Electromechanically-integrated cycloidalpin wheel drive device

A technology of cycloidal pinwheel and driving device, which is applied in the direction of gear transmission, transmission, transmission control, etc. It can solve the problems of axial distance extension, system reliability reduction, power cannot be divided, etc., and reduce the installation size and weight, reducing the number of installation and positioning, and improving the force condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

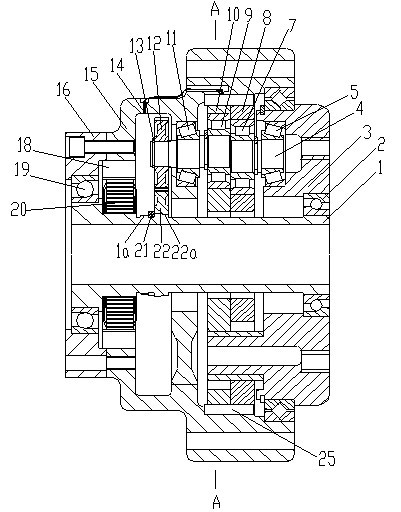

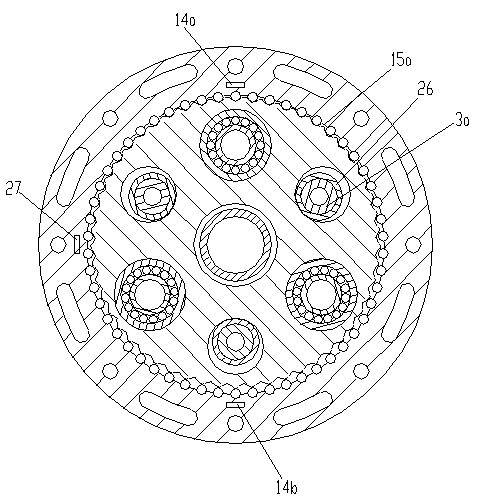

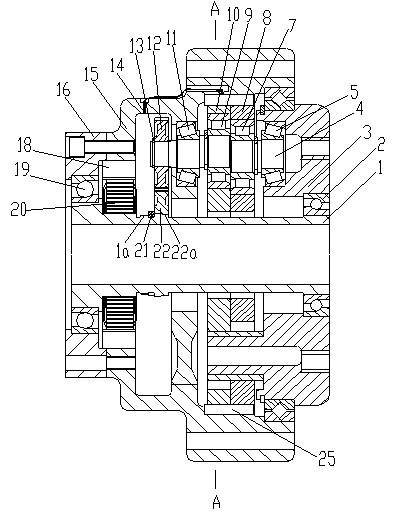

[0025] attached figure 1 Schematic diagram of the structure of the electromechanical integrated cycloid drive device, attached figure 2 for figure 1 Sectional view along A-A direction. As shown in the figure, the electromechanical integrated cycloidal pinwheel driving device of this embodiment is an electromechanical integrated cycloidal pinwheel driving device, which is characterized in that it includes a cycloidal pinwheel reducer assembly, a high-speed cylindrical gear meshing pair, Servo motor, hollow input shaft 1 and power output shaft 3;

[0026] The cycloid pin wheel planetary reducer assembly includes three power eccentric input shafts 4 uniformly arranged in the circumferential direction, pin teeth 25, double row planetary gears 8 and 10, power output shaft 3 and reducer housing 15, the power The eccentric journal section of the eccentric input shaft rotates with the double-row planetary wheel through cylindrical rolling bearings 7 and 9, and one end of the non-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com