Dual-middle-shaft all synchromesh ten-gear transmission

A technology of double intermediate shafts and synchronizers, which is applied to gear transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of high driving skills requirements, difficult shifting, complicated assembly, etc., and achieve transmission speed ratio Reasonable allocation, simple structure, and the effect of reducing shift time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

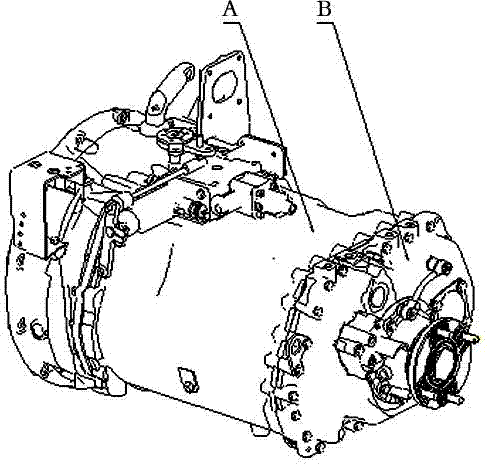

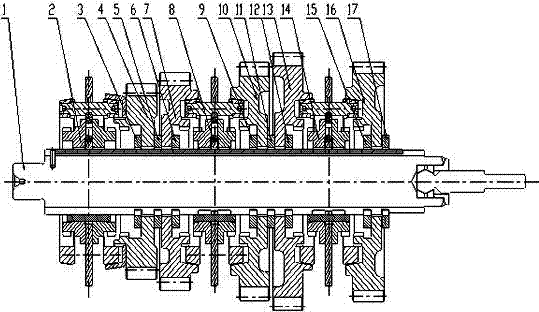

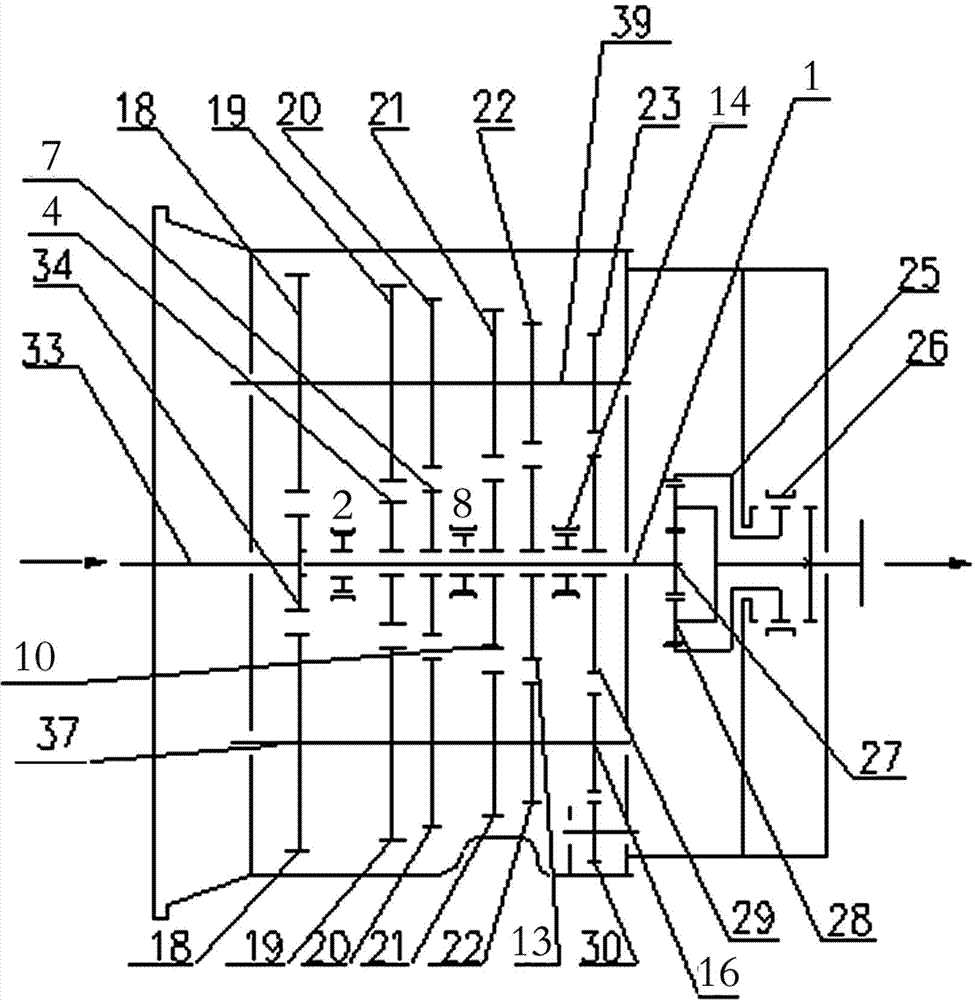

[0023] As shown in the attached figure, a ten-speed transmission with dual intermediate shafts and full synchronizer is a two-stage structure composed of a main box and an auxiliary box. There is a main transmission in the main box, and an auxiliary transmission in the auxiliary box. The main transmission has five forward gears. and one reverse gear, the auxiliary transmission has two gears, constitutes a 5×2 structure, forming ten forward gears and two reverse gears, the main transmission includes an input mechanism and a speed change mechanism, and the input mechanism includes an input shaft and two Subshafts-left subshaft 37 and right subshaft 39; the transmission mechanism includes a main shaft 1, an idler 30, a main shaft shifting self-energizing lock pin synchronizer 2 that is splined to the main shaft 1 and can sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com