Novel gear selecting and shifting mechanism assembly for speed changer

A technology for transmission and gear selection, which is applied in the field of auto parts, can solve the problems of high requirements for drivers' driving skills and difficult shifting, and achieves the effects of compact structure, easy shifting and avoiding contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

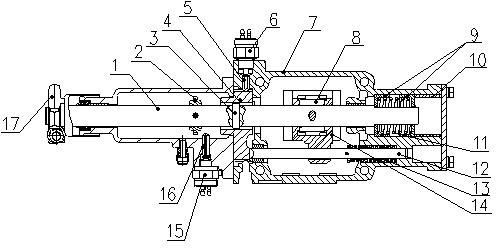

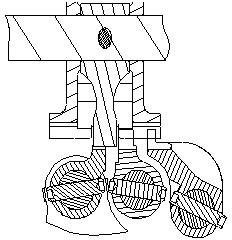

[0029] Aiming at the double countershaft transmission newly designed by our company for main box synchronizer shifting, on the basis of the existing gear selection and shifting mechanism, adaptive development is carried out to obtain a new type of transmission shifting mechanism assembly, that is, when the main box of the transmission adopts the synchronizer When shifting gears, it can make the gear selection and shifting process of the transmission reliable, light and stable.

[0030] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

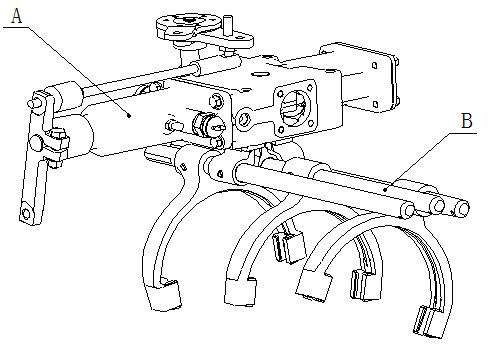

[0031] figure 1 Shown is the structural representation of the present invention.

[0032] The present invention provides a novel transmission gear selection and shifting mechanism assembly, which includes a small cover assembly A and a shift fork shaft assembly B.

[0033] Part A of the small cover assembly completes the operation of selecting and shifting gears, and part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com