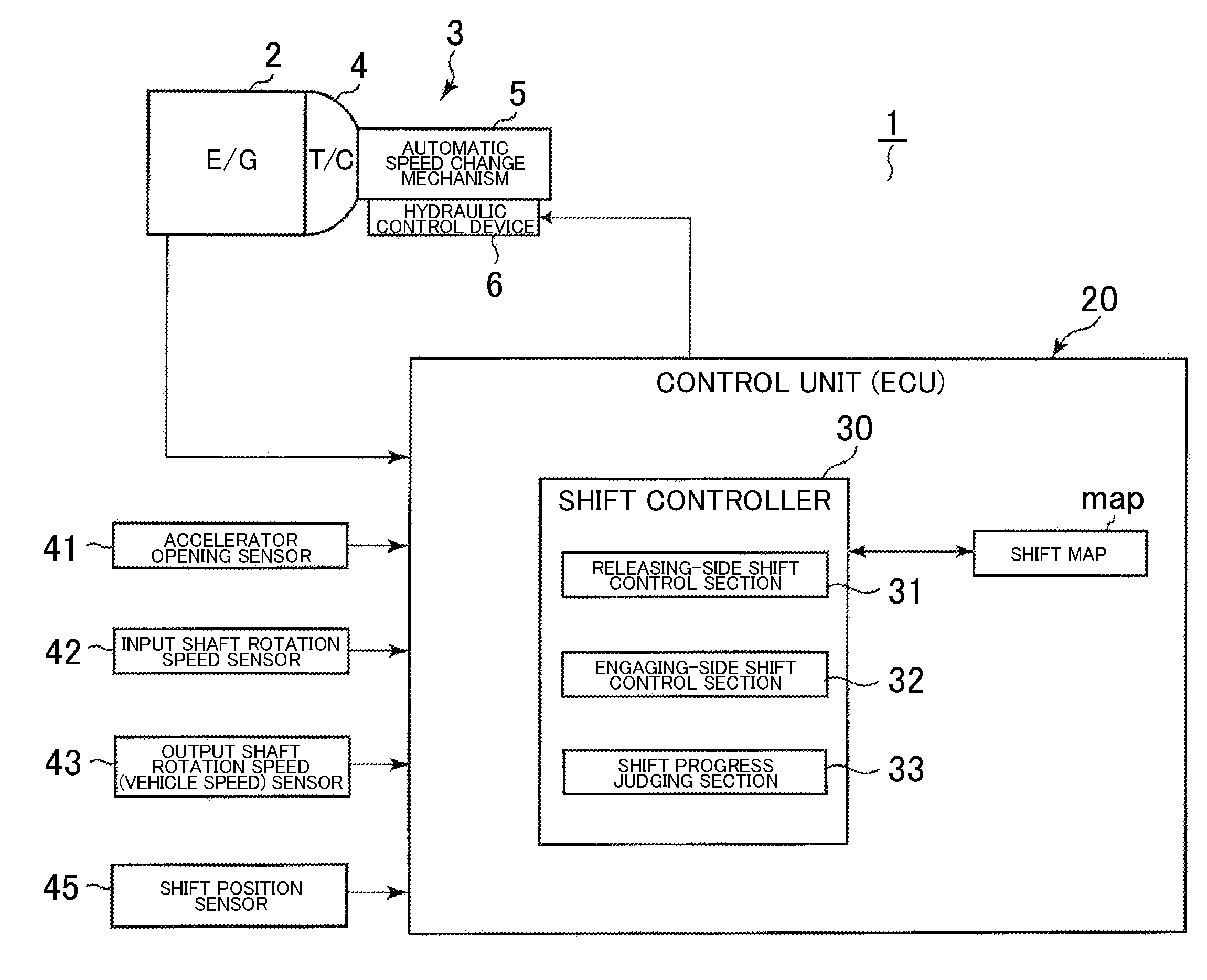

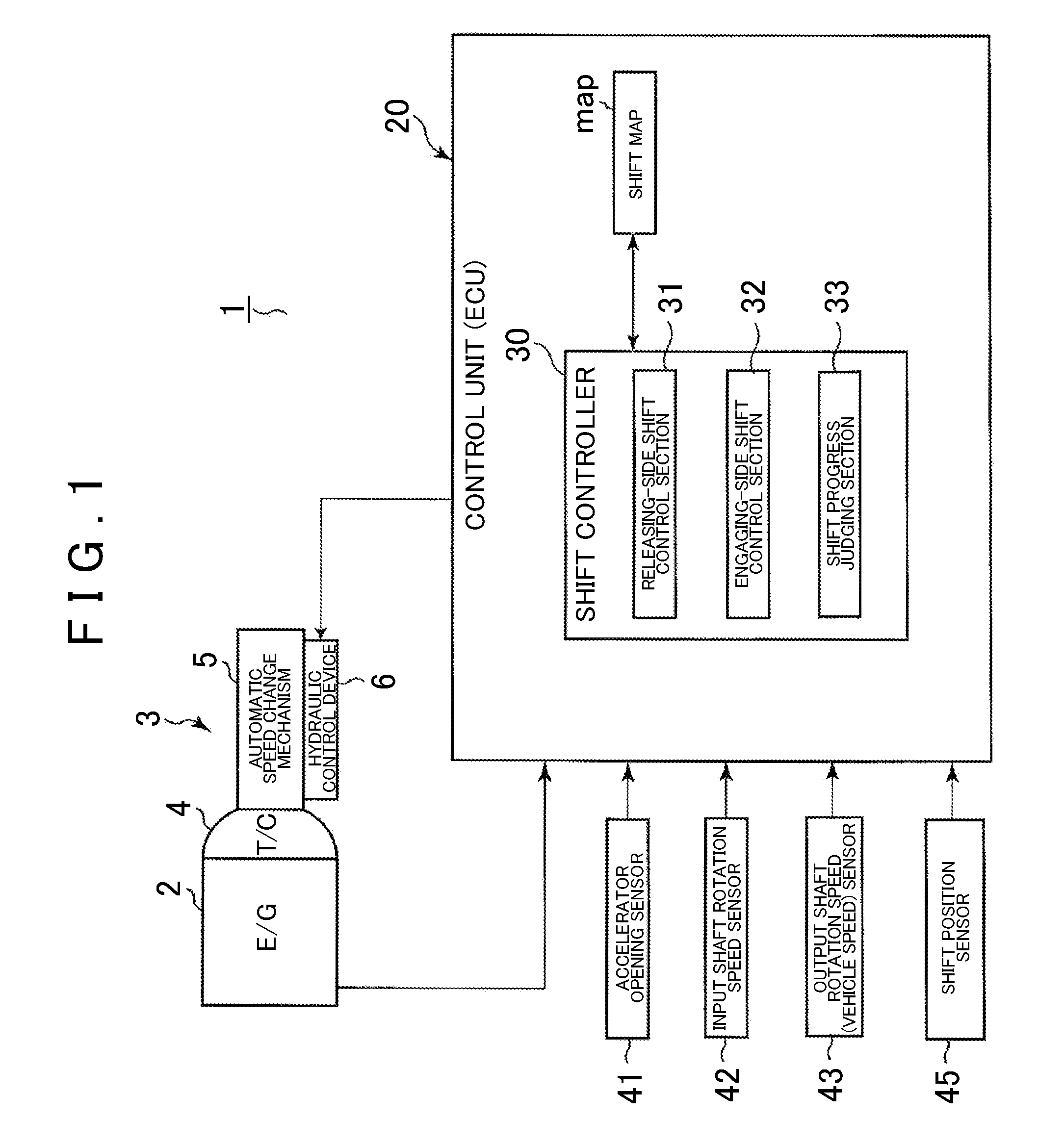

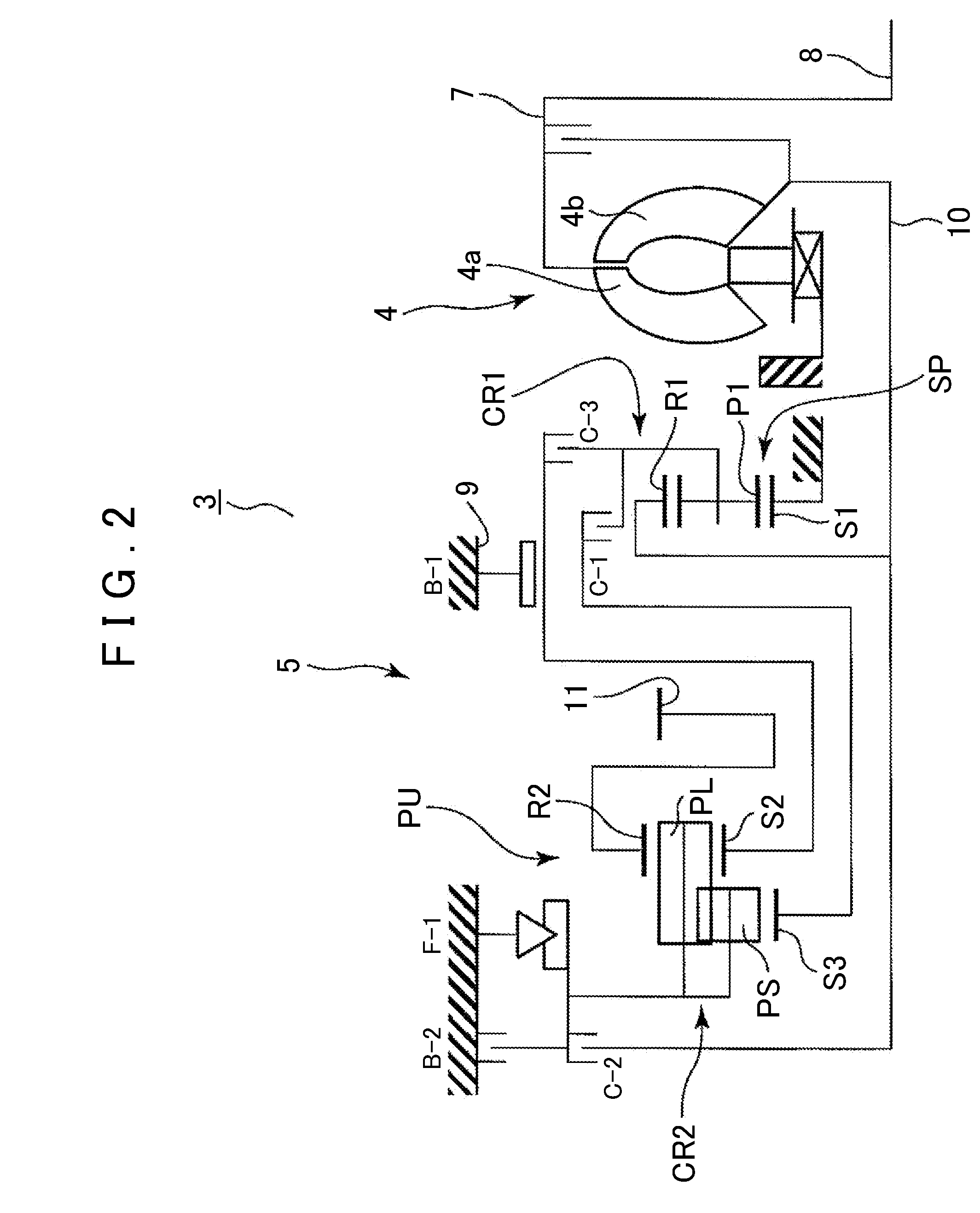

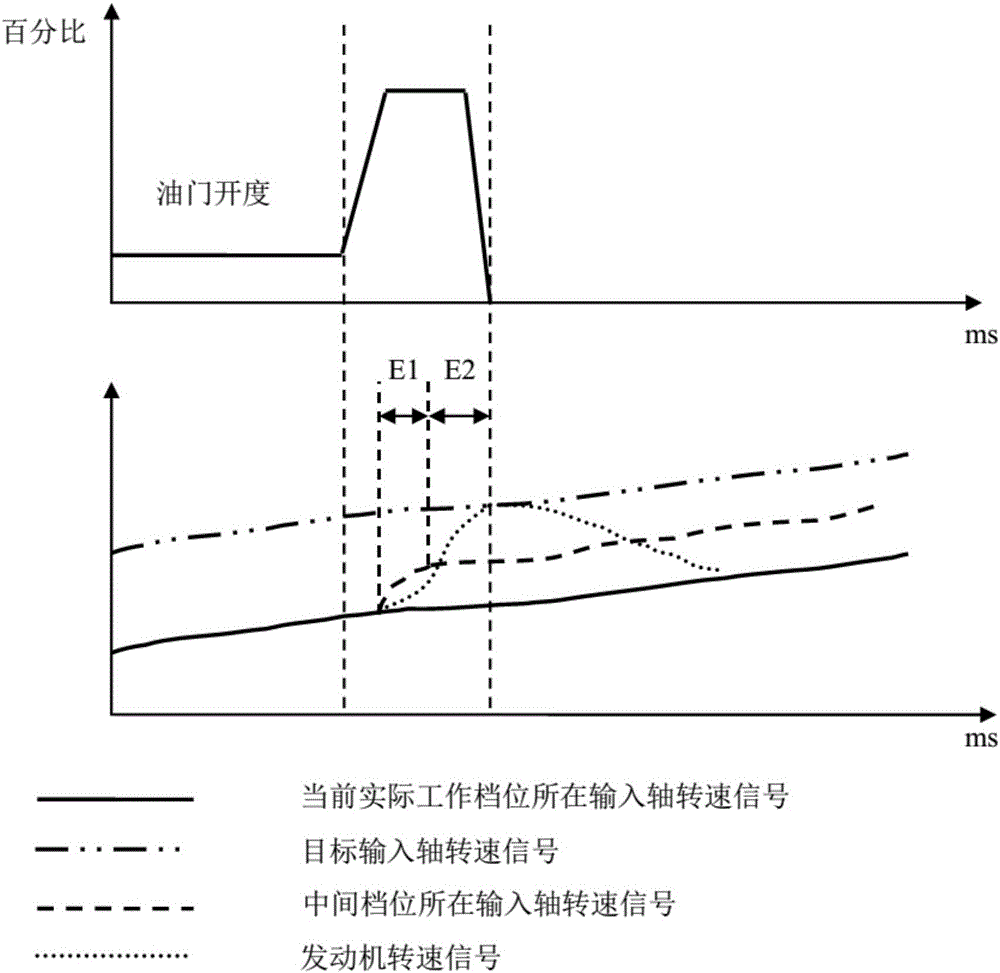

Shift control apparatus for automatic transmission

ActiveUS20090171543A1Eliminate torque fluctuationsShift quicklyDigital data processing detailsGearing controlAutomatic transmissionEngineering

A shift controller controls a downshift to a low shift speed, spaced apart from a high shift speed by two or more steps, through an intermediate shift speed, by first releasing first and second shift release elements, then engaging a first shift engagement element, and finally engaging a second shift engagement element, while controlling the torque capacity of the second shift release element by feedback control. As a result of releasing the first and second shift release elements before engaging the first shift engagement element, it is possible to rev up an input rotation at maximum performance of an engine to reduce the time for shifting. As a result of the feedback control of the torque capacity of the second shift release element after engaging the first shift engagement element, a torque fluctuation at the intermediate shift speed can be reduced to avoid occurrence of an uncomfortable shift shock.

Owner:AISIN AW CO LTD

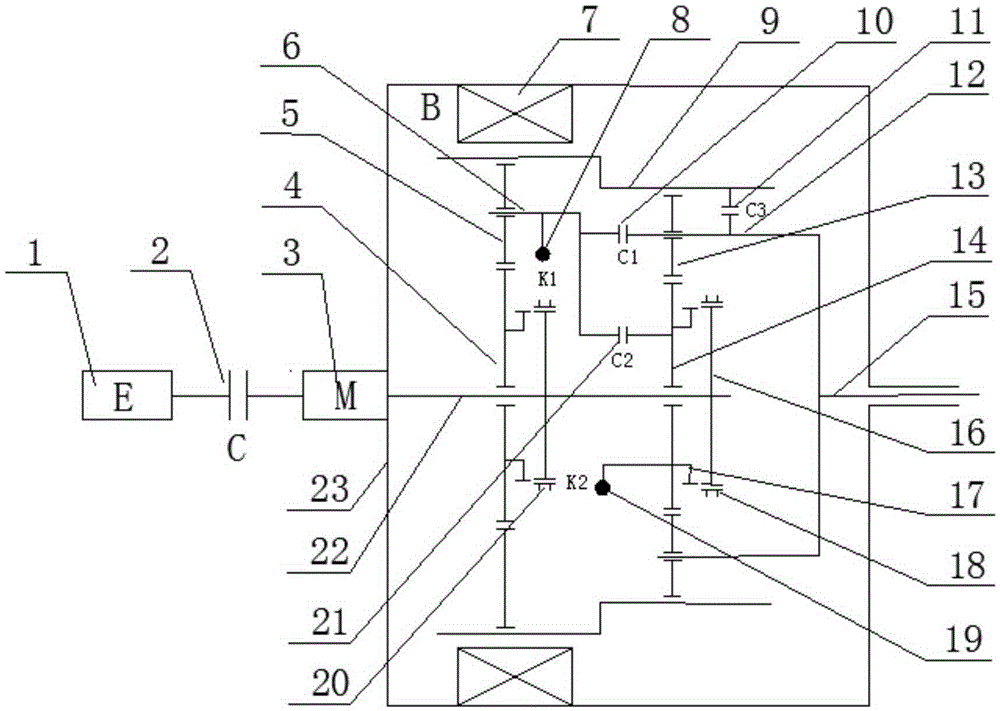

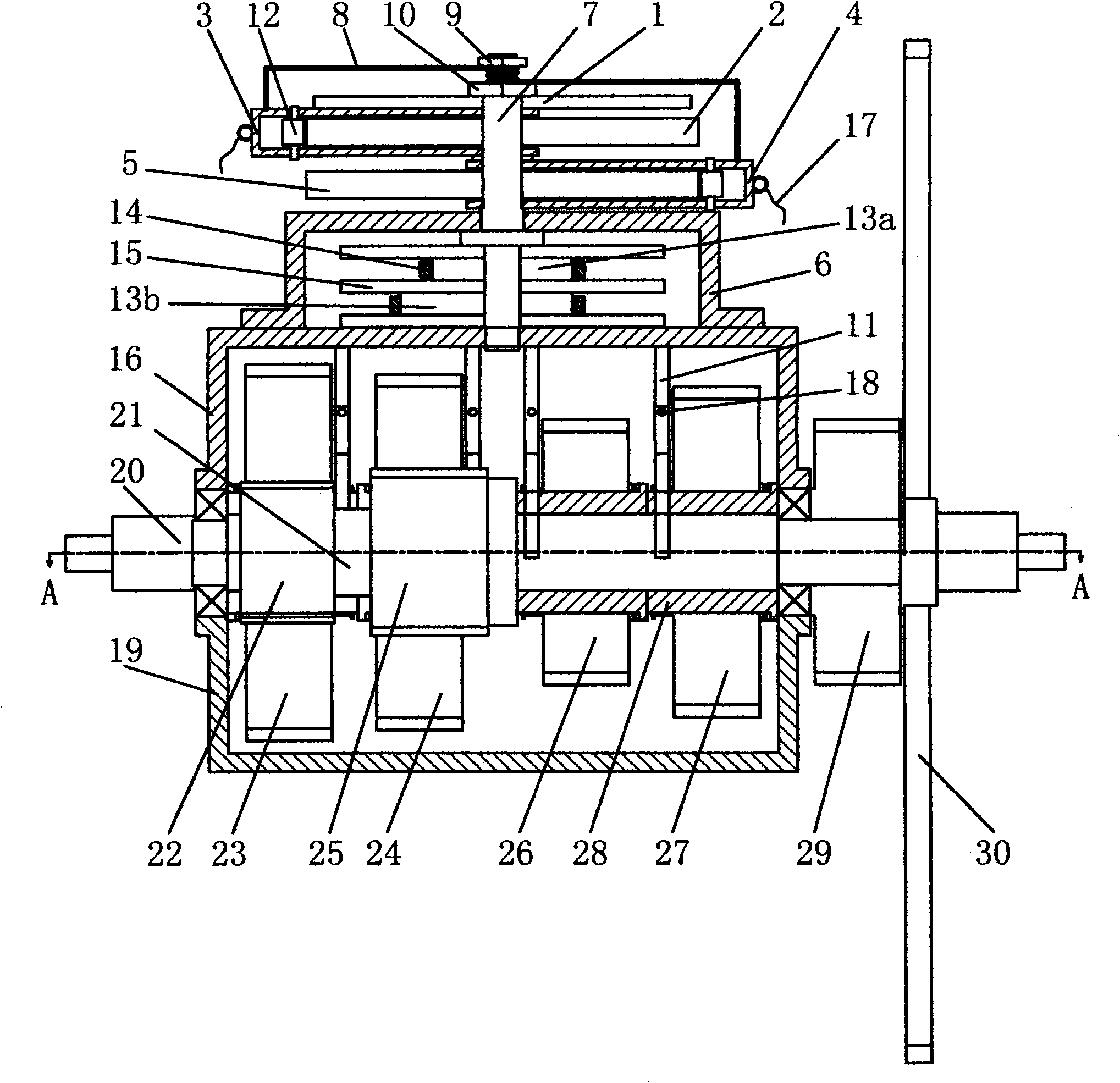

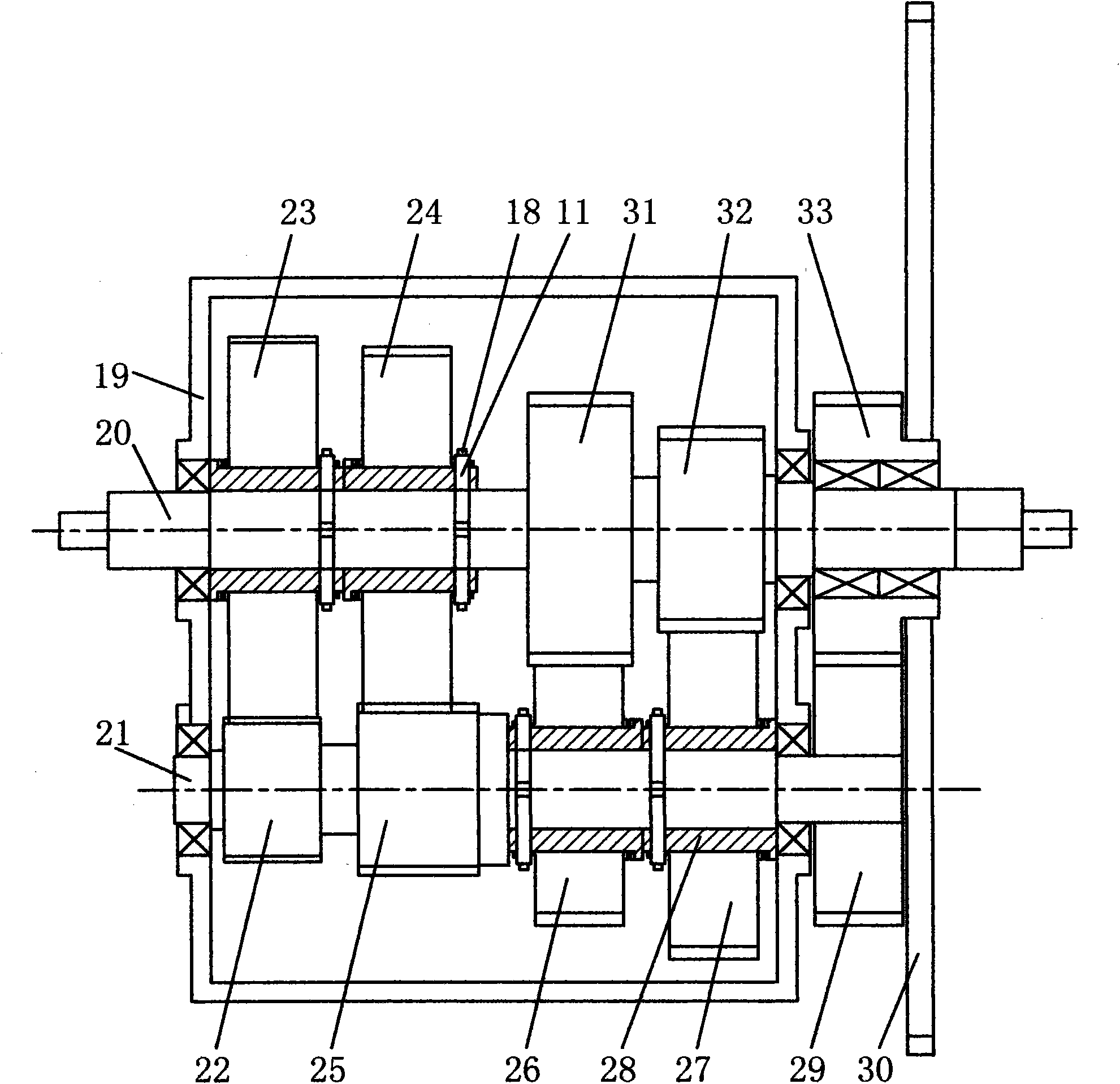

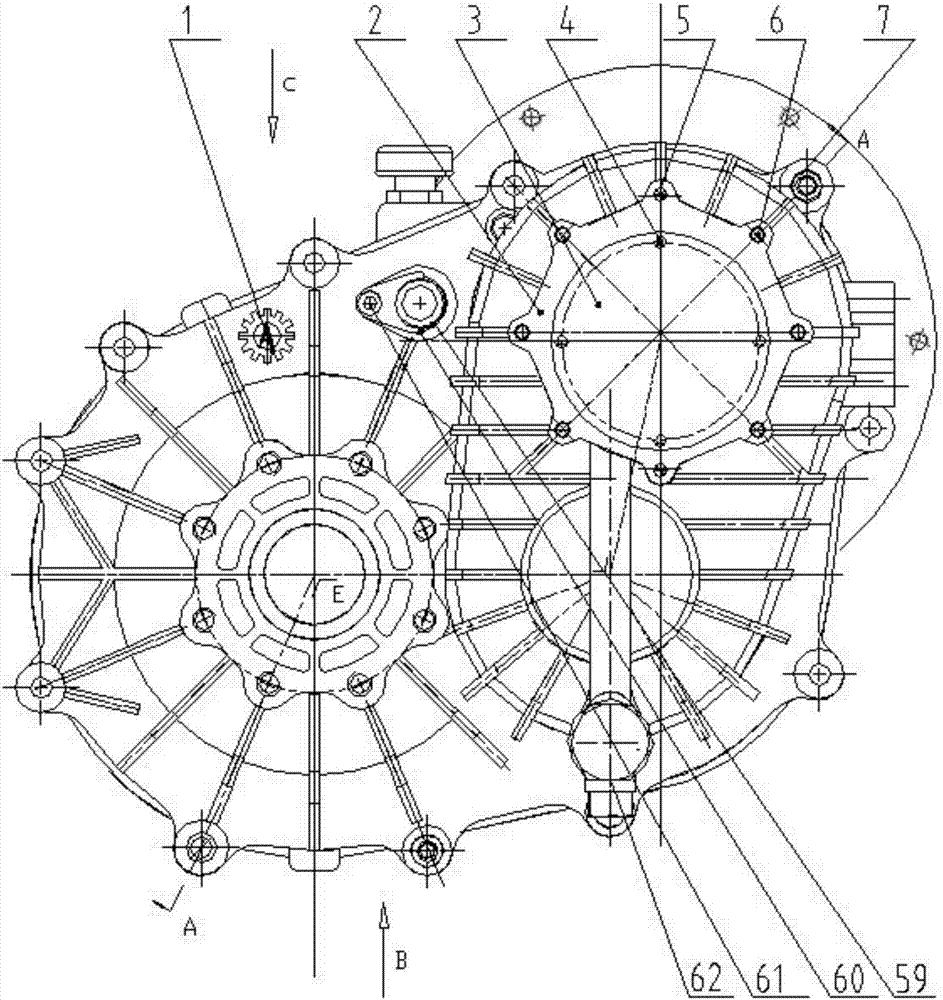

Four-gear mechanical automatic transmission power assembly system based on planetary gear mechanisms

ActiveCN105402334ASmall sizeReduce processing difficultyToothed gearingsAutomatic transmissionGear wheel

The invention discloses a four-gear mechanical automatic transmission power assembly system based on planetary gear mechanisms. The four-gear mechanical automatic transmission power assembly system comprises an engine, a main clutch, a motor, a first planet row, a second planet row, two engagement devices, three auxiliary clutches, an electromagnetic brake, two brakes, a gear ring, and a transmission input shaft as well as a transmission output shaft; the first planet row, the second planet row and a splined hub are orderly arranged on the transmission input shaft; the splined hub is engaged with an engagement sleeve; and switching of four forward gears, a neutral gear and a reverse gear is realized by means of mutual cooperation of the engagement sleeve, the electromagnetic brake and the clutches. Compared with a traditional mechanical transmission, the four-gear mechanical automatic transmission power assembly system based on the planetary gear mechanisms is provided with no synchronizer, and instead, the motor is adopted for accurate speed regulation to realize smooth gear shifting, and two planetary gear mechanisms are used to take the place of traditional a plurality of pairs of gear mechanism; as a result, the overall mechanism is simple, small in volume, low in cost and easy to manufacture.

Owner:包头北奔重汽桥箱有限公司

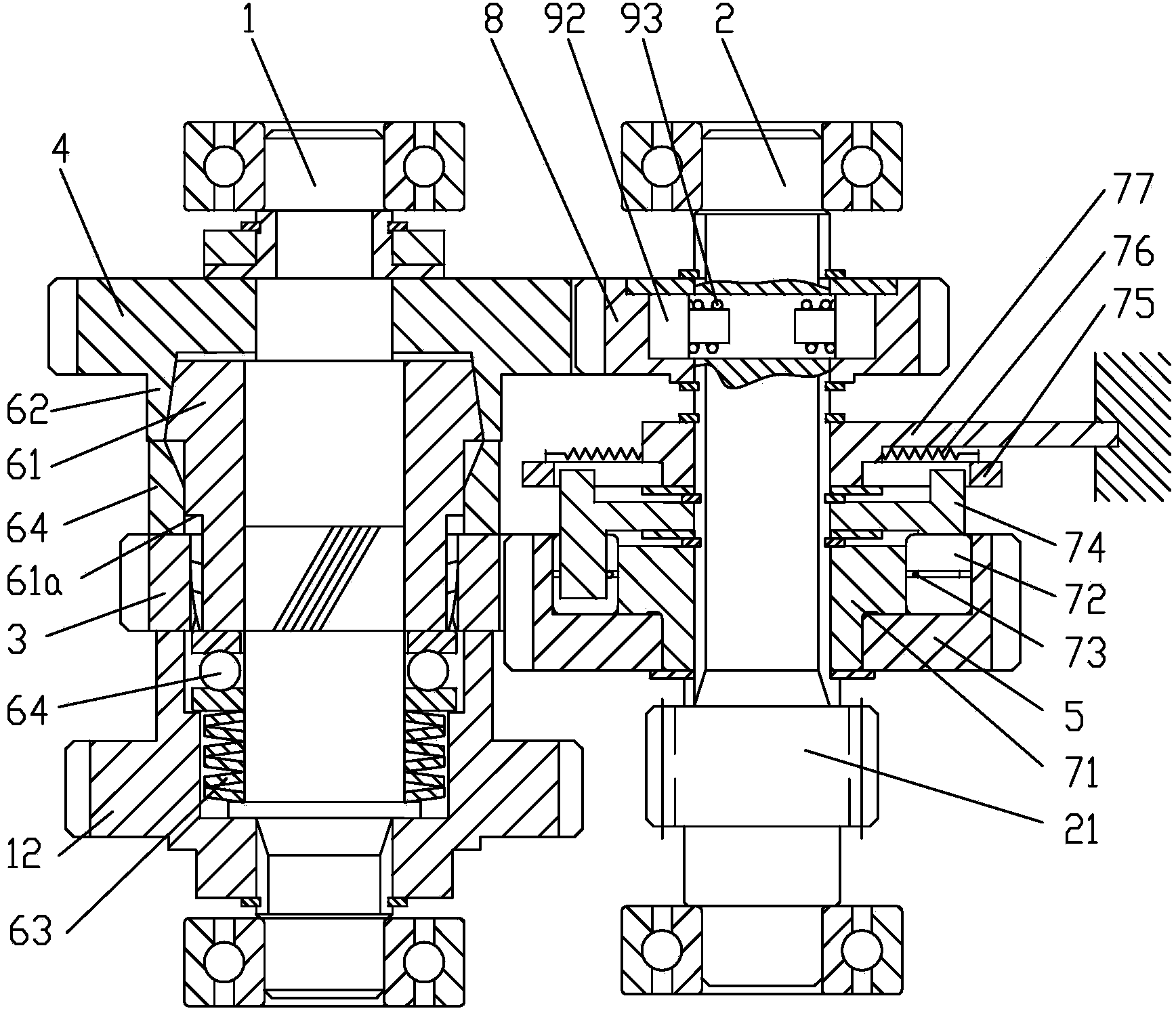

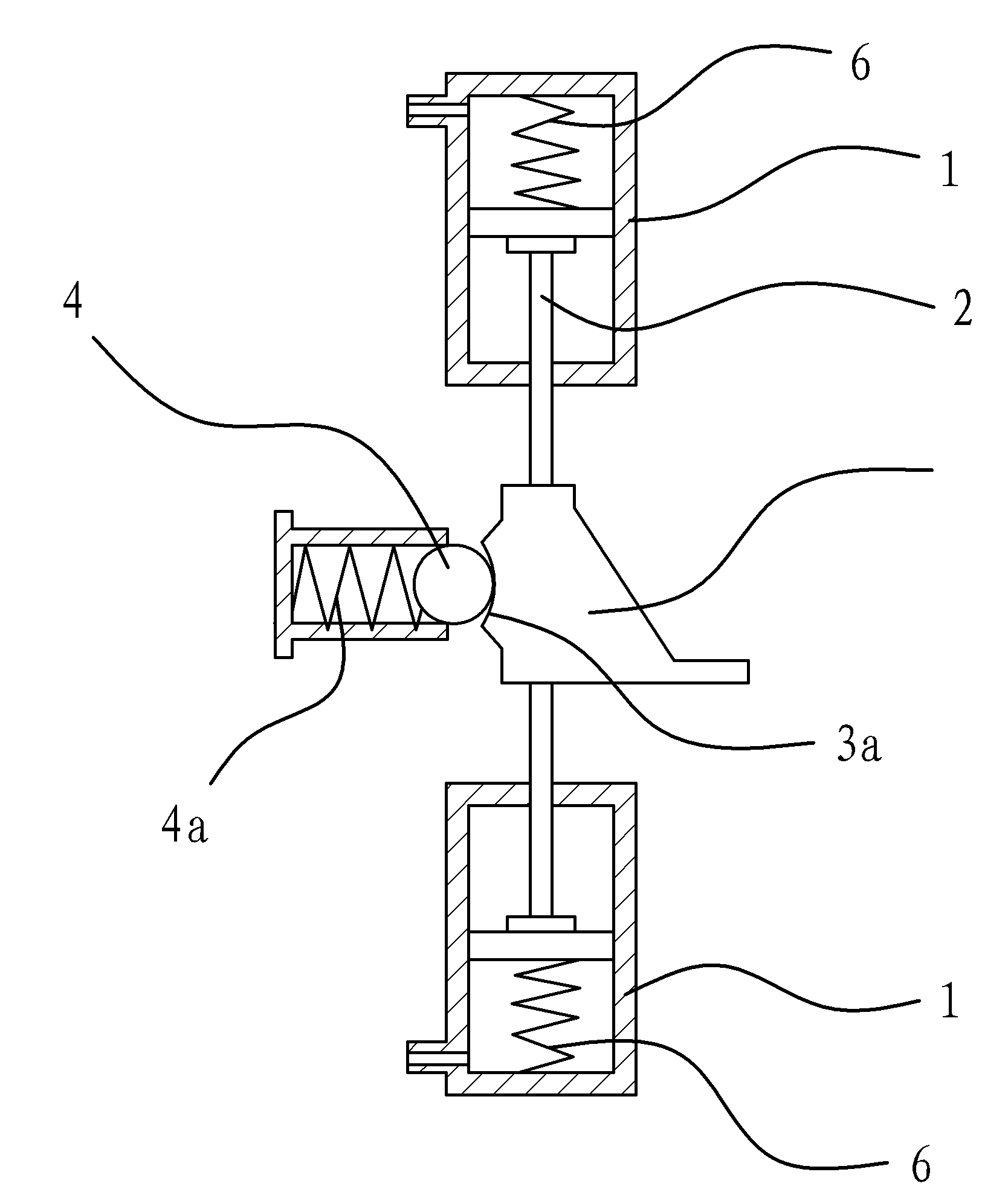

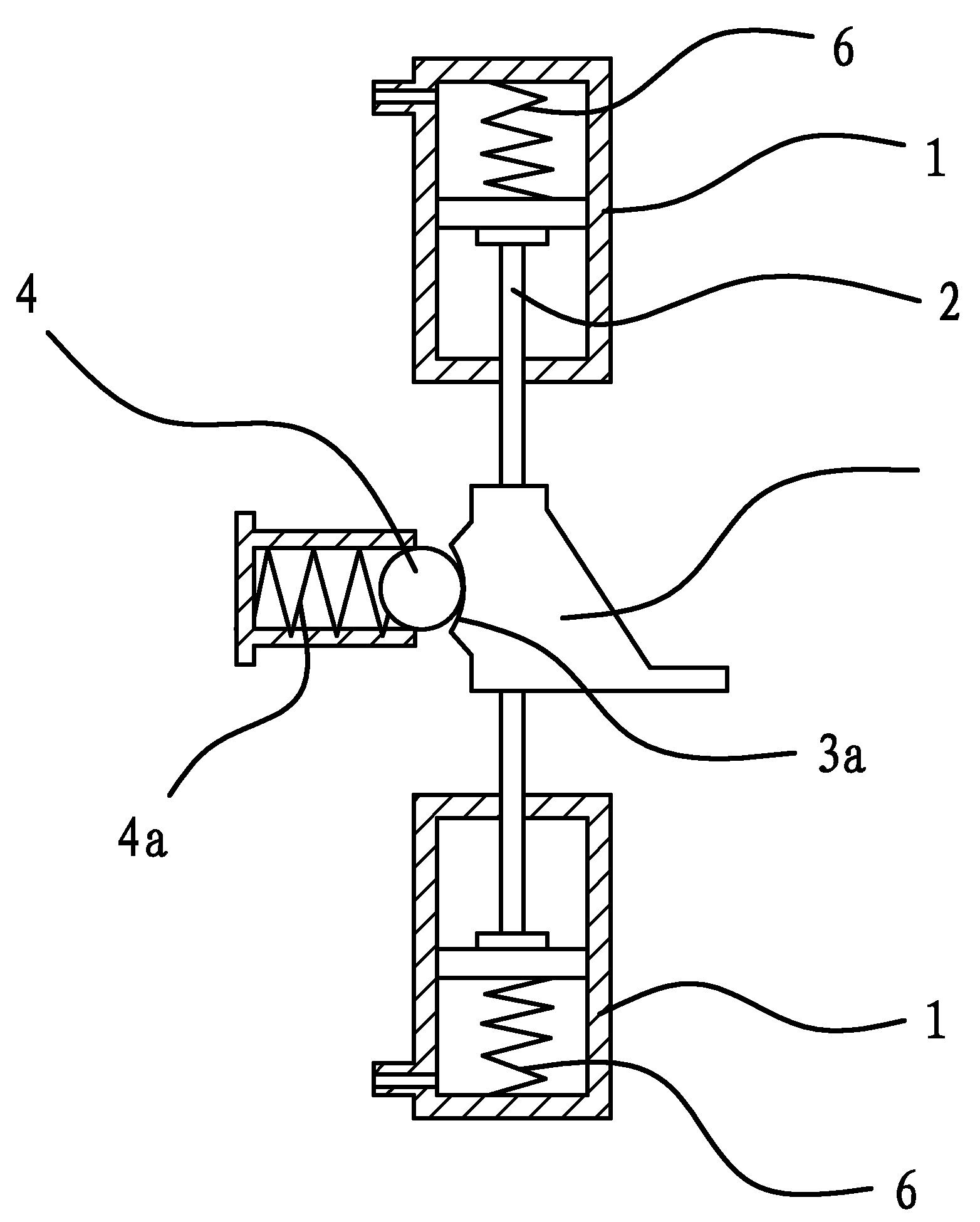

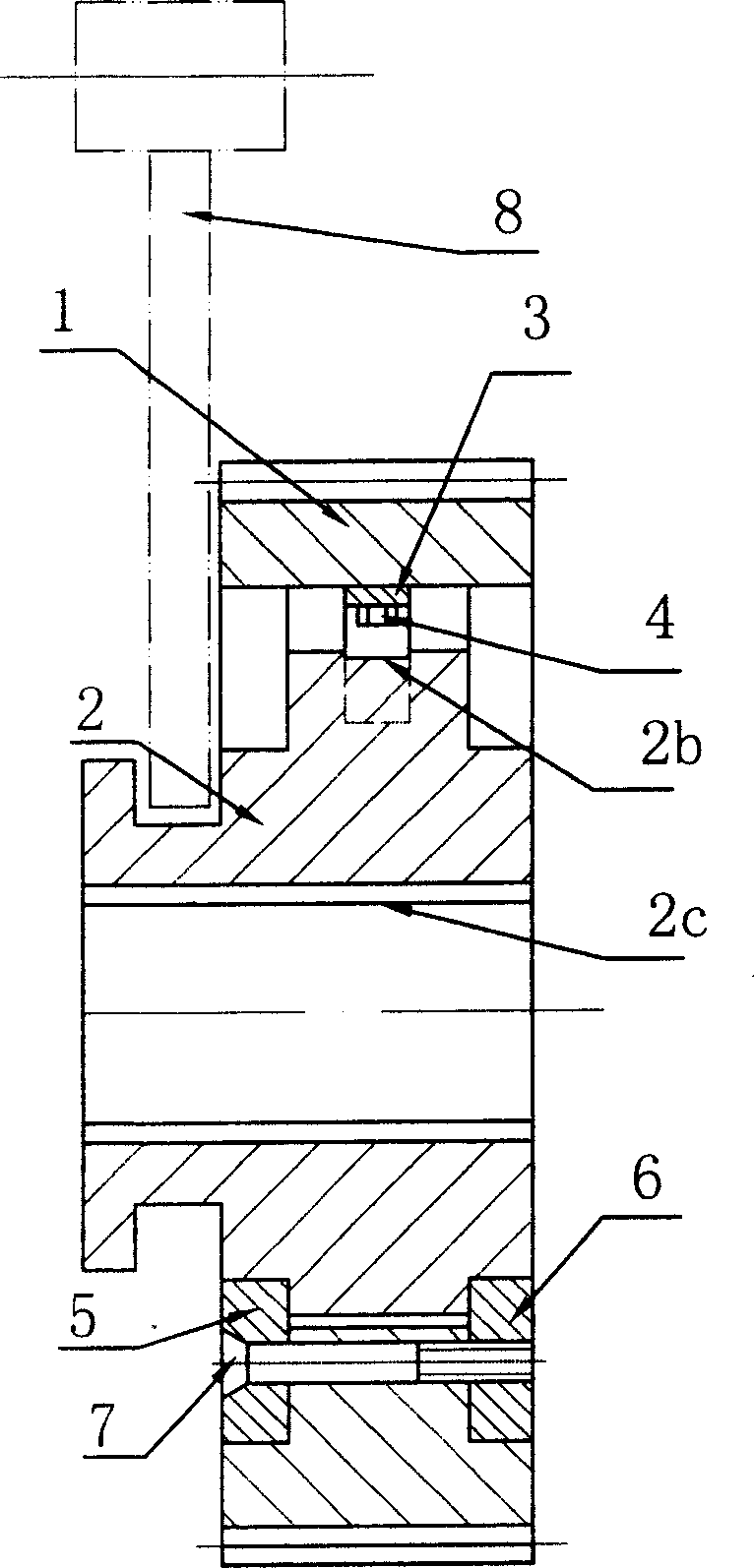

Automatic speed change gear with torsion limiting clutch and speed change shaft

InactiveCN103982602AWith reverse drive functionRealize functionToothed gearingsGearing controlClutchTransmission function

The invention discloses an automatic speed change gear with a torsion limiting clutch and a speed change shaft. The speed change gear comprises a high-speed drive gear, a low-speed drive gear, a high-speed driven gear and a low-speed driven gear, wherein the high-speed drive gear and the low-speed drive gear are arranged on a drive shaft, the high-speed driven gear and the low-speed driven gear are arranged on a driven shaft, and the high-speed drive gear, the low-speed drive gear, the high-speed driven gear and the low-speed driven gear are correspondingly and constantly meshed. The drive shaft is provided with the normally-closed torsion limiting clutch used for power connection of the high-speed drive gear and the drive shaft. A connection structure capable of synchronously rotating is formed by the low-speed drive gear and the drive shaft. A one-way overrunning clutch or a two-way overrunning clutch is arranged between the high-speed driven gear and the driven shaft and between the low-speed driven gear and the driven shaft respectively. The speed change shaft comprises the drive shaft, the high-speed drive gear, the low-speed drive gear and the normally-closed torsion limiting clutch, wherein the high-speed drive gear and the low-speed drive gear are arranged on the drive shaft and the normally-closed torsion limiting clutch is used for power transmission between the high-speed drive gear and the drive shaft. The drive end of the clutch is connected with the drive shaft through a spiral spline structure. The automatic speed change gear and the speed change shaft have the advantages that the speed change gear enables the automatic two-gear shifting function of forward transmission and the inverted transmission function to be achieved and is simple in structure and rapid in gear shifting; the high-speed inverted output torsion of the speed change shaft is larger than the forward output torsion.

Owner:傅元才

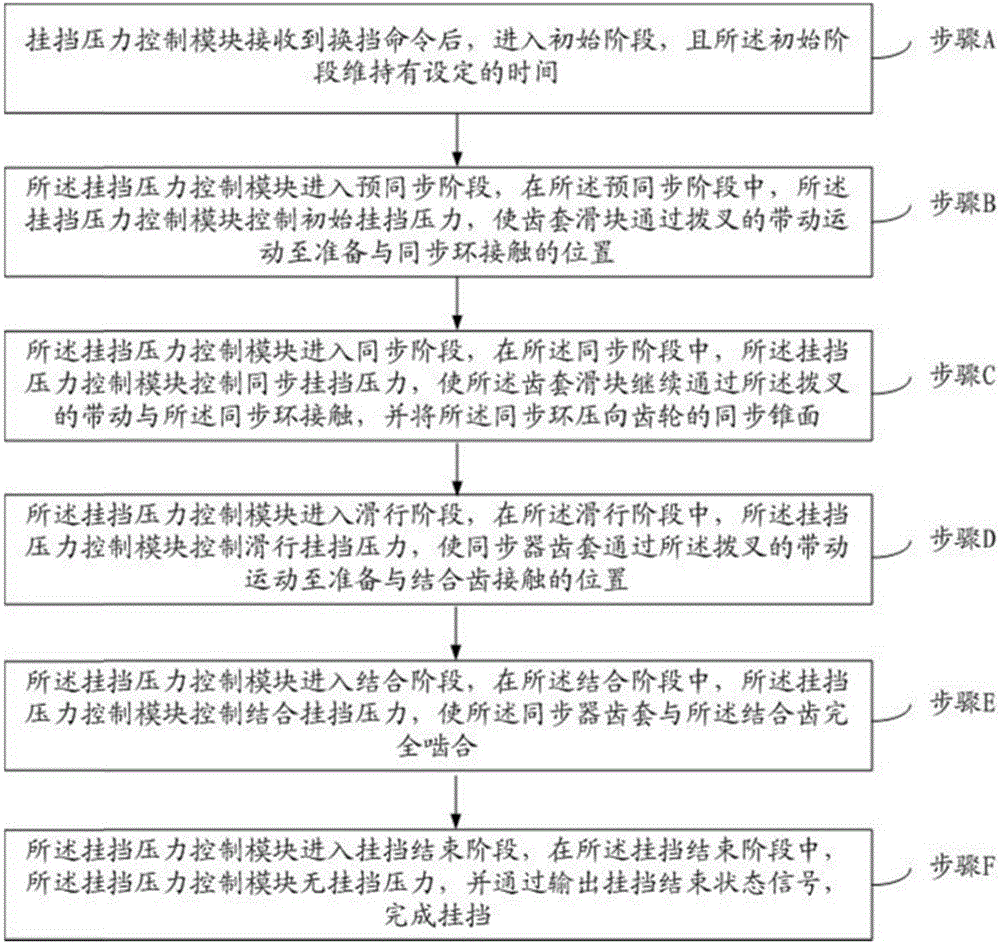

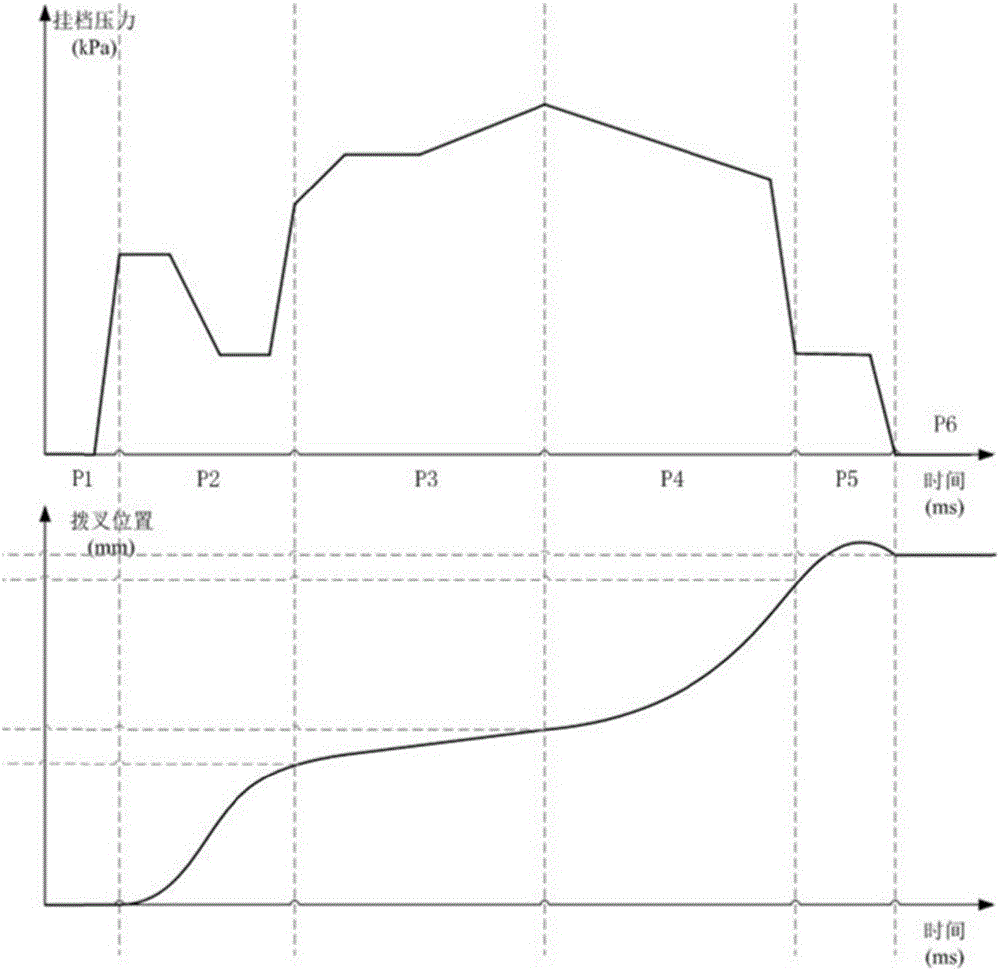

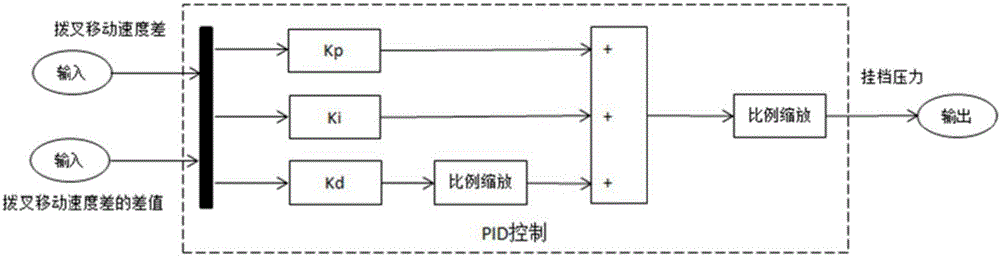

Control method of gear shifting force of shifting fork of automatic dual-clutch transmission

ActiveCN106286813AAchieving Adaptive ChangesSmooth in-gear pressure curveGearing controlPressure curveAutomatic transmission

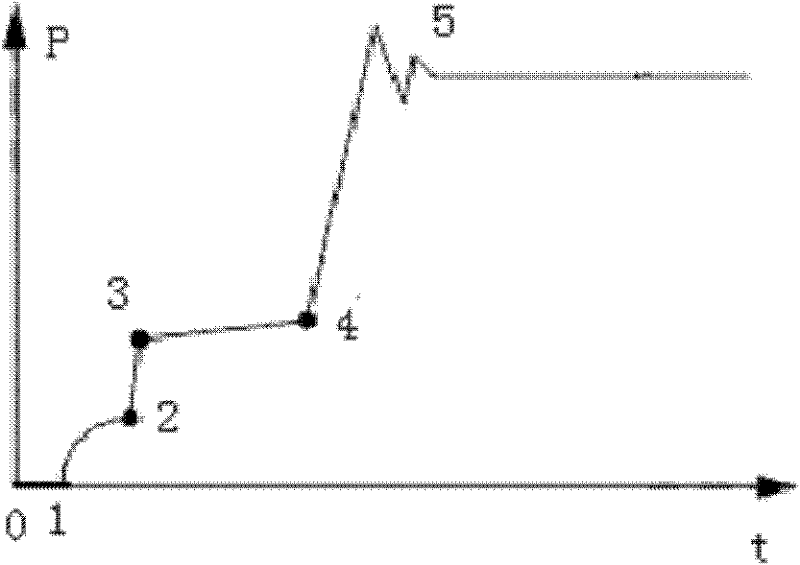

The invention discloses a control method of gear shifting force of a shifting fork of an automatic dual-clutch transmission. After a gear shifting pressure control module receives a gear shifting command, the initial stage is switched to the pre-synchronization stage, initial gear shifting pressure is controlled, and a gear sleeve sliding block is driven by the shifting fork to move to the position where the gear sleeve sliding block is to make contact with a synchronizing ring; in the synchronization stage, the synchronous gear shifting pressure is controlled, and the gear sleeve sliding block is continued to be driven by the shifting fork to make contact with the synchronizing ring; in the sliding stage, the sliding gear shifting pressure is controlled, a synchronizer gear sleeve is driven by the shifting fork to move to the position where the synchronizer gear sleeve is to make contact with a conjunction gear; in the conjunction stage, the conjunction gear shifting pressure is controlled, and the synchronizer gear sleeve is engaged with the conjunction gear; and in the termination stage, gear shifting is completed by outputting a gear shifting termination state signal. According to the control method of the gear shifting force of the shifting fork of the automatic dual-clutch transmission, adaptive change of gear shifting force of gears is achieved, a gear shifting pressure curve is smooth in the gear shifting process, and one-time fast gear shifting is achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

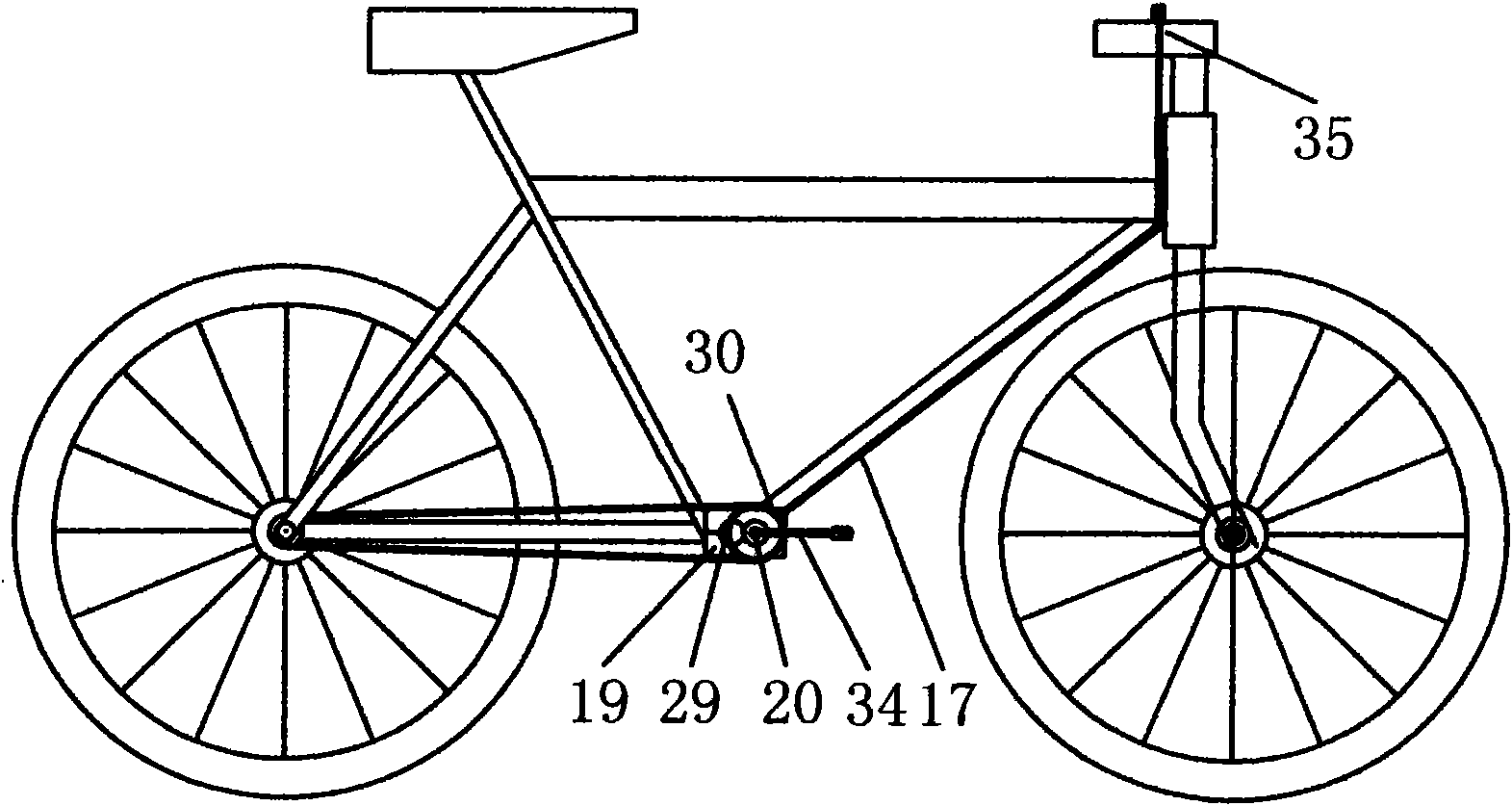

Bicycle with miniature box transmission on middle axle

ActiveCN101979273ASimple shiftingUnique designWheel based transmissionCycle control systemsAgricultural engineeringRoad condition

The invention discloses a bicycle with a miniature box transmission on a middle axle. The bicycle comprises a frame device, a transmission device, a moving device and a safety device and is characterized in that: the middle axle of the frame device is provided with the miniature box transmission consisting of a box speed transformation device and a shifting device; the middle axle and an auxiliary axle are arranged in a box; a clutch sleeve and a driving gear are fixedly arranged on the middle axle; the right outer end of the middle axle is in movable fit with a middle axle driven gear and a chain wheel; a clutch sleeve and a driven gear are fixedly arranged on the auxiliary axle; and an auxiliary axle driving gear is fixedly arranged at the right outer end of the auxiliary axle and engaged with the middle axle driven gear. The bicycle has a small and compact structure, large transmission ratio range, high climbing capability, high level road speed, low production cost and high popularization value, is convenient to use, flexible and rapid to shift, easy to manufacture and easy to accept by bicycle enthusiasts and can particularly realize quick shifting under various road conditions.

Owner:石幸运

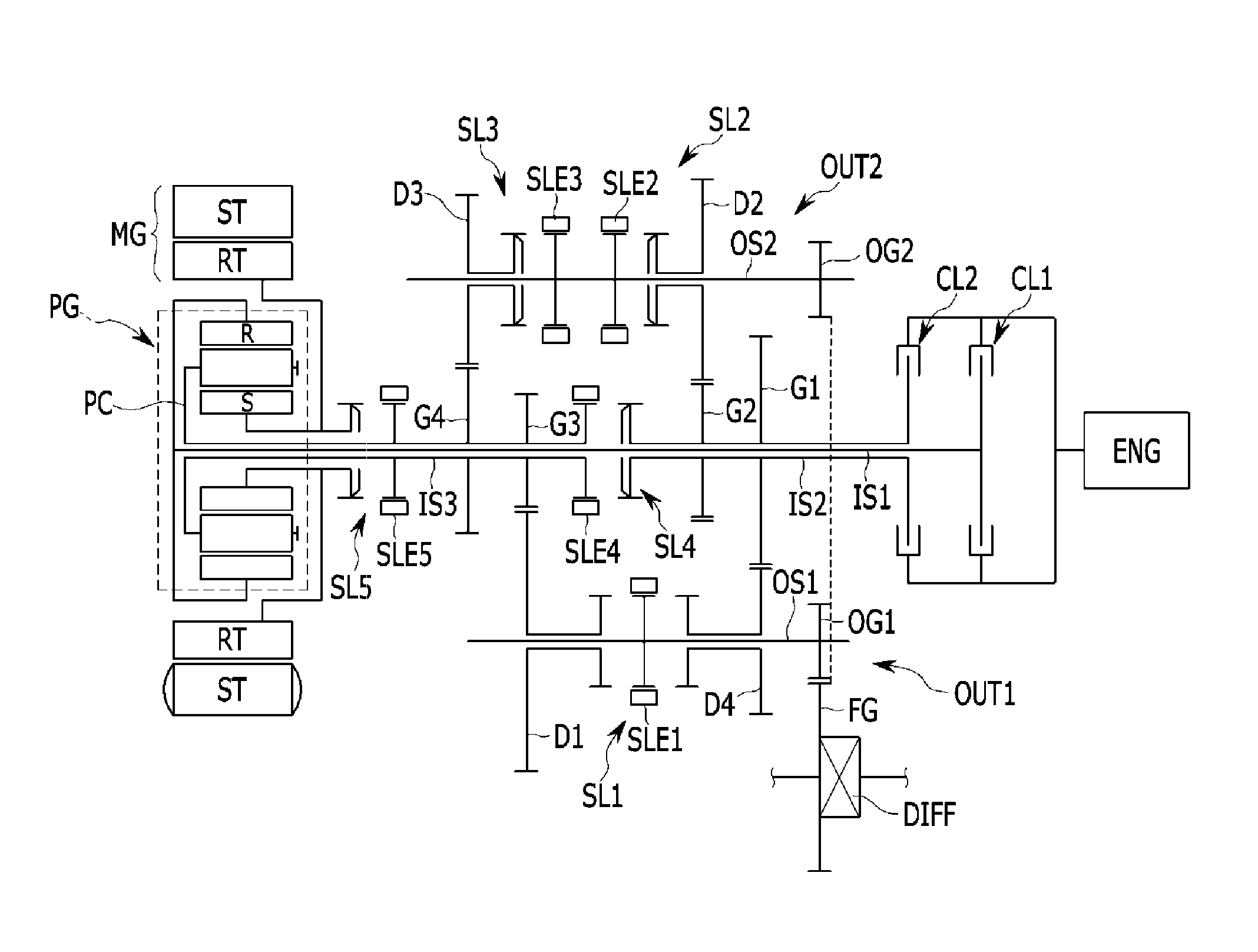

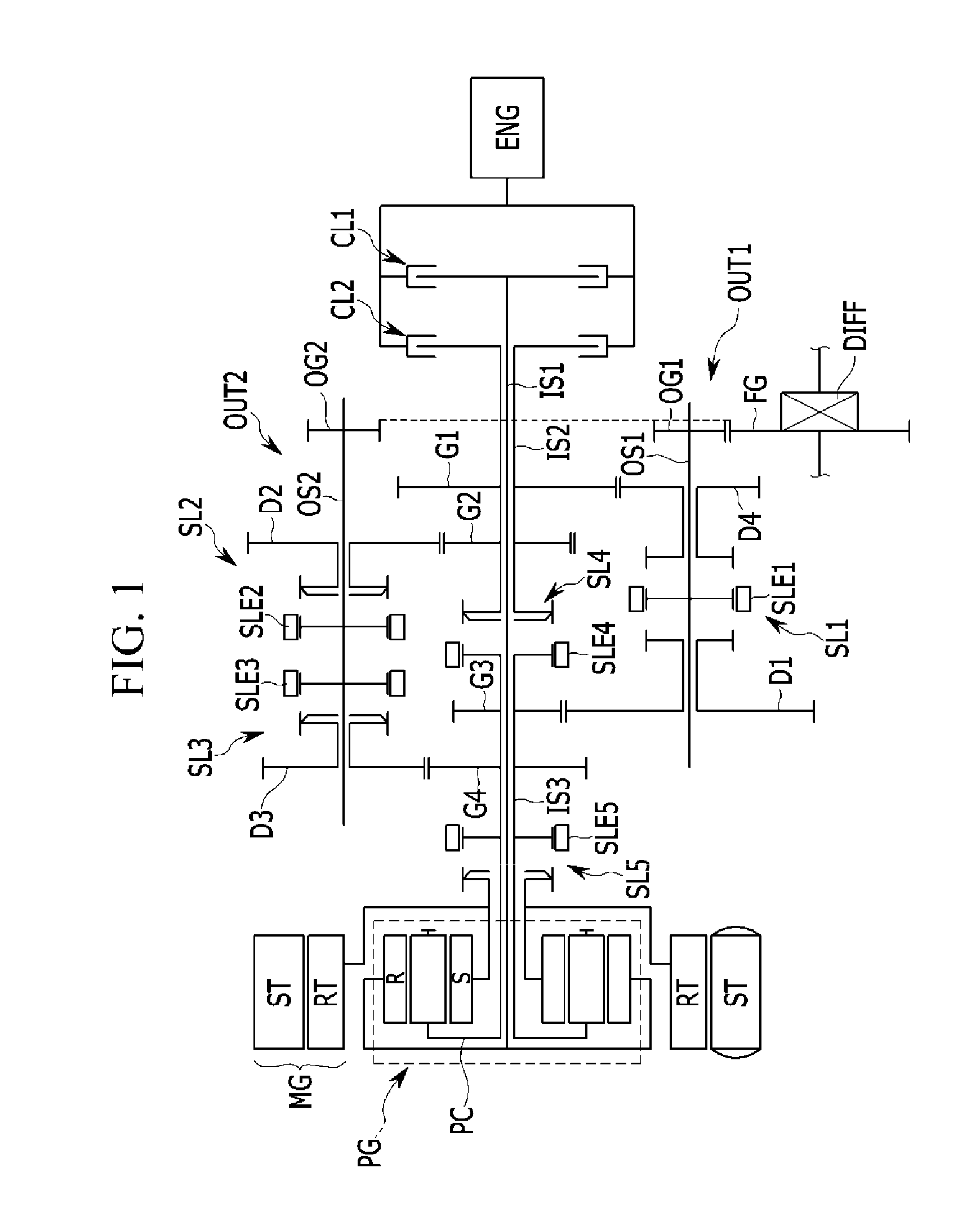

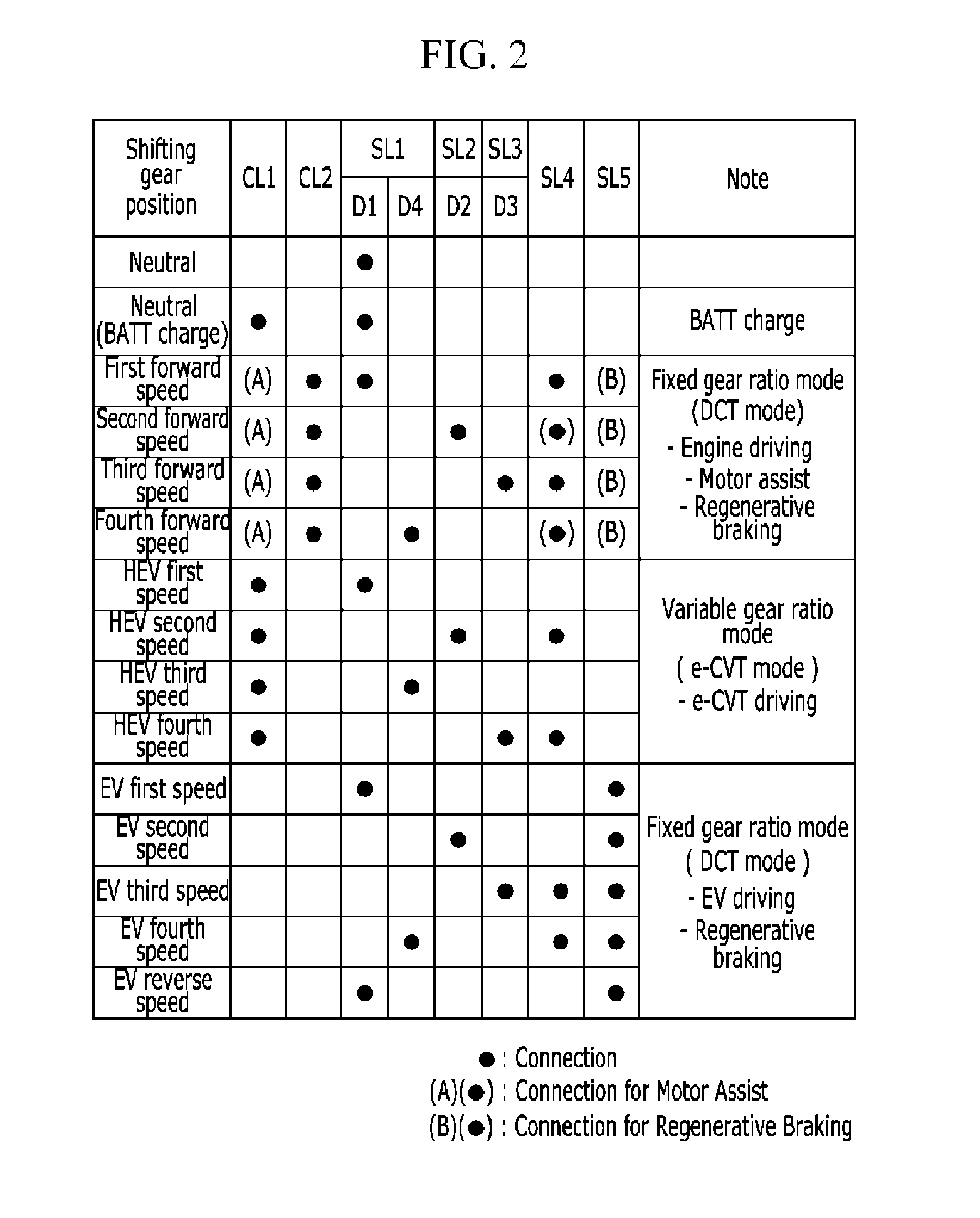

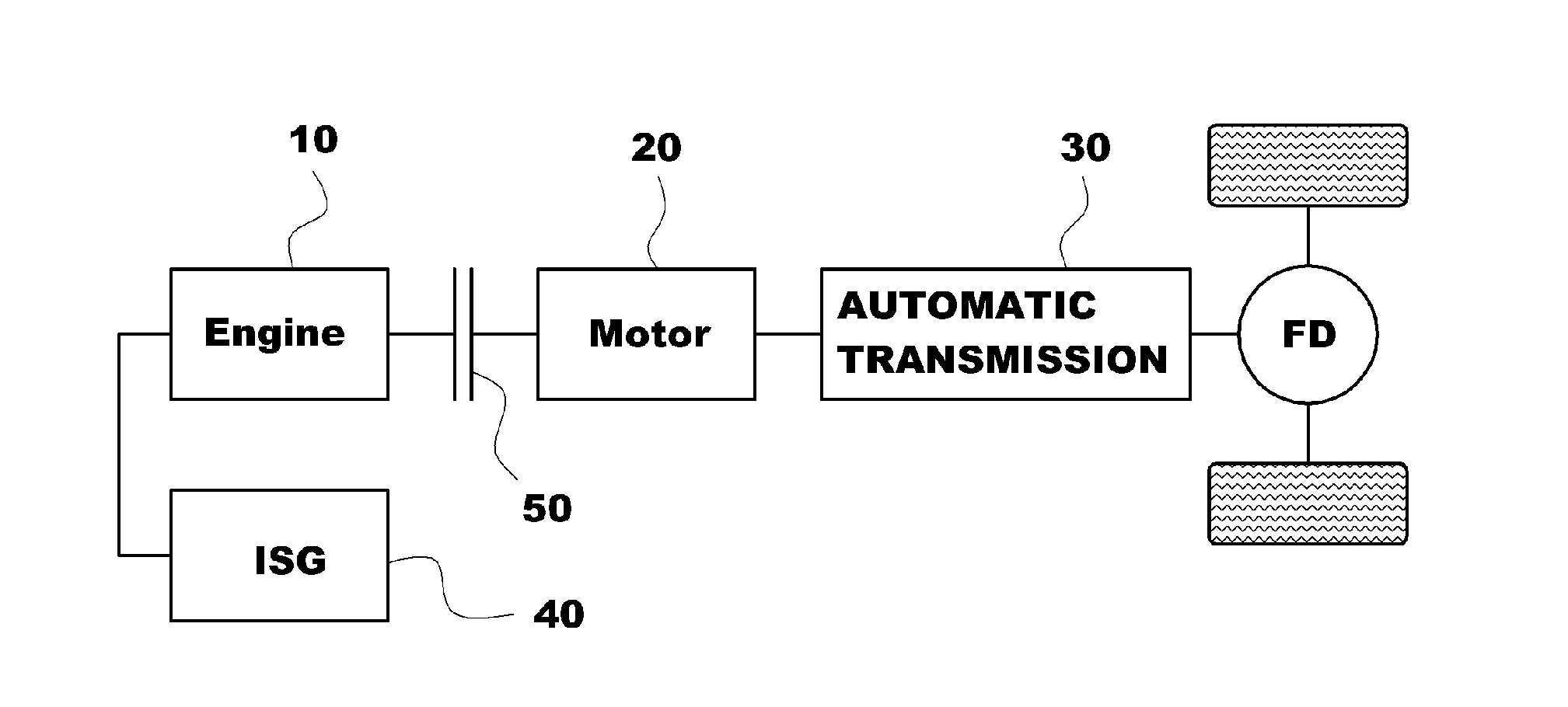

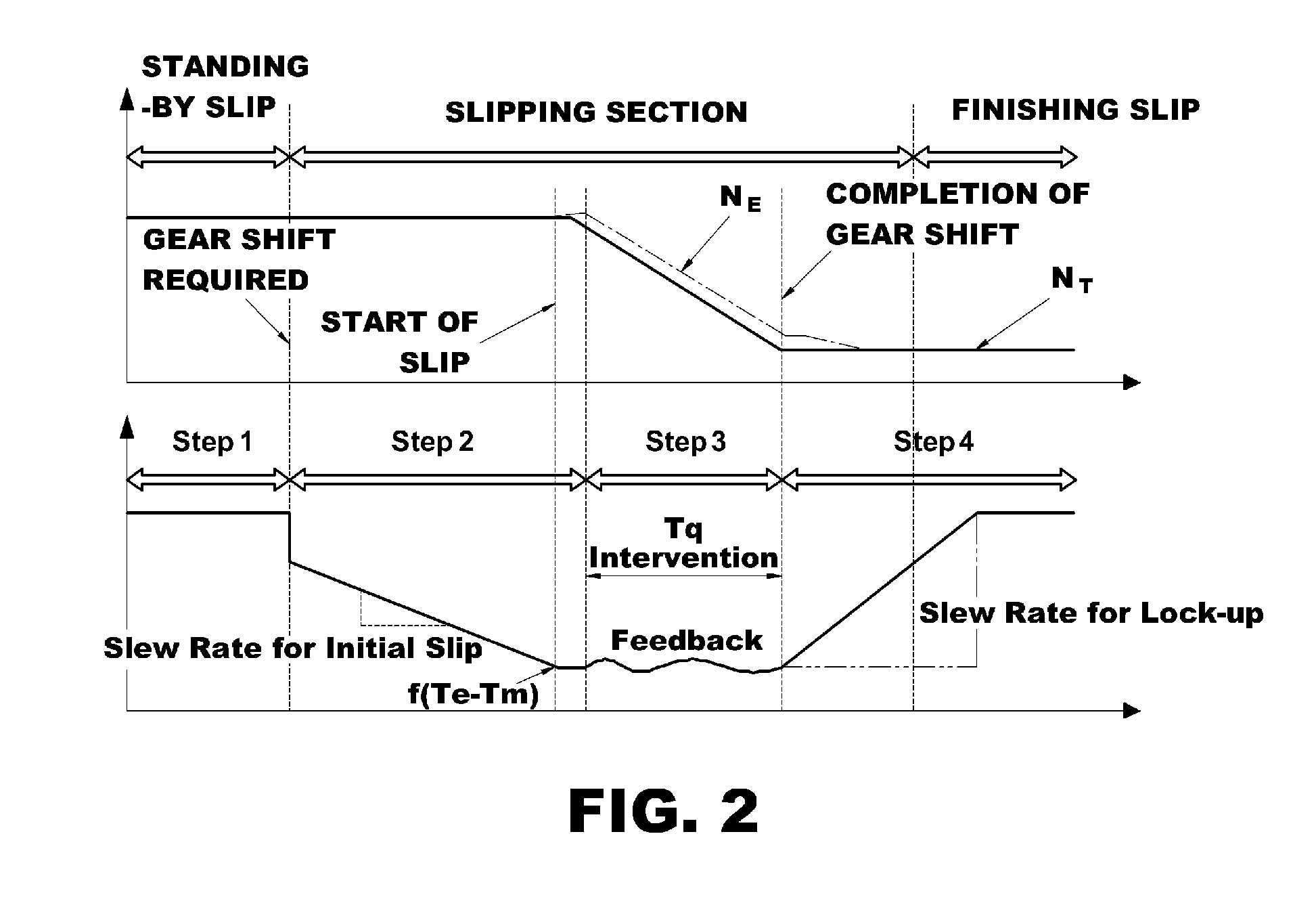

Power transmission apparatus for vehicle

ActiveUS20160167503A1Improve power delivery efficiencyPower Loss MinimizationHybrid vehiclesGas pressure propulsion mountingEngineeringInternal combustion engine

A power transmission apparatus for a vehicle may include a first input shaft selectively connected to an output side of an internal combustion engine through a first clutch, a second input shaft disposed at the first input shaft without any rotational interference and selectively connected to the output side of the internal combustion engine through a second clutch, a motor / generator performing a function of a motor and a generator, and a planetary gear set including first, second, and third rotation elements such that the first rotation element is directly connected with the motor / generator, the second rotation element is selectively connected with the second input shaft so as to be in synchronization with each other, and the third rotation element is directly connected with the first input shaft.

Owner:HYUNDAI MOTOR CO LTD

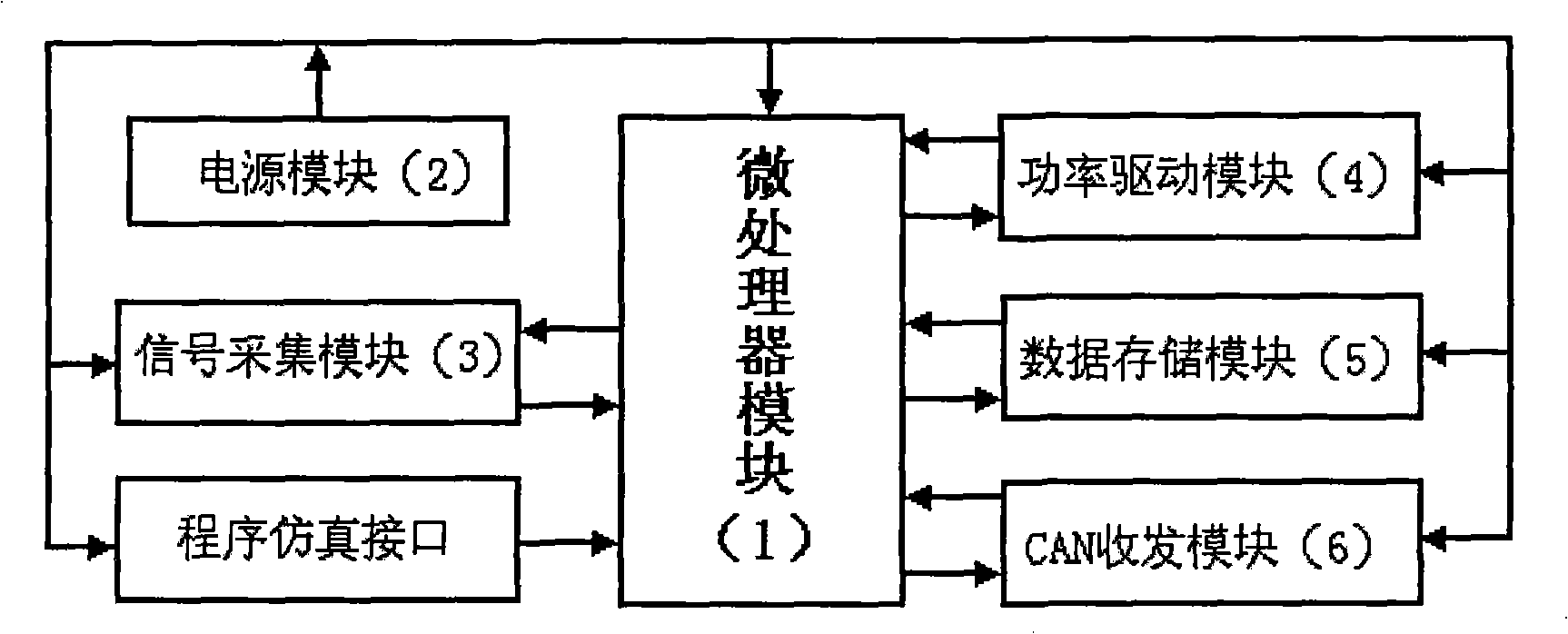

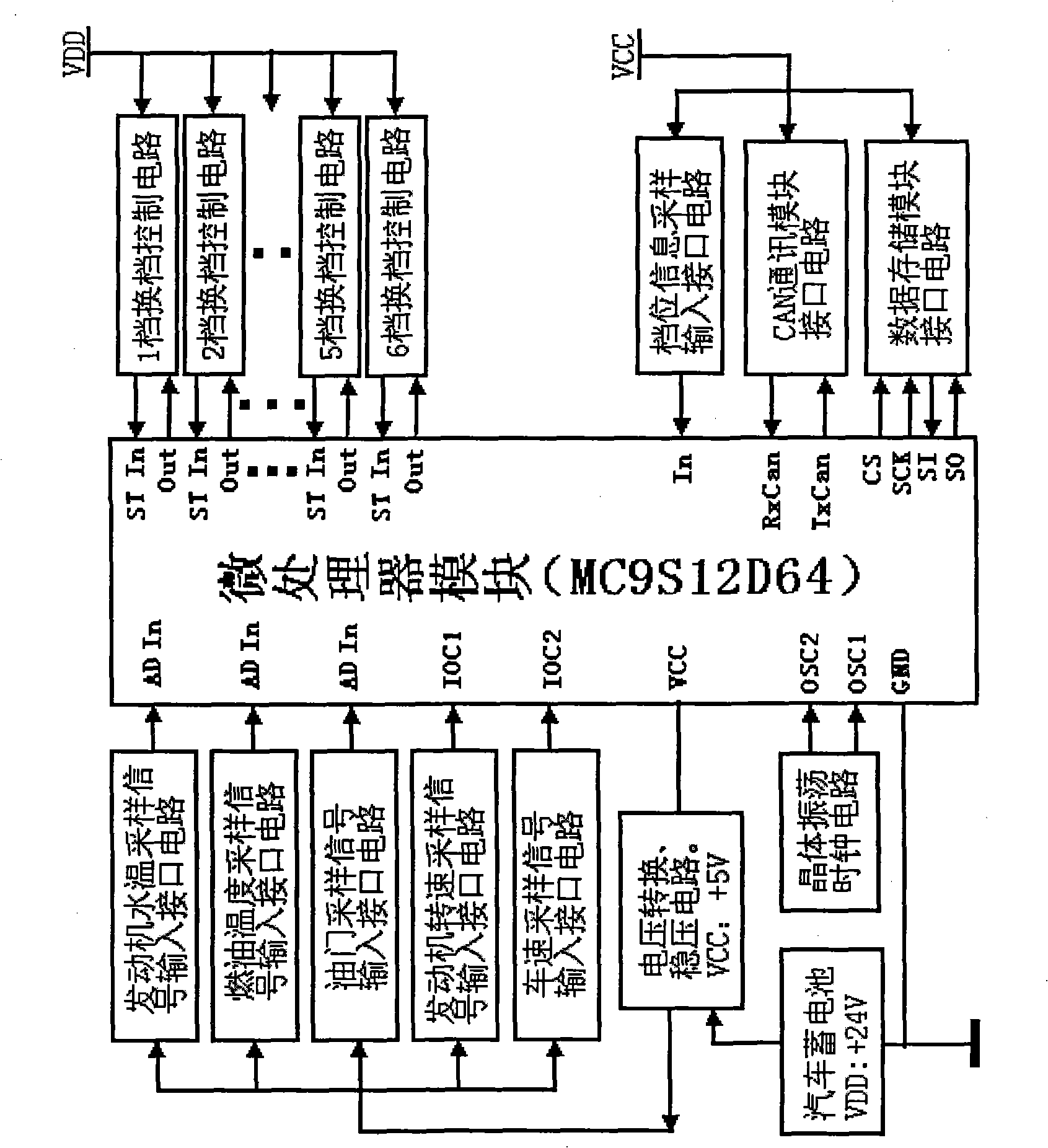

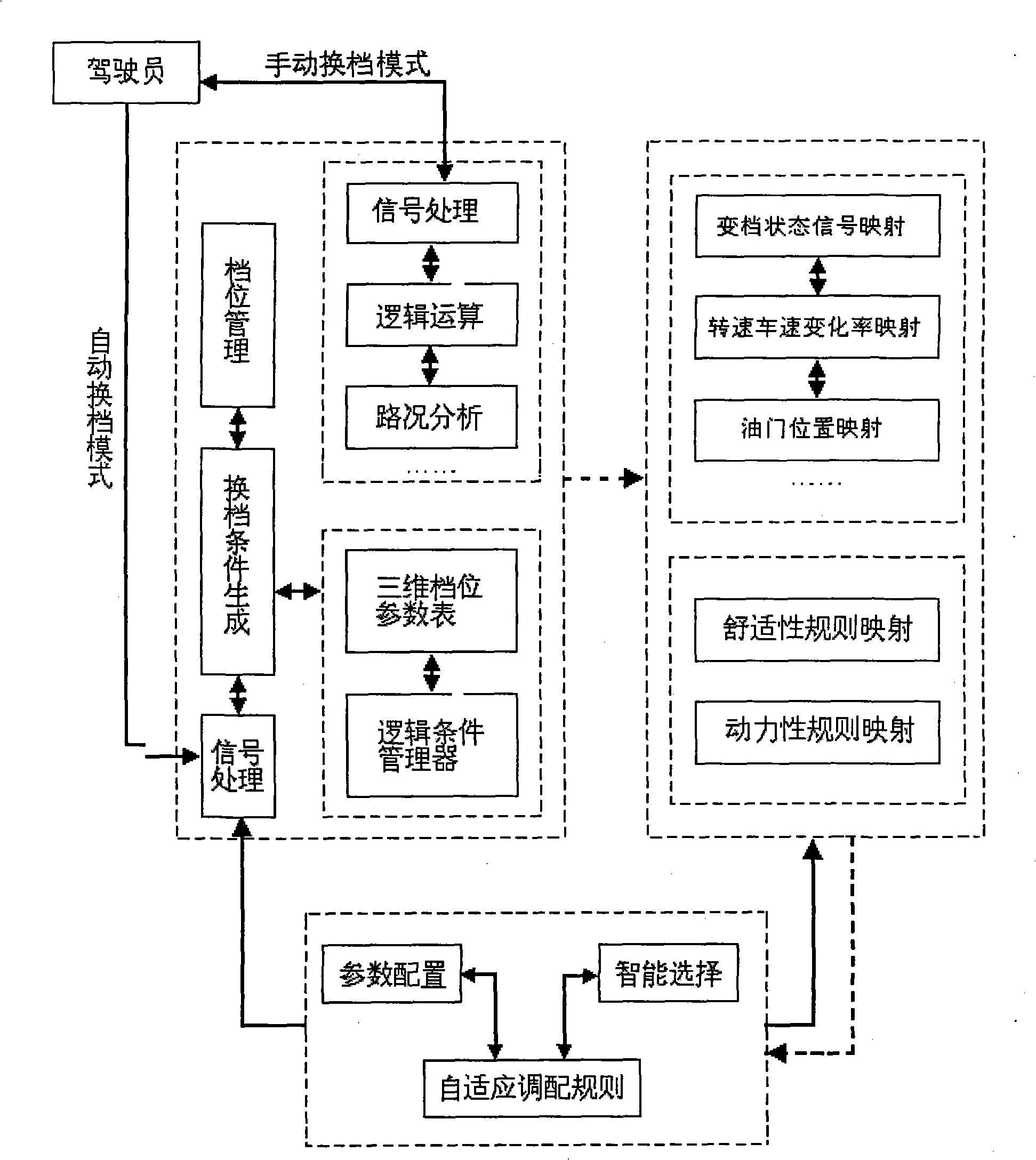

Electric control gear of automobile manual operation and automation integrated automatic speed transmission and control method thereof

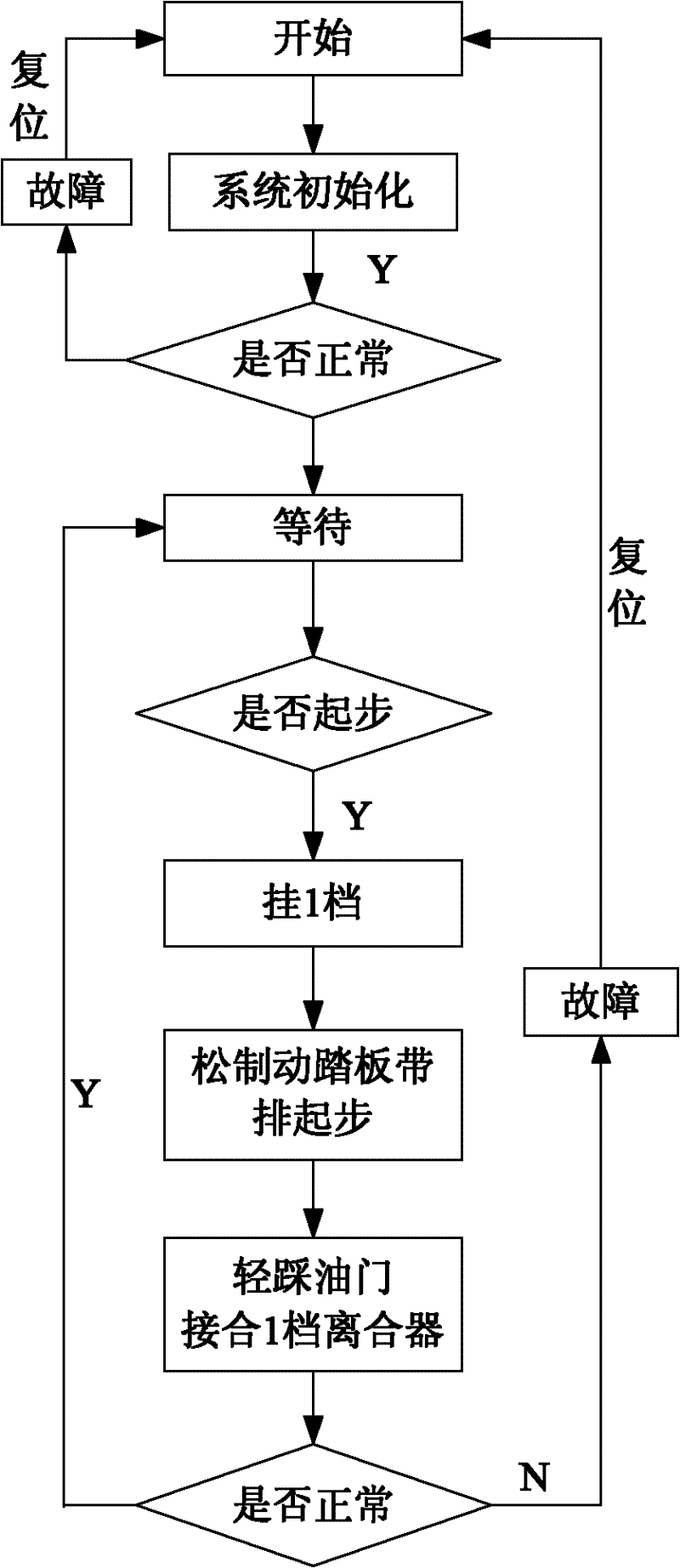

InactiveCN101353017AStable jobWork reliablyGearing controlControl devicesAutomatic transmissionExternal data

The invention aims at solving a technical problem of providing an electronic control device and a realization method of an automatic automobile transmission of manual automatic integration. The electronic control device of the automatic automobile transmission of manual automatic integration comprises a microprocessor module, a power supply module, a signal collection module, a power drive module, a data storage module and a CAN transceiver module. The invention designs various stable and reliable signal collecting and processing circuits, adopts an optimal control method, designs the function of fault self-diagnosis and causes the controller to be characterized by fast and accurate gear shifting, stable and reliable work, etc. At the same time, an external data storage module and the CAN transceiver module are added, which causes the design to have good scalability. Based on the existing hydraulic transmission automatic transmissions (AT), the electronic control device improves the efficiency of gear-shift operation and has the advantages of good production inheritance, low investment cost, high efficiency, easy manufacturing, convenient control, etc.

Owner:NANJING TACKING AUTOMOTIVE ELECTRONICS CO LTD

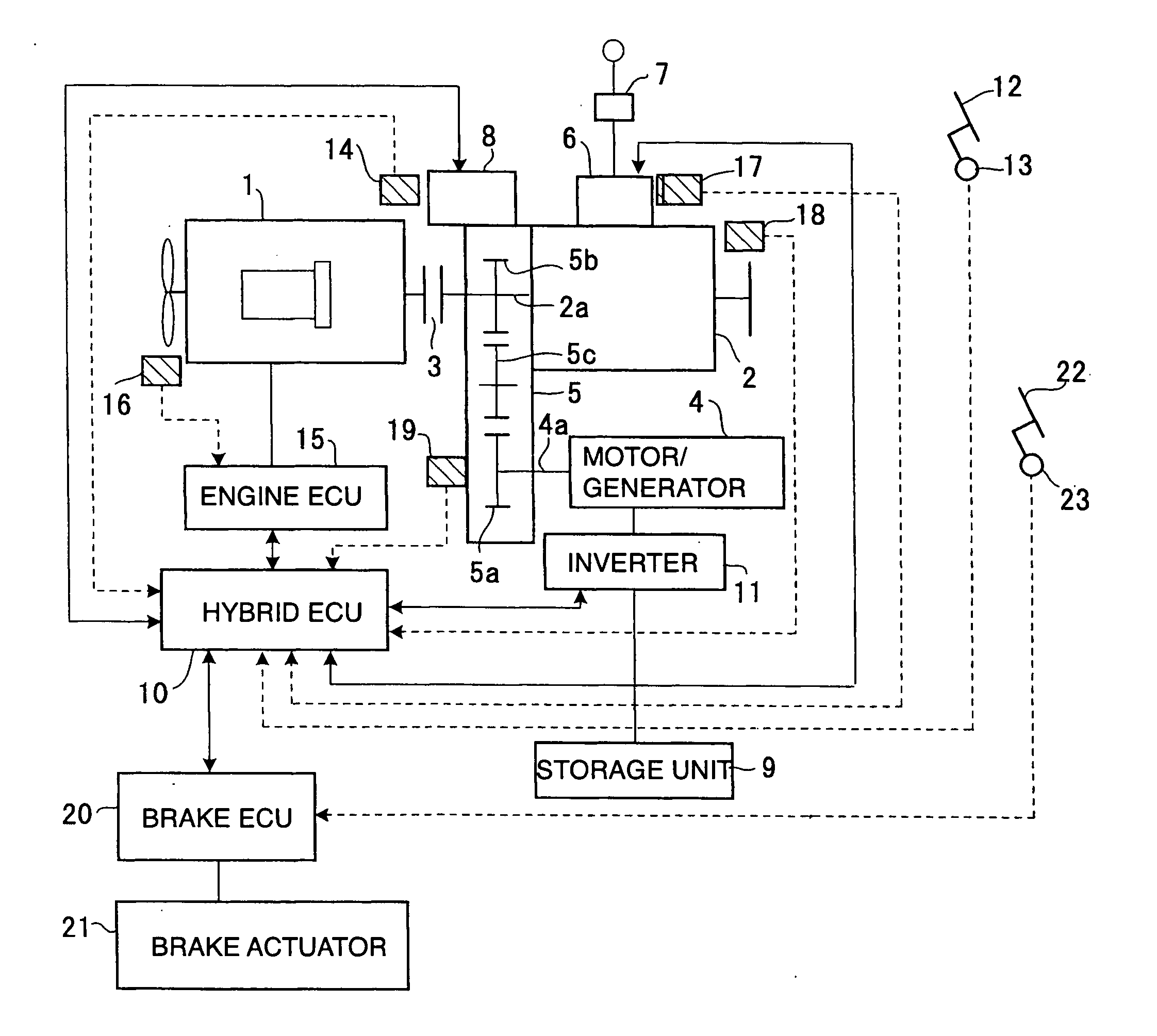

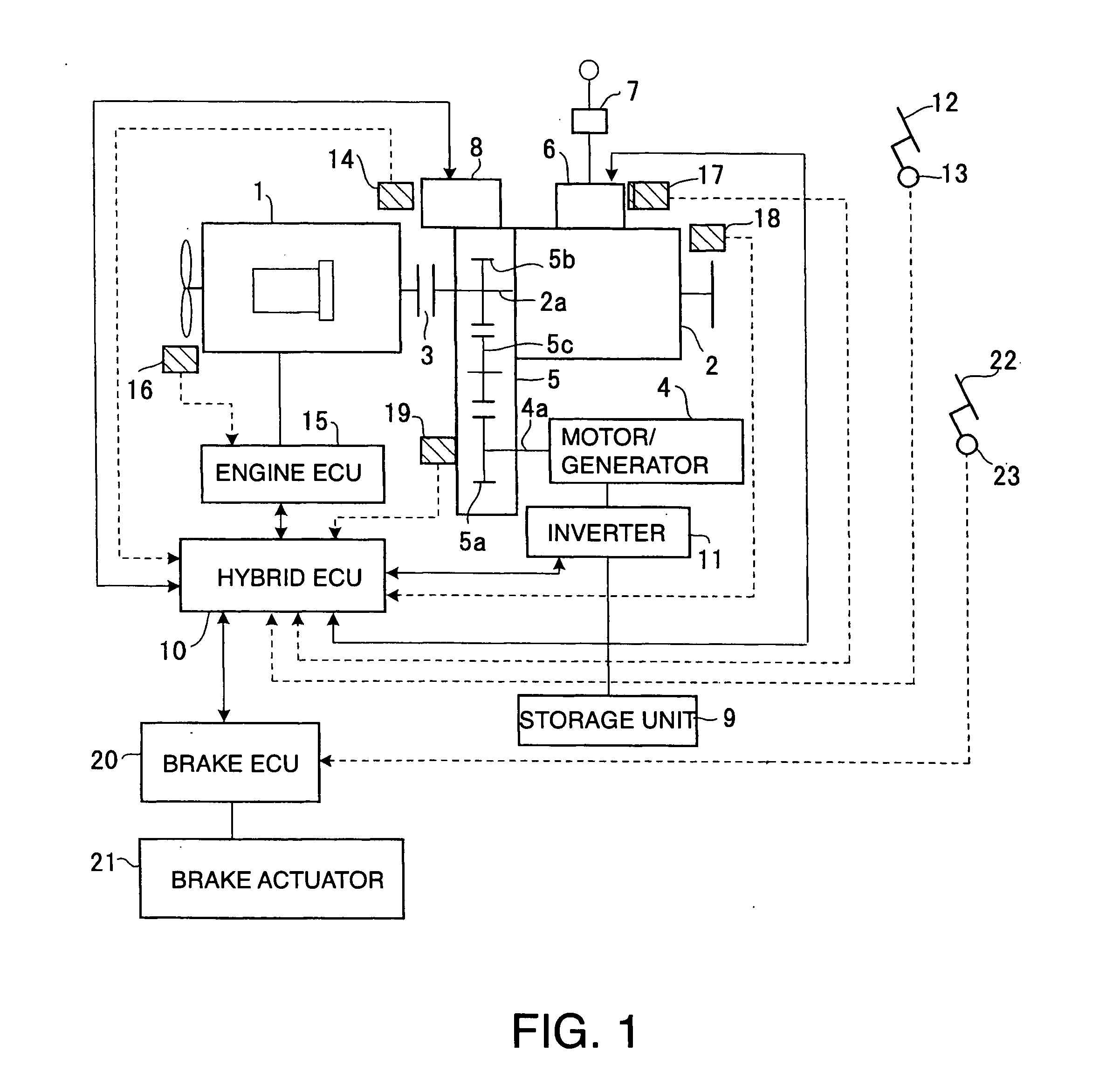

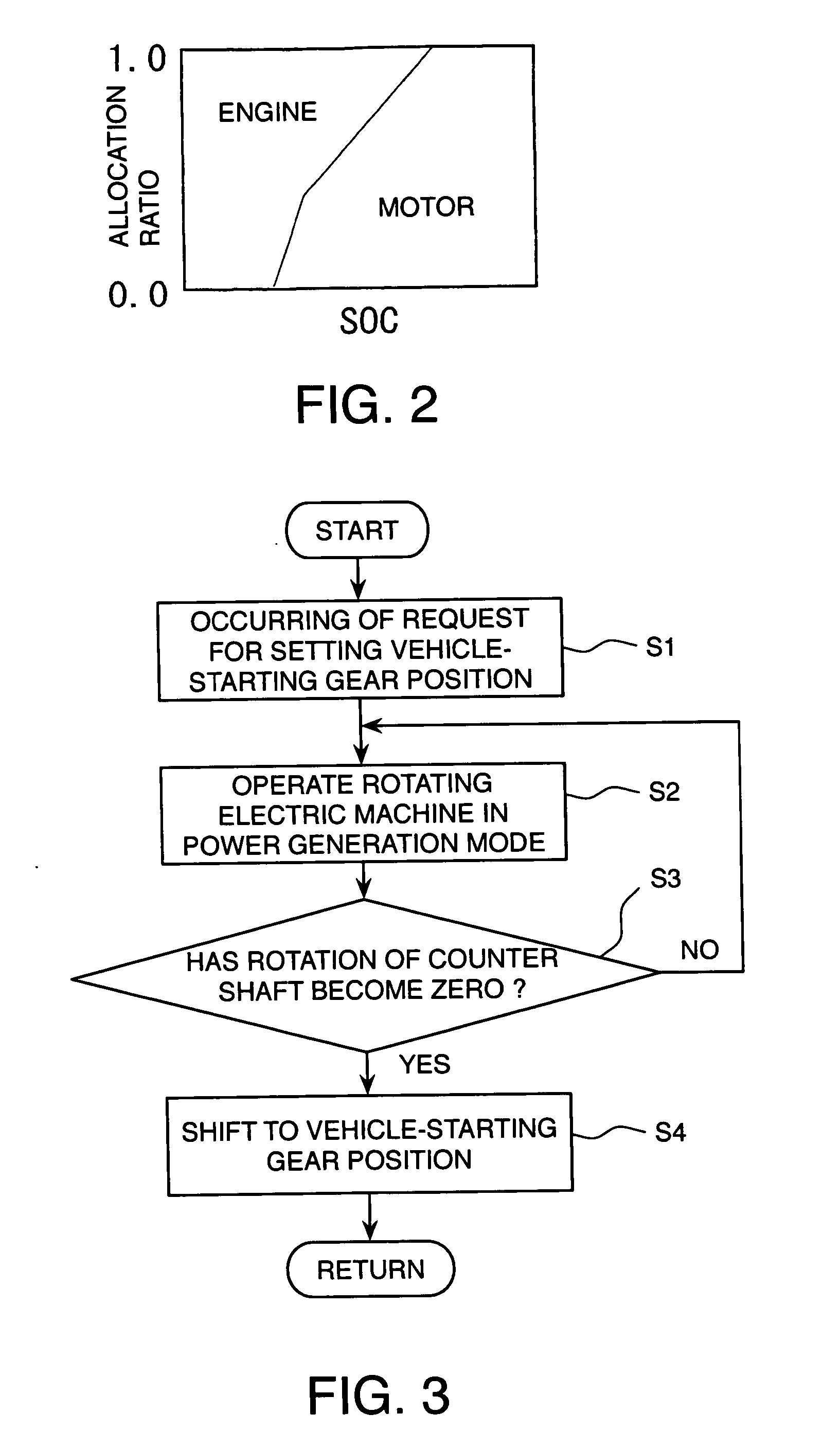

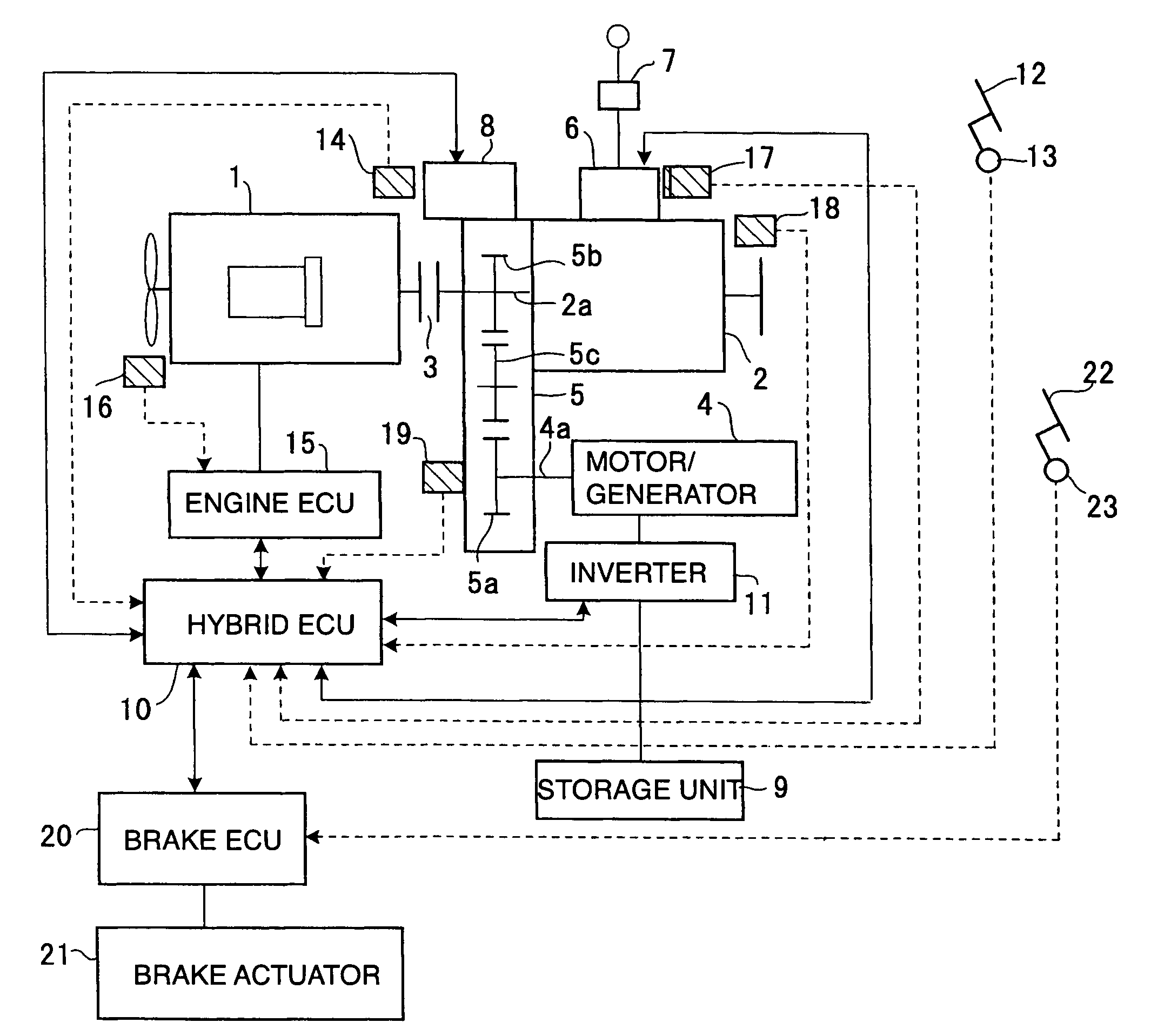

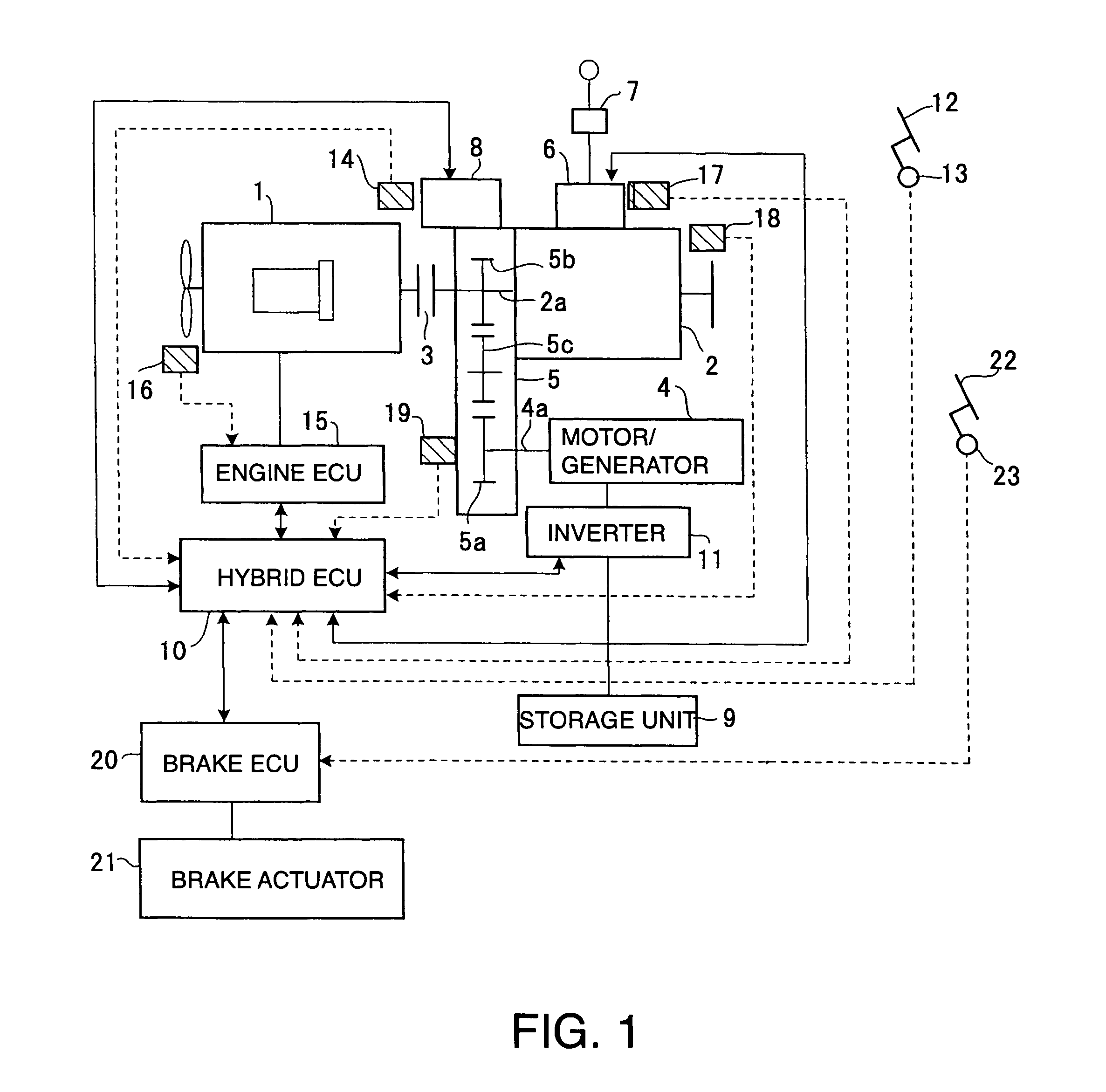

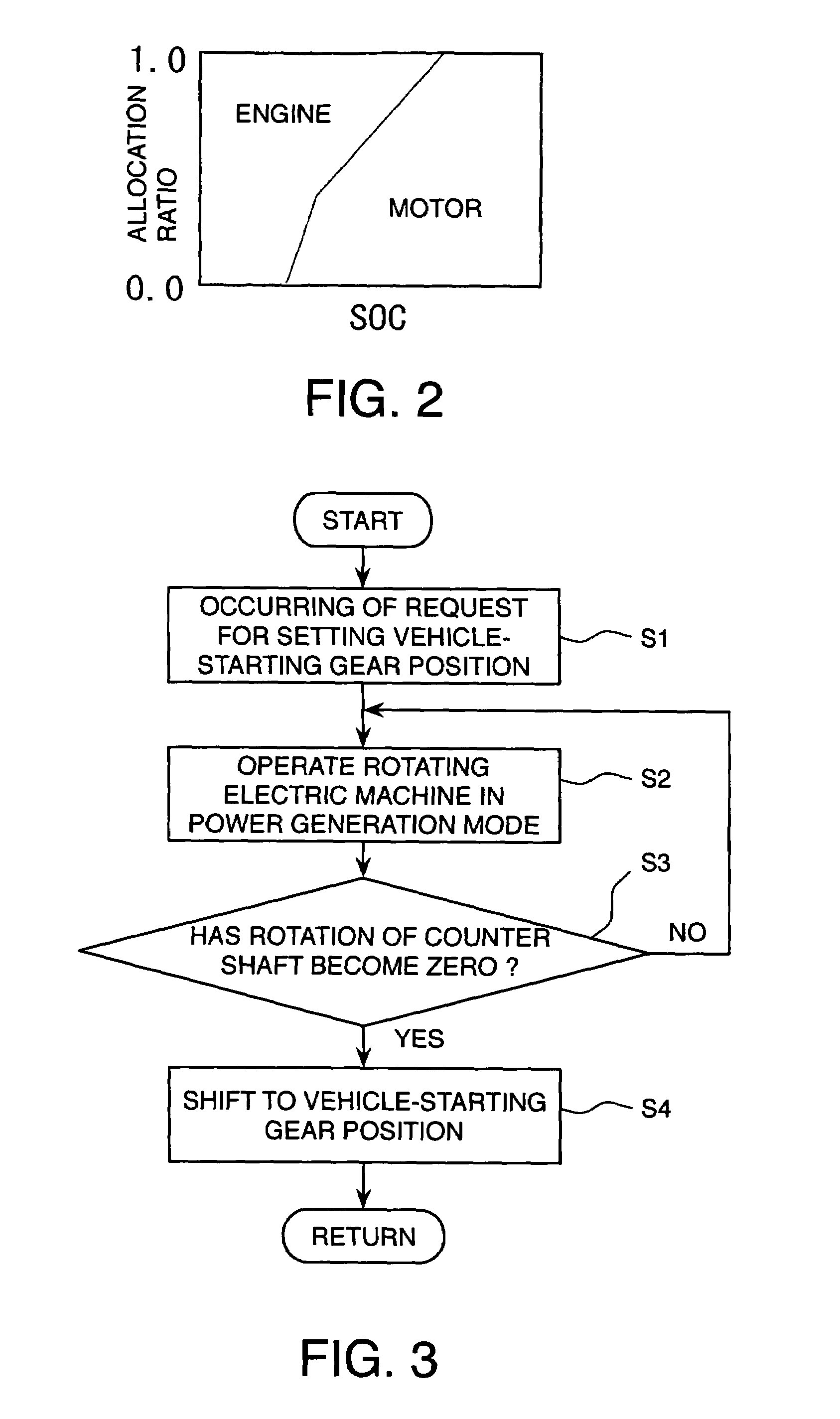

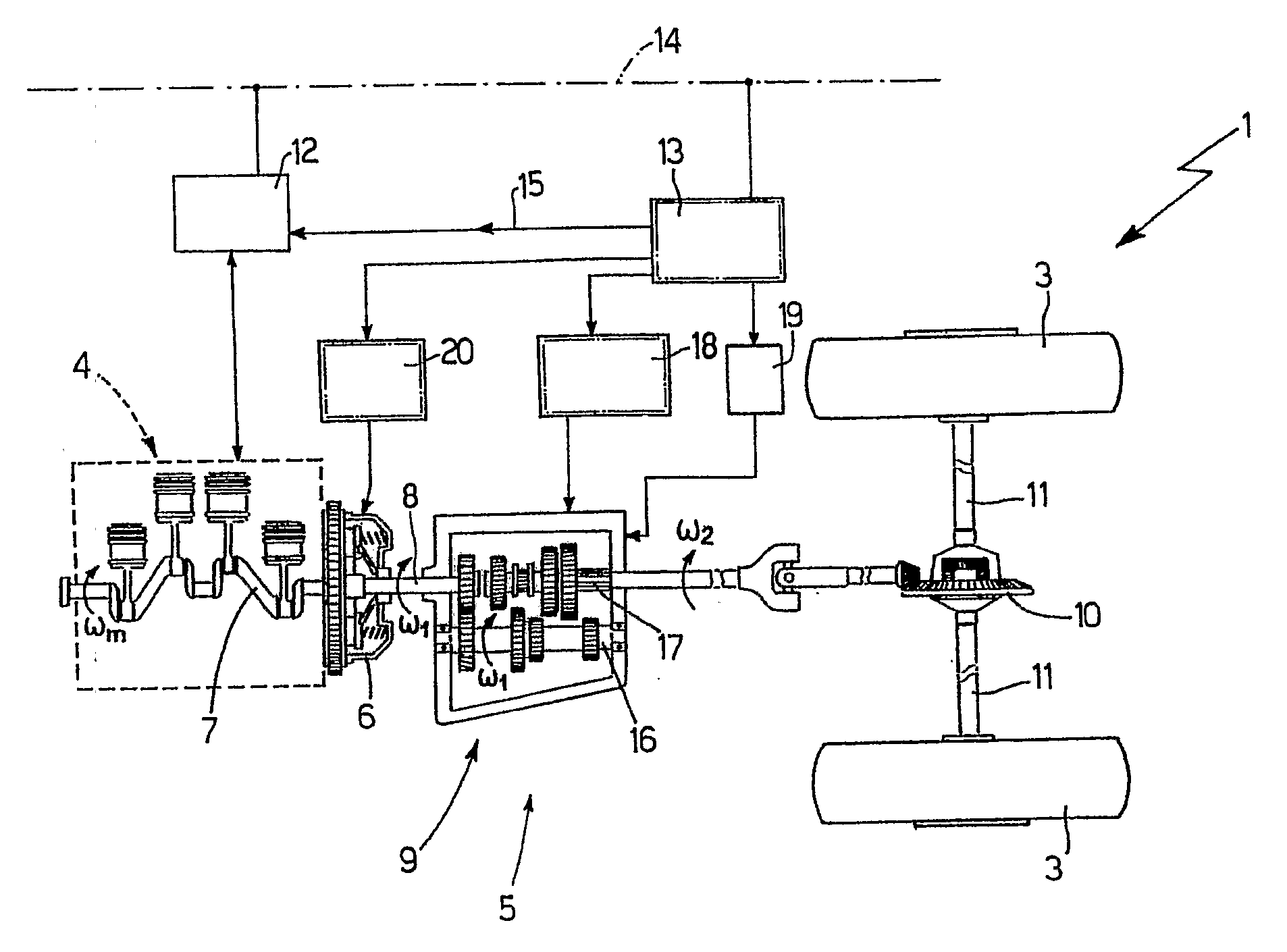

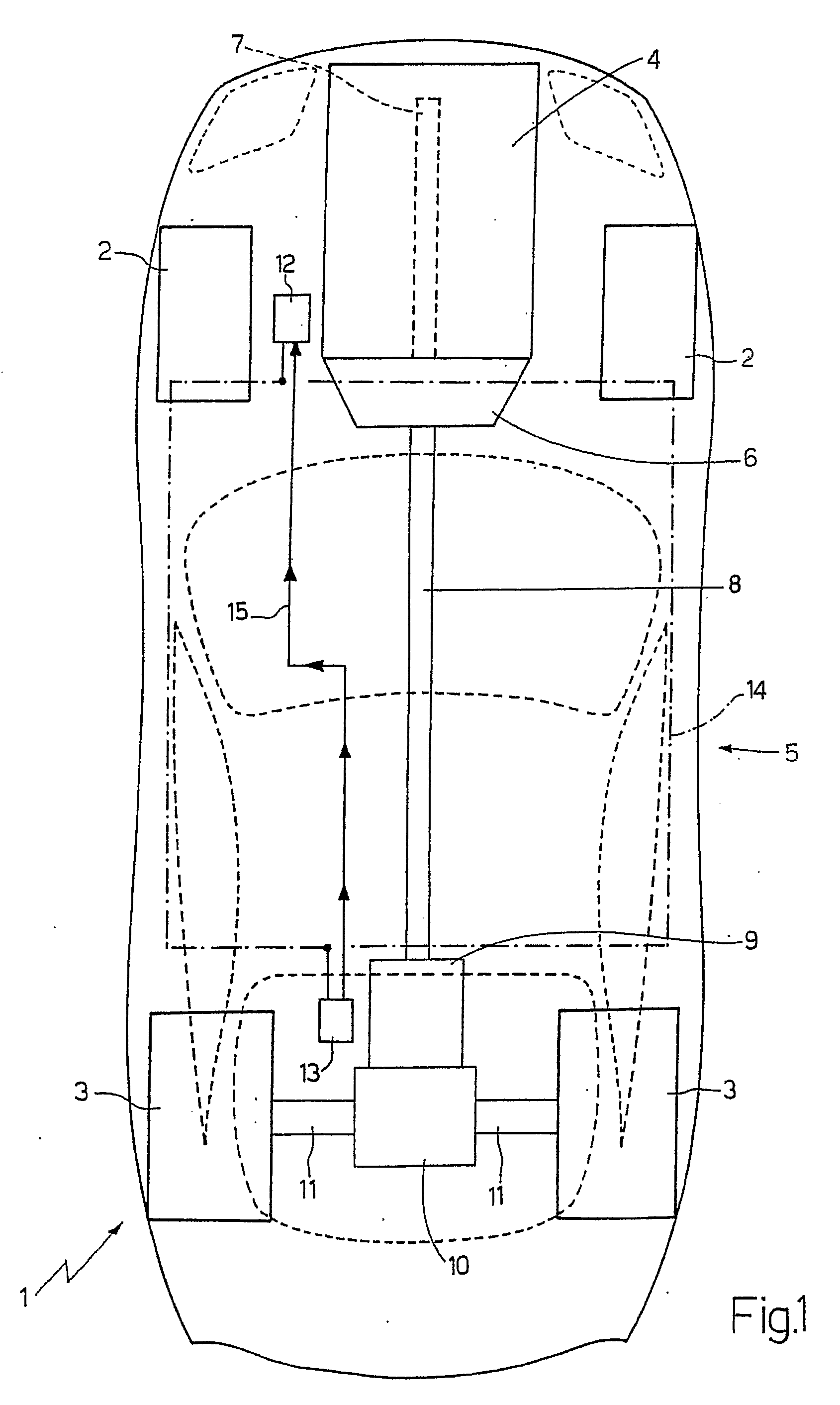

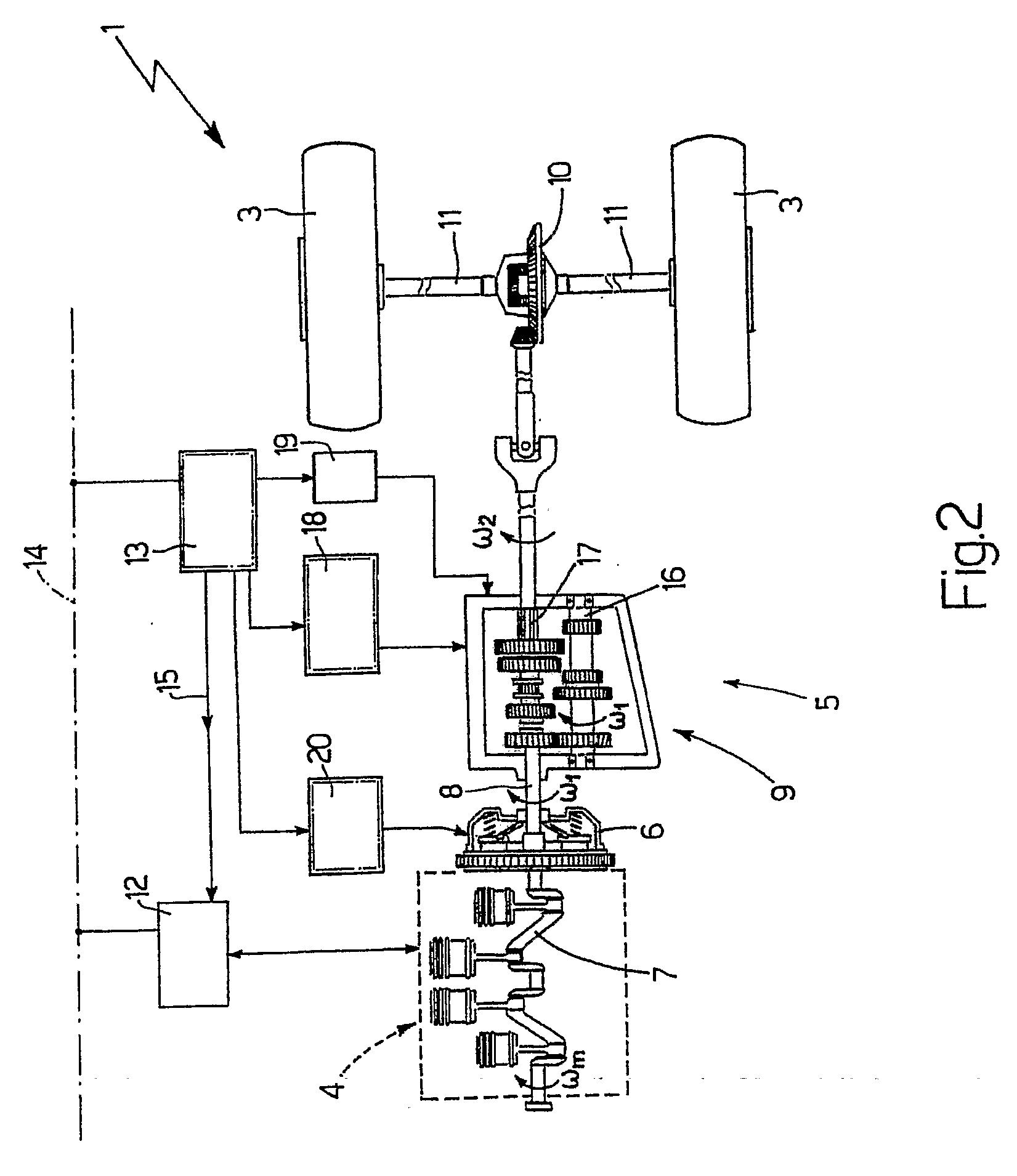

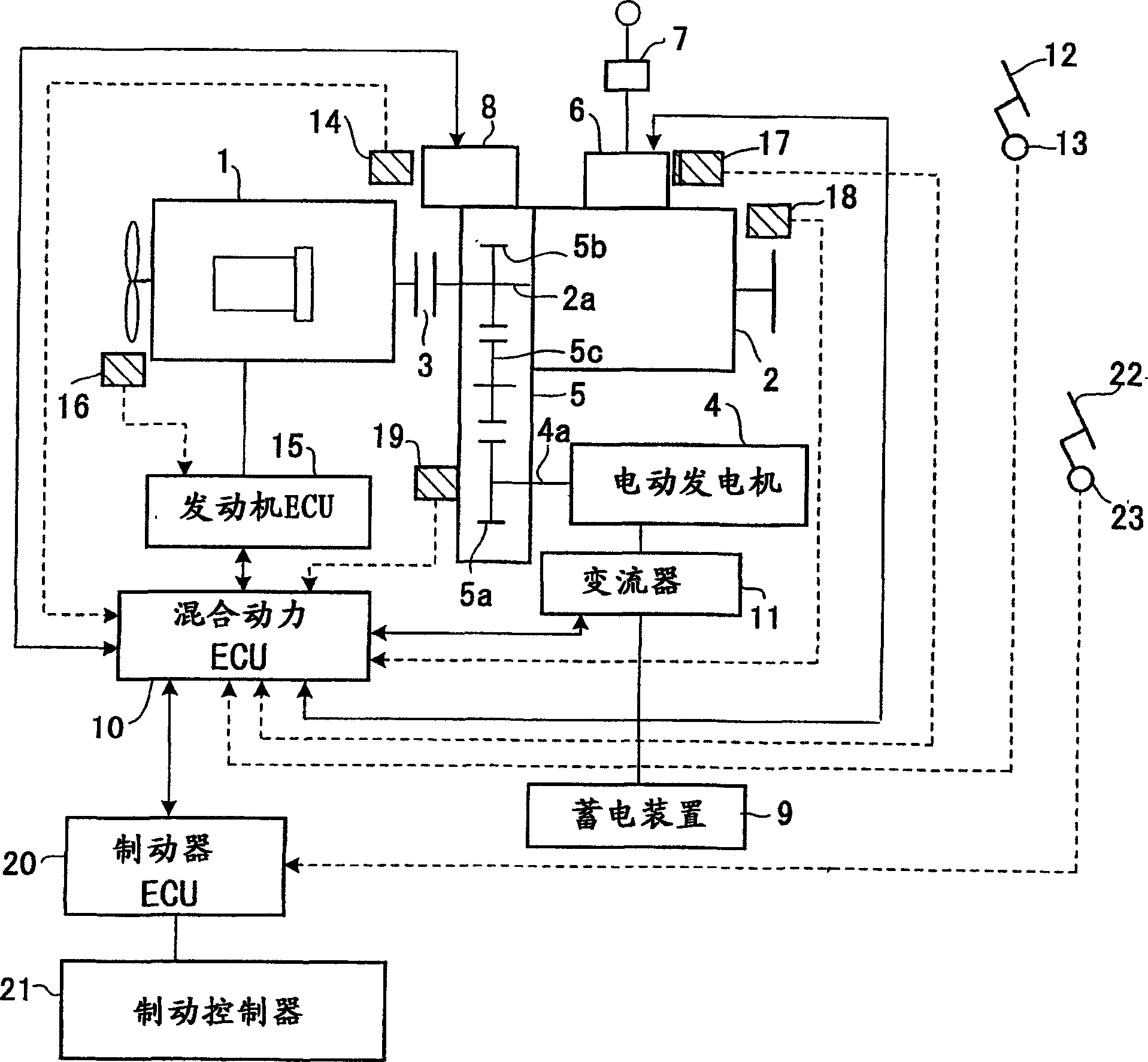

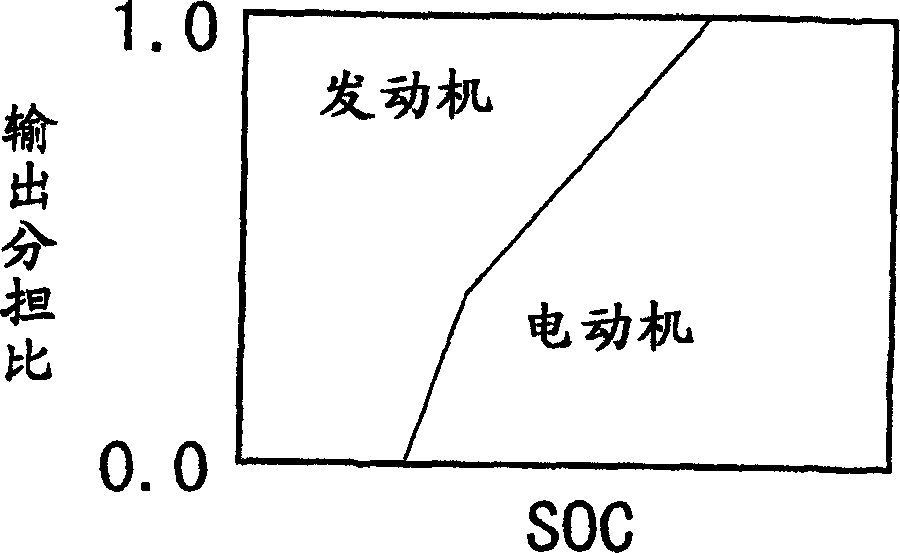

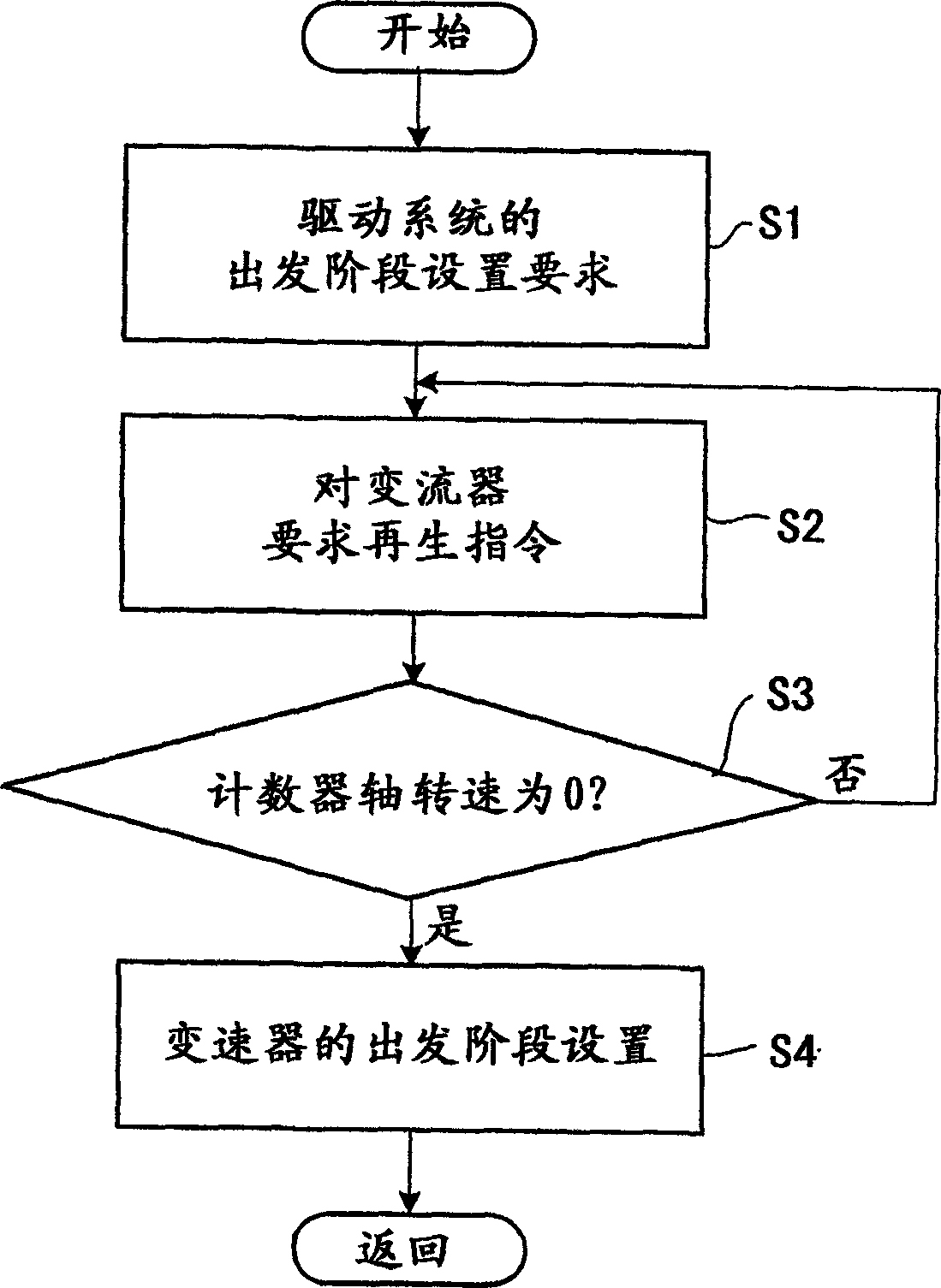

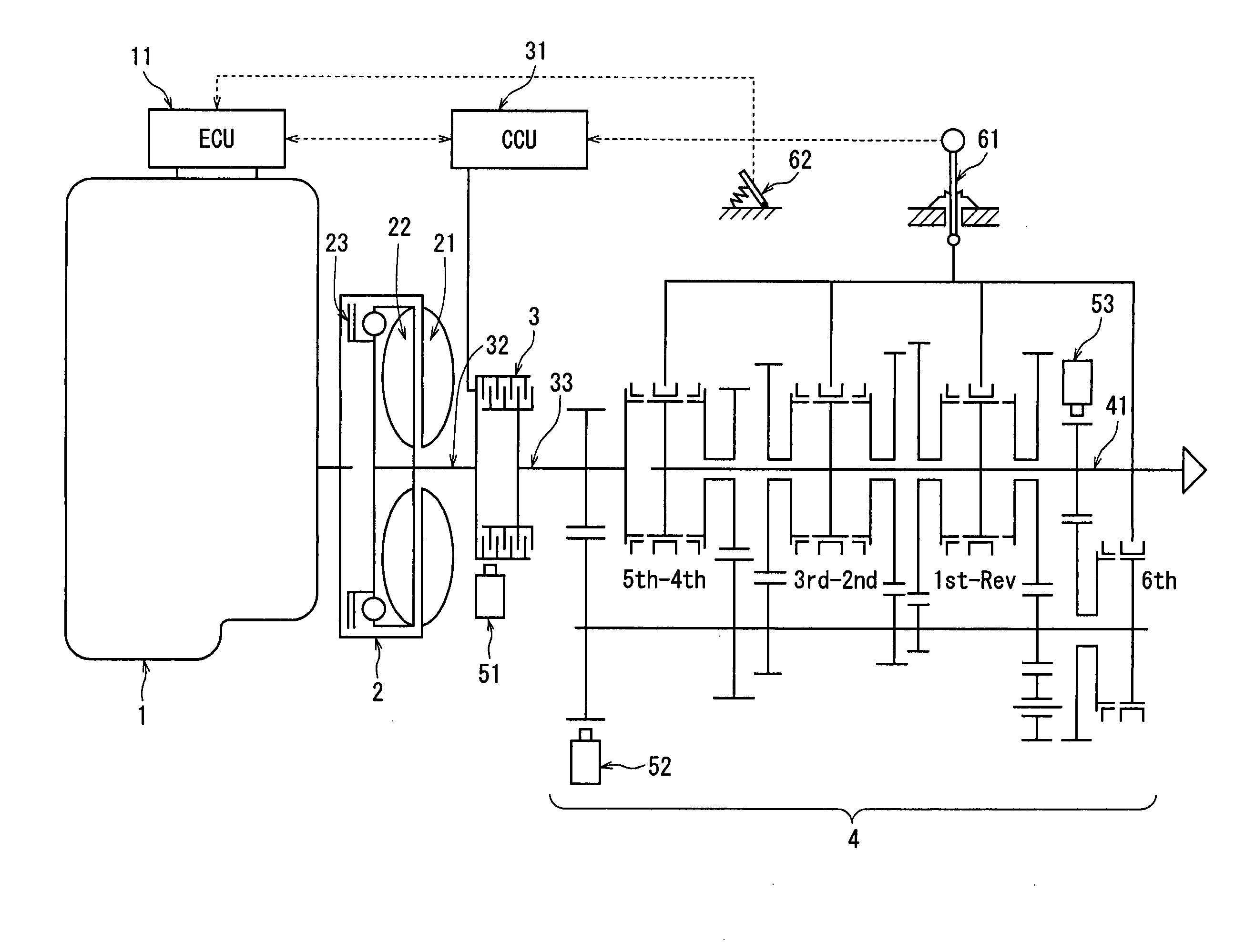

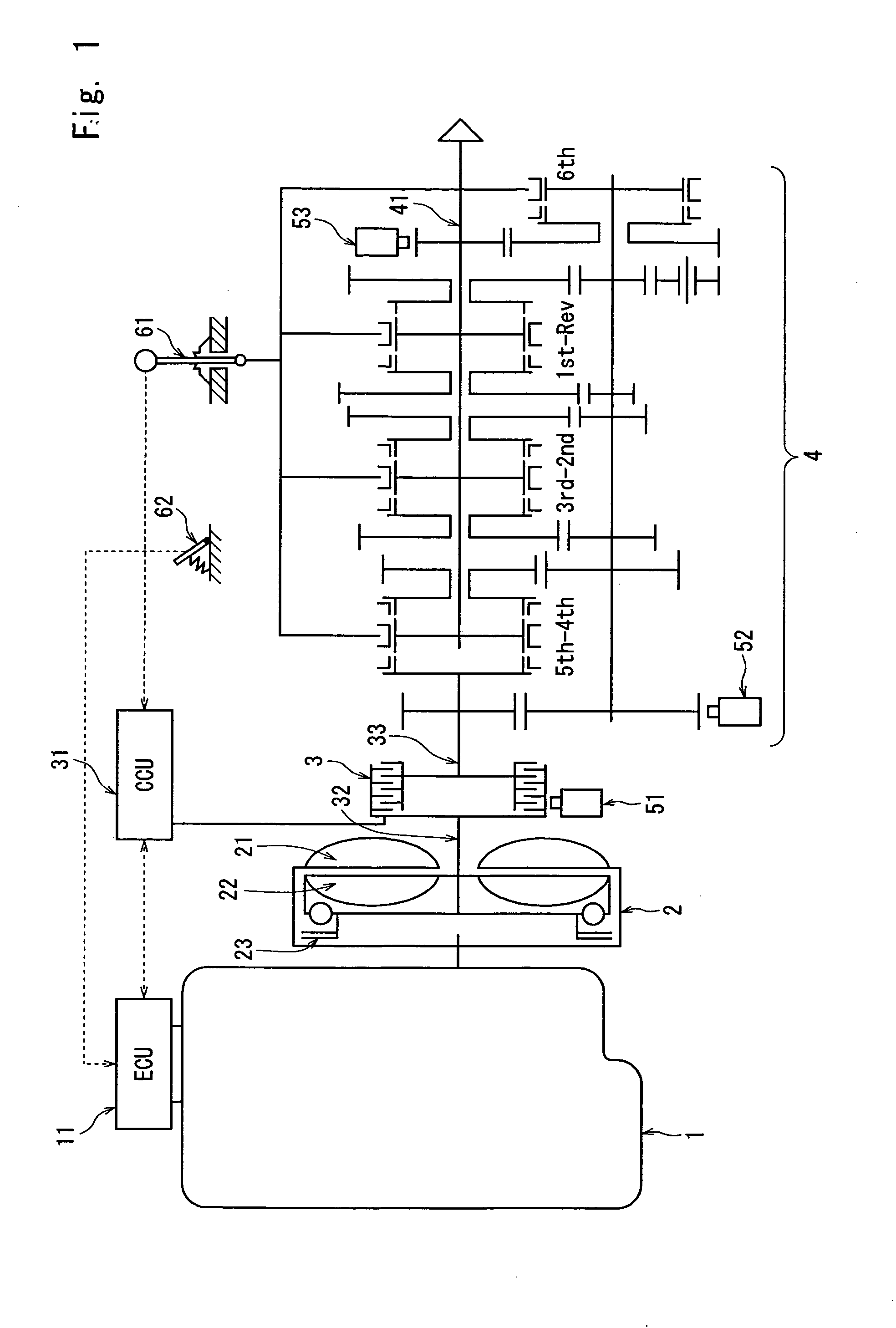

Gear shift control system of hybrid vehicle

ActiveUS20060293144A1Reduce sync timeFast convergenceClutchesToothed gearingsControl systemEngineering

In a hybrid-drive electric vehicle, upon request of gear shifting of a transmission (2), a clutch (3) is first disconnected and the transmission (2) is set to a neutral position. The rotating electric generator 4 is then operated in a motor mode or a power generating mode so that a rotational speed of an input shaft of the transmission (2) reaches a region of a synchronizing rotational speed in accordance with a requested gear position. When the rotational speed of the input shaft of the transmission (2) reaches the region of the synchronizing rotational speed, the gear position of the transmission (2) is changed over from the neutral position to the requested gear position. Thus the rotation synchronizing time for the gear shifting in the transmission (2) is reduced, making it possible to perform the gear shifting for a short period of time.

Owner:VOLVO LASTVAGNAR AB

Speed changer

InactiveCN101818804AReduce speed differenceGuaranteed smoothnessToothed gearingsGearing controlPush and pullDrive shaft

The invention discloses a speed changer capable of solving the problems of large size, complex operation, high maintenance cost, and the like of the traditional speed changer. The speed changer has about 97 percent of transmission mechanical efficiency and easy and convenient operation and is characterized in that a power input gear can be fixed with a jacket; a sliding sleeve is matched with thejacket through a helical rack and is matched with a gear shaft through a spur rack; a pin shaft of the sliding sleeve contacts with a push rod of a gear shift shuttle; a crank arm is movably connected with a lug through the pin shaft; a shifting fork forks on a shaft rod of a push-and-pull rod; a hollow cavity or a sliding chute of the gear shaft is internally provided with the gear shift shuttle; the gear shift shuttle is provided with a top bulge; the gear shaft is provided with a sliding key and is assembled with an angle gear matched with a chamfered groove strip and a plurality of gearshift gears; the gearshift gears can be respectively meshed with a driven gear; the driven gear is assembled on a driven shaft; and the driven shaft is fixed with a power output gear. The invention can be used for an epicyclic gear train and realize the full-automatic speed change from two gears to more than ten gears.

Owner:HUNAN JINLONG MOTOR

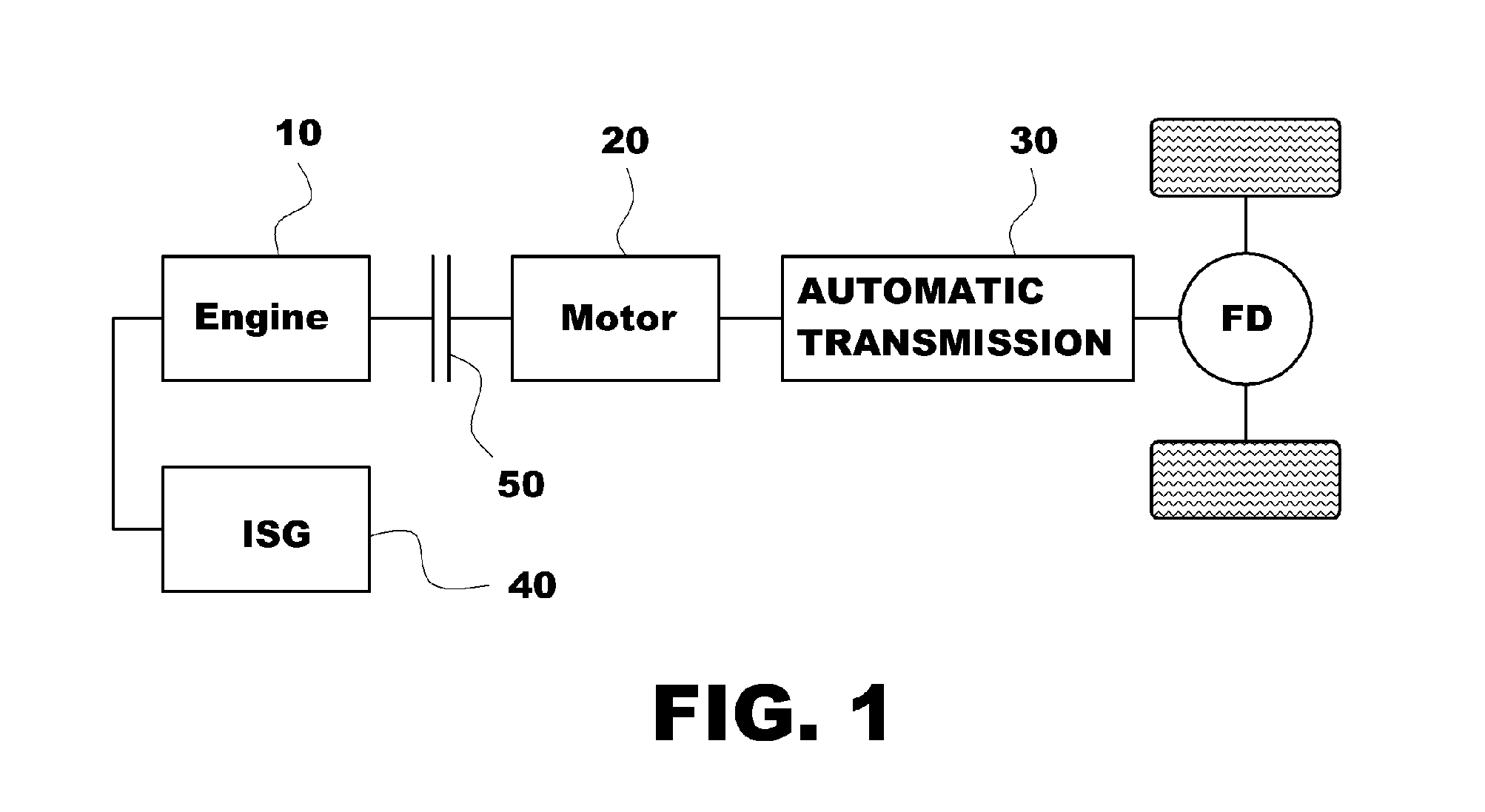

Method for reducing gear shifting shock of hybrid electric vehicle

The present invention provides a method which controls the hydraulic pressure of a clutch (an engine clutch) disposed between an engine and a drive motor, thus reducing gear shifting shock and vibration. The method comprises a slip preparation step of determining that gear shifting is required and reducing the hydraulic pressure of the clutch to a preset target hydraulic pressure from a point in time at which the gear shifting is required. The method further comprises a slip maintaining step of feedback-controlling the hydraulic pressure of the clutch such that a slip rate of the clutch is maintained constant after the hydraulic pressure of the clutch reaches the target hydraulic pressure; and a clutch lock-up completing step of increasing the hydraulic pressure of the clutch, from a point in time at which the gear shifting is completed, to a maximum hydraulic pressure for making a lock-up state of the clutch.

Owner:HYUNDAI MOTOR CO LTD

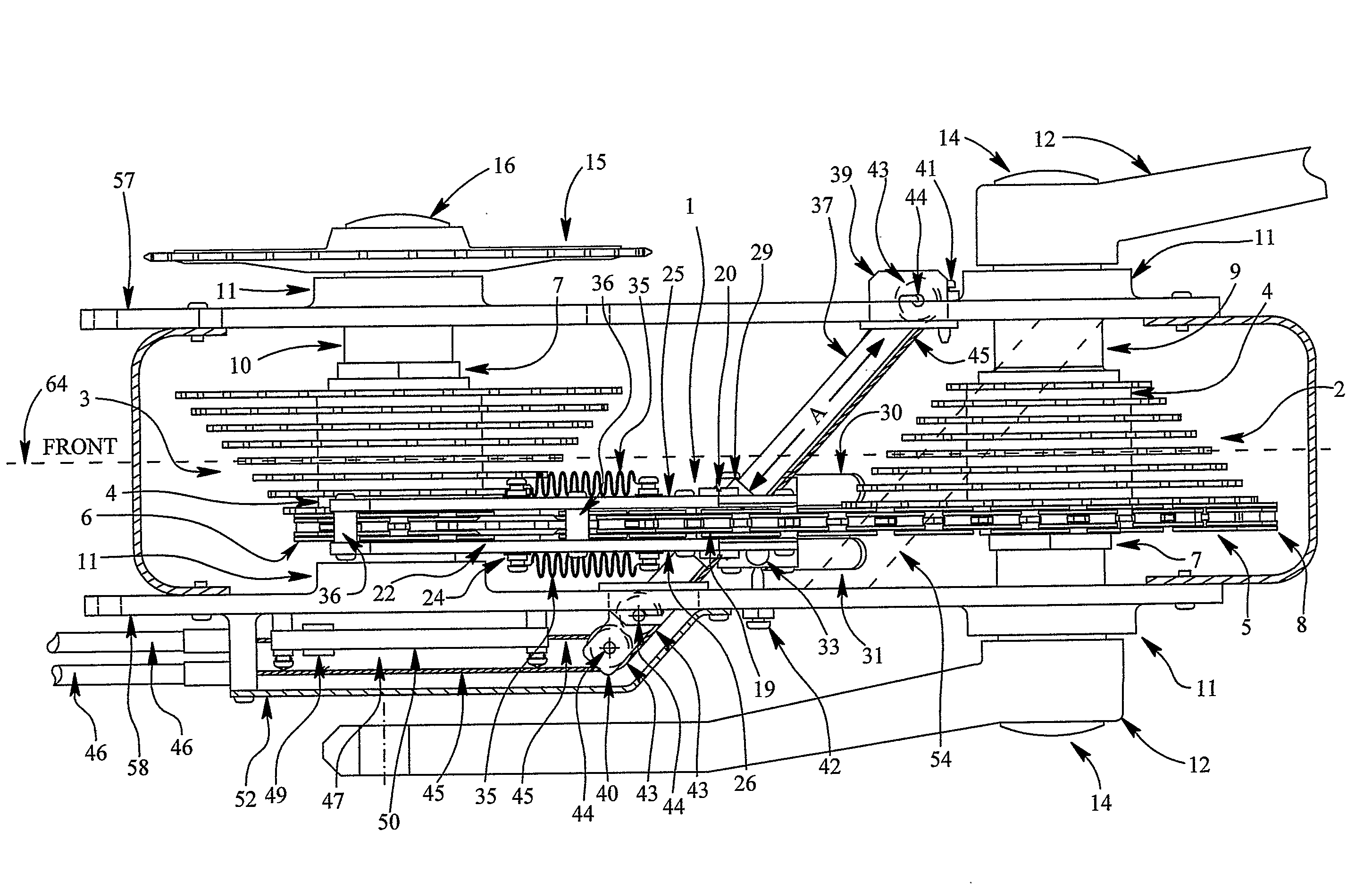

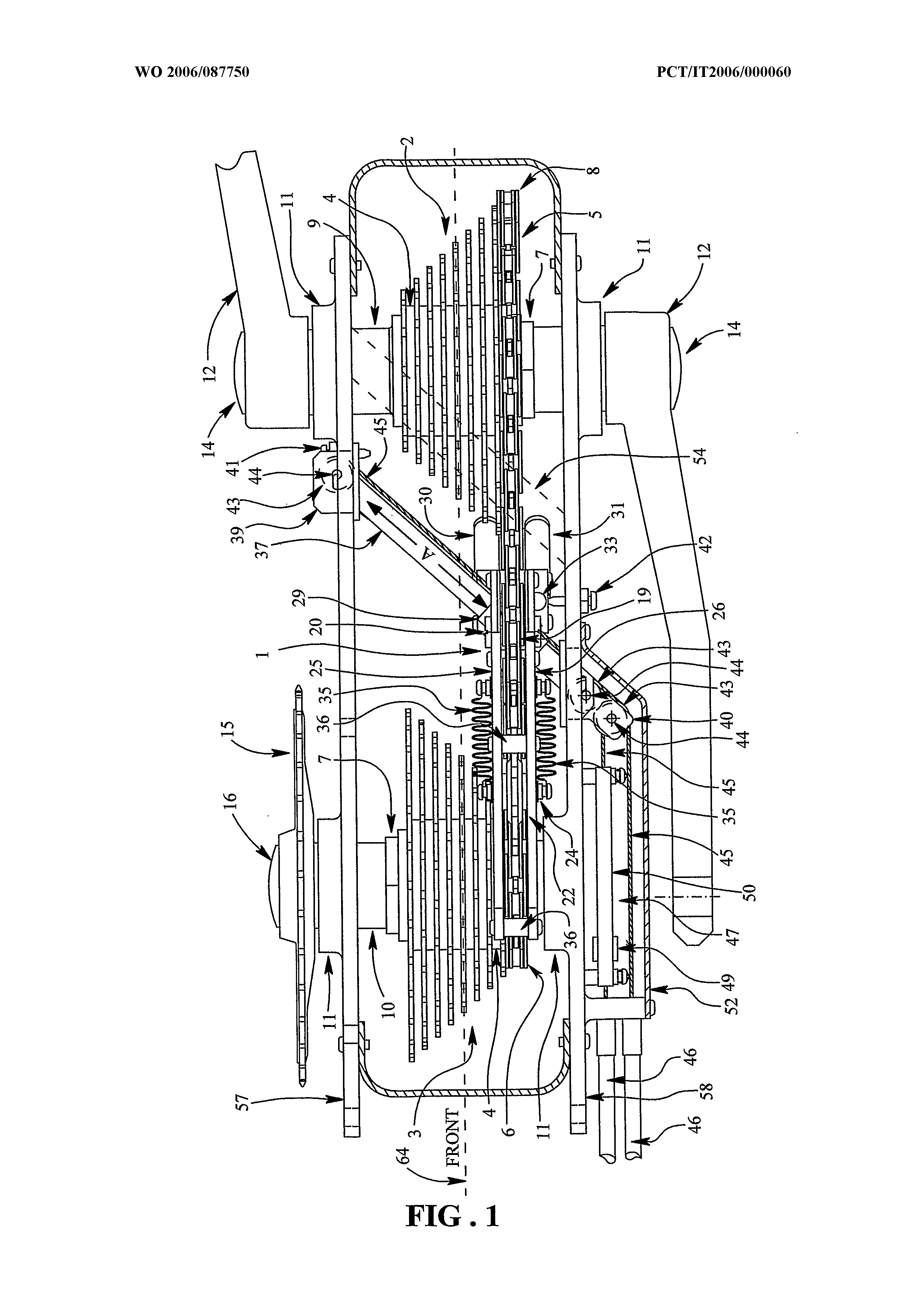

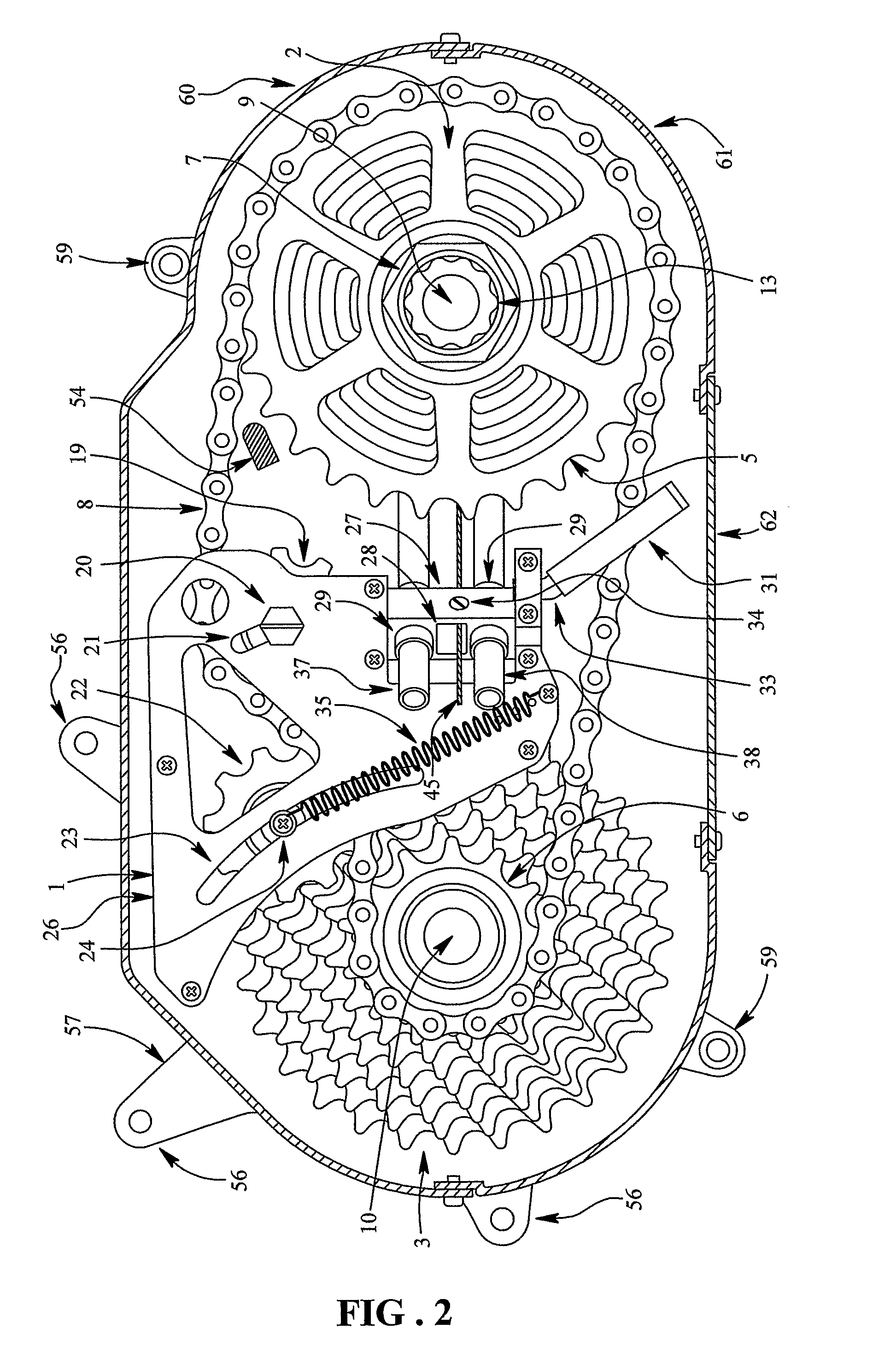

Transmission Case for Bicycles

InactiveUS20080261735A1Easy to testEasy to to lubrificateChain/belt transmissionGearingRotational axisGear wheel

To change the transmission gear ratios of a bike and reduce its dimensions as much as possible. The derailleur, located between the two cog sets (2,3), is the latest, newest and a very important device. Both cog sets (2,3) have parallel and reversed rotating axles so that the big diameter cog (5), located on the primary cog set (2) corresponds to the small diameter cog (6), located on the secondary cog set (3). The primary cog set is assembled on the primary axle and is linked to the secondary cog set by a primary looping ring roller chain (8); the secondary cog set (3) supports the single external cog (15), linked to the rear wheel by the secondary chain (8). When the derailleur is externally activated, it shifts the primary chain (8) to the primary and the secondary cog sets (2,3), having different diameters, so as to change gear.

Owner:CAPPELLINI DANIELE

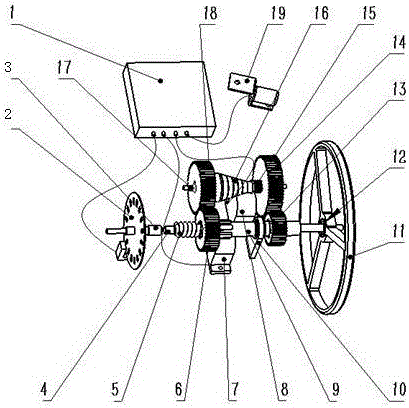

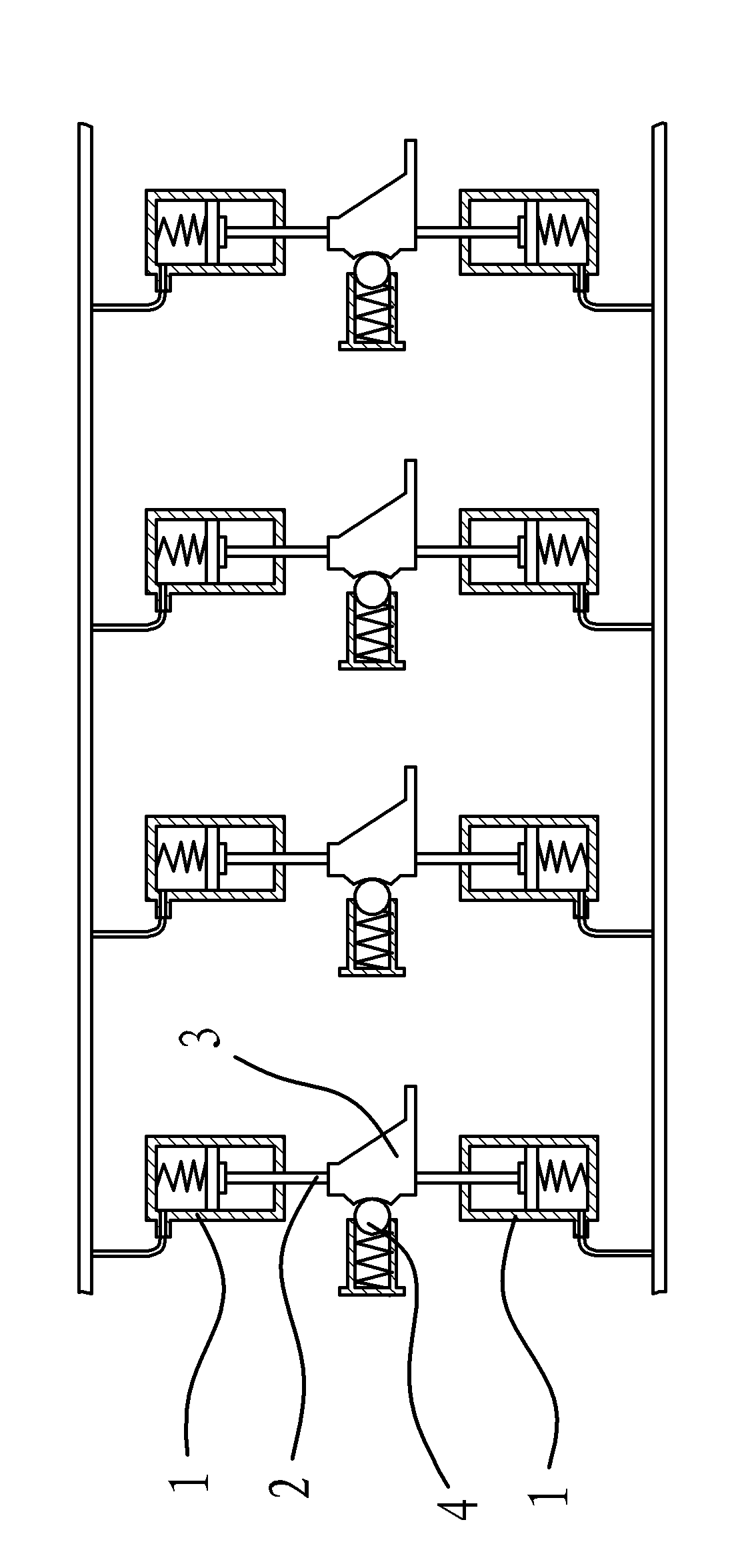

Gear shifting and sliding mechanism for carbon-free cart for traveling up and down hill

The invention discloses a gear shifting and sliding mechanism for a carbon-free cart for traveling up and down a hill. The gear shifting and sliding mechanism comprises a power transmission module and an electronic control module. The power transmission module comprises a rear driving wheel half axle, a rear driven wheel half axle and a winding shaft provided with a cone axle sleeve. The rear driving wheel half axle is connected with an inside and outside spline sleeve capable of axially moving through a spline, and the sleeve is connected with the winding shaft through two pairs of constant mesh gears. The electronic control module comprises a single chip microcomputer, an infrared tube, a wheel speed sensor and two direct current type electromagnets capable of making the constant mesh gears shift gears. When the carbon-free cart travels up and down the hill, the single chip microcomputer sends different instructions according to electrical signals sent by the infrared tube and the grating wheel speed sensor to control the different direct current type electromagnets to be powered on or powered off, so that a power transmission line is converted between the two pairs of constant mesh gears to finish gear conversion between a level road and a ramp. The gear shifting and sliding mechanism has the advantages of being capable of performing intelligent detection, accurately changing driving force, saving gravitational potential energy and making the cart have a uniform traveling speed and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

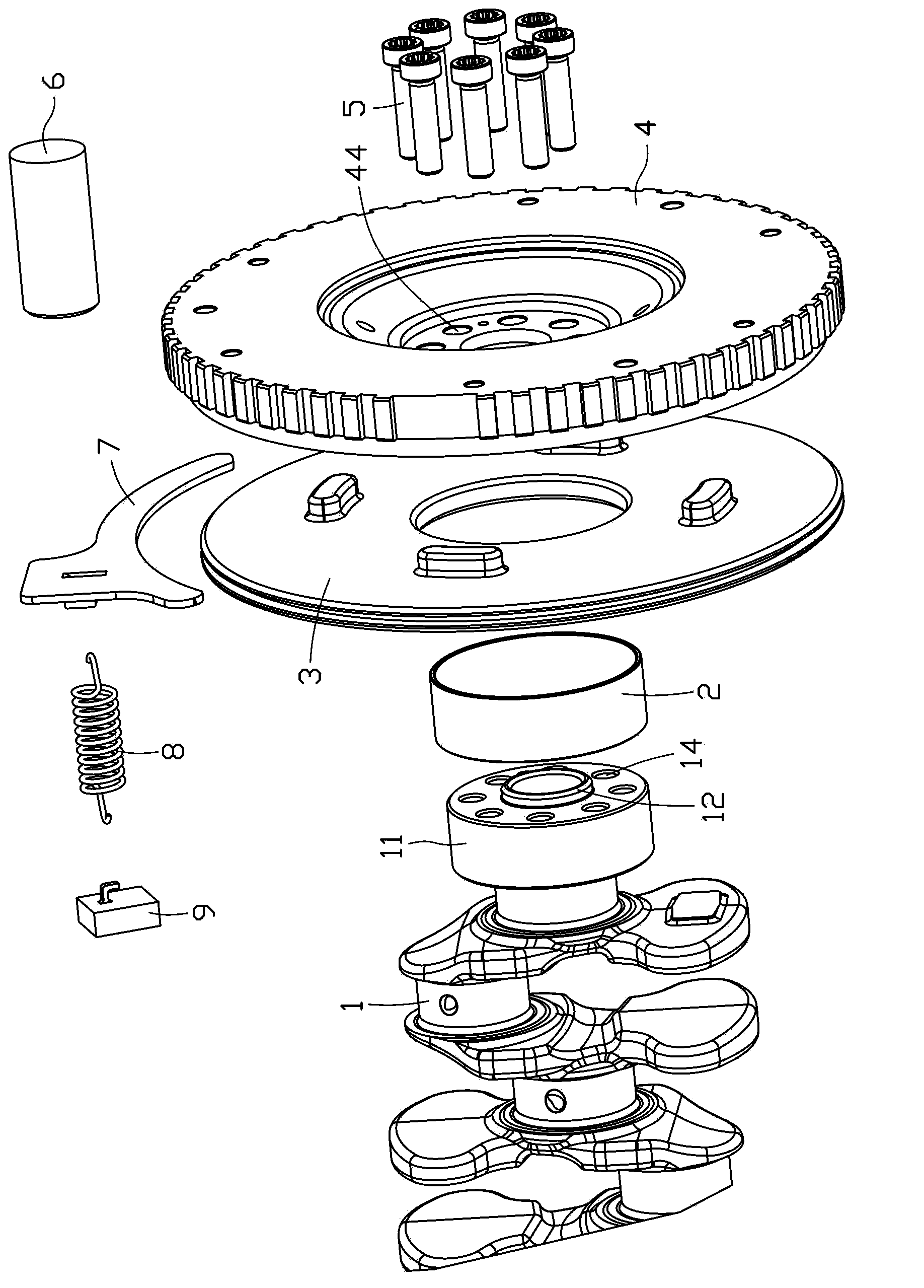

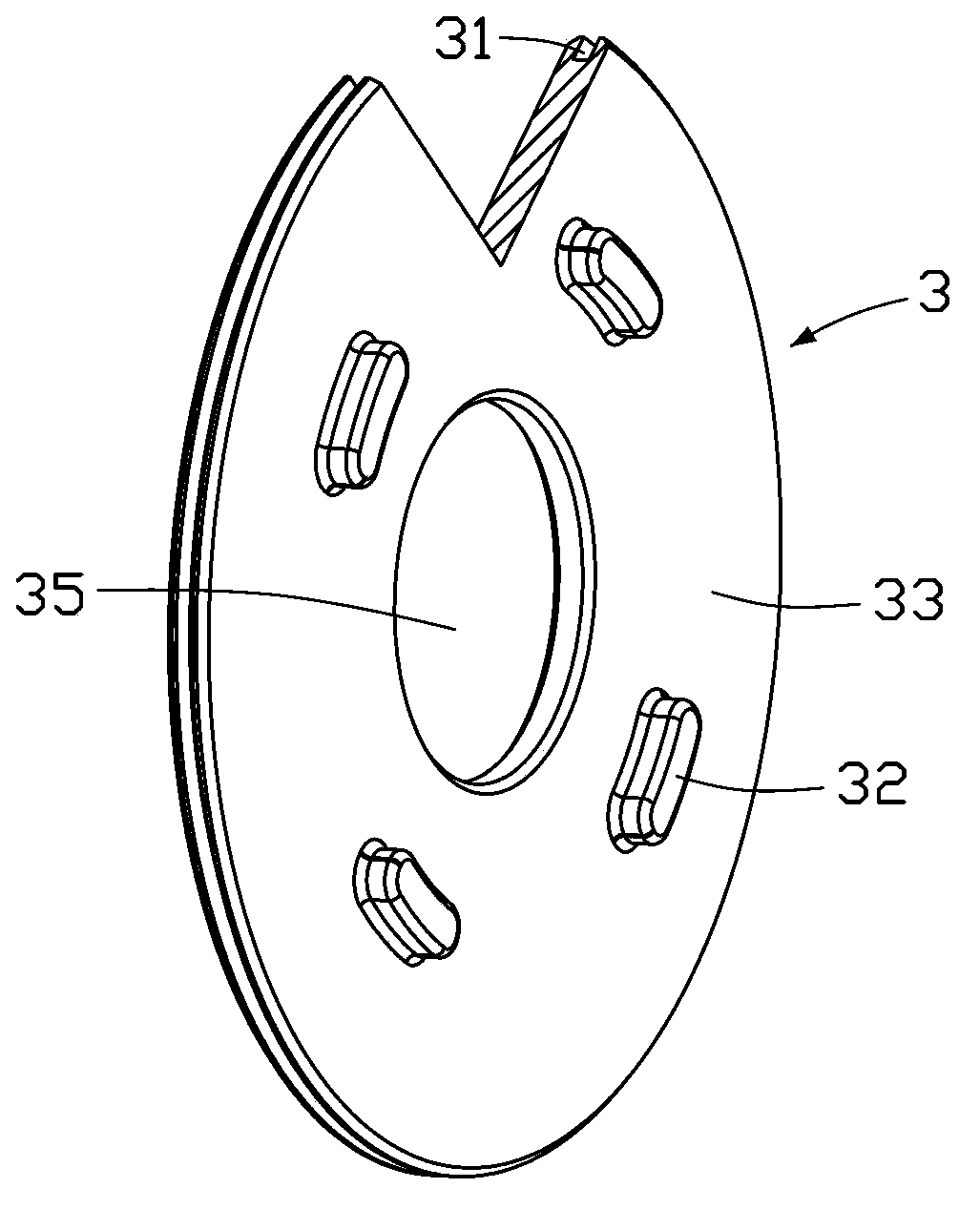

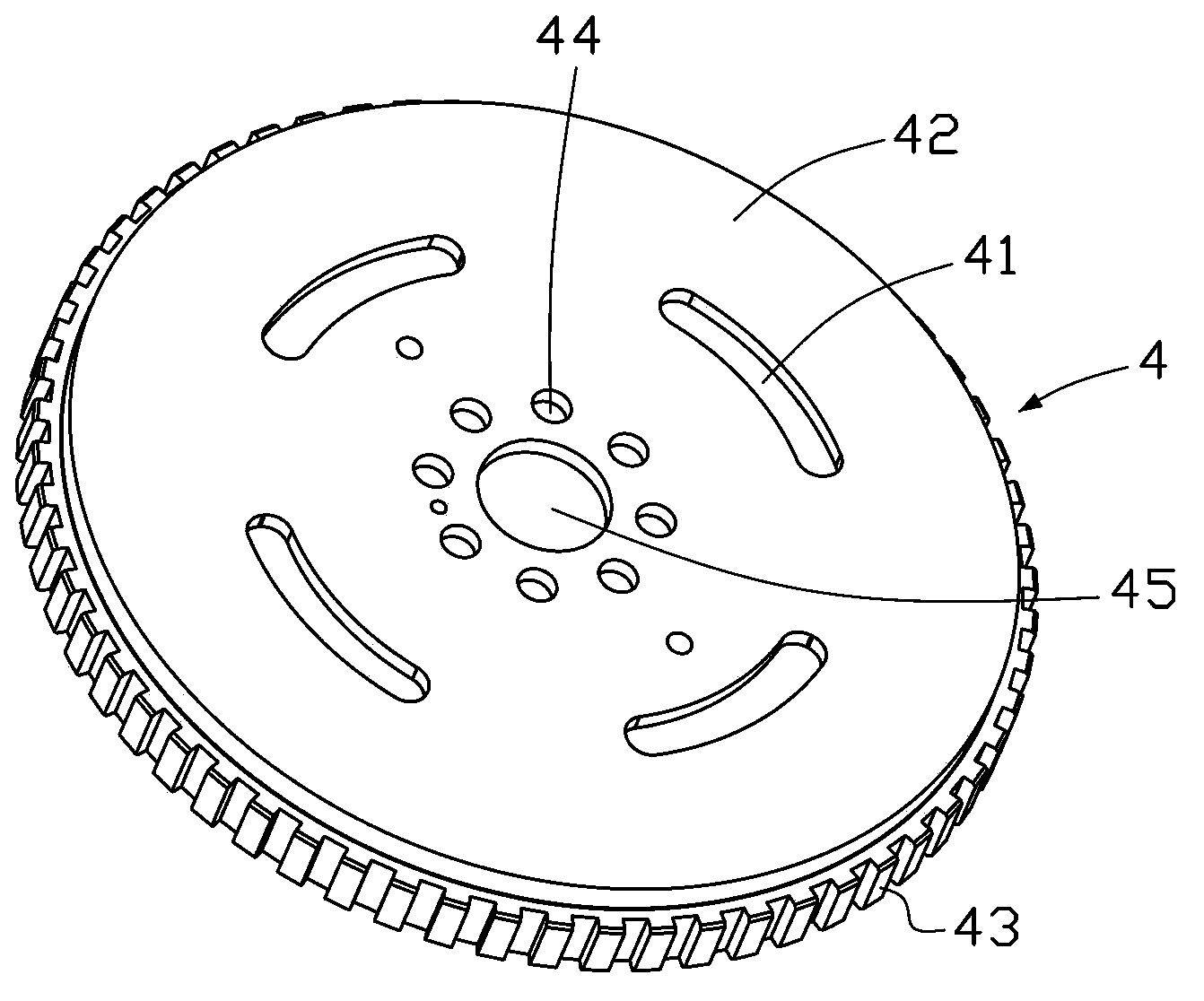

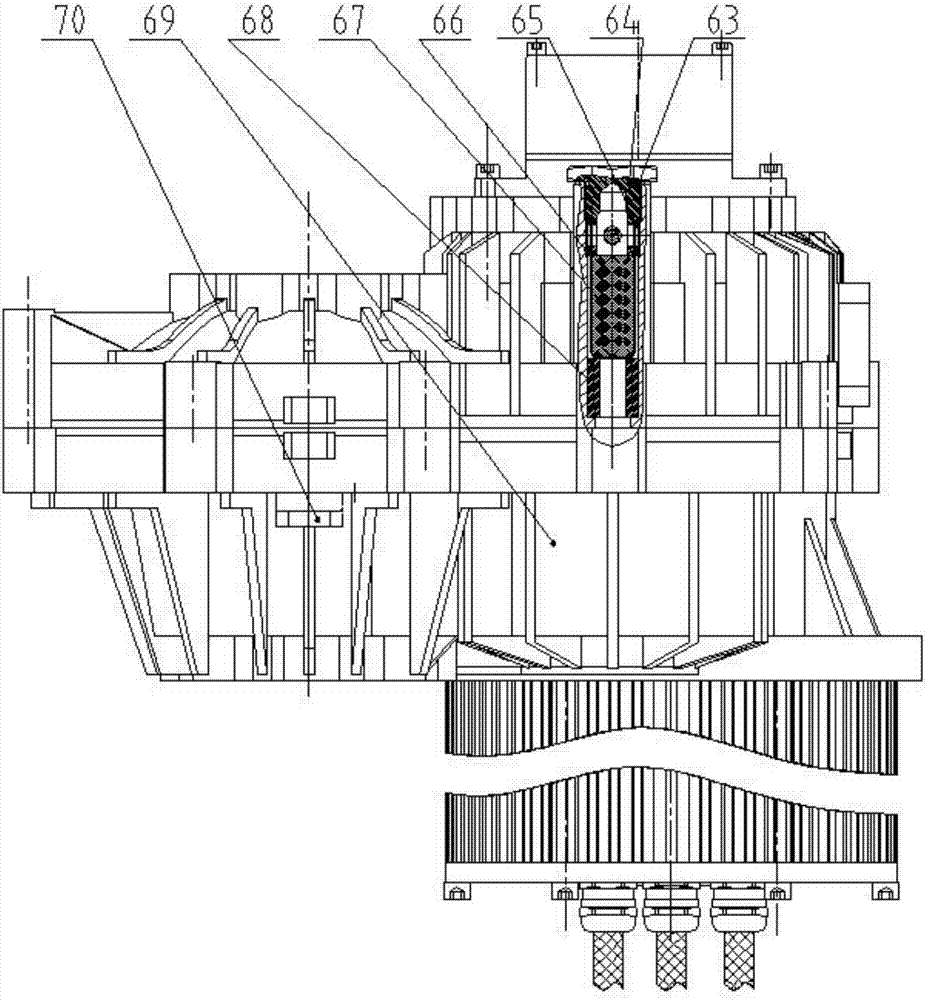

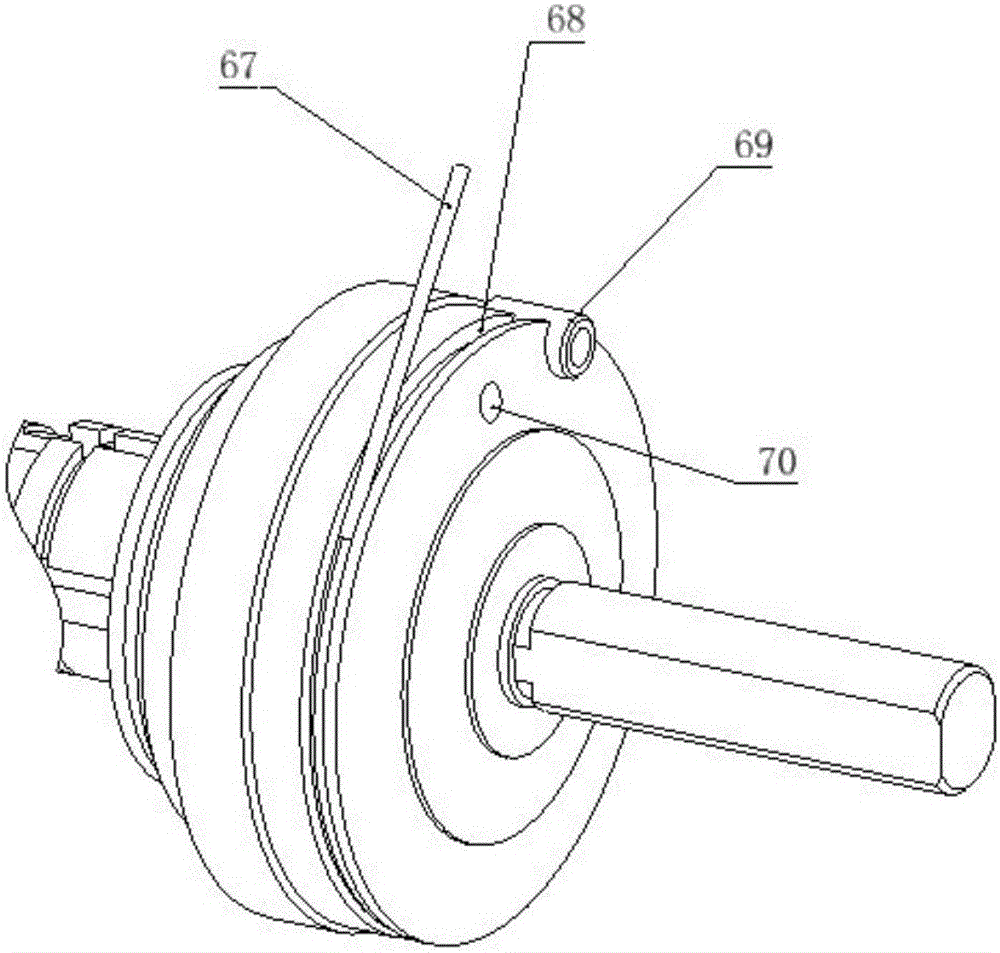

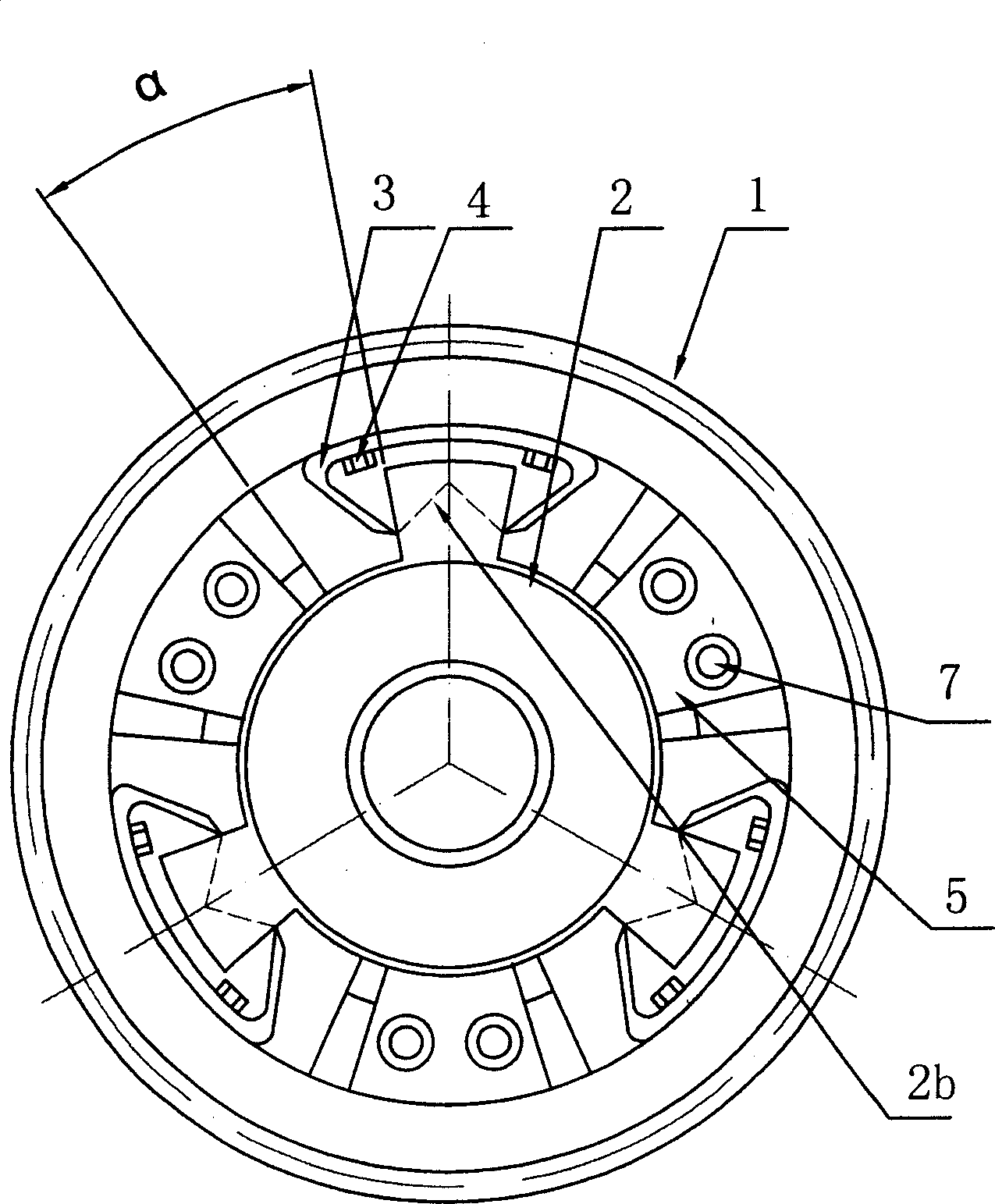

Variable inertia flywheel structure

The embodiment of the invention discloses a variable inertia flywheel structure, which comprises a first flywheel and a second flywheel, wherein the first flywheel is used for being fixedly connected with a crankshaft, and the first flywheel comprises a first flywheel disk; the second flywheel comprises a second flywheel disk, and a pawl slot is arranged on a disc surface of one of the first flywheel disk and the second flywheel disk; and a pawl is convexly arranged on a disc surface of the other one of the first flywheel disk and the second flywheel disk, and the pawl is correspondingly matched with the pawl slot. When the large inertia of the flywheel is needed, the pawl extends into the pawl slot, and the first flywheel drives the second flywheel to rotate together; when the small inertia of the flywheel is needed, the pawl is separated from the pawl slot, and the first flywheel rotates and the second flywheel does not rotate with the first flywheel. According to the variable inertia flywheel structure, when an engine runs at low speed, the inertia of the flywheel increases so as to improve the smoothness of operation; and when the engine runs at high speed, the moment of inertia of the flywheel is reduced, and the fuel consumption is saved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

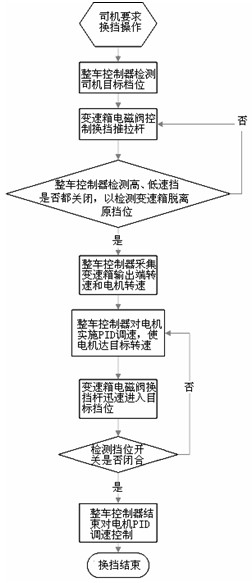

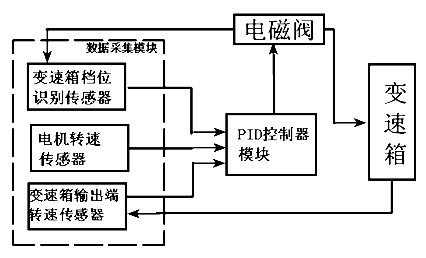

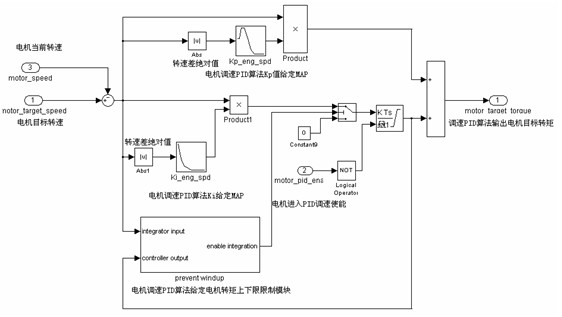

Quick gear-shift control method and control system for electric vehicle gearbox

ActiveCN102506163AShift quicklySafe and reliable quick shift control methodGearing controlProportion integration differentiationGear wheel

The invention discloses a quick gear-shift control method and control system for an electric vehicle gearbox. The quick gear-shift control system comprises a PID (Proportion Integration Differentiation) controller module and a data acquiring module, wherein the data acquiring module acquires the rotation speed of the gearbox output end, the current rotation speed of a motor and the shift gear signal of the driver; the data acquired by the data acquiring module is transmitted to the PID controller module which adjusts the rotation speed of the motor based on the data, so that drive and driven gears quickly and synchronously finish the gear-shift operation, thus the gear-shift time is greatly shortened.

Owner:CHANGSHA CRRC INTELLIGENT CONTROL & NEW ENERGY TECH CO LTD

Gear shift control system of hybrid vehicle

Owner:VOLVO LASTVAGNAR AB

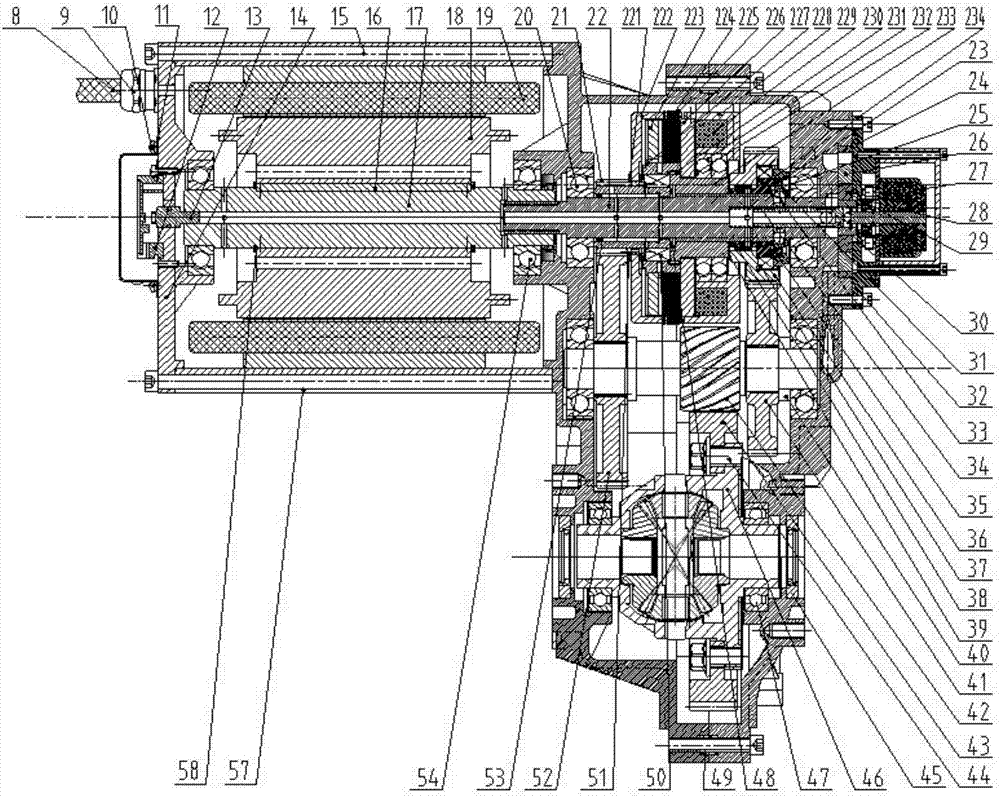

Electromobile power assembly and application thereof

PendingCN107020936AImprove work efficiencyImprove performanceElectric propulsion mountingElectric machinesSensori motorElectric machine

The invention relates to an electromobile power assembly and an application of the electromobile power assembly. The electromobile power assembly comprises an integrated drive motor, a transmission, a clutch, a differential mechanism and an oil pump; a motor shaft of the drive motor is in drive connection with one end of an input shaft of the transmission; the other end of the input shaft of the transmission is connected with the oil pump; the input shaft of the transmission is in drive connection with a differential mechanism gear of the differential mechanism through a first transmission gear and a second transmission gear; the clutch is arranged on the input shaft of the transmission and is in drive connection with the first transmission gear; and the drive motor is provided with a motor sensor. The electromobile power assembly effectively switches the gear according to the actual condition of an electromobile, so that the operating conditions of the electromobile better accords with the actual road condition, the working efficiency of the electromobile is improved, meanwhile, the performance of the existing electromobile is optimized, the starting is stable, the gear is smoothly and rapidly switched, the operation of the electromobile is efficient and safe, and the smoothness and the reliability of the operation the whole electromobile are improved.

Owner:荣成市荣佳动力有限公司

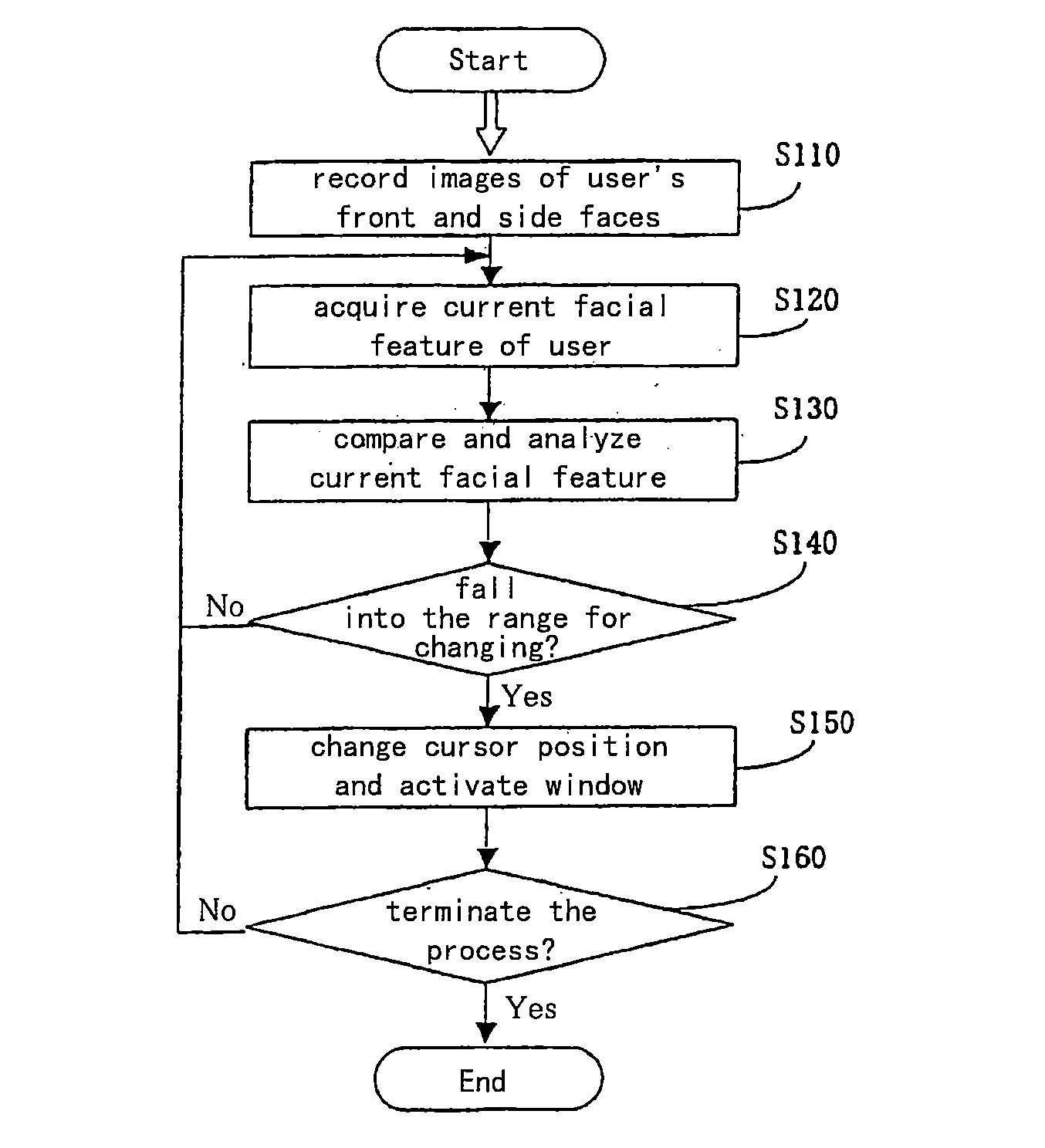

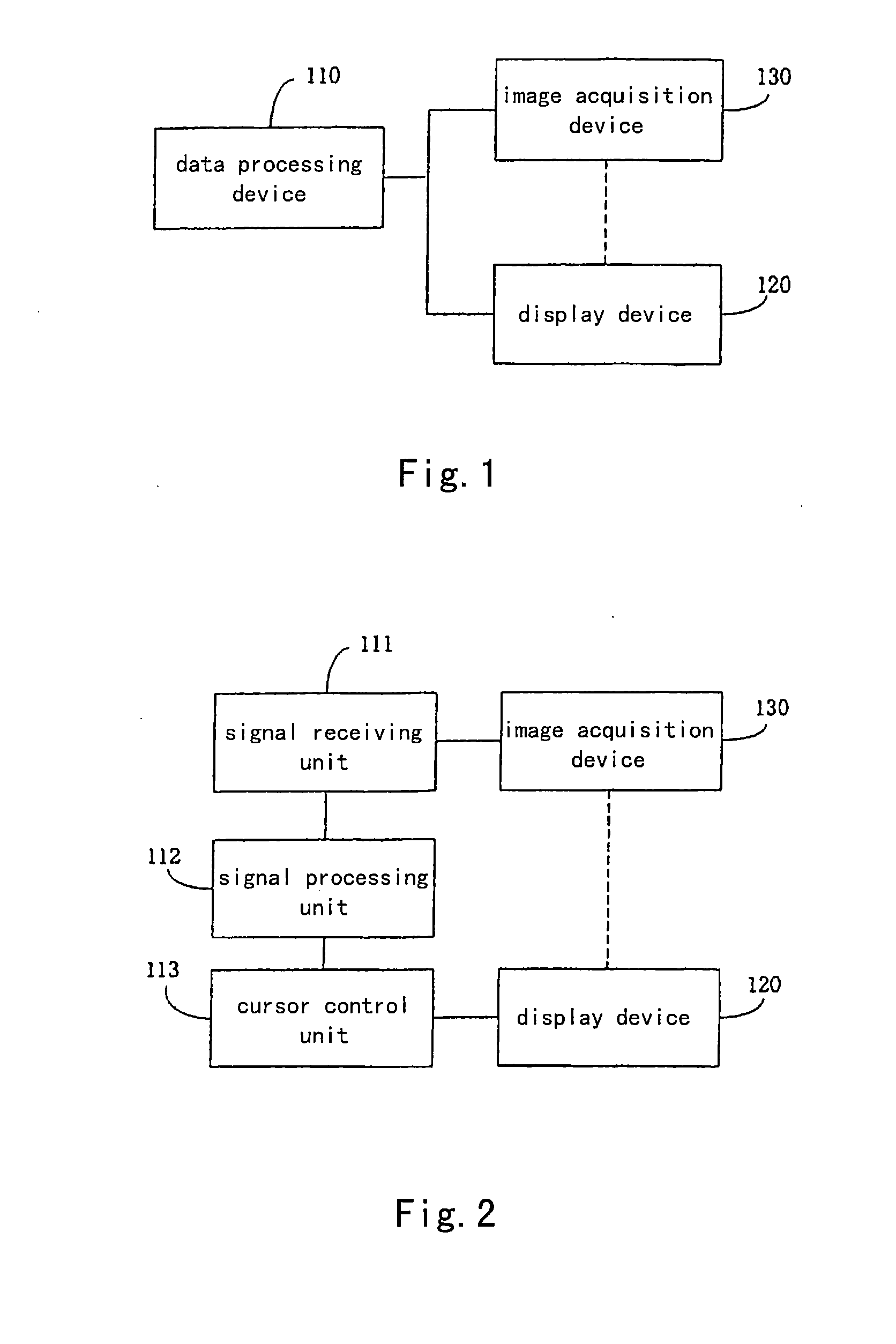

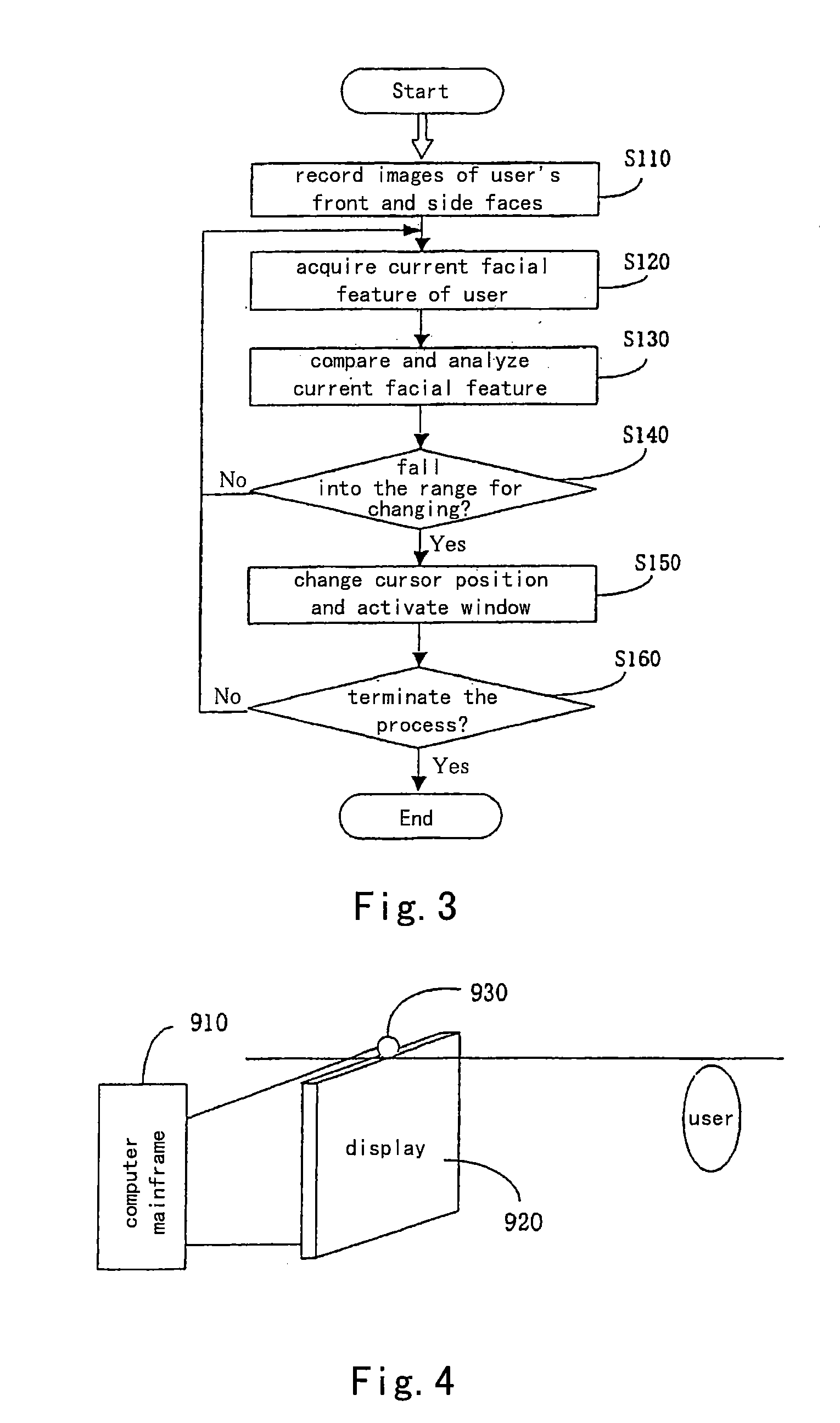

Control system and method for a cursor in display device

InactiveUS20090213071A1Fast transferImprove work efficiencyCathode-ray tube indicatorsInput/output processes for data processingControl signalControl system

The present invention discloses a control system for a cursor in display device, in which said display device is connected to a data processing device and said system comprises: an image acquisition device for acquiring user image information and sending a signal; a signal receiving unit for receiving the signal from the image acquisition device; a signal processing unit for parsing said signal and determining whether the cursor and the target region the cursor reaches need to be shifted or not; and a cursor control unit for sending a cursor control signal to said display device based on the determination result by the signal processing unit and shifting the cursor to said target region. Accordingly, the present invention further discloses a control method for a cursor in a display device.

Owner:LENOVO (BEIJING) CO LTD

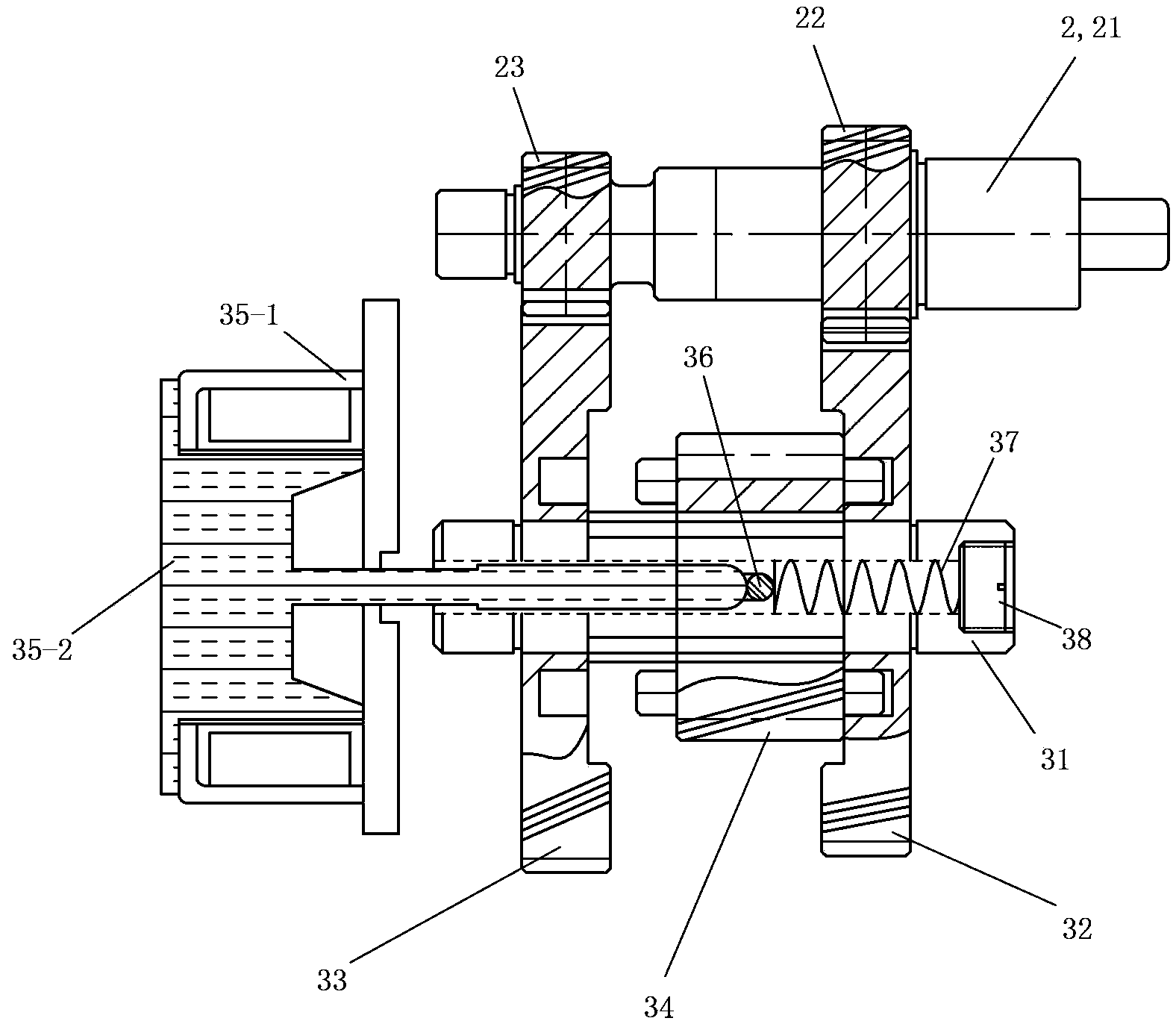

A gear selection actuator of an electronically controlled mechanical automatic transmission

InactiveCN102261461AReduce power interruption timeShift quicklyGearing controlAutomatic transmissionEngineering

The invention provides a gear selection actuator of an electronically controlled mechanical automatic gearbox, which belongs to the field of mechanical technology. It solves the problem that the existing AMT gear selection actuators with 5 gears and lower gears cannot meet the requirements of four gear selection positions. The gear selection actuator of the electronically controlled mechanical automatic transmission is arranged at the shift lever of the automatic transmission, and the mechanism includes several shift parts located between two adjacent shift rods. It is two oil cylinders and a piston rod located between the two oil cylinders. The two ends of the piston rod are respectively located in the above two oil cylinders and there is a shift fork on the piston rod that can toggle the shift rod. The above-mentioned several shift parts and The hydraulic lines are connected. The present invention is a plurality of shifting parts arranged between two adjacent shift levers. Each shifting part is independent and centrally controlled through hydraulic pipelines. There is no gear selection process when shifting gears, which greatly reduces the need for electronically controlled mechanical automatic The power interruption time when the gearbox shifts gears makes the shifting fast and stable.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Method of gear-shifting in a servo-controlled manual gearbox

ActiveUS20090216413A1Easy and cost-effective to implementRapid gear shiftingDigital data processing detailsGearing controlAngular velocityPower flow

A method of gear shifting in a servo-controlled gearbox. The method generates an oscillation on angular velocities of primary and secondary shafts of the gearbox, separates the primary shaft from the secondary shaft thus disengaging a first current gear when the oscillation has taken the angular velocity of the primary shaft close to the angular velocity that the primary shaft must assume to engage a second next gear, and connects the primary shaft to the secondary shaft thus engaging the second next gear when the oscillation has led the angular velocity of the secondary shaft to equalize the current angular velocity of the primary shaft multiplied by the transmission ratio of the second next gear.

Owner:SPAN FERRARI SPA

Speed changing device of electric car and gear shifting assembly

InactiveCN103423435AEasy to shift gearsSimple structureToothed gearingsGearing controlElectric carsEngineering

The invention discloses a speed changing device of an electric car. The speed changing device of the electric car comprises a case body, a power input member, a gear shifting assembly, a power output member and a transmission assembly. The power input member comprises an input shaft, a first driving gear and a second driving gear, wherein the input shaft is rotatably arranged in the case body through a corresponding bearing, one end of the input shaft extends out of the case body, and the first driving gear and the second driving gear are arranged on the input shaft sequentially from right to left and driven by the input shaft. The transmission assembly comprises a first transmission gear and a second transmission gear. The gear shifting assembly comprises a spline shaft, a clutch member, an electromagnet, a round pin and a spring. The working position of the clutch member of the gear shifting assembly can be changed by arranging an ejector rod, the round pin and the spring in the spinle shaft. Therefore, inside space of the speed changing device is greatly saved, volume and weight of the speed changing device can be reduced, and energy consumption when the electric car is reduced.

Owner:黄洪良

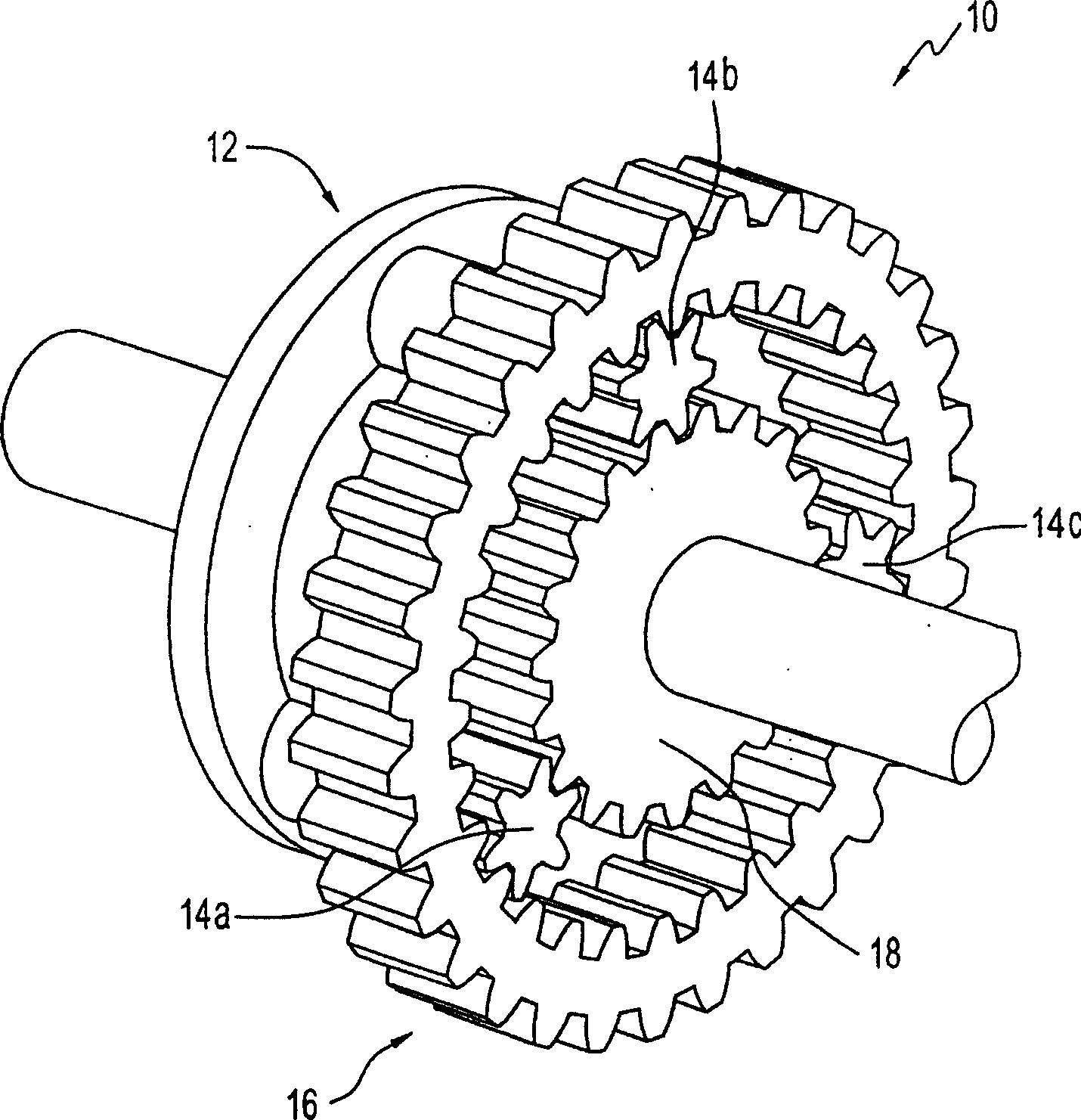

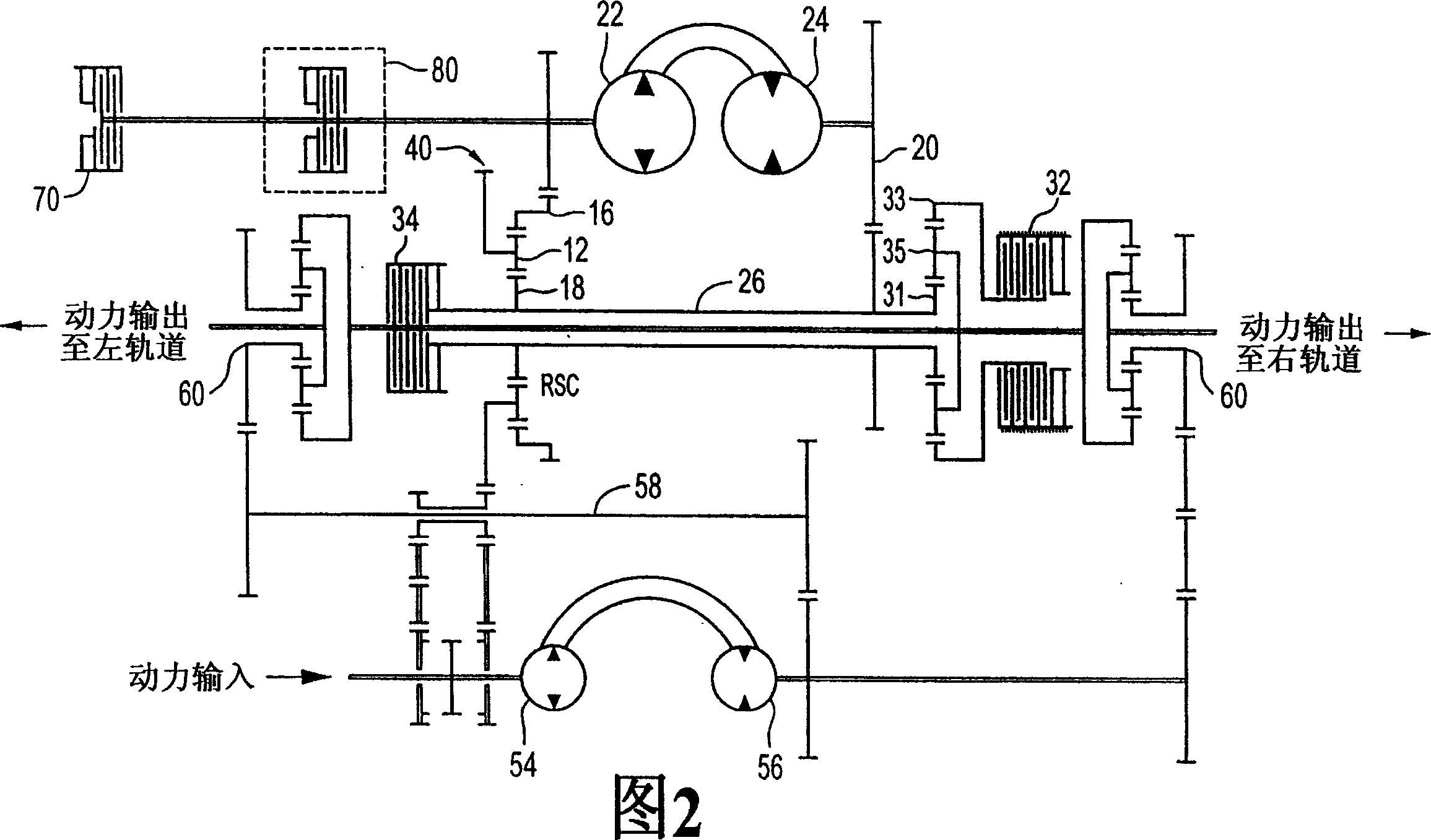

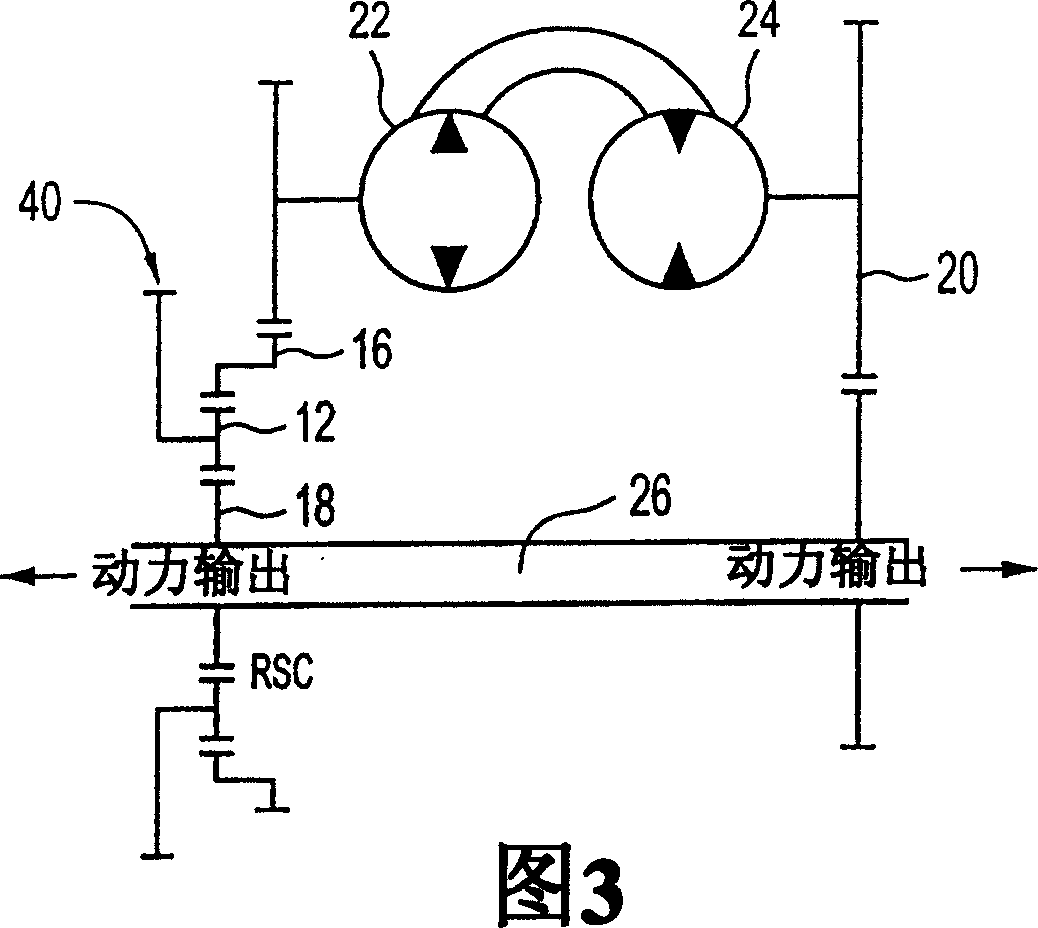

Hydro-mechanical continuously variable transmission

The invention comprises a hydro-mechanical continuously variable transmission (HMCVT) that uses a planetary gear system to provide a combination of hydraulic and mechanical power for a vehicle or stationary equipment. The invention further comprises various ancillary elements to improve the performance of the HMCVT.

Owner:SILVATECH GLOBAL SYST

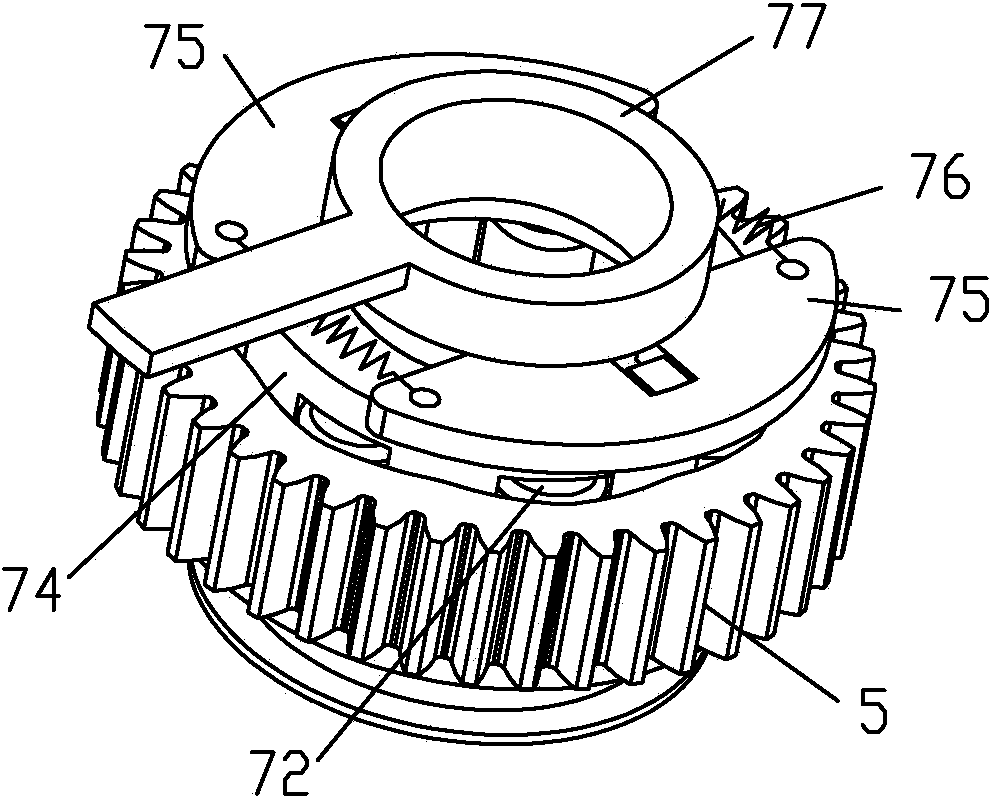

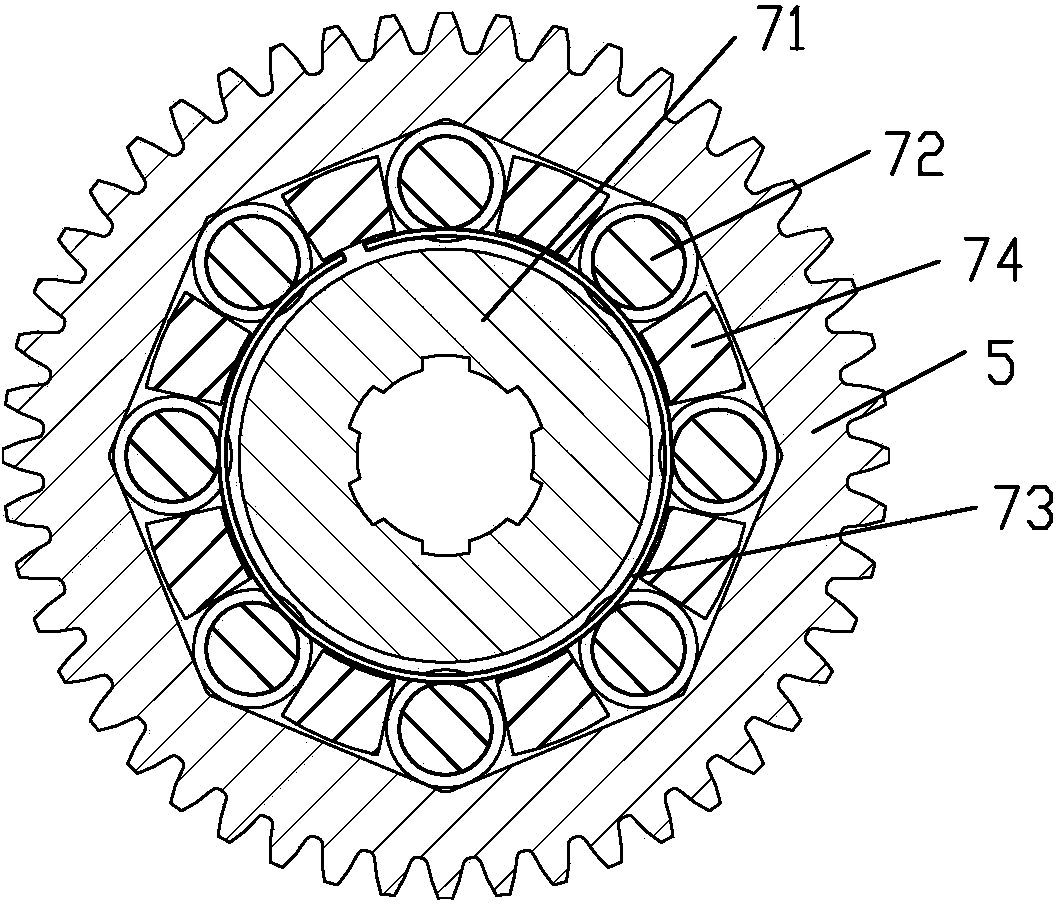

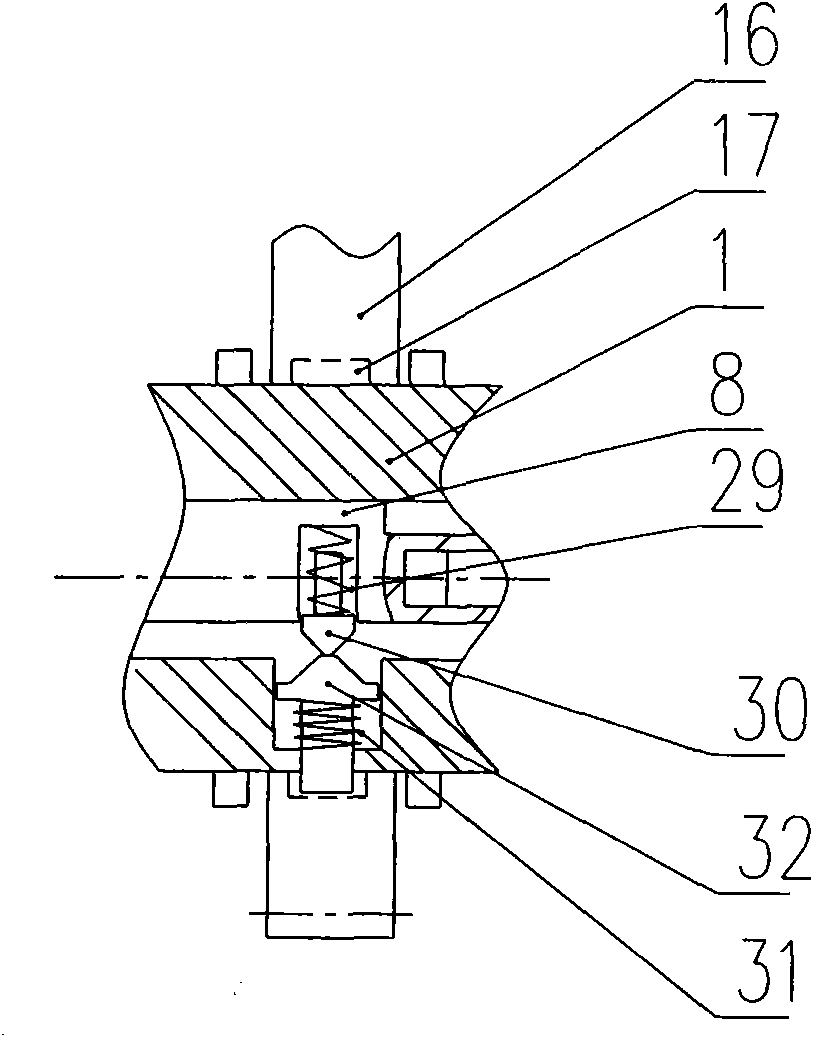

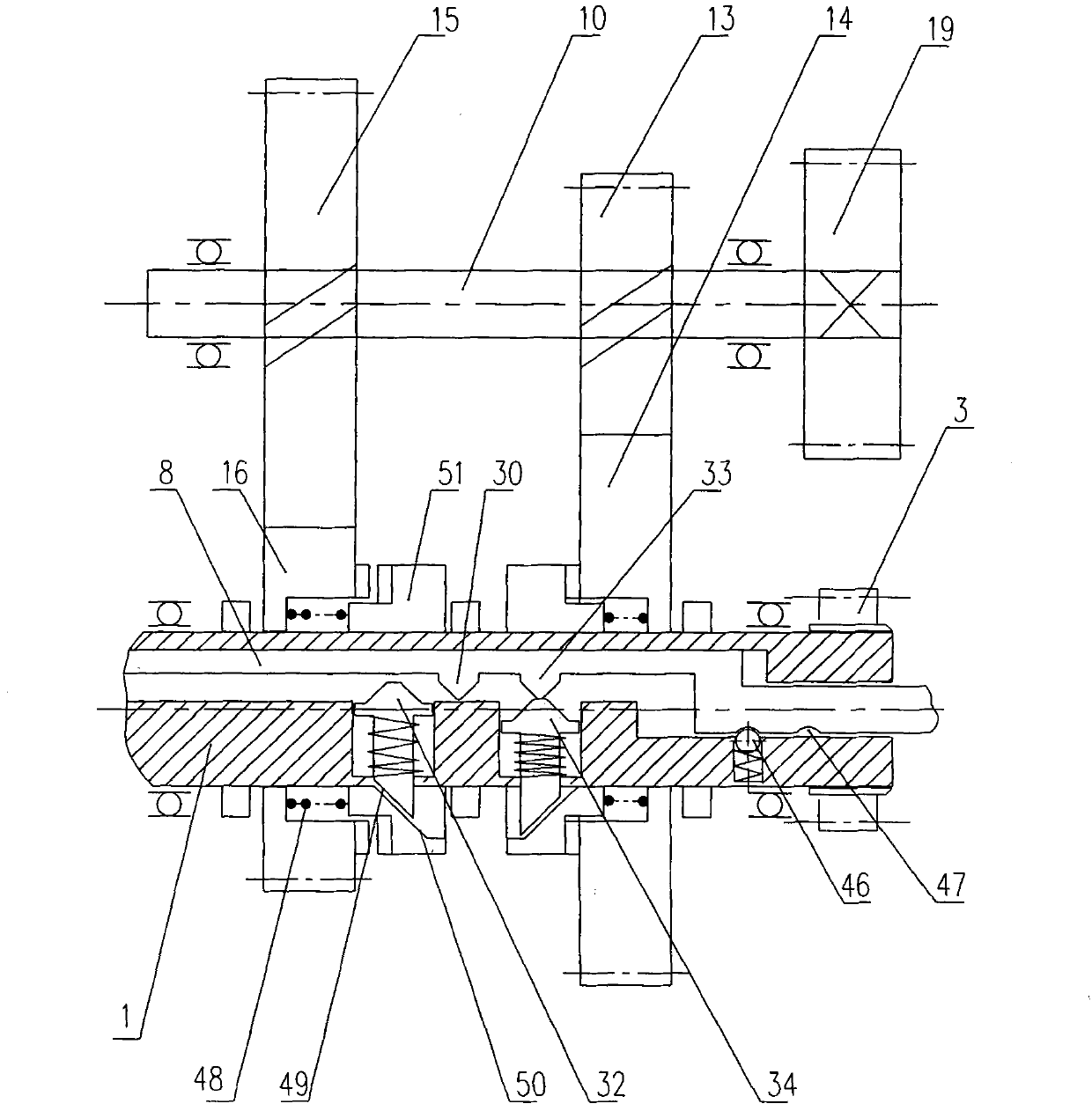

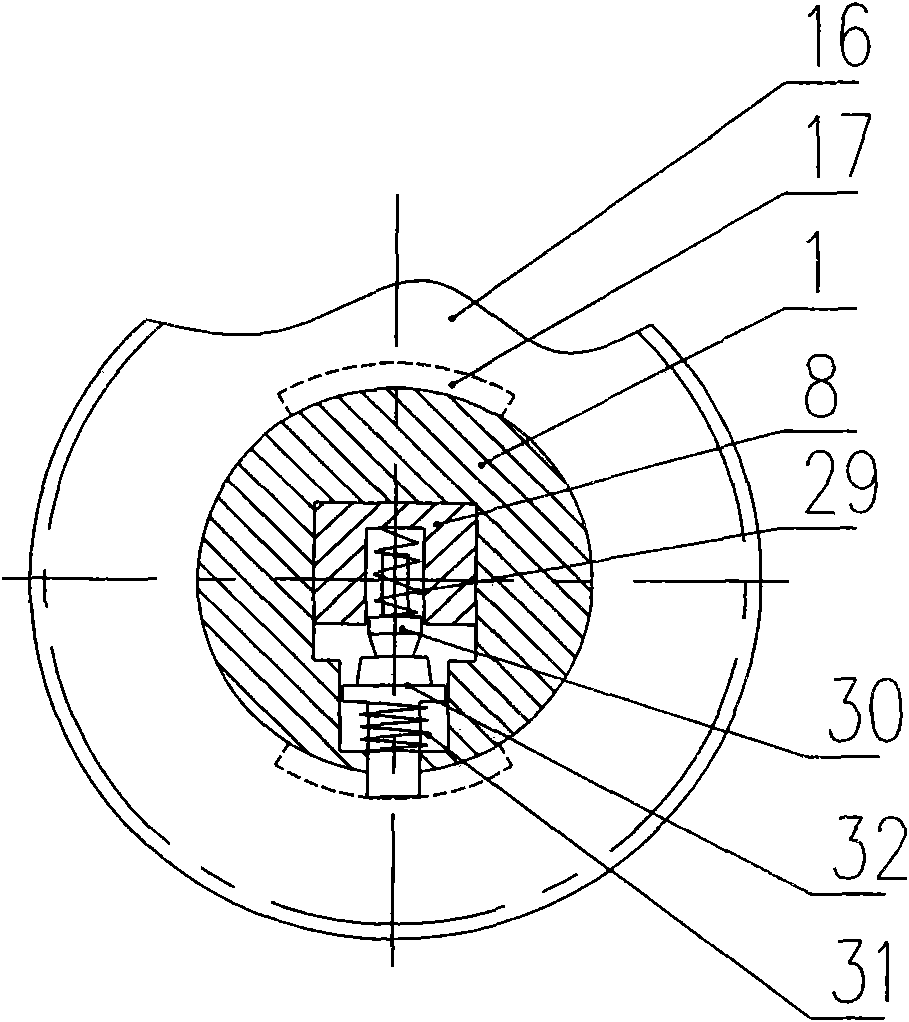

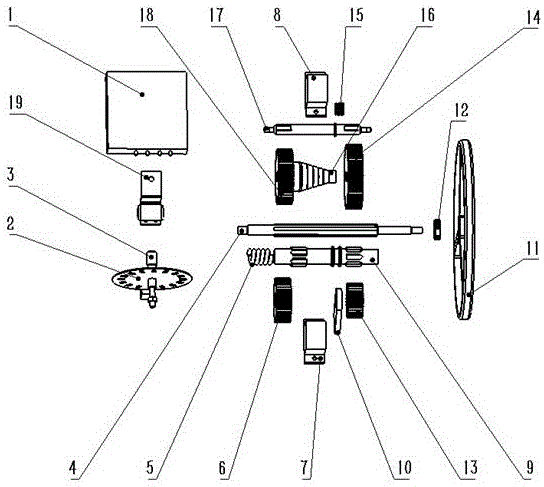

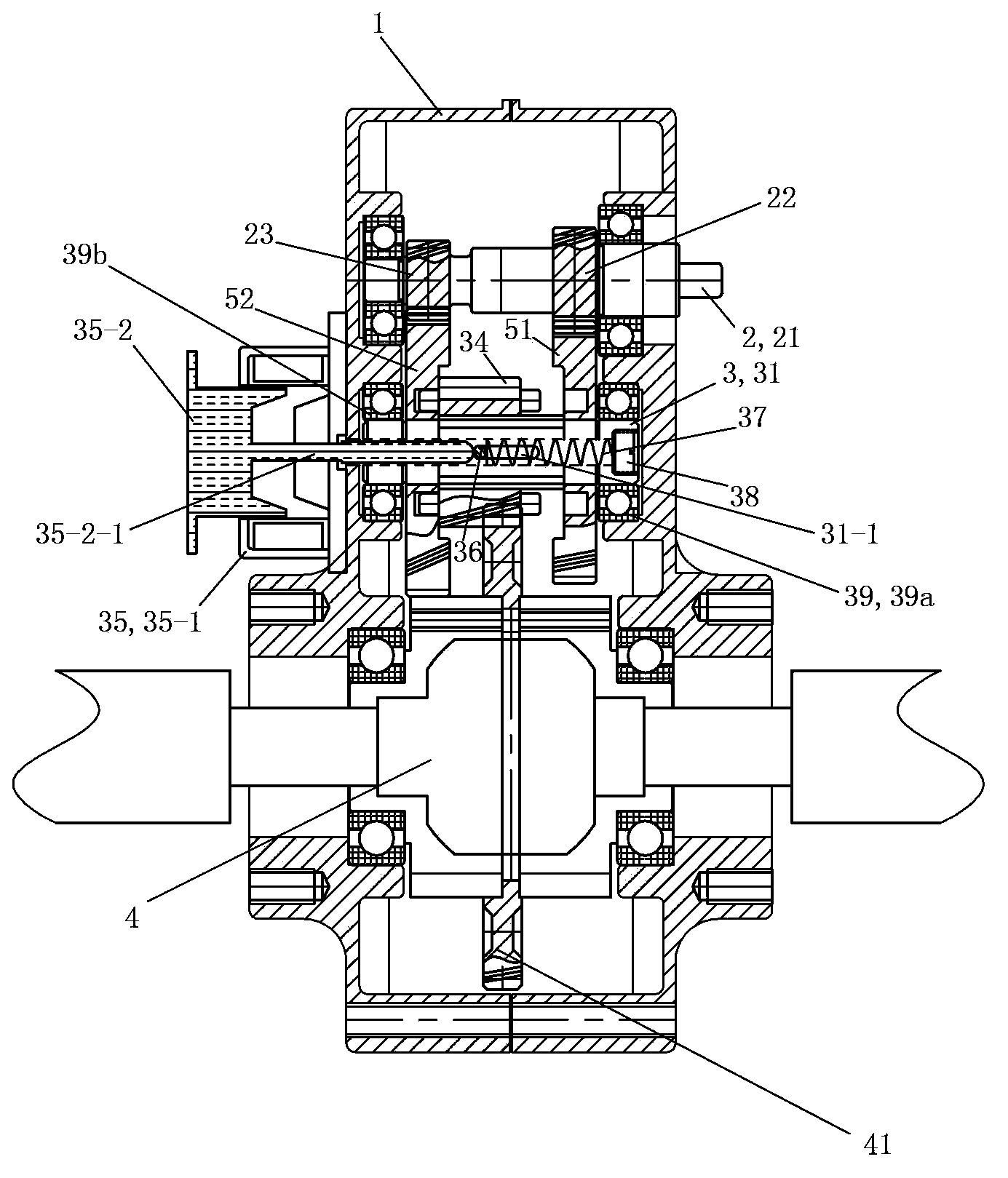

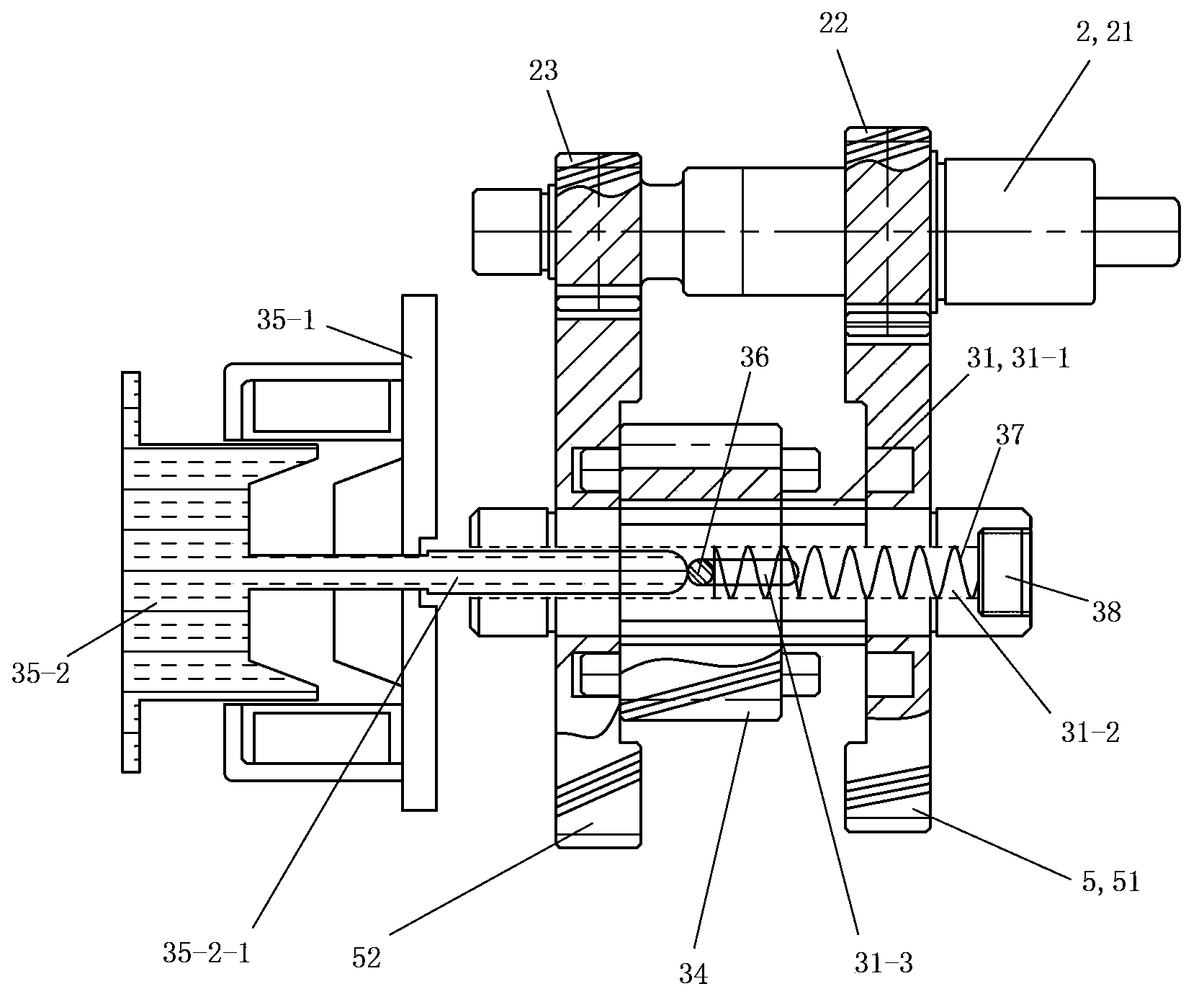

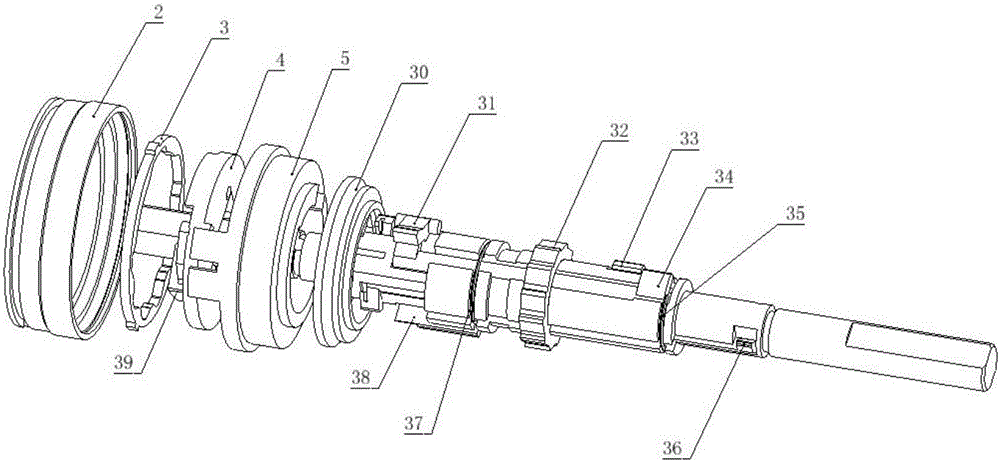

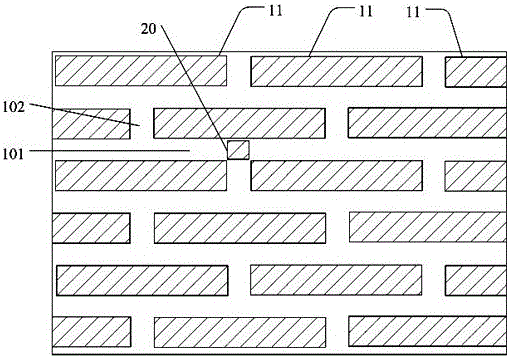

Multi-gear transmission and center wheel pawl installation structure used in same

ActiveCN105156664AReduce wearSave spaceGearing controlTransmission elementsStructural engineeringMechanical engineering

The invention discloses a multi-gear transmission and a center wheel pawl installation structure used in the same. A gear control assembly of the transmission comprises an operation device and a plurality of execution devices. The operation device comprises a sawtooth component arranged at the end of an output wheel hub rotationally, the sawtooth component drives a plurality of pawl rods, and the pawl rods are rotationally embedded in grooves formed in the axial direction of a main shaft; one ends of the pawl rods make contact with the sawtooth component, the pawl rods are controlled through the sawtooth component to rotate, a pawl of a corresponding center wheel connected with the other end of each pawl rod is operated to swing, and then the corresponding center wheels are controlled to be engaged and disengaged with the main shaft through the pawls. The pawl rods are subjected to gear shifting by rotating and shifting the pawls, and are small in abrasion and high in response speed. For the center wheels with a small size, the pawls are installed by arranging lengthening sleeves, the diameter of an inner gear ring can be reduced, the size of the inner transmission can be further effectively reduced, and light-weight design of the transmission is facilitated.

Owner:GUANGDONG LOFANDI INTELLIGENT TECH CO LTD

Gear shift control device of hybrid power vehicle

InactiveCN1839065AReduce sync timeShift quicklyClutchesElectric machinesElectric vehicleHybrid vehicle

In a hybrid-drive electric vehicle, upon request of gear shifting of a transmission (2), a clutch (3) is first disconnected and the transmission (2) is set to a neutral position. The rotating electric generator 4 is then operated in a motor mode or a power generating mode so that a rotational speed of an input shaft of the transmission (2) reaches a region of a synchronizing rotational speed in accordance with a requested gear position. When the rotational speed of the input shaft of the transmission (2) reaches the region of the synchronizing rotational speed, the gear position of the transmission (2) is changed over from the neutral position to the requested gear position. Thus the rotation synchronizing time for the gear shifting in the transmission (2) is reduced, making it possible to perform the gear shifting for a short period of time.

Owner:VOLVO TRUCK CORP

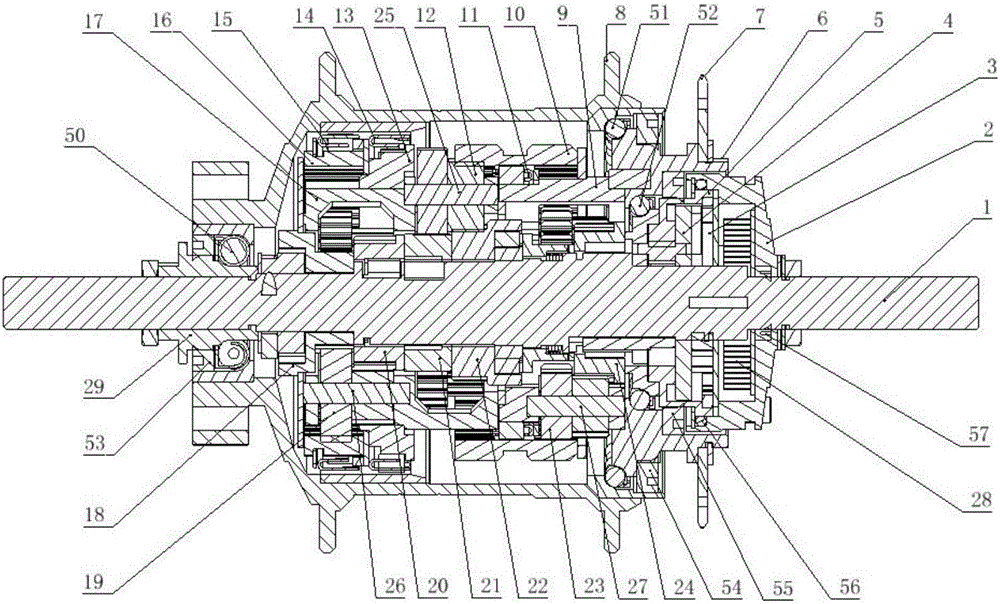

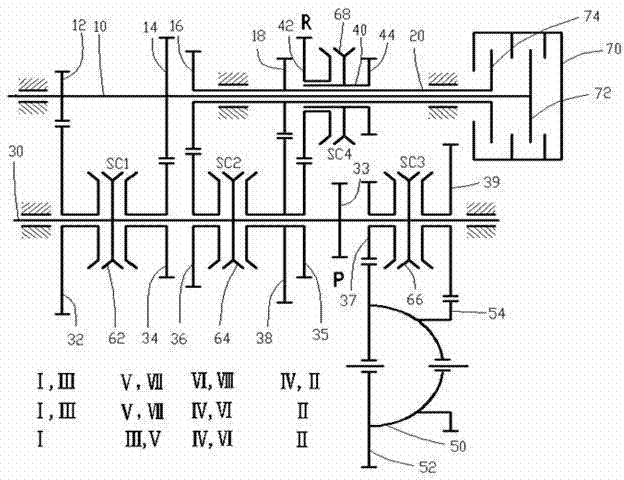

Double-clutch automatic transmission device

ActiveCN103671760AMeet the selection needsImprove comfortToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention relates to a double-clutch automatic transmission device which structurally comprises internal and external input shafts (10, 20) which are coaxially arranged, an auxiliary shaft (30) and a reverse gear shaft (40) which are parallel to the two input shafts, a double-clutch assembly (70), a differential assembly (50), multiple groups of normally engaged gear trains arranged on all the shafts as well as multiple groups of synchronizer devices (62, 64, 66 and 68) which are used for realizing selection of all gears. The double-clutch automatic transmission device can provide eight forward gears at most and a reverse gear, so that the transmission device has more excellent comfort performance and lower oil consumption. As two groups of optional reduction gear trains are adopted, each gear train can realize two different gears, so that one auxiliary shaft and assemblies thereof can be reduced, and the transmission cost is reduced. The double-clutch automatic transmission device has the characteristics of simple structure, large quantity of gears, low cost and the like.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

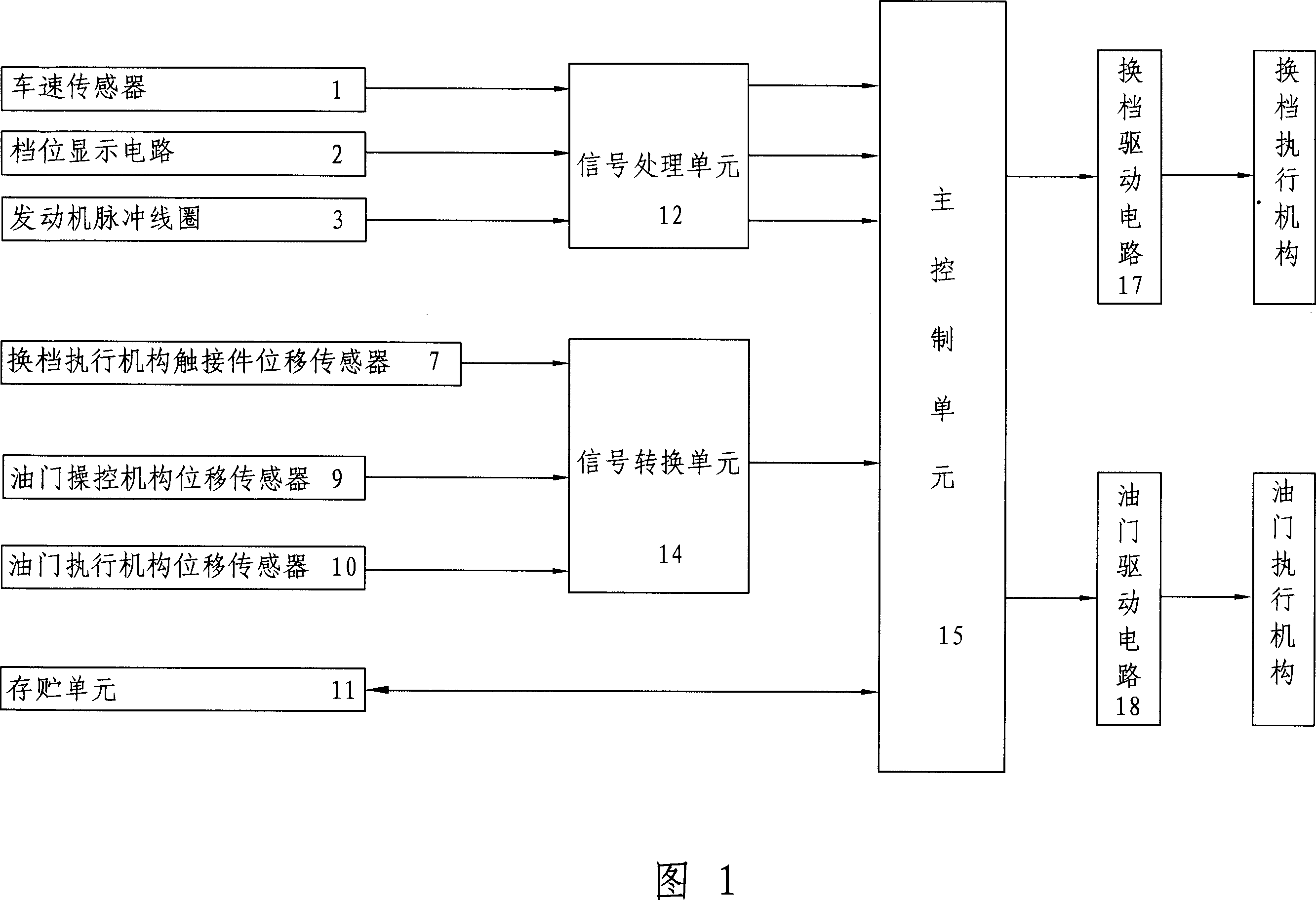

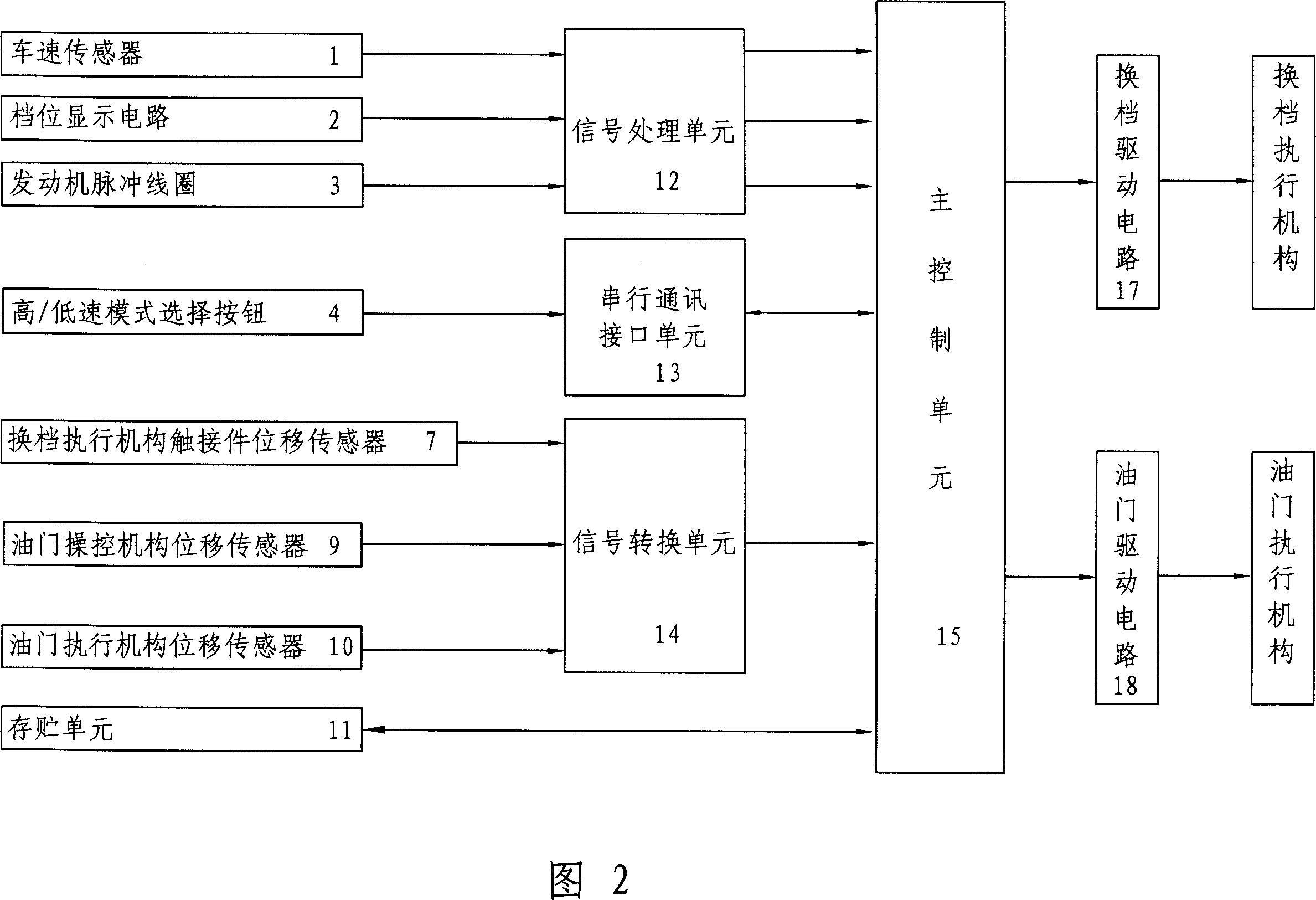

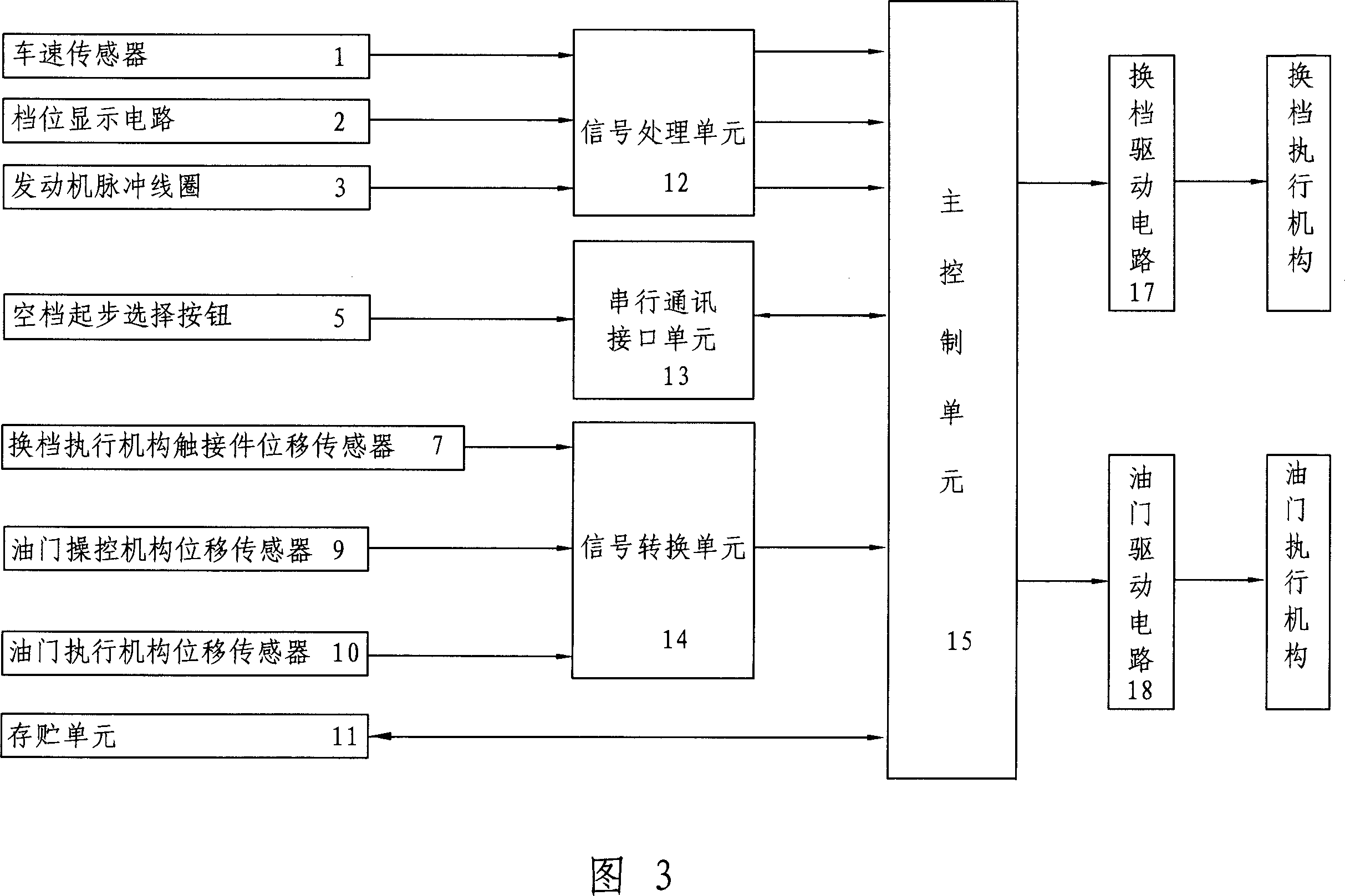

Intelligent control system of motorcycle, and control method

The present invention relates to a motorcycle intelligent control system. Said system is mainly composed of signal processing unit, signal conversion unit and main control unit. Said signal processing unit is connected with speed sensor, transmission display circuit and engine pulse coil; the signal conversion unit is connected with shifting actuator contact-connection component displacement sensor, accelerator control mechanism displacement sensor and accelerator actuating mechanism displacement sensor; the main control unit is connected with gearshift drive circuit and accelerator drive circuit, the gearshift drive circuit is connected with gearshift actuating mechanism and the accelerator drive circuit is connected with accelerator actuating mechanism. Said invention also provides a motorcycle intelligent control method. Said invention mainly is used in motorcycle using automatic clutch engine.

Owner:韩群山

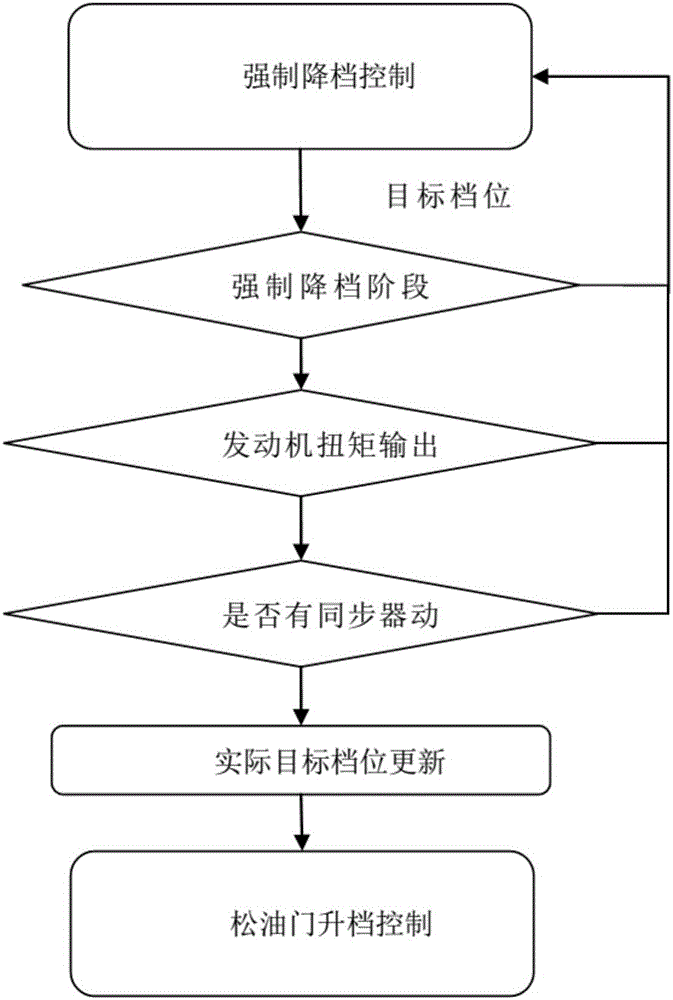

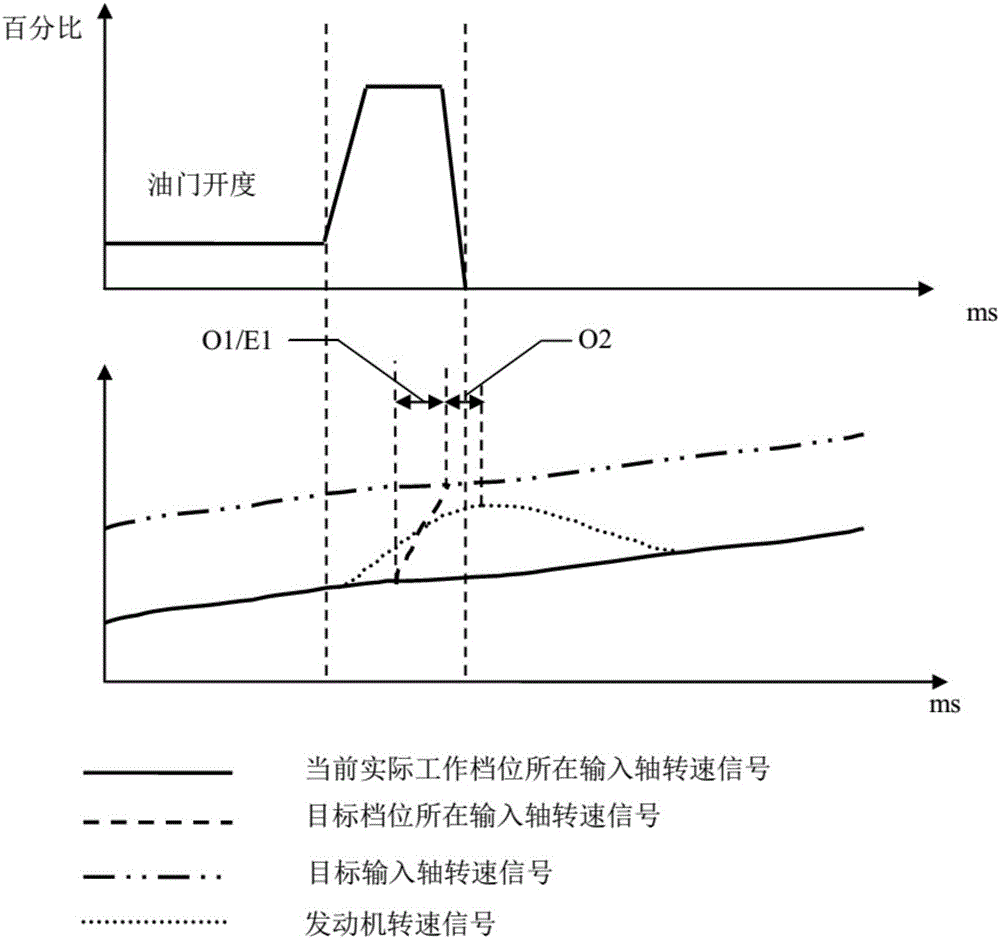

Gear-shifting control method for driving intention change during kick-down process

The invention discloses a gear-shifting control method for a driving intention change during a kick-down process in the field of automatic control of transmissions. The gear-shifting control method is characterized in that real-time monitoring of an accelerator pedal is maintained when a transmission starts the kick-down process, the driving intention is judged according to a driving state when the accelerator pedal is released, and the state of the transmission is adjusted from kick-down control to corresponding upshift control according to a judgment result. The gear-shifting control method aims to solve the problems that when a driver steps on an accelerator vigorously at a high rate during a stable driving process of a vehicle, a DCT (Dual Clutch Transmission) does kick-down action automatically to obtain stronger power output, and when the driver releases the accelerator at a higher rate before the DCT completes the kick-down action, a target gear obtained by the DCT through judgment is changed into one higher than the current kick-down target gear and immediately the upshift action is carried out. Therefore, through the gear-shifting control method, a stable and quick gear-shifting process can be realized actively, and the gear-shifting quality is remarkably improved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

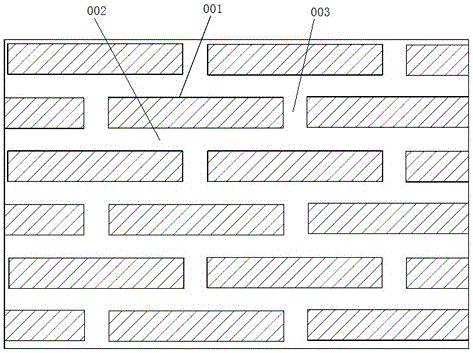

Printing screen plate for rapid detection of electrode dislocation, MLCC and detection method therefor

ActiveCN106206008AQuick checkShift quicklyFixed capacitor electrodesFixed capacitor dielectricEngineeringCeramic membrane

The invention discloses a printing screen plate for rapid detection of electrode dislocation, an MLCC and a detection method therefor. The printing screen plate for rapid detection of electrode dislocation comprises a screen plate body, and a plurality of parallel and staggered inner electrode graphs are arranged on the screen plate body; an identification graph is arranged in a screen plate body minor axis direction between two neighboring inner electrode graphs, and the identification graph is used for detecting electrode dislocation; the identification graph is arranged at a blank margin part of the printing screen plate, the identification graph along with the inner electrodes is printed on a ceramic membrane sheet during printing processes, and therefore an identification part is formed; after subsequent laminating and cutting processes, the identification part can be displayed on a side face of a chip, alignment condition of the inner electrodes can be directly determined via detection of graph arrangement of the identification part, cutting bias or displacement of the minor axis and a major axis can be rapidly detected, detection efficiency can be greatly improved, and product quality can be ensured.

Owner:SHENZHEN EYANG TECH DEV

Non-impact speed changing transmission gear

InactiveCN1844711AStable performanceSimple structurePortable liftingGearing elementsVariatorEngineering

The invention discloses a non-impact speed-change transmission gear wheel, which is formed by a tooth ring and a rim. Wherein, the tooth ring and the rim are connected via the tooth-embedded mesh device with flexible space; the tooth ring and the rim are axially limited via the clamp plates; the clamp plates are fixed on the tooth ring; said tooth-embedded mesh device comprises: mesh space between the mesh tooth that connecting the tooth ring and the rim; the flexible element can make the mesh tooth of rim at the middle of space while do not transmit torque to form a flexible space; the inner hole of rim is a inner-pattern key or a smooth hole with key groove. The invention has simple structure, which can avoid the lower shift speed, the impact and noise when meshing the gear wheels, while it can be used in duplicate gear or single gear wheel, or different speed changers.

Owner:HUBEI XINGSHENG TECH DEV

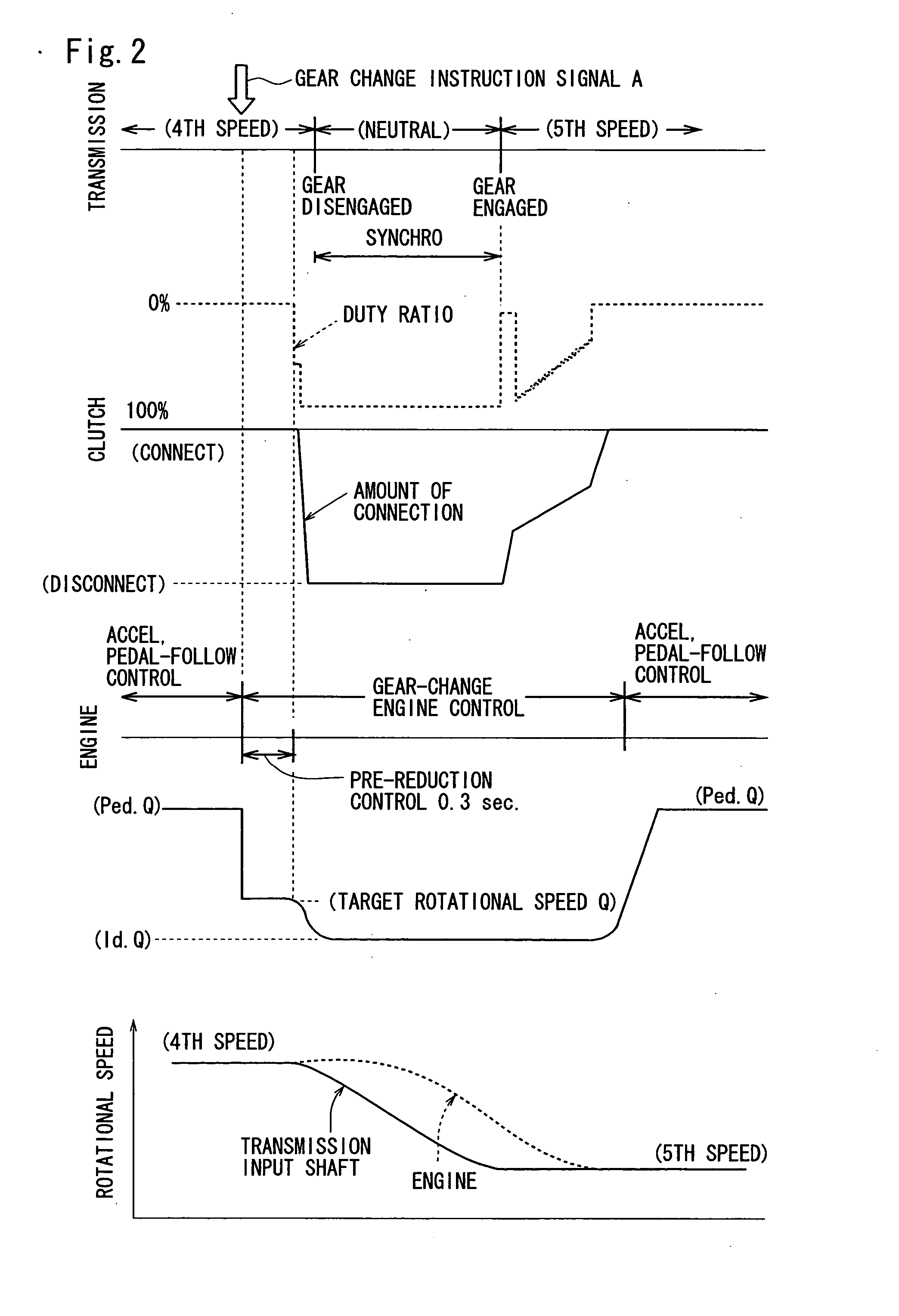

Vehicle controller of a vehicle power transmission device

InactiveUS20070173374A1Relaxing “ acceleration spoiling ”Increase engine speedEngine controllersMachines/enginesAcceleration UnitClutch

In a vehicle power transmission device equipped with an automatic clutch, the gear-change for shifting up is effected suppressing a sudden increase in the engine rotational speed that results when the automatic clutch is disconnected, preventing deterioration in the drive feeling caused by the change of gear such as a shock due to the change of gear. At the time of changing the gear for shifting up, an engine controller (11) executes a pre-reduction control for decreasing the output of the engine 1 for a predetermined period of time prior to disconnecting the clutch (3). Since the engine output has been decreased, the rotational speed of the engine (1) does not suddenly rise despite the vehicle traveling load is removed as a result of disconnecting the clutch 3. A target value for decreasing the engine output is suitably set depending upon the vehicle operating conditions, and a sudden increase in the rotational speed is prevented in all gears while relaxing the shock of gear-change caused by a sharp change in the acceleration.

Owner:ISUZU MOTORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com