Axial circular runout and total runout single displacement error separation device and method

A technology of error separation and circular runout, applied in the direction of measuring devices, instruments, etc., can solve the problems that cannot be separated from the axis rotation error of the instrument, the parallelism error of the instrument guide rail to the rotary axis, and cannot meet the ultra-precision circular runout and full runout measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

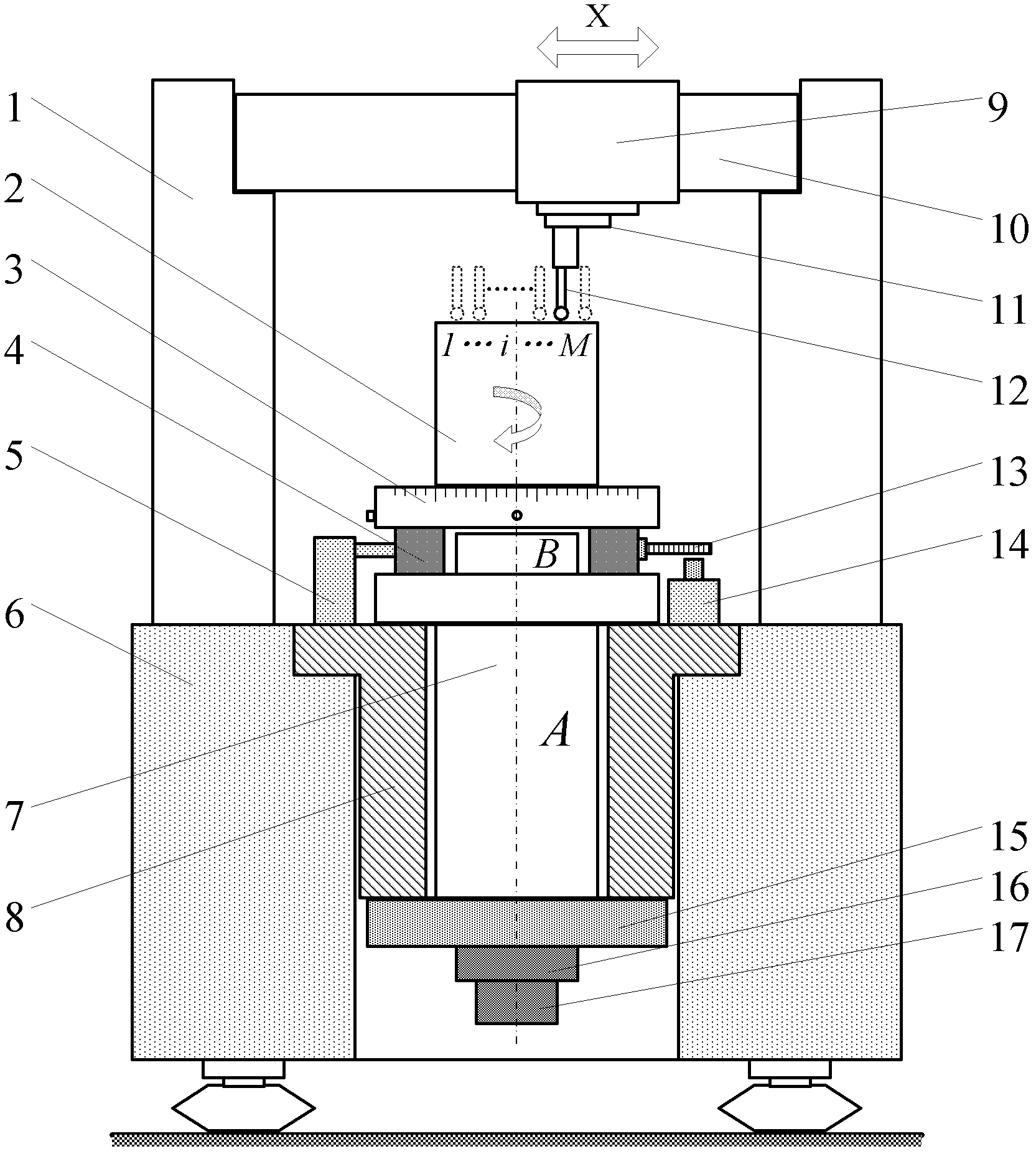

[0072] Taking the axial circular runout measuring instrument in which the spindle of the instrument rotates to drive the workpiece to rotate as an example, the method and specific steps of separating the spindle rotation error z(n) and the workpiece circular runout error g(n) are explained.

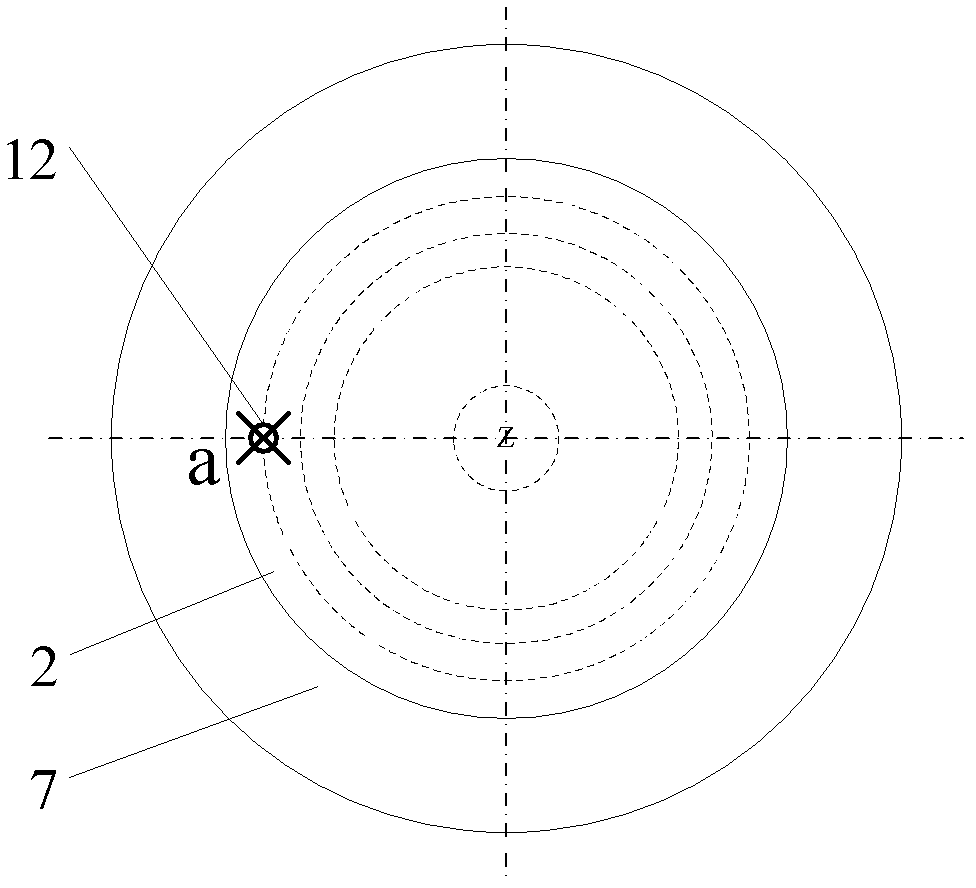

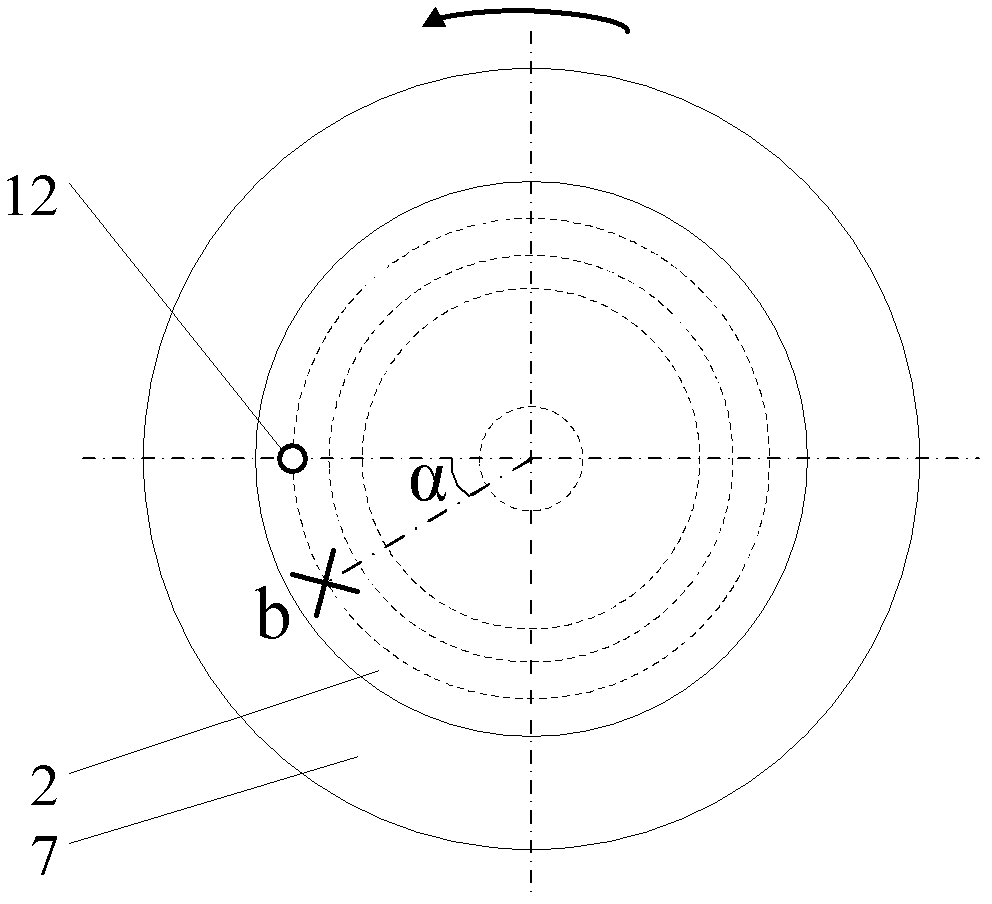

[0073] When actually measuring the circular jump or the full jump, a certain fixed position a on the rotary spindle 7 of the instrument is used as the starting point of the instrument measurement, the workpiece 2 to be measured is located on the rotary table 3, and the starting reference point of the workpiece is b. When the measurement sensor 12 is located on the workpiece 2 such as figure 2 When the first measurement circle 1 is shown, rotate the workpiece 2 to obtain the comprehensive error data A(θ) of the first measurement round, and turn the error separation turntable 4 so that the initial reference point b of the workpiece 2 is relative to the instrument The measurement starting p...

Embodiment 2

[0113] On the basis of Example 1, the index angle α is optimized.

[0114] For the displacement angle α, any k (k≥2) harmonic can be selected for discussion, and it can be obtained from formula (13):

[0115] C k (n)=a k cos(2nπk / N)+b k sin(2nπk / N) (16)

[0116] In the above formula

[0117] a k = 1 2 e k + sin kα 2 ( 1 - cos kα ) f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com