Follow-up type power assisting gear shifting operation device

A control device and follow-up technology, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as inability to arrange, limited space for vehicle layout, and small space occupied by the control system. , to achieve the effect of clear gear position, light shifting and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

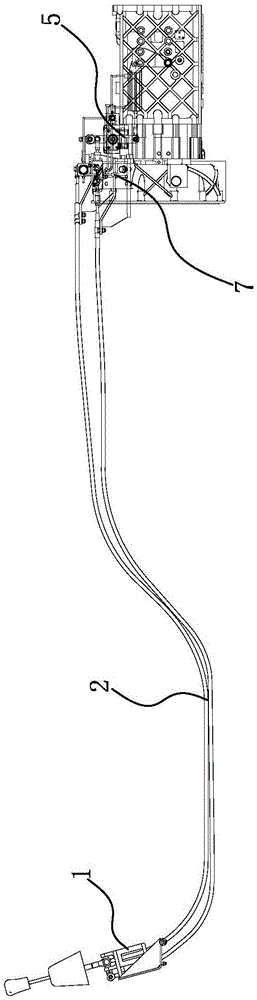

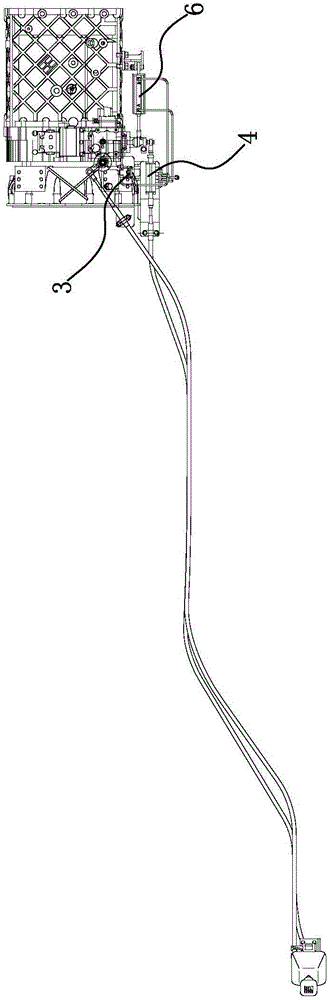

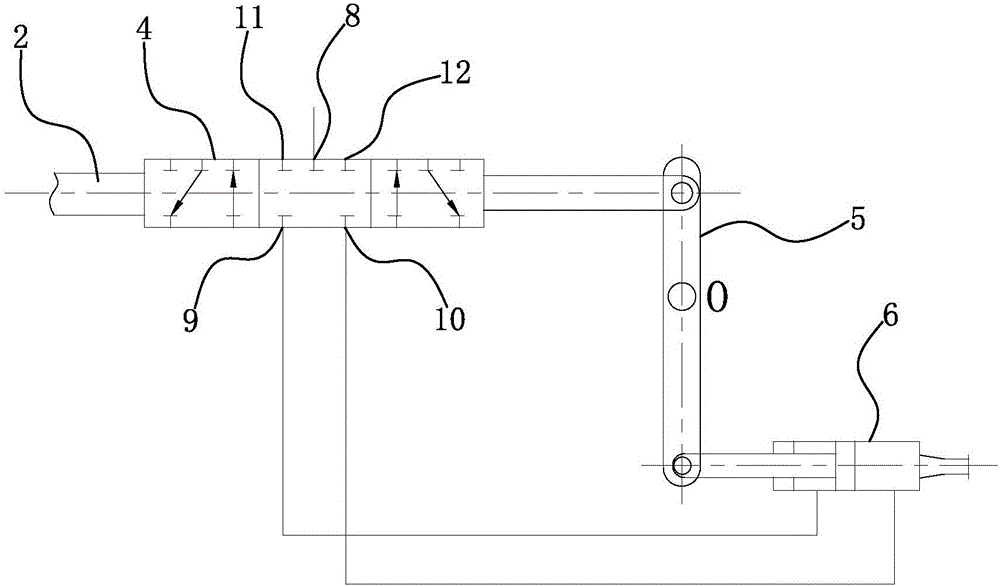

[0013] Such as figure 1 shown, combined with figure 2 As shown, the follow-up power-assisted shifting control device of the present invention includes a controller 1, a shifting flexible shaft 2, a control valve 4, a shifting rocker arm 5 and a booster cylinder 6, and the controller 1 communicates with the shifting flexible shaft 2 and The spool of the control valve 4 is connected, the other end of the spool is hinged to the shift rocker arm 5, the other end of the shift rocker arm 5 is hinged to the piston rod of the booster cylinder 6, and the shift rocker arm 5 is used to be fixedly connected with the spline shaft of the gearbox. The control valve 4 is provided with an air inlet 8, two air outlets and two exhaust ports. The two air outlets of the control valve 4 are respectively connected to the Both sides of the cylinder barrel of the booster cylinder 6 are communicated.

[0014] In the present invention, the follow-up power-assisted shifting control device, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com