Non-circular gear-based variable transmission mechanism

A technology of variable speed transmission and non-circular gears, which is applied to gear transmissions, transmissions, components with teeth, etc., can solve the problems of low transmission efficiency, complex structure, high cost, etc., and achieve low cost, simple speed change process, and easy to use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

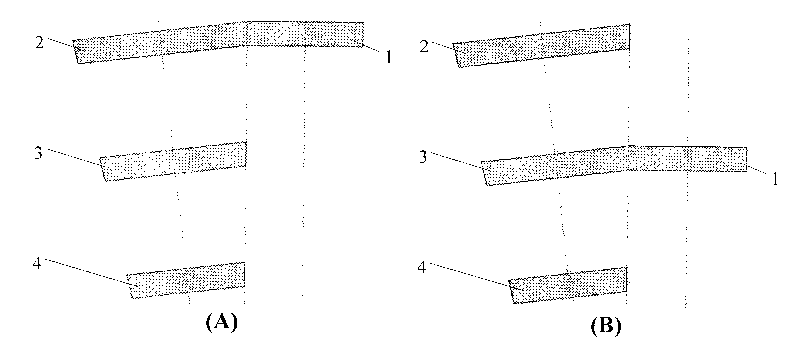

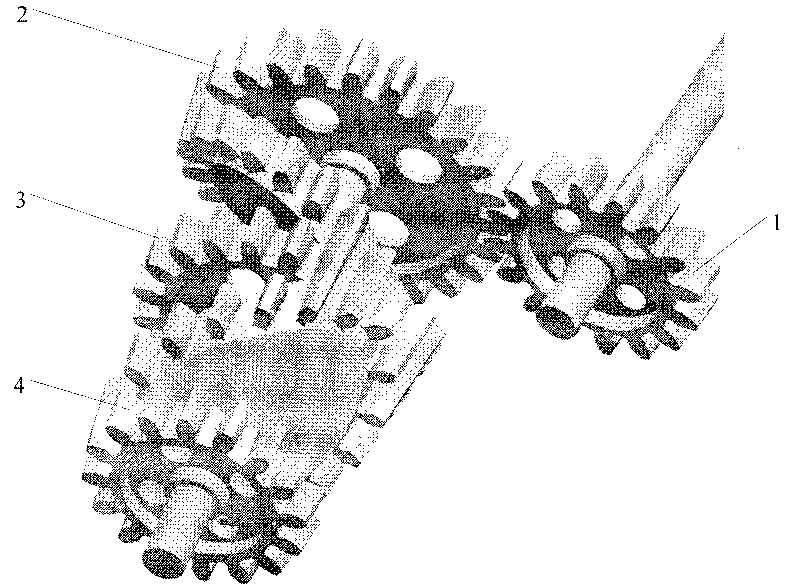

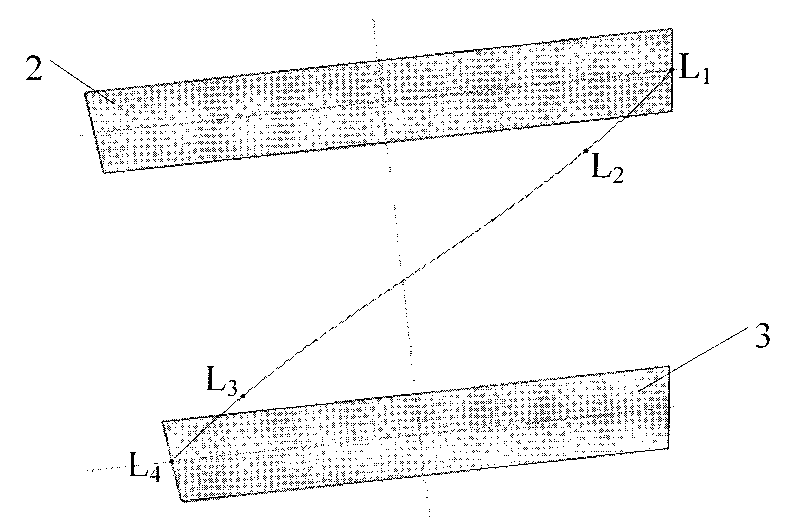

[0026] As we all know, the non-circular gear speed change transmission mechanism has two characteristics: one is that it can change speed without stopping, that is, when changing the meshing transmission ratio of the driving wheel and the driven wheel, there is no need for the gear to stop running, but it can maintain the original speed. Under the premise, gear shifting is realized, thereby improving the operating efficiency of the mechanism; second, the speed change transmission mechanism is not limited to the transformation of one or two gears, and the mechanism can be used to realize the transformation of multi-stage transmission ratios.

[0027] see Figure 1 to Figure 4 , to introduce the general structure of the non-circular gear speed change transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com