Five-point cylindricity error separation measurement method

A technology of cylindricity error and measurement method, applied in the direction of measuring devices, instruments, etc., can solve problems such as difficulty in meeting online measurement requirements, high cost of instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

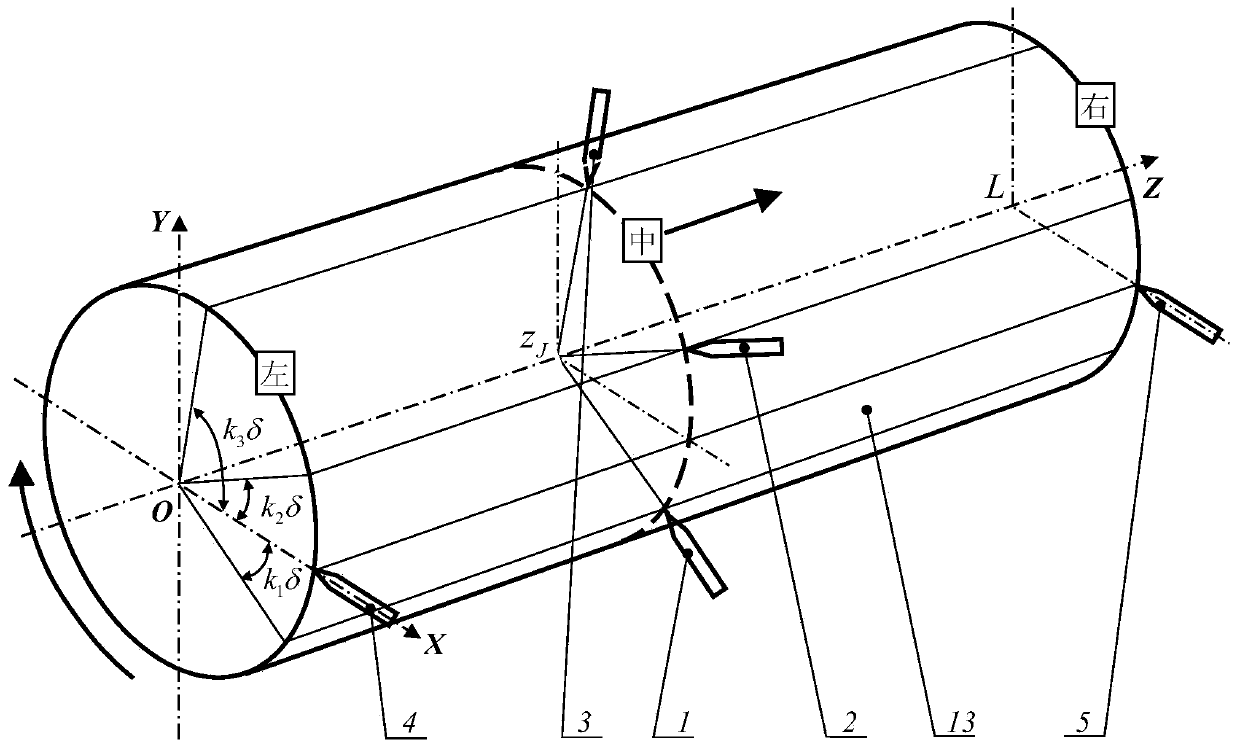

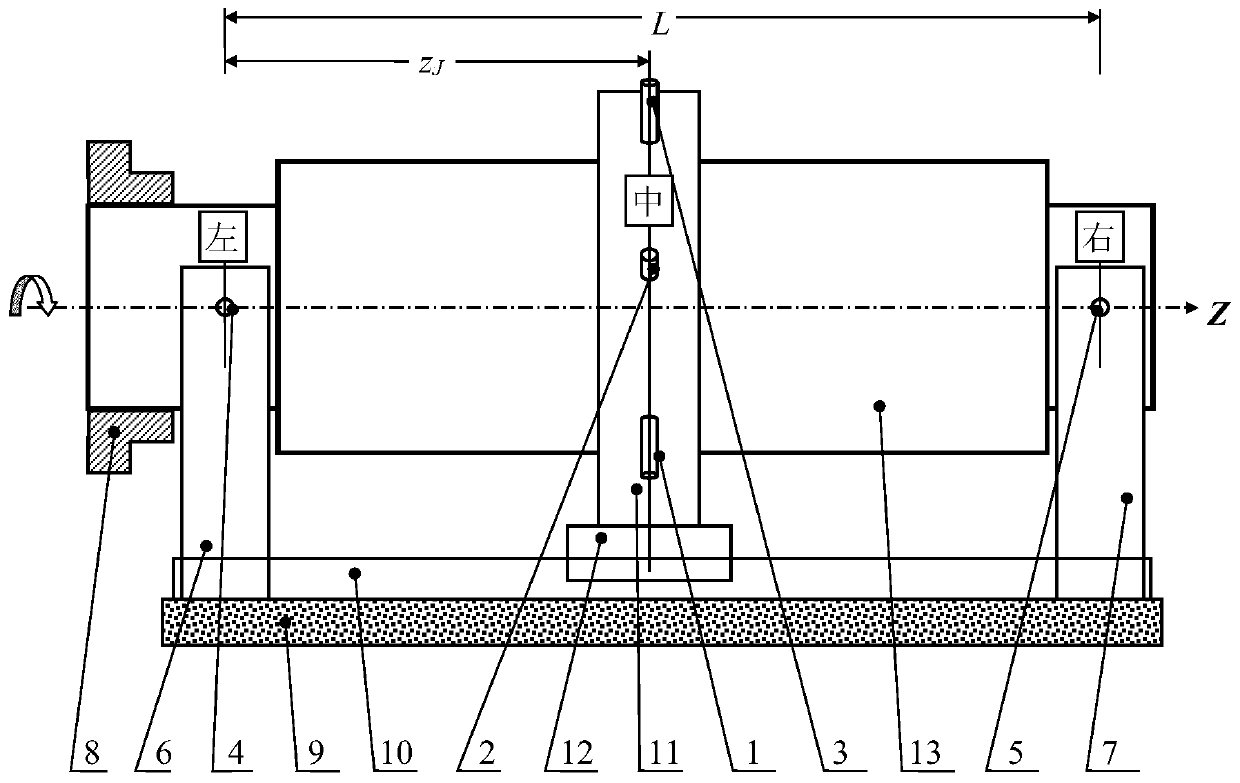

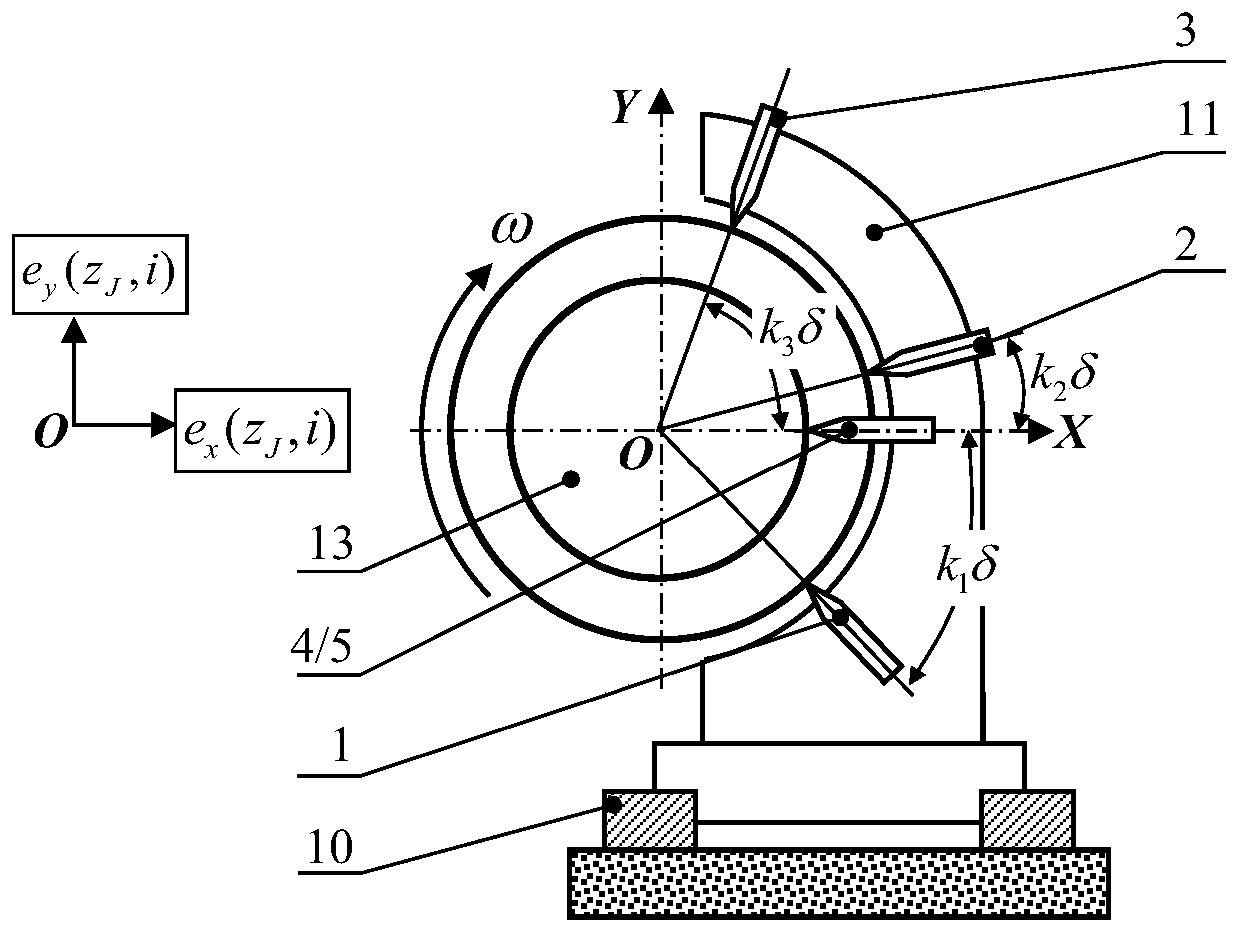

[0042] In this example, if figure 2 with image 3 As shown, the left frame 6 and the right frame 7 are fixed at both ends of the measured body 13, on which the fourth sensor 4 and the fifth sensor 5 are installed respectively, to sense the X-direction radial displacement of the cross-section at the left and right ends of the measured body 13 , the axial distance between the fourth sensor 4 and the fifth sensor 5 is L; the center frame 11 is supported on the mobile platform 12, and the mobile platform 12 is supported by the Z guide rail 10 and drives the center frame 11 to move along the Z direction , the Z guide rail 10 is parallel to the axial direction of the measured body 13, so that the moving step distance of the middle measuring frame 11 along the Z direction is d, and the middle measuring frame 11 is provided with a middle section perpendicular to the axial direction of the measured body 13. The first sensor 1 to the third sensor 3 are installed on it to sense the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com