Patents

Literature

243 results about "Displacement error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EUV light source

ActiveUS20050199829A1Sufficient sizeSufficient thermal massNanoinformaticsRadioactive sourcesControl systemDisplacement control

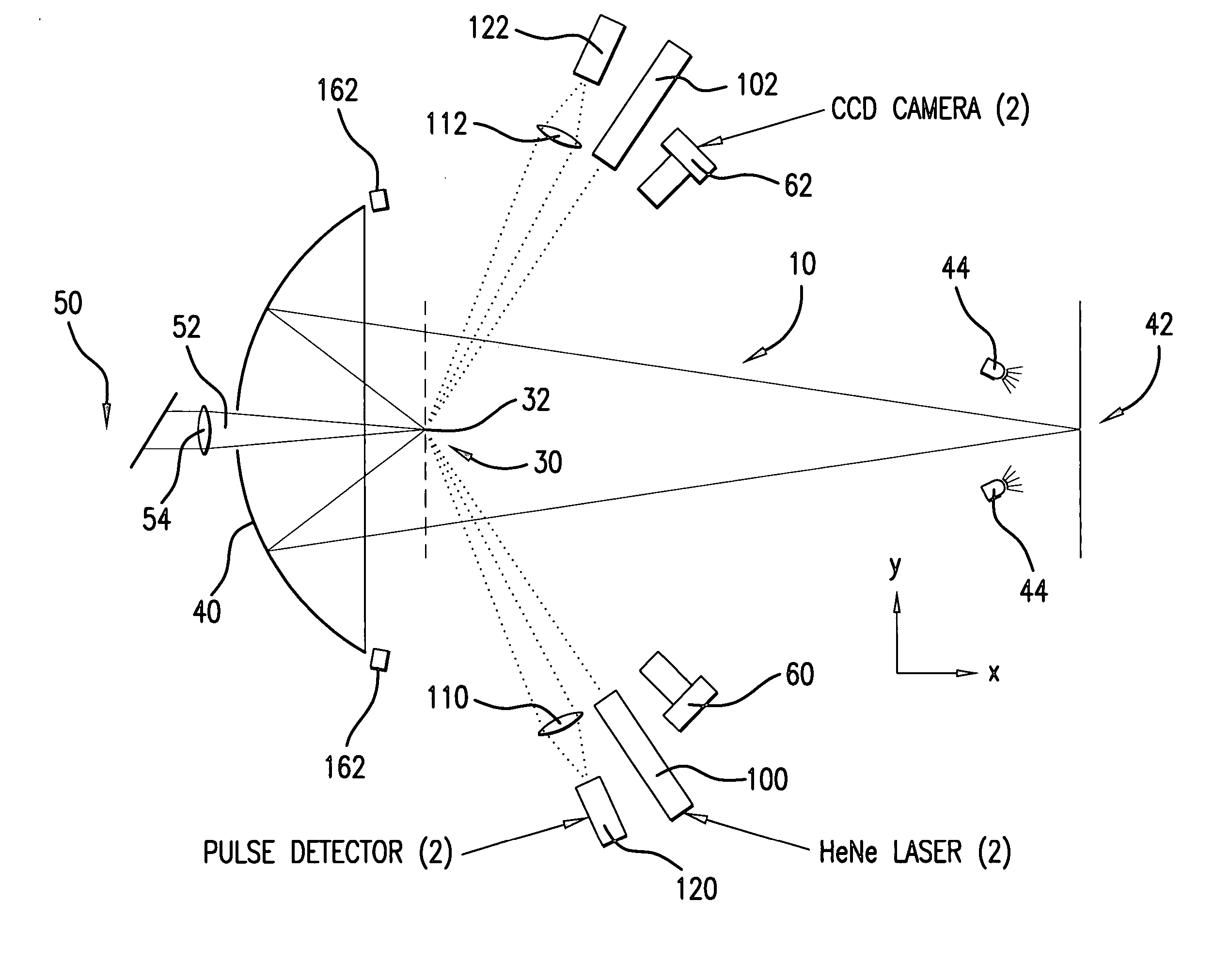

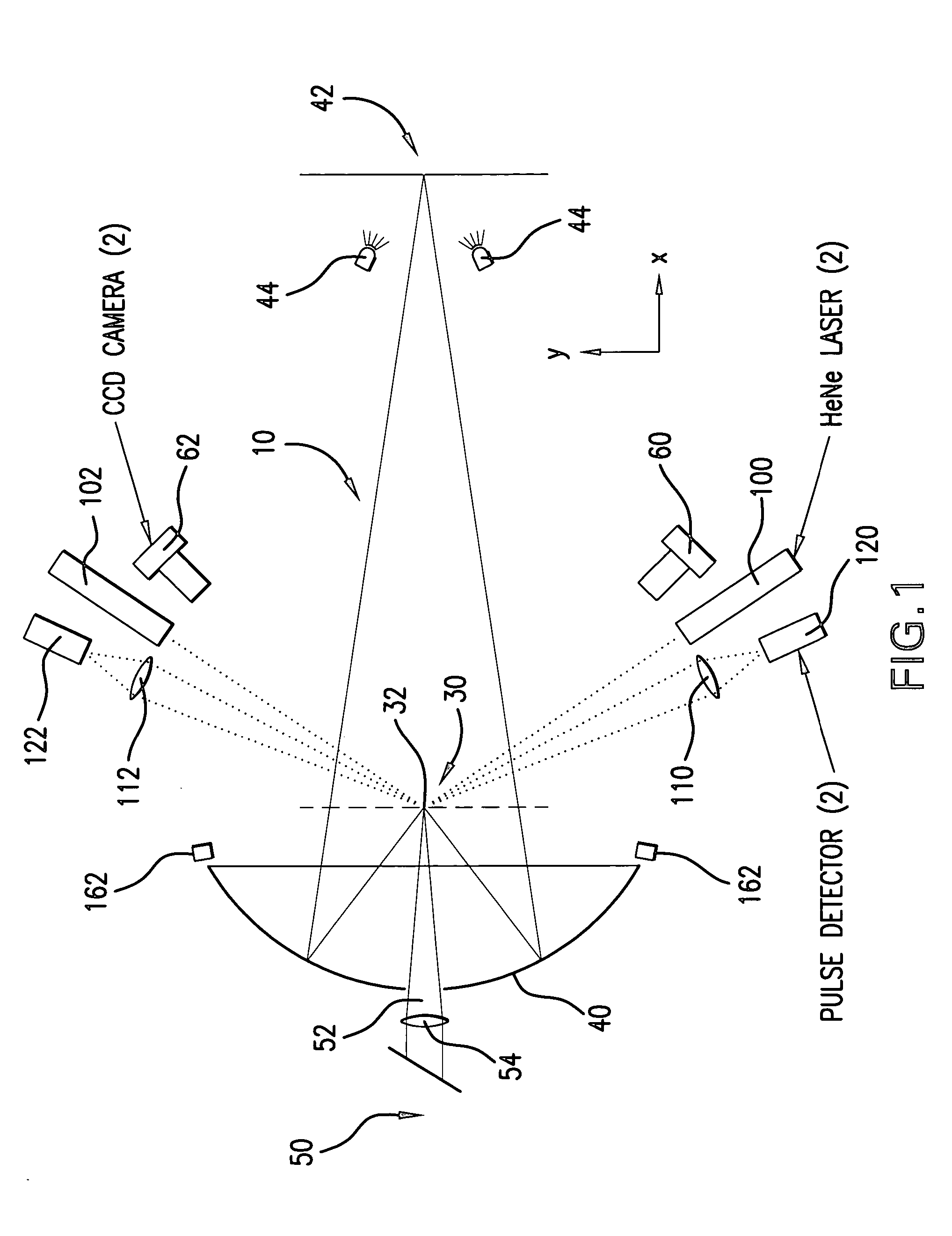

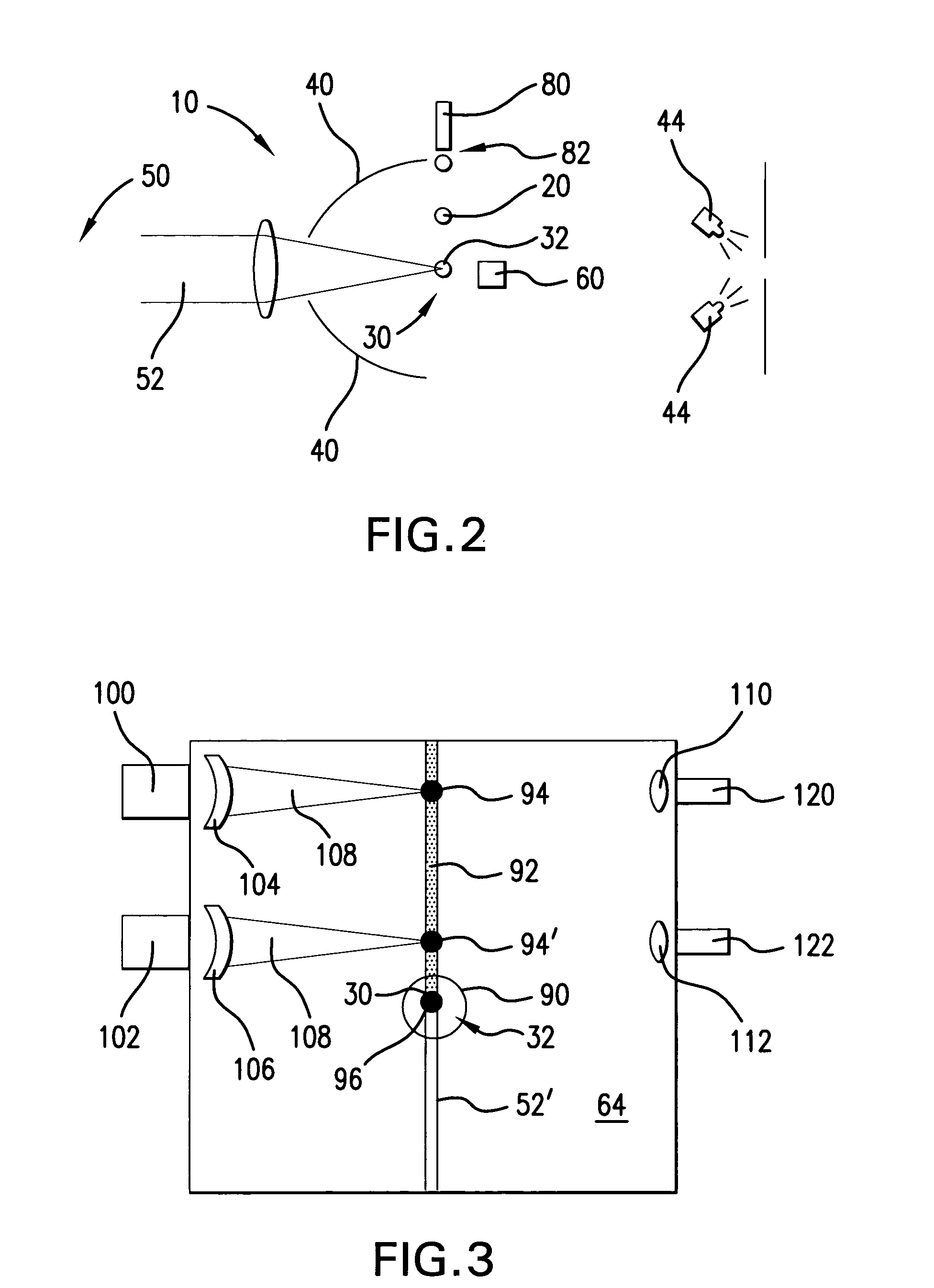

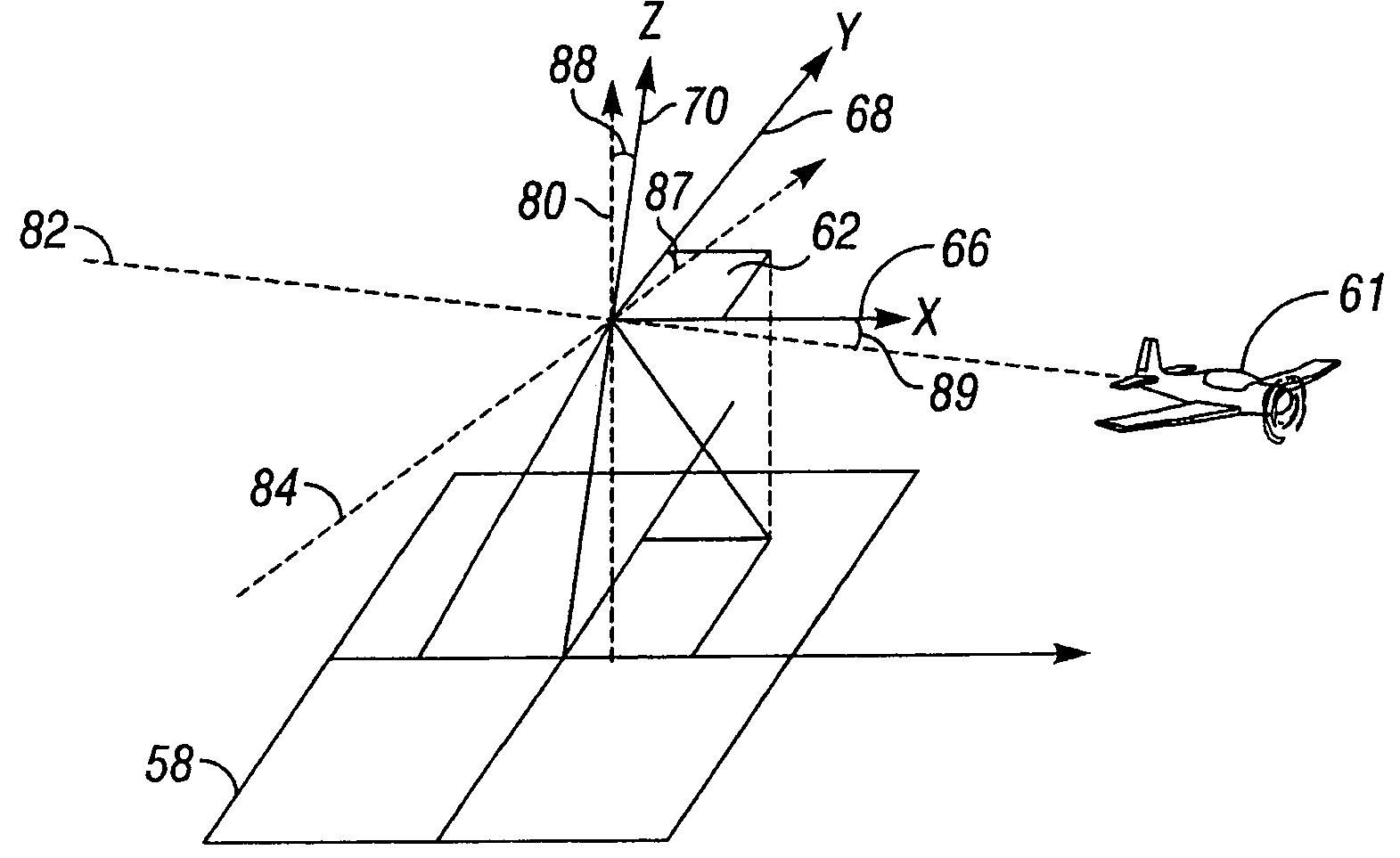

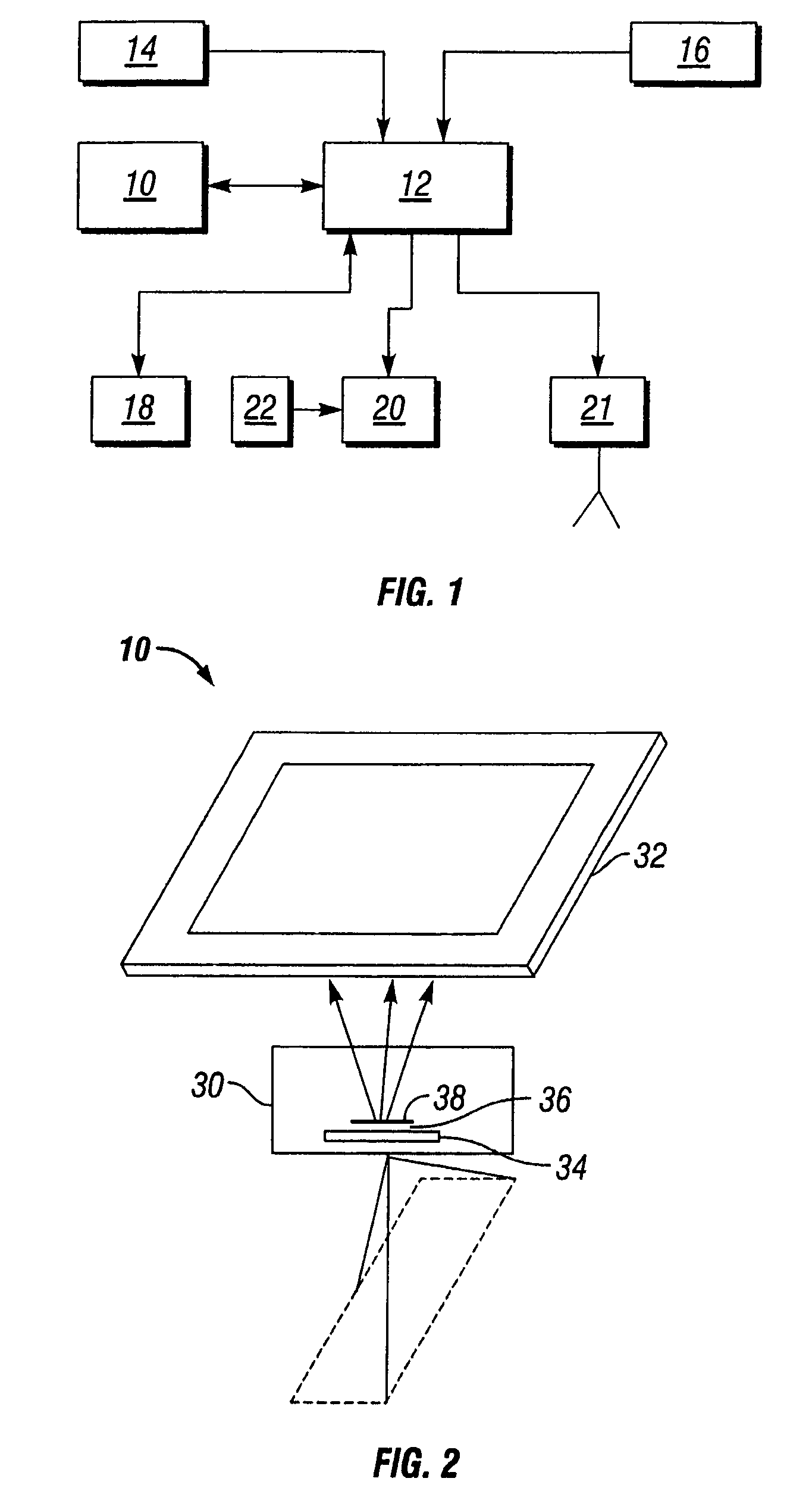

An apparatus and method for EUV light production is disclosed which may comprise a laser produced plasma (“LPP”) extreme ultraviolet (“EUV”) light source control system comprising a target delivery system adapted to deliver moving plasma initiation targets and an EUV light collection optic having a focus defining a desired plasma initiation site, comprising: a target tracking and feedback system comprising: at least one imaging device providing as an output an image of a target stream track, wherein the target stream track results from the imaging speed of the camera being too slow to image individual plasma formation targets forming the target stream imaged as the target stream track; a stream track error detector detecting an error in the position of the target stream track in at least one axis generally perpendicular to the target stream track from a desired stream track intersecting the desired plasma initiation site. At least one target crossing detector may be aimed at the target track and detecting the passage of a plasma formation target through a selected point in the target track. A drive laser triggering mechanism utilizing an output of the target crossing detector to determine the timing of a drive laser trigger in order for a drive laser output pulse to intersect the plasma initiation target at a selected plasma initiation site along the target track at generally its closest approach to the desired plasma initiation site. A plasma initiation detector may be aimed at the target track and detecting the location along the target track of a plasma initiation site for a respective target. An intermediate focus illuminator may illuminate an aperture formed at the intermediate focus to image the aperture in the at least one imaging device. The at least one imaging device may be at least two imaging devices each providing an error signal related to the separation of the target track from the vertical centerline axis of the image of the intermediate focus based upon an analysis of the image in the respective one of the at least two imaging devices. A target delivery feedback and control system may comprise a target delivery unit; a target delivery displacement control mechanism displacing the target delivery mechanism at least in an axis corresponding to a first displacement error signal derived from the analysis of the image in the first imaging device and at least in an axis corresponding to a second displacement error signal derived from the analysis of the image in the second imaging device.

Owner:ASML NETHERLANDS BV

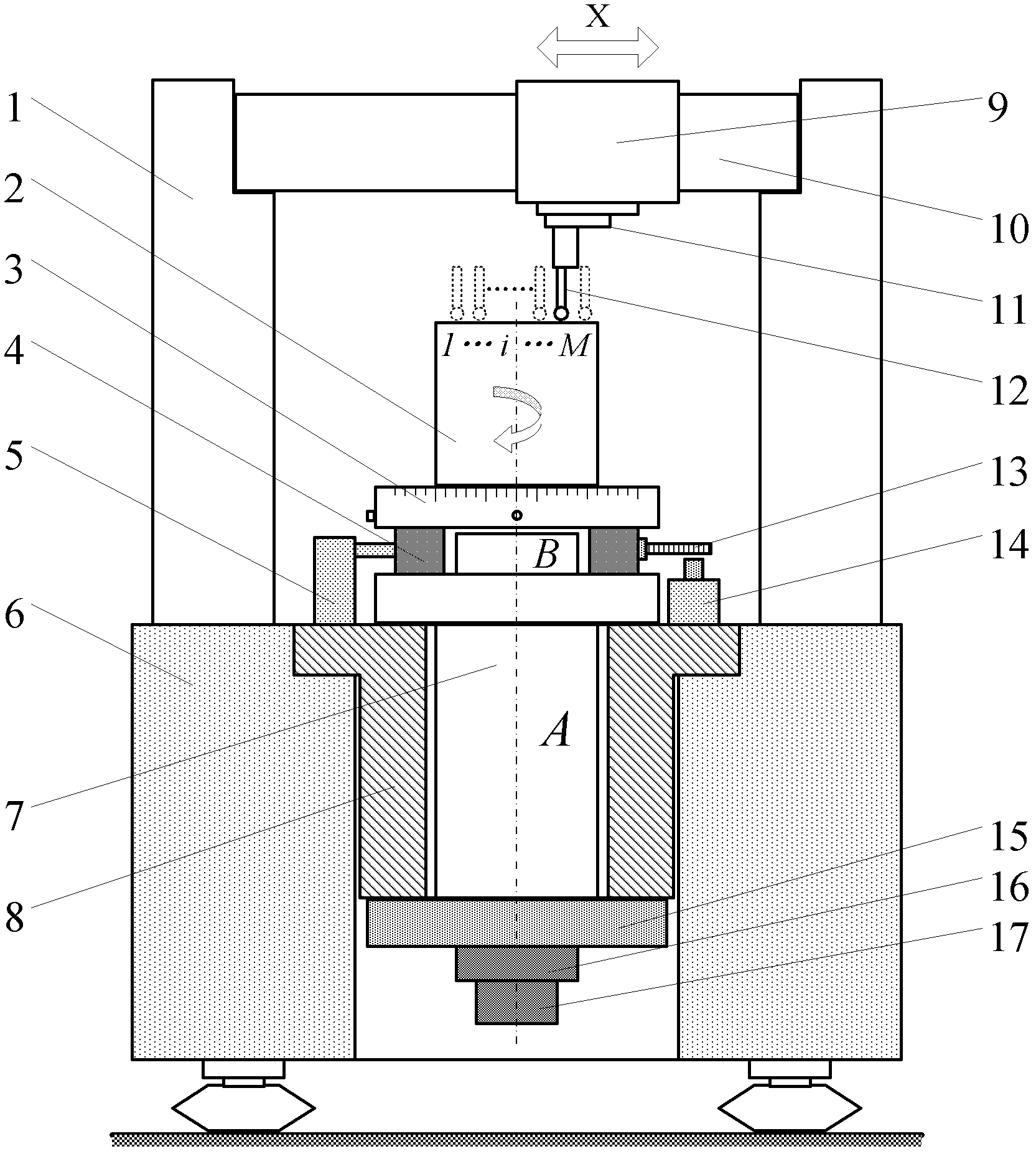

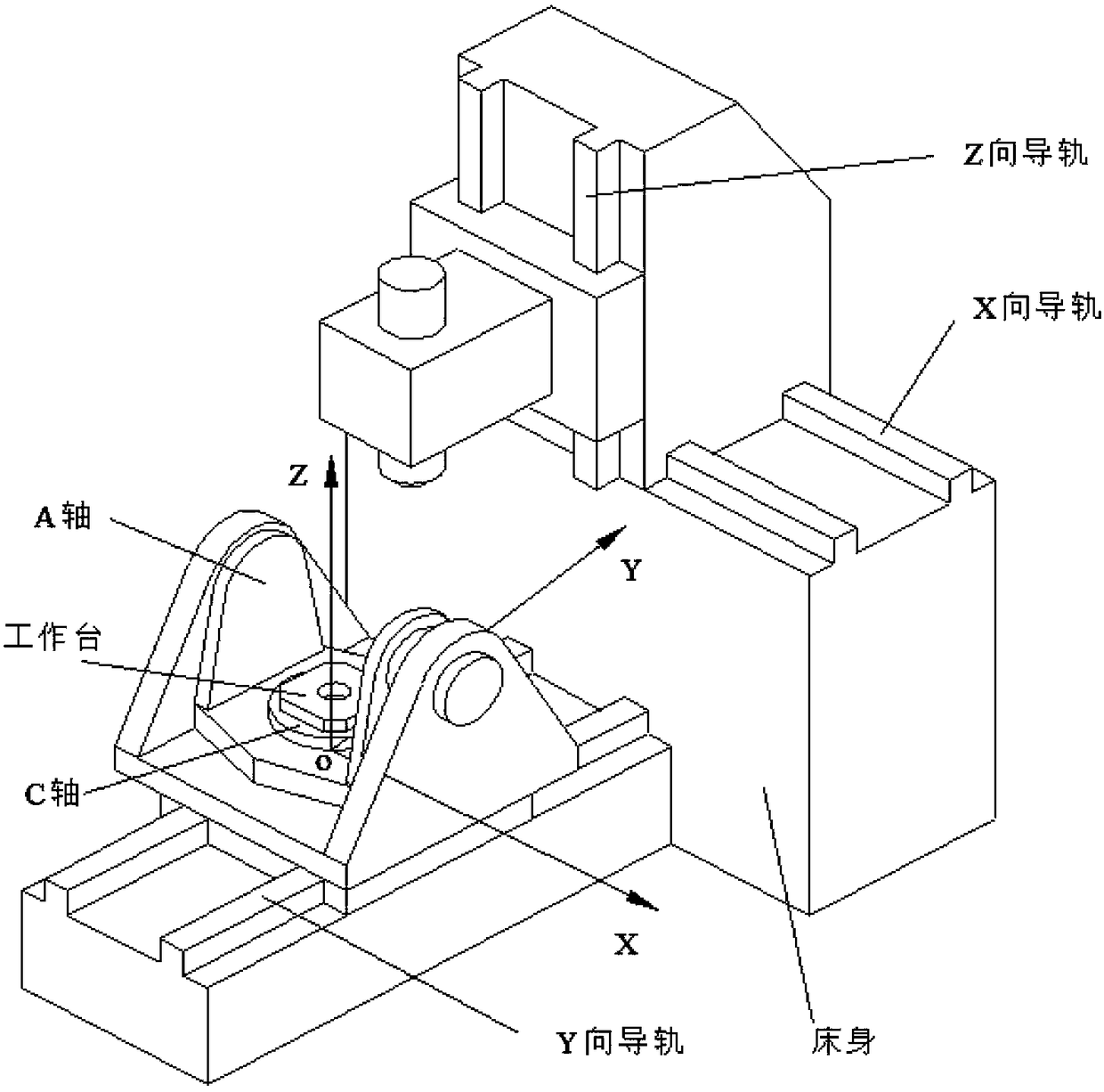

Method for measuring geometric error parameter value of rotary oscillation axis of five-axis linkage numerical control machine tool

The invention discloses a method for measuring a geometric error parameter value of a rotary oscillation axis of a five-axis linkage numerical control machine tool. The method comprises the following steps of: measuring displacement errors of X, Y and Z directions on at least three positions under different rotating angles of the rotary oscillation axis respectively by using a ballbar, wherein translation axis linkage coordinates provided by a revolving tool central point (RTCP) cutter central point movement control function of a five-axis machine tool serve as measurement datum; and performing data processing according to the displacement errors to identify and calculate the geometric error of each rotating angle of the rotary oscillation axis. The rotary oscillation axis is measured independently by the method, so the geometric error value of the five-axis linkage numerical control machine tools of various structures at each rotary oscillation angles can be obtained. The method is not limited by the structures of the machine tools, is convenient to arrange and has high measuring precision.

Owner:成都天佑创软科技有限公司

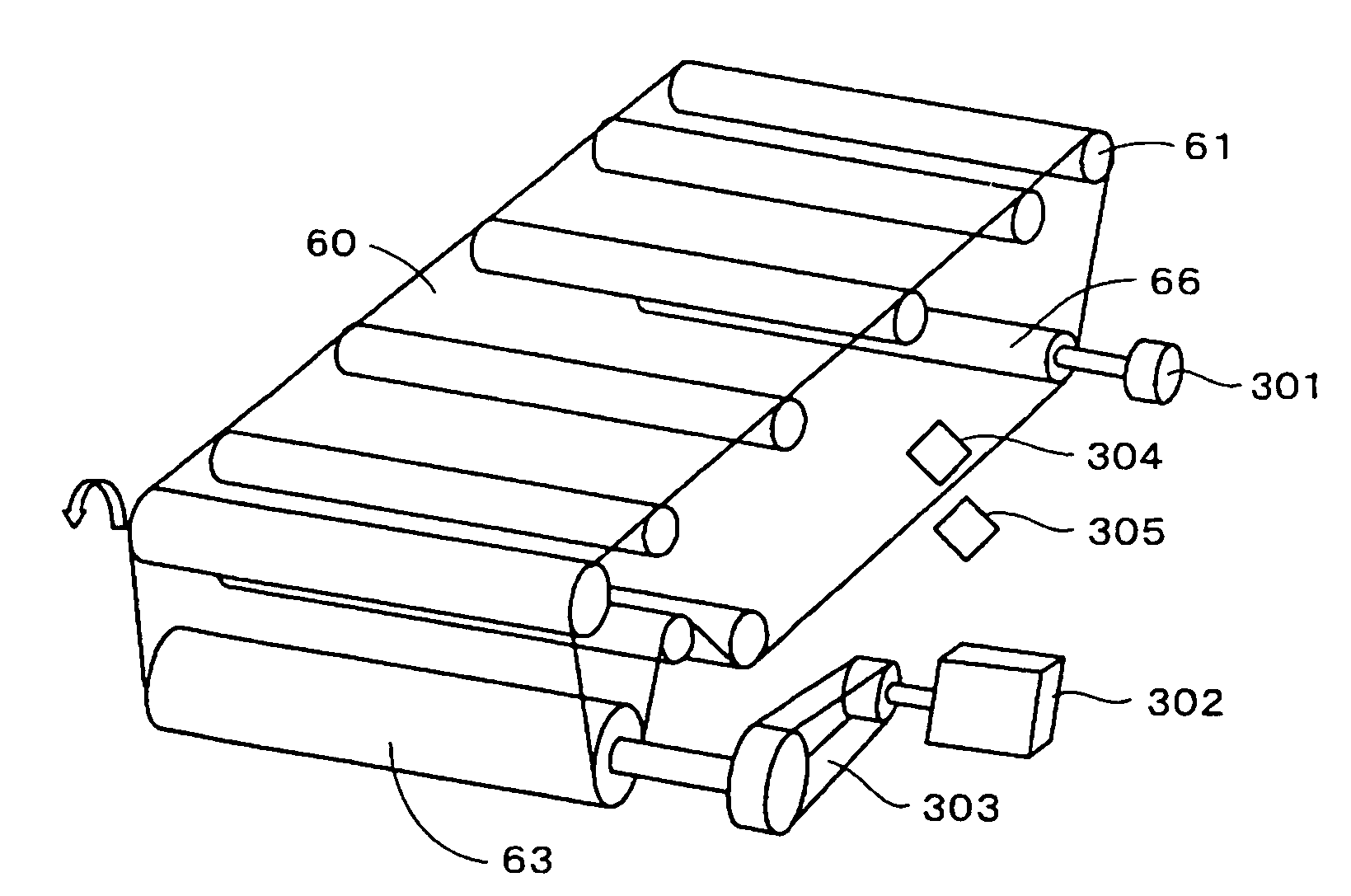

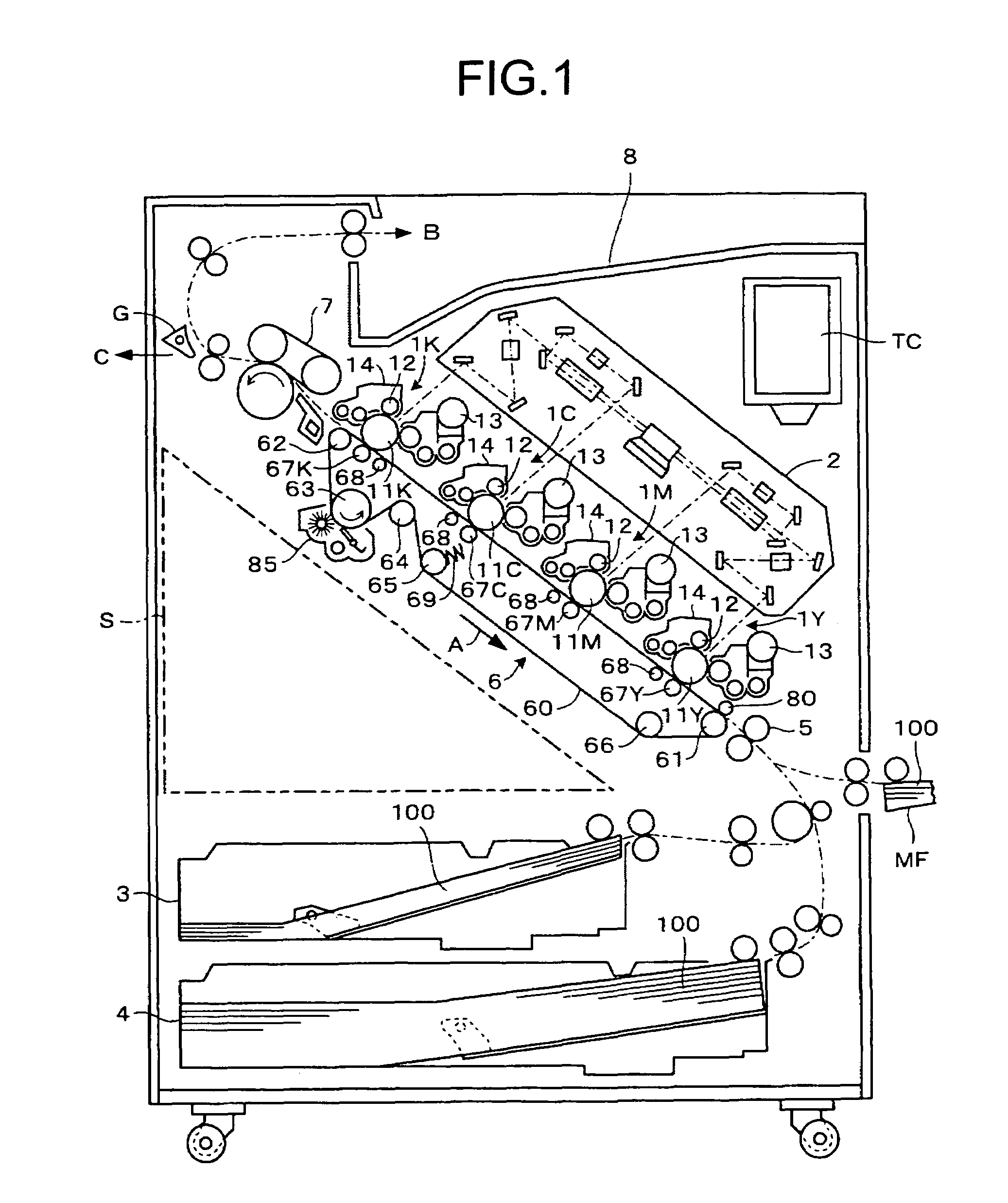

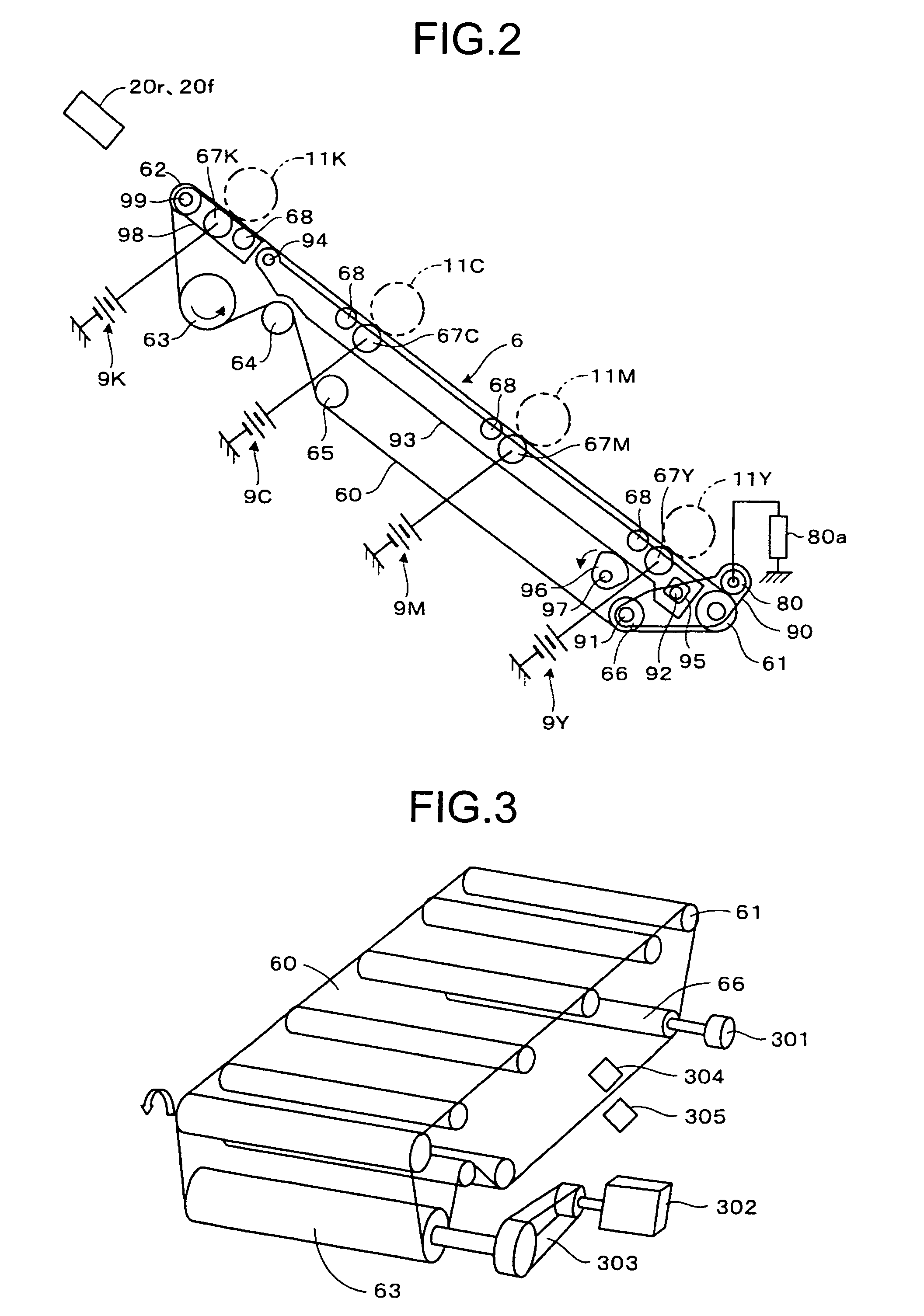

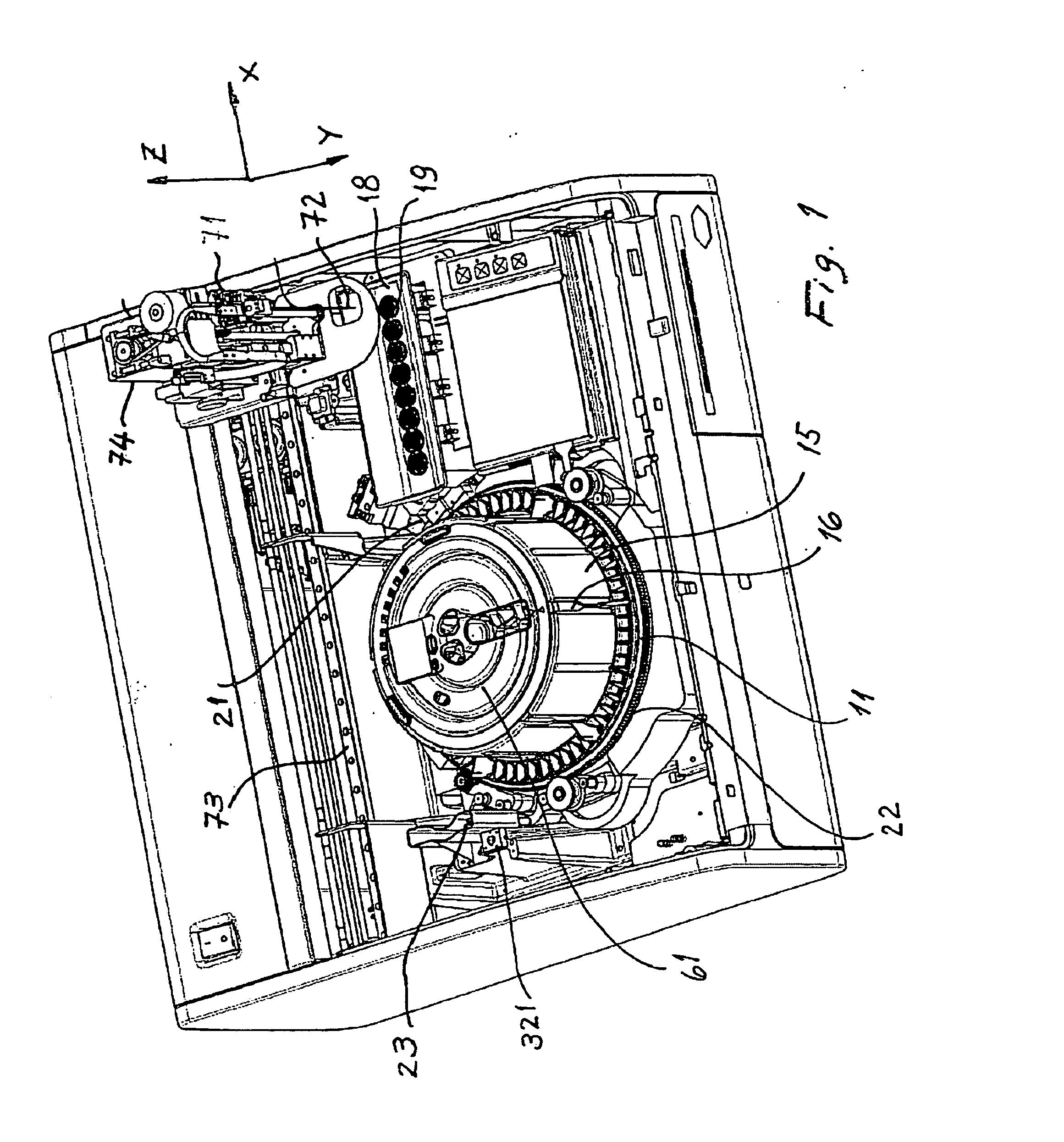

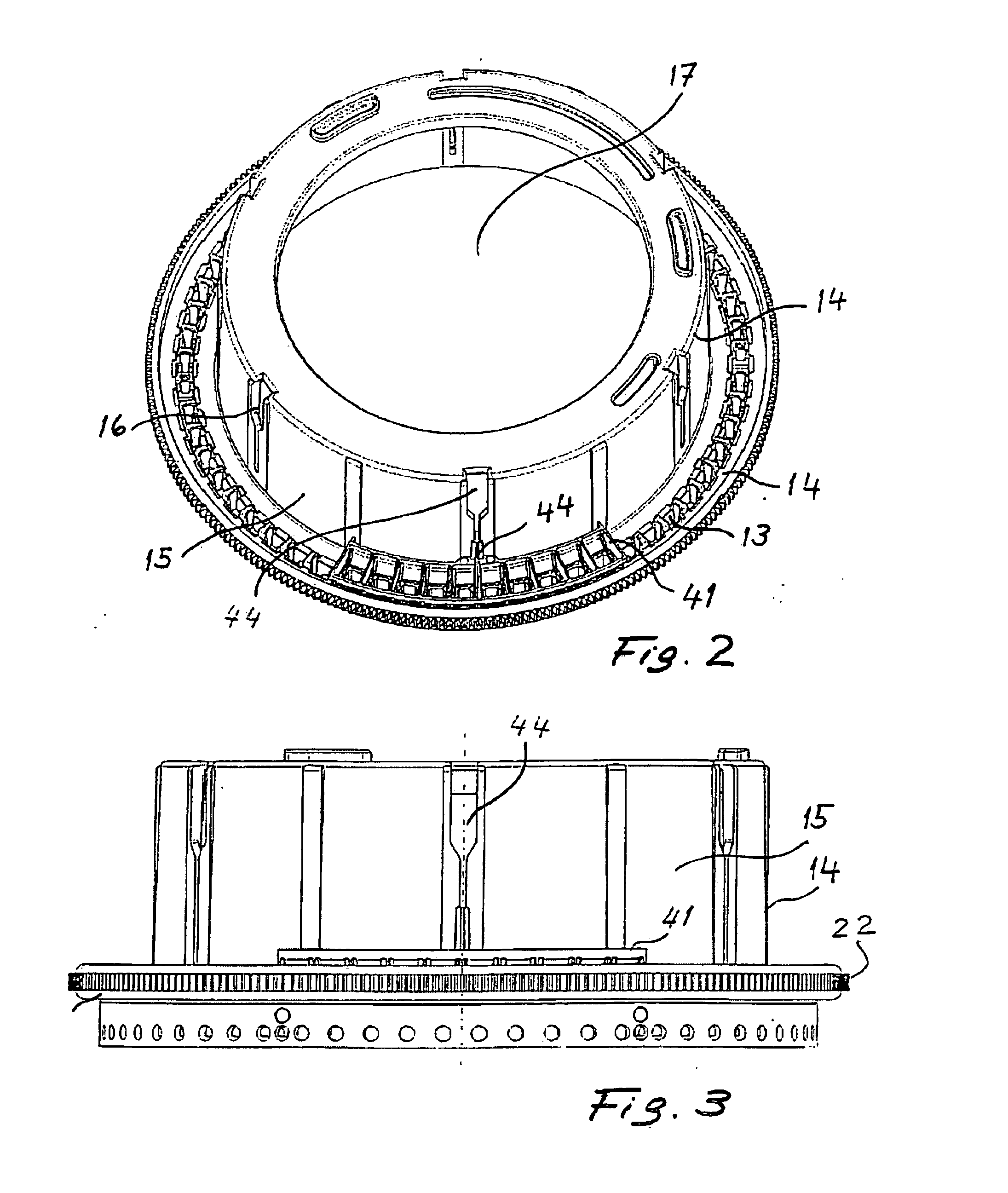

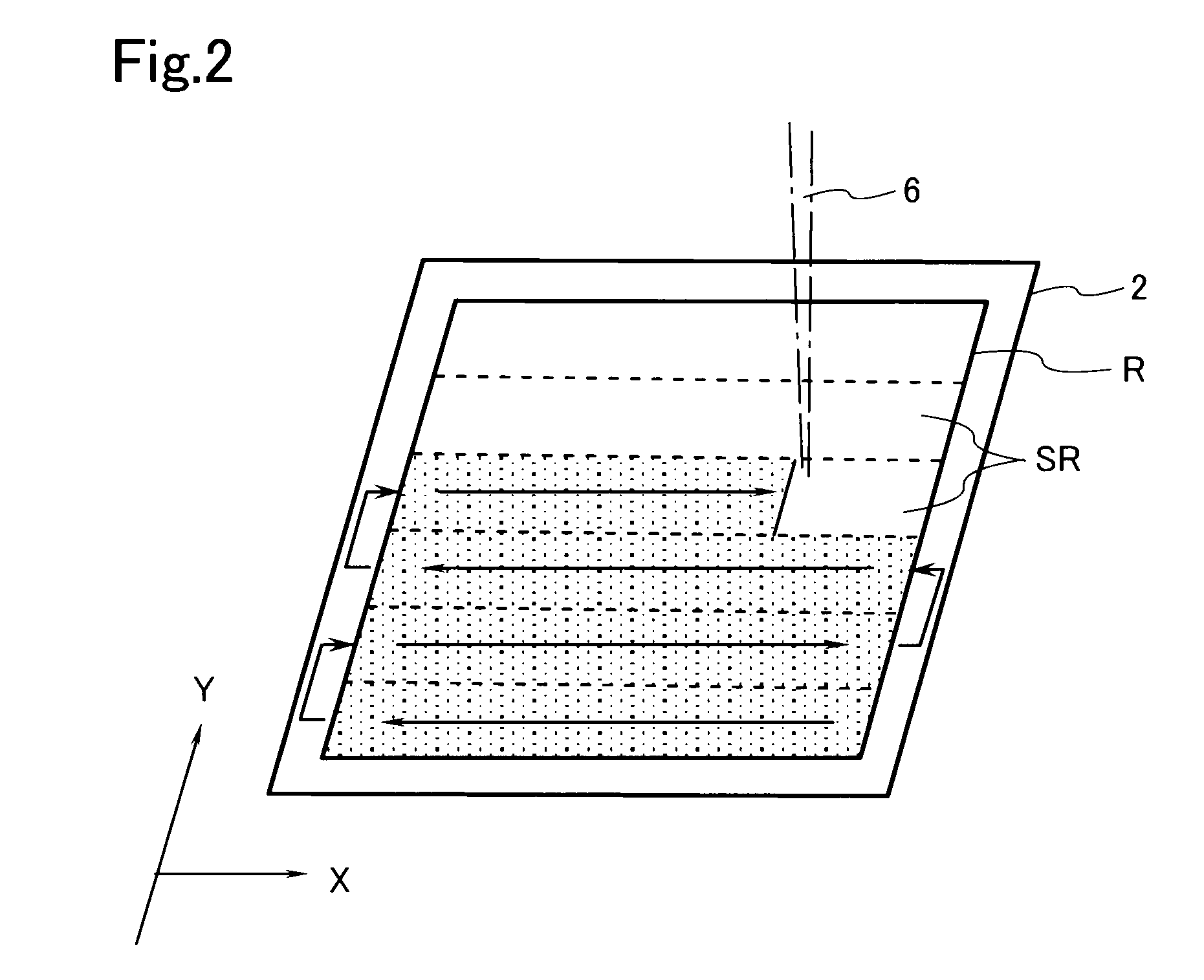

Belt-drive control device, color-shift detecting method, color-shift detecting device, and image forming apparatus

A mark detecting unit detects a mark that is a reference position of an endless belt. An angular-displacement-error detecting unit detects an angular displacement error of an encoder caused by thickness fluctuation of the endless belt. A first calculating unit calculates a phase and a maximum amplitude to the mark. A second calculating unit calculates correction data according to a distance from the mark on the endless belt. A belt-drive control device controls a belt driving unit by adding the correction data to a preset control target value to stabilize speed fluctuation of the endless belt due to the thickness fluctuation.

Owner:RICOH KK

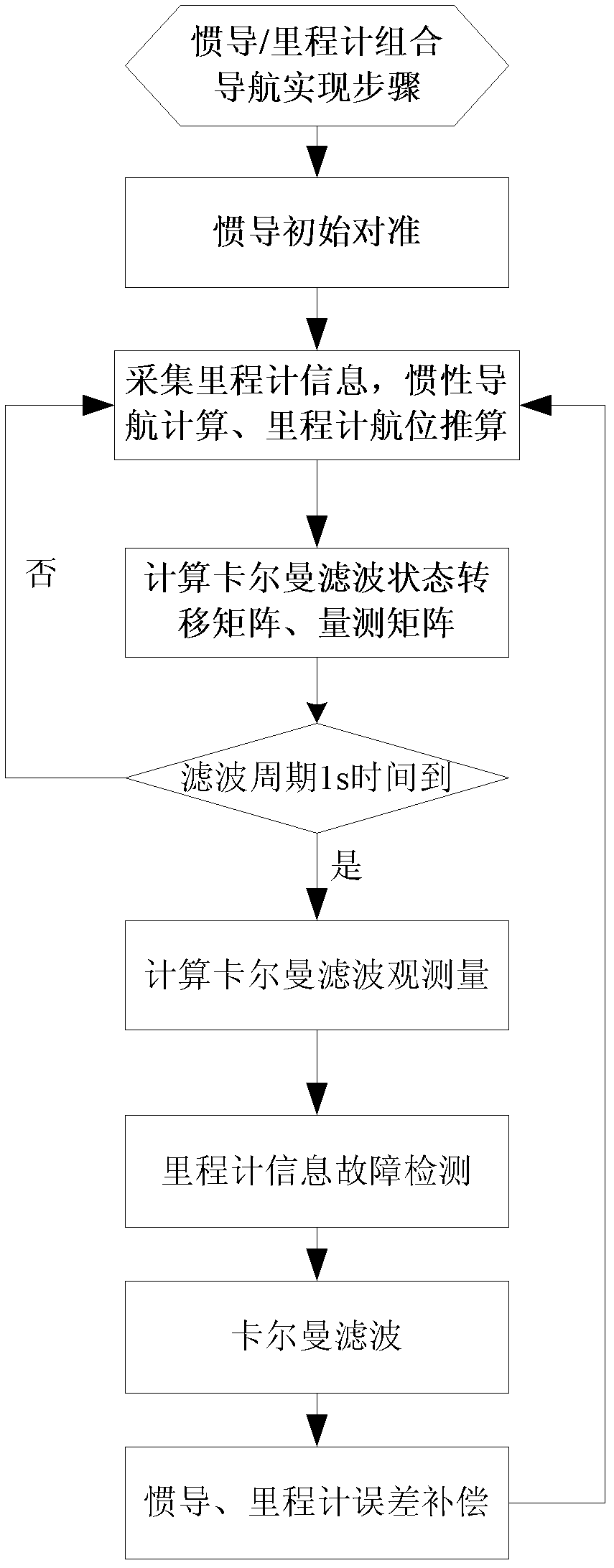

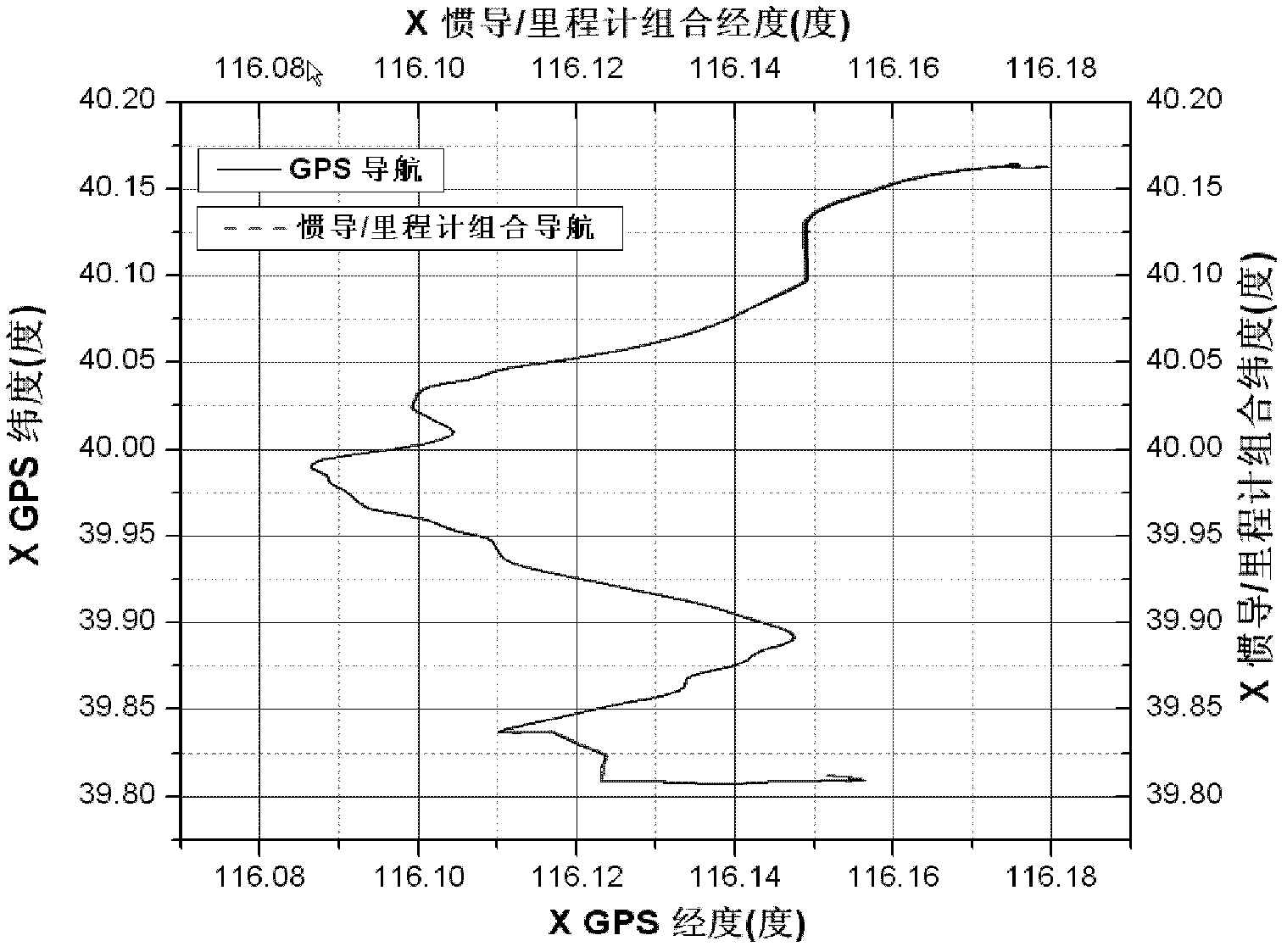

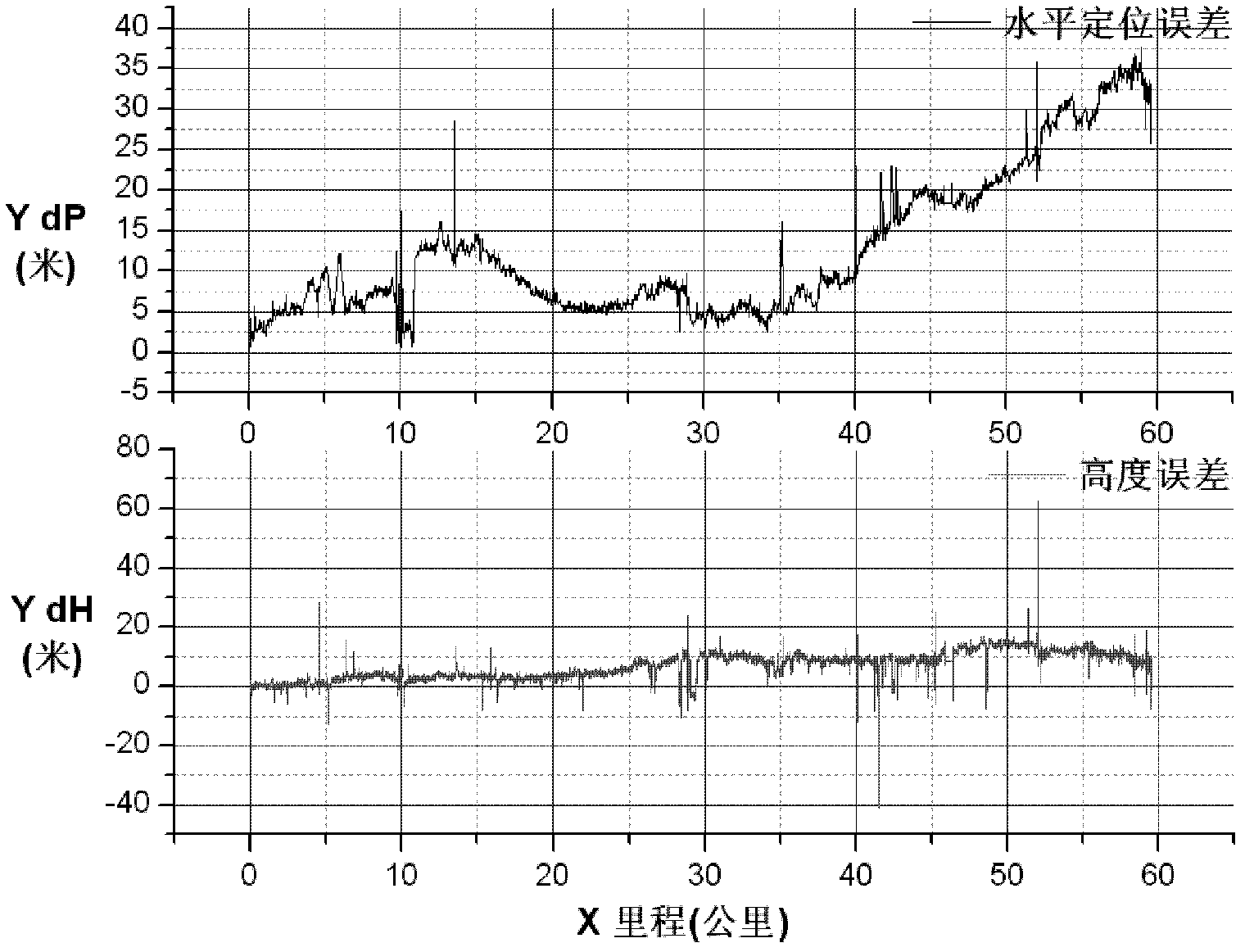

Inertial navigation/mileometer autonomous integrated navigation method

ActiveCN103217157AAchieve smooth compressionImprove signal-to-noise ratioNavigational calculation instrumentsDistance measurementKaiman filterTransfer matrix

The invention belongs to the technical field of navigation, and concretely relates to an inertial navigation / mileometer autonomous integrated navigation method. The method comprises the following steps: 1, initially aligning an inertial navigation system, and initializing parameters of a Kalman filter; 2, carrying out inertial navigation calculation to obtain a discrete state transfer matrix and a measurement matrix; 3, calculating based on the summation measurement of displacement errors to obtain a filtering observation; 4, carrying out mileometer information fault detection; 5, carrying out Kalman filtering; and 6, correcting. The method solves technical problems of too large mileometer quantification noise and reduced combination navigation precision of present inertial navigation / mileometer integrated navigation methods; and the method which adopts a displacement integration coupling based inertial navigation / mileometer integrated navigation strategy abandons a quantization noise introduced in the traditional methods utilizing a speed, which is obtained by performing calculation on a displacement, as an observation, and substantially improves the reliability of an integrated navigation system.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Method and apparatus for positioning a pipetting device

ActiveUS20070065945A1Reliable methodLow costAnalysis using chemical indicatorsWithdrawing sample devicesVertical planeDisplacement error

A method for determining a reference position for a pipetting needle which is part of an automatic analytical apparatus. The method comprises the following steps: a first measuring step for measuring a first displacement error (ΔX) in a displacement of the pipetting needle effected by a transport device, a first correcting step for correcting the first displacement error (ΔX) by means of a corresponding correction of an angular error (φ) of the initial angular position of the pipetting needle, a second measuring step for measuring a second displacement error (ΔY) in a displacement of the pipetting needle in a second direction (Y-axis) perpendicular to the vertical plane, a second correcting step for correcting the second displacement error (ΔY) by means of a corresponding change (α) of the angular position of the pipetting needle along a circular path, a third measuring step for determining the position of a vertical reference line, and a fourth measuring step for determining the position of a reference point (X0, Y0, Z0) along said reference line,

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

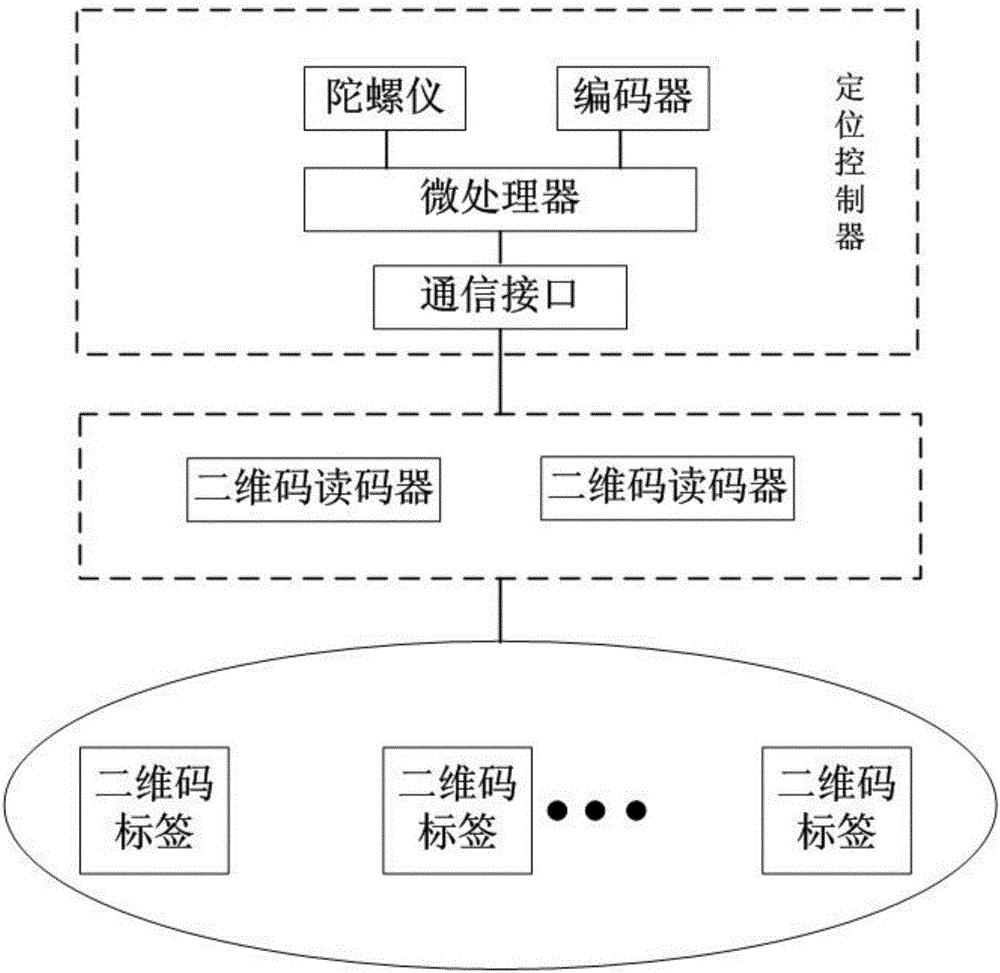

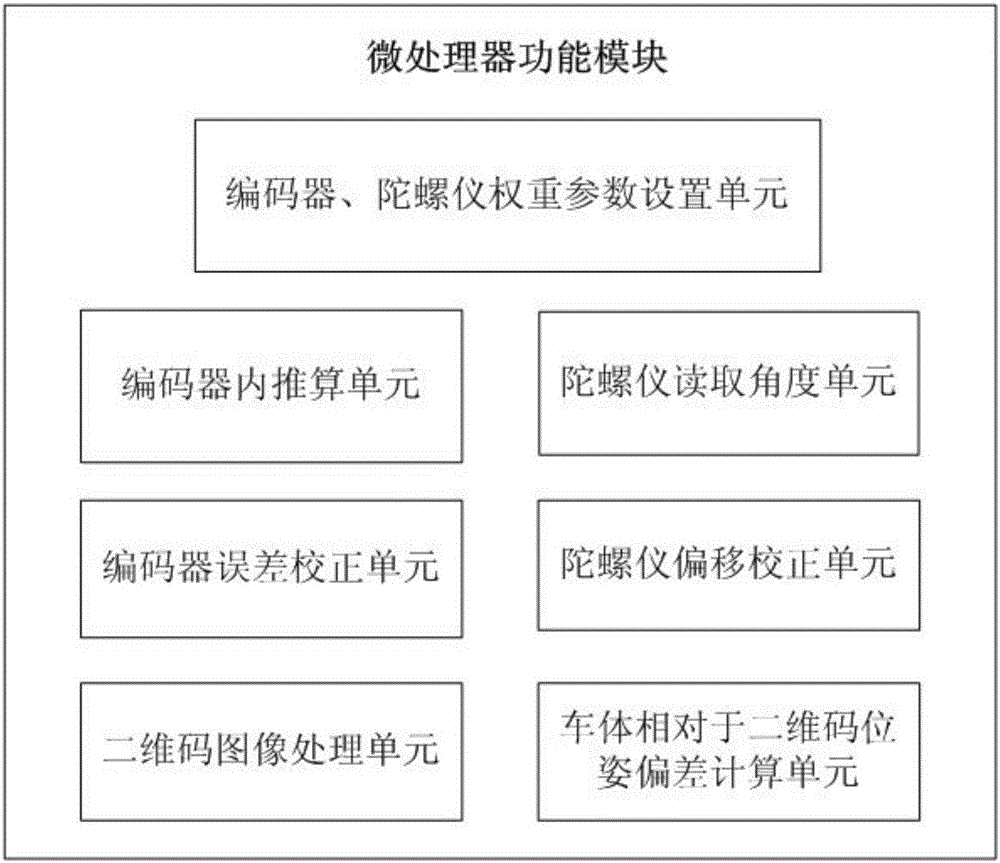

High-precision moving robot positioning system and method

InactiveCN106382934AOvercoming the shortcoming of real-time controlOvercoming pitfalls of indirect measurementsInstruments for road network navigationNavigational calculation instrumentsGyroscopeAngular degrees

The invention relates to a high-precision moving robot positioning system and method. The system and the method are technically characterized in that a positioning controller of the system comprises a microprocessor, a coder, a gyroscope and a communication interface; the coder, the gyroscope and the communication interface are connected with the microprocessor; the microprocessor respectively reads angle data through the coder and the gyroscope, reads two-dimensional code images through a two-dimensional code reader and performs calculation to realize the positioning function. The method comprises the following steps that (1) the positioning controller integrally calculates the AGV(Automatic guided vehicle) angle change according to the weight of the coder and the gyroscope; (2) the positioning controller obtains the AGV angle and the position through the two-dimensional code reader, corrects the angle deviation of the gyroscope, and corrects the relative displacement errors of the coder. According to the through the method provided by the invention, the two-dimensional code reader, the coder and the gyroscope are organically combined, so that the AGV angle precision reaches + / -0.1 degree; the position precision reaches + / -0.2mm; the navigation precision is greatly improved; the influence of angle drift of the gyroscope and the displacement errors of the coder on the angle change can be avoided.

Owner:SHENZHEN PUZHILIANKE ROBOT TECH CO LTD

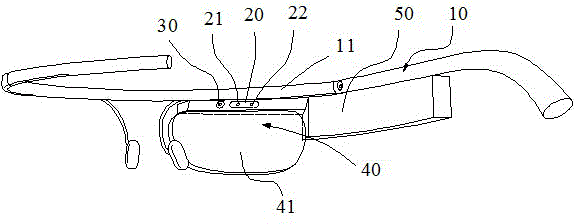

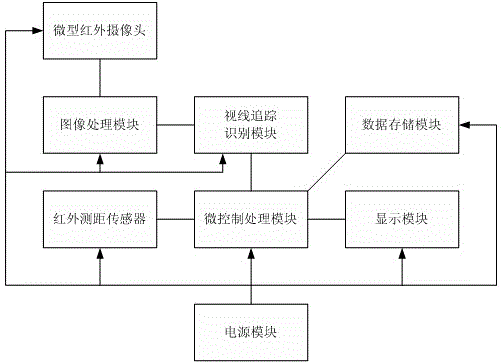

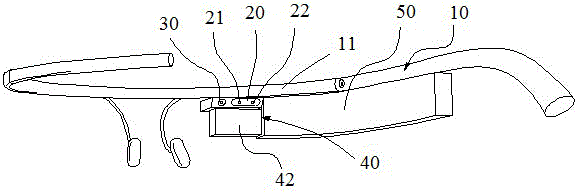

Operation pointer indication control device based on human eye image and sight tracking

ActiveCN104090659AImprove human-computer interactionSolve the problem of promoting the applicationInput/output for user-computer interactionGraph readingHuman bodySight-reading

The invention provides an operation pointer indication control device based on a human eye image and sight tracking. The device can be worn on the head of a human body, and human-computer interaction can be achieved by means of operation control over an operation pointer through actions of eyes. In the interaction control process of the device, interference caused by a dark visible light environment and other situations can be avoided, a displacement error generated due to jittering can be relieved and even shielded, and the human-computer interaction effect that the indication position of the operation pointer and a real scene observed by human eye sight overlap is achieved. Thus, the human-computer interaction ability of a head-worn computer terminal is enhanced, and abundant operability and powerful expandability can be achieved. Consequently, the problem that in the prior art, popularization and application of the head-worn computer terminal in the technical field of industry and commerce are limited because the human-computer interaction ability of the head-worn computer terminal is limited is effectively solved, and the operation pointer indication control device has broad application prospect in the technical field of wearable computer terminals.

Owner:刘超

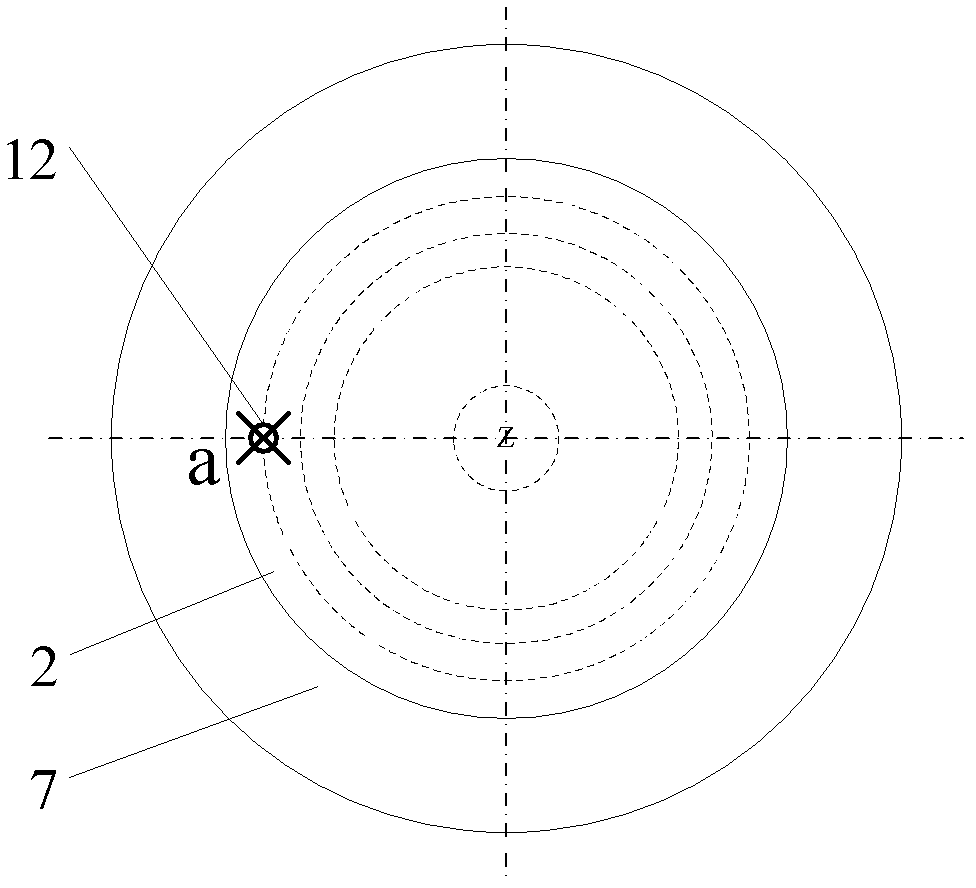

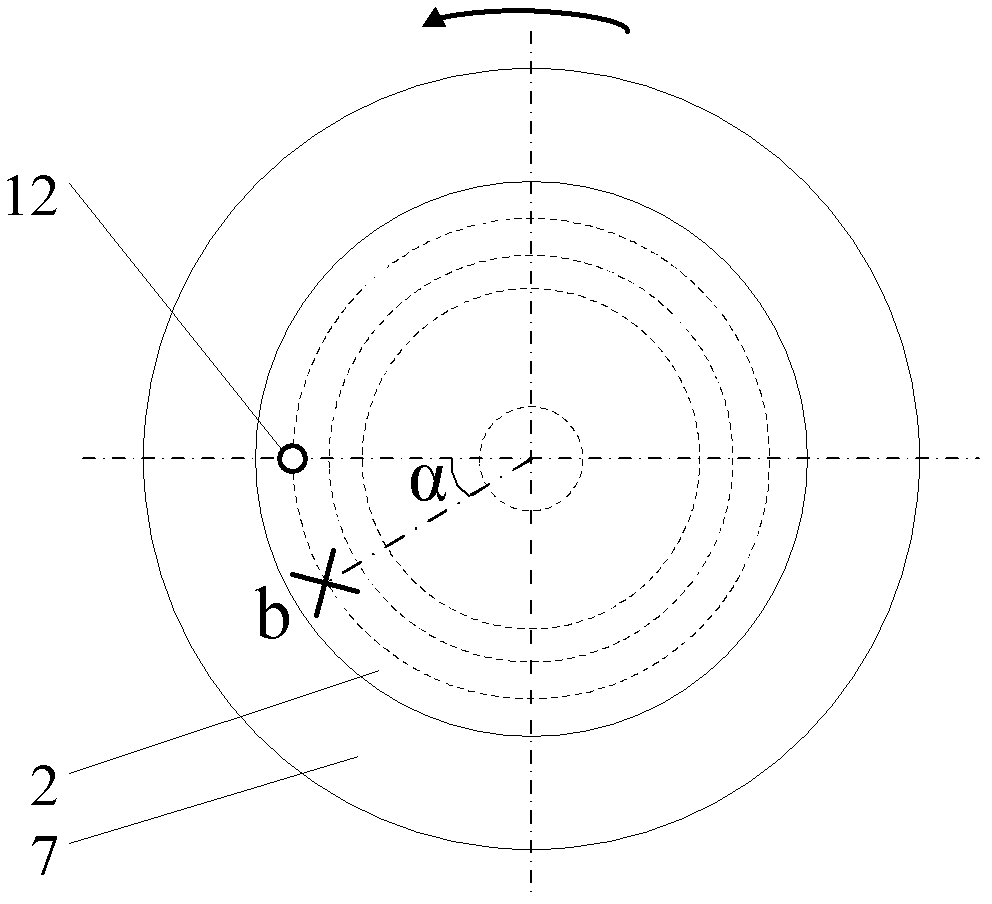

Axial circular runout and total runout single displacement error separation device and method

InactiveCN102426001AAxial circular runout realizationAchieve full harmonic separationMeasurement devicesMeasurement deviceHarmonic analysis

The invention relates to an axial circular runout and total runout single displacement error separation device and method, and belongs to the technical field of micro-nanometer ultra-precise measurement. In the method, an axial circular runout and total runout measurement device and an error separation system are organically integrated into a whole, a proper displacement angle alpha is selected in an error separation process, so that a workpiece performs a single small-angle displacement of a corresponding angle relative to a rotary main shaft, total harmonic separation of z(n) and g(n) in a harmonic range of between 1 and 100upr by measuring comprehensive errors A(n) and B(n) including a workpiece axial circular runout error g(n) and a main shaft rotary error z(n) before and after displacement of the workpiece, and utilizing fast Fourier series transform, harmonic analysis and other mathematic processing methods. According to the device and the system, when an existing error separation method is used for circular runout error separation, the defects that an error introduced by a rotary shaft cannot be completely separated, error separation time is long, various larger drifts are easily introduced and the like can be overcome, and the error separation device and the error separation process can be greatly simplified.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method of using a self-locking travel pattern to achieve calibration of remote sensors using conventionally collected data

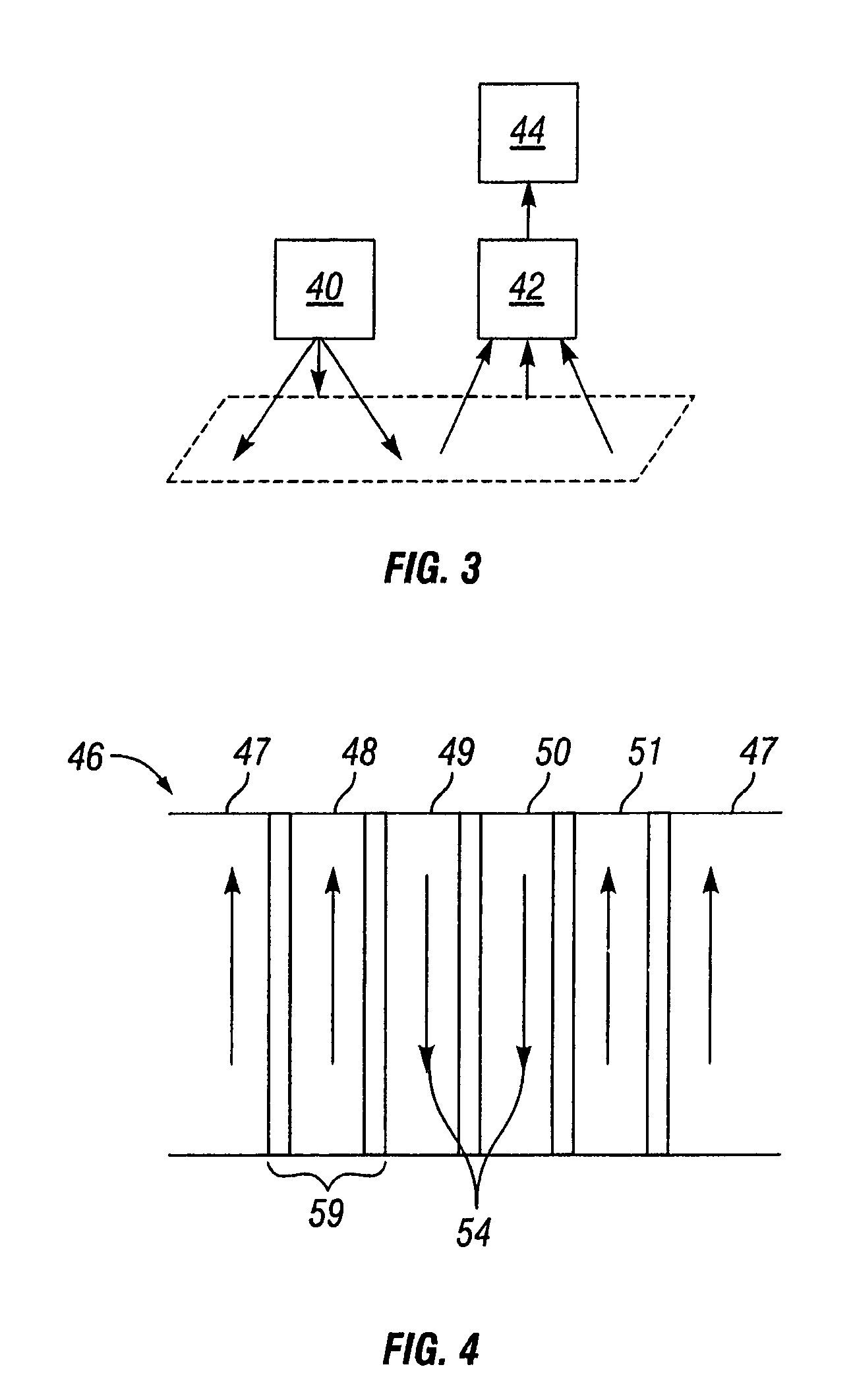

InactiveUS7212938B2Eliminate biasWave based measurement systemsTesting/calibration apparatusSensing dataOn board

The present invention provides a method to calibrate an on-board remote sensing system using a self-locking travel pattern and target remote sensing data. The self-locking travel pattern includes a number of parallel travel lines having overlapping swath widths between adjacent travel lines. The overlapping swath widths are used to determine the boresight angles and range offset of the remote sensor device. In addition, the method can be used to generate estimated horizontal and vertical displacement errors. These estimated errors can be used as correction factors for the range offset and boresight angles.

Owner:VI TECH LLC

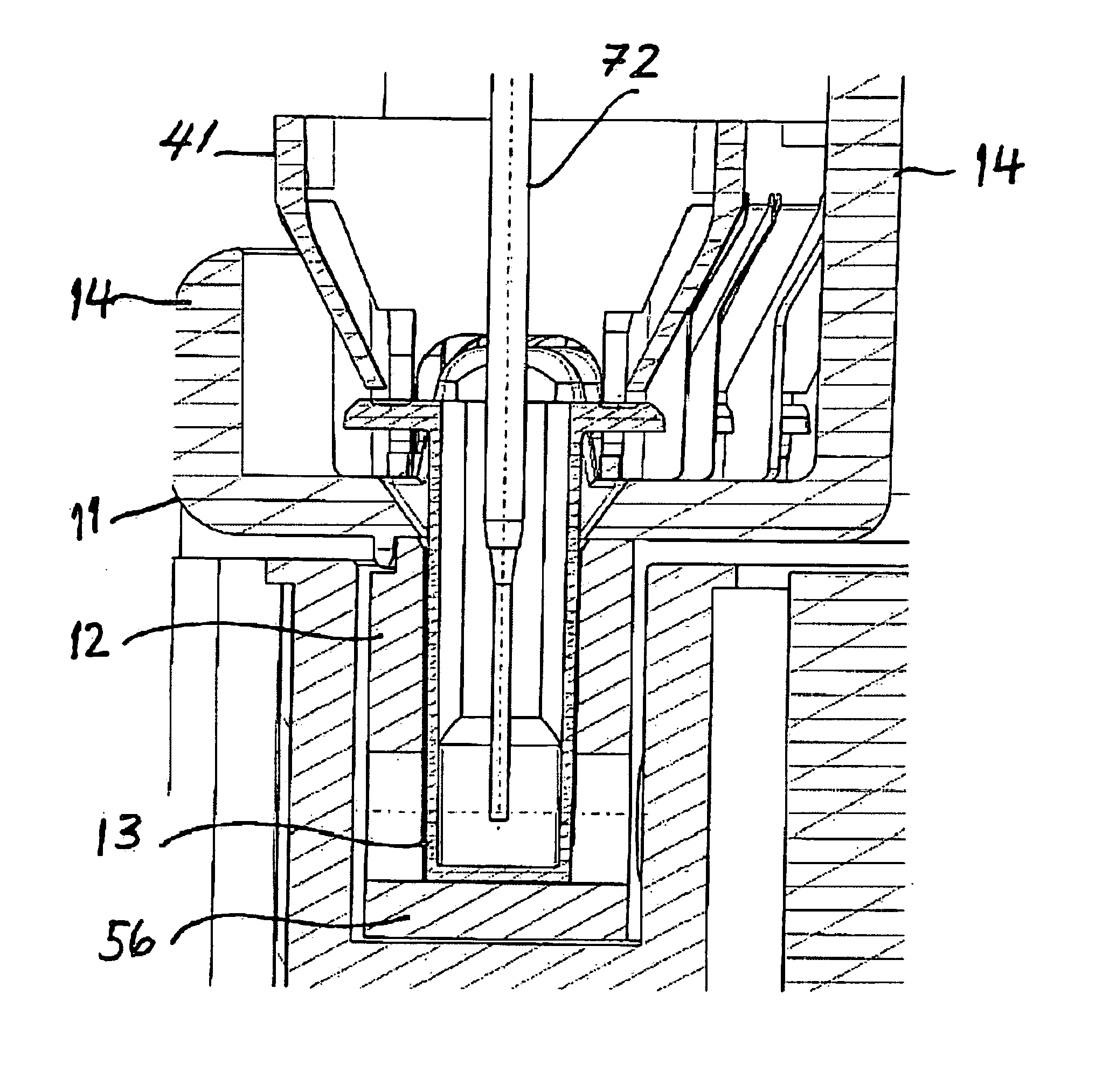

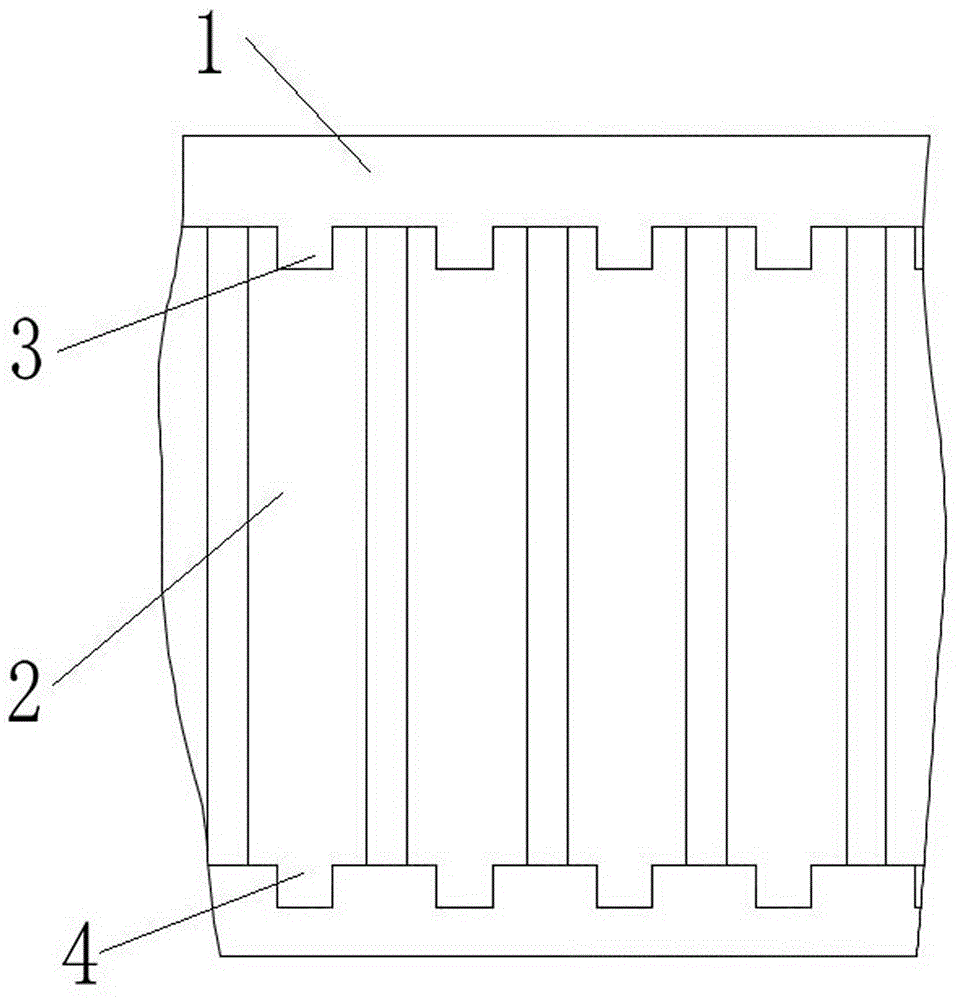

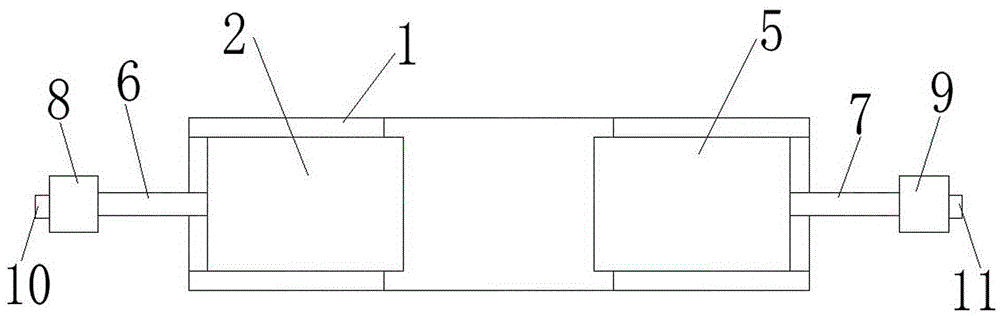

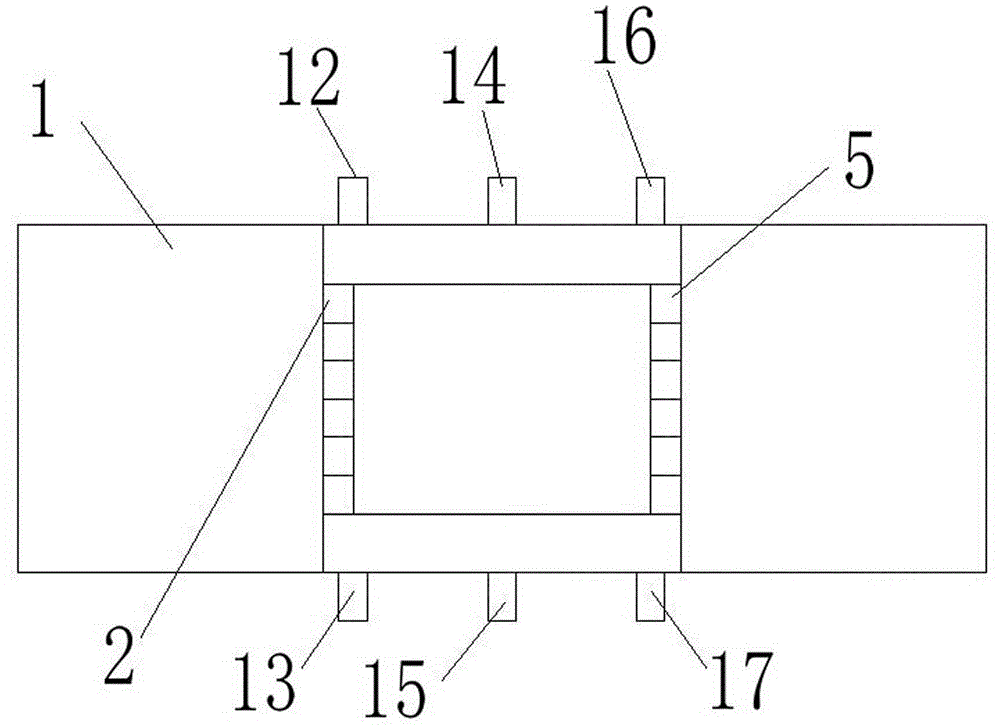

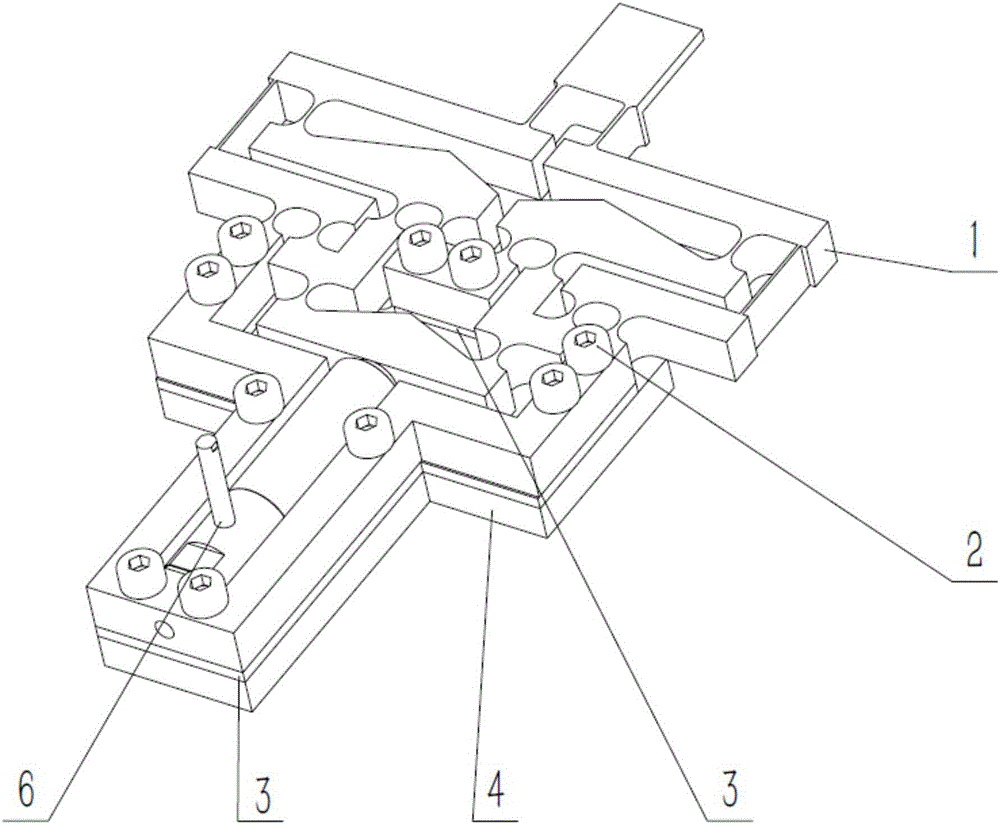

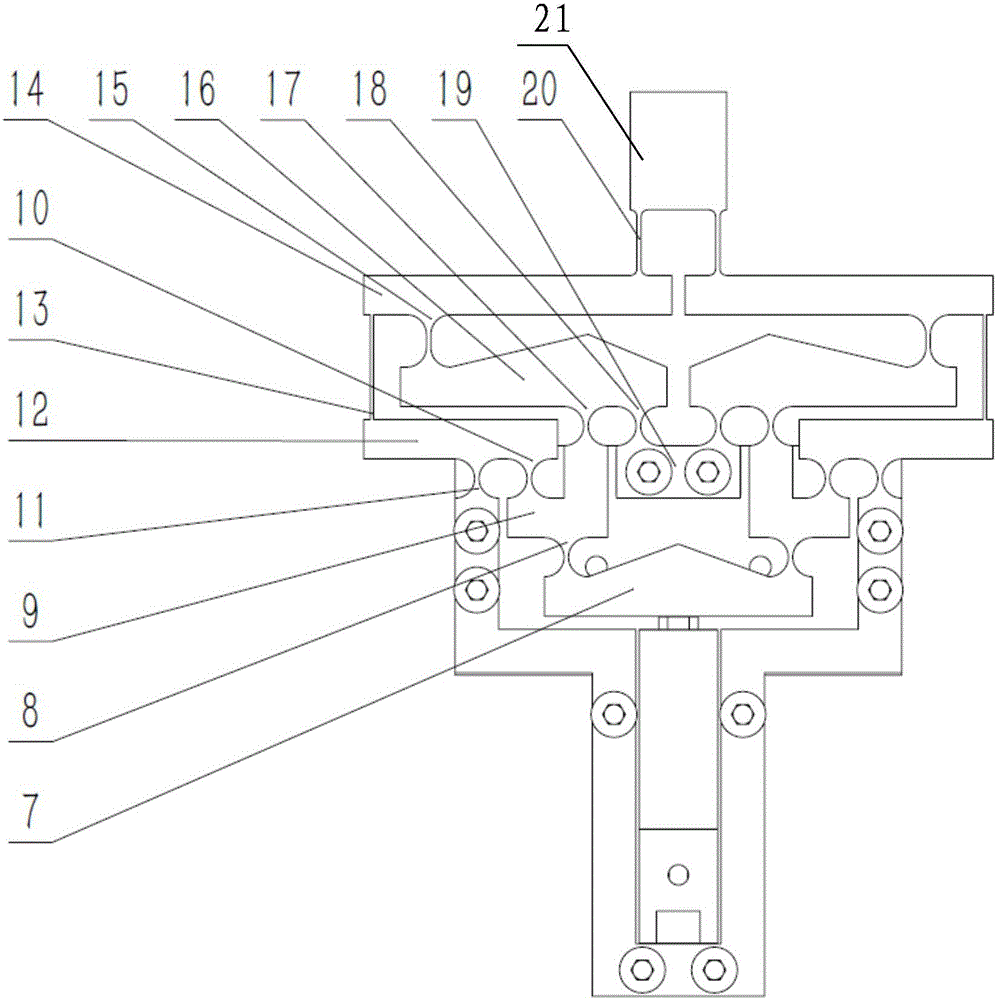

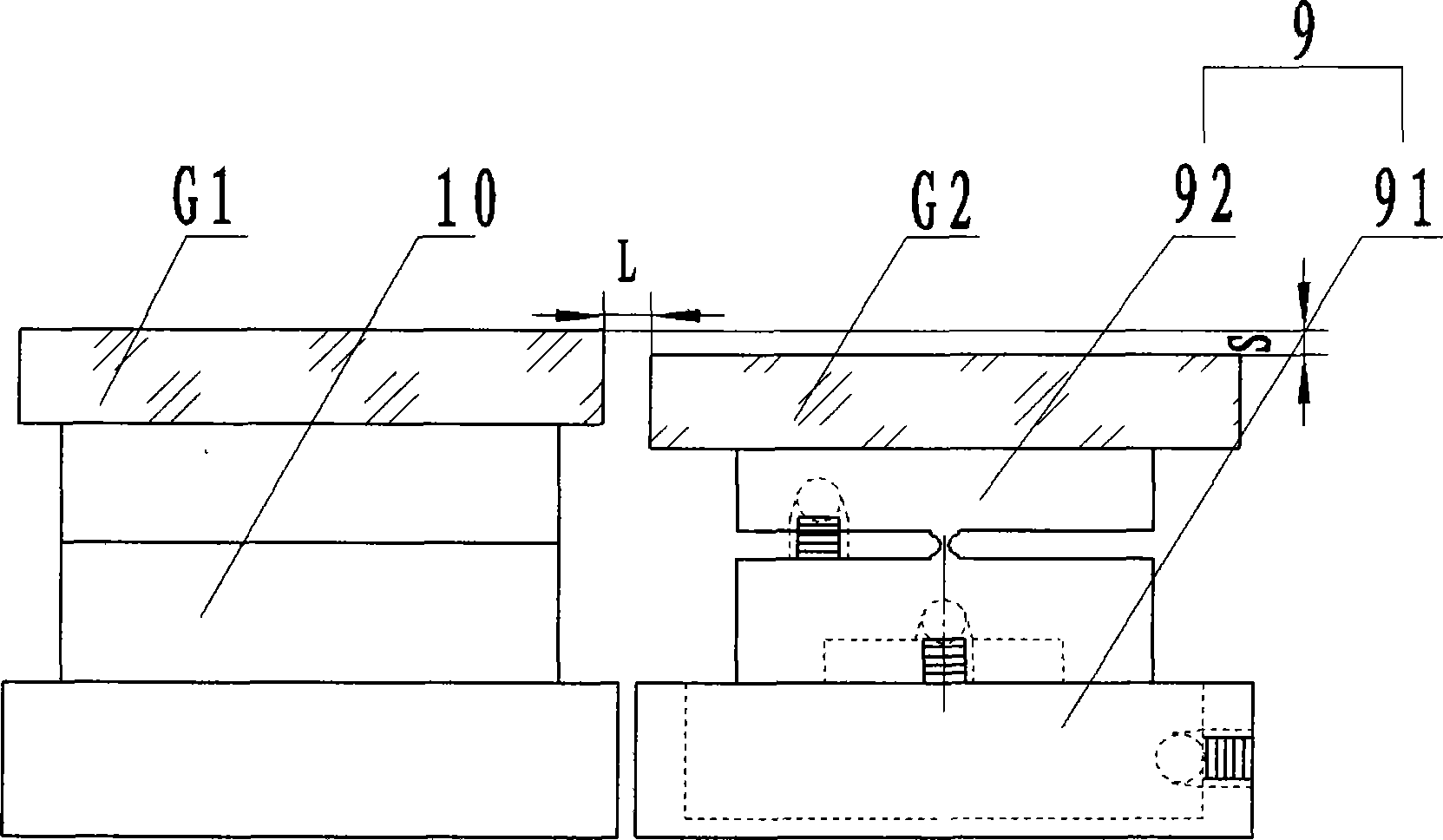

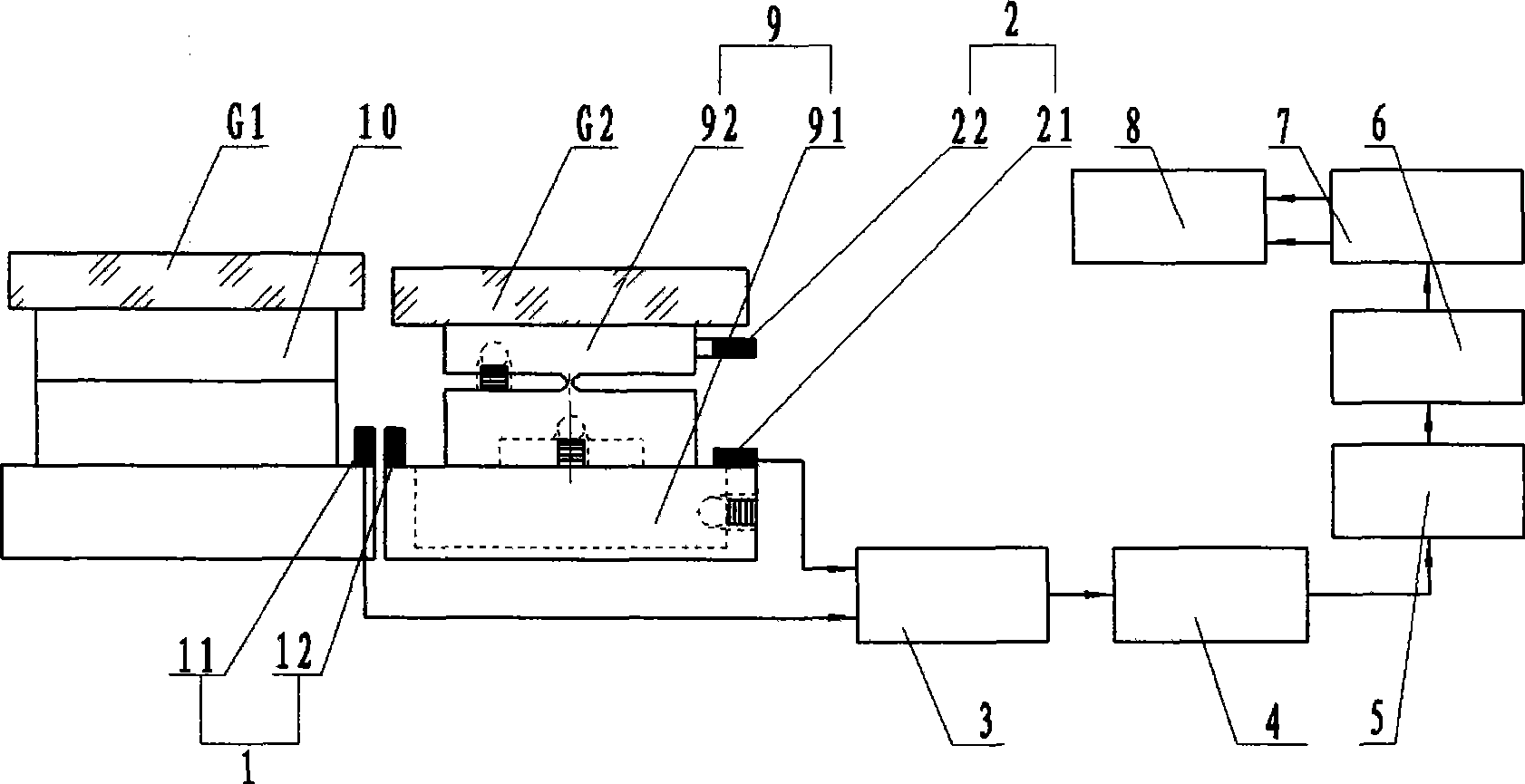

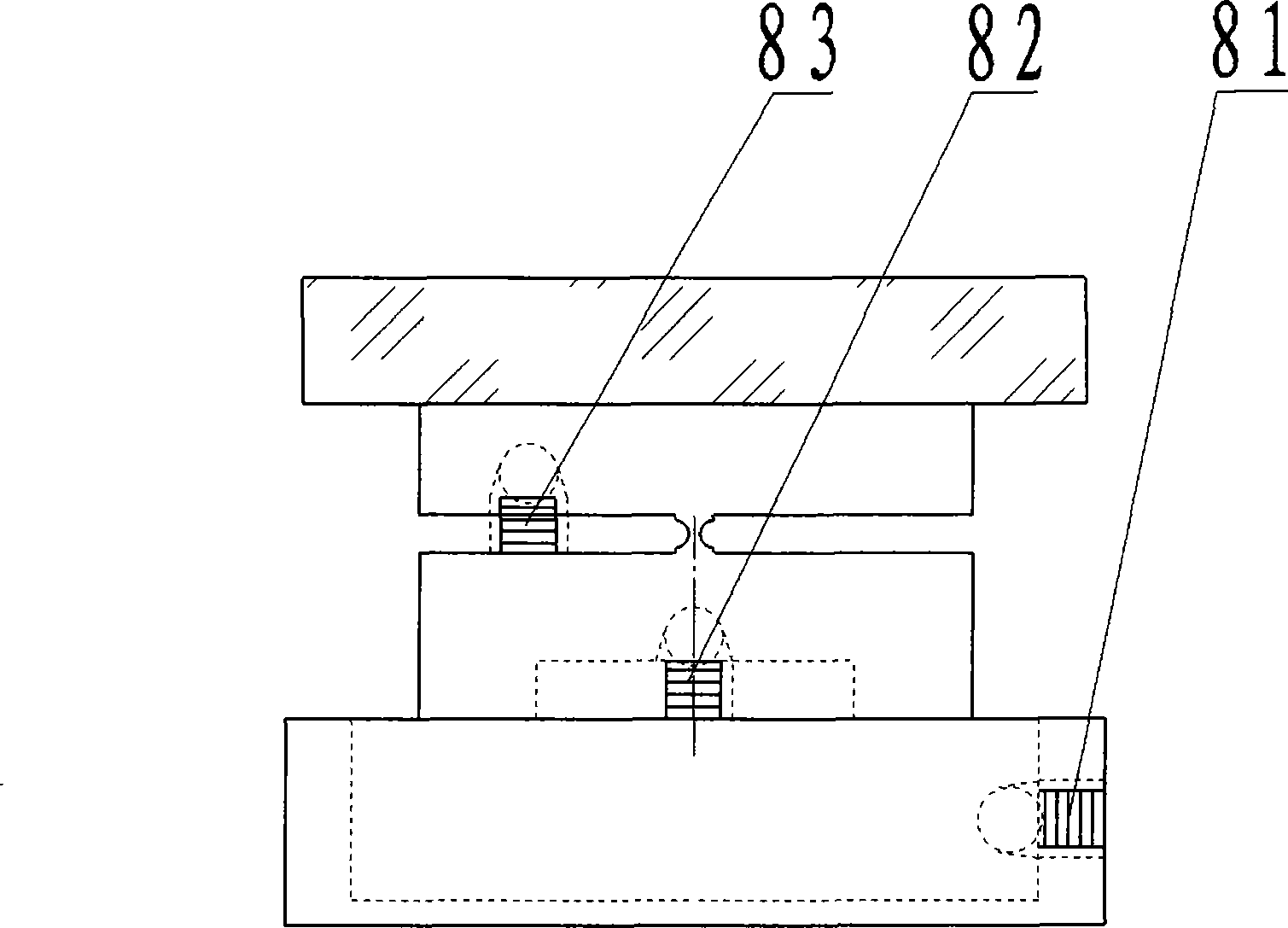

Vane displacement error detection device of multi-vane collimator

InactiveCN104147712ASolve the excessive hysteresisSolve the problem that the hysteresis value cannot be accurately measuredX-ray/gamma-ray/particle-irradiation therapyControl systemEngineering

The invention relates to a vane displacement error detection device of a multi-vane collimator. The vane displacement error detection device of the multi-vane collimator comprises a shell, a plurality of left vanes and right vanes, a lead screw I, a lead screw II, a motor I and a motor II, wherein the left vanes are installed at the left end inside the shell in a sliding mode through a sliding device, the right vanes are installed at the right end inside the shell in a sliding mode through a sliding device, the lead screw I is screwed on the left vanes, the lead screw II is screwed on the right vanes, and the motor I and the motor II are fixed to the left side and the right side of the shell respectively. Encoding signals of an encoder I and an encoder II are read and compared with the interval between an infrared laser sensor emitting end I or an infrared laser sensor emitting end III and an infrared laser sensor emitting end II, so that the differential value between the actual movement displacement amount of the vanes and the theoretical displacement amount output by a control system is obtained, and the vane displacement error detection device of the multi-vane collimator is simple in structure and convenient to operate. The practically obtained differential value is used for compensation accurately and reliably, and the problems that as the lead screws are abraded due to long-time operation, the return difference is too large and the return difference value can not be accurately measured are solved.

Owner:SHANDONG JIAOTONG UNIV

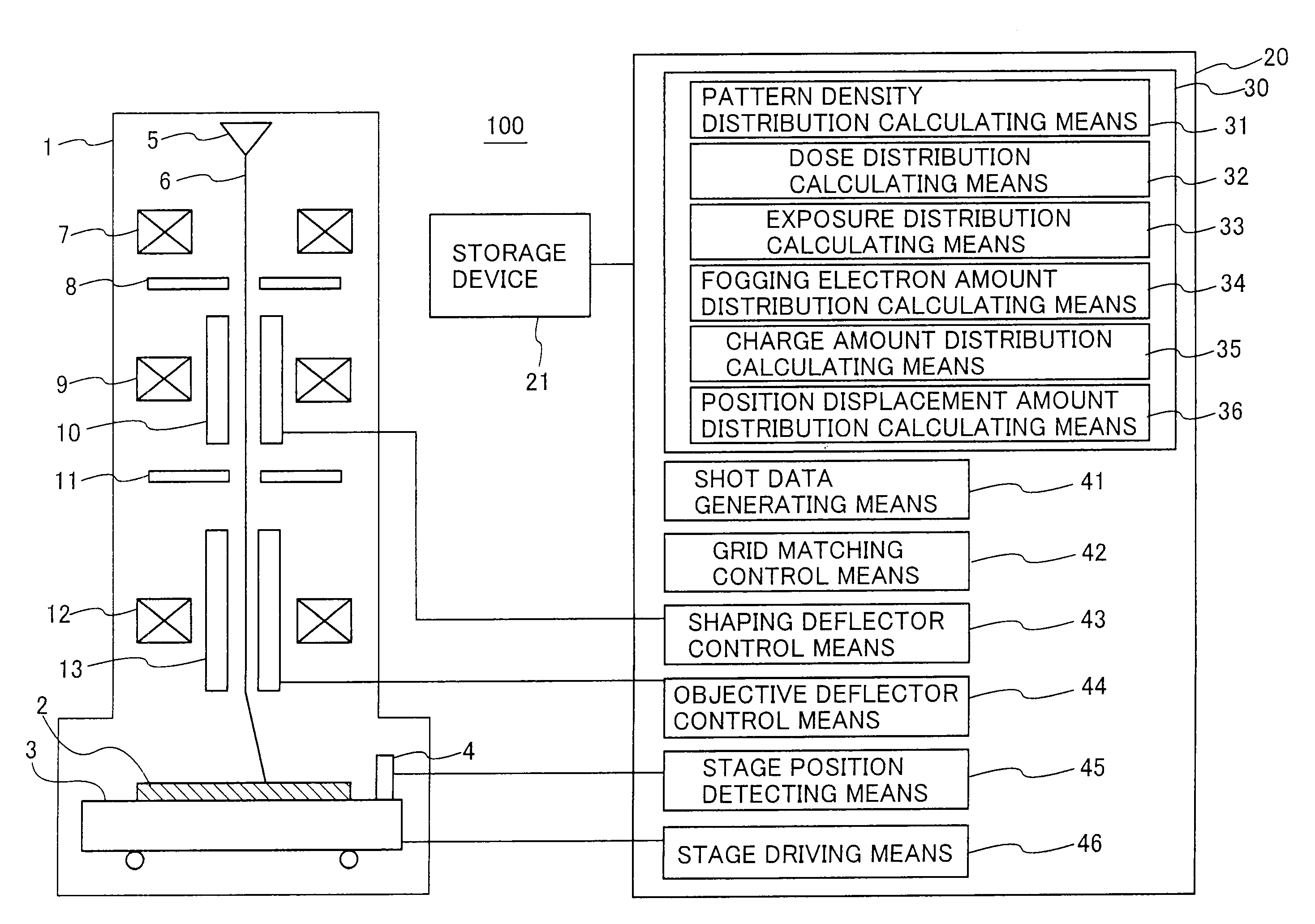

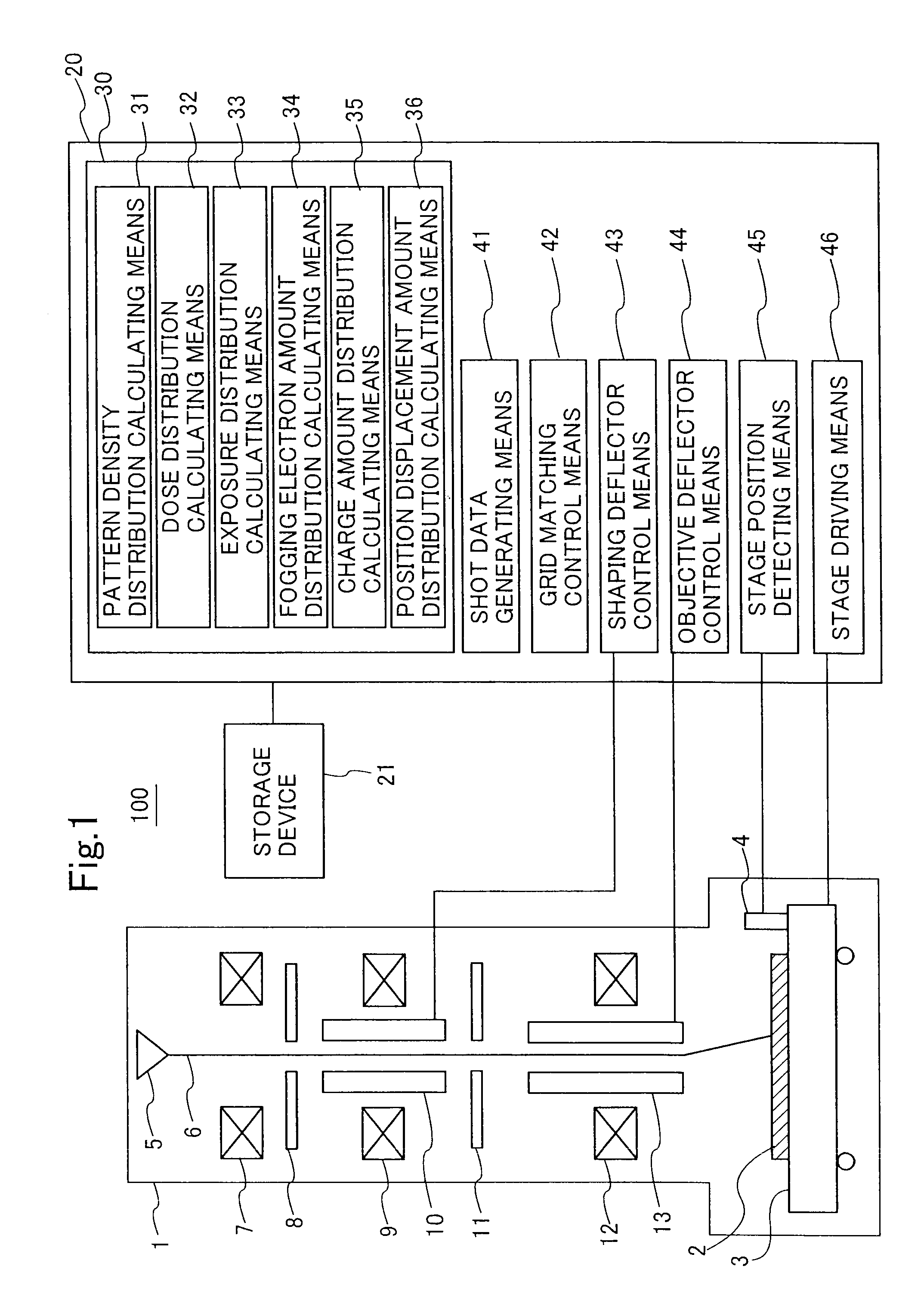

Charged-particle beam writing method and charged-particle beam writing apparatus

ActiveUS20090242787A1Stability-of-path spectrometersNanoinformaticsDensity distributionDisplacement error

A pattern density distribution and a dose distribution calculated using the pattern density distribution are multiplied by each other to calculate an exposure distribution. A fogging electron amount distribution is calculated using the exposure distribution and a function descriptive of a fogging spread distribution. Charge amount distributions in irradiation and non-irradiation regions are calculated using the exposure distribution and the fogging electron amount distribution. A position displacement amount distribution is calculated using the charge amount distributions and a response function for converting a charge amount to a position displacement error.

Owner:NUFLARE TECH INC

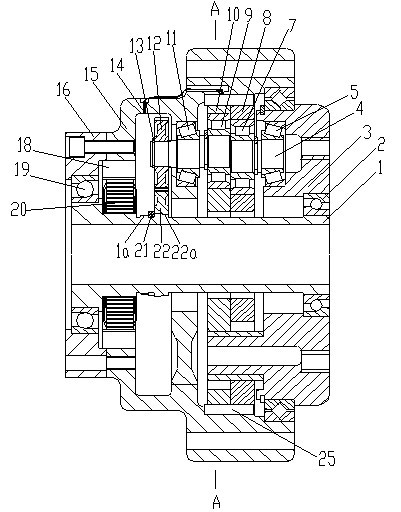

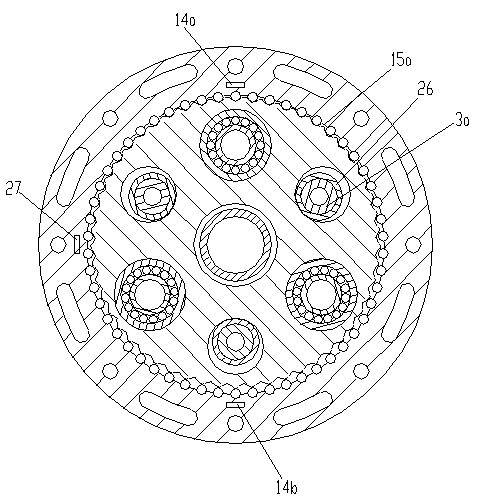

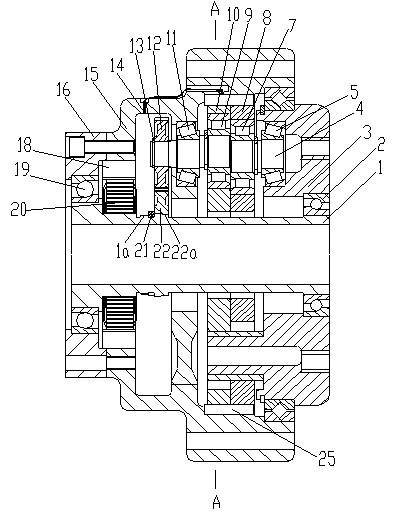

Electromechanically-integrated cycloidalpin wheel drive device

InactiveCN102278425ASave intermediate joinsReduce install targetingGearboxesToothed gearingsCouplingEngineering

The invention discloses an electromechanically-integrated cycloidalpin wheel drive device which comprises a cycloidalpin wheel speed reducer assembly, a high-speed cylindrical gear meshing pair, a servo motor, a speed and temperature sensor, a hollow input shaft and an output shaft with a flange. According to the invention, a planetary speed reducer assembly with three eccentric shafts, an external meshing gear pair, the servo motor and the sensor are integrated into a whole, a coupler is omitted, thus the electromechanically-integrated cycloidalpin wheel drive device has the advantages of compact structure, energy consumption reduction and reduced transmission angle and displacement error between the shafts and improved system precision. The sensor detects an operation state online and feeds back the operation state to a signal processing center, therefore accidents are immediately prevented and controlled. Therefore, the electromechanically-integrated cycloidalpin wheel drive device has the advantages of no need of replacement of lubricating agents, compact structure, strong instantaneity, long service life, high transmission efficiency, strong bearing capacity, low vibration, high precision, convenience for maintenance and the like, and can be widely applied to fields of robots, ships, vehicles and the like.

Owner:CHONGQING AEROSPACE POLYTECHNIC COLLEGE

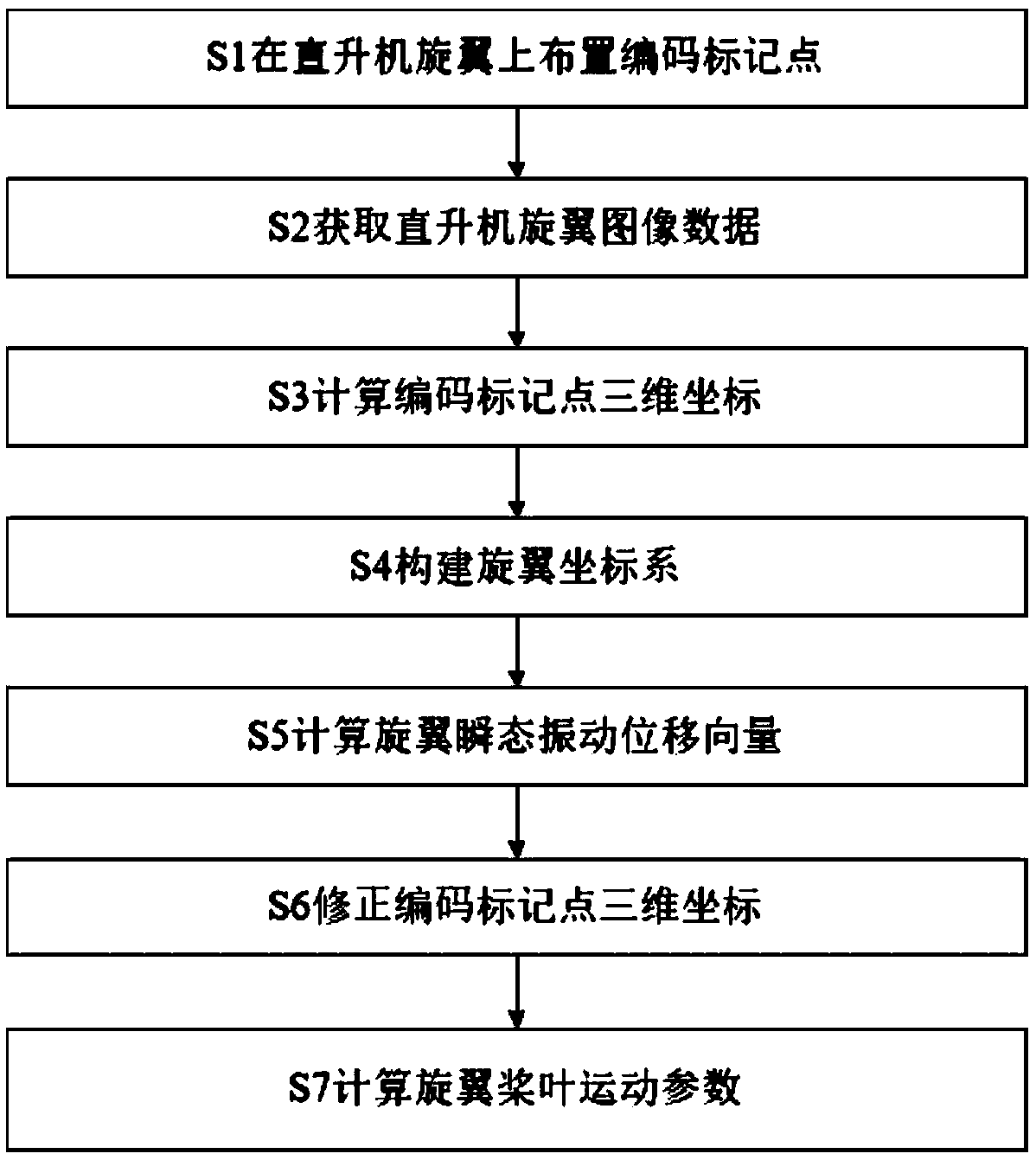

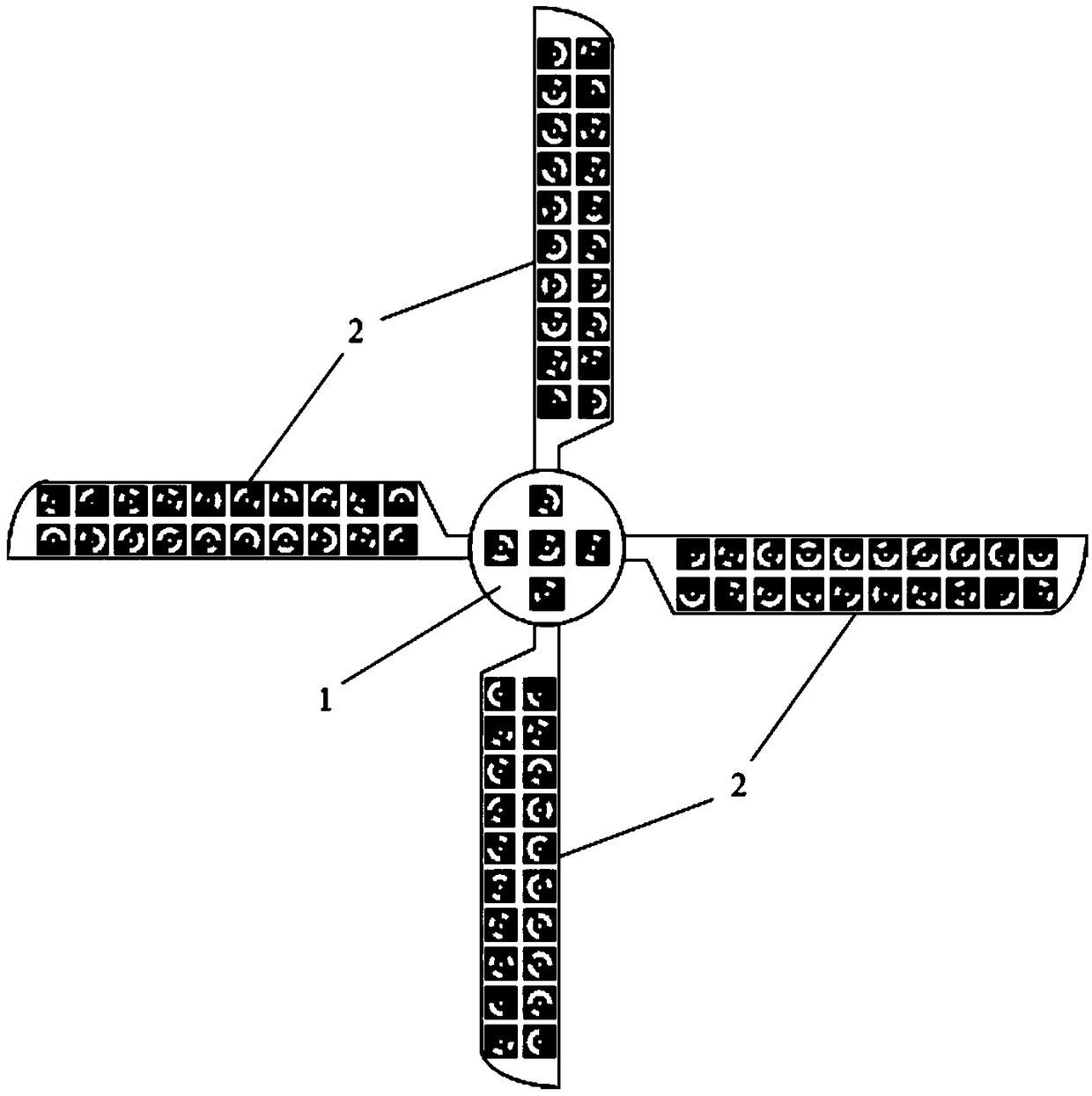

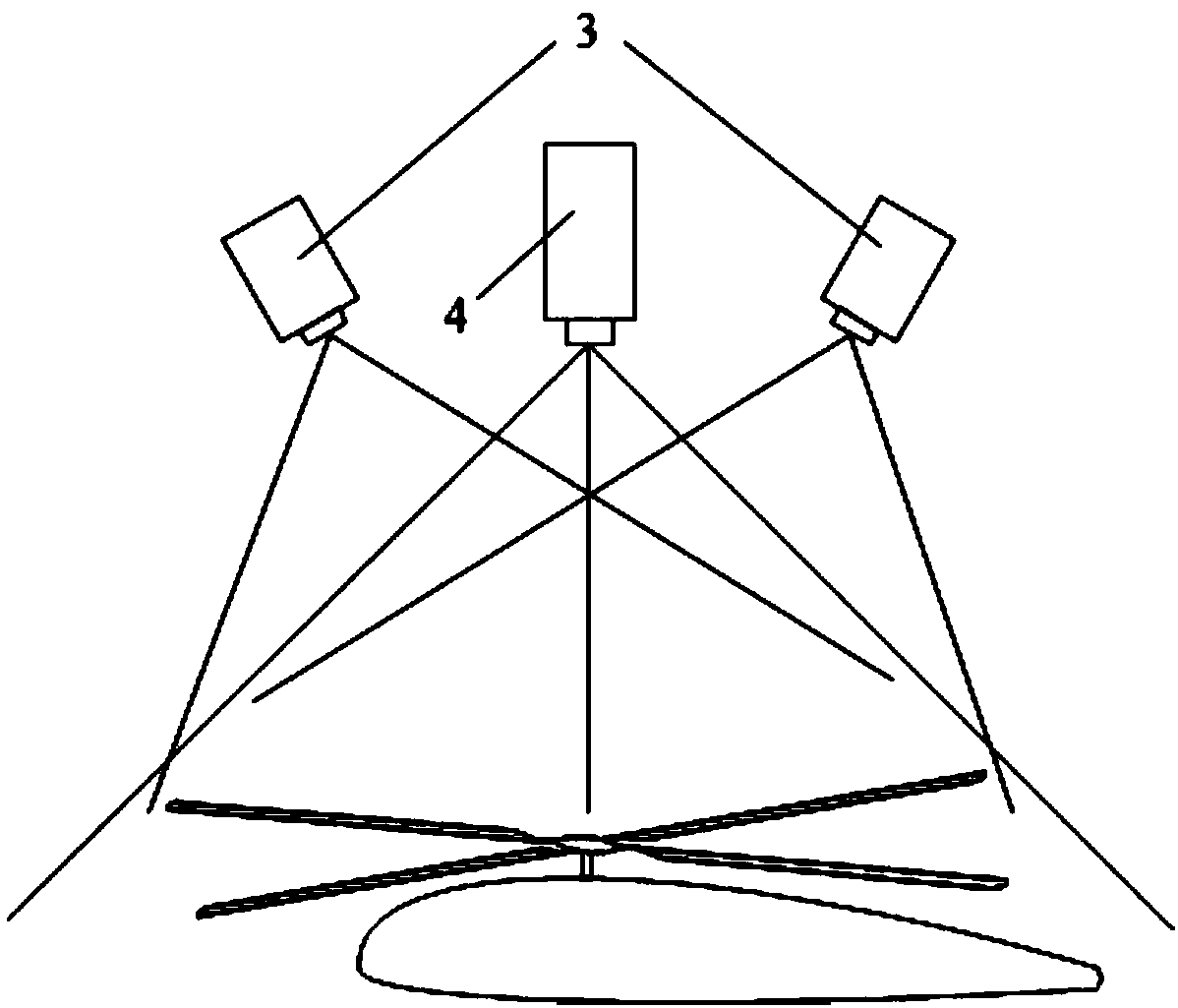

Helicopter rotor blade movement parameter measurement method based on vibration correction

ActiveCN108844524AAccurate measurementHigh precisionPicture taking arrangementsAircraft components testingTransient stateTransient vibration

The invention discloses a helicopter rotor blade movement parameter measurement method based on vibration correction and belongs to the technical field of vision measurement. The helicopter rotor blade movement parameter measurement method based on vibration correction comprises the following steps of placing a certain number of coded mark points on a hub and blades of a helicopter rotor; constructing a binocular stereo vision system to obtain helicopter rotor image data; calculating three-dimensional coordinates of the coded mark points and constructing a rotor coordinate system; calculatinga transient vibration displacement vector of the rotor in a high speed rotation state to correct the three-dimensional coordinates of the coded mark points; and on the basis of the corrected three-dimensional information of the coded mark points, calculating movement parameters of the rotor blades in the current transient state according to definitions of the movement parameters of the rotor blades. The helicopter rotor blade movement parameter measurement method based on vibration correction, disclosed by the invention, has the advantages that the movement parameters of the rotor blades can be accurately measured by correcting vibration displacement errors caused by rotor high speed rotation, the operation is simple, the method is in the non-contact form, the accuracy is high, and the safety is good.

Owner:AERODYNAMICS NAT KEY LAB +1

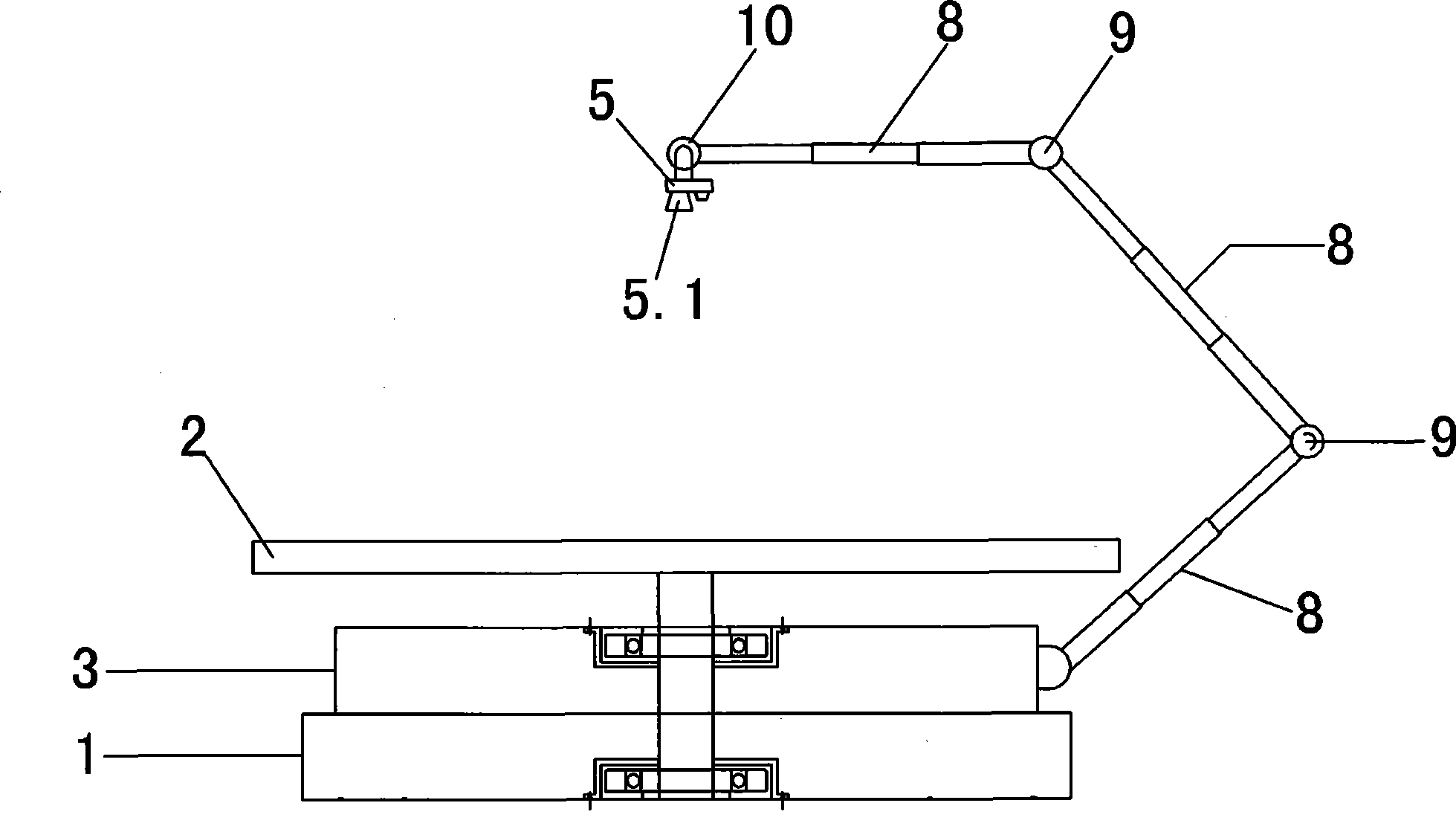

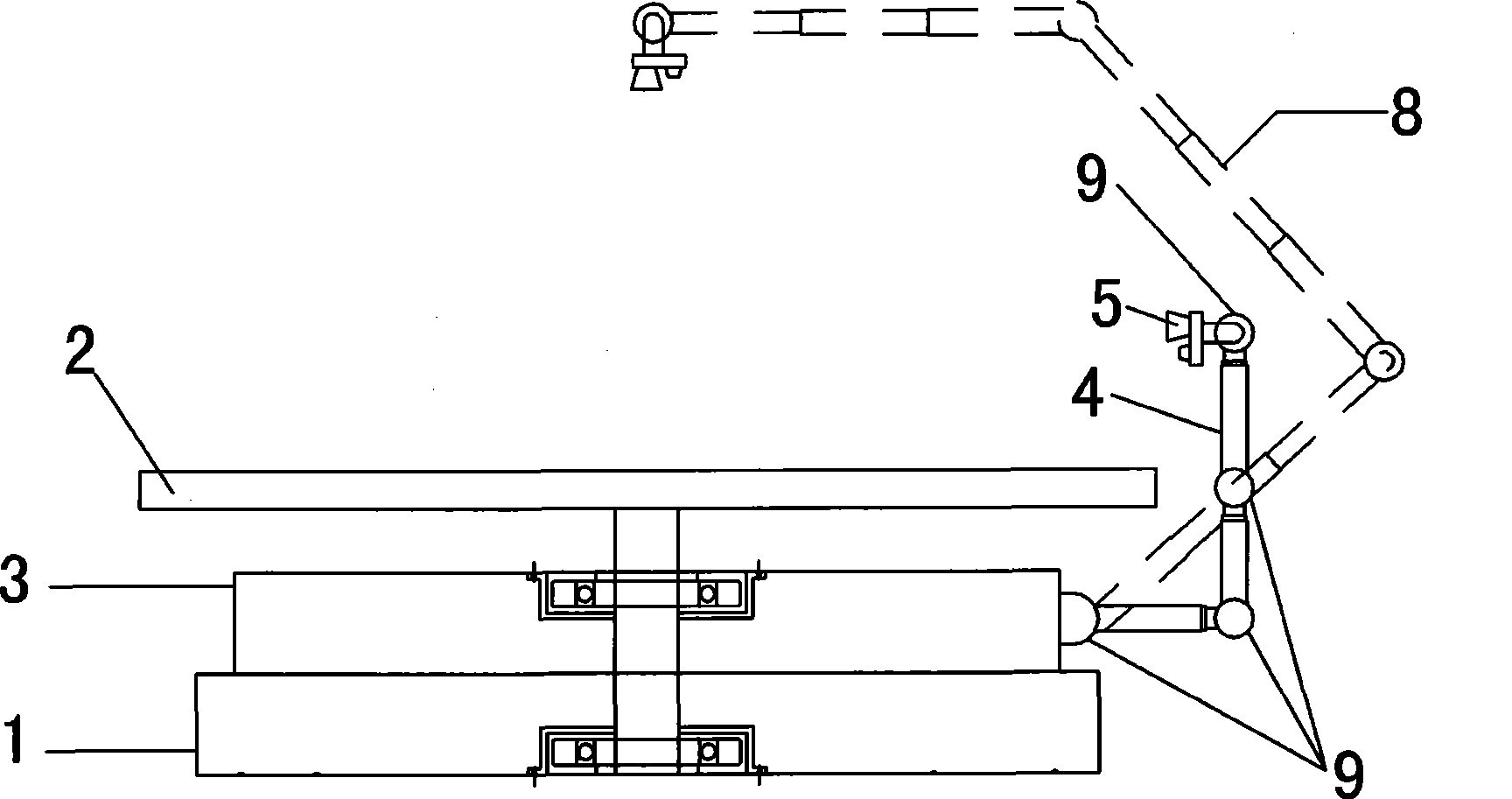

Camera shooting platform capable of rotating around shot object

InactiveCN101452186ANovel structureEasy to usePrintersProjectorsComputer graphics (images)Displacement error

The present invention provides a camera shooting platform which can rotate around a shot object for camera shooting. The camera shooting platform comprises a base, an object holding platform and a turnable. A technical scheme adopted is that the object holding platform and the turnable are rotatablely connected relatively. The turnable is installed with a camera shooting arm. The camera on the camera shooting arm can do horizontal to vertical (0-90 DEG) displacement to the shot object placed on the object holding platform. The camera shooting platform has the beneficial effects of novel structure, convenient use, effectively reducing the shake and displacement error in shooting, good camera shooting effect, good practicability, etc.

Owner:刘洋

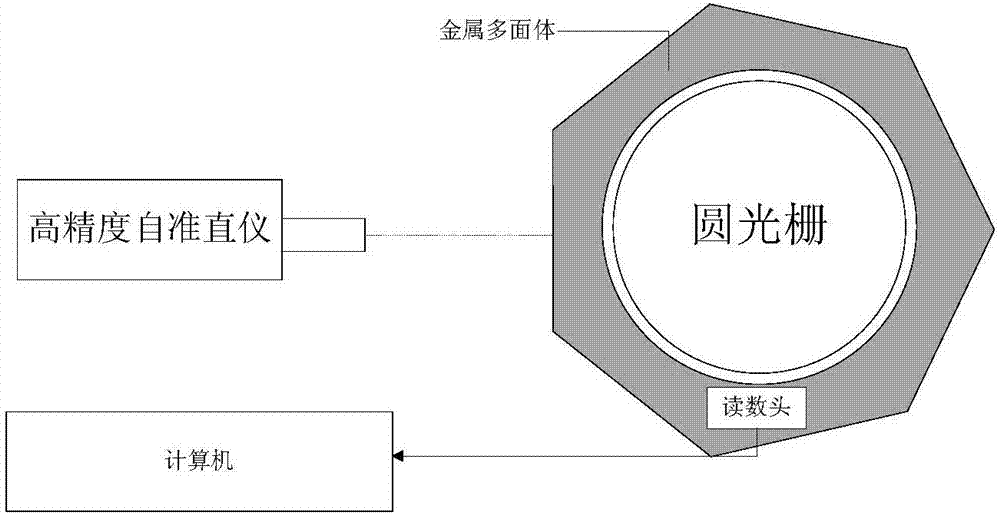

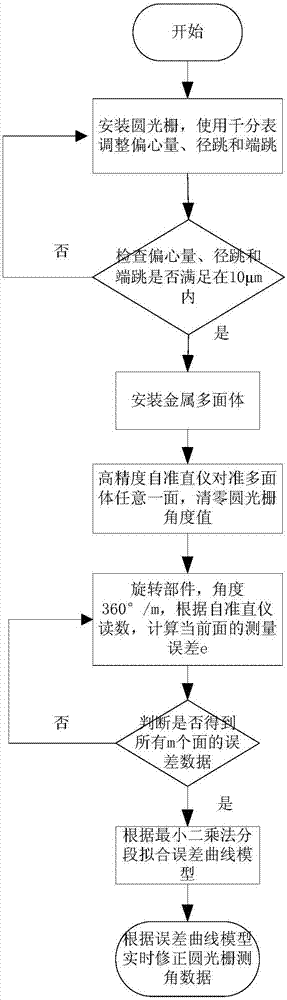

Circular grating installation error calibration and correction method based on single reading head

InactiveCN106871821AImproved error correction accuracyReduce high difficulty requirementsUsing optical meansGratingCurve fitting

The invention relates to a circular grating installation error calibration and correction method based on a single reading head, relating to the precision machinery field and solving the problems that the conventional precision angle measurement cannot achieve low cost, high precision, high reliability, and high temperature adaptability. The method includes that a dial gauge is used to guarantee the circular grating installation displacement error is within 10[mu]m, a metal polyhedron and a high-precision autocollimator are adopted to carry out the multi-area calibration on the circumference angle measurement error caused by the displacement error, and the angle measurement error is corrected in real time by means of least squares polynomial curve fitting in the area. The error caused by the displacement can be directly converted to the circumference angle measurement error through the space coordinate transformation method, the error correction parameters can be fitted by means of a multi-area precision calibration method, the real-time correction can be carried out during the measurement, therefore, the installation requirement of circular gratings can be reduced, and the ideal angle measurement precision can be realized by the single reading head.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

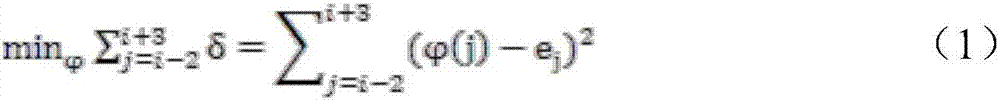

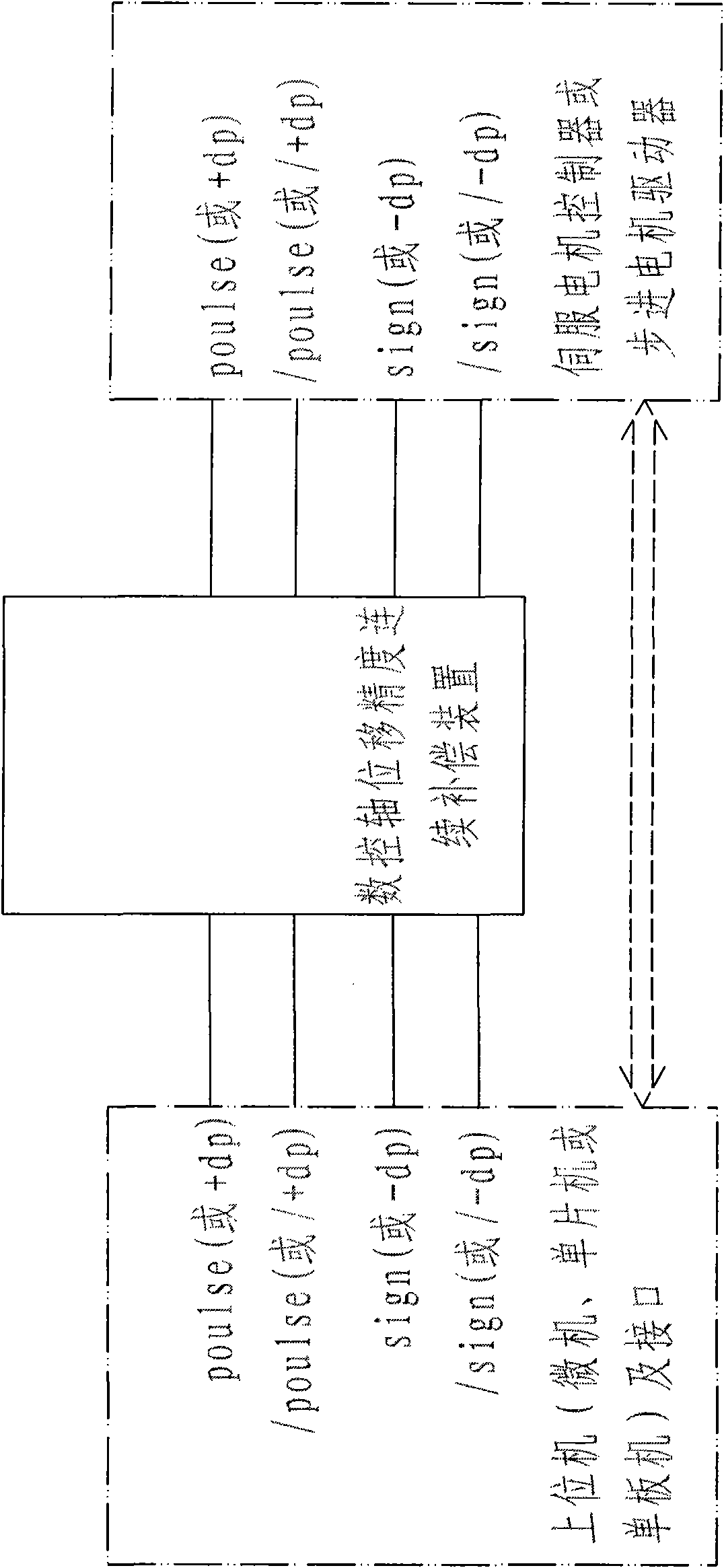

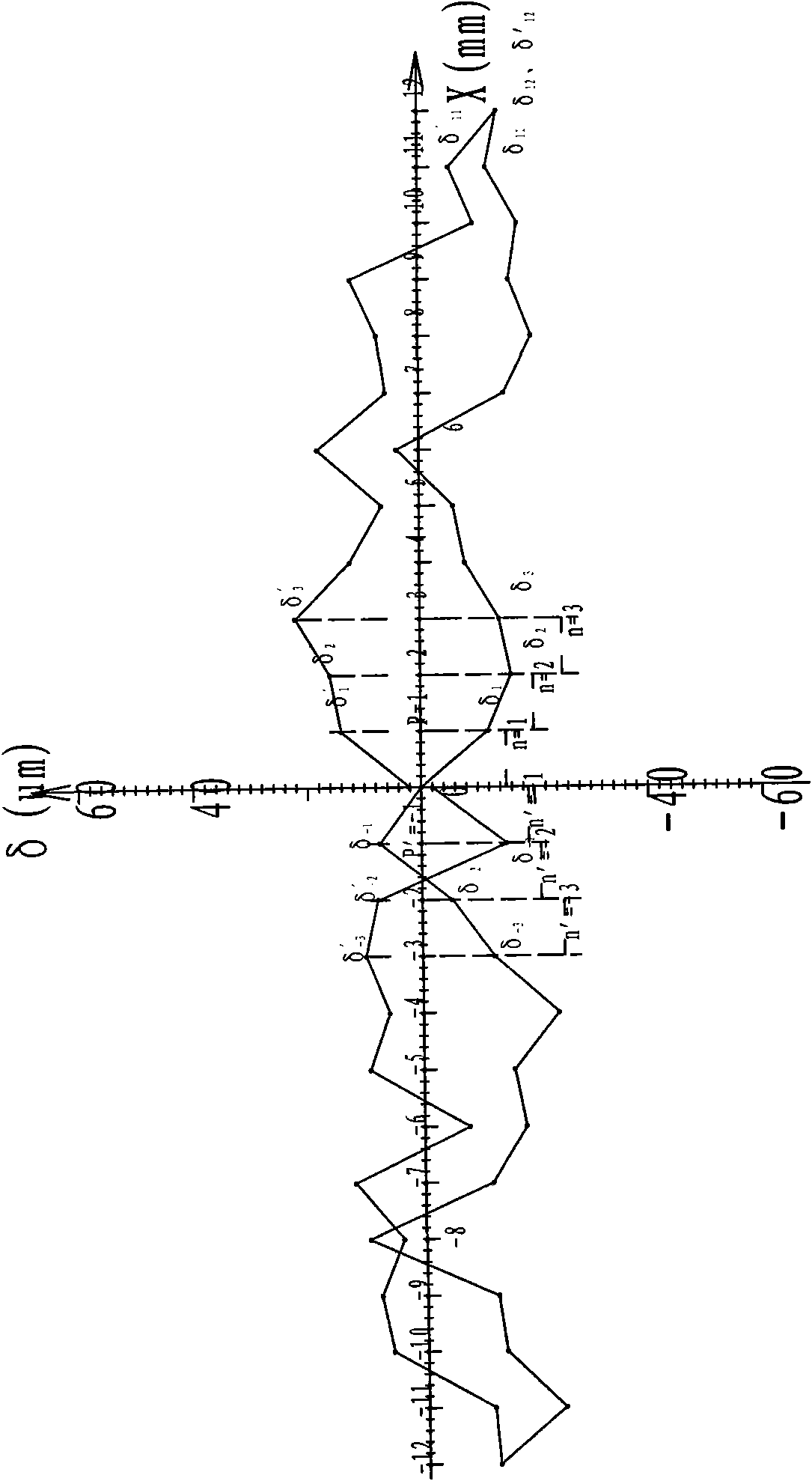

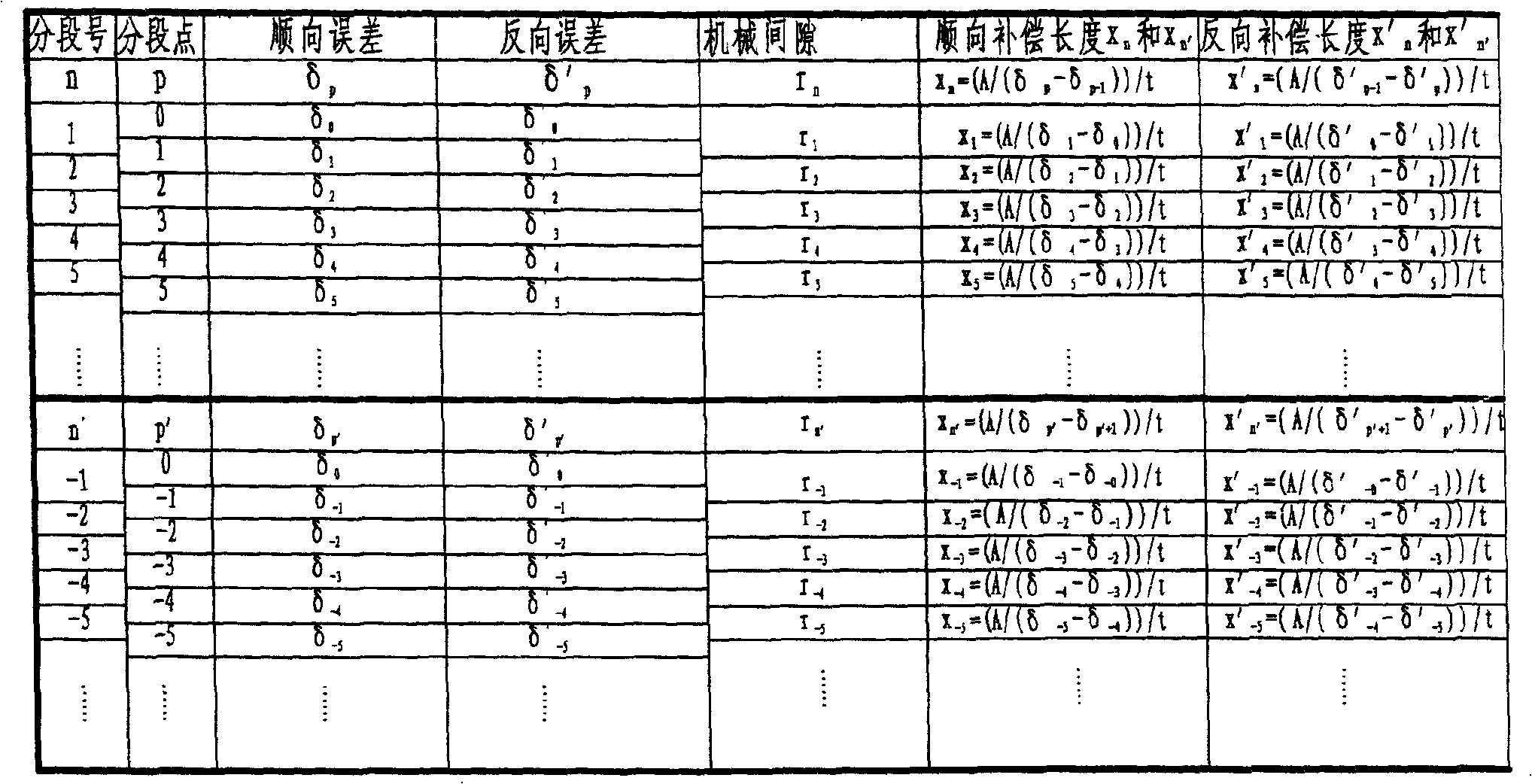

Continuous compensating method of displacement precision of digital controlled shaft of digital controlled machine tool

InactiveCN101564819AHigh precisionAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention discloses a continuous compensating method of the displacement precision of a digital controlled shaft of a digital controlled machine tool. The effective stroke of a digital controlled shaft is divided into a plurality of equal segments with A length by taking a reference point as an original point, the reference point is used as the boundary for dividing the effective stroke into positive sections and negative sections, the point of the positive sections is marked as p, the point of the negative sections is marked as p', the number of the positive sections is marked as n, and the number of the negative sections is marked as n'. The running of the digital controlled shaft along the direction leaving the reference point is defined as consequent running, and the running of the digital controlled shaft along the direction close to the reference point is defined as reversed running. The reference point is used as a starting point, and a laser interferometer is used for measuring the consequent and reversed error values delta p and delta p' of every section point of the digital controlled shaft corresponding to the reference point, and the displacement-error curve of the digital controlled shaft is acquired. The consequent and reversed error linear functions of every section are respectively established according to the measuring result. Unit conversion, data list preparation and compensation are respectively carried out. The continuous compensating method of displacement precision of the digital controlled shaft of the digital controlled machine tool can realize the positioning precision compensation of the digital controlled shaft, the error compensation of the moving track of the digital controlled machine tool and the section gap compensation of the digital controlled shaft.

Owner:贵州科邦科技实业有限责任公司

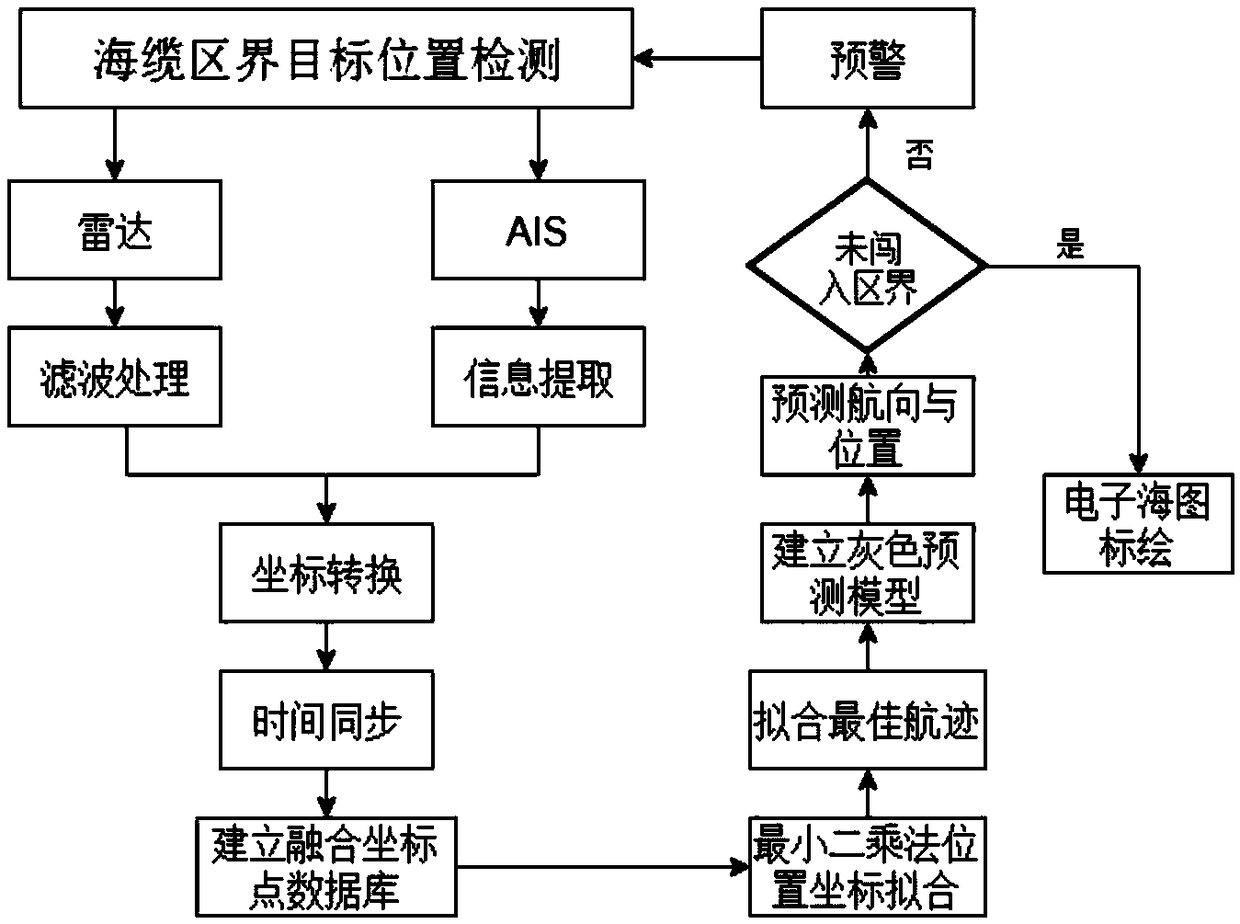

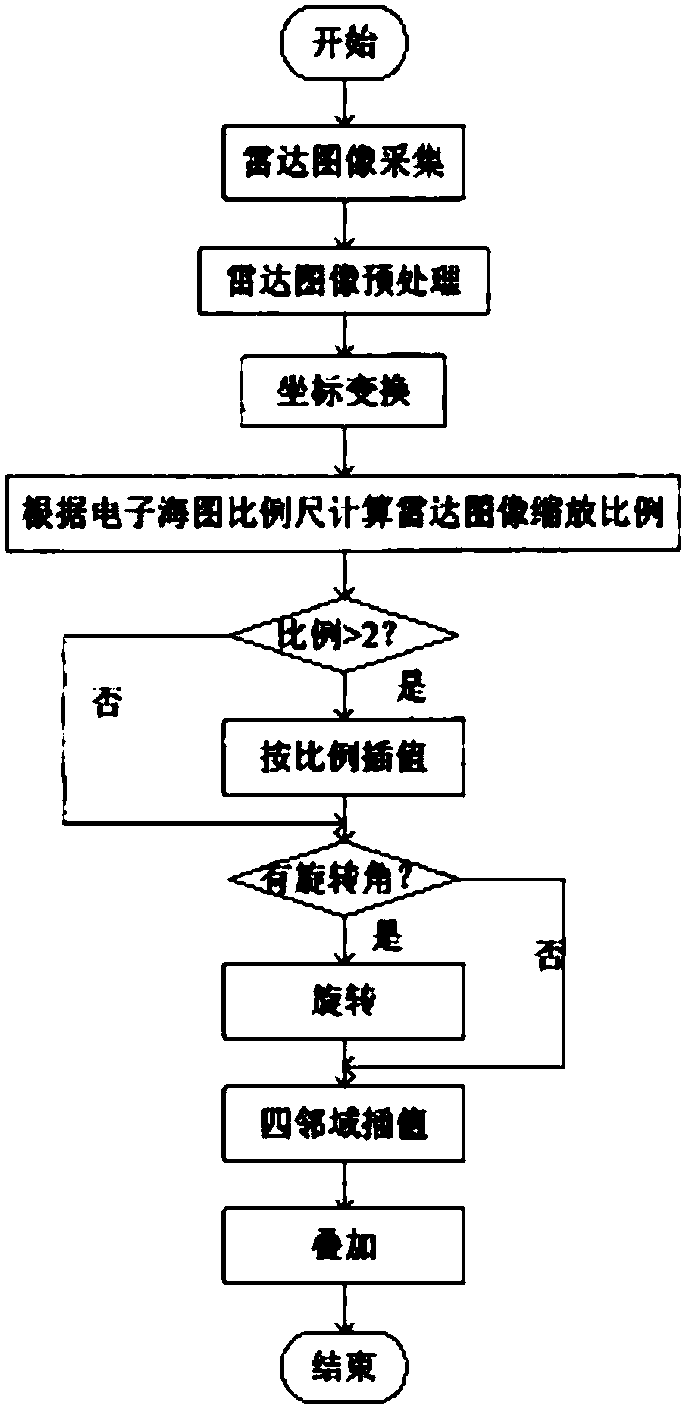

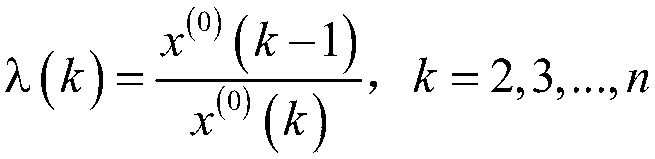

Method for detecting ship target position at submarine cable zone

The invention relates to a method for detecting a ship target position at a submarine cable zone, in particular to a data fusion position detection algorithm based on a radar target recognition technology and a shore-based ship automatic identification system. The method comprises firstly plotting a surrounding geographical situation on a radar chart by using shore-based radar position detection;confirming a dynamic target by filtering; tracking a heading and a polar coordinate position; fusing with target position information by time synchronization; correcting a radar-plotted target position by the ship position information received by a B-type shore-based AIS; predicting the heading and the speed of the ship at the next moment by target position detection; finally obtaining the real geographical position of the target; superposing the radar chart on an electronic chart, and drawing a submarine cable zone by using an electronic auxiliary navigation mark to ensure the safety of the submarine cable zone. The method, by using the instantaneity of the AIS position information and in combination with radar data comparison fusion, reduces the displacement error of a radar-positioned sea surface target, and achieves an accurate position detection result.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

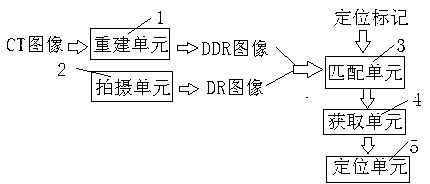

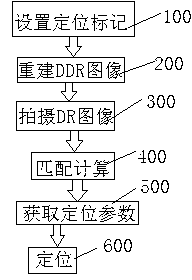

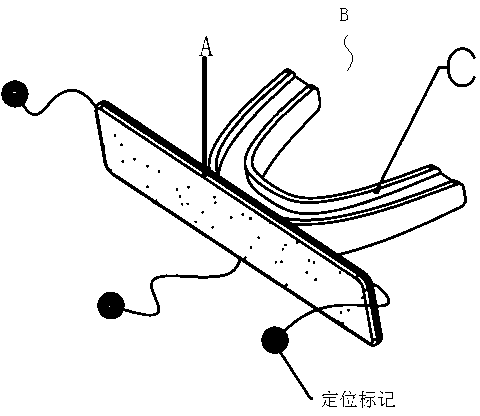

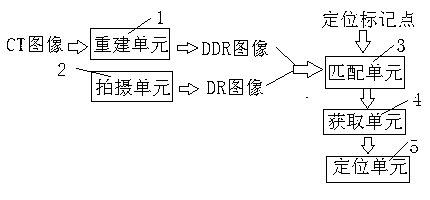

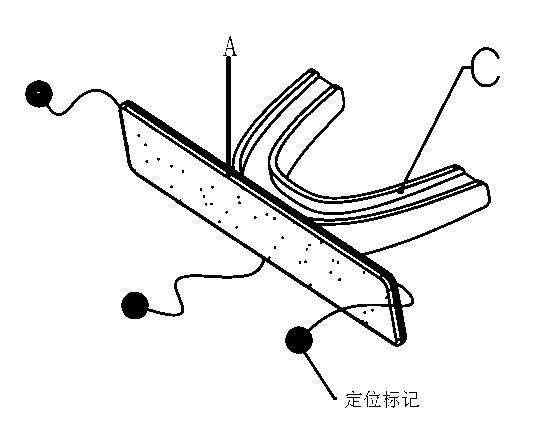

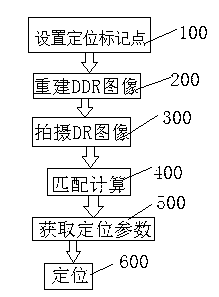

Non-invasive in-vitro tumor positioning system and method by fixing mark points

The invention relates to a non-invasive in-vitro tumor positioning system and method by fixing mark points. A concept of time is introduced based on the three-dimensional radiation technology. Displacement errors of movement of an anatomical structure in a treatment process and movement of the anatomical structure among every-time treatment processes are fully considered, and the displacement errors include situations in the aspect of change of radiation dose distribution and influence on a treatment plane due to respiratory movement, setup errors, target area contraction and the like. Real-time monitoring can be performed on cancers and health organs by utilizing various advanced imaging devices before treatment of patients or during treatment of the patients, and treatment conditions can be adjusted according to changes of the positions of the organs to enable an irradiation filed to tightly follow a target area. Therefore, accurate treatment can be achieved actually. Generally speaking, the mark points are placed through denture when the cancers in the head or the neck are positioned. Due to the fact that the denture is fully meshed with patients' teeth, the positions of the mark points are firm.

Owner:YITI INTELLIGENT TECH LTD SHENZHEN CITY

One-freedom-degree flexible micro-positioning platform

ActiveCN106113022AImprove the stroke of the zoomAccurate magnificationProgramme-controlled manipulatorHinge angleDisplacement error

The invention discloses a one-freedom-degree flexible micro-positioning platform. The one-freedom-degree flexible micro-positioning platform comprises a motion input device, a flexible motion platform and a platform base used for fixing the flexible motion platform; and the flexible motion platform comprises two half motion mechanisms, and each half motion mechanism comprises a motion platform connected through flexible hinges and multi-stage differential motion levers. According to the design, displacement is amplified and can be accurately amplified on the conditions that the positions and the sizes of the flexible hinges and the levers are accurate; the design structure is simple, the occupied space is relatively small, displacement can be output stably through the symmetric structure, lateral additional displacement can be effectively removed, longitudinal coupling displacement errors of the platform can be reduced, the displacement amplification accuracy is improved, and the flexible hinges can be integrally machined easily due to the design, and assembly errors can be avoided. Displacement amplification is accurately realized in relatively-small space and at low cost, and the problem that large stroke and high accuracy of the flexible micro-positioning platform cannot be balanced is solved.

Owner:GUANGDONG UNIV OF TECH

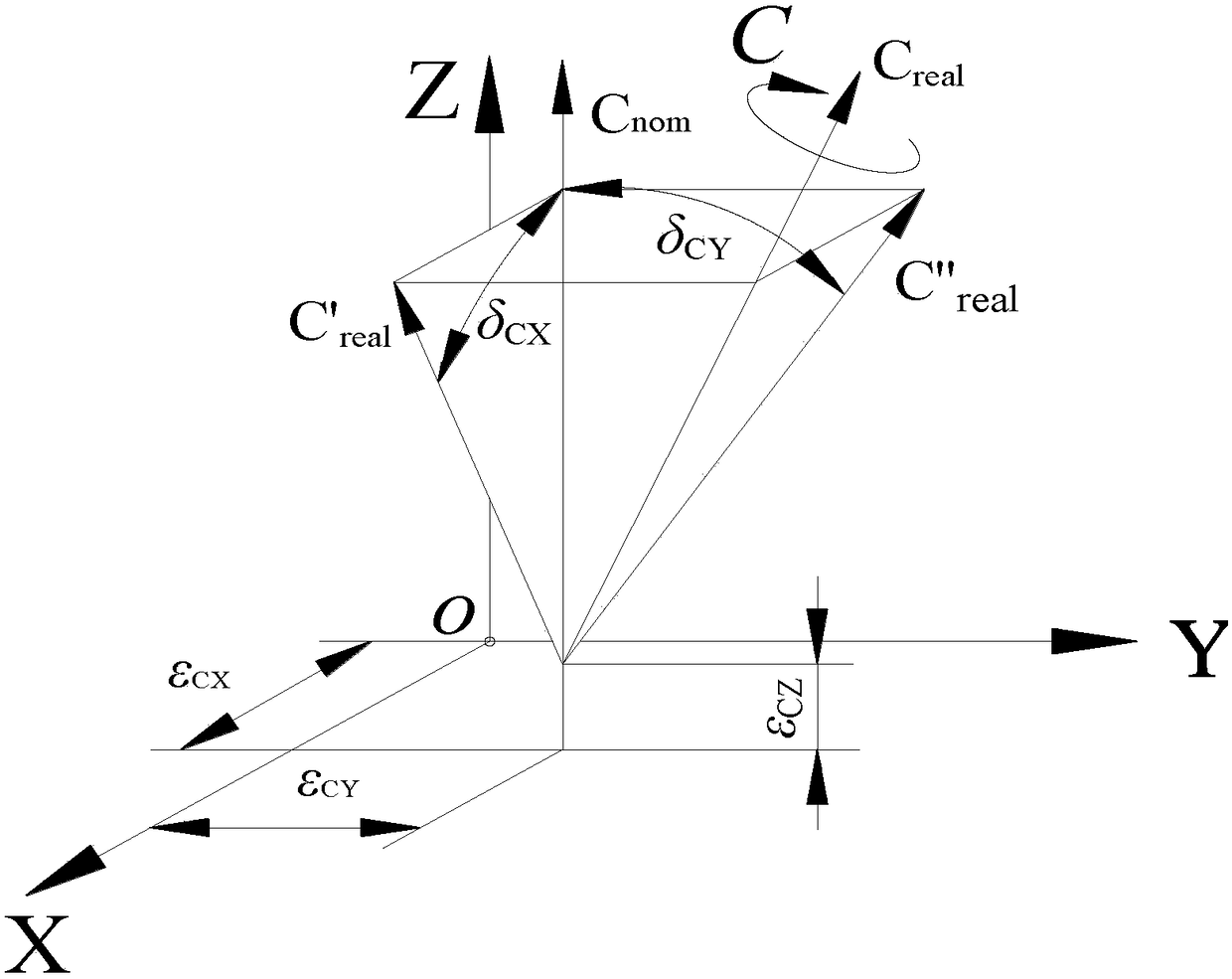

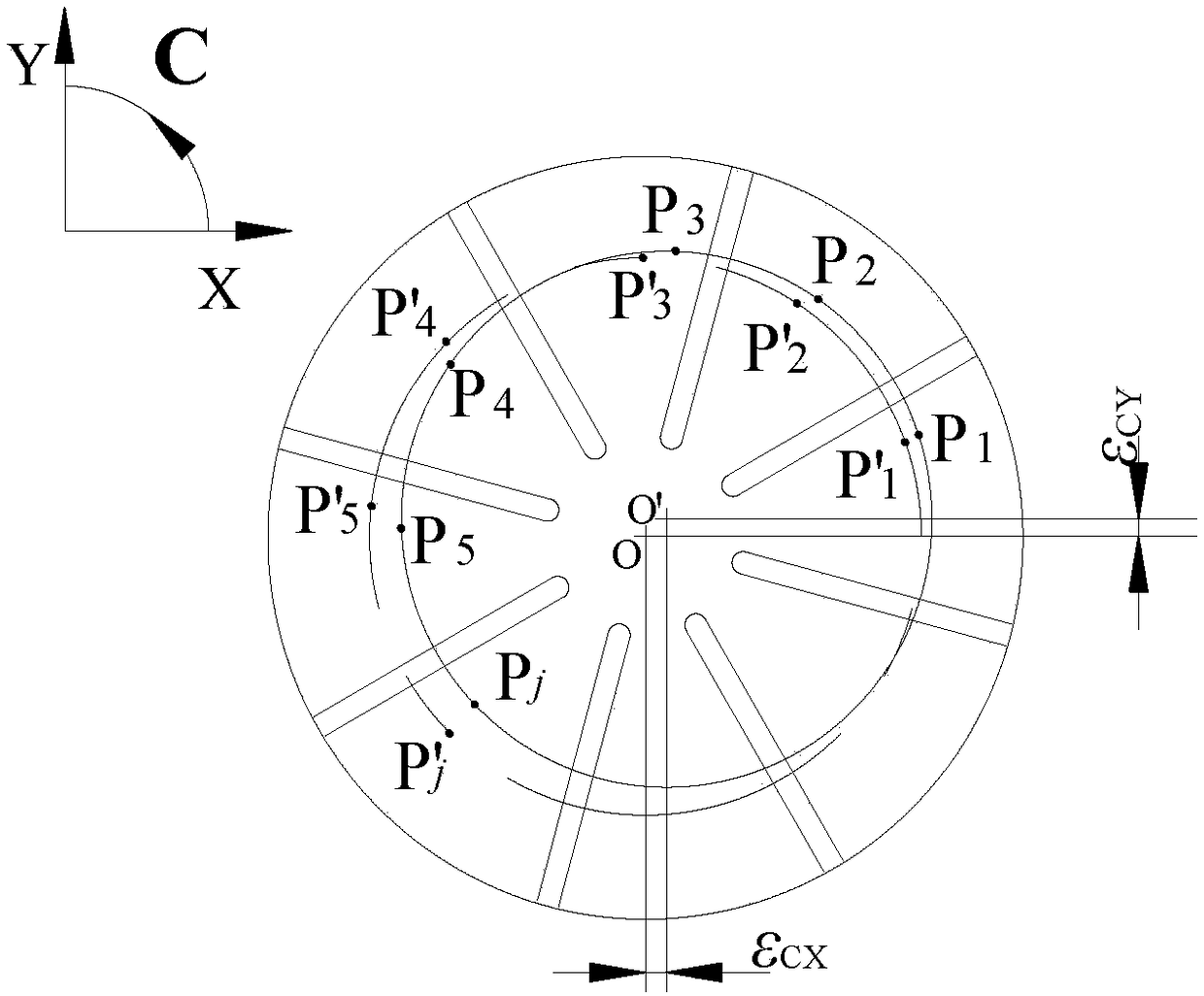

Installation error identification method based on rotating shaft integration error measurement value

InactiveCN108469782AEasy and fast installation errorAccurate installation errorProgramme controlComputer controlNumerical controlMeasuring instrument

The invention discloses an installation error identification method based on a rotating shaft integration error measurement value. The method comprises the following steps of step1, taking the intersection point of a workbench rotation C rotation shaft axis and a workbench surface as an original point, and establishing a measured coordinate system; step2, through a measuring instrument, acquiringthe comprehensive error measurement value of the theoretical point and the actual point of the different rotation angles of a point P around a C shaft; step3, extracting the error projection point ofthe comprehensive error measurement value in an XOY measurement coordinate plane, and carrying out plane circle fitting to obtain the displacement error of a C shaft axis; and step4, extracting the error projection points of the comprehensive error measurement value in an XOZ measurement coordinate plane and a YOZ measurement coordinate plane, and carrying out straight line fitting and acquiring the perpendicularity errors of the C shaft, an X shaft and a Y shaft. In the invention, the four installation errors of the rotation shaft of a five-shaft numerical control machine tool can be conveniently, rapidly and accurately acquired, a data reference is provided for the assembling and debugging and the installation error of the rotation shaft of the five-shaft numerical control machine tool,and the method is suitable for all structural types of the five-shaft numerical control machine tools.

Owner:SOUTHWEST JIAOTONG UNIV +1

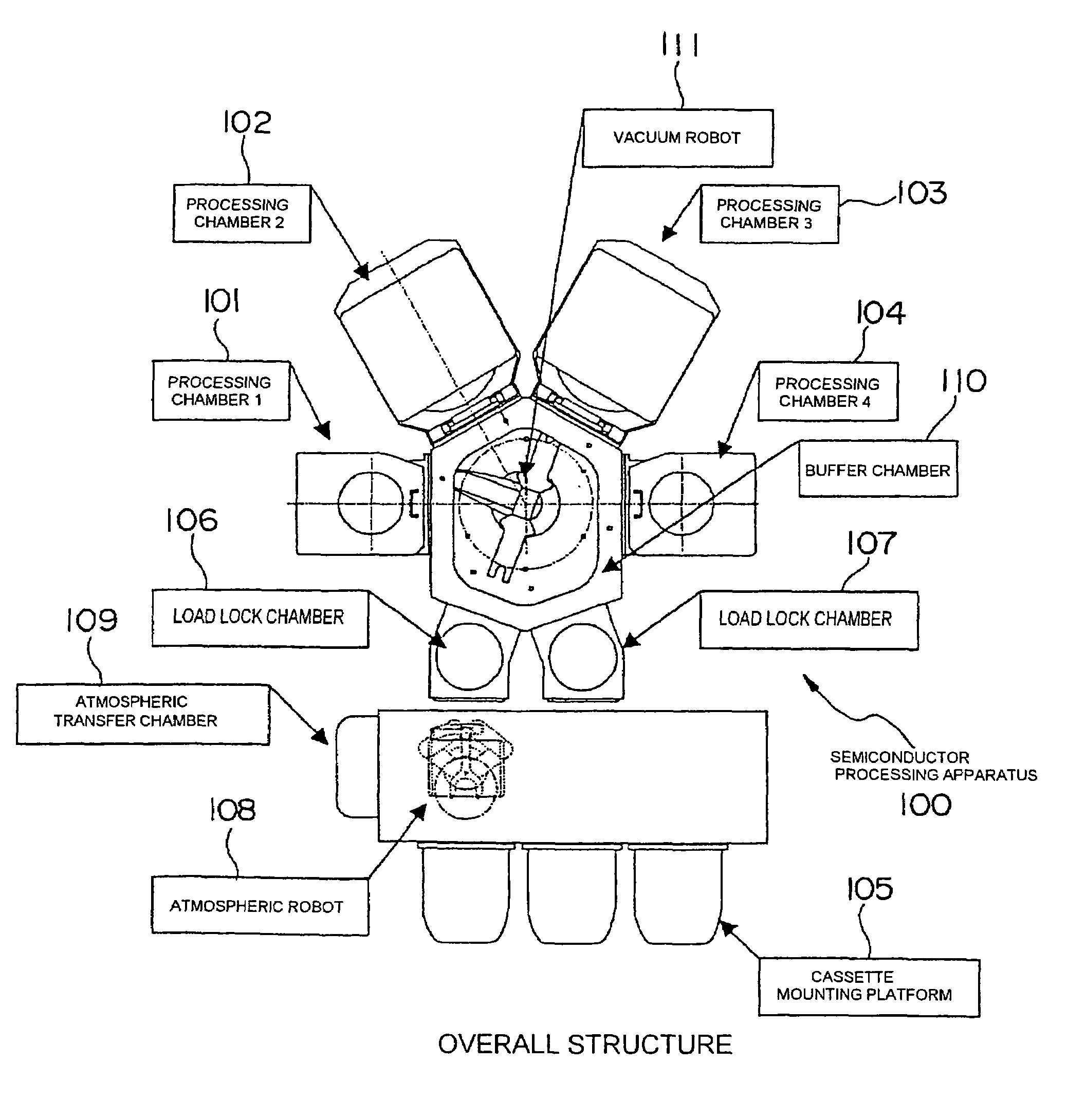

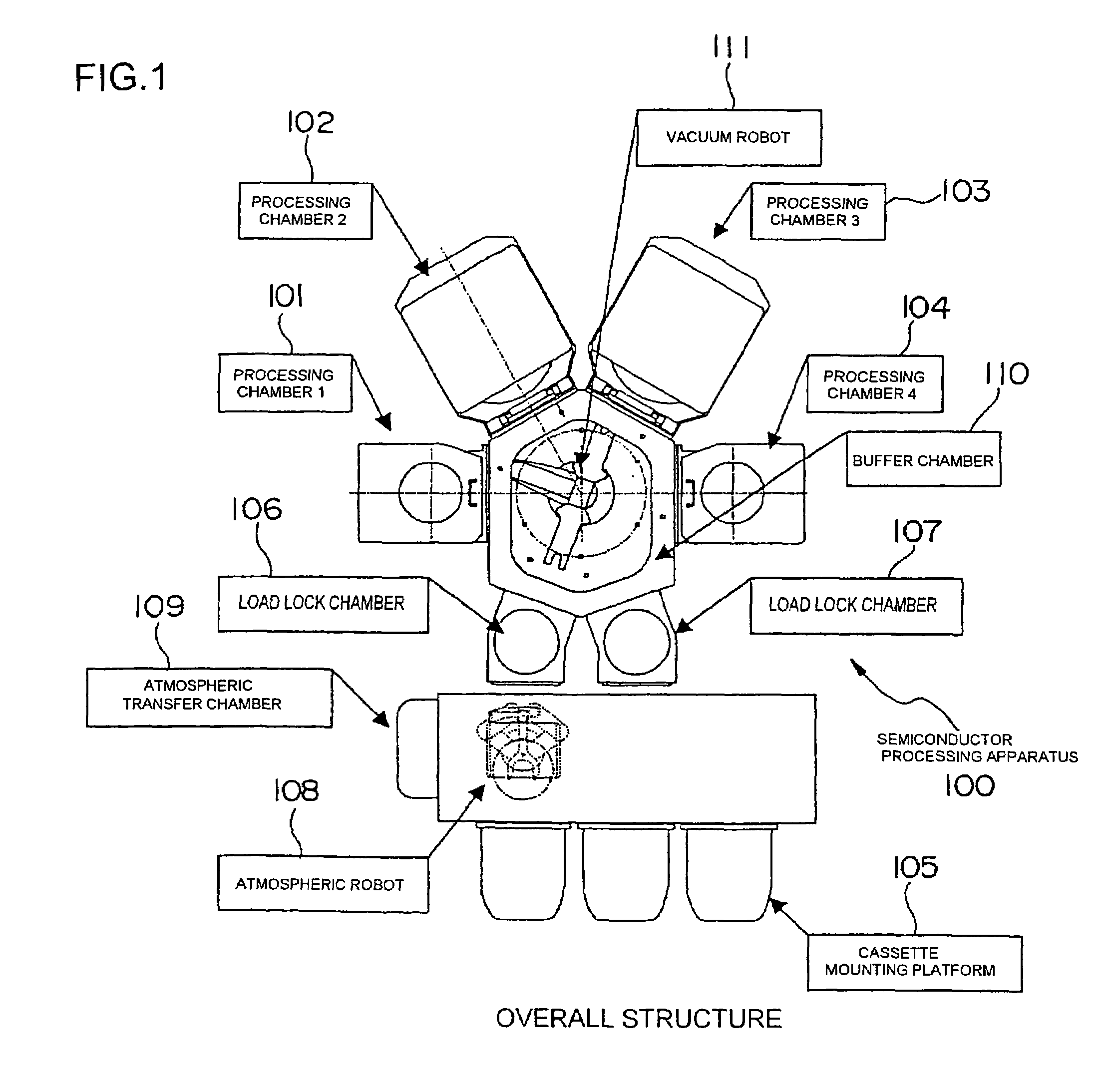

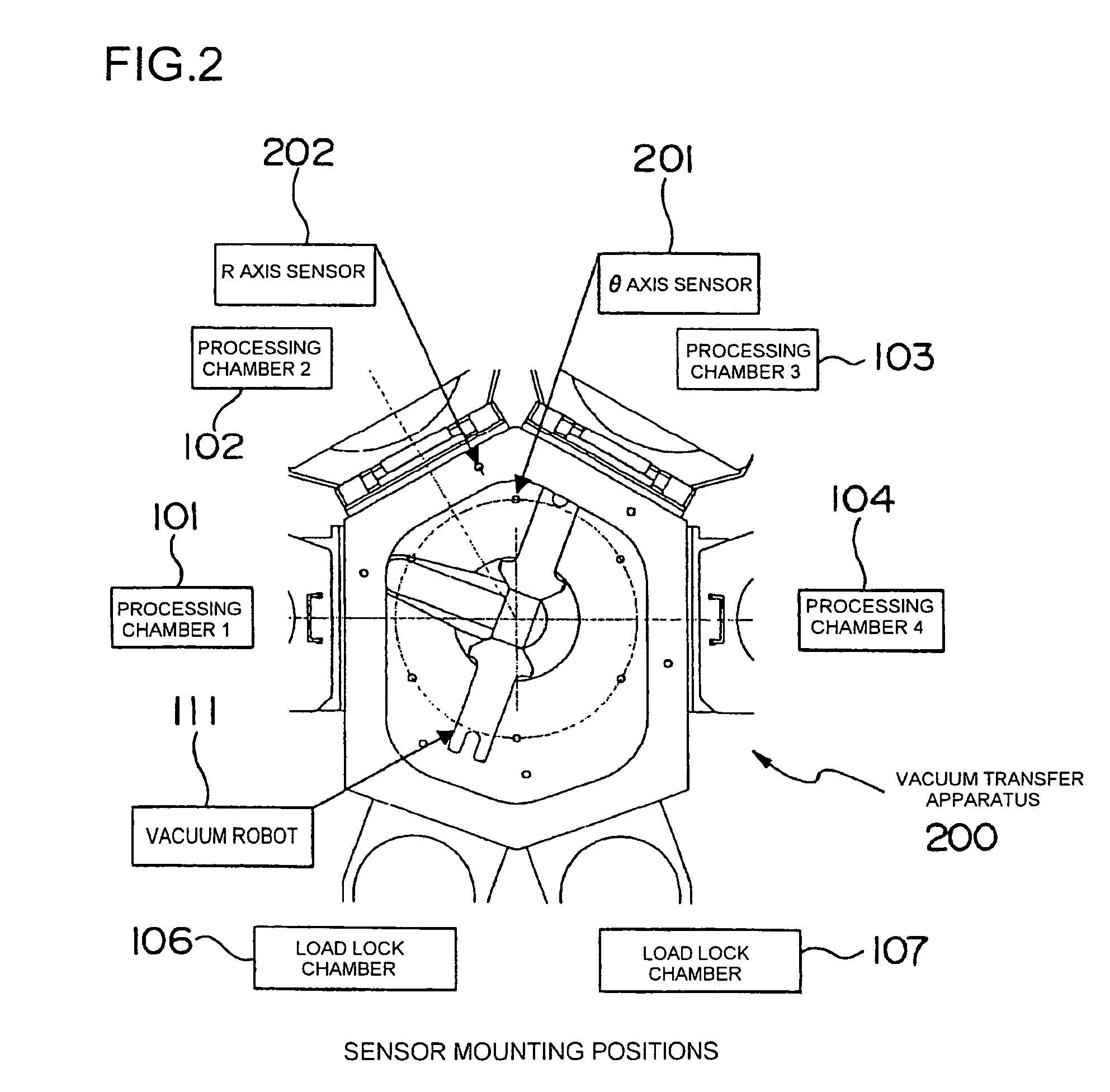

Vacuum processing method and vacuum processing apparatus

ActiveUS7353076B2Improve throughputSemiconductor/solid-state device manufacturingSpecial data processing applicationsDisplacement errorControl theory

The invention provides a semiconductor processing apparatus having a high throughput capable of appropriately coping with the positional displacement that may occur during transfer of the wafer after correcting the position thereof, without slowing down the transfer speed of the wafer. A position correction quantity of the wafer with respect to a vacuum robot is computed based on the outputs of a θ axis sensor for detecting the interception angle of the wafer during rotation of the vacuum robot and an R axis sensor for detecting the interception distance of the wafer during expansion and contraction of the vacuum robot. If the position correction quantity exceeds a predetermined standard value, an operation to change the position data is performed, and if the distance data obtained based on the outputs from the θ axis sensor and the R axis sensor exceeds a predetermined permissible value, it is determined that a displacement error has occurred and the operation is stopped.

Owner:HITACHI HIGH-TECH CORP

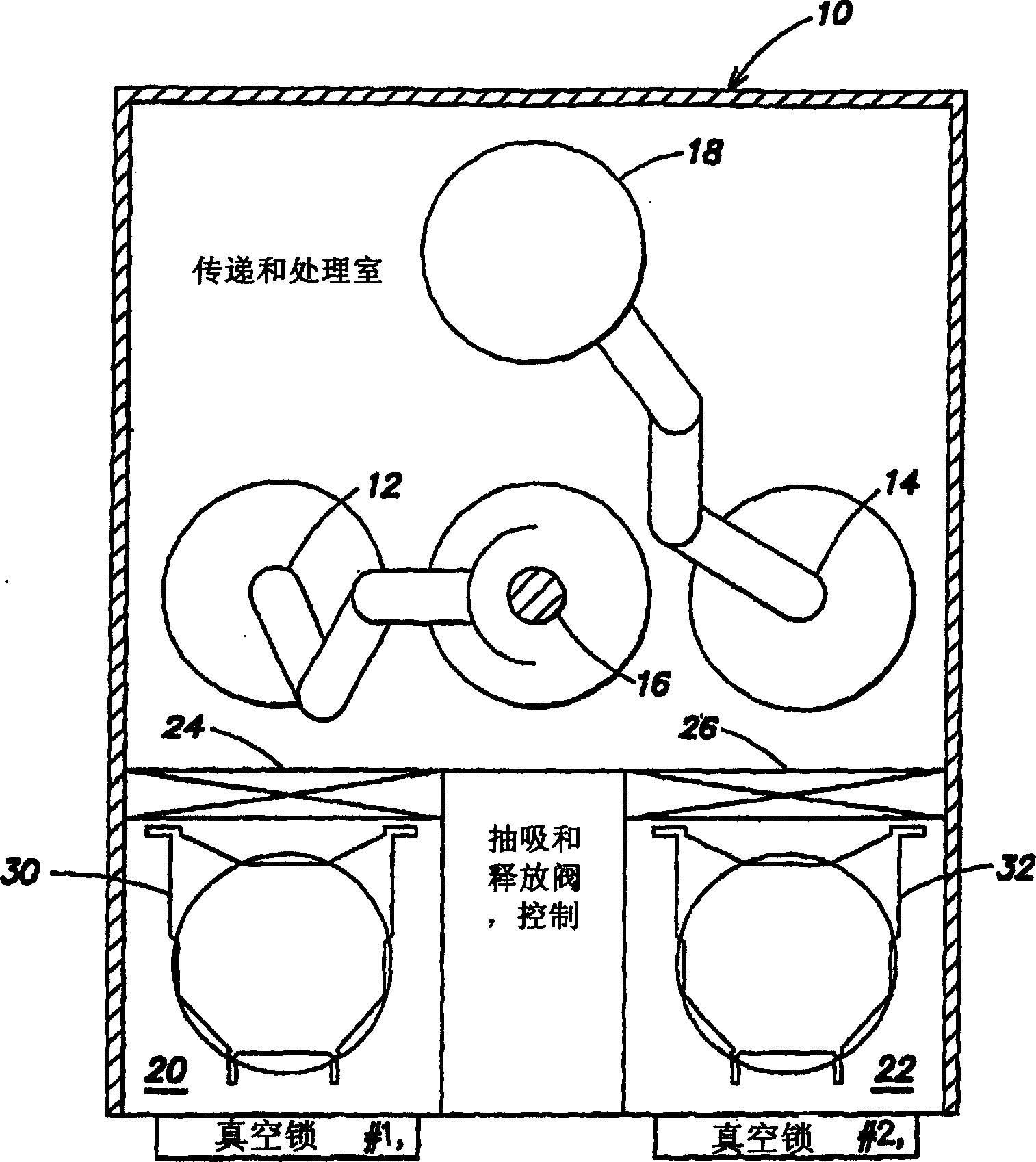

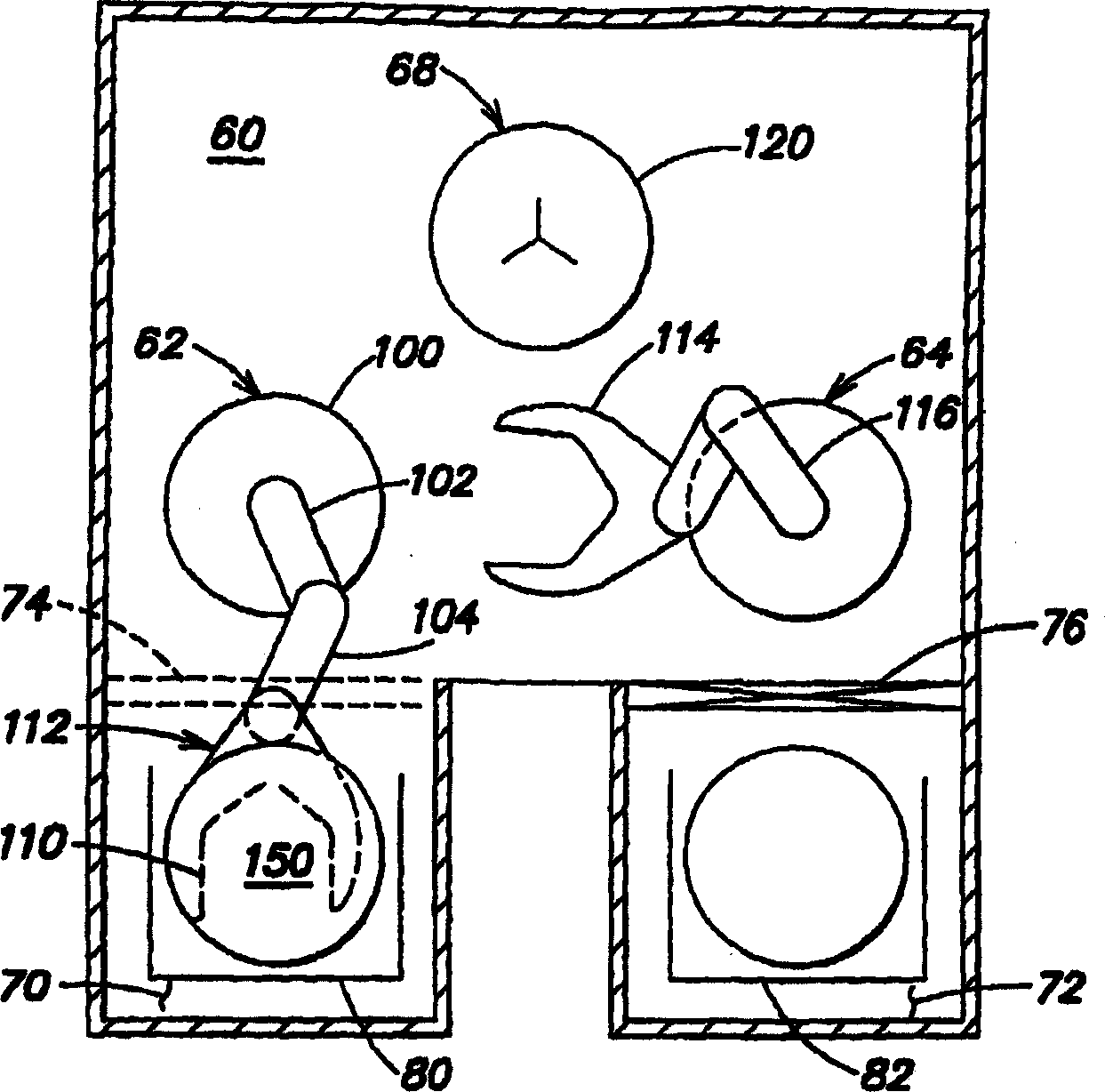

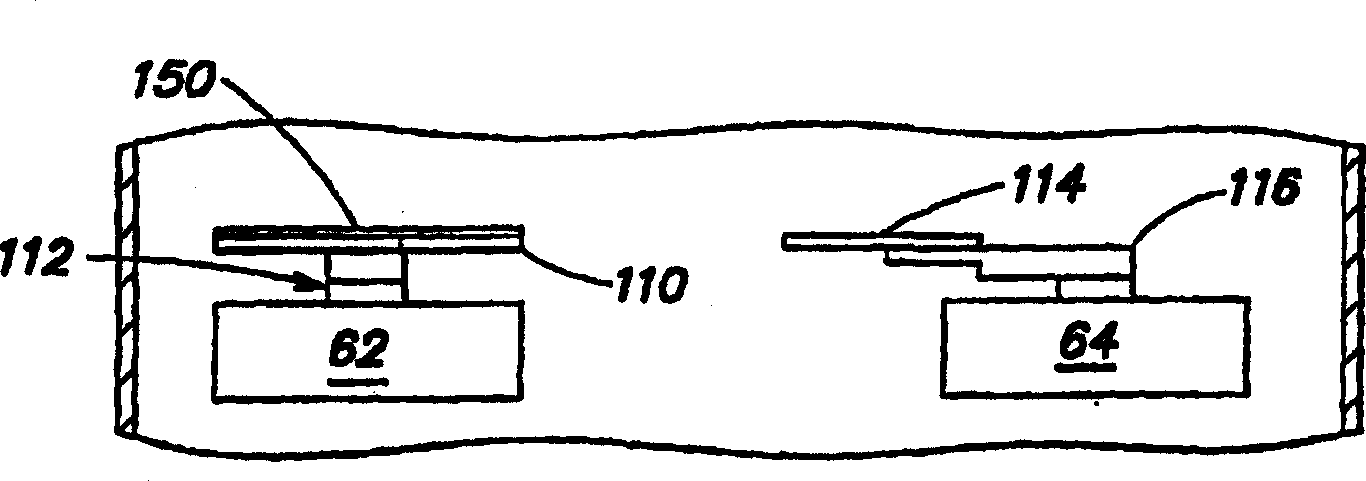

Methods and apparatus for high speed object handling

InactiveCN1765004ADigital data processing detailsSemiconductor/solid-state device manufacturingObject handlingRotational error

Methods and apparatus for high speed workpiece handling are provided. A method for workpiece handling includes: utilizing a first robot to remove a workpiece from a first magazine; transferring the workpiece from the first robot directly to a second robot without transferring the workpiece to a transfer station; utilizing the A second robot places the workpiece on a workpiece holder at a processing station; and transfers the workpiece from the workpiece holder to the first cassette with the first robot after processing. The end effectors of the first and second robots may each have a plurality of vertical positions for efficient workpiece handling. The displacement and rotation errors of the workpiece can be sensed and corrected without using a transfer station. The method and apparatus are useful for handling semiconductor wafers.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Split pattern displacement deviation monitoring system

InactiveCN101419319AImprove stabilityGood adjustment and control stabilityUsing electrical meansMountingsElectricityCapacitance

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Non-invasive tumor locating system and method

InactiveCN102697560AReal time monitoringDiagnosticsInstruments for stereotaxic surgeryAbnormal tissue growthPeristalsis

The invention relates to a non-invasive tumor locating system and a non-invasive tumor locating method. The time concept is introduced on the basis of a three-dimensional radiotherapy technology; the motion during the treatment process and the displacement error of fractionated treatment of anatomy tissue are fully considered, such as the situations at the aspects of changes of radiotherapy dose distribution and influences to the treatment plan caused by breathing peristalsis motion, daily positioning error, target region contraction and the like; and the tumor and the normal organs are monitored in real time by utilizing various kinds of advanced image devices before and during the treatment of patients, and the treatment conditions can be regulated according to the changes of the organ position, thus the radiation field follows the target region closely, and the accurate treatment is really achieved.

Owner:YITI INTELLIGENT TECH LTD SHENZHEN CITY

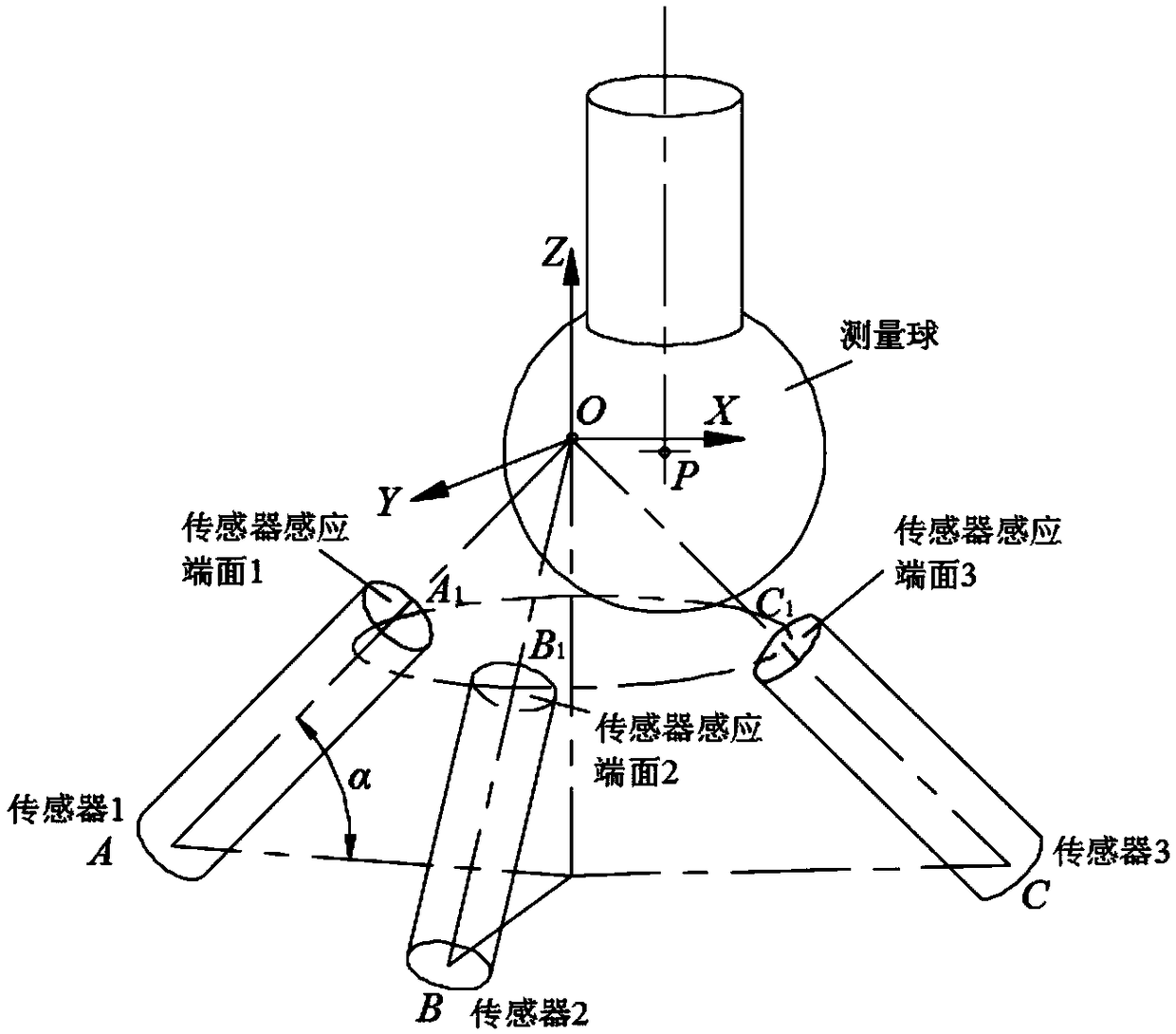

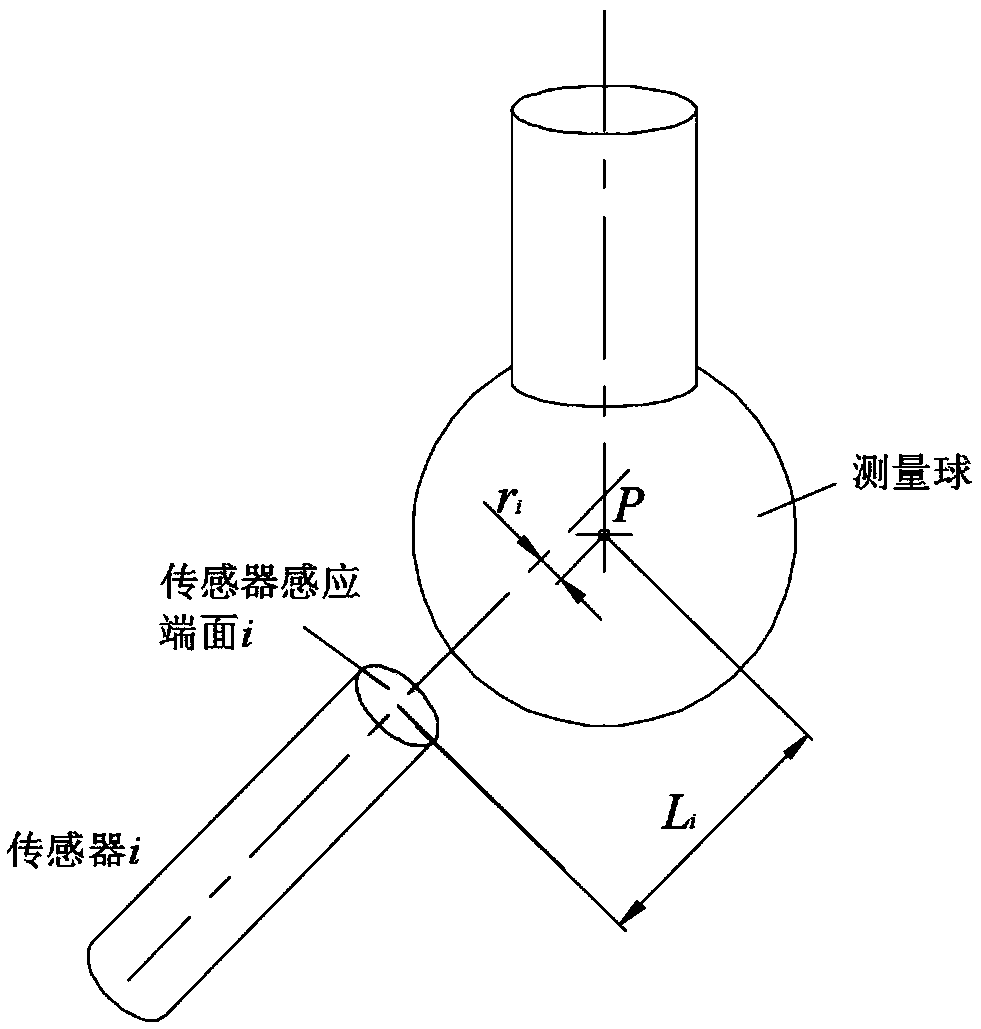

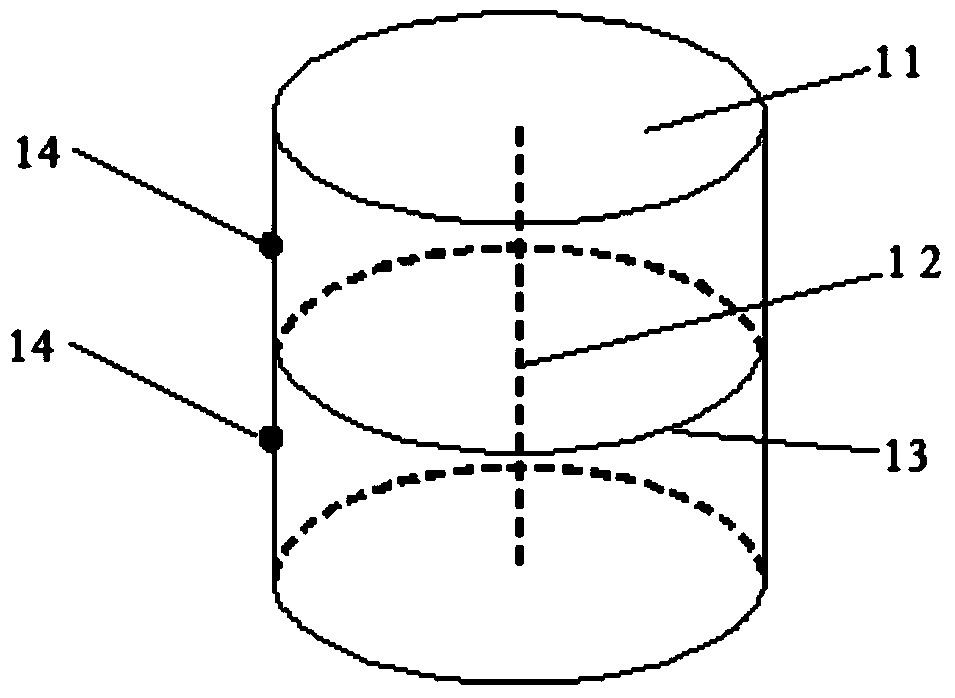

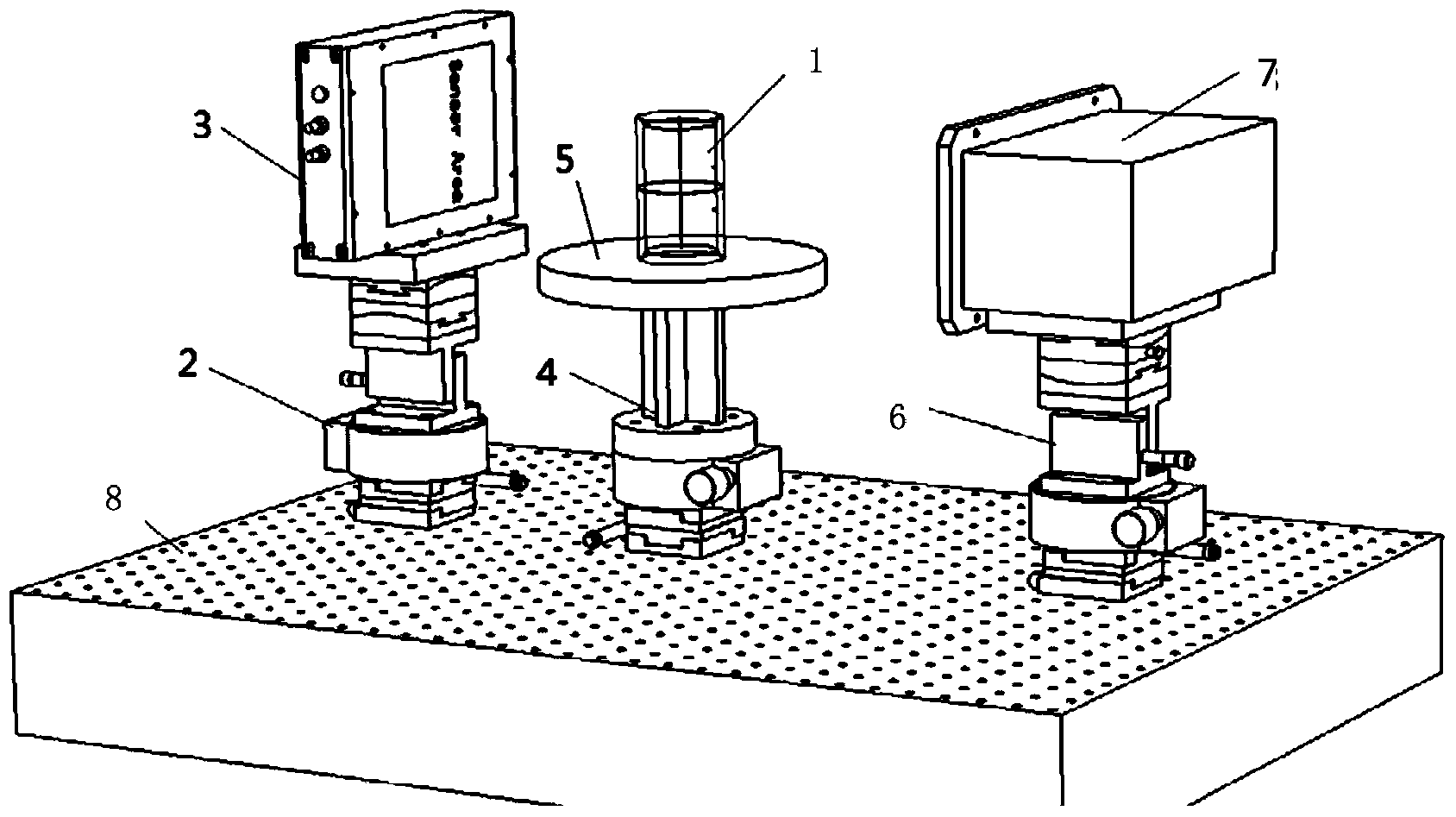

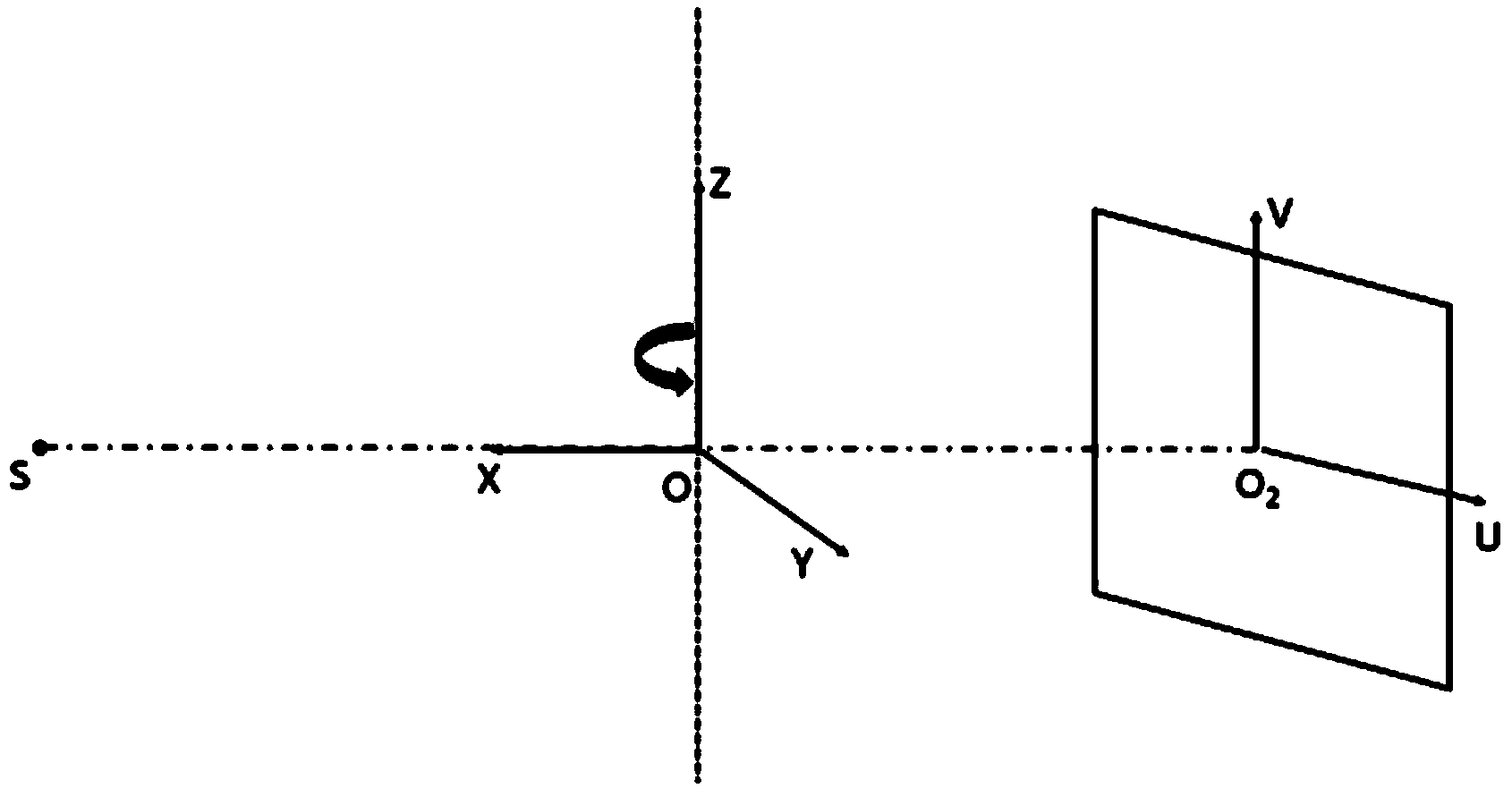

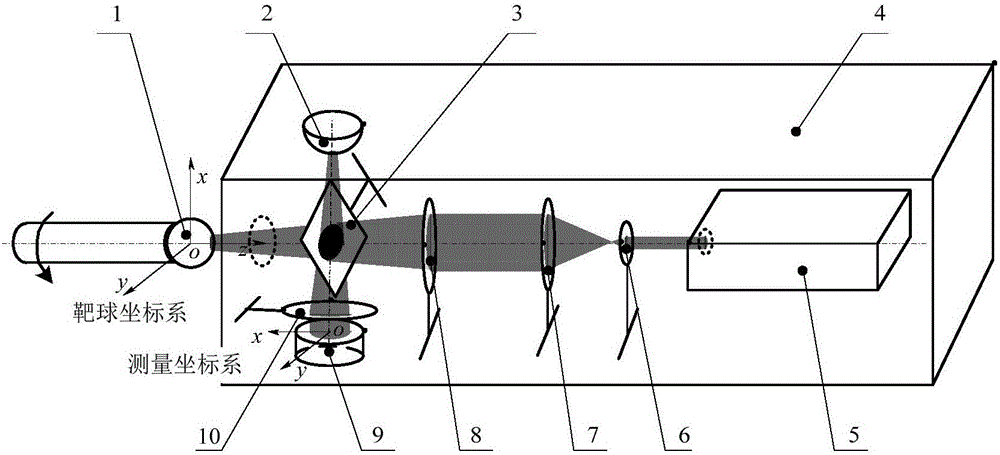

Calculating method for ball center coordinate of non-contact R-test measuring instrument using eddy current displacement sensor

ActiveCN109032069AAvoid measurement errorsHigh measurement accuracyProgramme controlComputer controlMeasuring instrumentCutter location

The invention discloses a calculating method for a ball center coordinate of a non-contact R-test measuring instrument using an eddy current displacement sensor. The calculating method includes the steps that a measuring coordinate system of the non-contact R-test measuring instrument is calibrated according to design and measuring characteristics of the non-contact R-test measuring instrument; and a coordinate result of a ball center point in the measuring coordinate system is solved and exacted using a differential evolution algorithm according to an eddy current displacement sensor inducedvoltage characteristic curve equation and a sensor induced plane equation. According to the calculating method for the ball center coordinate of the non-contact R-test measuring instrument using the eddy current displacement sensor, accurate measuring of three-direction displacement errors of five-axis numerically controlled machine tool knife tool cutter location points is realized, and the measuring accuracy, range and stability are better.

Owner:SOUTHWEST JIAOTONG UNIV +2

Correction device and correction method for geometric position of cone beam CT system

ActiveCN103784160AFast and precise geometric correctionComputerised tomographsTomographyEngineeringDisplacement error

The invention discloses a correction device and correction method for the geometric position of a cone beam CT system. The correction device comprises a supporting body, a vertical rod, a horizontal ring and locating balls. The vertical rod, the horizontal ring and the locating balls are all fixed to the supporting body. All points on the horizontal ring are arranged in the same face. The vertical rod is perpendicular to the plane where the horizontal ring is located. The two locating balls are arranged on the two sides of the horizontal ring respectively in the direction parallel to the vertical rod, and the distances between the locating balls and the horizontal ring are equal. The geometric correction device including the vertical rod, the horizontal ring and the locating balls is adopted, the projection characteristics of corresponding points, lines and faces are observed, the size and direction of the displacement errors and the angle errors of a detector are judged, corresponding adjustment is carried out, and therefore the geometric correction of the cone beam CT system is achieved faster and more accurately. After correction is completed, a relatively precise geometric parameter value can be calculated according to imaging of one or more points in the device at different positions.

Owner:北京锐视康科技发展有限公司

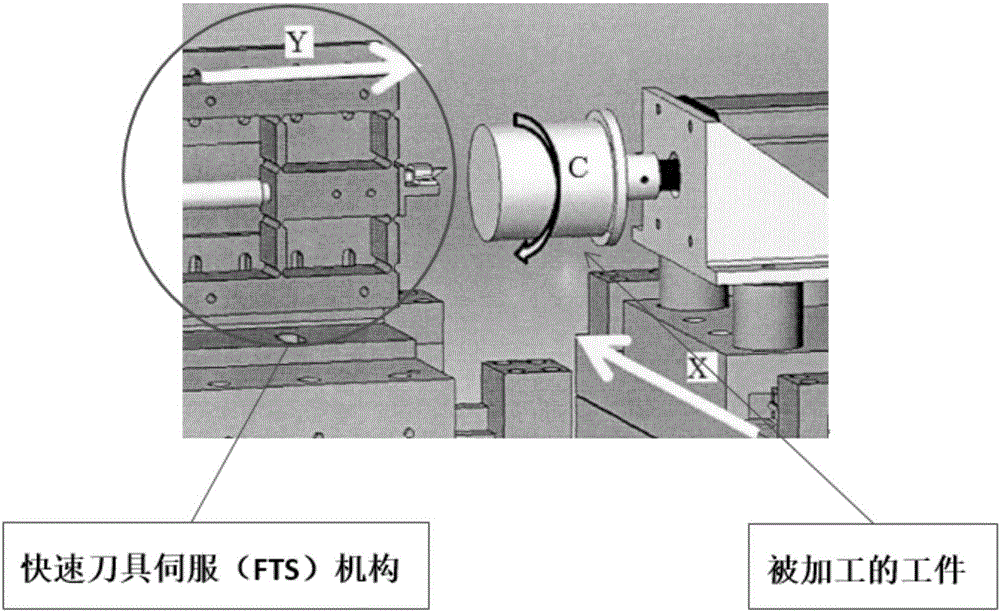

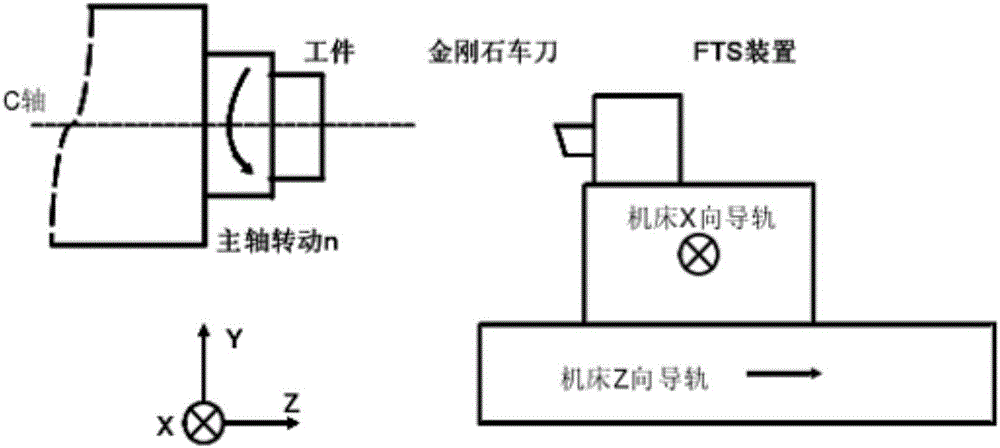

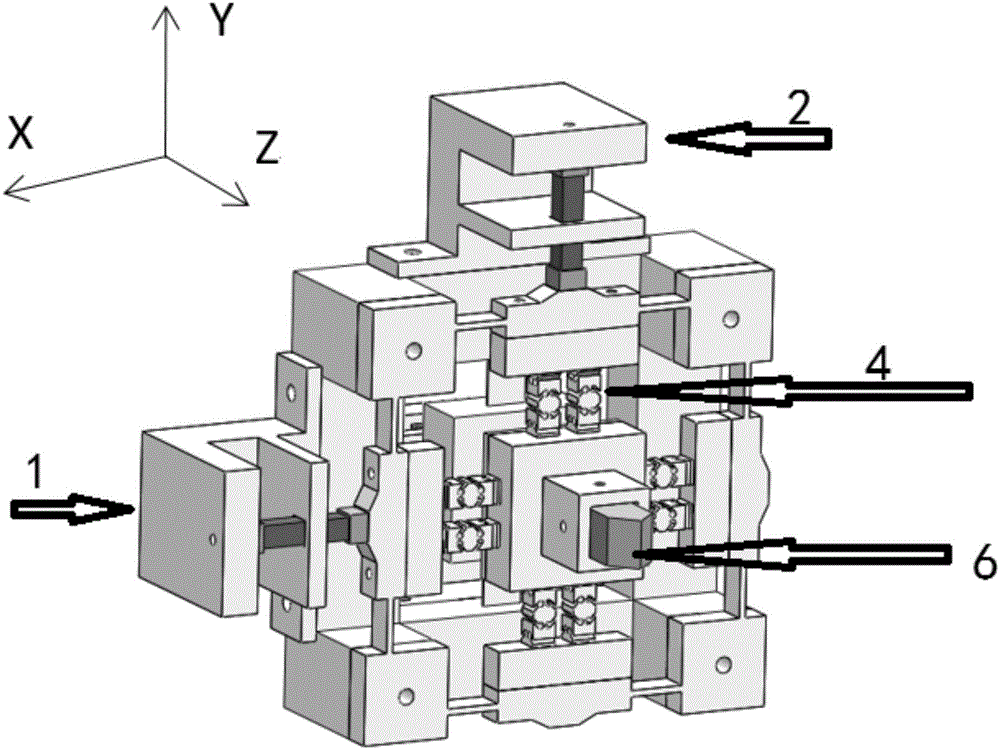

Parallel-connection translational three-dimensional rapid servo device of numerical control ultraprecision processing machine tool

ActiveCN106736797AEasy to processGood symmetryFeeding apparatusNumerical controlMulti degree of freedom

The embodiment of the invention discloses a parallel-connection translational three-dimensional rapid servo device of a numerical control ultraprecision processing machine tool, and aims to solve the technical problems of a traditional FTS device that machining cost is high; machining efficiency is low; multi-degree of freedom displacement error compensation cannot be realized; and absolute rigidity in other directions cannot be ensured. The parallel-connection translational three-dimensional rapid servo device comprises an X-direction driving platform, a Y-direction driving platform, a Z-direction driving platform, main flexible hinges, a subsidiary flexible hinge and a tool, wherein the X-direction driving platform and the Y-direction driving platform are connected with the tool through the main flexible hinges; and the Z-direction driving platform is connected with the tool through the subsidiary flexible hinge.

Owner:GUANGDONG UNIV OF TECH

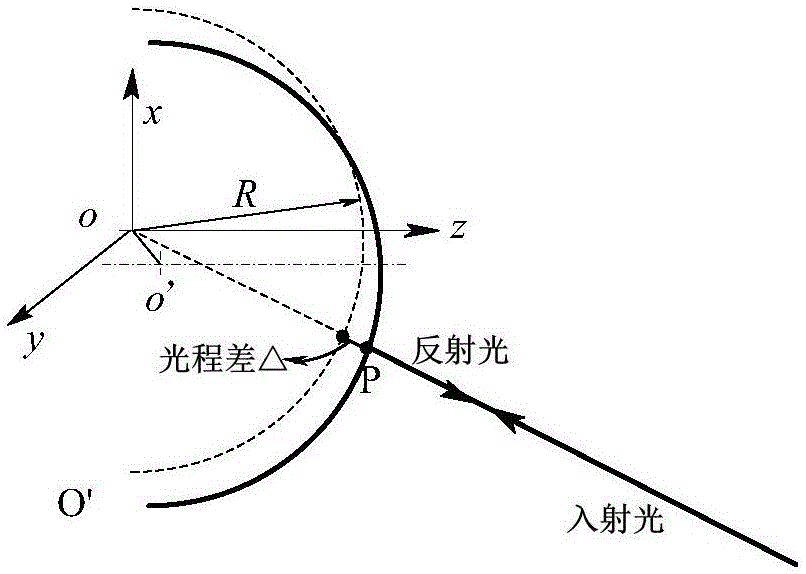

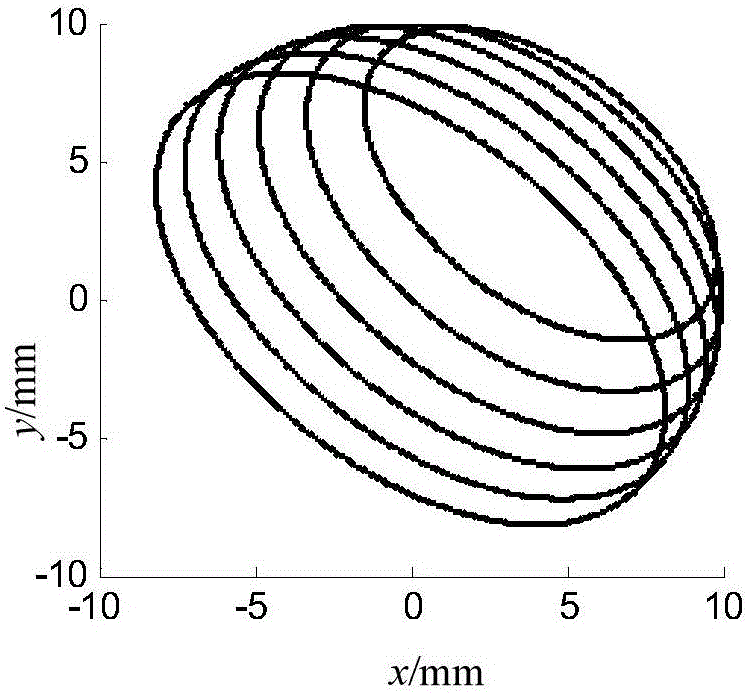

Laser interference principle-based precise main shaft rotation precision detecting device and method

ActiveCN106425691ALow machining accuracy requirementsLow materialMeasurement/indication equipmentsLaser transmitterCcd camera

The invention discloses a laser interference principle-based precise main shaft rotation precision detecting and analyzing method. A precise main shaft rotation precision detecting light path comprises a box body which is used for mounting required instruments, a laser transmitter which is mounted in the box body, four optical convex lenses, a half transparent and half reflecting mirror, a reference ball and a CCD camera; part laser beams emit out from a circular hole in a square box and are projected on a target ball; the target ball is mounted on a precise main shaft through an extending rod. A laser interference pattern which is acquired by the CCD camera is analyzed through an analysis principle to acquire the rotating speed and a three-directional displacement error of the precise main shaft. The laser interference principle-based precise main shaft rotation precision detecting and analyzing method is conveniently used for engineering detection; error separation is not required; the rotating speed, and the axial and radial displacement errors of the precise main shaft can be detected simultaneously; moreover, the detection precision reaches nano scale.

Owner:XI AN JIAOTONG UNIV

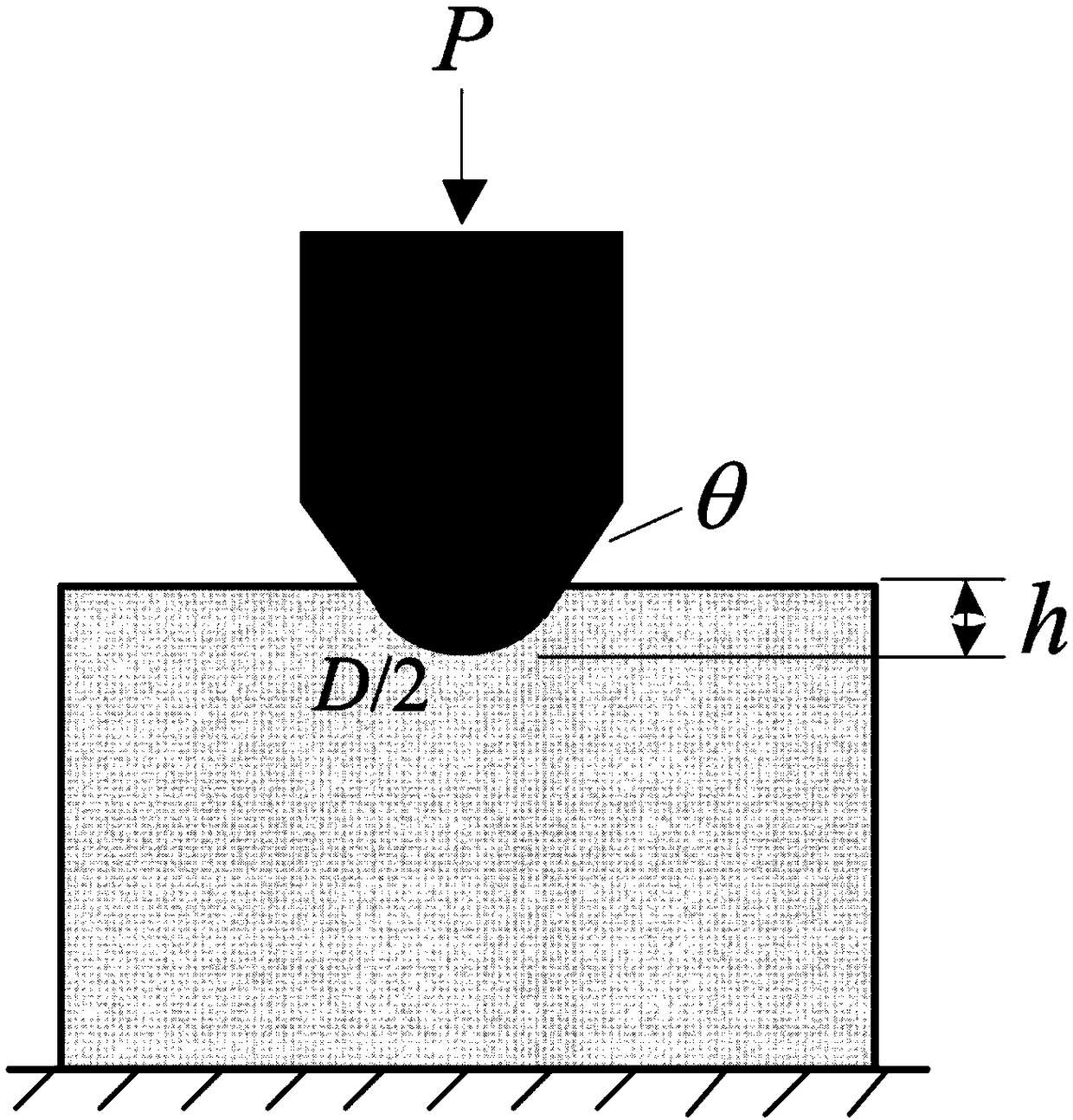

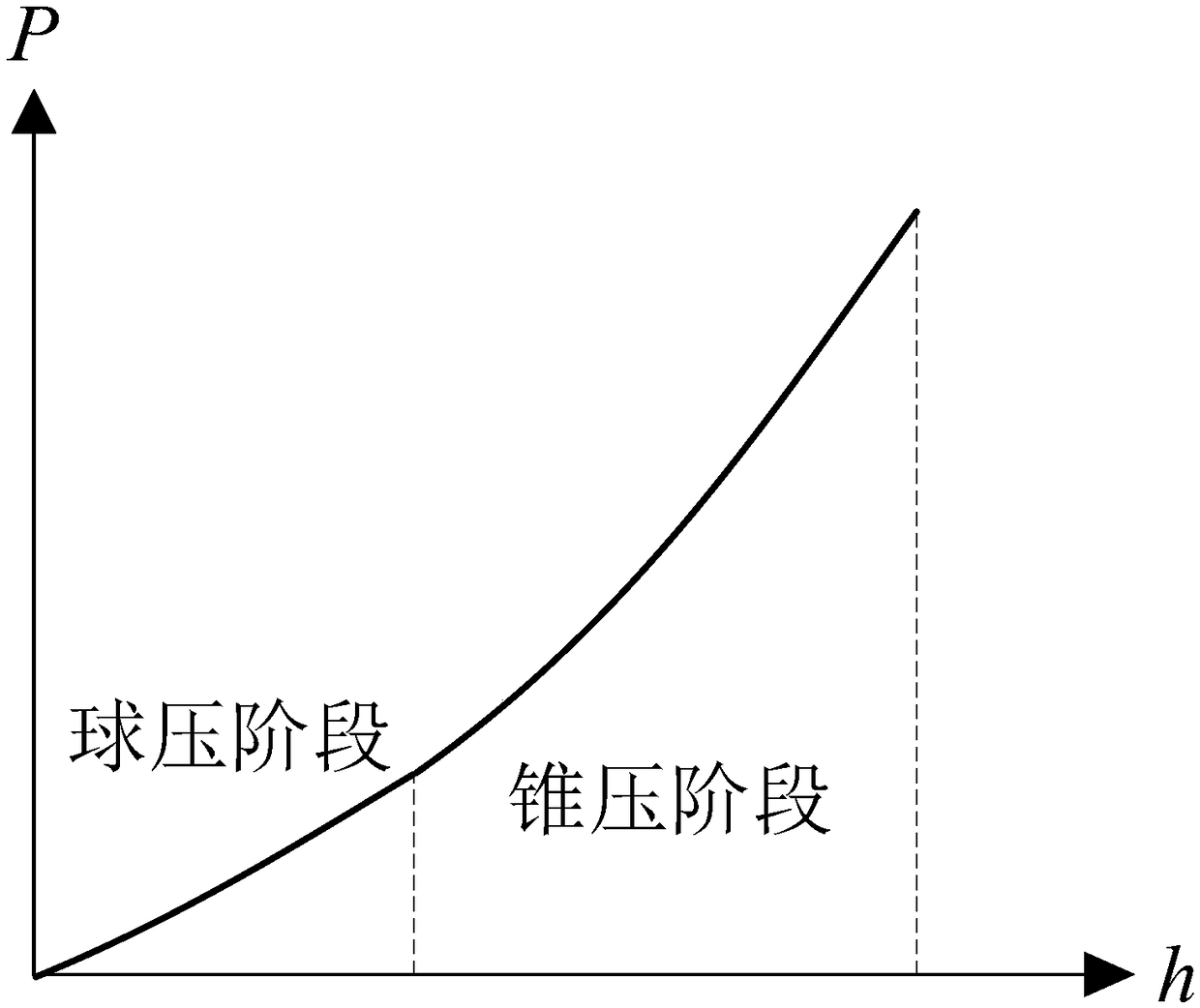

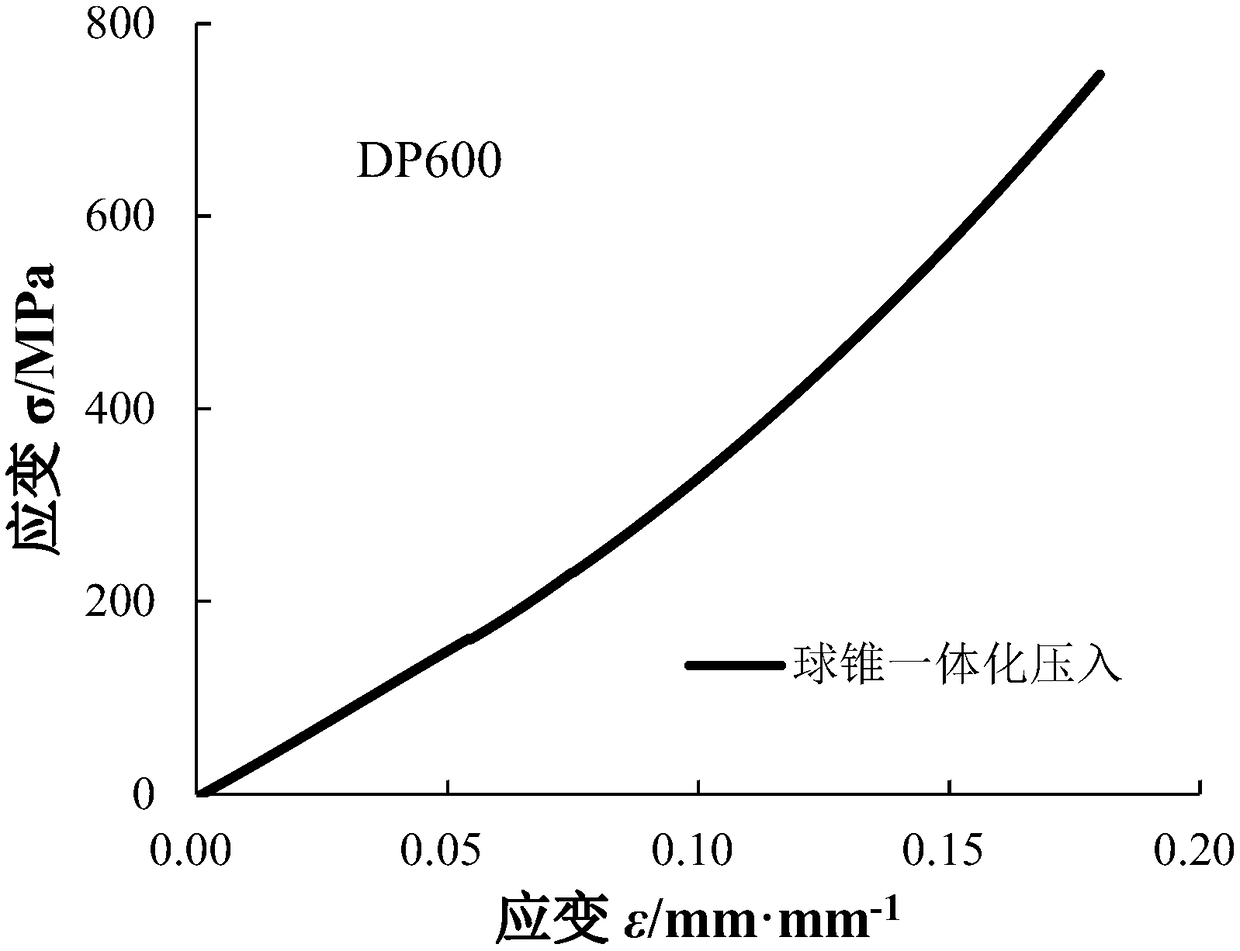

Method for predicting material equivalent stress-strain relation based on sphere and cone integrated pressure head

ActiveCN108897946ASimple methodOvercome the cumbersome process of multi-stage loading-unloadingDesign optimisation/simulationSpecial data processing applicationsEngineeringTest material

The invention discloses a method for predicting a material equivalent stress-strain relation based on a sphere and cone integrated pressure head. The method includes the following steps that 1, a tested material is subjected to a quasi-static press-in text through the sphere and cone integrated pressure head, so that a continuous load-depth curve is obtained, wherein the lower portion of the pressure head is a spherical pressure head body, and the upper portion of the pressure head is of a conical structure; 2, a spherical loading curvature Cs (delta) and a spherical loading index m (delta) ofthe load-depth curve at a spherical pressure stage are obtained in consideration of displacement errors; 3, a loading curvature Cc of the load-depth curve at a conical pressure stage is obtained; 4,according to Cs (delta) and m (delta) obtained in the step 2 and Cc obtained in the step 3, constitutive parameters of the material are obtained, and the equivalent stress-strain relation is obtained.The method is simple, has universality, and can be used for performing mechanical effect analysis of equivalent stress-strain and related factors of the material under the loading conditions of creeping, impacting and others.

Owner:SOUTHWEST JIAOTONG UNIV

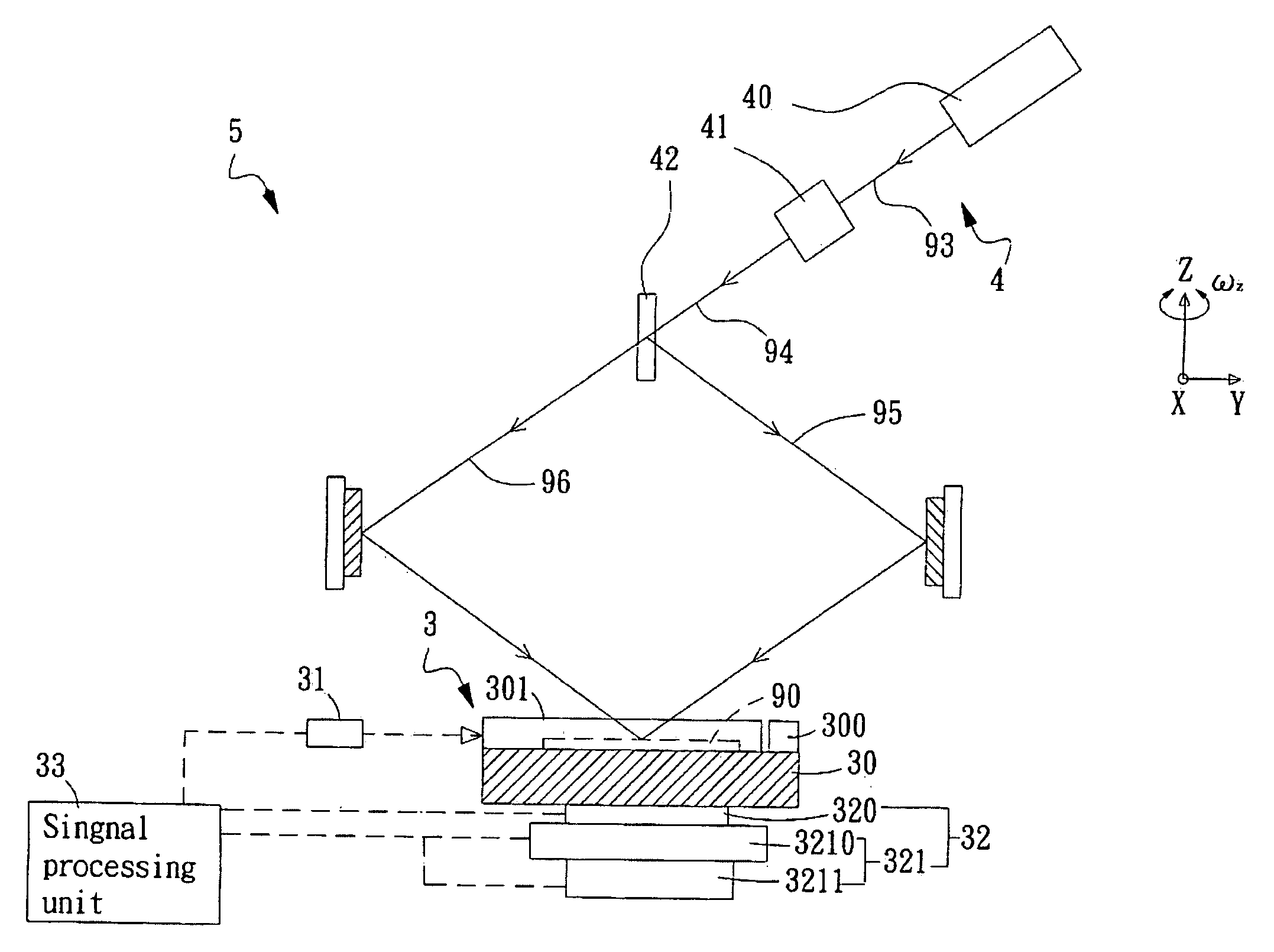

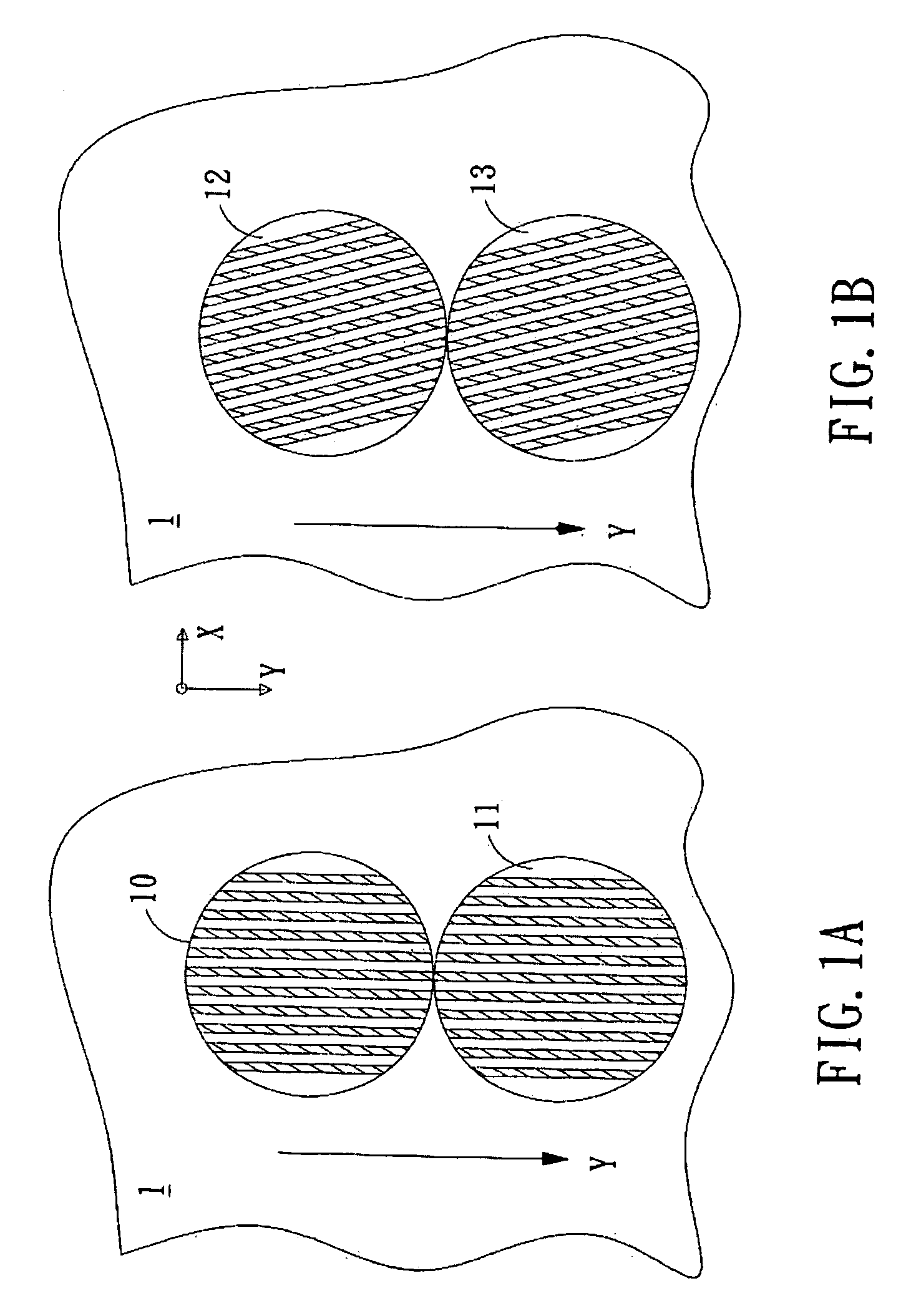

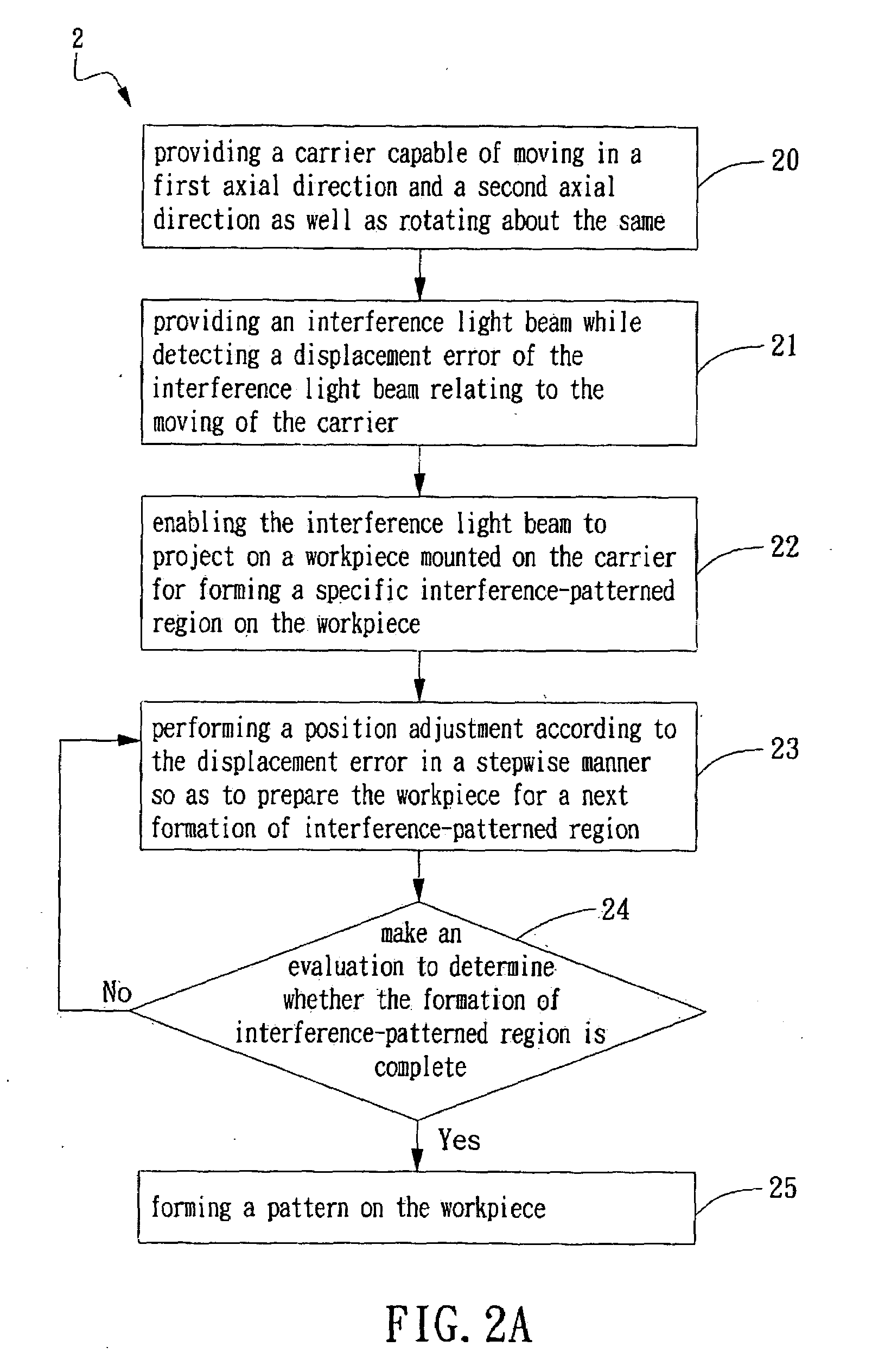

Method and system for step-and-align interference lithography

InactiveUS20090323078A1Precise alignmentImprove accuracyPhotomechanical apparatusUsing optical meansLight beamEngineering

A method for step-and-align interference lithography is provided in the present invention, by which a displacement error relating to the moving of an interference light beam as the source of the interference light beam is being carried to move by a carrier is measured before interference lithography, and then the displacement error is used as a reference to compensate a positioning error between adjacent interference patterns during step-and-align interference lithography. Besides, the present invention further provides a system for step-and-align interference lithography, which is capable of compensating the positioning error caused by a stepping movement control used for moving a substrate or the light beams in a stepwise manner to form interference-patterned regions by interference lithography and thus the so-generated interference-patterned regions are accurate aligned with one another on a two-dimensional plane for preparing the same to be stitched together to form a two-dimensional large-area periodic structure.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com