Patents

Literature

104results about How to "Easy to shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

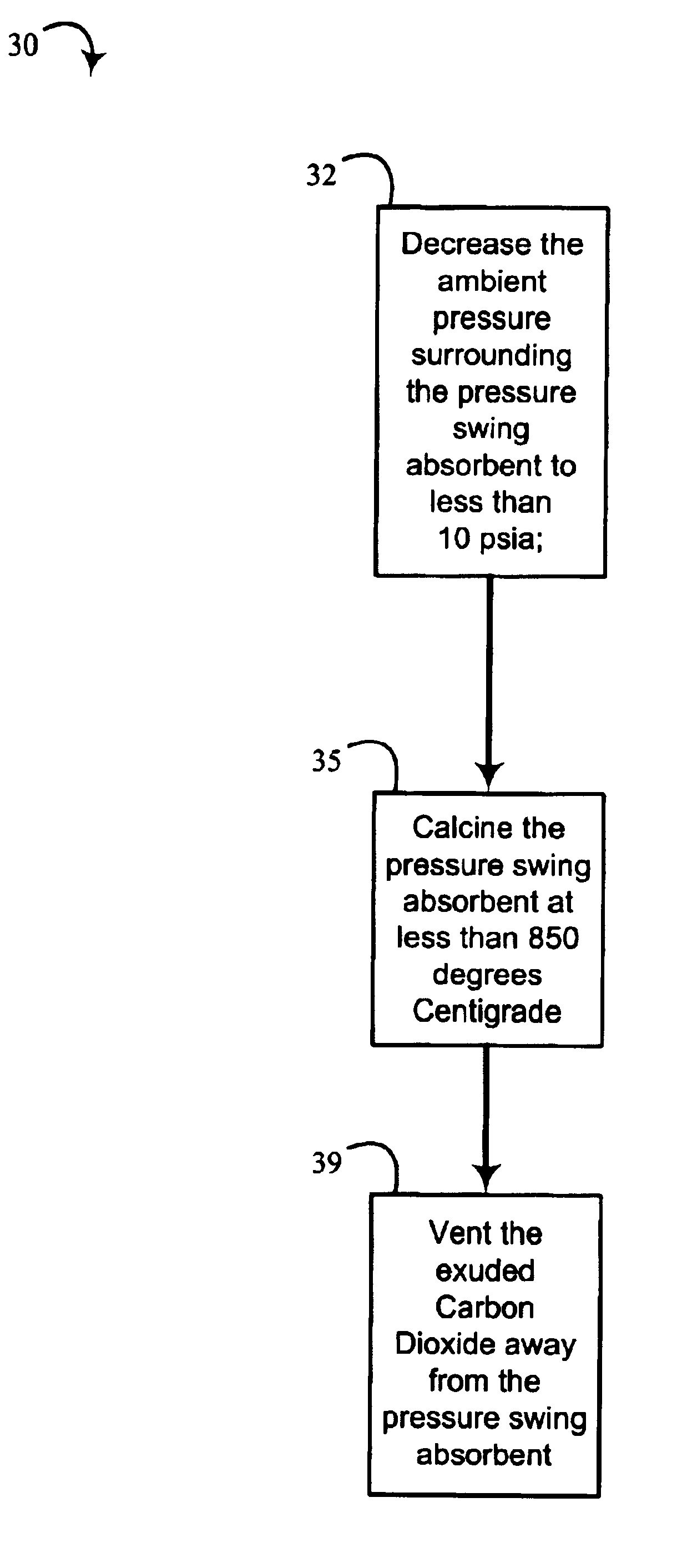

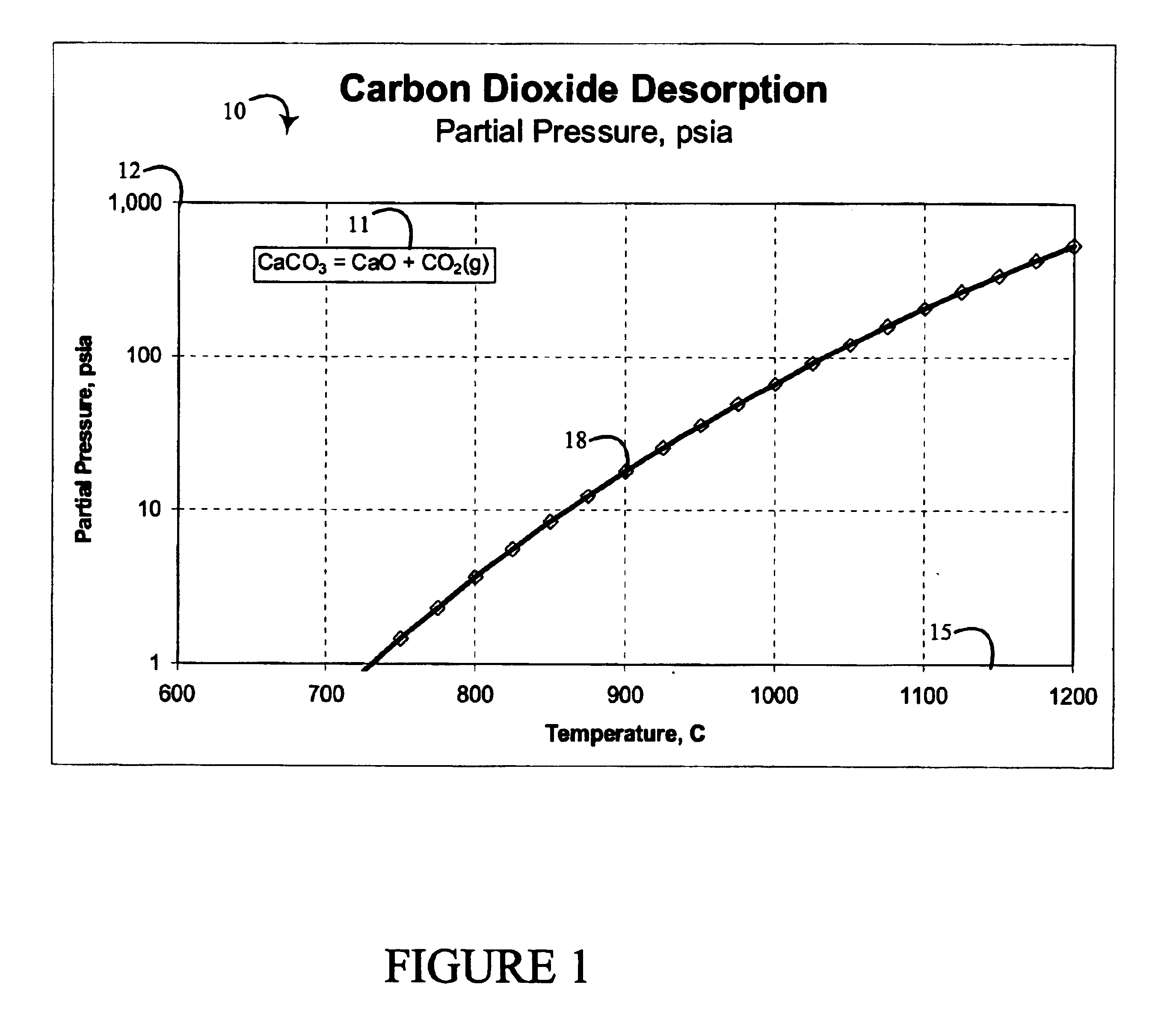

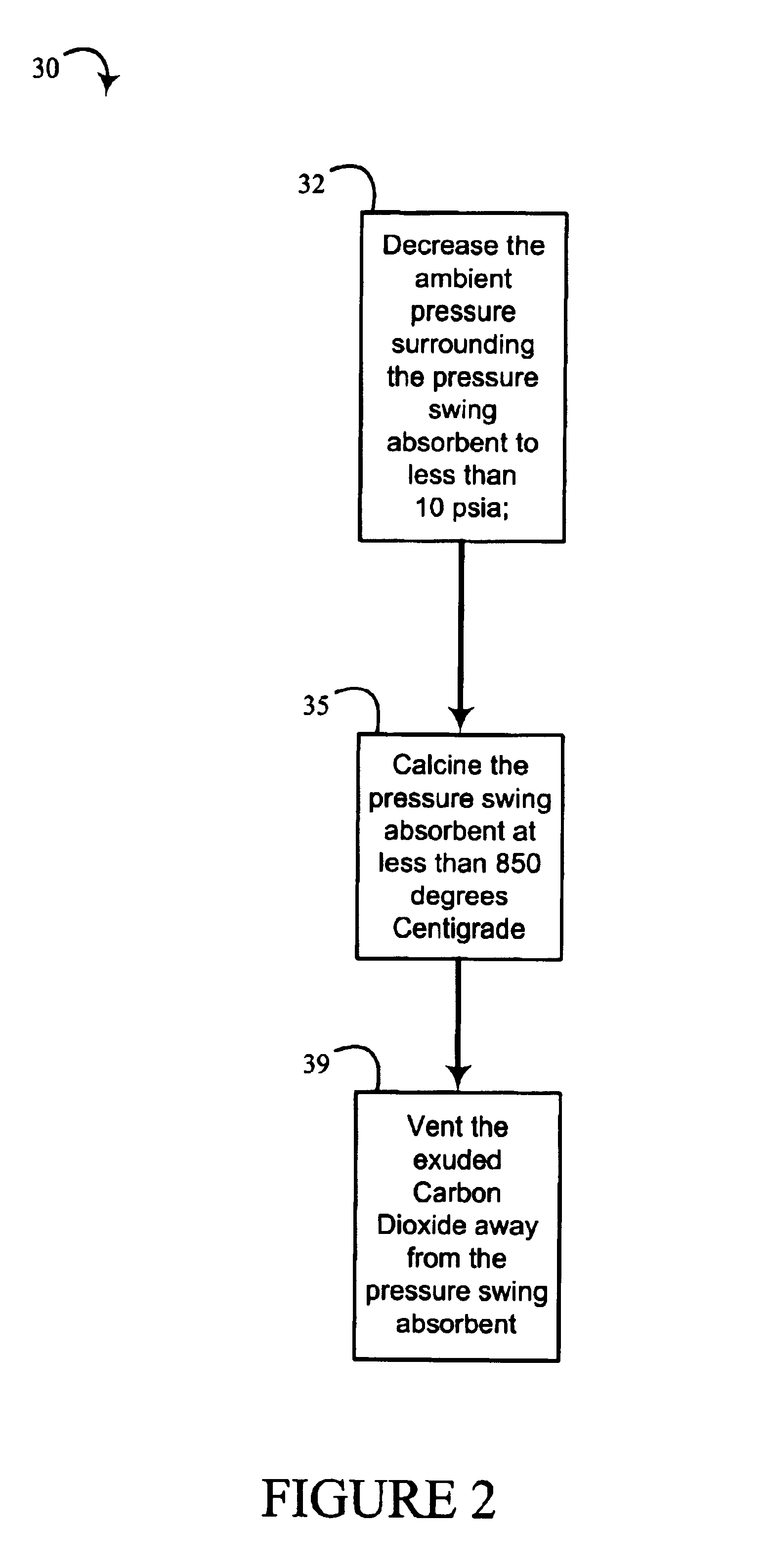

Methods and systems for pressure swing regeneration for hydrogen generation

InactiveUS6942719B2Promote catalytic reformingEasy to shiftOther chemical processesHydrogen separation using solid contactSteam reformingHydrogen

Methods and systems for pressure swing absorption for hydrogen generation are presented. In one embodiment, a method includes absorbing at least one oxide of carbon with a pressure swing absorber from a steam reformation of methane. The steam reformation may occur at an ambient pressure in excess of 300 psia and at an ambient temperature in excess of 600° centigrade. The steam reformation of methane produces a stream of product gas. The steam reformation of methane is interrupted allowing the regenerating of the pressure swing absorber at an ambient pressure of less than 10 psia and at an ambient temperature sufficient to calcine the pressure swing absorber to exude carbon dioxide.

Owner:GAS TECH INST +1

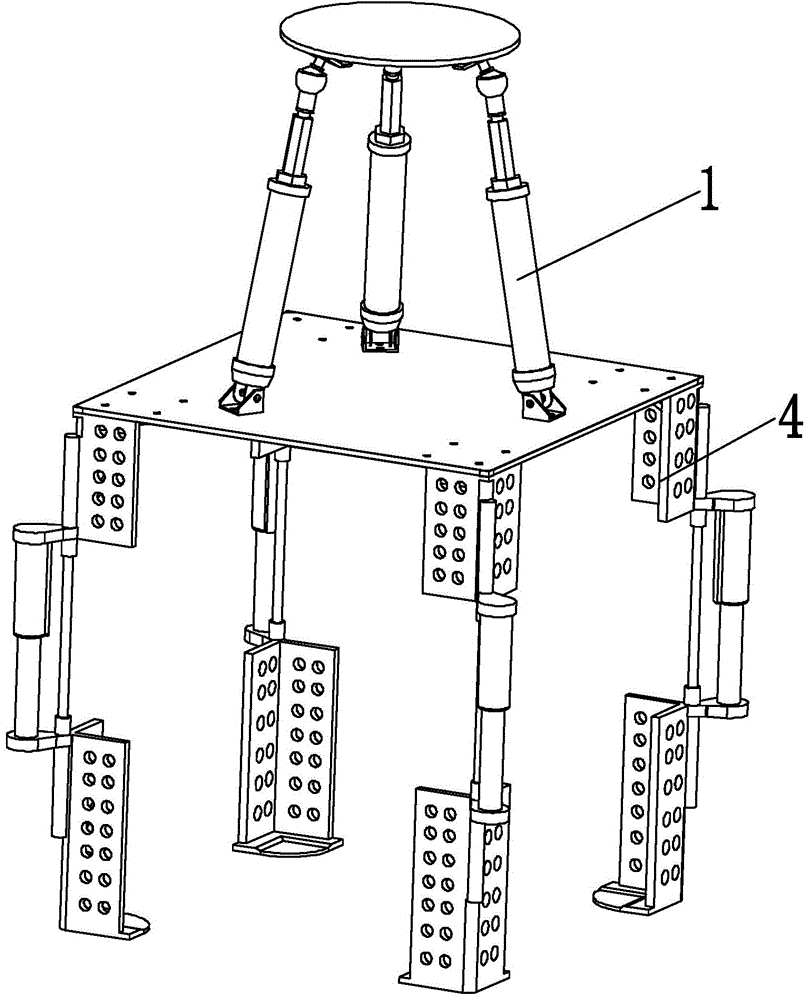

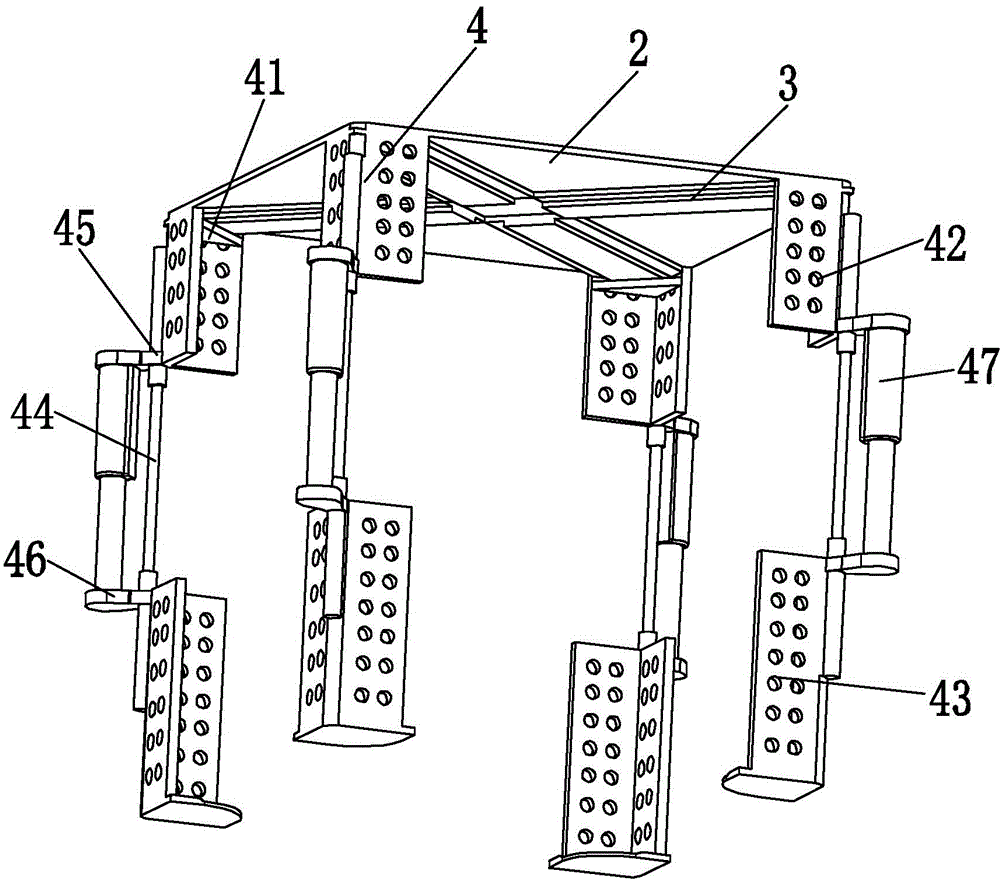

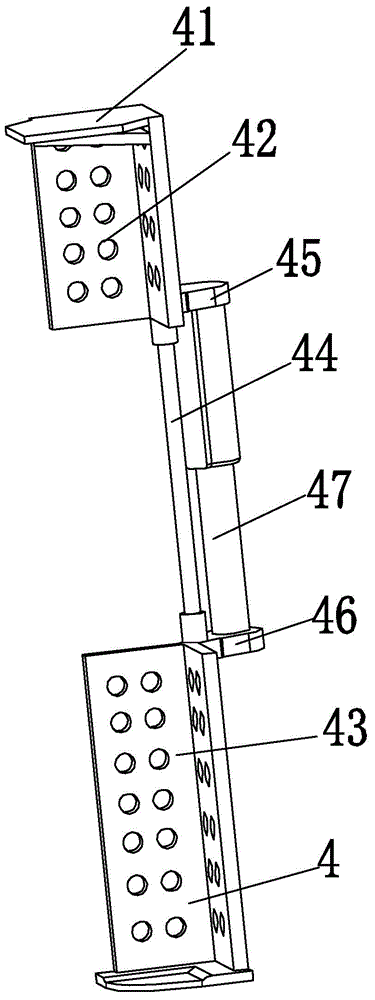

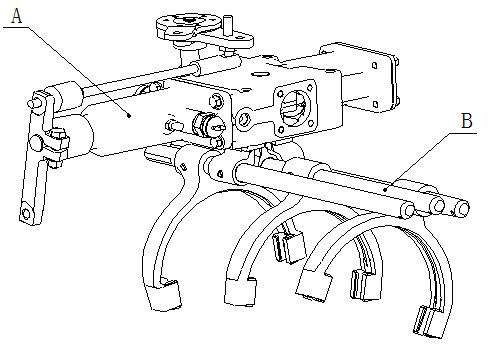

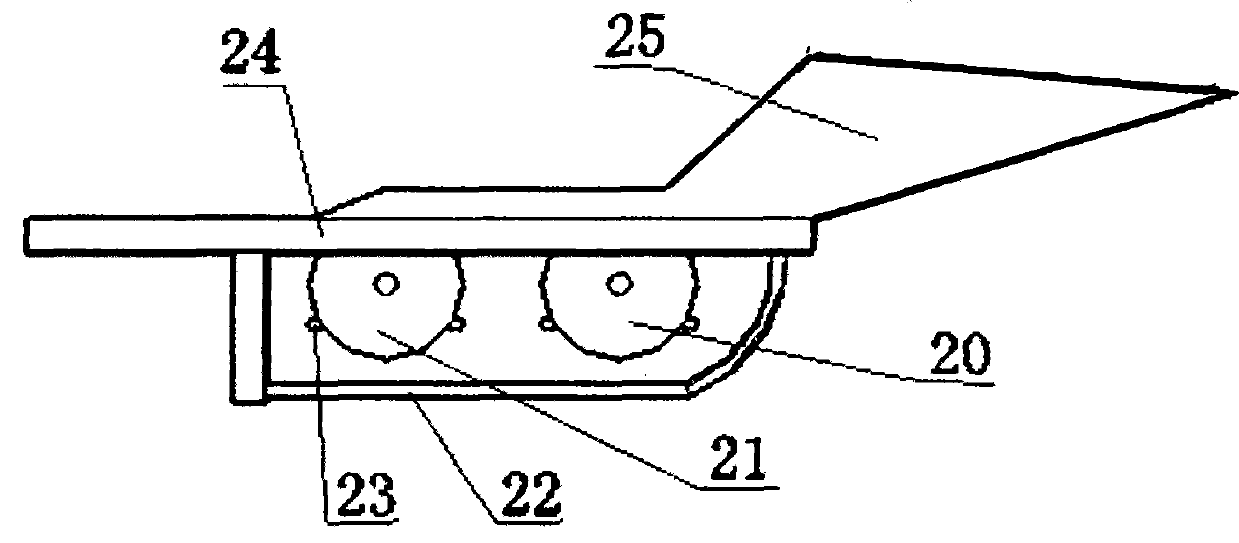

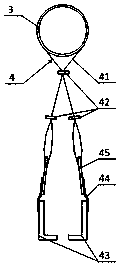

Three degree-of-freedom self-stabilizing box body grab bucket based on parallel mechanism

ActiveCN104891332ACompact structureEasy to operateLoad-engaging elementsThree degrees of freedomEngineering

The invention relates to a three degree-of-freedom self-stabilizing box body grab bucket based on a parallel mechanism. The grab bucket comprises the three degree-of-freedom parallel mechanism, a fixing plate, four electric slide tracks and four machine claws, wherein the three degree-of-freedom parallel mechanism is arranged right above the fixing plate, and connected with the fixing plate through bolts; the fixing plate adopts a square structure; the electric slide tracks are respectively arranged on the four top angular bisectors of the fixing plate and are fixedly connected with the fixing plate; the machine claws are respectively mounted under the electric slide tracks. The space motion states of the grab bucket can be realized by controlling the rising, falling, speed changing and stopping operation of an electric push rod; the three degree-of-freedom parallel mechanism adopting a 3-RPS mode can perform motion in one translating direction and two rotating directions, namely three degree of freedom directions; the control is simple; the motion property is excellent; the stability in box body grabbing is enhanced; the box body is prevented from shaking in a conveying or lifting process.

Owner:JIANGSU KAIXIN ELECTRIC EQUIP

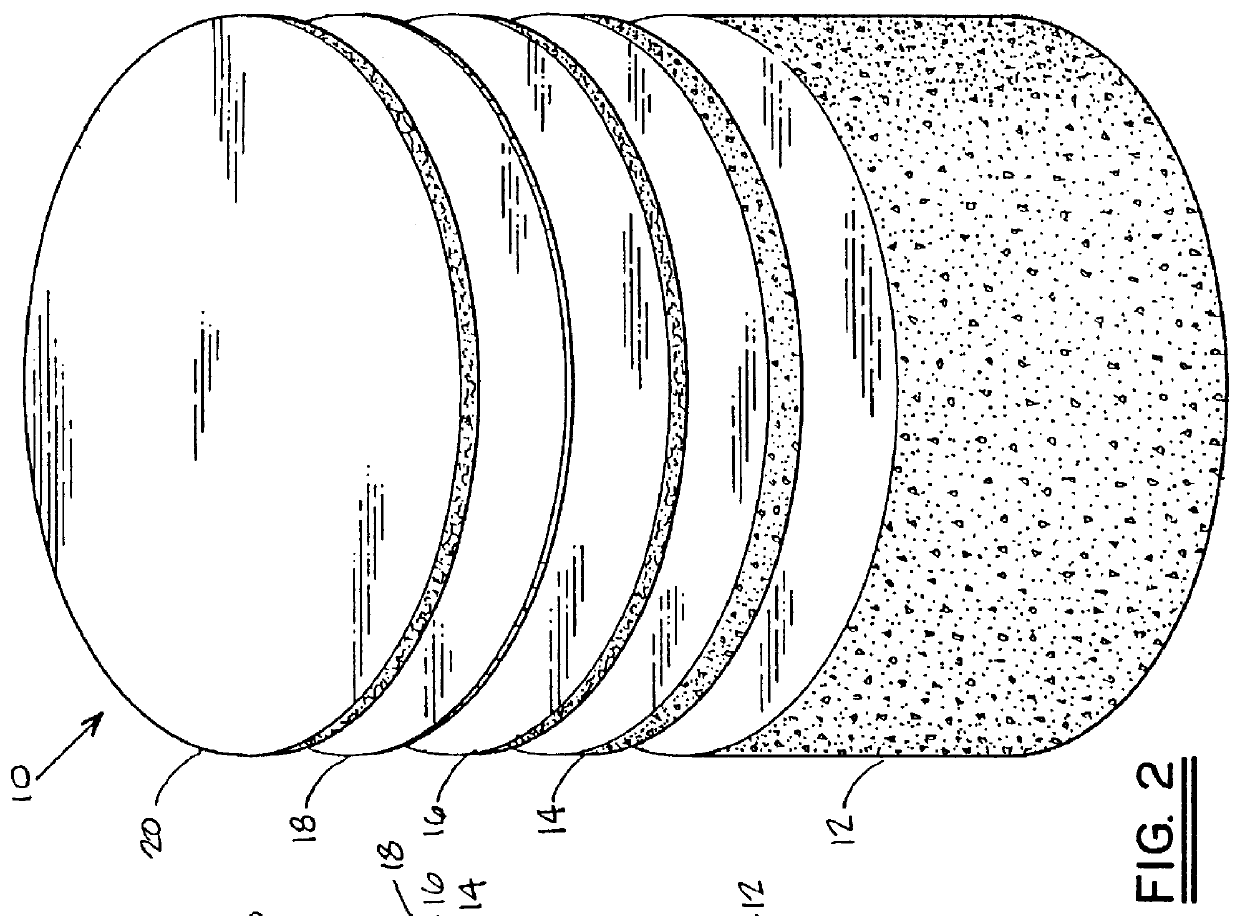

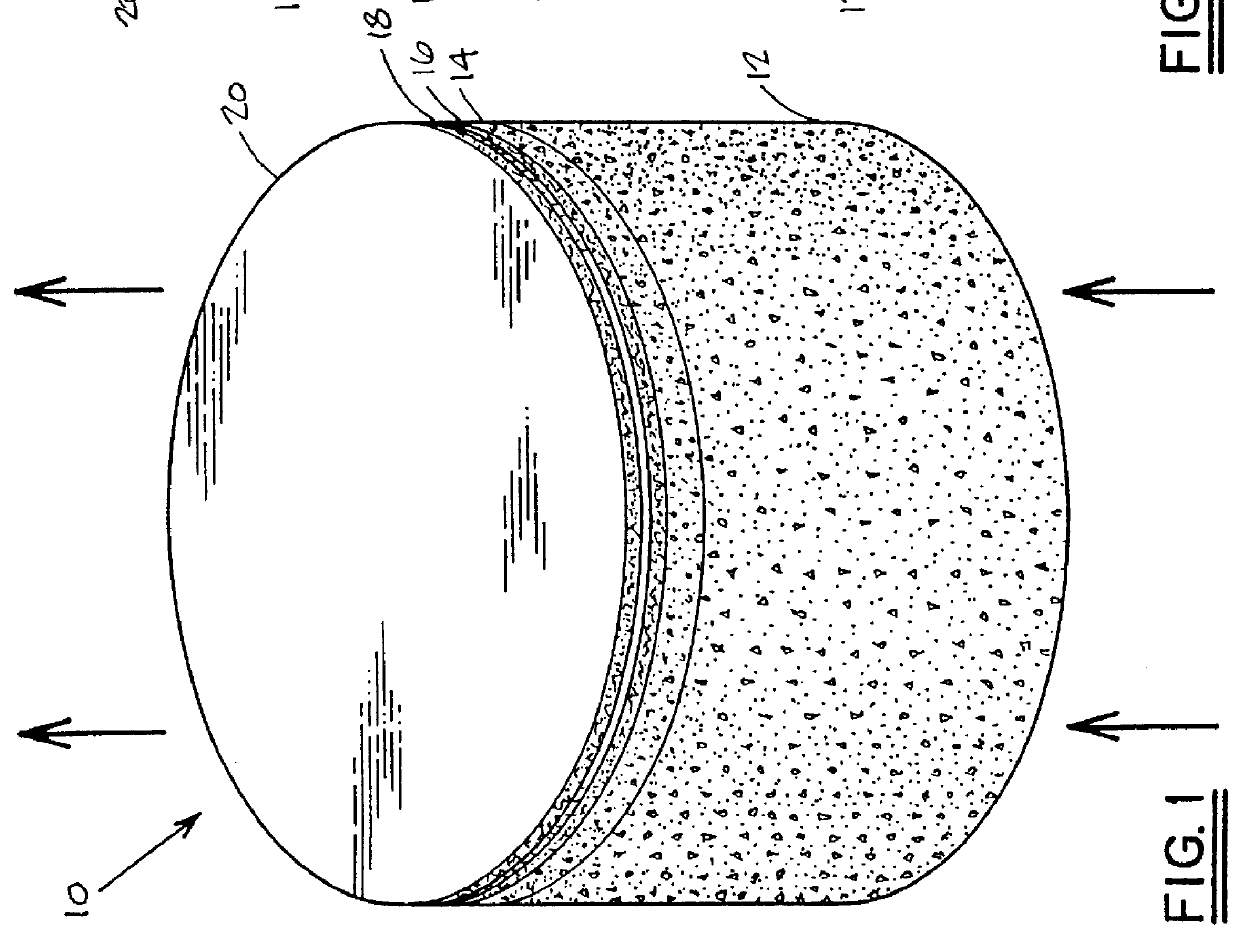

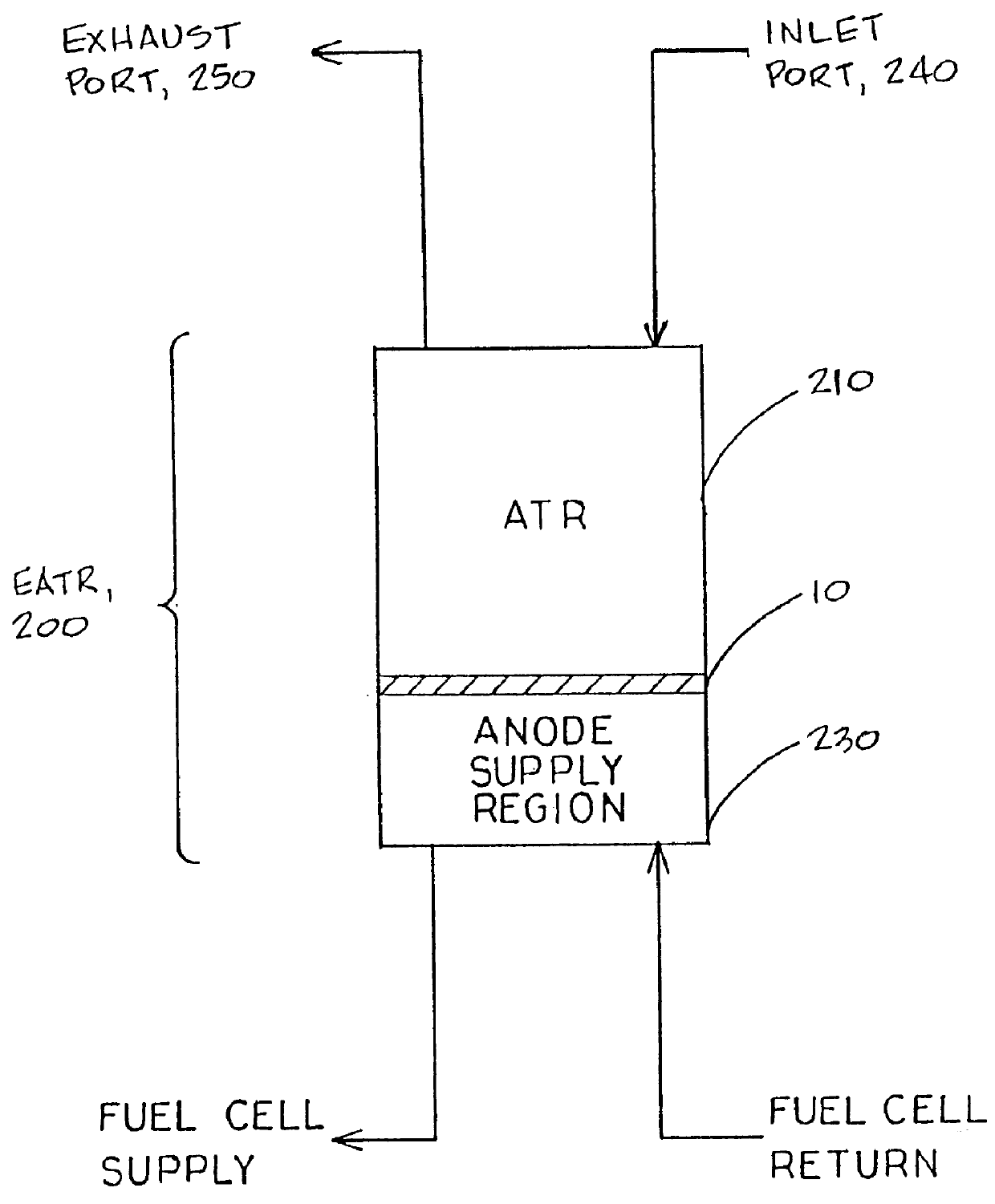

Electrochemical autothermal reformer

InactiveUS6143159AEfficient and reliableEnhance partial oxidationIsotope separationFuel cellsHydrogenElectrochemistry

An electrochemical autothermal reformer (EATR) provides hydrogen. The EATR includes an autothermal reformer region, a reformer anode supply region, and a composite membrane layer separating the reformer anode from the autothermal reformer region. The composite membrane layer includes a mechanically stable porous ceramic support member with a thin gas permeable ceramic substrate layer overlaying the support member. Overlaying the substrate layer is a first thin metallic catalyst layer which promotes the dissociation of H2 to 2H++2e31 . Overlaying the first catalyst layer is a metallic oxide layer capable of conducting 2H++2e- at elevated temperatures. Overlaying the metallic oxide layer is a second thin metallic catalyst layer which promotes the recombination of 2H++2e31 to H2.

Owner:NIAGARA MOHAWK POWER CORP

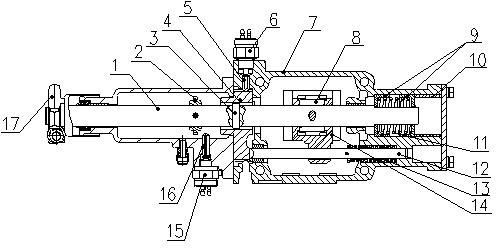

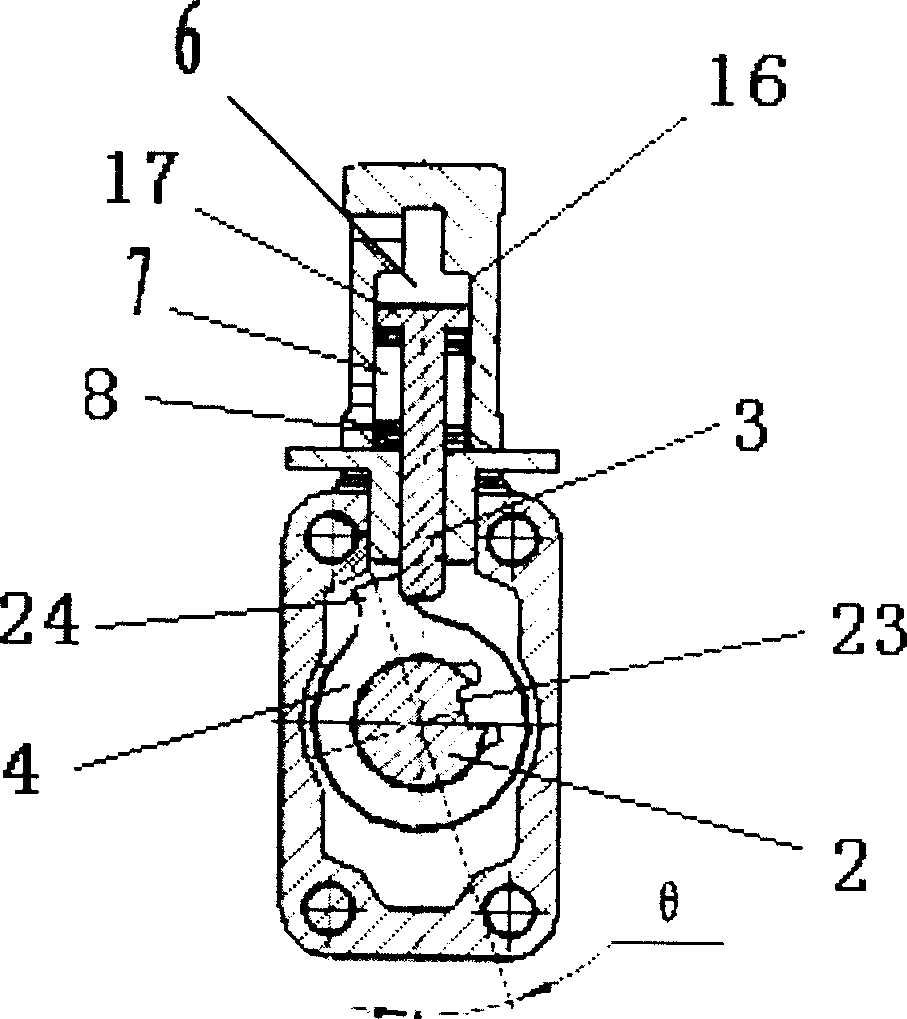

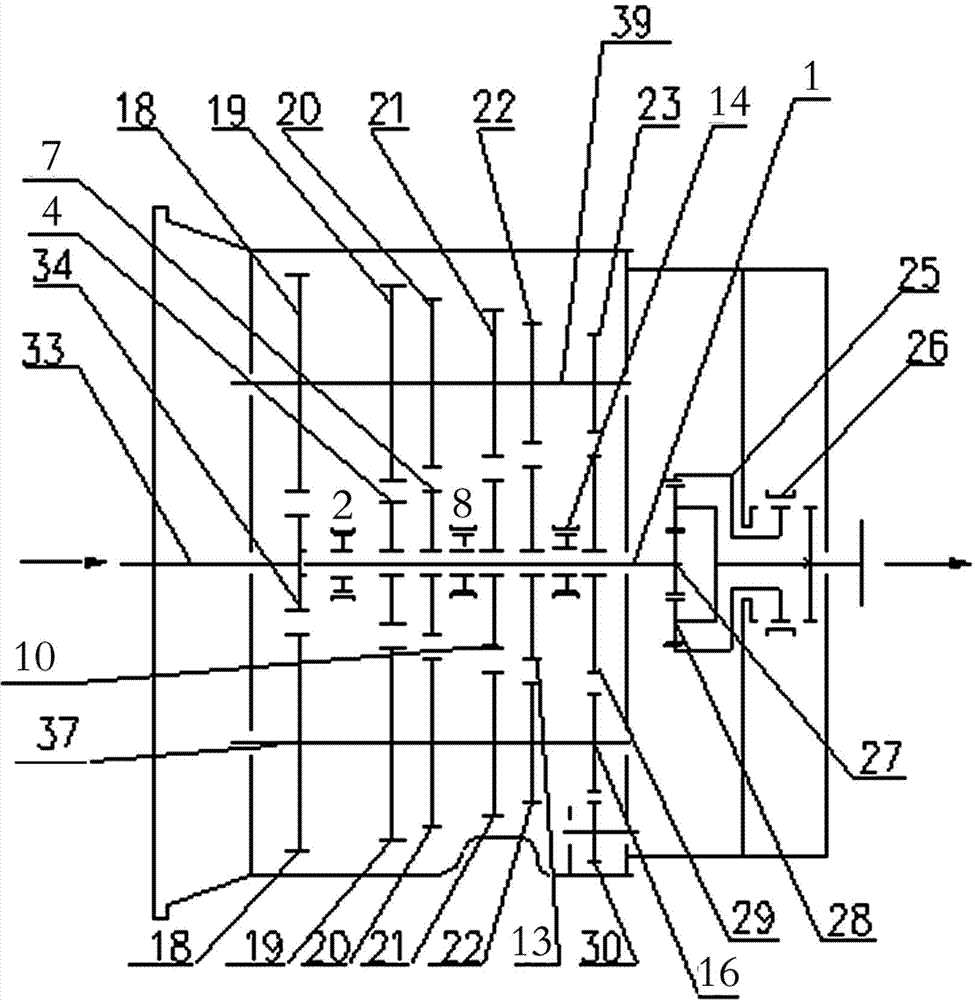

Novel gear selecting and shifting mechanism assembly for speed changer

InactiveCN102494120AAvoid contactCompact structureGearing controlFriction liningLocking mechanismEngineering

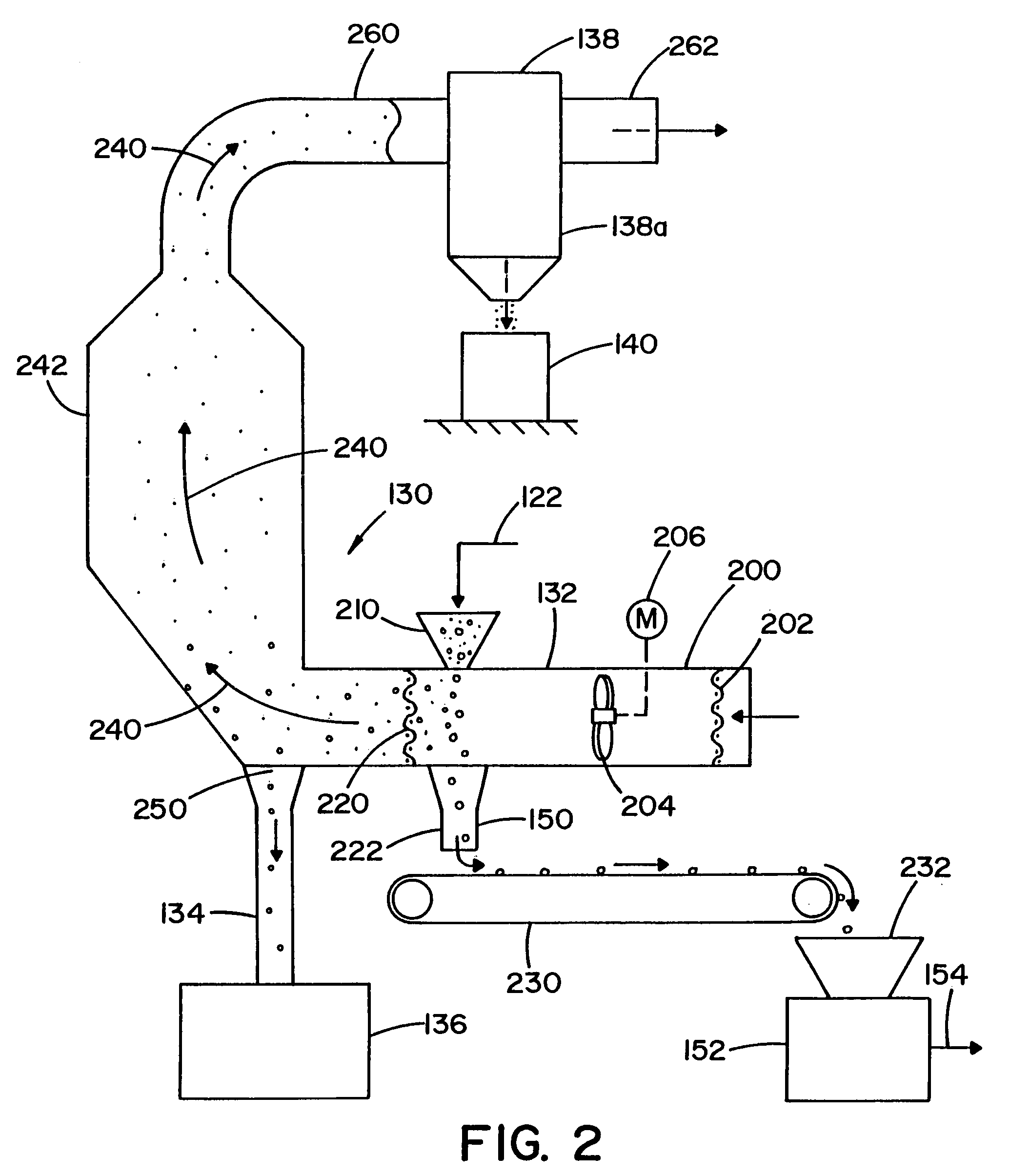

The invention discloses a novel gear selecting and shifting mechanism assembly for a speed changer. The novel gear selecting and shifting mechanism assembly comprises a small cover assembly and a shifting fork shaft assembly, wherein the small cover assembly comprises a self-locking mechanism, an interlocking mechanism and a neutral gear and reverse gear signal selecting device; six gear shifting positions are set in the shifting fork shaft assembly; the self-locking mechanism consists of a self-locking pin shaft and a fan-shaped self-locking block; the interlocking mechanism consists of a fork-shaped interlocking fork; the small cover assembly comprises a small cover shell, a gear shifting shaft, a sensor driving ring, a driving pin, a fan-shaped self-locking block, a gear shifting head, a centering base ring, a distance ring, a centering spring, the self-locking pin shaft and the interlocking fork; the shifting fork shaft assembly comprises a shifting fork shaft, a shifting block, a shifting fork and a friction plate; the friction plate is arranged in a fork pin of the shifting fork and is compressed with the surface of the shifting fork tightly; and a synchronizer sliding disc is arranged in a fork pin groove of the shifting fork. Compared with the prior art, the novel gear selecting and shifting mechanism assembly has the advantage that in the gear shifting process, a friction material can buffer impact when the synchronizer sliding disc is shifted by the shifting fork, so that gears is shifted stably.

Owner:SINO TRUK JINAN POWER

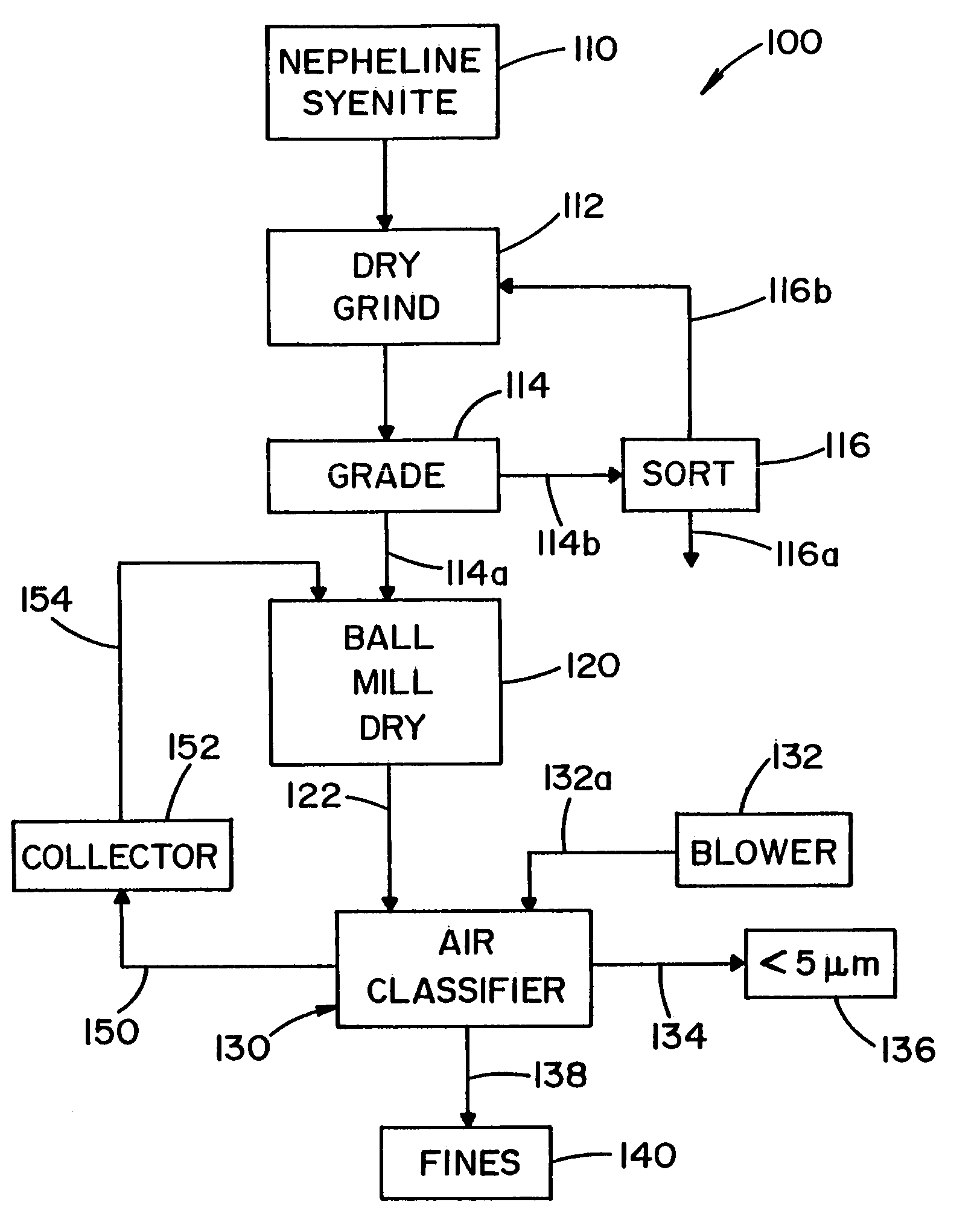

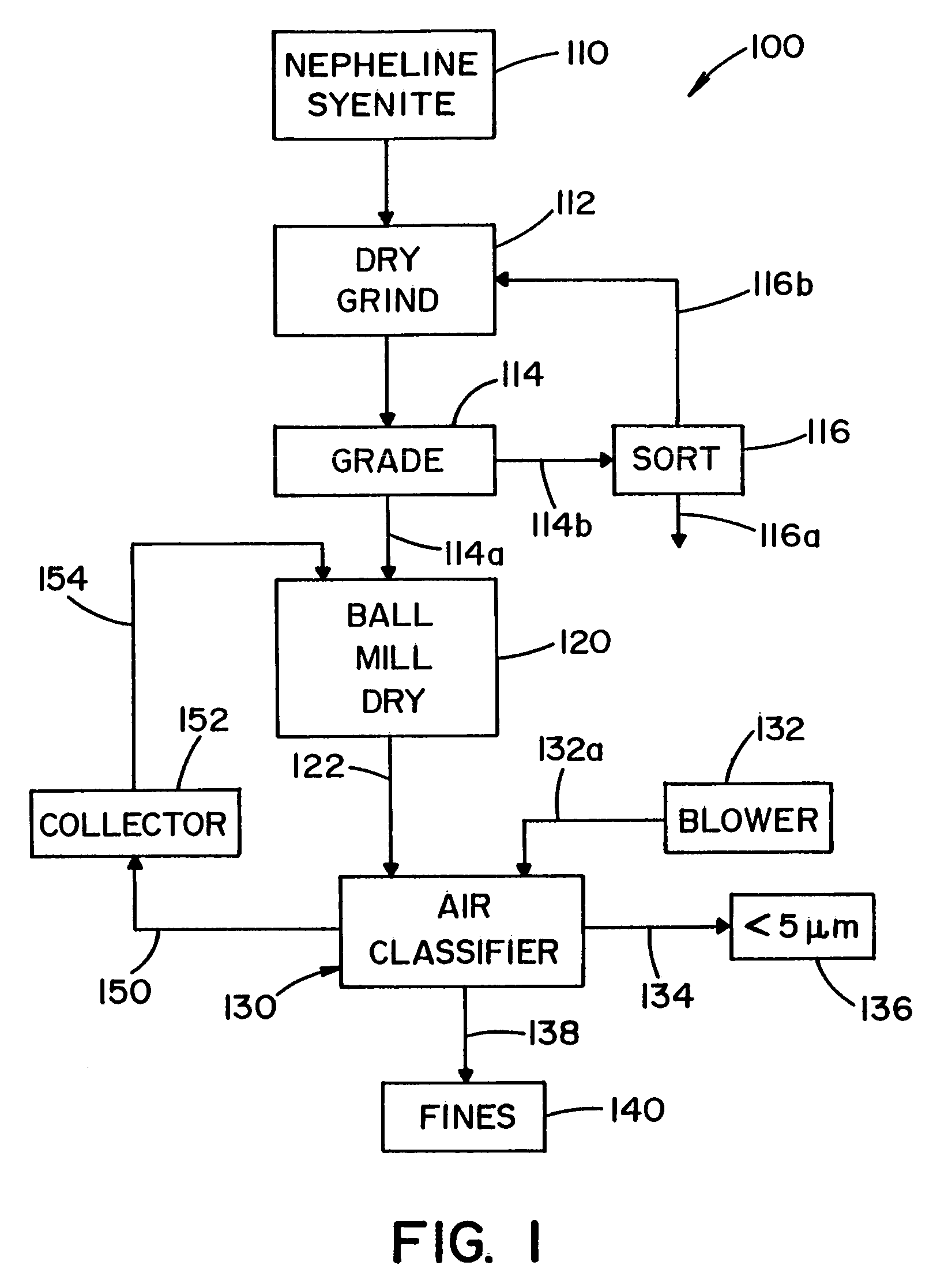

Method of processing nepheline syenite powder to produce an ultra-fine grain size product

The method of converting nepheline syenite particulate feedstock with a grain size profile to an ultra-fine grain finish product for subsequent commercial use, the ultra-fine grain final product has a maximum grain size of less than about 6 microns. The method comprising: providing a dry feedstock with a controlled maximum particle size greater than about 20 microns; grinding the feedstock in a dry state by passing the feedstock vertically downward through a continuous, high-speed stirred ball mill whereby the feedstock is ground into an intermediate powder having a drastically reduced grain size profile than the grain size profile of the feedstock; and passing the intermediate powder from the mill through an air classifier using a rapidly moving high speed air stream moving along a given path to convey the ultra-fine grain product along the path and from the classifier and to allow coarse particulate material including particles larger than the ultra-fine product to be separated and then expelled from the classifier.

Owner:COVIA HLDG CORP

Shift locking device for transmission

ActiveCN1763403APrevent automatic disengagementWon't come outGearing controlManual transmissionAutomotive engineering

The invention relates to a car hand transmission grade-position locking arrangement, which consists of telescoping lockpin system on the transmission case and shift rotation shaft within stopping linked system, wherein the telescoping lockpin system mates the stopping linked system on the transmission shaft, which is set on the transmission case corresponding to the stopping linked system. The arrangement is easy to reequip and operate, which contains high reliability and simple structure.

Owner:DONGFENG MOTOR CORP HUBEI

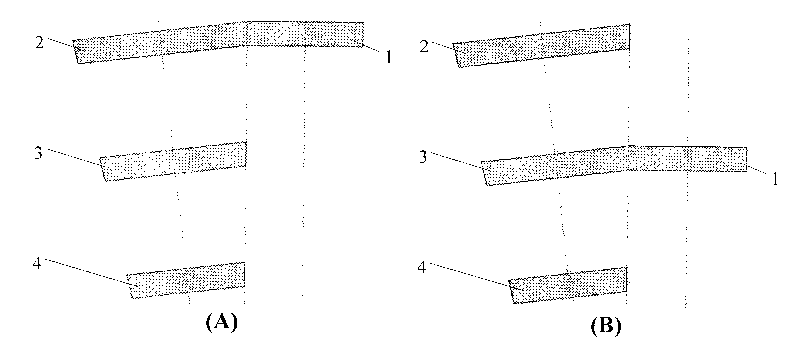

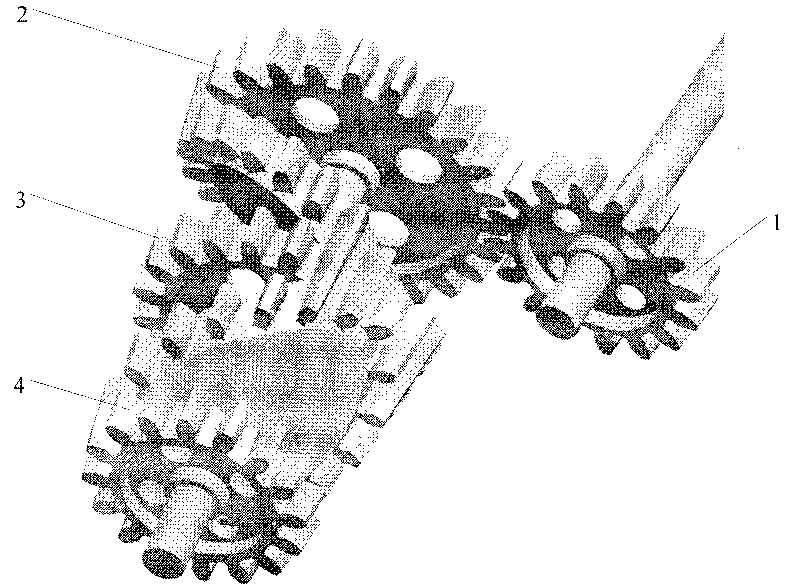

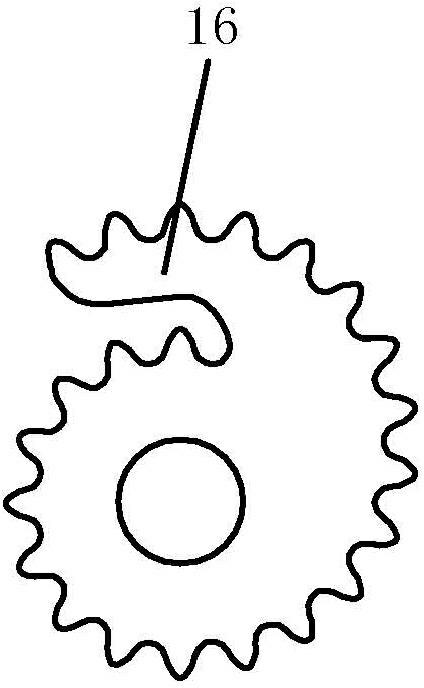

Non-circular gear-based variable transmission mechanism

InactiveCN101737461AOmit stallHigh transmission precisionToothed gearingsPortable liftingDrive wheelDynamic balance

The invention relates to a non-circular gear-based variable transmission mechanism. The mechanism is provided with a driving wheel, a plurality of driven wheels, transition gear teeth and transmission gear teeth, wherein the driving wheel and the plurality of driven wheels are fixedly arranged on a driving shaft and a driven shaft at a set included angle respectively, and have the same modulus of the gear teeth; the transition gear teeth and transmission gear teeth are positioned on a non-circular pitch curve between the adjacent driven wheels; the transition gear teeth and transmission gear teeth on the non-circular pitch curve are used for completing gear shifting of the driving wheel between the two adjacent levels of driven wheels, namely axial feed movement is applied to the driving wheel on the premise of keeping the rotating speed of the driving wheel invariable, so that the driving wheel can be meshed with the transition gear teeth, the transmission gear teeth and the transition gear teeth on the non-circular pitch curve between each level of driven wheels in sequence to complete gear shifting and variable speed without the process of stalling and clutching. The device abandons a clutch, realizes variable transmission between the two shafts by using a non-circular gear on the non-circular pitch curve, and has the characteristics of compact structure, precise transmission, reliability, stability and easy dynamic balance of non-circular gear transmission mechanisms.

Owner:BEIJING UNIV OF POSTS & TELECOMM

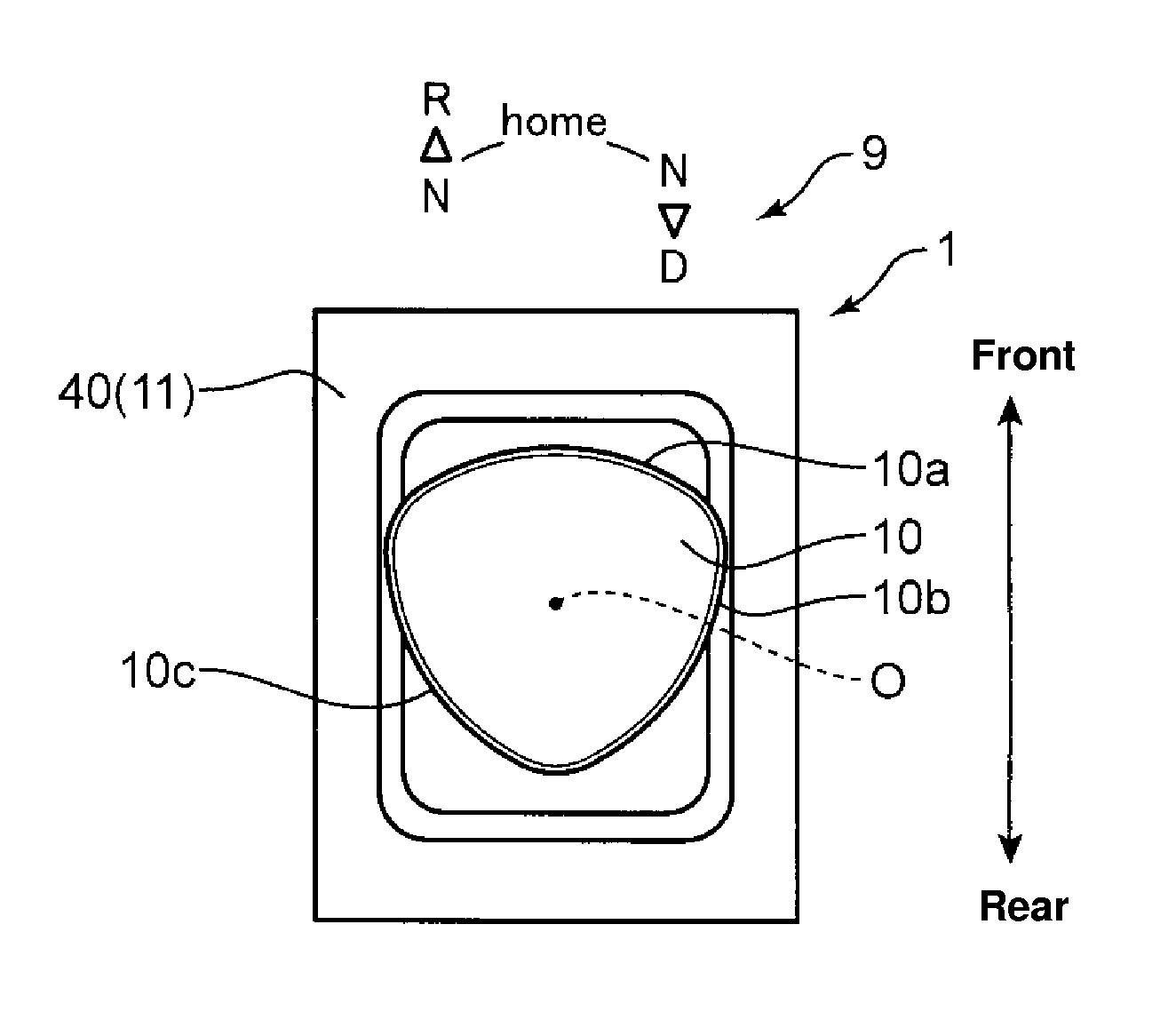

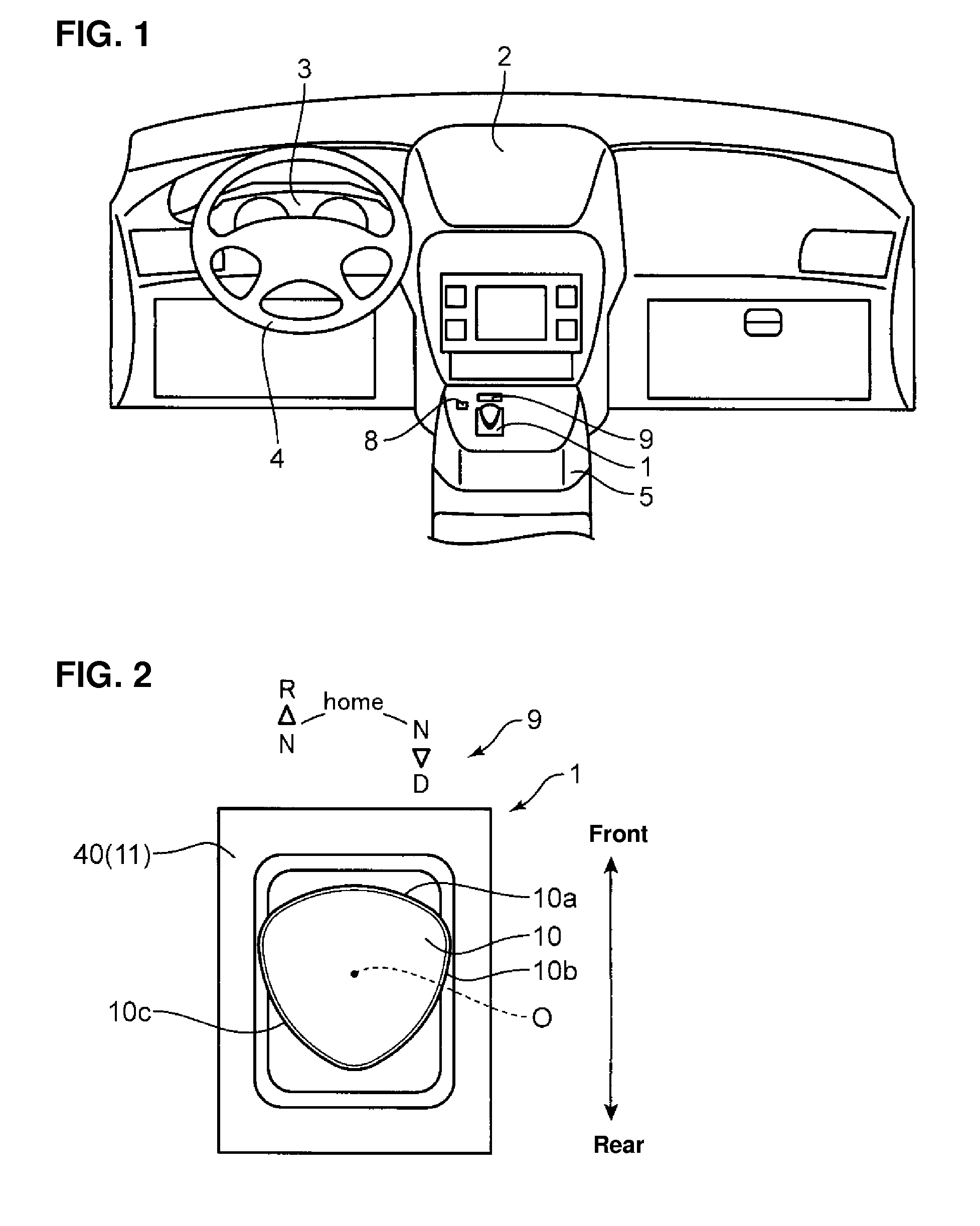

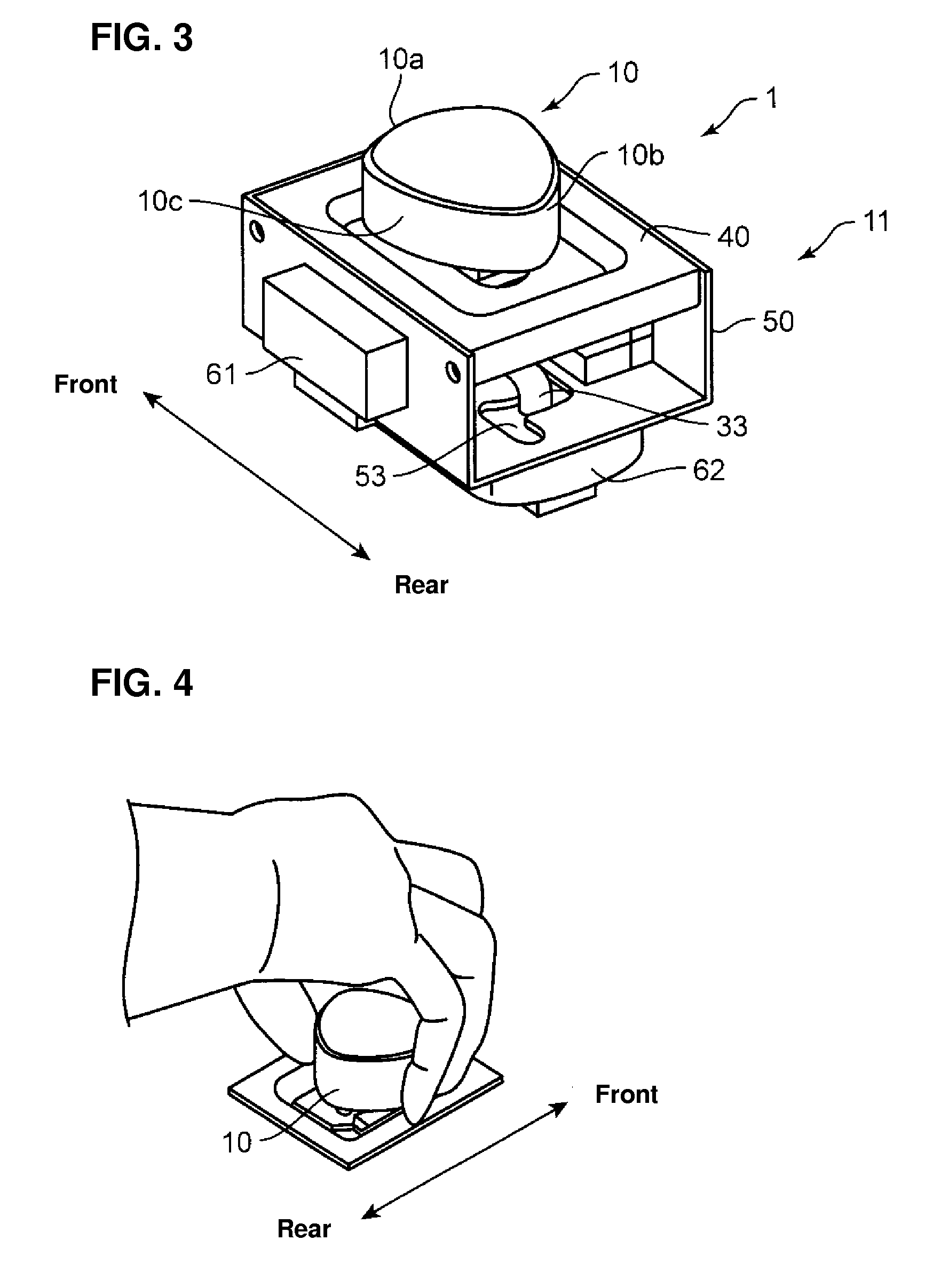

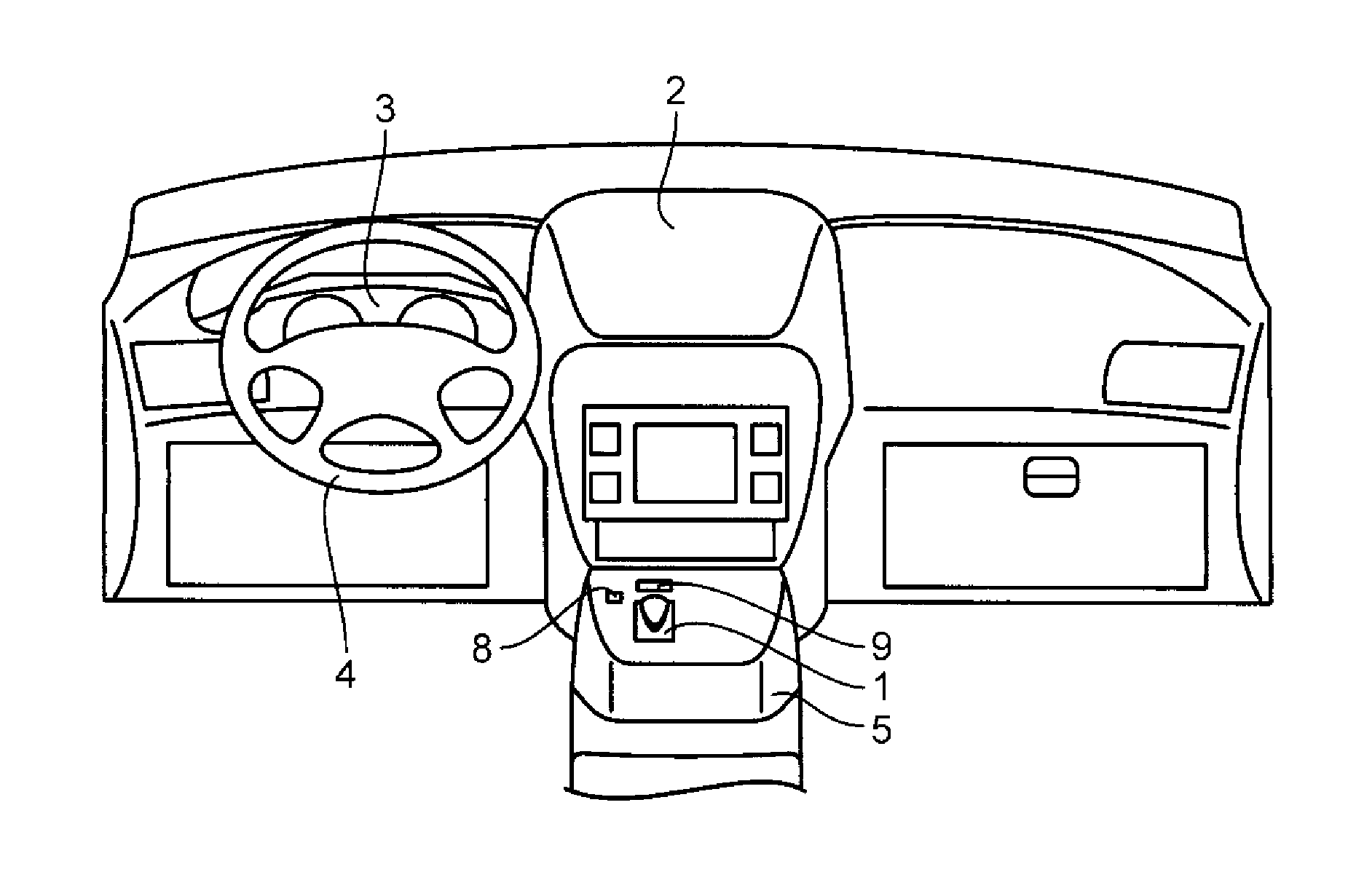

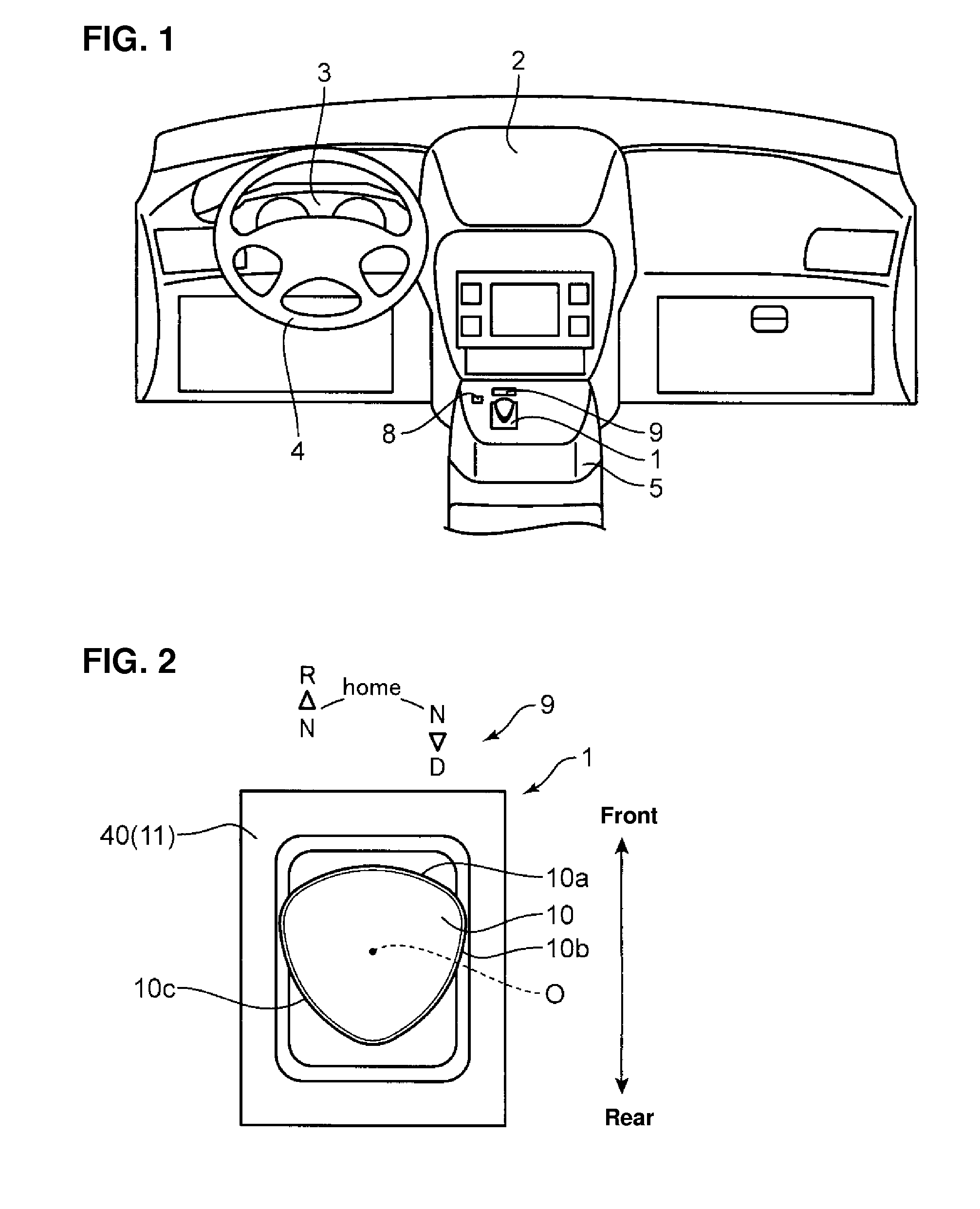

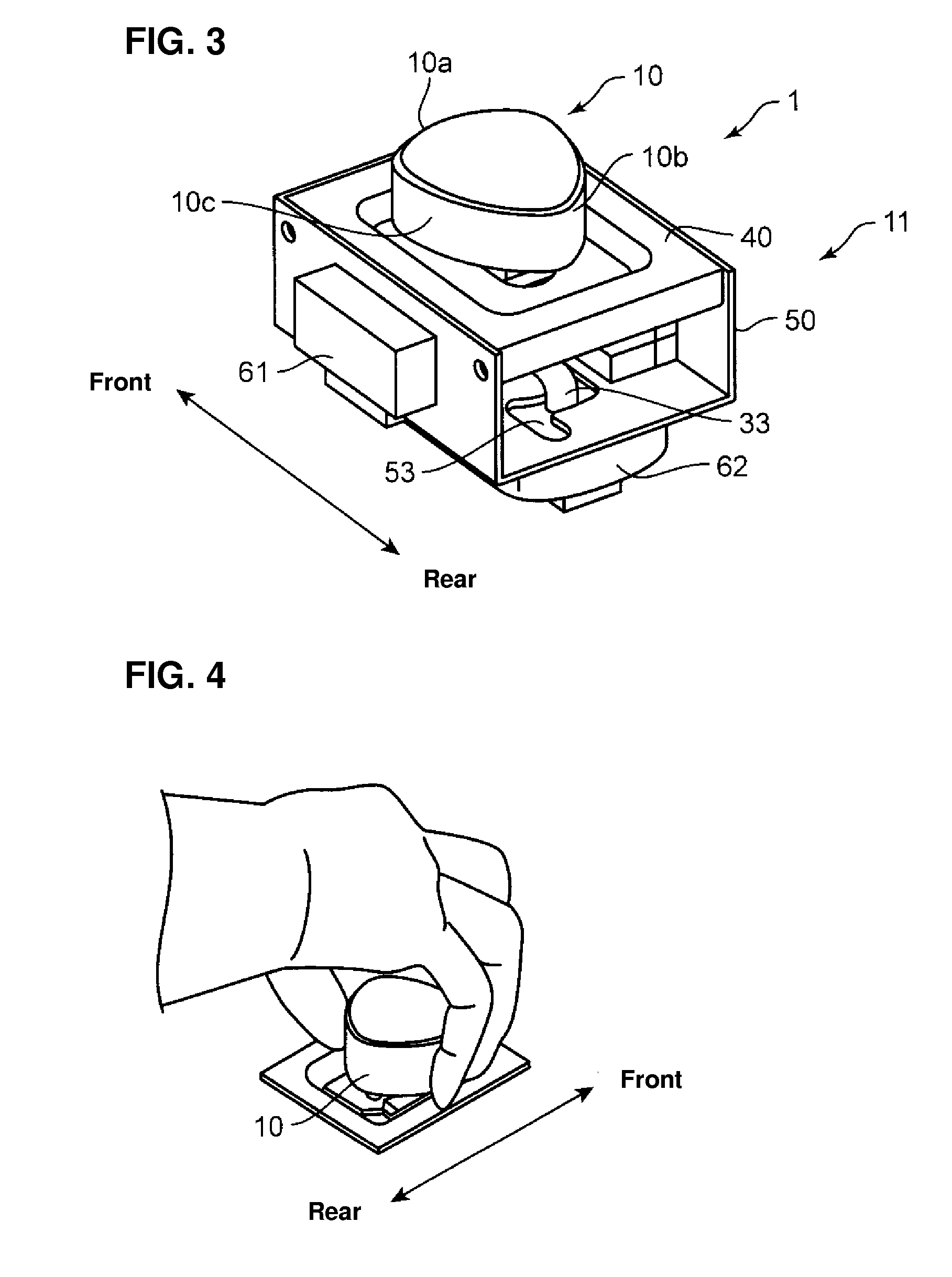

Shift control device for vehicle

ActiveUS9254745B2Easy to shiftReduce stepsGearing controlLimiting/preventing/returning movement of partsEngineeringDriving range

Owner:MAZDA MOTOR CORP

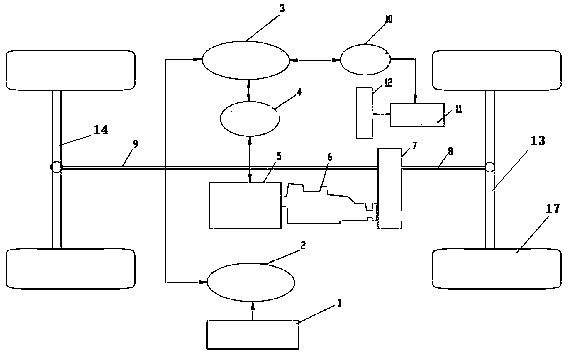

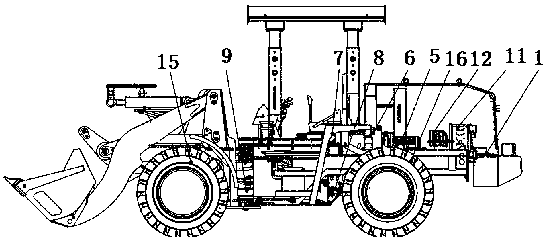

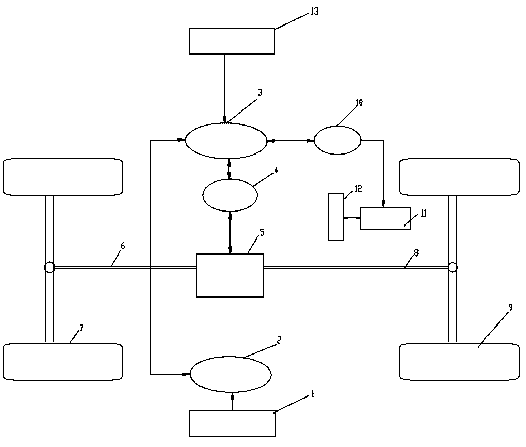

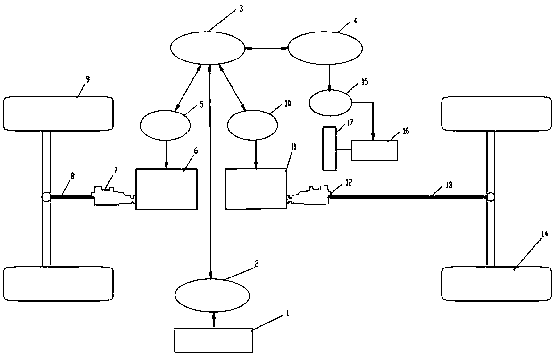

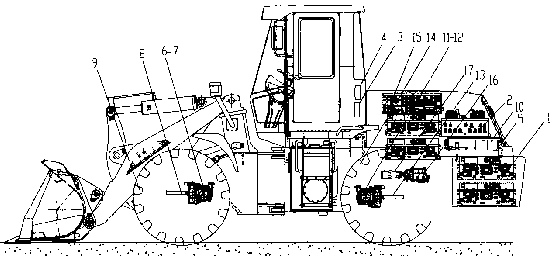

Drive control system for pure electric loader

PendingCN109457744AReduce use costReduce noiseMechanical machines/dredgersHydraulic motorTransfer case

The invention discloses a drive control system for a pure electric loader and belongs to the technical field of shoveling-transferring engineering mechanical vehicles. A traveling system is connectedto the lower side of a machine body. The machine body is provided with a hydraulic system and further provided with a hydraulic motor and a traveling motor. The hydraulic motor is connected with a hydraulic pump. The hydraulic pump supplies power to the hydraulic system. The traveling motor is connected with a traveling system through a transmission system. The transmission system comprises a fully-automatic speed changing box connected with the hydraulic motor. The output end of the fully-automatic speed changing box is connected with a transfer case. The transfer case is connected with the traveling system and supplies power to the traveling system. According to the drive control system, the traveling system is driven by the traveling motor, and the hydraulic system is driven by the hydraulic motor; compared with mechanical transmission adopted in the prior art, the traveling system is high in transmission efficiency, electrodeless speed changing can be achieved, and gear shifting isachieved easily; the power is great; the hydraulic system can provide stable and efficient powerful driving force; the drive control system is great in universality and convenient to maintain; and defects of an existing loader are overcome.

Owner:XCMG CONSTR MACHINERY

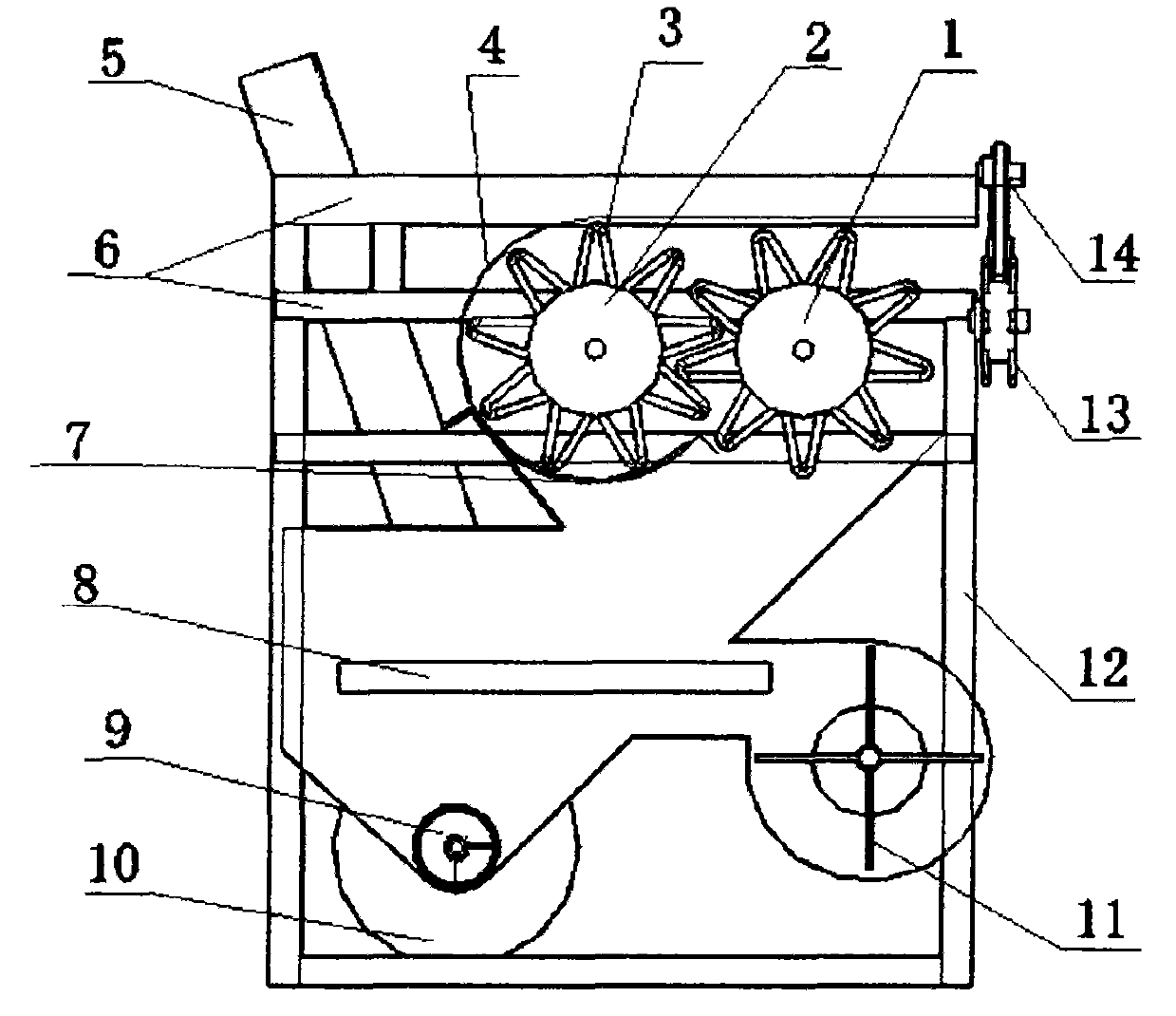

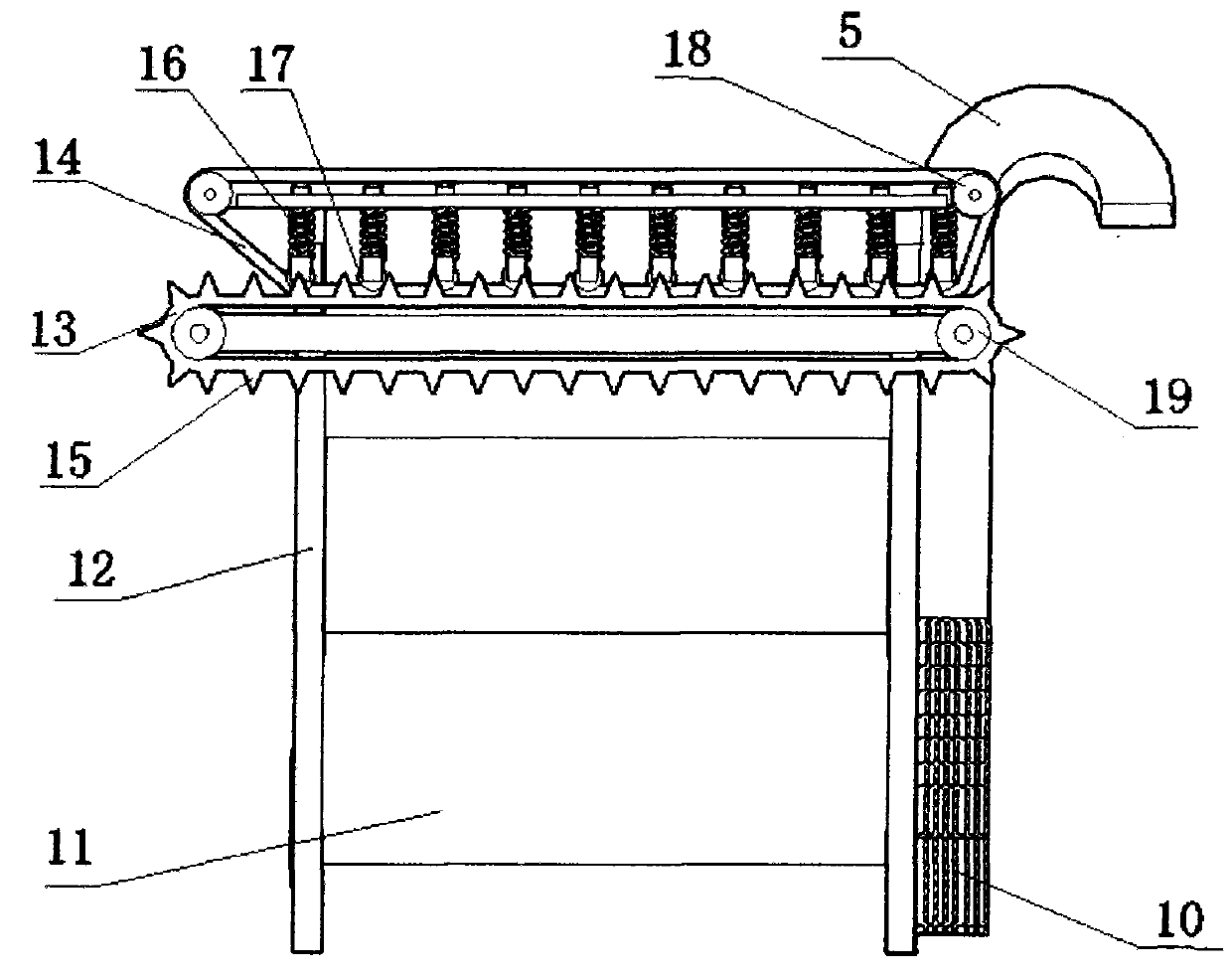

Module combined multifunctional threshing machine

The invention provides a module combined multifunctional threshing machine, which relates to the technical field of combined threshing machines. The module combined multifunctional threshing machine comprises a common cleaning rack, a common transmission mechanism, a common screening and impurity removing mechanism, a common spiralconveying mechanism and a common grain blow-out mechanism, and further comprises replaceable feeding and threshing modules, wherein the feeding and threshing modules are arranged aiming at similar crop characteristics; internal members in the replaceable feeding and threshing modules are connected into a whole body; each feeding and threshing module is connected with the rack through a locking device in a replaceable manner. According to the module combined multifunctional threshing machine, each feeding and threshing component which is independently arranged according to the similar crop threshing characteristic is integrated to be a specific module, meanwhile, the components such as the transmission component and the screening and impurity removing component are shared, a unit can be quickly replaced to finish threshing during threshing aiming at specific crops; each feeding and threshing module of the threshing machine is arranged aiming at similar crops, so that the threshing machine has higher pertinence; since some components are shared, the production cost is reduced; the maintenance cost and the use cost are also reduced because of the simple and compact structure; easy shift, assembly and operation can be realized.

Owner:大连玖汇农业科技有限公司

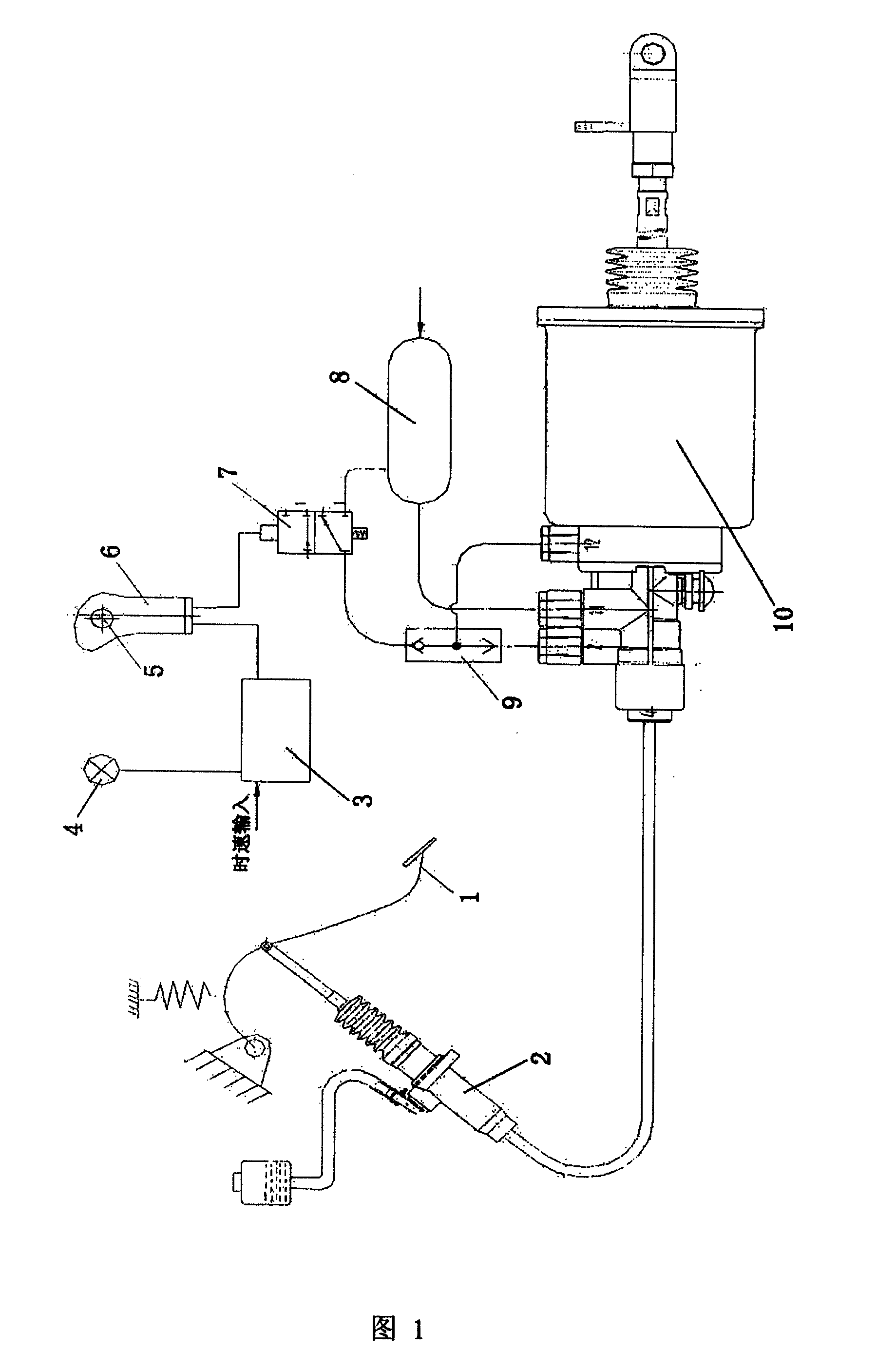

Shifting system

ActiveCN101249800AImprove simplicityImprove comfortClutchesControl devicesMaster cylinderMagnetic valve

The invention relates to an easy shift system, which consists of a clutch pedal and a clutch master cylinder, wherein, the clutch master cylinder is connected with an air channel of a clutch booster, on the other hand, the clutch booster is communicated with an air reservoir through a bi-pass one-way valve and a two-position three-way magnetic valve, the two-position three-way magnetic valve is controlled by a power circuit of an easy shift button, the easy shift button is arranged on a shift handle and connected with a controller. The controller connects / disconnects the power circuit of the easy shift button according to signals received from a speed-per-hour sensor. When the speed per hour detected by the speed-per-hour sensor is more than 5 kilometers per hour, the signal is sent to the controller, while no signal is sent when the speed-per-hour is not in the section. The easy shift system results in easy and relaxed shift, which is particularly suitable for female drivers and can greatly prolong the service life of a clutch shift operational structure.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

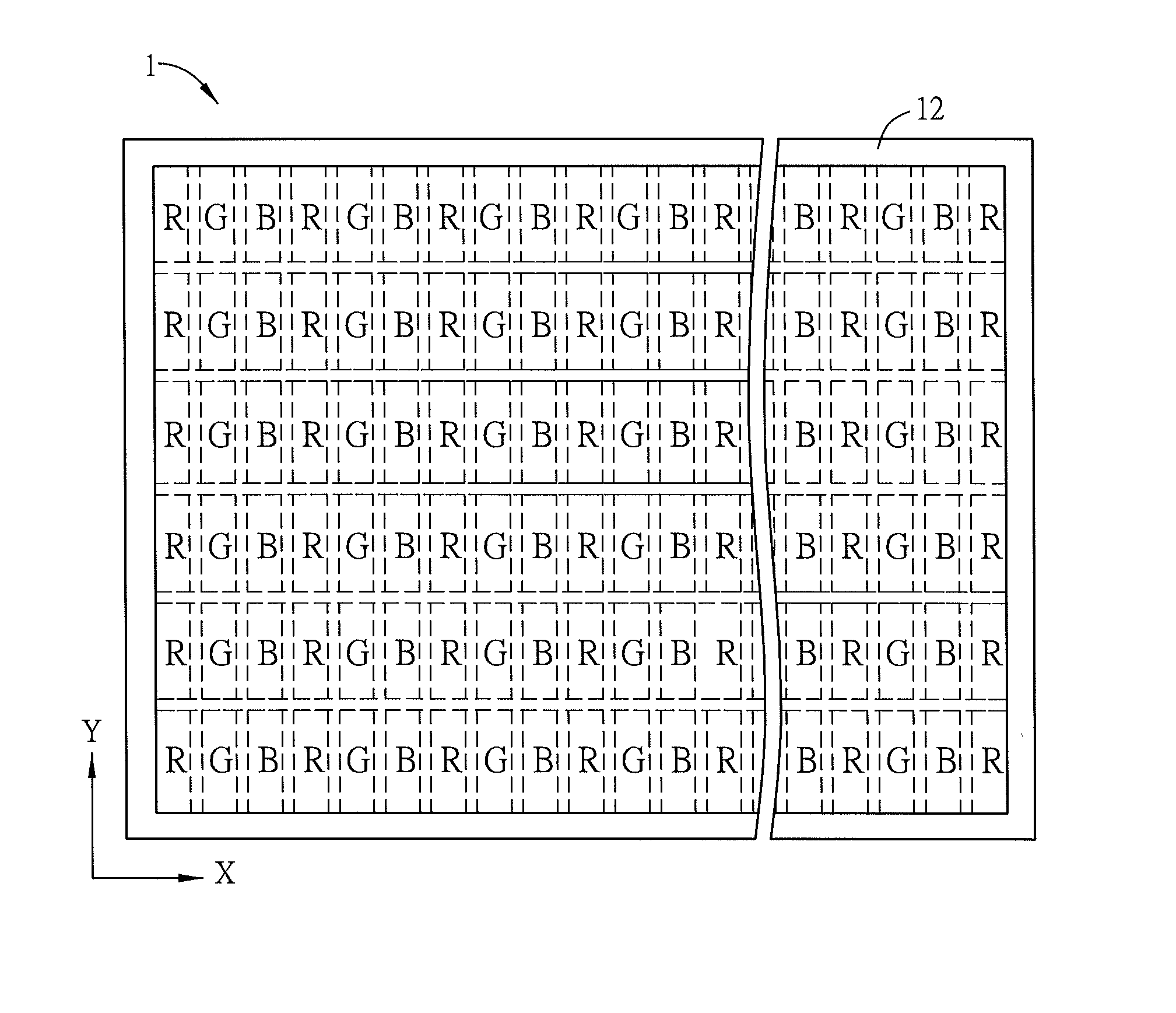

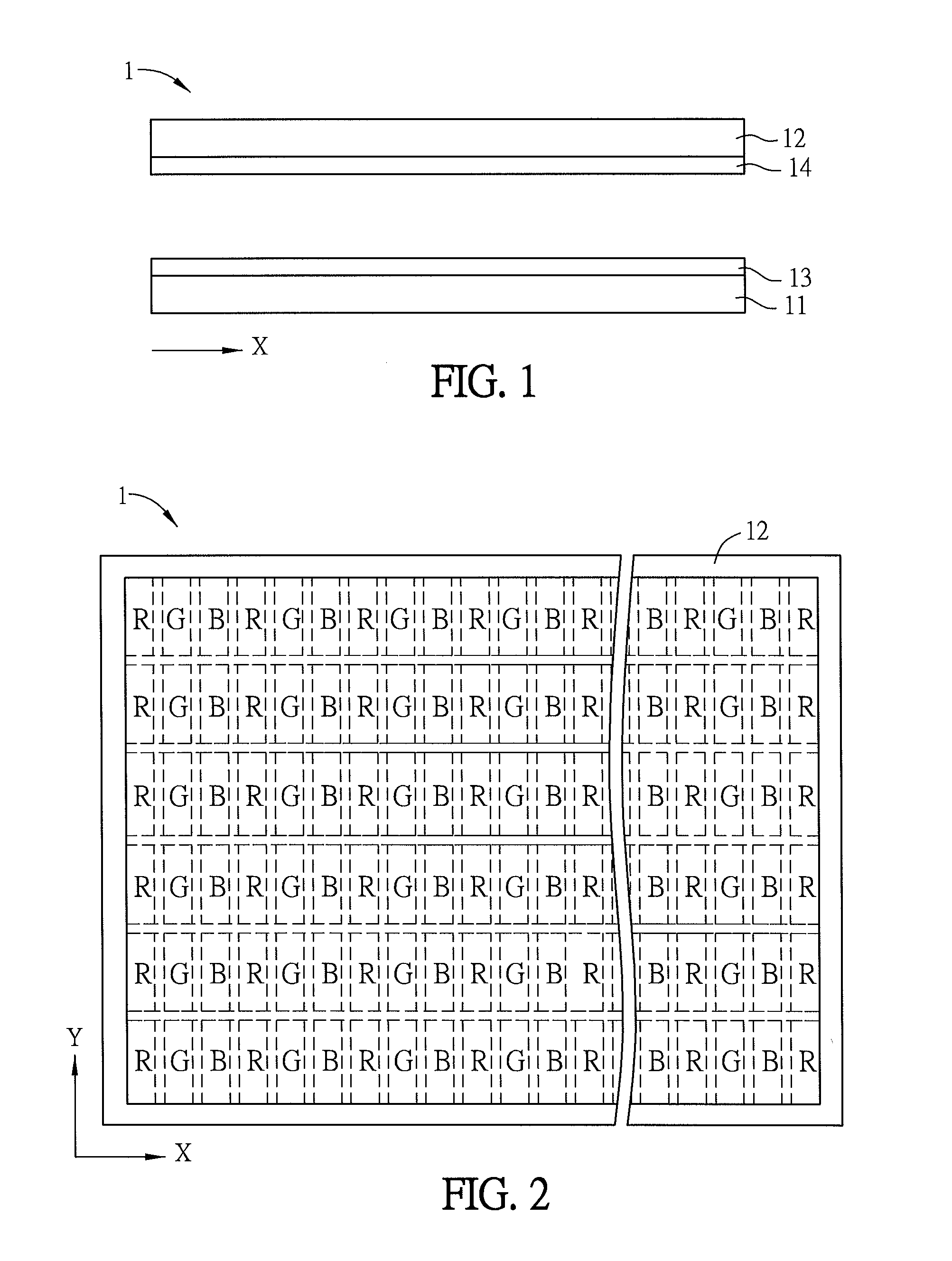

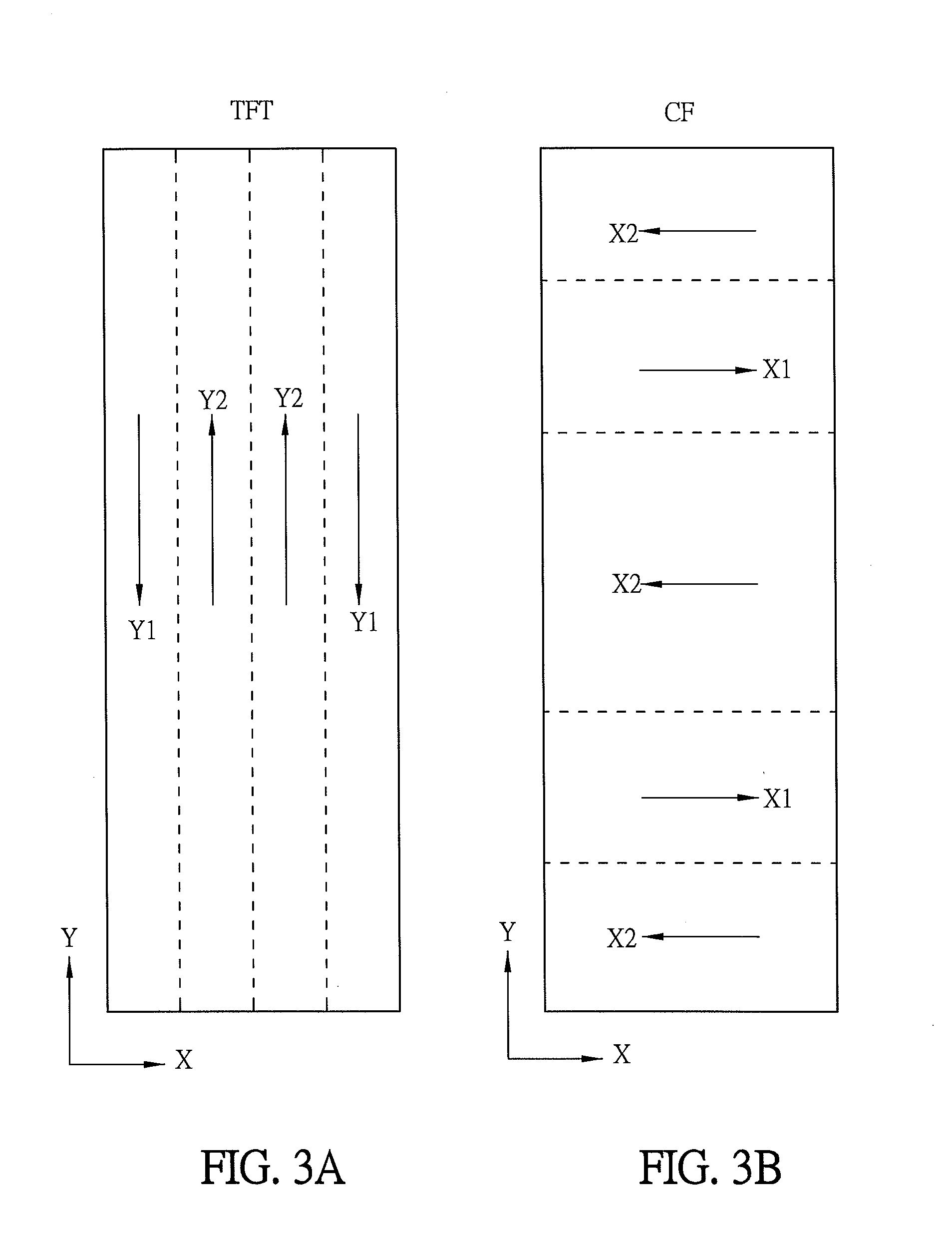

Liquid crystal display panel

InactiveUS20150055072A1Improve display qualityImprove viewing effectNon-linear opticsComputer scienceLiquid crystal molecule

A liquid crystal display (LCD) panel includes a plurality of pixel units, a first alignment layer and a second alignment layer. The pixel units are configured in a matrix formed by columns and rows, and each pixel unit is divided into a plurality of domains. The alignment direction of the first alignment layer is parallel to the column direction, while the alignment direction of the second alignment layer is parallel to the row direction. The domains of the pixel units have different tilt directions for liquid crystal molecules defined by the first and second alignment layers. In two adjacent pixel units arranged in the row direction, the domains adjacent to a boundary between the two adjacent pixel units have the same tilt direction for liquid crystal molecules defined by the first and second alignment layers.

Owner:INNOLUX CORP

Novel energy-saving electric loader drive control system and control method

PendingCN111236353ARealize infinitely variable speedEasy to shiftSoil-shifting machines/dredgersPower batteryControl system

The invention discloses a novel energy-saving electric loader drive control system and control method, and belongs to the technical field of shoveling engineering machinery vehicles. A control handleis connected with a vehicle control unit (VCU); the VCU is electrically connected with a motor controller I, a motor controller II and a power battery controller BMS; the motor controller I is in control connection with a double-output-shaft walking motor, and the double-output-shaft walking motor drives front wheels and rear wheels through a front transmission shaft and a rear transmission shaft;the motor controller II is in control connection with a hydraulic pump control motor, and the hydraulic pump control motor drives a hydraulic pump to provide power for a hydraulic system of a loader;and the power battery controller BMS is in control connection with a power battery pack, and the power battery pack supplies power to the double-output-shaft walking motor and the hydraulic pump control motor. The motor is in a mode of a double-output-shaft structure, the whole machine is easy to arrange, the structure is simple and convenient, the reliability is high, the problems that an existing loader is complex in structure and control are solved, the working efficiency is high, and the good energy-saving effect is achieved.

Owner:XCMG CONSTR MACHINERY

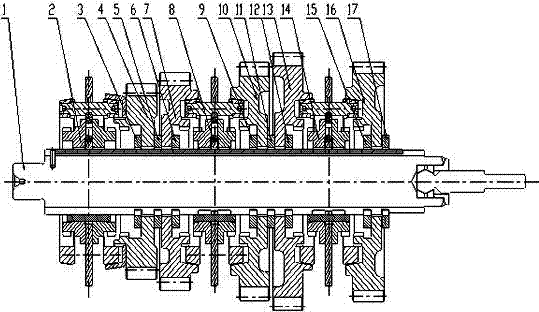

Dual-middle-shaft all synchromesh ten-gear transmission

The invention discloses a dual-middle-shaft all synchromesh ten-gear transmission, which has a two-segment structure consisting of a main tank and an auxiliary tank, wherein a main transmission is arranged in the main tank; an auxiliary transmission is arranged in the auxiliary tank; the main transmission is provided with five forward gears and a reverse gear, and the auxiliary transmission is provided with two gears, so that a 5*2 structure is constructed, and ten forward gears and two reverse gears are formed; the main transmission comprises an input mechanism and a speed change mechanism; the input mechanism comprises an input shaft and two auxiliary shafts; the two auxiliary shafts are parallel to a main shaft, and are arranged on both sides of the main shaft at 180 degrees; an idler wheel is meshed with reverse gears of the auxiliary shafts; the auxiliary transmission comprises an auxiliary tank planet mechanism which is connected with the main shaft through a spline; the output end of the auxiliary tank planet mechanism is provided with an auxiliary tank lock ring synchromesh; and a main shaft gear is positioned axially through a spline separation blade. In the design, the entire set of device has the advantages of simple structure, reliable connection, flexible shifting, high generality, convenience for loading in series, high assembling property, full adaptability to the requirements of users and wide market prospect.

Owner:SINO TRUK JINAN POWER

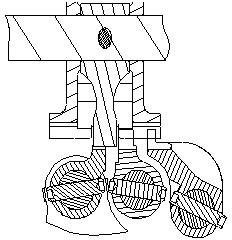

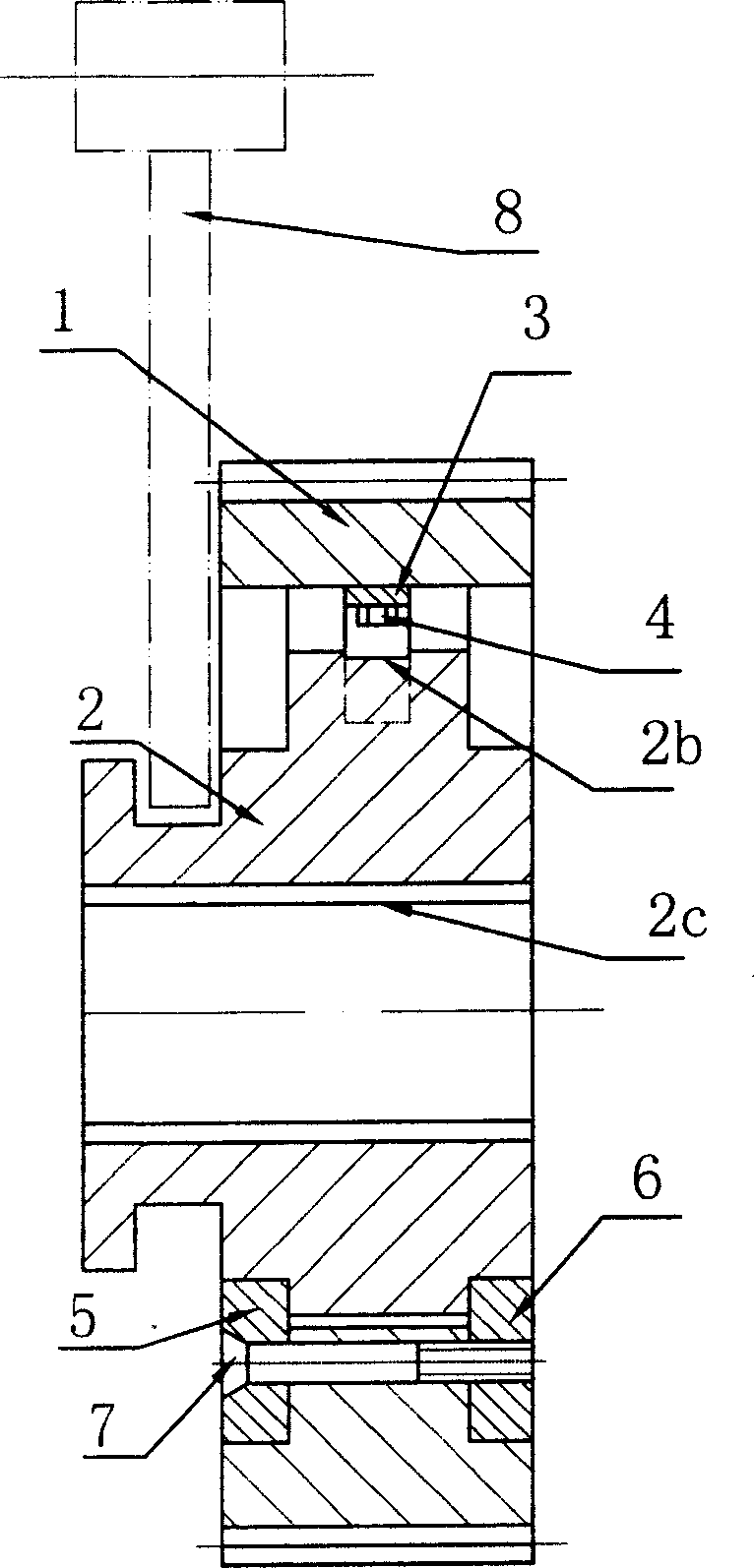

Non-impact speed changing transmission gear

InactiveCN1844711AStable performanceSimple structurePortable liftingGearing elementsVariatorEngineering

The invention discloses a non-impact speed-change transmission gear wheel, which is formed by a tooth ring and a rim. Wherein, the tooth ring and the rim are connected via the tooth-embedded mesh device with flexible space; the tooth ring and the rim are axially limited via the clamp plates; the clamp plates are fixed on the tooth ring; said tooth-embedded mesh device comprises: mesh space between the mesh tooth that connecting the tooth ring and the rim; the flexible element can make the mesh tooth of rim at the middle of space while do not transmit torque to form a flexible space; the inner hole of rim is a inner-pattern key or a smooth hole with key groove. The invention has simple structure, which can avoid the lower shift speed, the impact and noise when meshing the gear wheels, while it can be used in duplicate gear or single gear wheel, or different speed changers.

Owner:HUBEI XINGSHENG TECH DEV

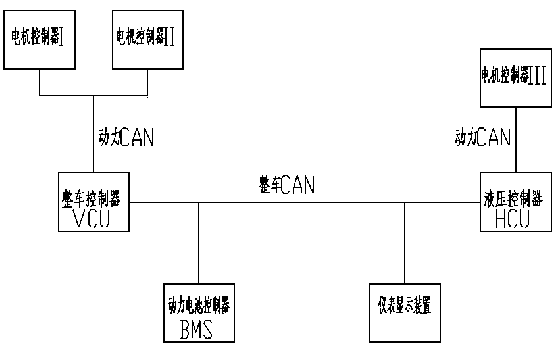

Three-motor novel pure electric loader drive control system

PendingCN110816296ADriving force is stableEfficient driving forceSpeed controllerFluid steeringHydraulic pumpControl theory

The invention discloses a pure electric loader, and belongs to the shoveling and conveying engineering machine vehicle technology. A whole vehicle controller VCU is electrically connected with a motorcontroller I, a motor controller II, a hydraulic controller HCU and a power battery controller BMS. The motor controller I is connected with a walking motor I, the walking motor I drives a front transmission shaft through an AMT speed changing box I, and the front transmission shaft drives a front wheel. The motor controller II is connected with a walking motor II, the walking motor II drives a rear transmission shaft through an AMT speed changing box II, and the rear transmission shaft drives a rear wheel. The hydraulic controller HCU is connected with a motor controller III, the motor controller III is connected with a hydraulic motor, the hydraulic motor drives a hydraulic pump, and the hydraulic pump provides power for a hydraulic system. The power battery controller BMS is connectedwith a power battery set. The pure electric loader is low in noise and free of pollution, an independent electric drive walking system and an electric drive hydraulic system are adopted so that stepless speed changing and easy gear shifting can be achieved, the power is strong, and the hydraulic system can provide stable and efficient powerful drive force.

Owner:XCMG CONSTR MACHINERY

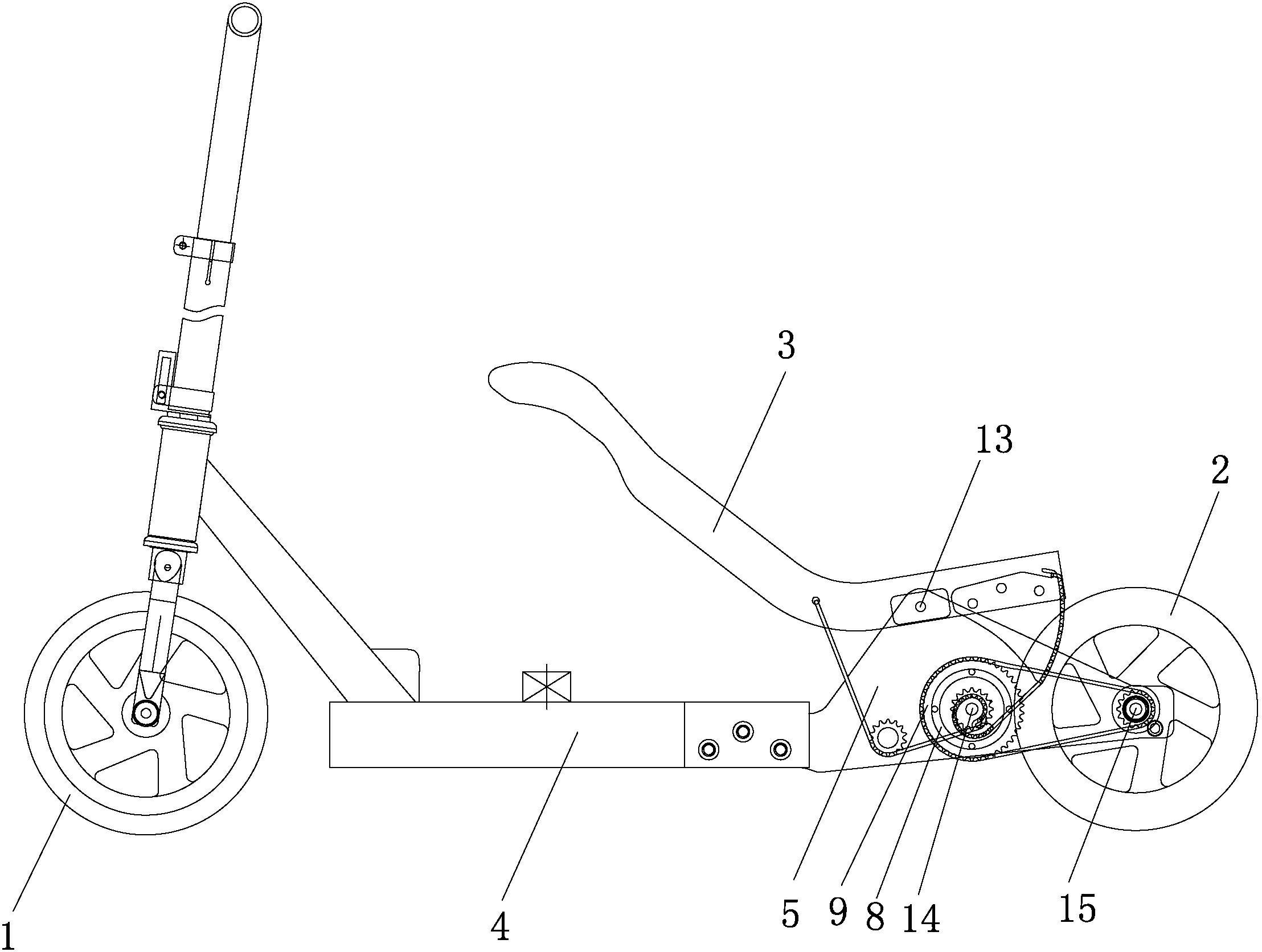

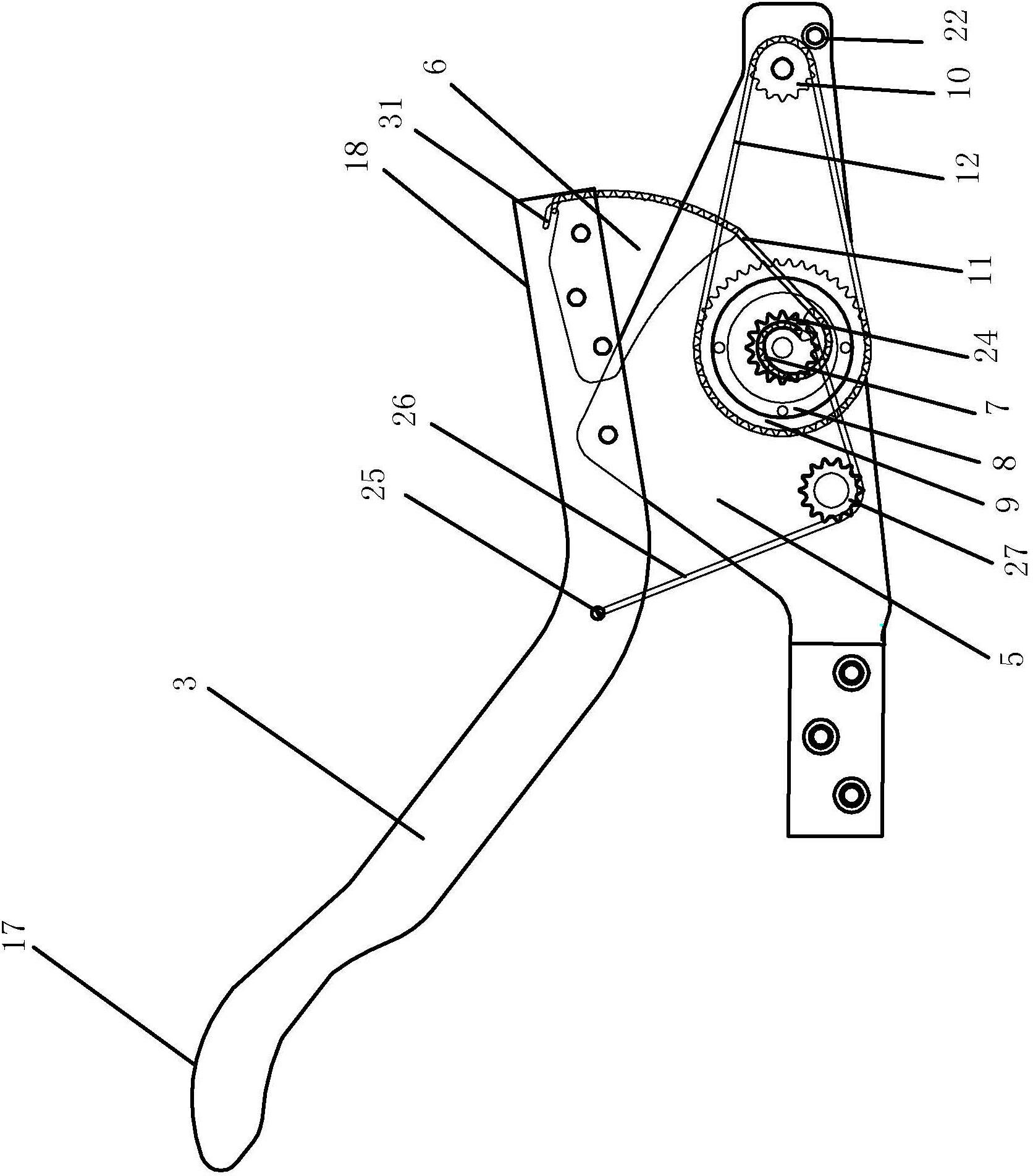

Variable speed scooter

ActiveCN102180221AEasy to shiftTo achieve the purpose of power outputChain/belt transmissionRider propulsionGear driveGear wheel

The invention relates to the technical field of scooters, in particular to a variable speed scooter. The variable speed scooter comprises a scooter body, a front wheel, a rear wheel and a driving system, wherein the scooter body comprises a power lever and a scooter body bracket; the scooter body bracket is provided with an upper power spindle, a front power spindle and a rear power spindle; the power lever is arranged on the upper power spindle; the driving system comprises a power system and a returning system; the power system comprises an eccentric wheel and a gear driving system, the eccentric wheel is arranged on the front power spindle; the front power spindle is driven to be connected with the rear power spindle by the gear driving system; the power lever is driven to be connected to the eccentric wheel; and the rear wheel is arranged on the rear power spindle. According to the eccentric wheel, the variable speed scooter saves power and has simple variable speed process, and different speeds can be realized by changing a treading travel angle, thereby satisfying the requirements of large upslope power and high flat ground speed.

Owner:佛山市苏普尔科技有限公司

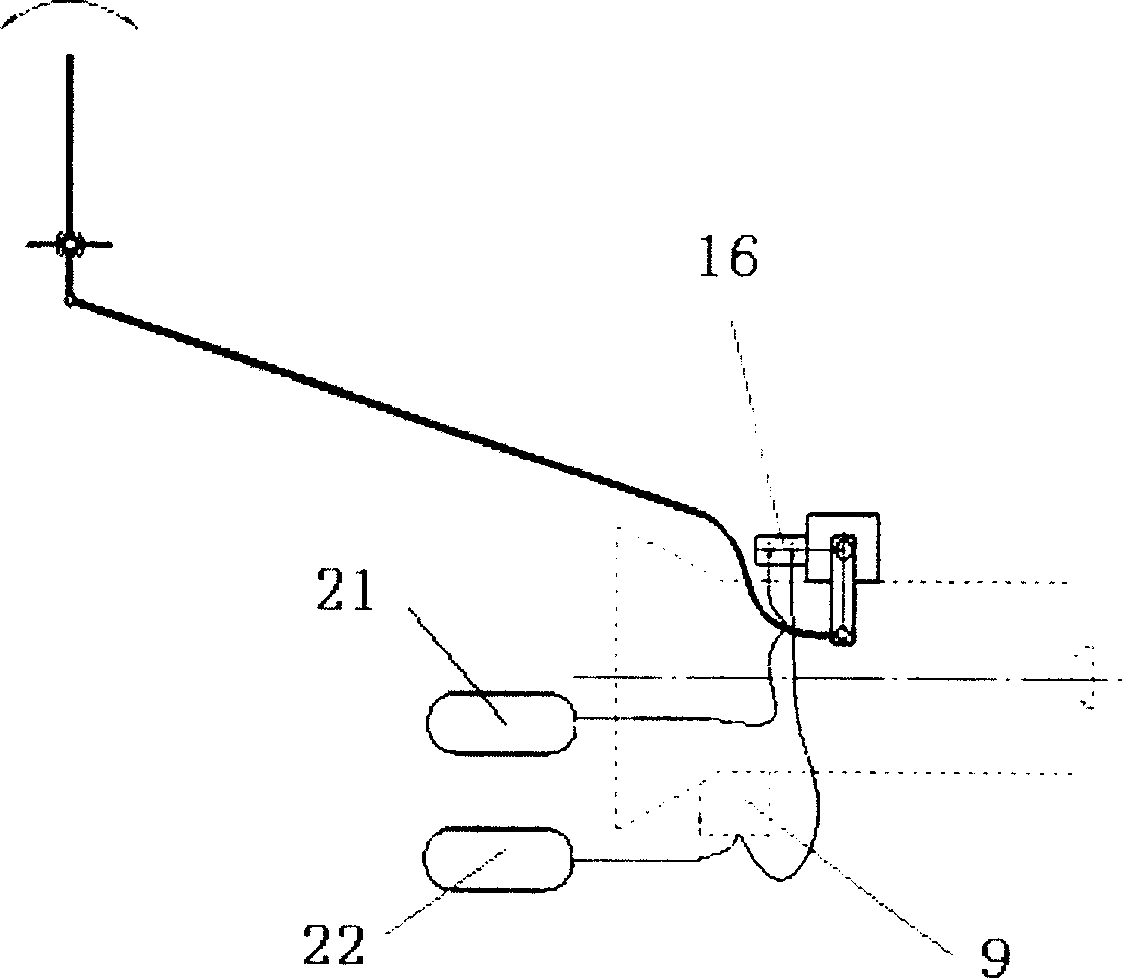

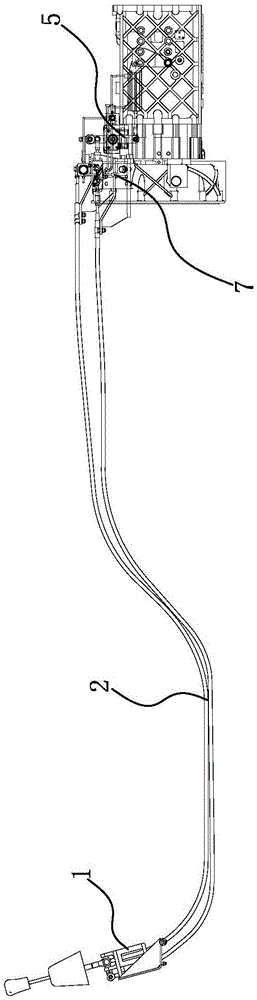

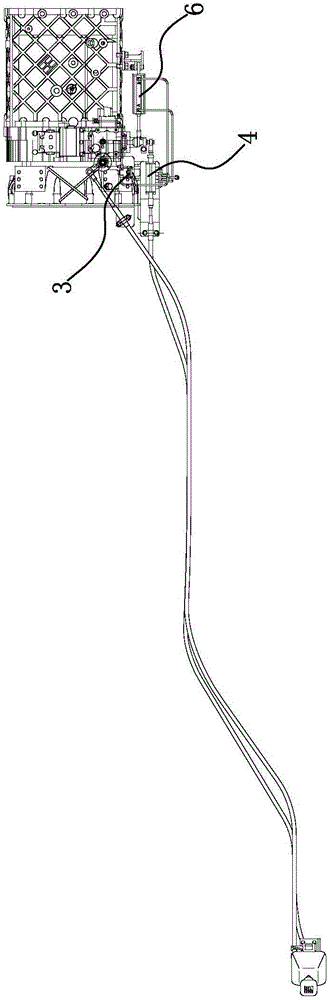

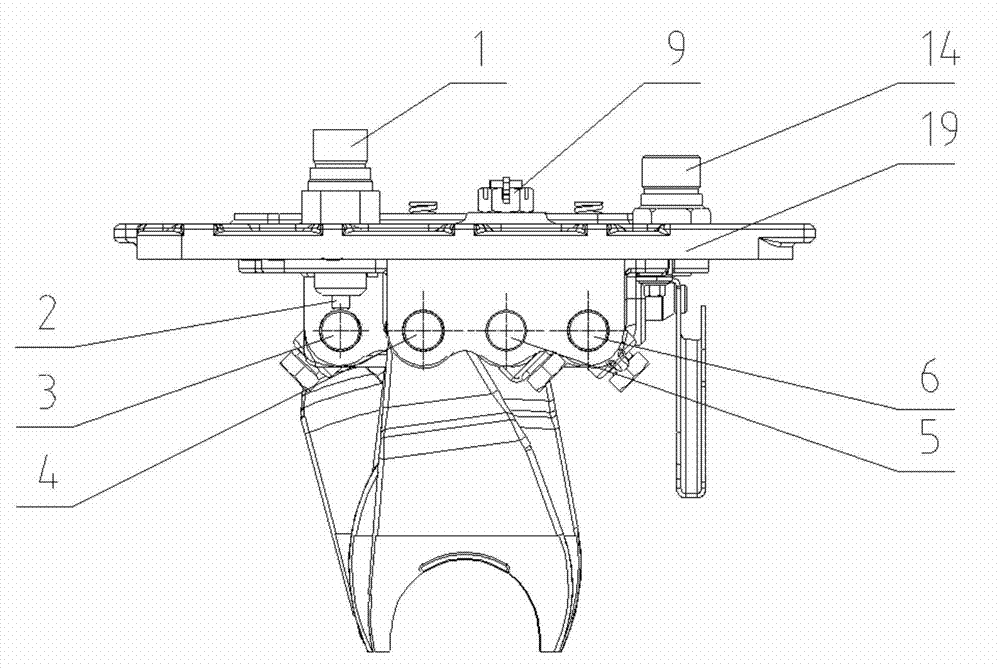

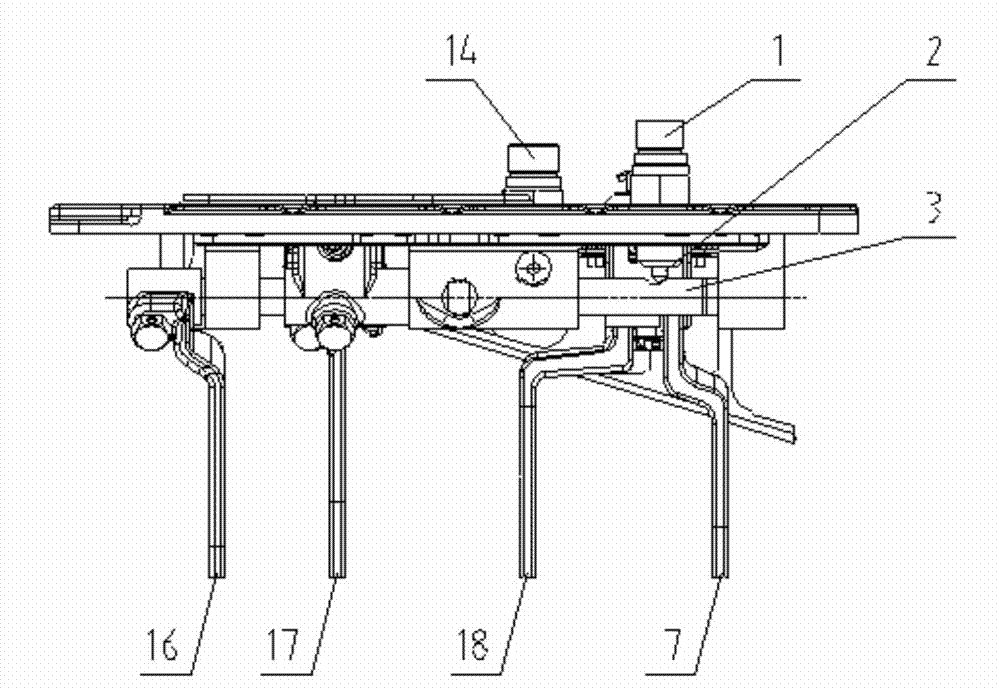

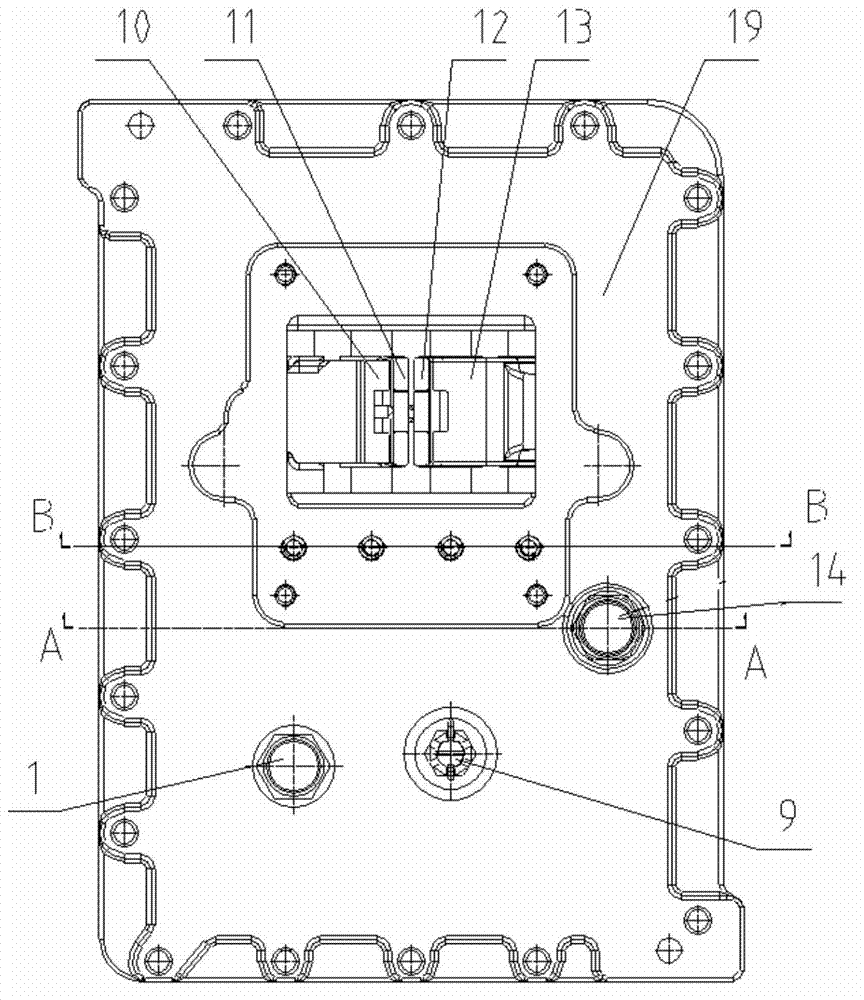

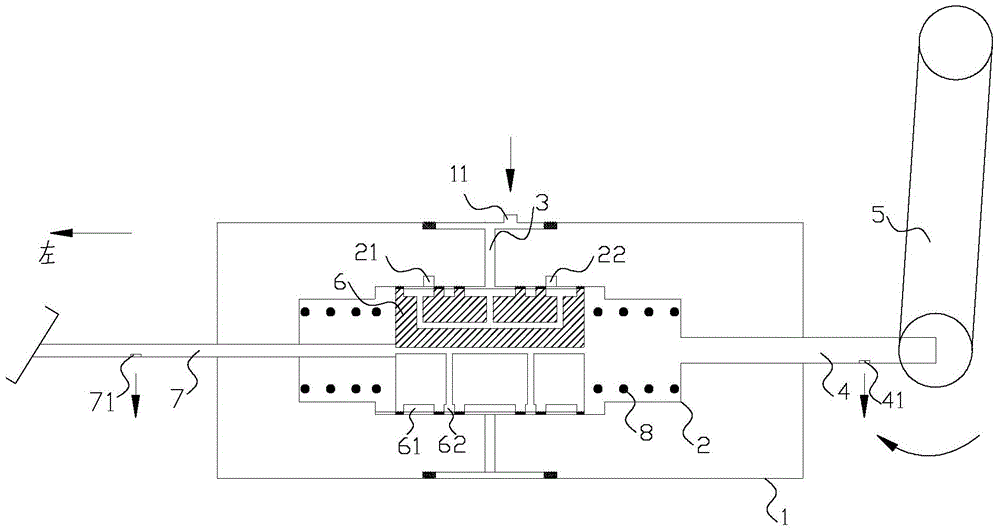

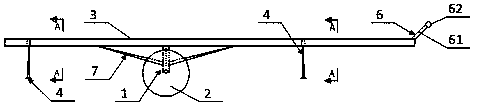

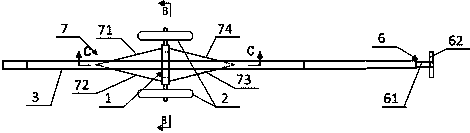

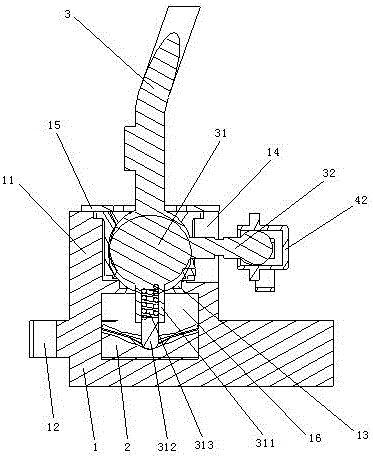

Follow-up type power assisting gear shifting operation device

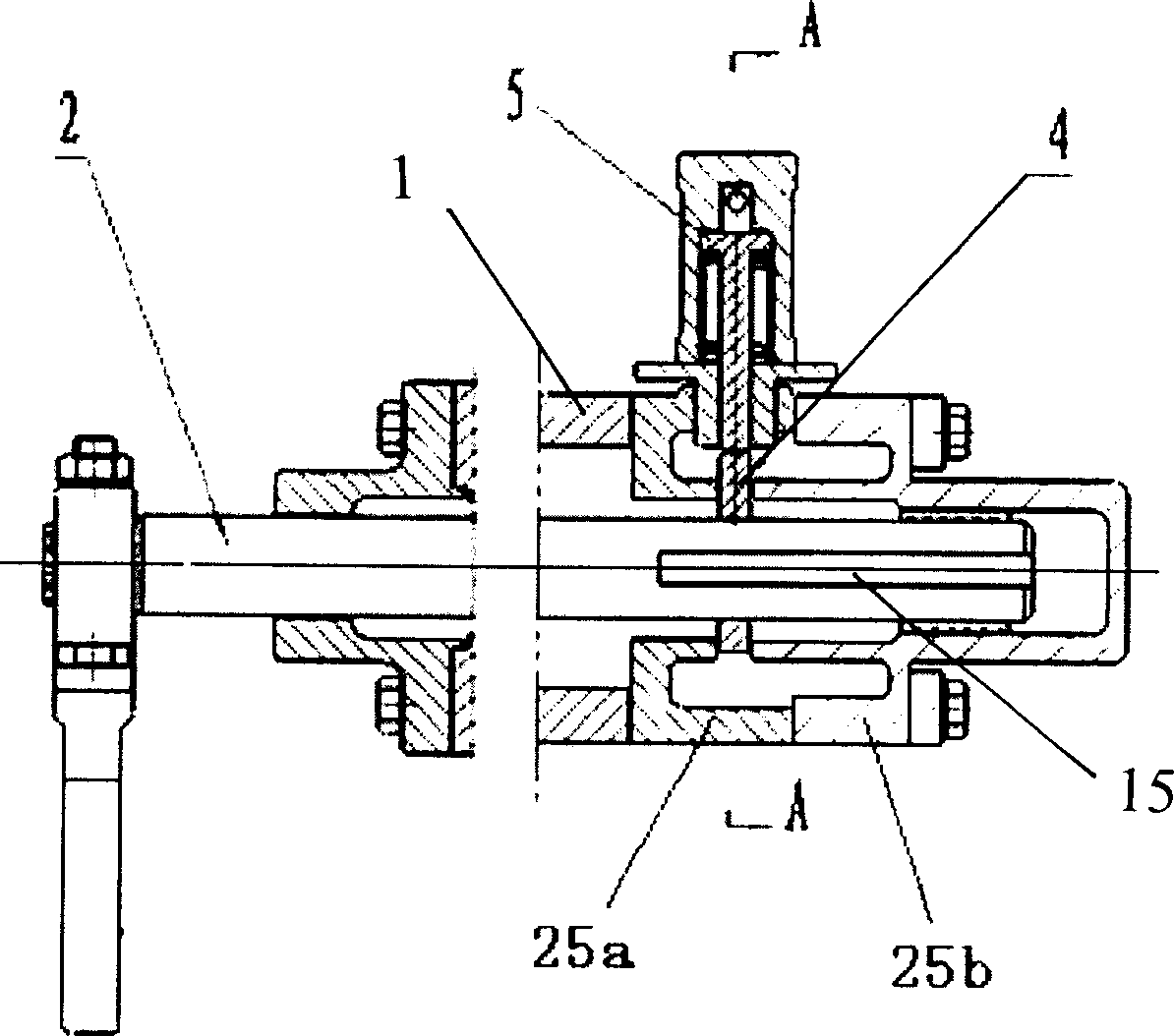

The invention relates to a speed change box operation device for a special vehicle chassis and aims at providing a follow-up type power assisting gear shifting operation device capable of guaranteeing light and convenient gear shifting, guaranteeing clear gears as well and occupying small installing space. The follow-up type power assisting gear shifting operation device comprises a controller (1), a gear shifting flexible shaft (2), a control valve (4), a gear shifting rocker arm (5) and a power assisting air cylinder (6). The controller is connected with a valve element of the control valve through the gear shifting flexible shaft, and the other end of the valve element is hinged to the gear shifting rocker arm. The other end of the gear shifting rocker arm is hinged to a piston rod of the power assisting air cylinder. The gear shifting rocker arm is used for being fixedly connected with a spline shaft of a speed change box. The control valve is provided with an air inlet, two air outlets and two exhaust ports. The two air outlets of the control valve communicate with the two sides of a cylinder barrel of the power assisting air cylinder through pipelines.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

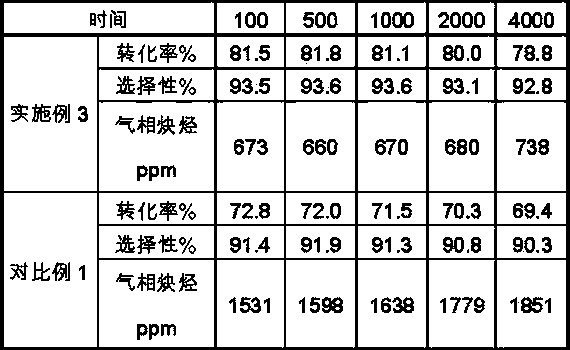

Preparation method of catalyst for butylene oxidative dehydrogenation to produce butadiene

ActiveCN104226351AEasy active site performanceChange active site performancePhysical/chemical process catalystsHydrocarbonsButadiene DioxideDehydrogenation

The invention relates to a preparation method of a catalyst for butylene oxidative dehydrogenation to produce butadiene, and mainly solves the problems of easy loss of components in precipitation process and poor reproducibility in the existing preparation of the catalyst. The invention adopts ball milling method to grind iron oxide, magnesium oxide, zinc oxide and a catalytic promoter in the form of oxides into powder, so as to obtain a mixture of complex metal oxides, the mixture is subjected to high-temperature calcination to obtain butylene, and butylene is subjected to oxidative dehydrogenation to obtain butadiene. The technical scheme well solves the problem, and can be used in industrial production of butadiene from butylene oxidative dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

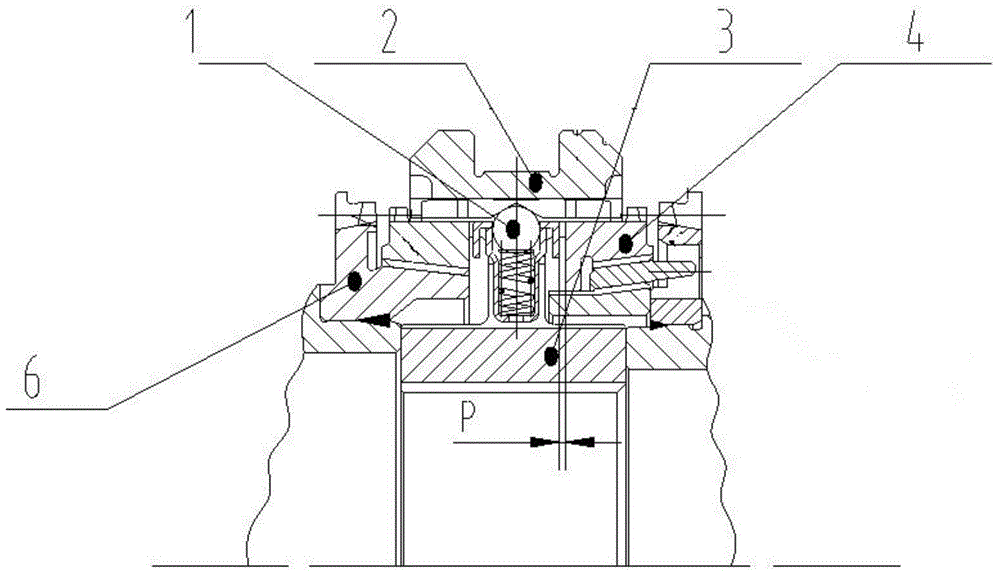

Transmission shifting mechanism assembly

InactiveCN104712756AImprove powerSimple structureControlled membersGearing controlSelf lockingEngineering

The invention belongs to the field of automobile transmissions, and particularly relates to a transmission shifting mechanism assembly. A four-fork-shaft structure is adopted, a self-locking device, an interlocking device and a reverse gear locking device are included, and meanwhile a reverse gear and neutral position triggering mechanism is included. The transmission shifting mechanism assembly comprises a transmission upper cover, a first-second gear shifting fork shaft, a third-fourth gear shifting fork shaft, a fifth-sixth gear shifting fork shaft and a reverse gear shifting fork shaft, and altogether four shifting fork shafts are arranged. Each shifting fork shaft is fixedly provided with a gear shifting guide block and a gear shifting fork. The distribution positions of the four gear shifting guide blocks are even and form four gear selecting positions, and a rail groove which allows a gear shifting block to move is formed in the middle of the positions. Fork feet of the four gear shifting forks are in an arc shape, and the four arcs are concentric in the radial direction. The fork feet of the four gear shifting forks are inserted into a groove of a first-second gear shifting tooth sleeve, a groove of a third-fourth gear shifting tooth sleeve, a groove of a fifth-sixth gear shifting tooth sleeve and a groove of a reverse gear shifting tooth sleeve. The first-second gear shifting guide block and the first-second gear shifting fork are of an integral structure. The transmission shifting mechanism assembly is simple in structure, reliable in quality and portable in gear shifting, and improves the dynamic property, the fuel economy and the handling comfort of an entire automobile.

Owner:CHINA FIRST AUTOMOBILE

Shift control device for vehicle

ActiveUS20150266376A1Easily changeRestrain operationGearing controlLimiting/preventing/returning movement of partsDriving rangeHome position

There are provided an operational member and a body portion supporting the operational member rotatably, clockwise or counterclockwise, from a home position and movably in a vehicle longitudinal direction from its rotated position. The body portion is configured to allow the rotated or moved operational member to return to the home position automatically. A shift range is changed to a neutral range when the operational member is rotated from the home position, and the shift range is changed to a traveling range (a drive range or a reverse range) when the operational member is moved in the vehicle longitudinal direction from the rotated position after the operational member is rotated from the home position. Herein, changing of the shift range to the drive range or the reverse range depends on the direction of the rotation of the dial from the home position.

Owner:MAZDA MOTOR CORP

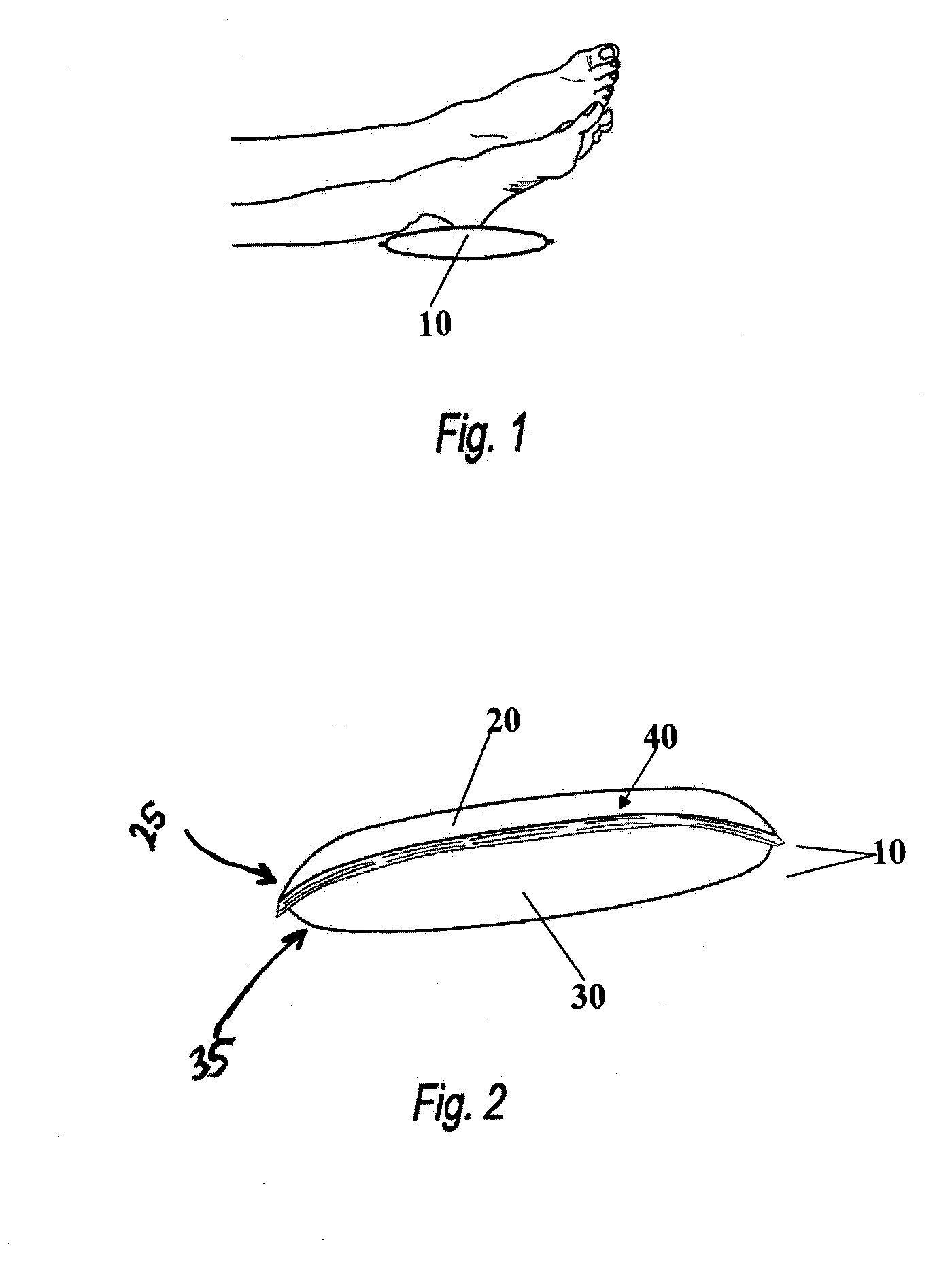

Heel support

The present invention is a heel and elbow cushioning device, having a sleeve with a flat top surface and a bottom surface and with the inner cavity of said sleeve being filled with a dry, visco-elastic polymer cushioning material having a 50% compression force deflection in a range of 2.5 to 4 psi and a 25% compression force deflection in a range of 0.25 psi to 1 psi. The sleeve may have a dimension of between 3 inches to 12 inches and may be between ¼ inch and 2 inches thick. The sleeve may have a specialized cover to protect it from dirt and damage. Such a cover would further contain an opening and closing mechanism for the sleeve.

Owner:RIEBER MICHAEL

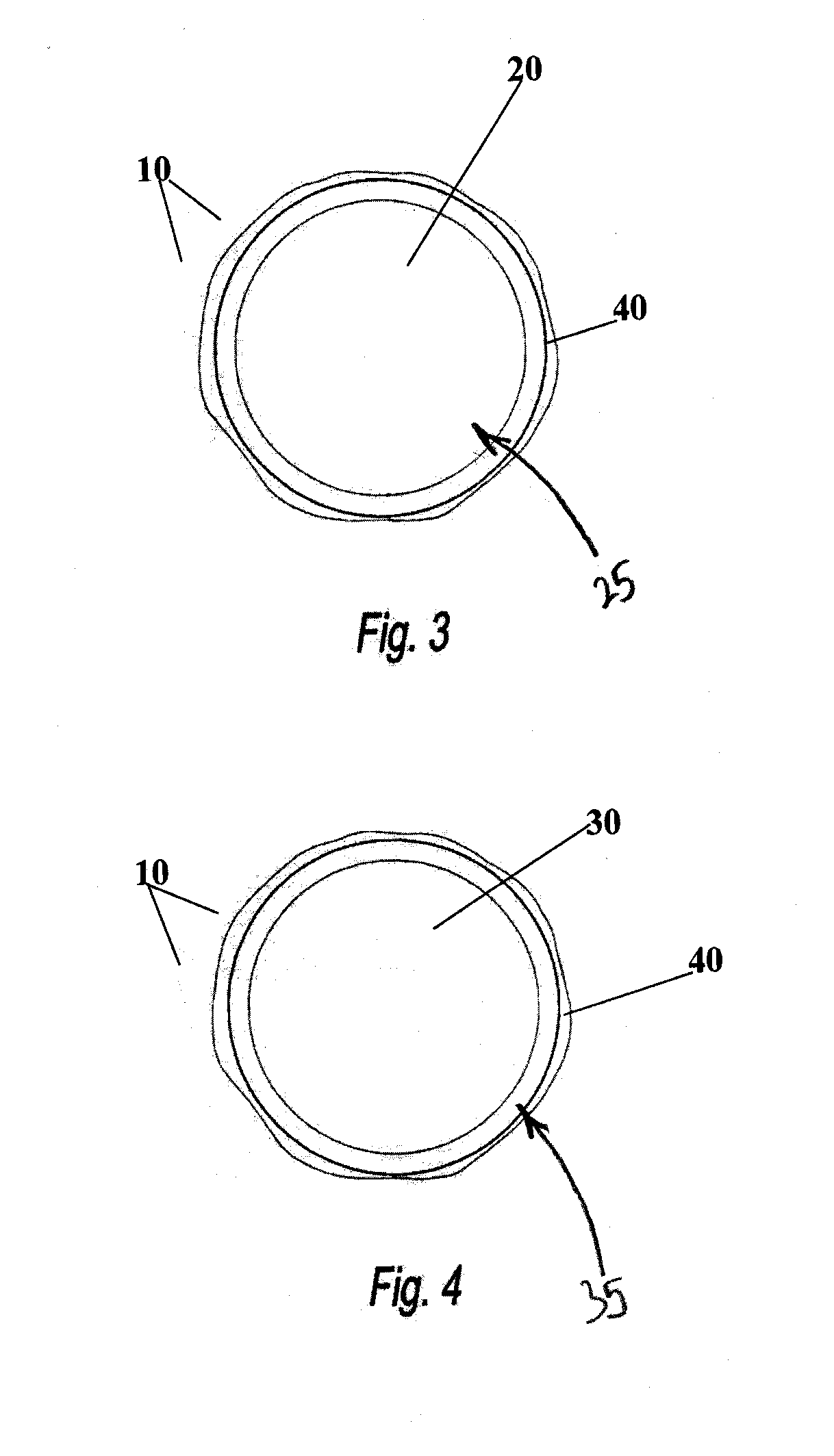

Image processing method and apparatus using elastic mapping of vascular plexus structures

PendingUS20190247142A1Improve deformationEasy to shiftImage enhancementImage analysisImaging processing3d image

The invention relates to an image processing method and a medical observation device (1) such as a microscope (2) or endoscope. The device and method are used for displaying output image data (54) of soft biological tissue (12). In image-guided surgery, pre-operative three-dimensional image data (6) of the soft biological tissue (12) are elastically matched to interoperative image data (14) which are acquired during surgery. By displaying the elastically matched pre-operative three-dimensional image data (6) together with the interoperative image data (14), the surgeon may be made aware of the consistence of the soft biological tissue (12) below the visible surface layer. Existing systems for image-guided surgery need to be manually readjusted if surgery is done on soft biological tissue (12), which may deform and shift. To avoid this, the device and method according to the invention perform an elastic matching of the pre-operative three-dimensional image data (6) based on the interoperative image data (14) of the soft biological tissue (12). At least one vascular plexus structure (48) is first identified in the interoperative image data (14) and then the same vascular plexus structure (48) is identified in the pre-operative three-dimensional image data (6). The vascular plexus structure (48) in the pre-operative three-dimensional image data (6) is then elastically matched to the vascular plexus structure (48) in the interoperative image data (14). Output image data (54) are generated combining the elastically matched pre-operative three-dimensional image data (6) to the interoperative image data (14). Preferably, the at least one vascular plexus structure (48) is identified using fluorescent light from a fluorophore (22) which has been injected into the soft biological tissue (12).

Owner:LEICA INSTR SINGAPORE PTE

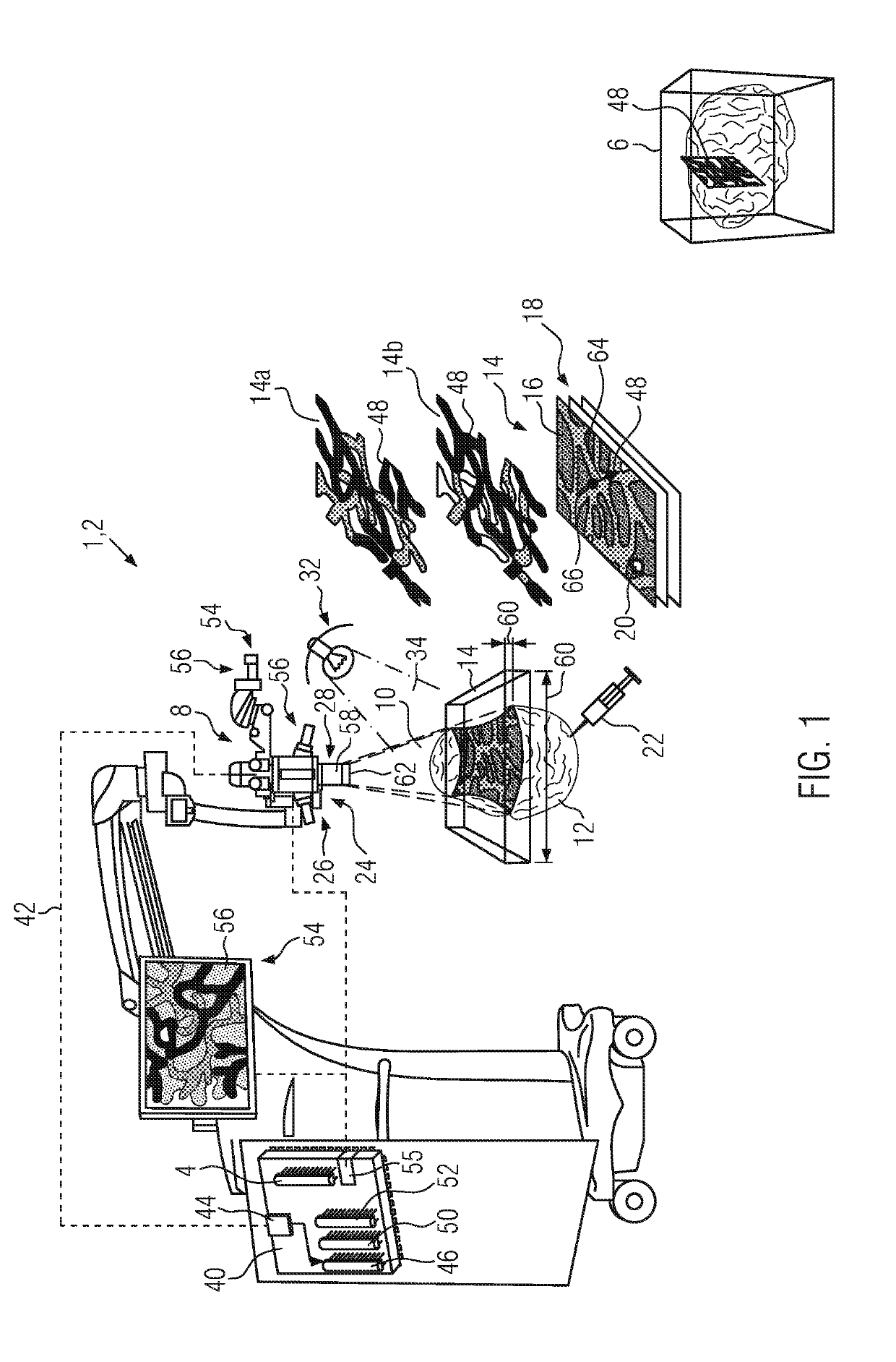

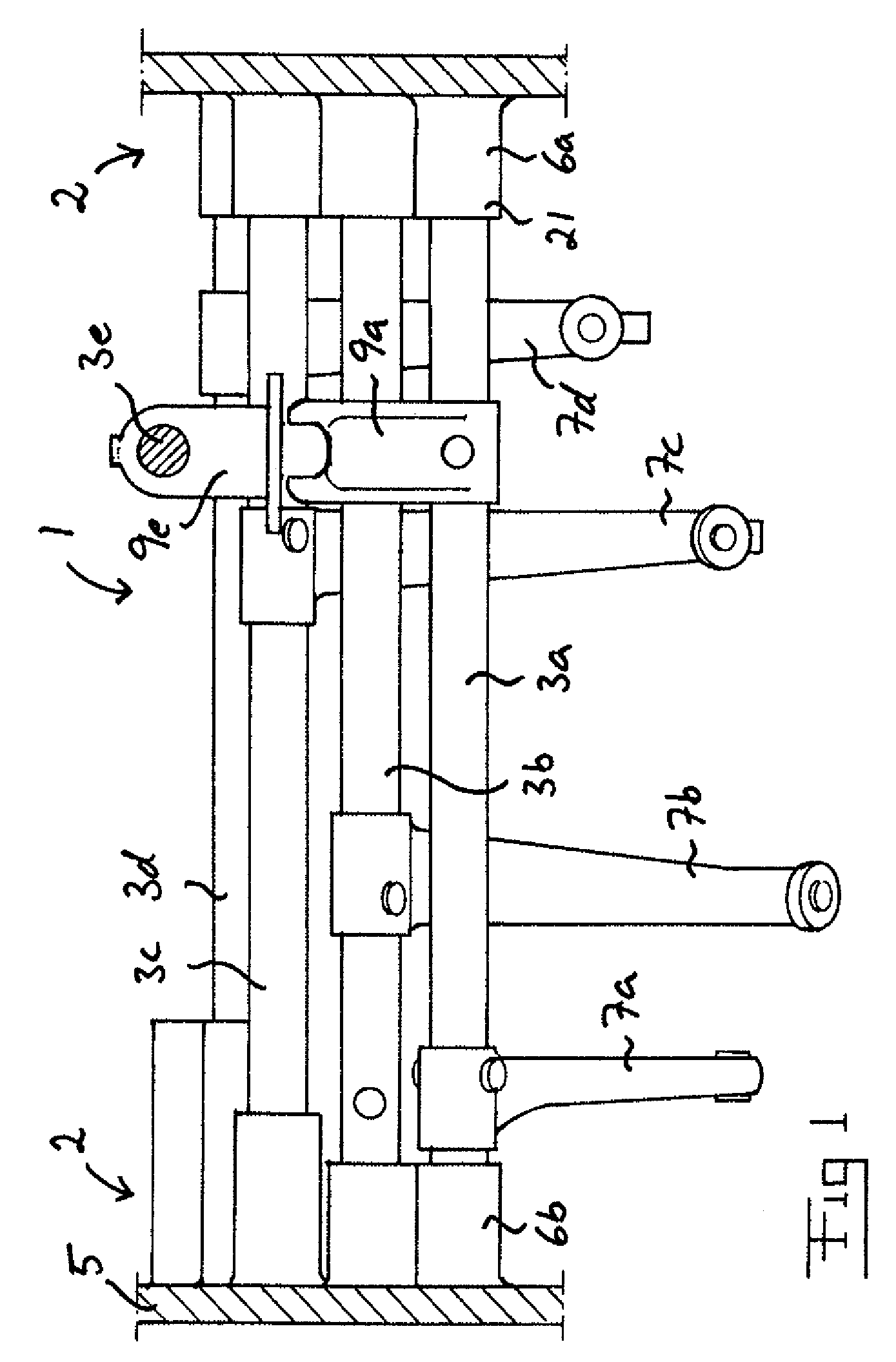

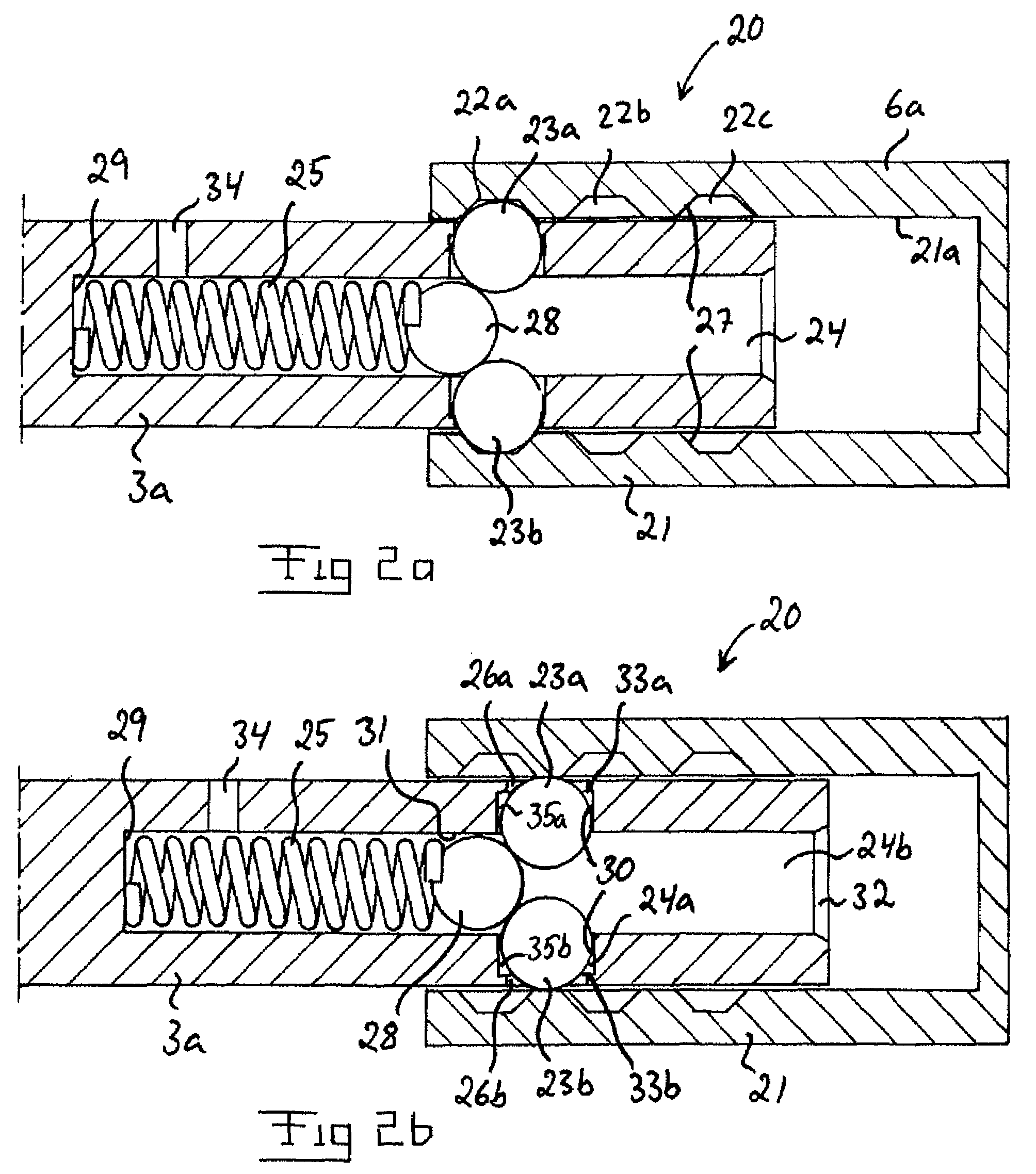

Control arrangement and gearbox

InactiveUS7997160B2Easy constructionLittle wearManual control with multiple controlled membersControlling membersEngineeringMotorized vehicle

Owner:SCANIA CV AB

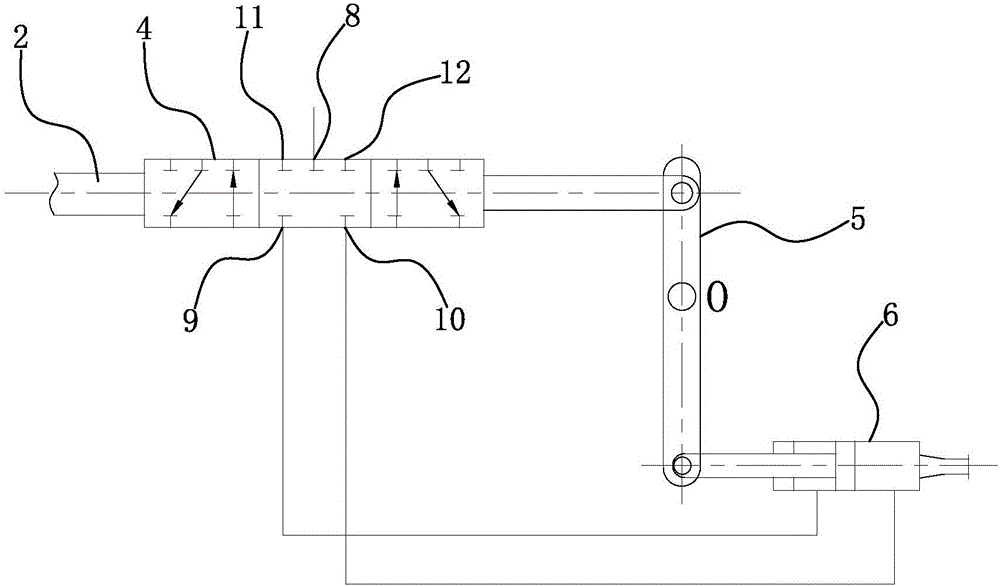

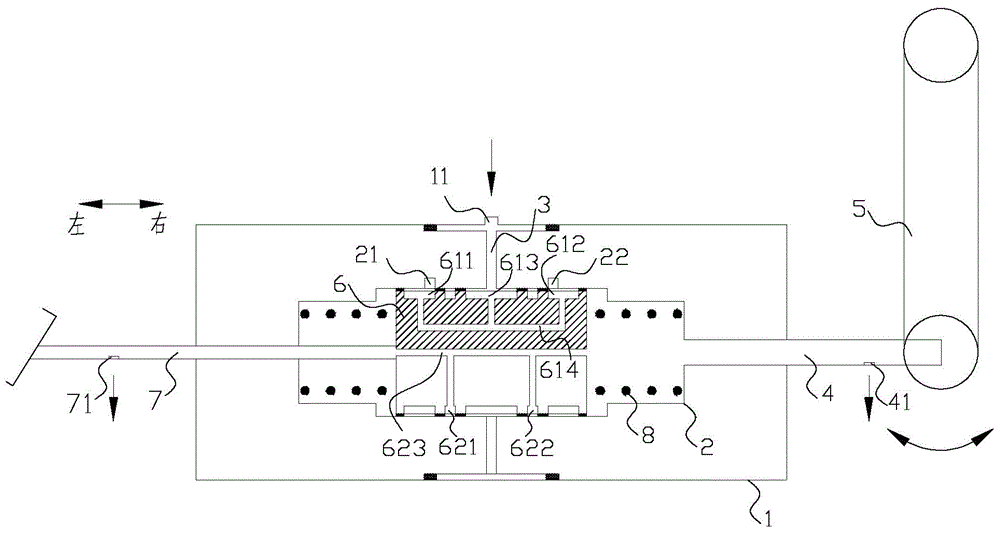

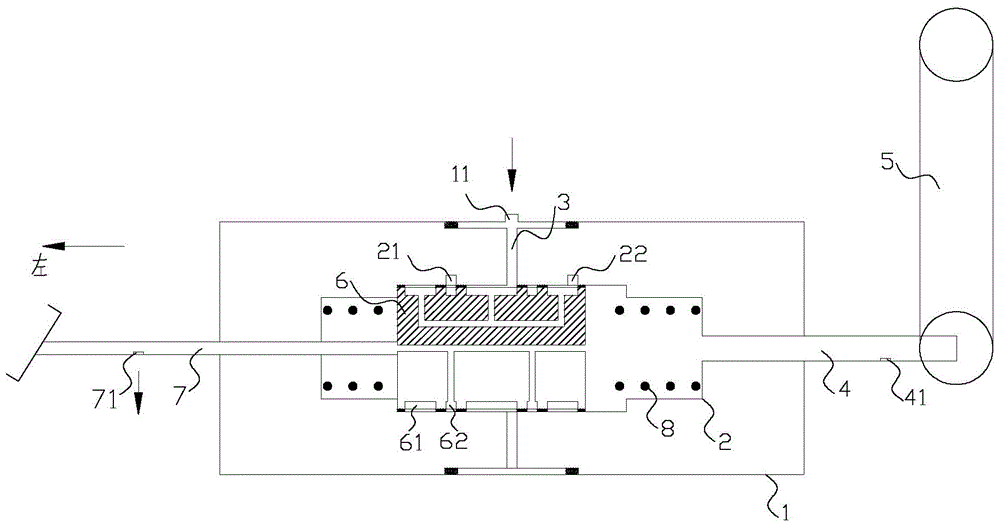

Speed change control mechanism and medium-pressure servo gear shifting power-assistance air cylinder thereof

ActiveCN104964030AImprove handling feelImprove the control experienceGearing controlChange controlEngineering

The invention discloses a speed change control mechanism and a medium-pressure servo gear shifting power-assistance air cylinder thereof. The medium-pressure servo gear shifting power-assistance air cylinder comprises a cylinder body, and a valve body, an air cylinder piston and a rocker arm that are mutually connected, wherein the valve body is provided with a left cavity air vent and a right cavity air vent; the interior of the valve body is connected with a valve body piston; the valve body piston is connected with a draw bar, and provided with an air inlet passage and an air exhaust passage; the air inlet passage is provided with a left cavity air inlet and a right cavity air inlet; the air exhaust passage is provided with a left cavity exhaust vent and a right cavity exhaust vent; when the valve body piston is positioned in the middle, the left cavity air inlet and the right cavity air inlet are communicated with the left cavity air vent and the right cavity air vent correspondingly; when the valve body piston moves leftwards, the left cavity air vent is communicated with the left cavity exhaust vent and the right cavity air inlet is communicated with the right cavity air vent to drive the air cylinder piston to move leftwards; and when the valve body piston moves rightwards, the right cavity air vent is communicated with the right cavity exhaust vent and the left cavity air inlet is communicated with the left cavity air vent to drive the air cylinder piston to move rightwards. The air cylinder realizes power assistance during gear shifting and improves an operation experience.

Owner:WEICHAI POWER CO LTD

Transport cart for transferring components

PendingCN109625044AEasy to shiftImprove stabilityHand carts with one axisHand cart accessoriesElectricityVehicle frame

The invention provides a transport cart for transferring components. The transport cart for transferring components comprises a frame, wheels, a lever and lifters; the frame is a door-type bracket andis arranged on a wheel axle connected between the wheels; the lever is arranged on the frame and has an included angle with the frame; the lever is provided with the lifters on the two sides of the frame for lifting components to be transferred so that the components to be transferred can be elevated to be above the ground for transferring. The heavy components can be easily moved by utilizing the lever principle and the wheel rolling principle; meanwhile, as the frame is the door-type bracket, the stability of the transport cart is greatly improved; compared with a common carrier, labor is saved, the working period is shortened, no oil or power resource is consumed, and the transport cart is light, convenient to use, affordable and environmentally friendly.

Owner:MCC5 GROUP CORP SHANGHAI

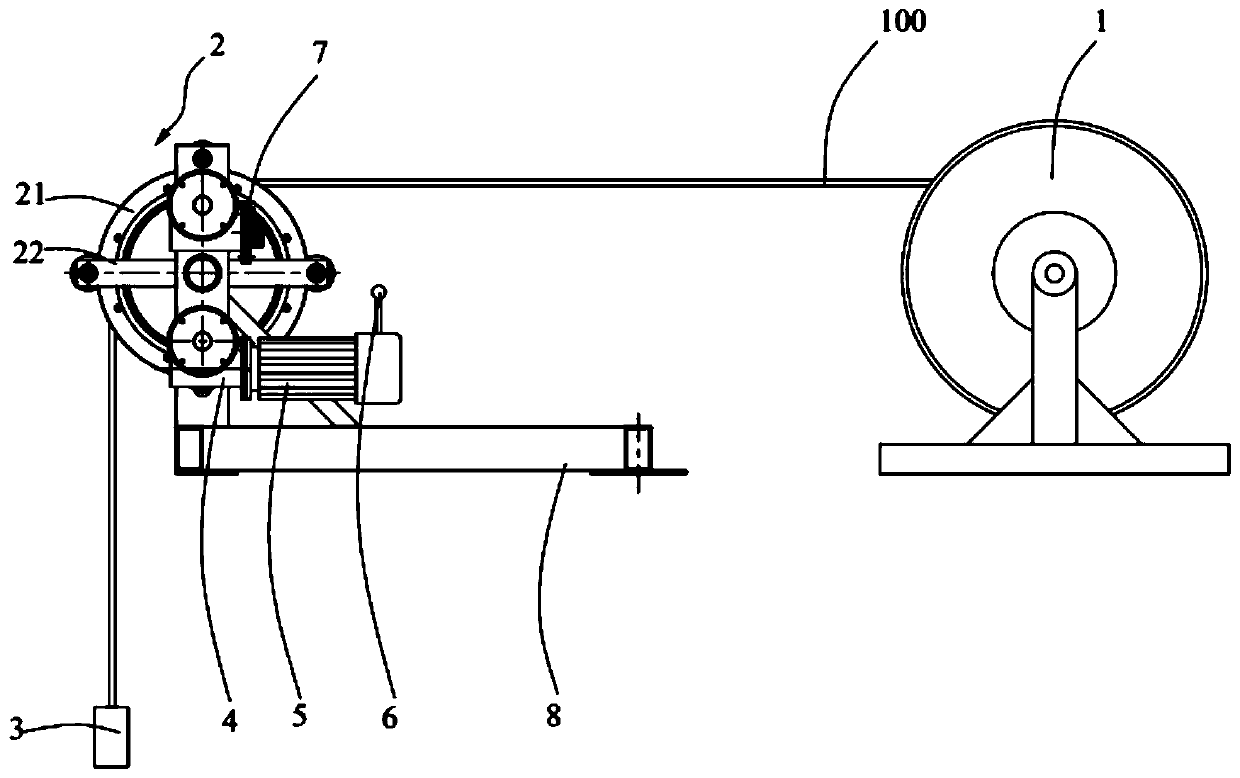

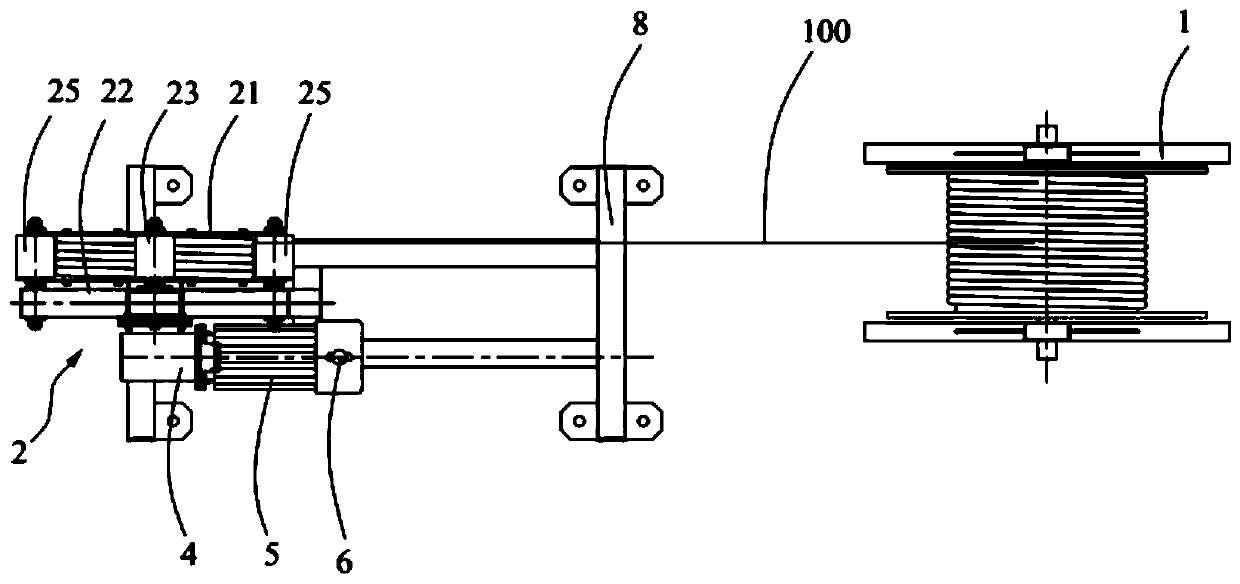

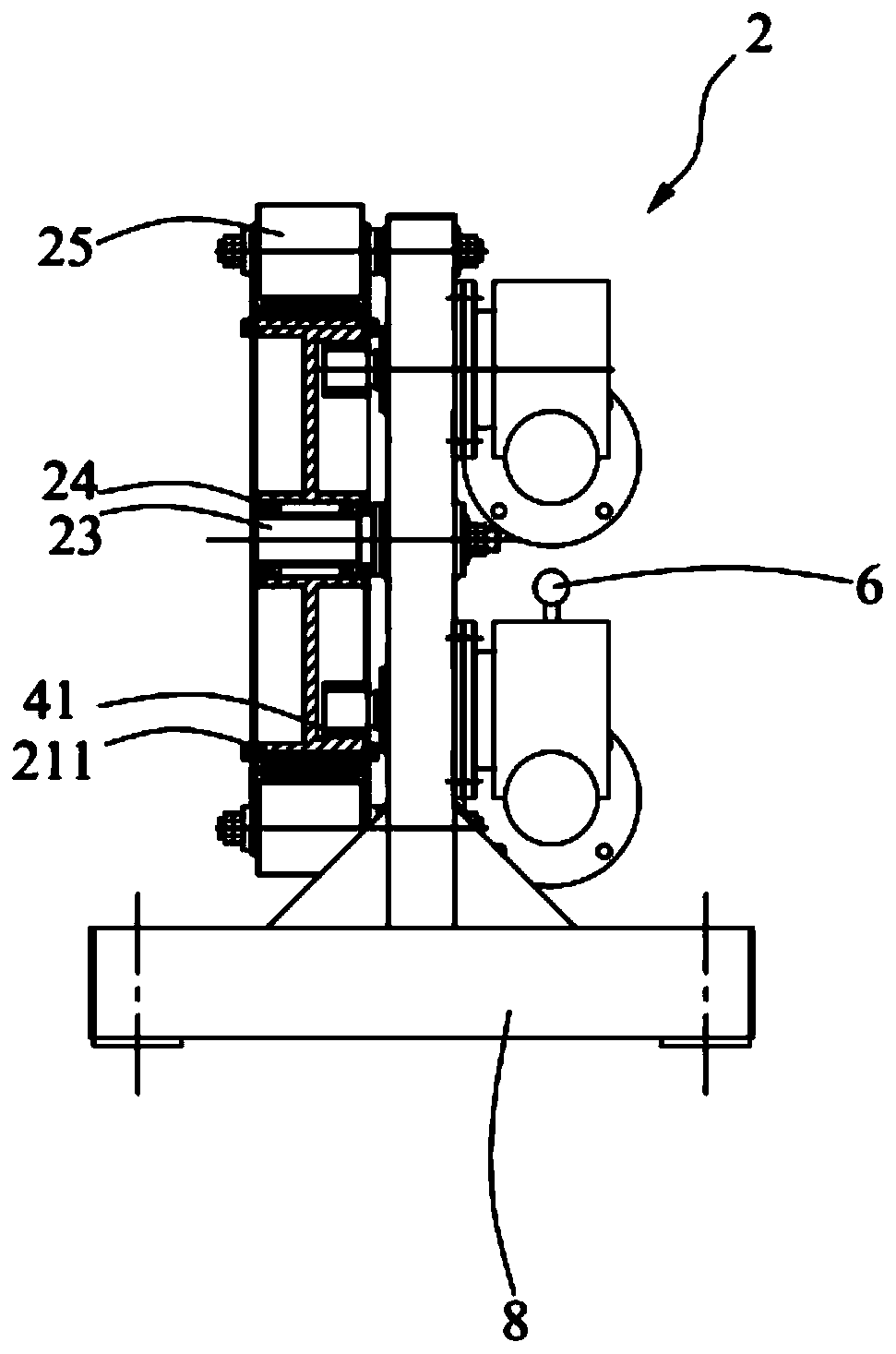

Rope retracting and releasing device

The invention belongs to the technical field of high-rise buildings, and discloses a rope retracting and releasing device. The rope retracting and releasing device comprises a rope containing cylinder, a rope retracting and releasing coiling block, a counter weight, a speed reducer and a driving source, a steel wire rope is wound around the rope containing cylinder, the end of the steel wire ropeis wound around the rope retracting and releasing coiling block and then connected to the counter weight, the speed reducer is in transmission connection with the rope retracting and releasing coilingblock, the driving source is in transmission connection with the speed reducer, and the driving source can drive the rope retracting and releasing coiling block to rotate through the speed reducer and is used for releasing and taking-up of the steel wire rope. According to the rope retracting and releasing device, through mutual cooperation of the rope retracting and releasing coiling block, thespeed reducer and the driving source, manual releasing is replaced with electric mechanical rope releasing, easy shifting can be achieved, and handiness and safety are achieved. By arranging the roperetracting and releasing coiling block, the rope retracting and releasing coiling block achieves the effects of transmission and pulling on the steel wire rope, the end of the steel wire rope is woundaround the rope retracting and releasing coiling block and then connected to the counter weight, thus the balancing effect is achieved, and falling of the steel wire rope is facilitated.

Owner:SHENXI MACHINERY

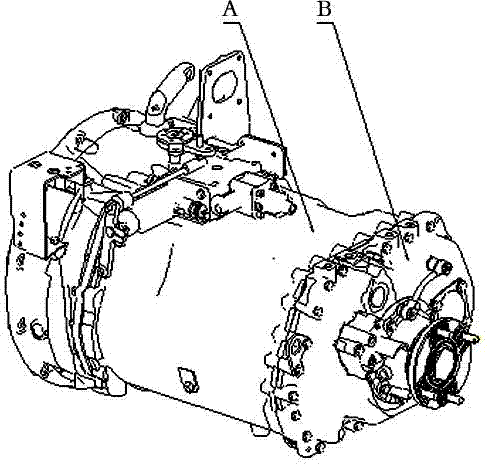

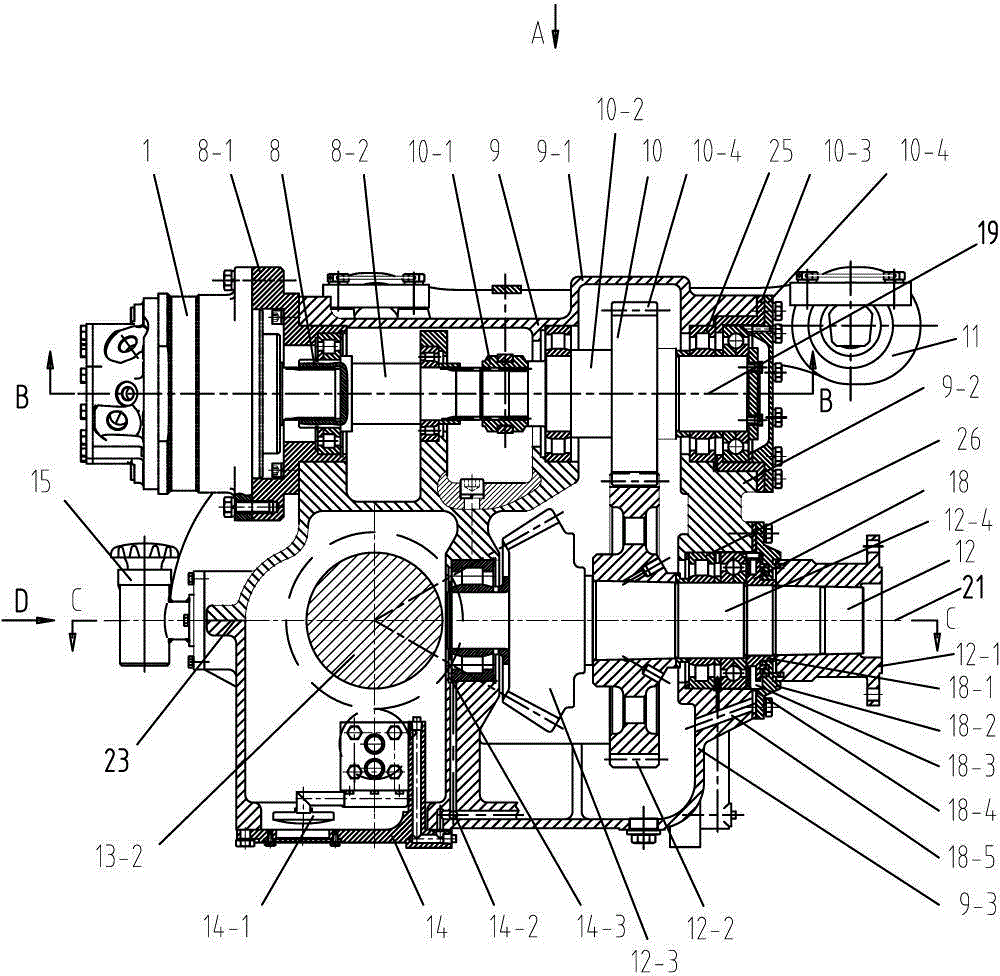

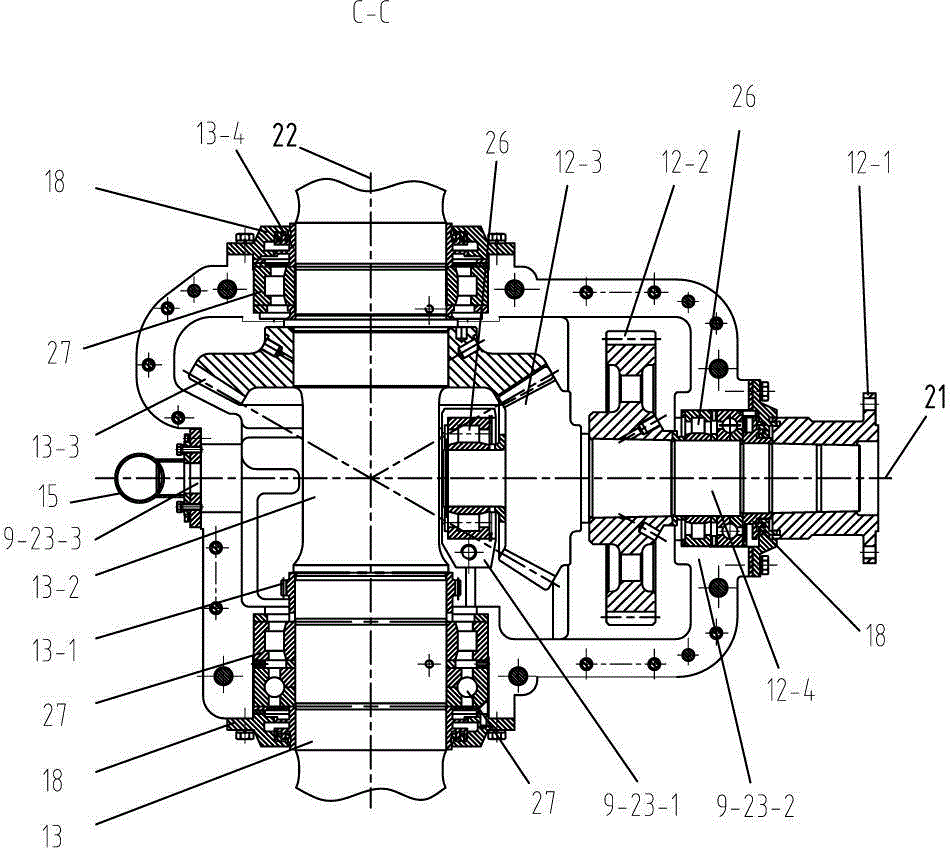

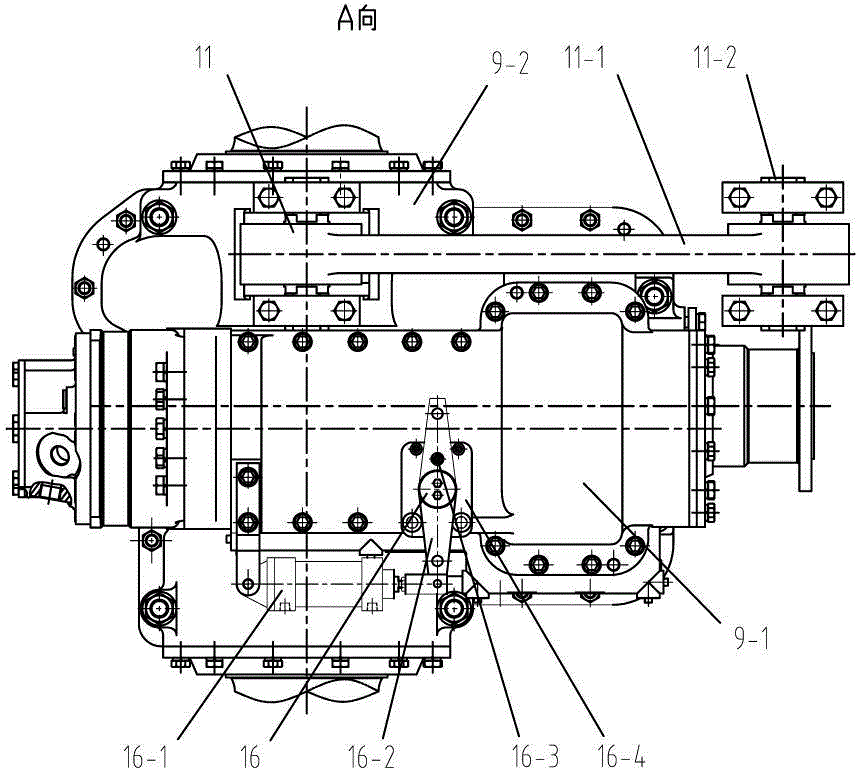

Hydraulic-hydraumatic comprehensive driving axle gear box

ActiveCN104251296BHigh speed performanceExcellent low constant speed performanceGearboxesGear lubrication/coolingDriving mode

The invention discloses a hydraulic-hydraumatic comprehensive driving axle gear box for a high-speed railway maintaining vehicle. The hydraulic-hydraumatic comprehensive driving axle gear box comprises a box assembly, a motor input spline shaft assembly, an input gear shaft assembly, a middle shaft assembly, an output shaft assembly, a gearshift assembly, a pull arm assembly, a lubricating system, a sealing structure and an aerator, wherein the box assembly comprises a box cover, an upper box body and a lower box body; the motor input spline shaft assembly and the input gear shaft assembly are mounted and supported on a bearing base hole between the box cover and the upper box body and are provided with the same first axis; the middle shaft assembly and the output shaft assembly are mounted and supported on the bearing base hole between the upper box body and the lower box body; a second axis of the middle shaft assembly and a third axis of the output shaft assembly are both located in a lower subdivision part and are vertical to each other; the second axis is parallel to the first axis and is deviated for a distance S; one end of the middle shaft of the middle shaft assembly extends out of the box assembly. The hydraulic-hydraumatic comprehensive driving axle gear box has compact layout, reasonable structure and capability of realizing the conversion of two driving modes.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

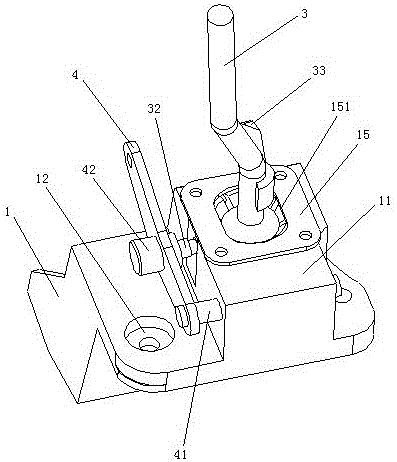

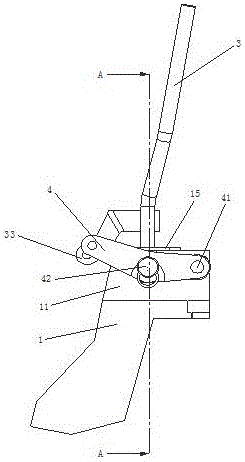

Gear-shifting controller

The invention relates to an automobile gear-shifting controller. The gear-shifting controller comprises a base, a limiting block, a control lever and a gear-shifting arm. A control lever mounting groove is formed in the top of the base, and a limiting block assembling groove is formed in the bottom of the base. A clamping groove is formed in the groove wall of one side of the control lever mounting groove. The limiting block is arranged in the limiting block assembling groove, and the top of the limiting block is provided with transverse and longitudinal guide grooves. A lever head at the lower end of the control lever is movably embedded into the control lever mounting groove. One side of the lever head at the lower end of the control lever horizontally extends outwards to form a push rod, and the bottom vertically extends downwards to form a casing pipe. The push rod movably penetrates through the clamping groove and horizontally penetrates out of the outer side of the base. A spring bolt is arranged in the casing pipe. One end of the spring bolt is sleeved with a spring bolt compressed spring, and is embedded into the casing pipe together with the spring bolt compressed spring, and the other end of the spring lock abuts against the transverse guide groove or the longitudinal guide groove and is in contact connection with the transverse guide groove or the longitudinal guide groove. One end of the gear-shifting arm is connected to one side wall of the base in a positioning mode, and the middle of the gear-shifting arm is hinged to a rod head at the end, horizontally penetrating out of the outer side of the base, of the push rod. The gear-shifting controller has the gear selecting self-resetting function, controlling comfort is high, the hand feeling is good and reliability is also high.

Owner:SHIYAN DAFENG FLEXIBLE CONTROL CABLES

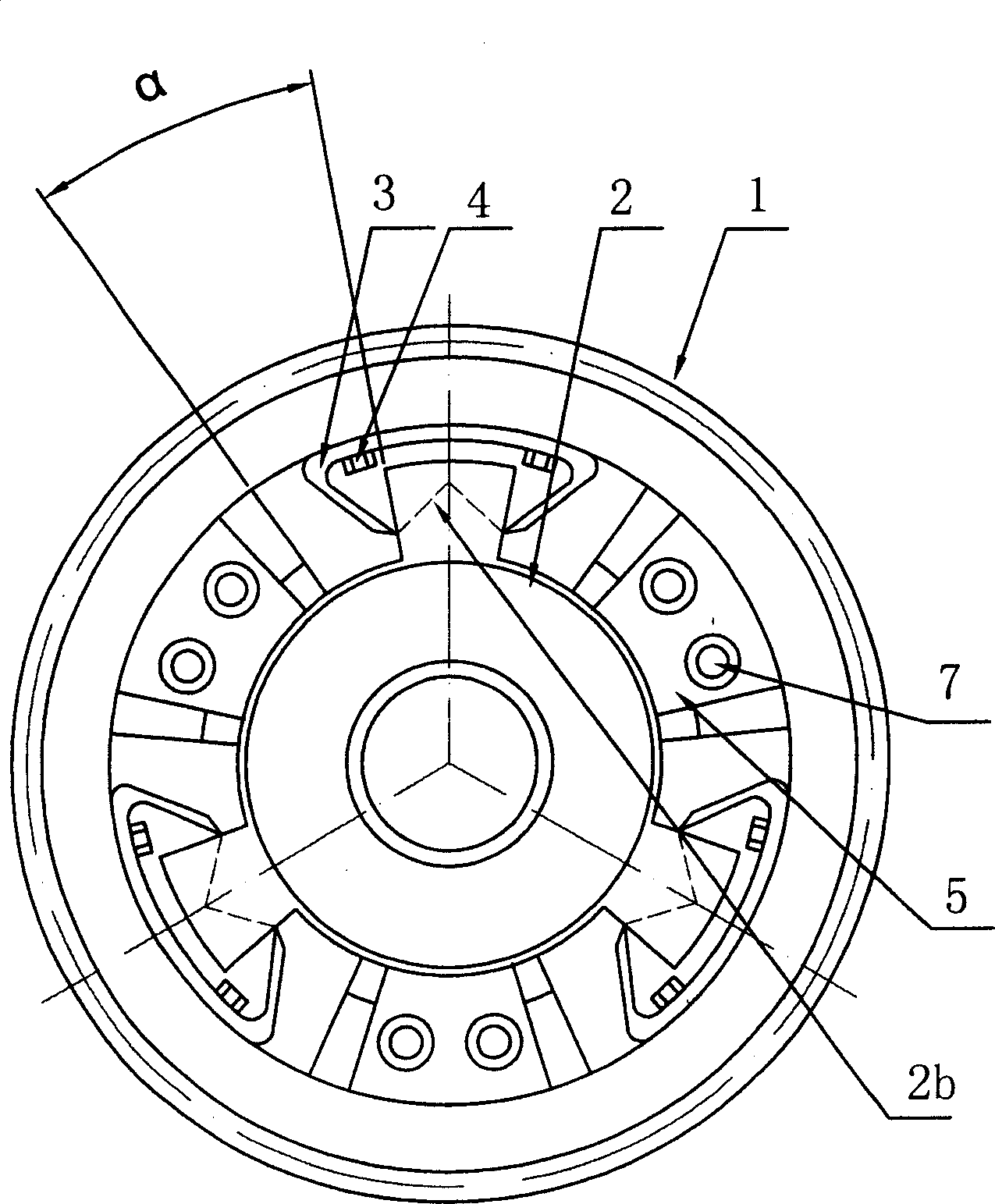

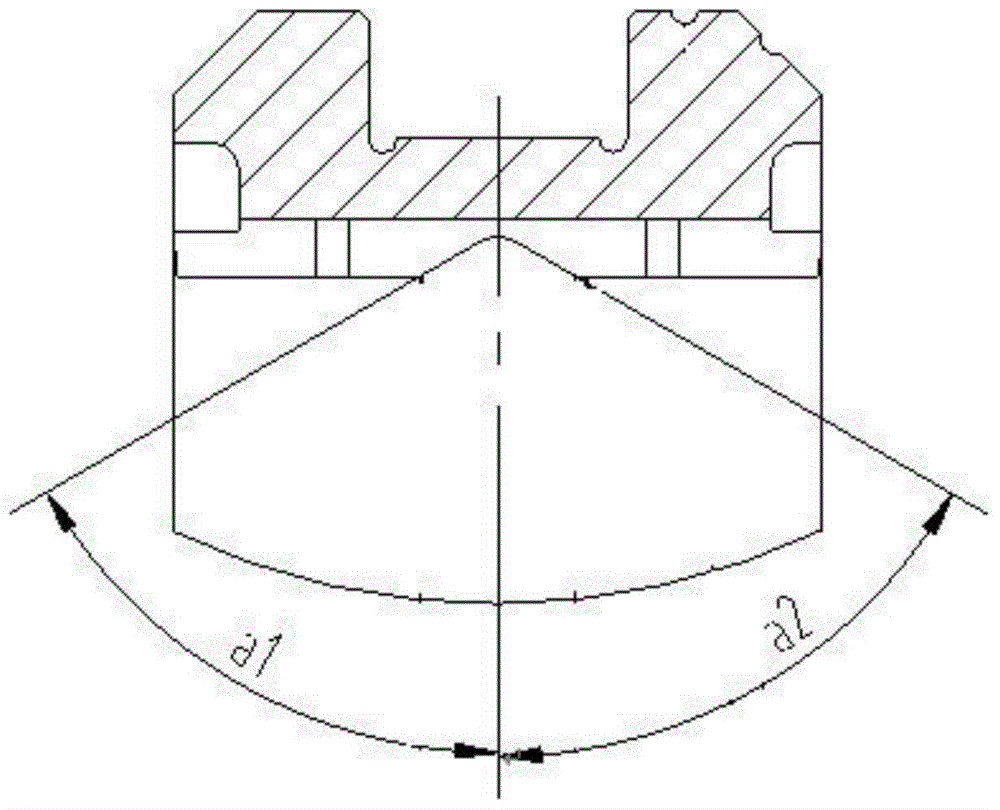

Vehicle synchronizer

InactiveCN104389918AOptimize space designSmooth shiftingMechanical actuated clutchesDriver/operatorGear wheel

The invention provides a vehicle synchronizer. The vehicle synchronizer comprises a slider, a gear sleeve, a gear hub, a synchronous ring and a gear soldered tooth, wherein the gear soldered tooth is arranged on the gear hub; the synchronous ring is arranged in the gear soldered tooth; the gear sleeve is arranged on the upper part of the synchronous ring; the slider is arranged between the gear sleeve and the synchronous ring; the slider consists of a spring, a steel ball and a drawn cup; the steel ball is in contact with a slider groove below the gear sleeve; the drawn cup is in contact with the gear hub; the slider is arranged between the gear sleeve and the gear hub. A gap between the synchronizer slider and the synchronous ring and a gap between the gear sleeve and the synchronous ring are in fit connection, the gear shifting handiness is perceived in the gear shifting process under the action of the synchronizer slider, and a driver clearly perceives the gear shifting smoothness, namely the gear shifting comfort is good; meanwhile, a gear shifting curve is good during objective evaluation.

Owner:ANHUI XINGRUI GEAR TRANSMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com