High-precision moving robot positioning system and method

A mobile robot and positioning system technology, applied to instruments, navigation through speed/acceleration measurement, and measurement devices, can solve problems such as gyroscope zero drift, insufficient real-time control of two-dimensional codes, hidden dangers of encoder indirect measurement, etc., to achieve The effect of improving navigation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

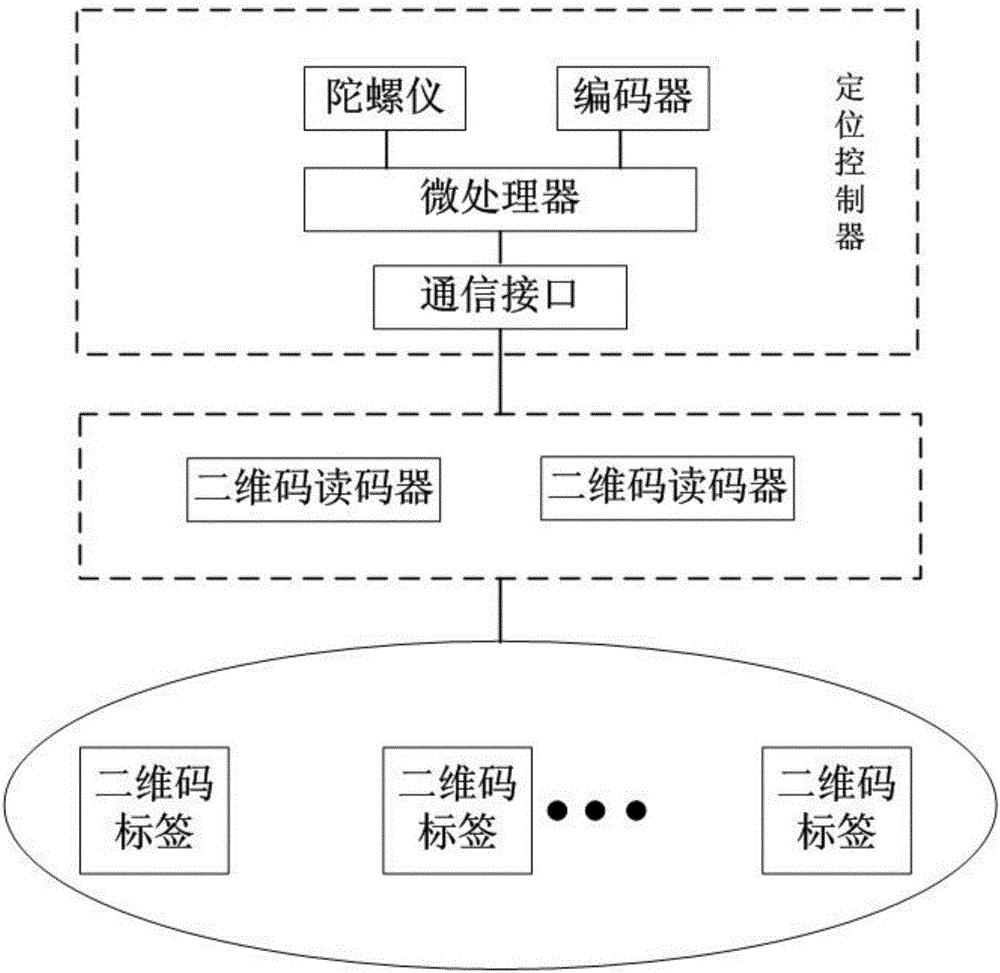

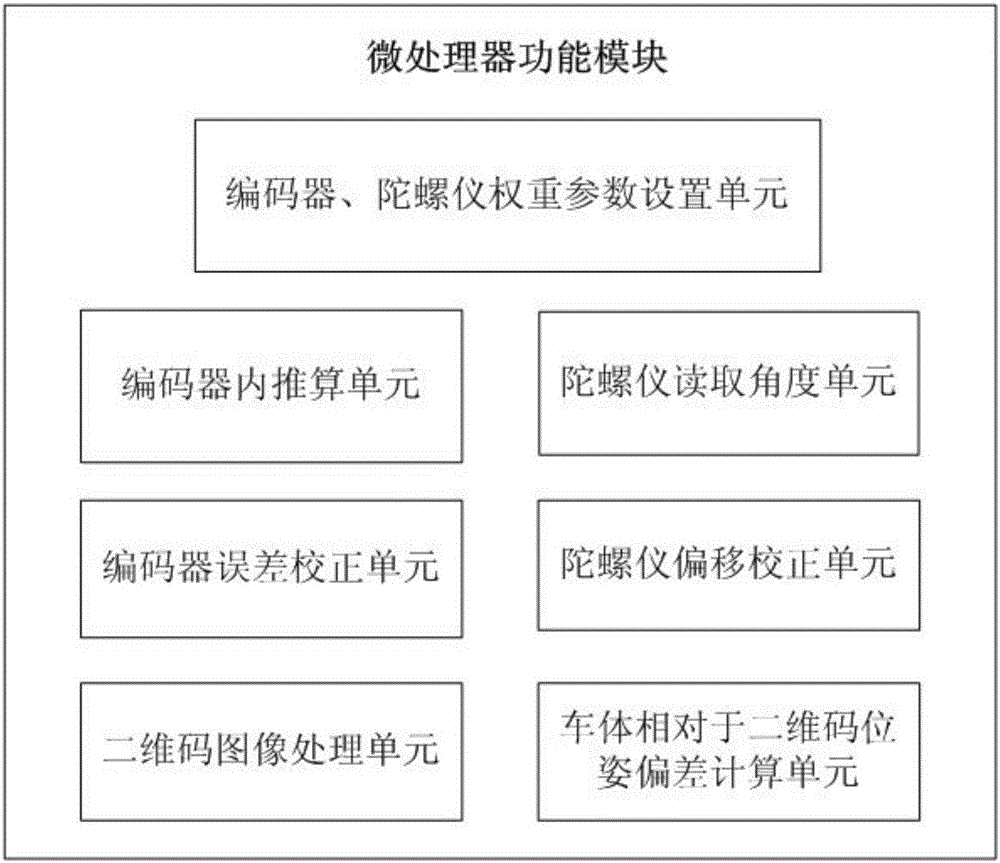

[0040] A high-precision mobile robot positioning system, such as figure 1 As shown, it includes a positioning controller installed on a mobile robot (AGV), a two-dimensional code reader and two-dimensional code labels distributed in an indoor environment. The positioning controller is composed of a microprocessor, an encoder, a gyroscope and The communication interface is connected, and the communication interface is connected with the two-dimensional code reader. The microprocessor reads the angle data through the encoder and the gyroscope, reads the two-dimensional code image through the two-dimensional code reader and performs calculation to realize the precise positioning function. The two-dimensional code label can be a single two-dimensional code label, or a two-dimensional code array label composed of two-dimensional codes, and there are on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com