Gear-shifting controller

A manipulator, joystick technology, applied in the direction of elements with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of high reliability, low cost, poor operating comfort, poor effectiveness, etc., to achieve reliability High, low manufacturing cost, easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

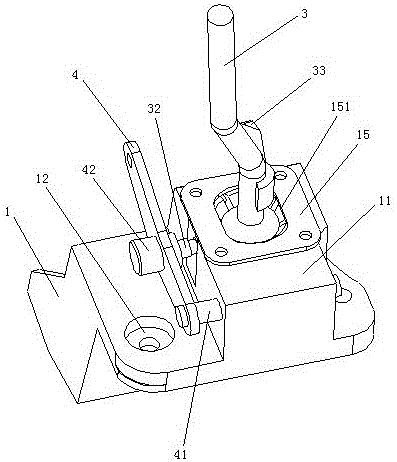

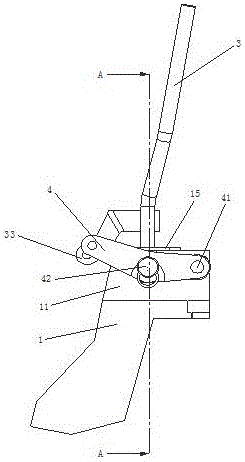

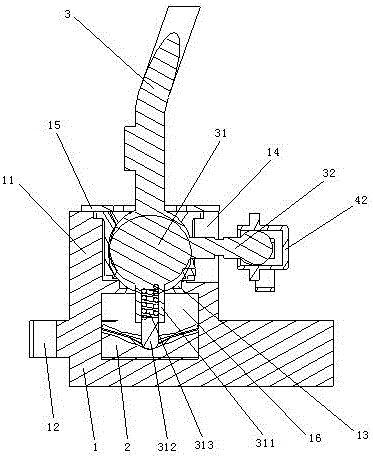

[0018] Such as Figures 1 to 6 As shown, the shift manipulator of the present invention includes a base 1 , a limit block 2 , a joystick 3 and a shift arm 4 .

[0019] The base 1 protrudes upwards from the top and is provided with a mounting boss 11, and a base fixing hole 12 is provided longitudinally on both sides of the mounting boss 11, and a joystick mounting groove 13 is opened downward from the top of the mounting boss 11; the joystick The groove wall on one side of the mounting groove 13 is provided with a draw-in groove 14 downward from the center of the top, and the upper end surface of the notch of the joystick mounting groove 13 is also fixedly equipped with a limit cover plate 15, and the middle part of the limit cover plate 15 is provided with a first pass. Hole 151. Wherein, the base 1 is provided with a limit block assembly groove 16 upward from the bottom, and the limit block assembly groove 16 is set up and down correspondingly with the joystick installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com