Intelligent filtering and driving device

A driving device and intelligent filtering technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve the problems of reduced system reliability, increased number of parts and increased loss of parts, etc., to reduce the number of installation and positioning, reduce Volume and weight, the effect of increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

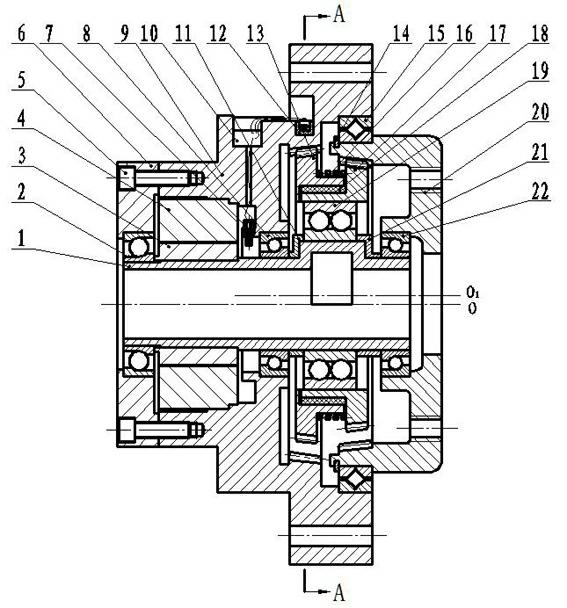

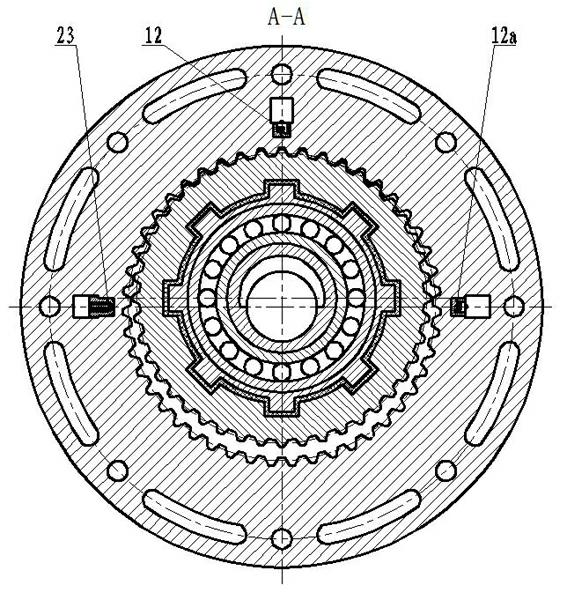

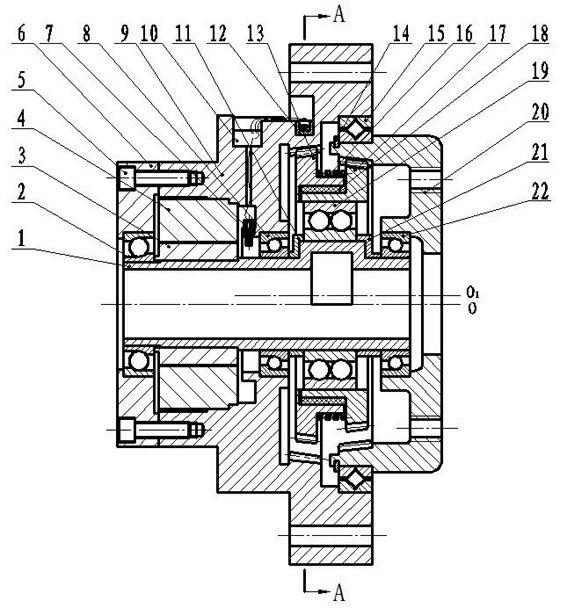

[0027] figure 1 The meanings of the parts represented by the reference signs in the are as follows: 1—power input eccentric shaft; 2—support bearing; 3—rotor; 4—stator; 5—set screw; 6—end cover; 7—speed sensor; 8— Bearing III; 9—fixed internal gear; 10—circuit board; 11—pillow block; 12, 12a—acceleration sensor; 13—external gear I; 14—bearing retaining ring; 15—cross bearing; 16—compression spring; 17 —external gear II; 18—elastic body; 19—bearing I; 20—power output internal gear; 21—retaining ring; 22—bearing II; 23—temperature sensor.

[0028] Such as figure 1 As shown, the intelligent filter driving device includes a filter reducer assembly and a servo motor; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com