Non-impact speed changing transmission gear

A variable-speed transmission and gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as high manufacturing process requirements, large space occupied between shafts, and inconvenience for manufacturers and users , to achieve the effect of simple manufacturing process and equipment, reducing axial space occupation, and eliminating inconvenience in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

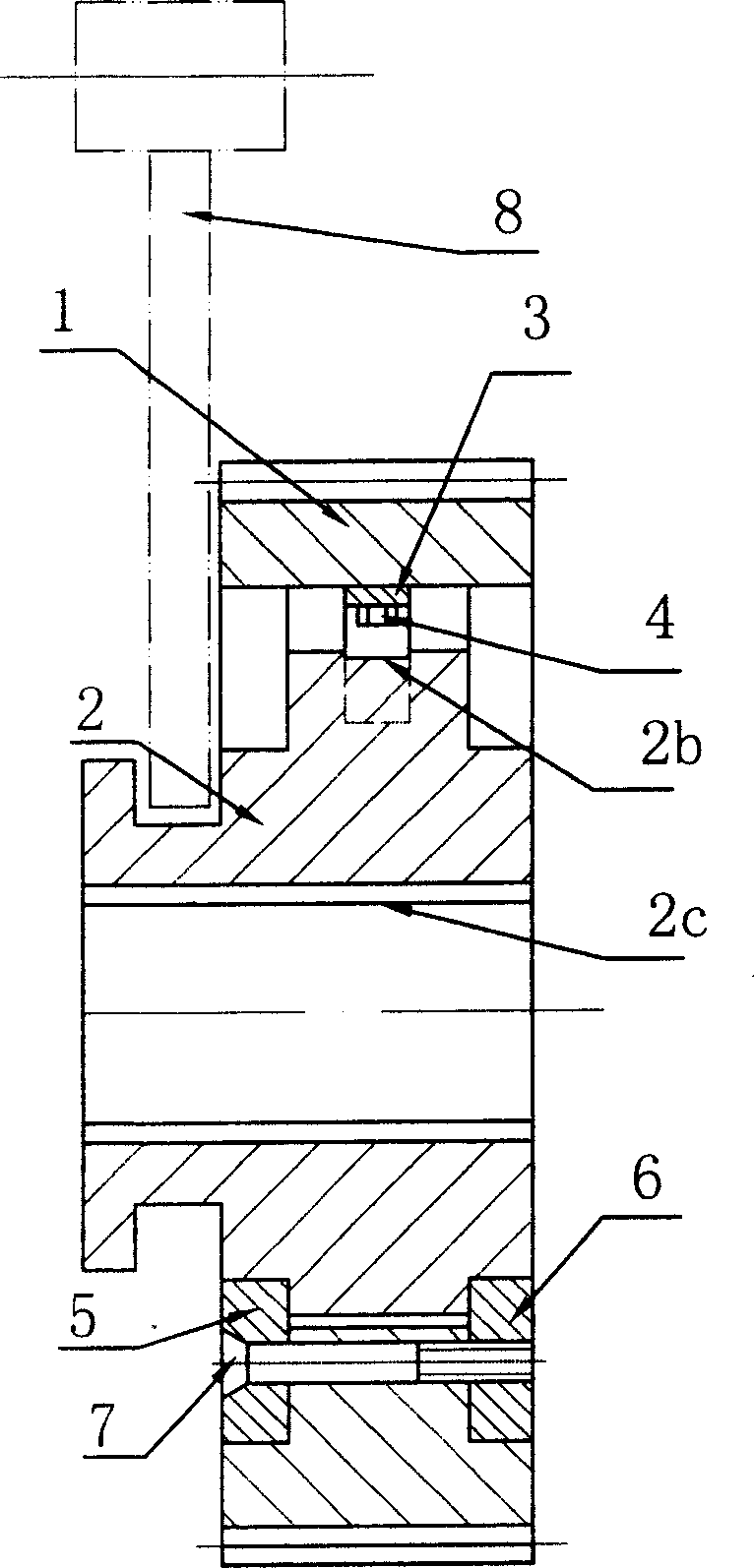

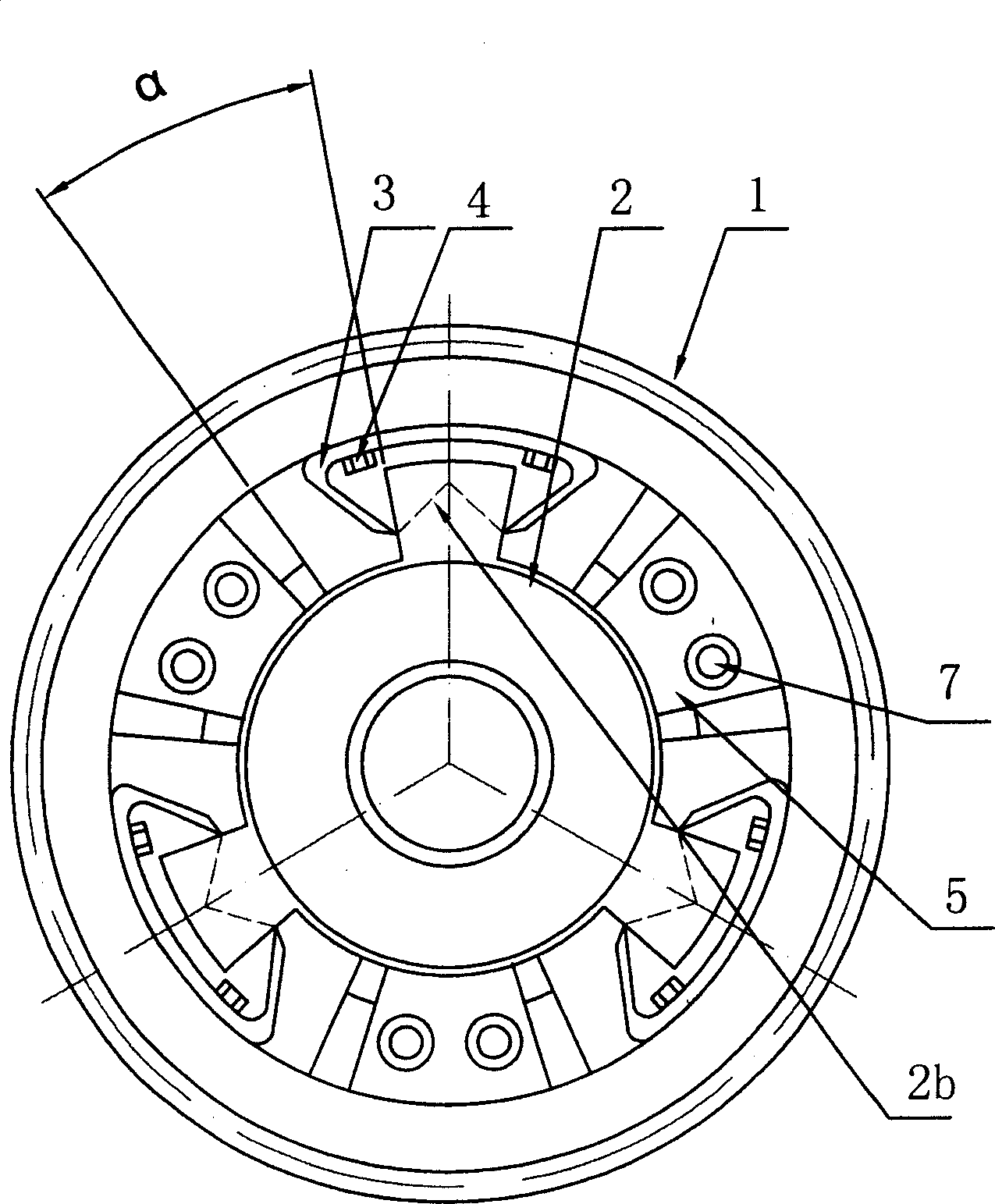

[0009] Such as figure 1 , 2 The non-impact variable speed transmission gear shown is composed of gear ring 1 and hub 2; gear ring 1 and hub 2 are connected by an interlocking constant mesh mechanism through the elastic gap, and gear ring 1 and hub 2 pass through splint 5 and splint 6 with screws 7 is connected as an axial limit, and splints 5 and 6 are fixed on the gear ring 1.

[0010] The jaw-type constant meshing mechanism of the elastic gap is specifically: the jaw-type constant meshing mechanism of the elastic gap is specifically: an meshing gap is provided between the meshing teeth connected between the ring gear 1 and the hub 2, and the unilateral clearance angle is α, using elastic elements to make the meshing teeth on the hub in the middle of the gap under the condition of no torque transmission, forming an elastic gap structure. Such as figure 2 As shown, the elastic element is a leaf spring 3, and the leaf spring 3 is connected to the ring gear 1 through a screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com