Module combined multifunctional threshing machine

A thresher and combined technology, applied in the fields of threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of occupying a large space, increasing the difficulty, and entraining a lot of debris, so as to increase production costs and reduce maintenance. The effect of using cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

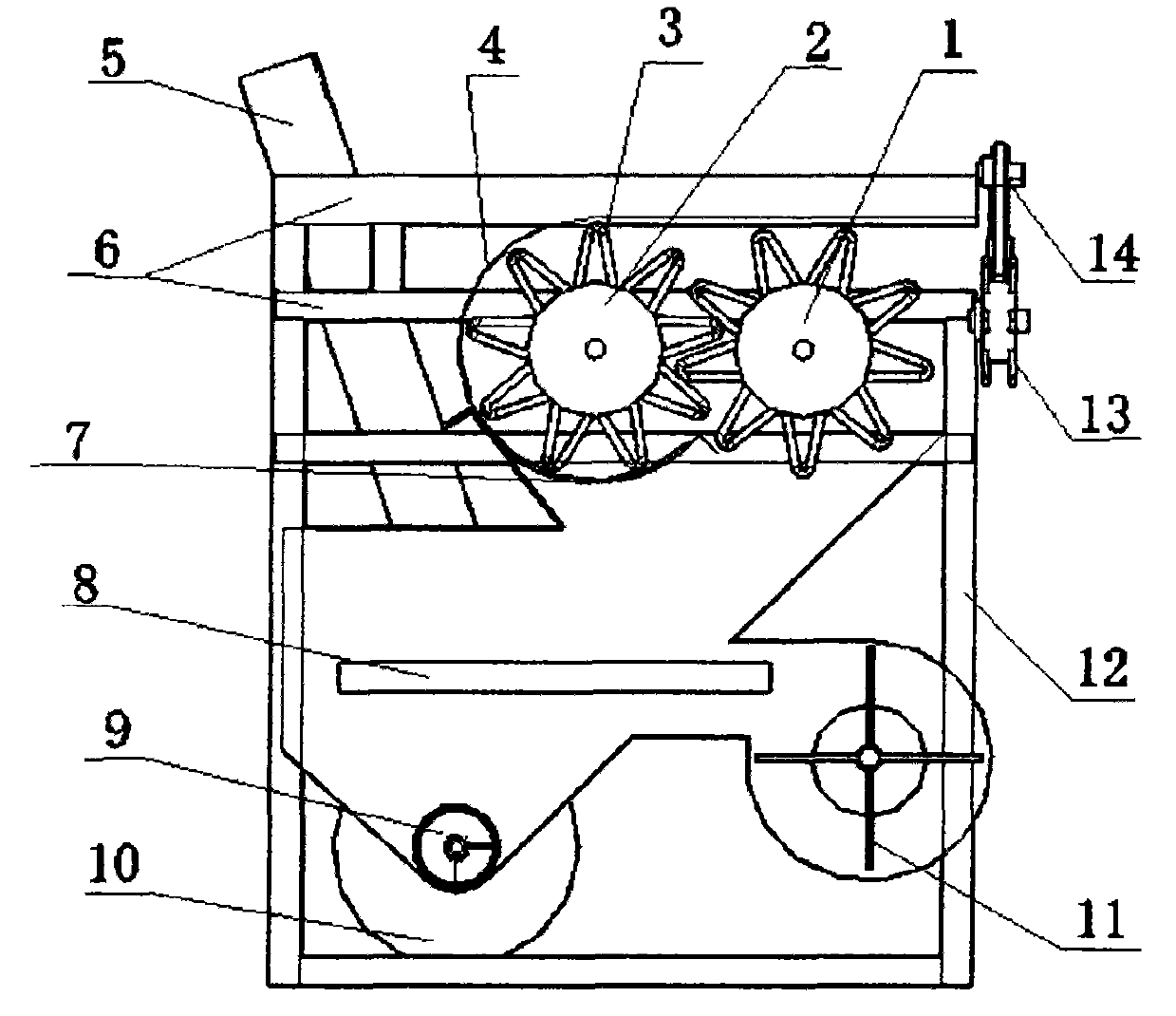

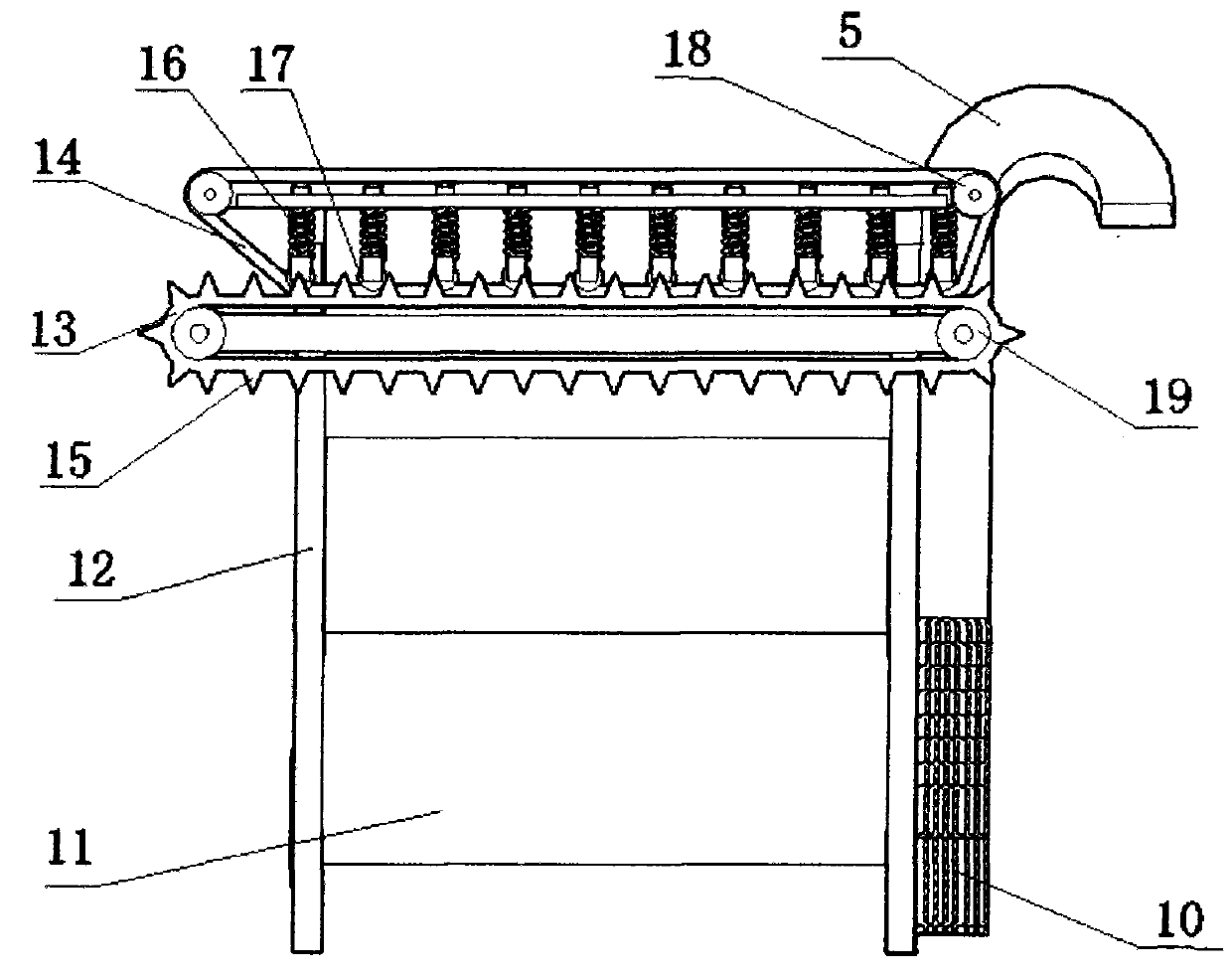

[0026] Such as figure 1 , 2 As shown, the threshing machine described in this embodiment is equipped with a rice, wheat, and bean feeding threshing module, and the threshing machine includes a shared cleaning frame 12, a transmission mechanism, a screening and impurity removal mechanism, a screw feeding mechanism, and a net grain blowing out mechanism. The mechanism also includes a feeding threshing module for rice, wheat and beans. The cleaning frame 12 is supported on the ground. There is an installation space reserved inside the cleaning frame 12, and a screening and impurity removal mechanism, a screw feeding mechanism, and a cleaning frame are provided. The grain blowing mechanism, the three mechanisms are wrapped in the same space by the shell, wherein, at the lower end of the feeding threshing module, the shell is in the shape of an inclined funnel, which is used to guide the detached crop particles to the screening and impurity removal mechanism.

[0027] The screenin...

Embodiment 2

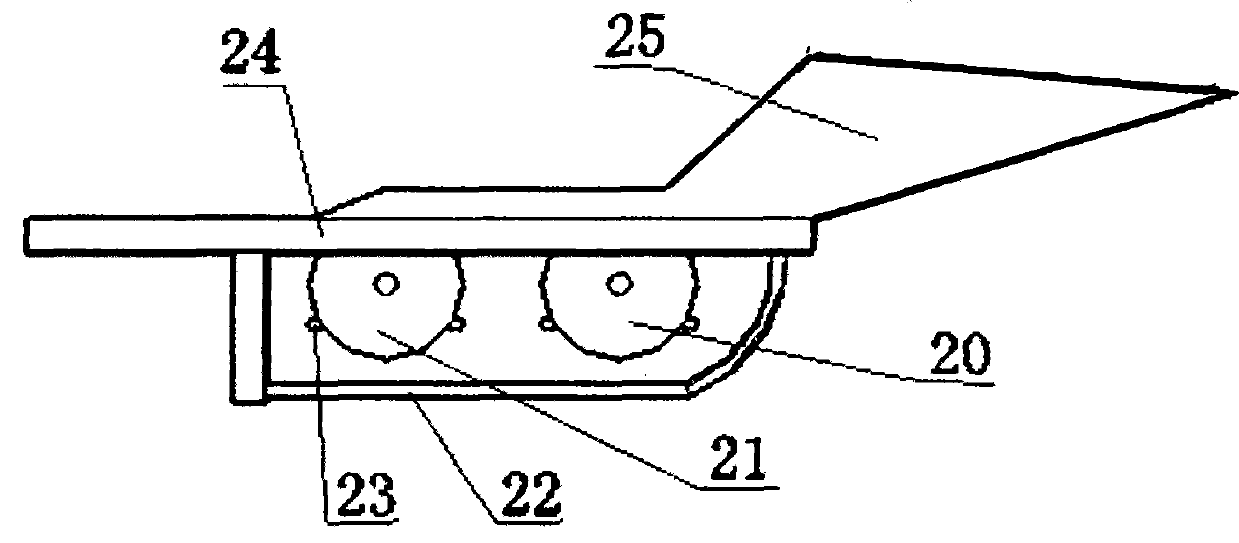

[0032] Such as image 3 , 4 As shown, the threshing machine described in this embodiment is equipped with a corn feeding threshing module, and the structure and function of its functional mechanism are consistent with the corresponding mechanism described in Example 1. The difference is that the corn feeding threshing module includes a front Threshing roller 20, rear threshing roller 21, steel bar 22, dial bar 23, corn threshing frame 24, feeding hopper 25; feeding hopper 25 is provided with a feeding port, and feeding hopper 25 extends to the rear threshing roller 21 above, the front threshing roller 20 and the rear threshing roller 21 are provided with a dial bar 23, and the surroundings of the front threshing roller 20 and the rear threshing roller 21 are provided with a casing, and a space for accommodating the corn to be threshed is formed between them. The screen 22 is provided below the front threshing roll 20 and the rear threshing roll 21 .

[0033] During work, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com